Flylight Airsports Skyranger Swift Operator's Manual

1

F

Skyranger Swift Operators Manual

G_______ Serial No.: BMAA/HB/_ _ _

Approving Authority

British Microlight Aircraft Association

The Bullring, Deddington, Banbury

Oxon, OX15 0TT, United Kingdom

by delegation from the United Kingdom Civil Aviation Authority

Manufacturer

Flylight Airsports Ltd, Sywell Aerodrome, Sywell Northants NN6 0BT

This manual is approved for use with Skyranger Swift aircraft issued with a United Kingdom

type accepted (amateur-built) Permit to Fly. It must remain with the aircraft, and not be

amended or altered without authority from the manufacturer in conjunction with the BMAA

or UK CAA.

All pilots should read this manual before flying as pilot in command of the aircraft to which

it refers.

Skyranger Swift Operators Manual (issue 3)

2

Skyranger Swift Operators Manual (issue 3)

3

Contents

1. Introduction ............................................................................................................... 5

2. Description of the Aircraft .......................................................................................... 6

3. Limitations ................................................................................................................. 8

4. Flying the Skyranger Swift ........................................................................................ 10

5. Performance ............................................................................................................. 21

6. Emergencies ............................................................................................................. 23

7. Rigging and De-rigging ............................................................................................ 25

8. Weight and Balance .................................................................................................. 26

9. Maintenance ............................................................................................................. 27

9.7 Check A .................................................................................................................... 30

9.8 Routine maintenance worksheet ............................................................................... 32

10. Repairs ..................................................................................................................... 40

11. Trim and tuning ....................................................................................................... 42

12. Vital Statistics ........................................................................................................... 44

Annex A The BMAA Airworthiness Approval Note recommending issue of a

permit to fly

Annex B Engine Manual

Annex C Weight and balance report for this aircraft (form BMAA/AW/028).

Annex D Minor modifications fitted to this aircraft (MinMods)

Annex E Major modifications fitted to this aircraft (MAANs)

Annex F Instructions and Manuals for other devices fitted to this aircraft

Skyranger Swift Operators Manual (issue 3)

