Flyitalia MD 3 RIDER Aircraft Maintenance Manual

!!!!!!!!!!!!

AIRCRAFT MAINTENANCE

MANUAL

Flyitalia S.r.l tel.: +39 0373978008

Via Umberto I, 51\1 fax.: +39 037394571

26010 Dovera (CR) website.: http://www.flyitalia.it

Italy mail.: info@flyitalia.it

Aircraft maintenance manual MD3

RIDER

AIRCRAFT MAINTENANCE MANUAL

Model: MD 3 RIDER

Serial number:

Registration:

Owner: .............................................................

.............................................................

.............................................................

Aircraft maintenance manual MD3

RIDER

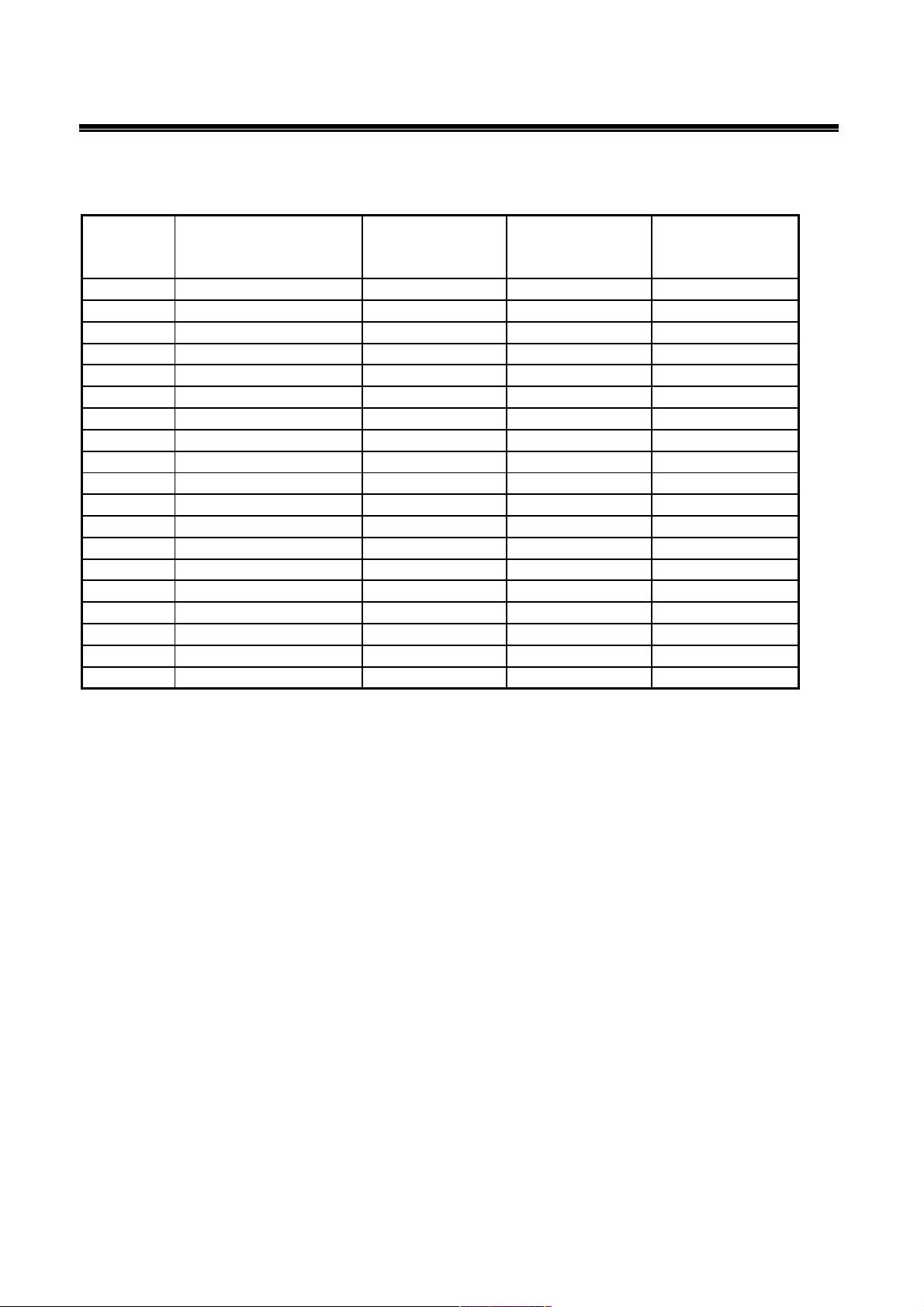

LIST OF THE REVISIONS AND THE REPAIRS

Ordinal

No.

Number of

document -

bulletin

It concerns to

pages No.

Date of issue: Signature :