4

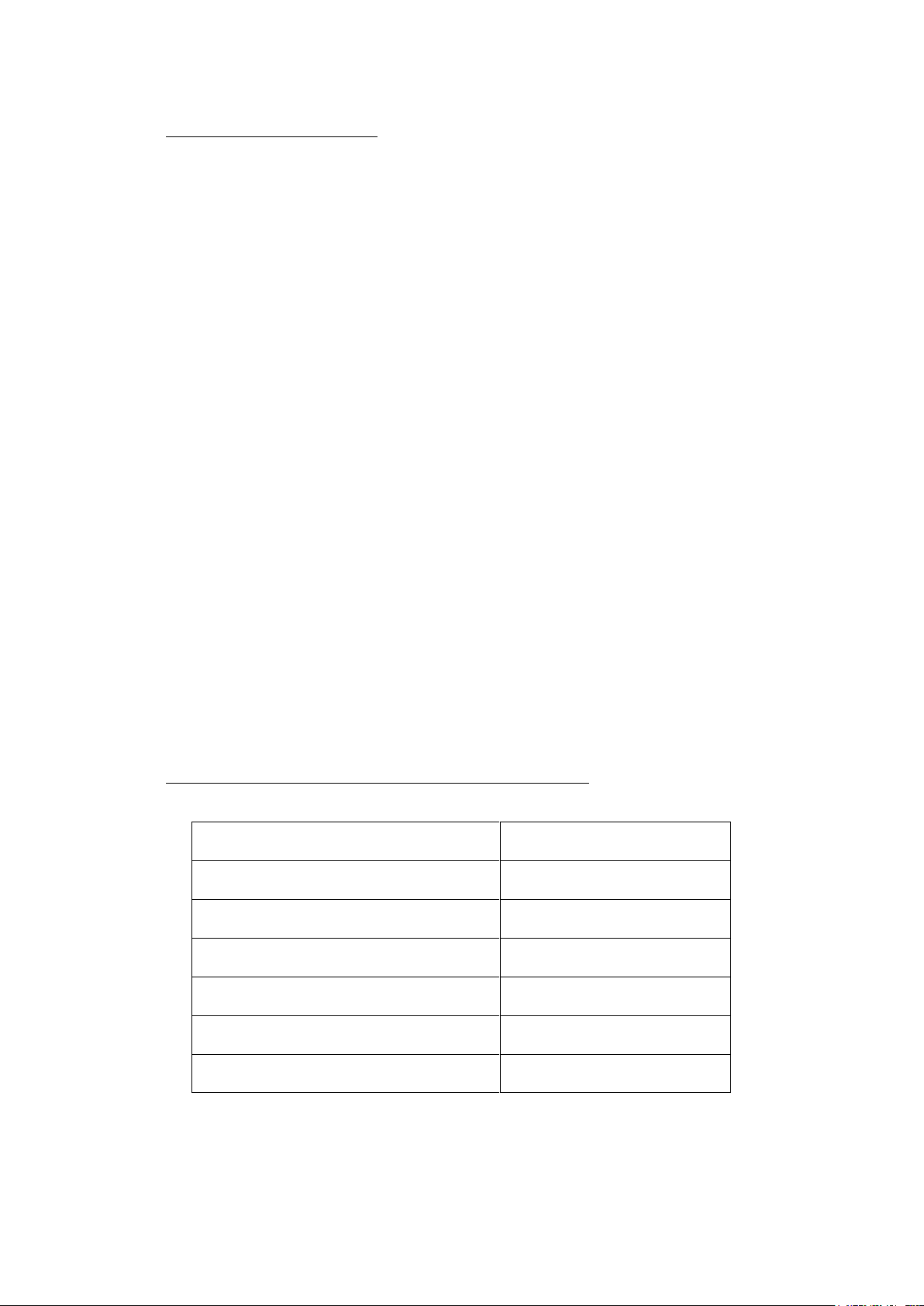

TABLE OF AMENDMENTS

Reference

Changes incorporated

date

Issue 3

Revision of maintenance requirements

and worksheet. Addition of trim and

tuning section. Description of fuel

system, many other small corrections /

changes.

04.10.18

Skyranger Swift Operators Manual (issue 3)

5

1. Introduction

1.1 The Skyranger Swift is a three-axis aeroplane, it was certified in the

United Kingdom to the requirements of British Civil Airworthiness

Requirements (BCAR) Section S.

1.2 This manual is not intended to teach you to fly the aircraft, or to build

it. Learning to fly should be accomplished under the supervision of a

flying instructor experienced on the type. A separate build manual

exists to instruct you in building the Skyranger Swift from a kit.

1.3 What this manual will do, is provide the information which a qualified

pilot requires to safely fly this aircraft (although a conversion by an

instructor, CRI, Coach, familiar with the type is strongly

recommended), and to carry out routine maintenance and minor

repairs. Manuals exist for this aircraft for use overseas which also

include guidance on fitting modifications. All modifications to a British

Skyranger Swift must be approved by the British Microlight Aircraft

Association.

1.4 The license required to fly the Skyranger Swift in the UK are either a

EASA PPL / LAPL, UK PPL (A) with SEP or Microlight ratings, UK NPPL

with microlight rating or NPPL SSEA with differences training for

microlight aircraft. Pilots with licenses and experience confined to

heavier GA aircraft must carry out differences training to fly the

Skyranger Swift. Pilots with microlight ratings trained for Flexwing

aircraft should carry out differences training for 3 Axis control systems

before attempting to fly the Skyranger Swift.

1.5 This aircraft must be operated using airframe and engine log books.

Entries must be made in the logbooks in ink and within 7 days.

Skyranger Swift Operators Manual (issue 3)