Aircraft maintenance manual MD3

RIDER

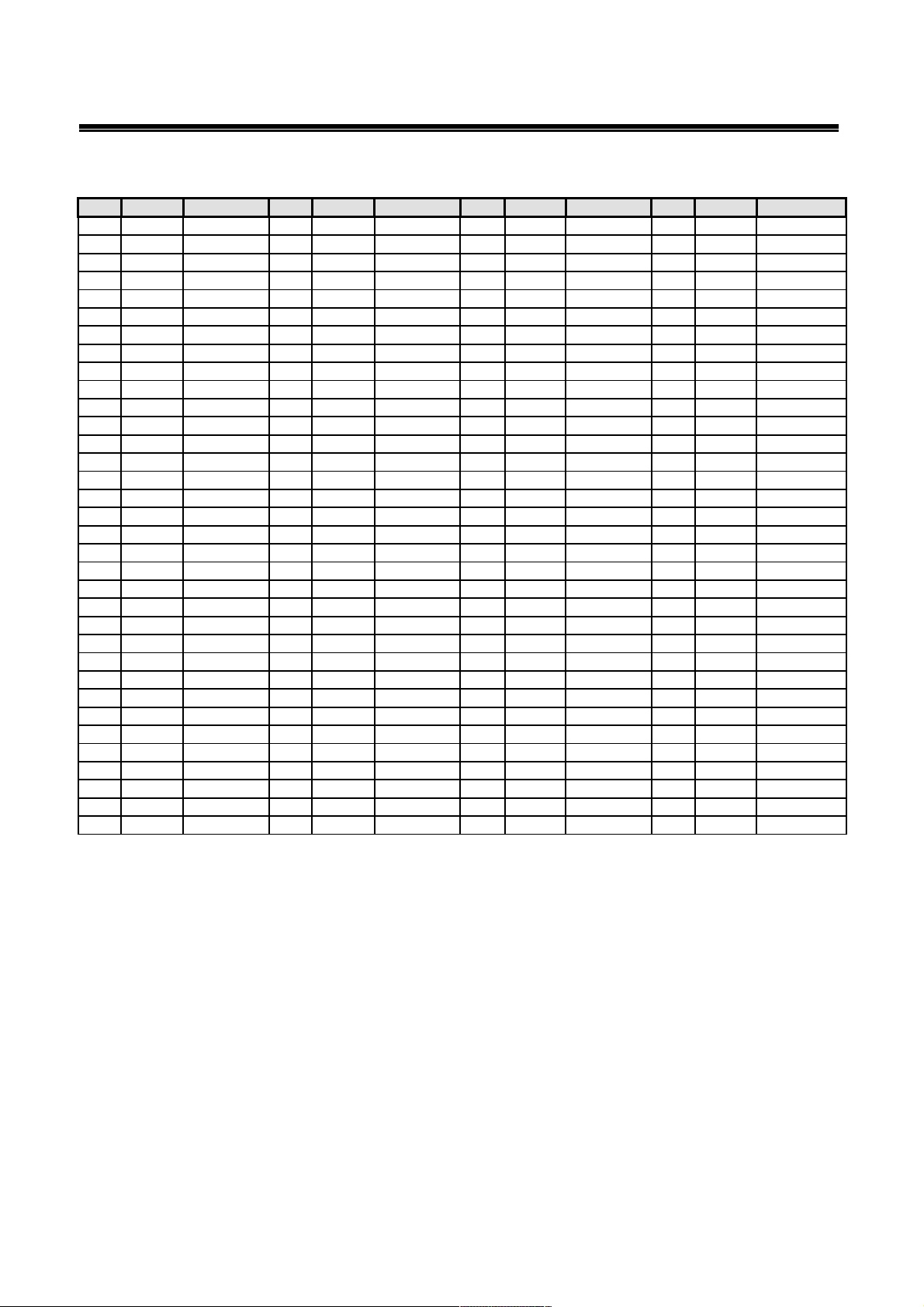

LIST OF EFFECTIVE PAGES

Sec. Page Date Sec. Page Date Sec. Page Date Sec. Page Date

1 1-8 9/6/2005 2 2-1 9/6/2005 4 4-1 9/6/2005 5 5-1 9/6/2005

1-9 9/6/2005 2-2 9/6/2005 4-2 9/6/2005 5-2 9/6/2005

1-10 9/6/2005 2-3 9/6/2005 4-3 9/6/2005 5-3 9/6/2005

1-11 9/6/2005 2-4 9/6/2005 4-4 9/6/2005 5-4 9/6/2005

1-12 9/6/2005 2-5 9/6/2005 4-5 9/6/2005 5-5 9/6/2005

1-13 9/6/2005 2-6 9/6/2005 4-6 9/6/2005

1-14 9/6/2005 2-7 9/6/2005 4-7 9/6/2005

1-15 9/6/2005 2-8 9/6/2005 4-8 9/6/2005

1-16 9/6/2005 2-9 9/6/2005 4-9 9/6/2005

1-17 9/6/2005 2-10 9/6/2005 4-10 9/6/2005

1-18 9/6/2005 2-11 9/6/2005 4-11 9/6/2005

1-19 9/6/2005 2-12 9/6/2005 4-12 9/6/2005

1-20 9/6/2005 2-13 9/6/2005 4-13 9/6/2005

1-21 9/6/2005 2-14 9/6/2005 4-14 9/6/2005

1-22 9/6/2005 4-15 9/6/2005

1-23 9/6/2005 4-16 9/6/2005

1-24 9/6/2005 4-17 9/6/2005

1-25 9/6/2005 3 3-1 9/6/2005 4-18 9/6/2005

1-26 9/6/2005 3-2 9/6/2005 4-19 9/6/2005

1-27 9/6/2005 3-3 9/6/2005 4-20 9/6/2005

1-28 9/6/2005 3-4 9/6/2005 4-21 9/6/2005

1-29 9/6/2005 4-22 9/6/2005

1-30 9/6/2005 4-23 9/6/2005

1-31 9/6/2005 4-24 9/6/2005

1-32 9/6/2005 4-25 9/6/2005

1-32 9/6/2005 4-26 9/6/2005

1-33 9/6/2005 4-27 9/6/2005

1-34 9/6/2005 4-28 9/6/2005

1-35 9/6/2005 4-29 9/6/2005

1-36 9/6/2005

1-37 9/6/2005

1-38 9/6/2005

1-39 9/6/2005

Aircraft maintenance manual MD3

RIDER

TABLE OF CONTENTS

1. Technical descriptions....................................................................................................................8

1.1. Basic and general descriptions:..............................................................................................8

1.1.1. Designation.........................................................................................................................8

1.2. Basic Technical data...............................................................................................................9

1.2.1. Airplane views....................................................................................................................9

1.2.2. Three – view drawing......................................................................................................10

1.2.3. Basic dimensions..............................................................................................................12

1.2.4. Tires-inflation...................................................................................................................12

1.2.5. Weights ............................................................................................................12

1.2.6. Power plant.......................................................................................................................12

1.2.7. Operation fillings..............................................................................................................12

1.2.8. Propellers..........................................................................................................................13

1.3. Technical description of the plane........................................................................................14

1.3.1. Technology.......................................................................................................................14

1.3.2. General.............................................................................................................................14

1.3.3. Fuselage............................................................................................................................15

Side Canopy doors from carbon fiber with integral 3D shaped plexiglas windows on its full

surface enables great view and easy access. Doors are hinged on the front hinges and locked in

2 points on the top and bottom rear corners, equipped by classic outside handles with key

locks, and lever handles from the inside in the bottom frame....................................................17

1.3.5. Wing.................................................................................................................................18

1.3.6. Tail....................................................................................................................................20

1.4. Landing gear..........................................................................................................................21

1.4.1. General description...........................................................................................................21

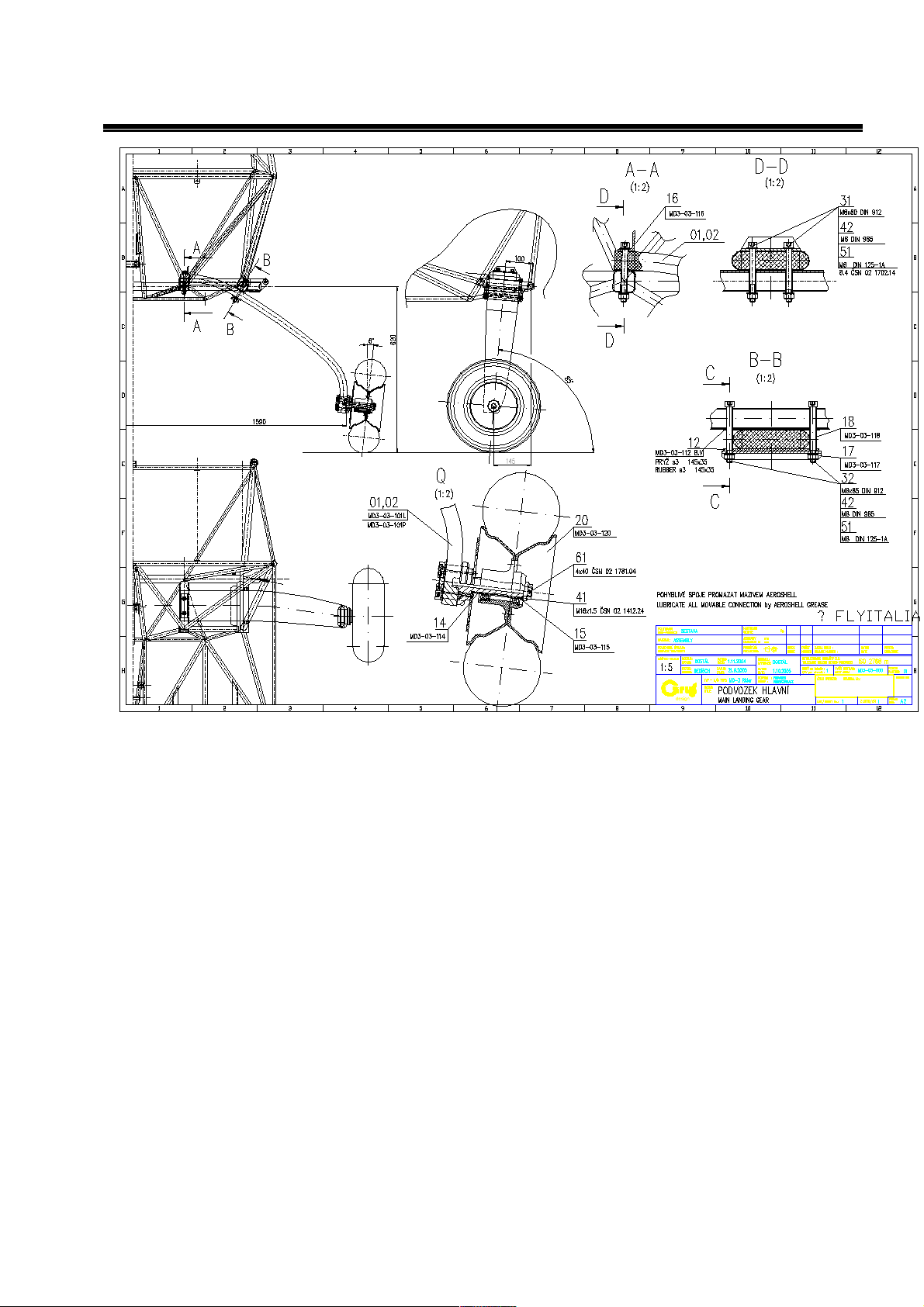

1.4.2. The main landing gear......................................................................................................22

1.4.3. Nose wheel landing gear..................................................................................................23