6

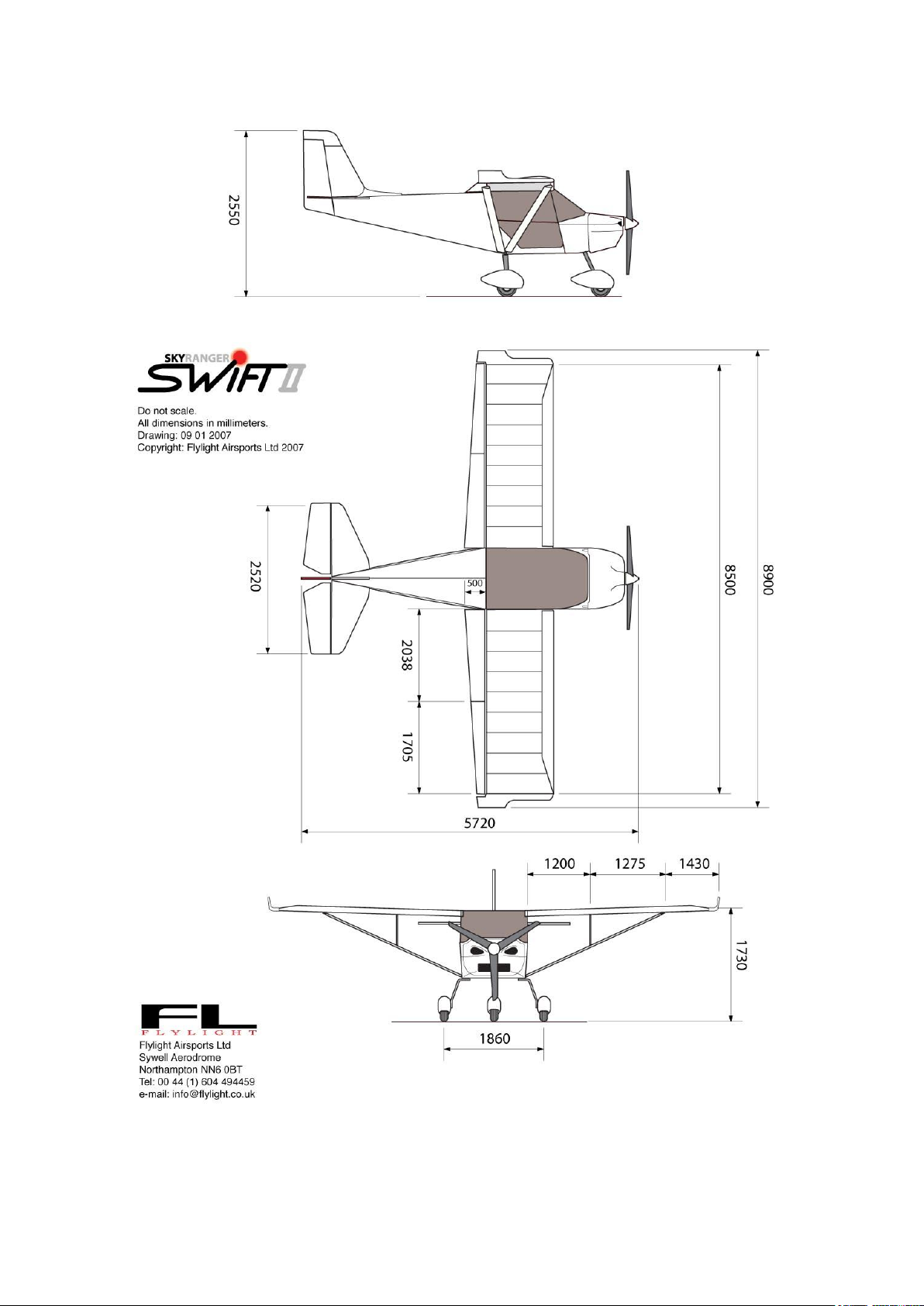

2. Description of the Aircraft

2.1 Ancestry

The Skyranger was conceived by Philippe Prevot in 1991. The first 200

examples were manufactured under licence by Synairgie between 1994

and 1998. The manufacture of the Skyranger was moved to Aeros in

the Ukraine in 1998, incorporating many developments in the design.

An updated shorter wing model – The Skyranger Swift then followed,

updated again in 2014 (known as ‘Swift2’) to incorporate several

features / options with the Skyranger Nynja. This manual is for all Swift

versions.

2.2 Construction

The Skyranger Swift is predominately constructed of pin-jointed

straight aluminium tubes with wings and tail covered with pre-sewn

polyester or optional laminate fabric. The fuselage is covered in non

structural glassfibre panels.

2.3 Flying Controls

2.3.1 Pitch control is by fore-aft movement of the control stick, with

movement transmitted to a conventional elevator through cables.

2.3.2 Pitch trimming is by a hand-operated lever mounted in the central

console between the seats, with movement transmitted through a cable

to a trim-tab on the starboard elevator, reacted with springs.

2.3.3 Roll control is by sideward movement of the control stick, with

movement transmitted through cables to part-span, differentialmovement ailerons.

2.3.4 Yaw control is by dual-control foot pedals, with movement to the

rudder transmitted through cables.

2.3.5 Braking is by hand lever operated hydraulic disc brakes.

2.3.6 The undercarriage is of tricycle arrangement, with nose wheel steering

mechanically linked to the dual-control rudder pedals.

2.3.7 Flaps are lowered in two stages by lifting a hand-operated lever

located between the seats whilst gripping an integral latching lever.

Skyranger Swift Operators Manual (issue 3)

7

2.4 Fuel system

2.4.1 The standard fuel system consists of two polyethelene tanks linked

together with a balance pipe. As such they work as one single tank for

fuel management purposes.

2.4.2 Fuel is drawn from a single outlet through a single fuel tap which

isolates all supply.

2.4.3 Fuel is pumped by an engine driven mechanical fuel pump, and an

(optional) electrical back-up fuel pump. An anti vapour-lock restricted

return allows fuel flow back from the engine compartment to the fuel

tanks.

2.4.4 The tank outlet has a strainer, and an additional fuel filter is used in

the supply line.

Skyranger Swift Operators Manual (issue 3)

8

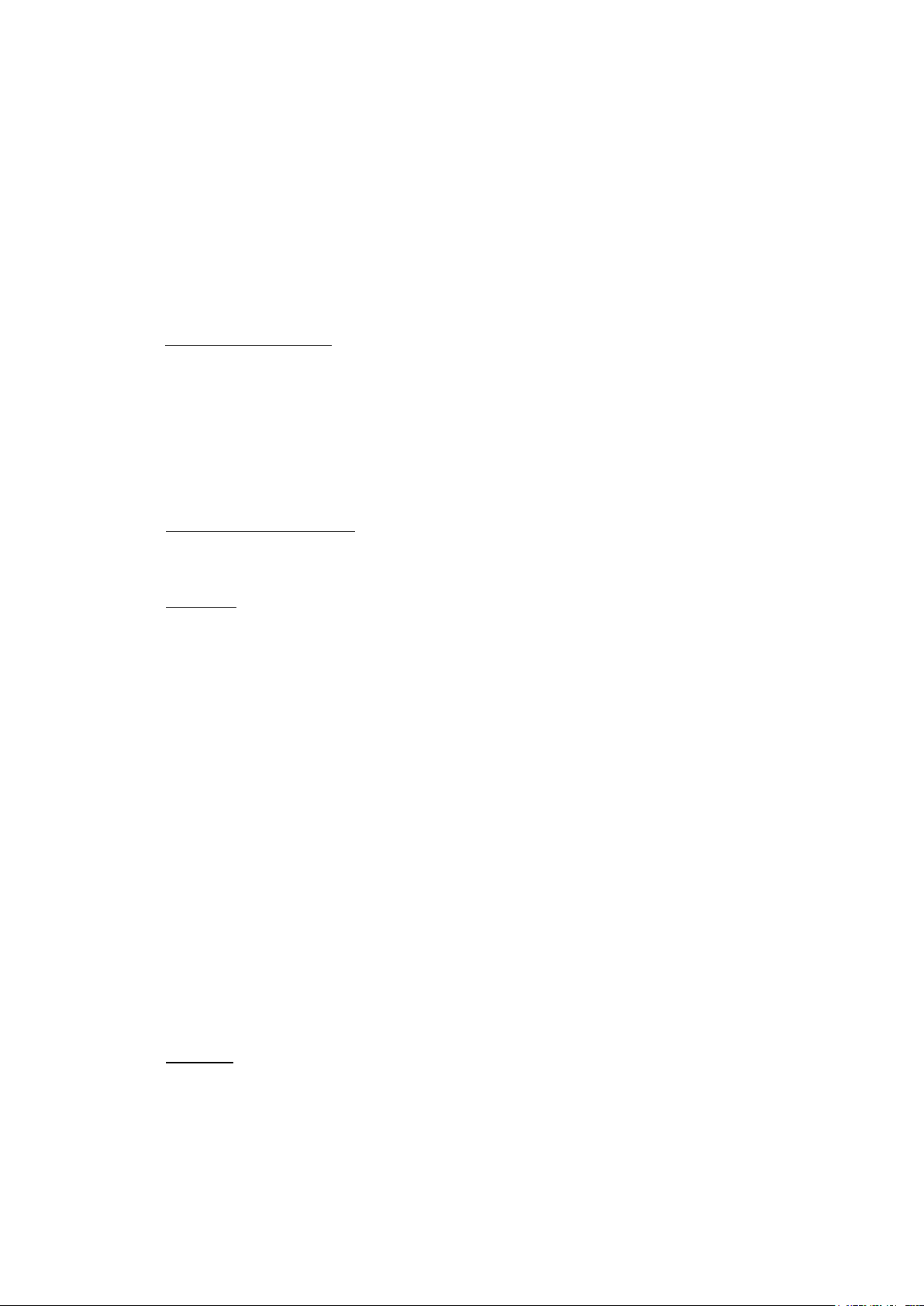

3. Limitations

Kn CAS

(Calibrated)

33.5

Vso

37

VS1

47

min sink

48

Best climb

angle

52

Best glide

angle

52

approach

speed

57

best

climb rate

70

Vfe

74

Va

111

Vne

IAS

(Indicated)

3.1 Introduction

This section includes the basic operating limitations for the Skyranger

Swift. The full limitations are contained in Homebuilt Aircraft Data

Sheet (HADS) HM4, which is used by the Inspector at Annual Permit

renewal to ensure, amongst other things, that the correct limitations

are placarded in the cockpit.

3.2 Units

When noting limitations, it is important to ensure that the limitations

which you are using use the same units and calibrations as the

instruments in the cockpit. The limitations shown below use knots

CAS (Calibrated Airspeed); your aircraft may have an instrument in

mph, and in any case will read IAS (Indicated Airspeed). The difference

between IAS and CAS is basically the accuracy of your Pitot-static

system. The IAS limits for your aircraft were determined when the