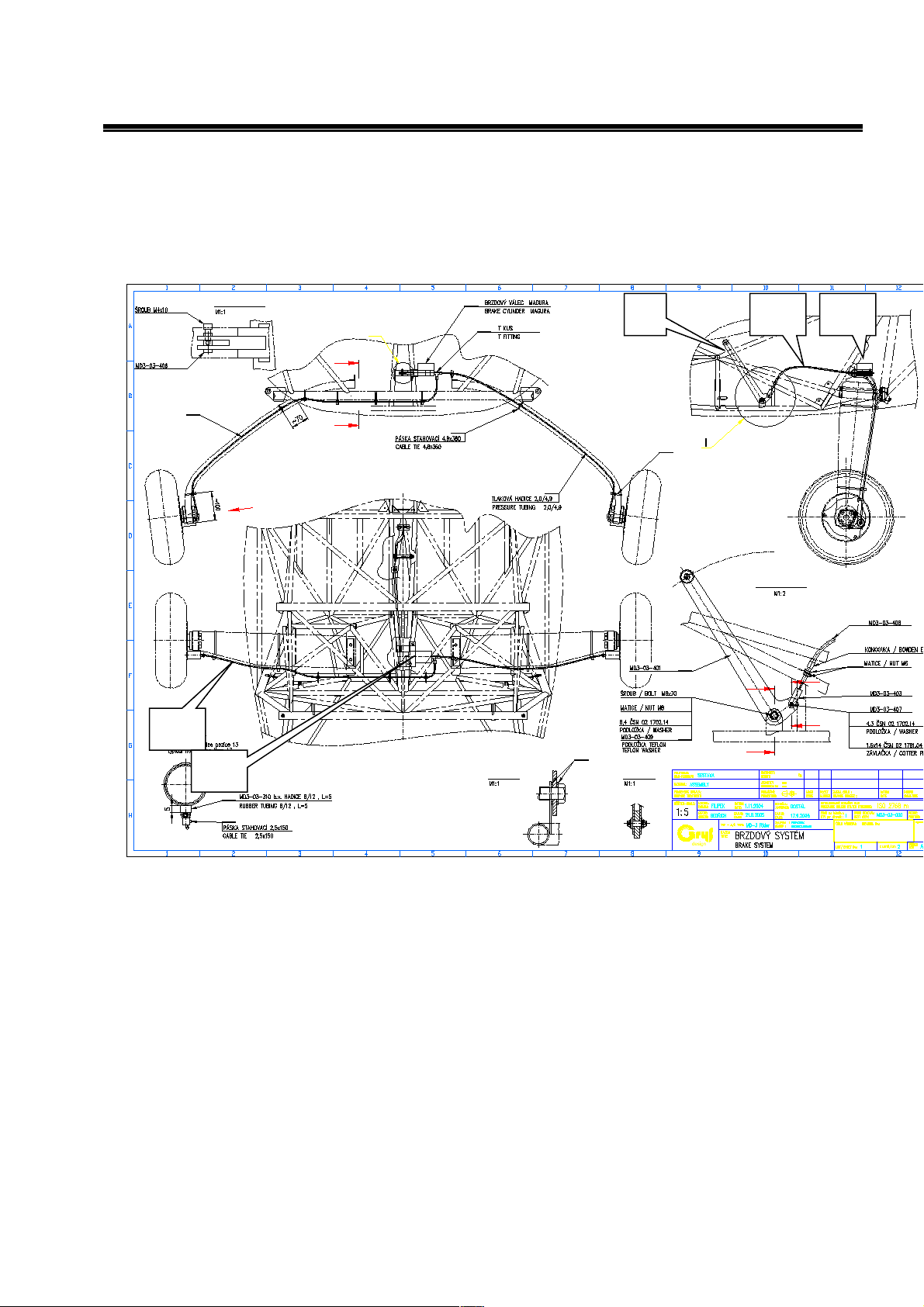

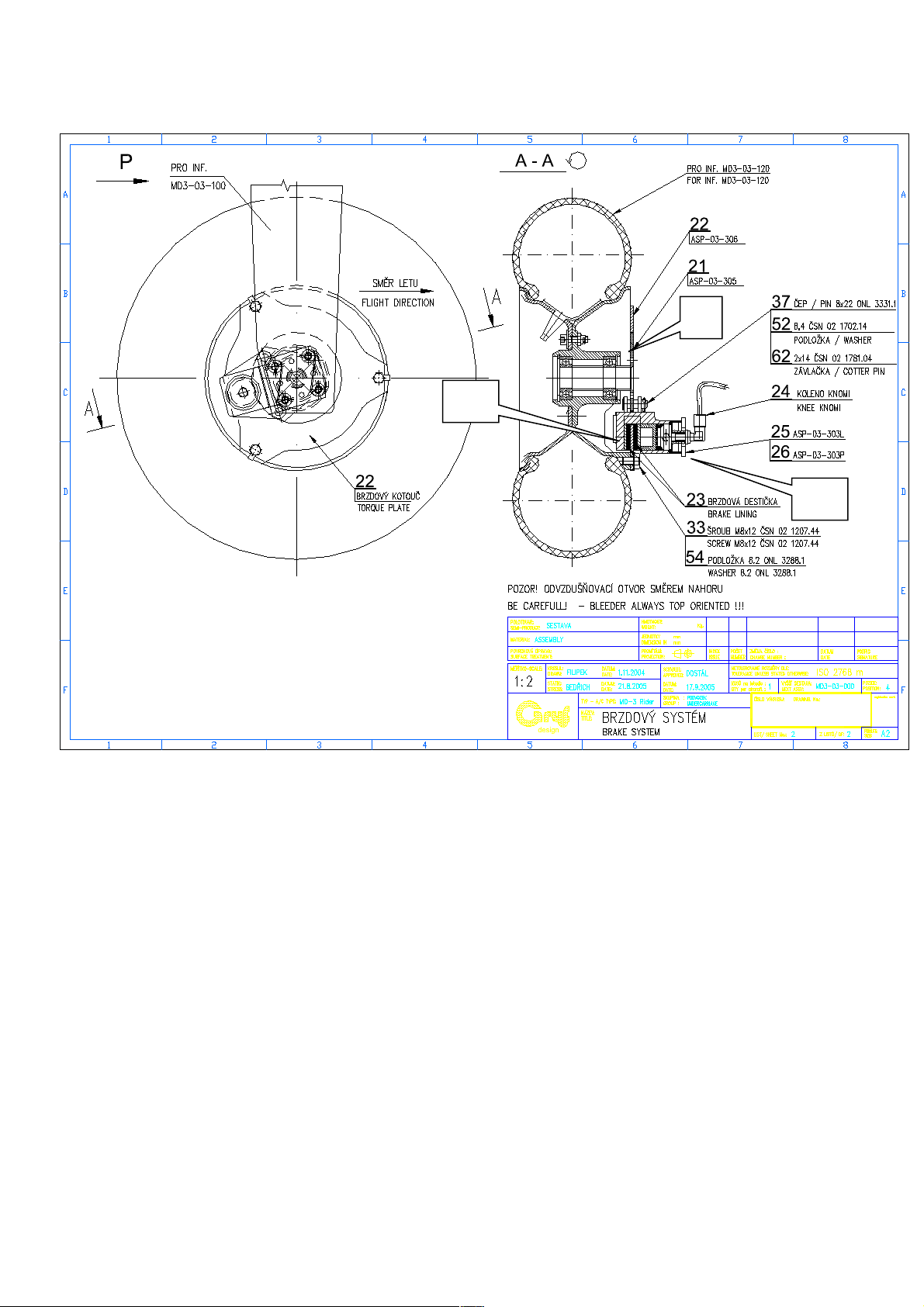

1.4.4. Wheel brakes....................................................................................................................25

1.4.5. Wheel fairings .................................................................................................................27

1.5. Auxiliary tail skid..................................................................................................................27

1.6. Three-axis control..................................................................................................................28

1.6.1. Elevator control................................................................................................................29

1.6.2. Rudder control..................................................................................................................29

1.6.3. Ailerons control ...............................................................................................................31

1.6.4. Flaps control.....................................................................................................................32

1.6.5. Elevator trim tab control...................................................................................................34

1.7. Cockpit ...................................................................................................................................35

1.7.2. Instrument panel...............................................................................................................36

1.7.3. Standard analog flight instruments...................................................................................40

1.7.4. Digital Aveo flight instruments........................................................................................41

1.7.5. Radio – transceivers.........................................................................................................42

1.7.6. Headsets............................................................................................................................42

1.7.7. GPS...................................................................................................................................43

1.7.8. Transponder......................................................................................................................44

1.7.9. Standard engine instruments............................................................................................45

1.7.10. Digital Aveo engine istruments......................................................................................46