aircraft was test flown, and are shown in Annex A to this manual.

There will also be a placard in the cockpit, however space is allowed

below for you to insert the IAS limitations and calibration details for

your aircraft.

IAS Calibration Card for Skyranger Swift G-_______.

Unless all errors are less than 2 knots, a copy of this calibration card must be

displayed in the cockpit near to the ASI.

Skyranger Swift Operators Manual (issue 3)

9

3.3 Operational Limitations

Skyranger Swift

Never exceed speed, Vne

111 kn CAS [ IAS]

Manoeuvring speed, Va

74 kn CAS [ IAS]

Flap limiting speed, Vfe

70 kn CAS [ IAS]

Door open limit speed

72 kn CAS [ IAS]

Speed for best rate of climb Vy

57kn CAS [ IAS]

Speed for best climb angle Vx

48 kn CAS [ IAS]

3.3.1 The Skyranger Swift must only be flown in day VMC conditions

3.3.2 The Skyranger Swift is certified to a "permit to fly" standard. This

prohibits commercial operation.

3.3.3 UK Skyranger Swifts are approved to a UK standard, this means that

permission is required from the host country to fly it overseas.

However a reciprocal agreement for homebuilt aircraft means that no

permission is required for flights to other ECAC (European Civil

Aviation Conference) member states.

3.3.4 The minimum instrumentation required will depend on the engine

fitted. Details for each is specified in the type Homebuilt Aircraft Data

Sheet (HADS) HM4. Latest issues of which are available on the BMAA

website.

3.3.5 It is recommended that the Skyranger Swift is not flown where a

crosswind component above 15 knots is predicted.

3.3.6 Do not fly above 10,000ft standard pressure altitude without the use of

personal oxygen.

3.3.7 Do not fly if any ice is present on the airframe. Performance, stability

and handling will all be degraded with dangerous consequences. Do

not fly the aircraft into known icing conditions.

3.4 Flight Limitations and key performance speeds

3.4.2 Maximum Bank angles are 60° either way.

3.4.3 Maximum Pitch attitudes are 450 nose up and down from the

horizontal.

Skyranger Swift Operators Manual (issue 3)

10

3.4.4 Normal acceleration limits are +4g / -2g.

3.4.5 At least 55kg (121lb / 8 stone 9lb) must be in the cockpit for flight, no

more than 120kg (264lb / 18stone 12lb) may be carried in each seat.