1.7.11. Optional instruments......................................................................................................47

1.8. Power plant............................................................................................................................48

1.8.1. The EMS – engine monitoring system ( if installed).......................................................50

Aircraft maintenance manual MD3

RIDER

1.8.2. Analog engine instruments...............................................................................................51

1.9. Fuel..........................................................................................................................................52

1.10. Oil..........................................................................................................................................52

1.11. Propeller...............................................................................................................................52

1.12. Engine bed............................................................................................................................54

1.13. Engine cowlings....................................................................................................................55

1.14. Fuel system...........................................................................................................................56

1.15. Engine lubrication system...................................................................................................58

1.16. Cooling system.....................................................................................................................59

1.17. Heating..................................................................................................................................59

1.18. Pitot-static system................................................................................................................60

1.19. Electric system.....................................................................................................................61

1.20. Placards................................................................................................................................63

2. Operation.......................................................................................................................................64

2.1. Operation outlines.................................................................................................................64

2.2. Airplane assembly..................................................................................................................65

2.2.1. Wing.................................................................................................................................65

2.2.2. Horizontal tail unit............................................................................................................67

2.2.3. Vertical tail unit................................................................................................................68

2.2.4. Landing gear.....................................................................................................................69

2.2.5. Removal and replacement of mudguards ..................70

2.2.6. Installation and relinstallation of instruments..................................................................71

2.3. Measurement of control surfaces deflections......................................................................72

2.3.1. Required deflections.........................................................................................................72

2.3.2. Aileron deflection measurement......................................................................................73

2.3.3. Flap deflection measurement............................................................................................73

2.3.4. Elevator deflections measurement....................................................................................74

2.3.5. Rudder deflection measurement.......................................................................................74

2.3.6. Trim tab deflections measurement...................................................................................75

2.4. Permissible Tolerances..........................................................................................................76

2.5. Weighing the airplane and C.G. calculation.......................................................................77

2.5.1. Empty weight determination............................................................................................77

2.5.2. Operating C. G. range calculation....................................................................................77

3. Ground handling...........................................................................................................................78

3.1. Assembling for transportation and hangaring..................................................................78

3.2. Unlocking, opening and turning up the rear baggage fairing .........................................78

3.3. Disconnecting aileron controls and front wing hinges......................................................78

3.4. Folding the wings ................................................................................................................79