3.4.6 Maximum Take-off weight: 450kg – or 472.5Kg if fitted with an

airframe mounted total recovery parachute system.

3.4.7 Aerobatics and deliberate spinning are prohibited.

3.5 Engine Limitations

The limitations for the engine are contained in Annex B, they are also

placarded in the cockpit.

4. Flying the Skyranger Swift

4.1 Pre-Flight Inspection

Pre flight inspection – Check A, is detailed in the maintenance section.

4.2 Starting

4.2.1 Before starting the engine ensure that the max takeoff weight will not

be exceeded (from fuel/weight placard).

4.2.2 The BMAA standard manual pre-start checks [STAIP] are recommended.

The actual starting procedures for a particular engine are contained in

Annex B to this manual. The STAIP checks are :-

Security aircraft, crew, equipment, secure, brakes ON.

Throttles full and free, and closed, choke set as required.

Area all around and behind aircraft clear.

Ignition mags ON.

Prop Shout ‘clear prop’, pause then start the engine.

Once the engine is running set the recommended warm up RPM and

slowly remove the choke.

4.3 Taxiing

4.3.1 Before Taxiing ensure that the engine has run for at least 2 minutes

from cold. Do not use high RPM until the engine has reached its

minimum flight operating temps.

Skyranger Swift Operators Manual (issue 3)

11

4.3.2 Taxy at no more than a brisk walking pace, somewhat less if the

surface is rough. Steering is effected through the rudder pedals which

are linked directly to the nosewheel. The turning circle normally is

around 20 feet in diameter (at the aircraft centreline).

4.3.3 Relatively light weight aircraft like the Skyranger Swift can be blown

over in winds over 25knots. It is imperative that when taxiing in strong

winds that the correct control placements are used. When the wind is

from the forward quarters hold the stick into wind and the elevator

neutral. When the wind is from the rear quarters the stick should be

positioned away from the wind and the elevator held down.

4.3.4 Taxy checks

When taxiing check:

Brakes functioning

Compass moving when aircraft turned

Slip ball moving when aircraft turned

Engine temps warming, no limits exceeded

Skyranger Swift Operators Manual (issue 3)

12

4.4 Pre take-off checks (vital actions)

Prior to take-off, it is recommended that the following pre takeoff

check is used. This check is a derivation of the mnemonic CHIFTWA as

used in many BMAA schools.

C - Controls

Position into wind - Check controls for full and free movement

Check visually that the controls are moving in the correct sense

H - Harness and Hatches

Check harnesses and hatches (doors) are secure, no loose objects

I – Instruments and engine

Check flight instruments are set and serviceable

Check engine instruments are serviceable, minimum operating temps

Check choke is OFF

Set 3000 RPM and check each ignition in turn – max RPM drop 150

Check for smooth idle around 1500-1700 RPM

Increase power to max brakes will hold for at least 10 seconds

Check engine indications normal. Reset RPM to 2000

F – Fuel and Flaps

Check fuel tap is ON

Check contents sufficient for flight

Cycle flaps and check symmetrical operation, detent operation

Set flap as required

T - Trim

Check trim set for takeoff (mid position)

W – Wind (and eventualities)

Check wind speed and direction / crosswind component

Consider emergency actions – abort point EFATO options etc

A – All clear

Confirm all clear on approach

R/T call if required and line up on runway

Skyranger Swift Operators Manual (issue 3)

13

4.5 Normal takeoff

4.5.1 For a non performance takeoff, into wind, flaps can either be left in

the fully up –CR (cruise) position, or with the first stage – TO (takeoff)

position.

4.5.2 When lined up and rolling straight smoothly apply full power. Keep

straight with rudder, ailerons neutral and with the elevator slightly up

to reduce the weight on the nosewheel.

4.5.3 When the airspeed rises to 45 knots CAS [ IAS] rotate and lift off

and adopt a shallow climb attitude. Allow the airspeed to rise to 60

knots CAS [ IAS] and adopt a climbing attitude to hold this

airspeed.

4.5.4 When above 200 feet AGL the airspeed can be reduced to 57 knots

CAS [ IAS] if a greater climb rate is required, and the flaps

selected to CR. The power can also be reduced a little for noise

abatement if required. When the flaps are retracted there will be a

slight tendency for the aircraft to pitch up, which will require a gentle

push on the stick to maintain a constant airspeed. Therefore after the

flap change re trimming may be required.

4.5.5 When in the climb, due to the excellent climb rate, the nose is high

and may obscure forwards view. Therefore it is recommended to

periodically weave or lower the nose to clear the blind spot. For

prolonged ascents a cruise climb at reduced power setting and

slightly higher airspeed is recommended and will increase forwards

field of view.

4.6 Short takeoff

4.6.1 For a short takeoff select first stage, (TO), flap. Start from as close to

the beginning of the field as possible. Hold on the brakes as power is

increased to full. When power is full or if the aircraft starts to ‘creep’

forwards, release the brakes. Elevator position should be neutral

(smooth surfaces only) or slightly up.

4.6.2 When the airspeed rises to 40 – 45 knots CAS [ IAS] rotate and lift

off. When airborne allow the aircraft to accelerate to 48 knots CAS [

IAS] for best obstacle clearance. Be aware that at this speed prompt

action will be needed to lower the nose and obtain glide speed in the

event of power loss.

Skyranger Swift Operators Manual (issue 3)

14

4.6.3 When clear of obstacles allow the aircraft to accelerate to 57 knots CAS

[ IAS], and at 200 feet AGL select CR flap.

4.6.4 It is important to always pick an abort point before attempting to take

off from a short field. If the aircraft approaches the abort point before

lifting, the takeoff should be aborted by fully closing the throttle and

braking firmly.

4.7 Soft field takeoff

4.7.1 Select first stage (TO) flap. Avoid stopping the aircraft whilst entering

the runway and roll into the takeoff run. Hold full up elevator until the

nosewheel lifts and then try to balance the aircraft in the rotated

attitude whilst speed is increased. This will help reduce rolling

resistance and keep overall drag to a minimum.

4.7.2 Allow the aircraft to lift off at around 40 knots CAS[ IAS] , and then

carefully allow the aircraft to accelerate to 57 knots CAS [ IAS] in

ground effect before adopting the climbing attitude. At 200 feet AGL

select CR flap.

4.7.2 It is important to always pick an abort point before attempting to take

off from a soft field. If the aircraft approaches the abort point before

lifting, the takeoff should be aborted by fully closing the throttle and

braking firmly.

4.8 Crosswind takeoff

4.8.1 The maximum demonstrated takeoff crosswind is a component of

15knots. Pilots are advised to avoid crosswind components of greater

than 10 knots until very experienced on type.

4.8.2 Select O (CR) flap. Start the takeoff roll with the stick held fully into

wind and the elevator neutral. Pressure may be required on the rudder

pedals to steer straight.

4.8.3 Allow the aircraft to accelerate. The amount of aileron can be reduced if

there is a tendency to lift the downwind wheel. Keep the elevator

neutral until the speed reaches 50-55knots CAS[ IAS], then cleanly

rotate and lift off.

4.8.4 As the aircraft lifts off, adopt a shallow climb attitude. Gently yaw the

aircraft into wind to set up the required drift angle, and centralise the

ailerons and balance ball.

Skyranger Swift Operators Manual (issue 3)

15

4.9 Normal landing

4.9.1 Generally the Skyranger Swift should be landed from an approach

speed of about 52knots CAS [ IAS], although in turbulent

conditions handling can be improved by increasing this by 5-10 knots.

Full flap (LD) position is the standard landing setting. As flap is

selected a gentle pull on the stick will be required to maintain constant

airspeed. Therefore re trimming will be required.

4.9.2 Maintain the approach speed until roundout, which should be initiated

around 15-20 ft ,and then hold-off initially 2-3 ft above the runway

and allow to settle gently when the speed decays. Aim to land on the

main wheels with the nose wheel well off the ground.

4.9.3 Pilots transitioning from more traditional lower performance microlight

aircraft should be aware that if the airspeed is allowed to increase on

the approach then the aircraft may exhibit considerable float during

the hold off period and this may cause a tendency to ‘balloon’ and will

cause more runway than expected to be used.

4.10 Short field landing

4.10.1 Select full flap (LD) position, and set up a powered approach at

around 45 – 50 knots CAS[ IAS]. Use power adjustments to control

the flight path and rate of descent whilst accurately maintaining

airspeed with elevator. If tall obstacles are present on the approach,

then transition into a glide approach once clear past them. Take care

however to maintain airspeed during this phase. 50 knots CAS [

IAS] is recommended as the minimum for a full glide approach at max

takeoff weight and full flap.

4.10.2 When round out height is reached close the throttle fully and round

out. Perform a brief hold off and land. Brakes can be used to shorten

the landing roll if required. Take care not to brake too sharply on

rough or soft surfaces. Braking efficiency is at its greatest if the

elevator is applied fully up after touchdown once below flying speed.

4.10.3 Accurate airspeed control is the key to short field performance and

pilots new to the Skyranger Swift must practice until this is achieved, to

be able to land in the published distance.

Skyranger Swift Operators Manual (issue 3)

16

4.11 Soft field landing

4.11.1 Fly the approach as in 4.10 above.

4.11.2 Fully hold off and try to touch down gently, and as slow as possible.

During the ground roll avoid braking and progressively apply full up

elevator to keep the nose wheel up for as long as possible. Continue to

hold up elevator when the nose wheel is on the ground.

4.12 Cross wind landing

4.12.1 The Skyranger Swift has a maximum demonstrated crosswind

component of 15 knots. Cross wind components above 10 knots

should not be attempted other than by experienced pilots fully familiar

with the type.

4.12.2 Either O (CR) or first stage (TO) flap can be selected. Fly a powered

approach at a little higher airspeed than normal – around 55 – 60 knots

CAS[ IAS]. Initially crab the approach to remain in balance and on

centreline.

4.12.3 During the final stages of the approach lower the into wind wing a

little and apply rudder pressure as required to align the fuselage with

the runway. Round out and hold off like this, and touchdown into wind

wheel first. Try to land after a short hold off without allowing the

airspeed to decay too much. This will assist in maintaining good

control response.

4.12.4 As with all crosswind landings the aircraft must still be accurately

‘flown’ whilst on the ground. Initially the aircraft will touchdown on the

upwind main wheel first. Progressive aileron deflection should applied

into wind as the speed decays during the ground roll to keep the

aircraft on one wheel and gently lower the downwind wheel as airspeed

reduces and aileron authority diminishes. The aircraft will need to be

accurately steered straight down the runway with rudder during this

process. The nose gear should be held off initially and gently lowered

before rudder authority reduces too far and aerodynamic directional

control is lost. As the nose wheel touches down rudder will have to be

straightened to avoid a steering snatch due to the rudder deflection

applied against the crosswind.

4.12.5 When the nose wheel is down, aileron will still need to be applied

against the crosswind and neutral or light forwards elevator pressure

Skyranger Swift Operators Manual (issue 3)

17

should be applied to ensure adequate steerage from the nose wheel

and to avoid yawing into wind.

4.13 Cruise

The Skyranger Swift has a large range of cruise speed. At the higher

values fuel consumption will be correspondingly higher. Cruise is set

up in the normal way by selecting the required attitude and power and

trimming off any residual pitch forces.

4.14 Turning

4.14.1 Turning is accomplished in the standard manner. In common with

many light aircraft the Skyranger Swift requires some rudder coordination to maintain balance when rolling into and out of a turn.

4.14.2 As with any other aircraft, the stall speed will increase with bank

angle. The stalling speed at 600 bank with no flap will rise to 52 knots

CAS[ IAS], at 450Kg takeoff weight.

4.15 Flight in Turbulence

The Skyranger Swift has powerful controls and handles turbulence well.

However in strong turbulence, do not fly above the manoeuvre speed

of 74 knots CAS [ IAS]

4.16 Stalling

During test flying of the UK prototype the following stalling speeds

were recorded:

VS1 – Stalling speed at max takeoff weight, forward CG and flaps up:

37kn CAS

VSO – Stalling speed at max takeoff weight, forward CG, full flap:

33.5kn CAS

These speeds should represent the worse case in normal service. Lower

takeoff weights and more rearward CG will lower the stalling speed –

but not by much! Pilots should also remember that stalling speed

increases during turns and manoeuvres. Any ice on the aircraft will also

increase stalling speeds – never takeoff with ice present on the aircraft.

Skyranger Swift Operators Manual (issue 3)

Loading...

Loading...