3.5. Parking..................................................................................................................................79

3.5.1. General............................................................................................................................79

3.5.2. Pressure sensor plug of the airspeed indicator................................................................79

3.6. Mooring.................................................................................................................................80

3.7. Hangaring..............................................................................................................................81

3.8. Towing ...................................................................................................................................81

4. Maintenance....................................................................................................................................1

4.1. Overall maintenance survey...................................................................................................1

4.2. Pre-flight inspection................................................................................................................1

4.2.1. Direction of pre-flight inspection.......................................................................................1

4.2.2. Steps of pre-flight inspection.............................................................................................2

4.3. Post-flight inspection...............................................................................................................3

Aircraft maintenance manual MD3

RIDER

4.4. Periodical inspection................................................................................................................3

4.4.1. Periodical inspection intervals............................................................................................3

4.4.2. Periodical inspections Sign off sheets................................................................................3

4.4.3. Periodical inspections – events...........................................................................................4

4.5. Fluids.......................................................................................................................................13

4.5.1. Engine oil.........................................................................................................................14

4.5.2. Coolant.............................................................................................................................14

4.5.3. Brake fluid........................................................................................................................15

4.5.4. Fuel...................................................................................................................................16

4.6. Lubrication.............................................................................................................................17

4.6.1. Lubrication fundamentals.................................................................................................17

4.6.2. Recommended lubricants.................................................................................................17

4.6.3. Lubrication points.............................................................................................................18

4.7. Mechanism adjustments........................................................................................................19

4.7.1. Torque moments...............................................................................................................19

4.8. Brake system efficiency adjustment.....................................................................................21

4.8.1. Brake pad replacement.....................................................................................................21

4.8.2. Bleeding............................................................................................................................22

4.9. Control surfaces deflection setting.......................................................................................23

4.9.1. Aileron deflection adjustment..........................................................................................23

4.9.2. Elevator deflection adjustment.........................................................................................23

4.9.3. Rudder deflection adjustment...........................................................................................23

4.9.4. Trim deflection adjustment...............................................................................................23

4.9.5. Flap deflection adjustment...............................................................................................23

4.10. Steerable nosewheel landing gear adjustment..................................................................25

4.11. Engine idle adjustment........................................................................................................25

4.12. Tire inflation pressure.........................................................................................................25

4.13. Door closing mechanism adjusting ...................................................................................26

4.14. Cleaning and care................................................................................................................27

4.14.1. Airplane care outlines.....................................................................................................27

4.14.2. External surfaces cleaning..............................................................................................27

4.14.3. Interior cleaning.............................................................................................................27

4.14.4. Cockpit canopy cleaning................................................................................................27

4.15. Winter operation..................................................................................................................28

4.15.1. General ..........................................................................................................................28

4.15.2. Preparing the aircraft for winter operation.....................................................................28

4.16. Necessary maintenance tools..............................................................................................29

4.17. Engine maintenance............................................................................................................29

4.18. Propeller maintenance.........................................................................................................29

5. Appendices......................................................................................................................................1

5.1. Record about the checking of control surfaces and tension of airplane cables.................2

5.2. Record about the weighting and location of gravity for MD-3 RIDER aircraft...............3

5.3. Record about the weighting and location of gravity for MD-3 RIDER aircraft...............3

5.4. Flight Test Record for MD-3 RIDER aircraft.......................................................................5

1.Technical descriptions

1.1.Basic and general descriptions:

Classical all-metal MD3 Rider with high-wing with side-by-side seats. The aircraft is equipped with

tricycle landing gear. Standard powerplant consist of, 4 cylinder, 4 stroke Rotax 912S or UL

(80,100hp) engine and three blade propeller. MD3 conforms to Czech UL-2 and Germany BFUDULV requirements for “sport flying vehicles”.

1.1.1.Designation

MD3 Rider designed to be ideal for training, CROSS-COUNTRY flying and flying for fun.

Aircraft maintenance manual MD3

RIDER

1.2. Basic Technical data

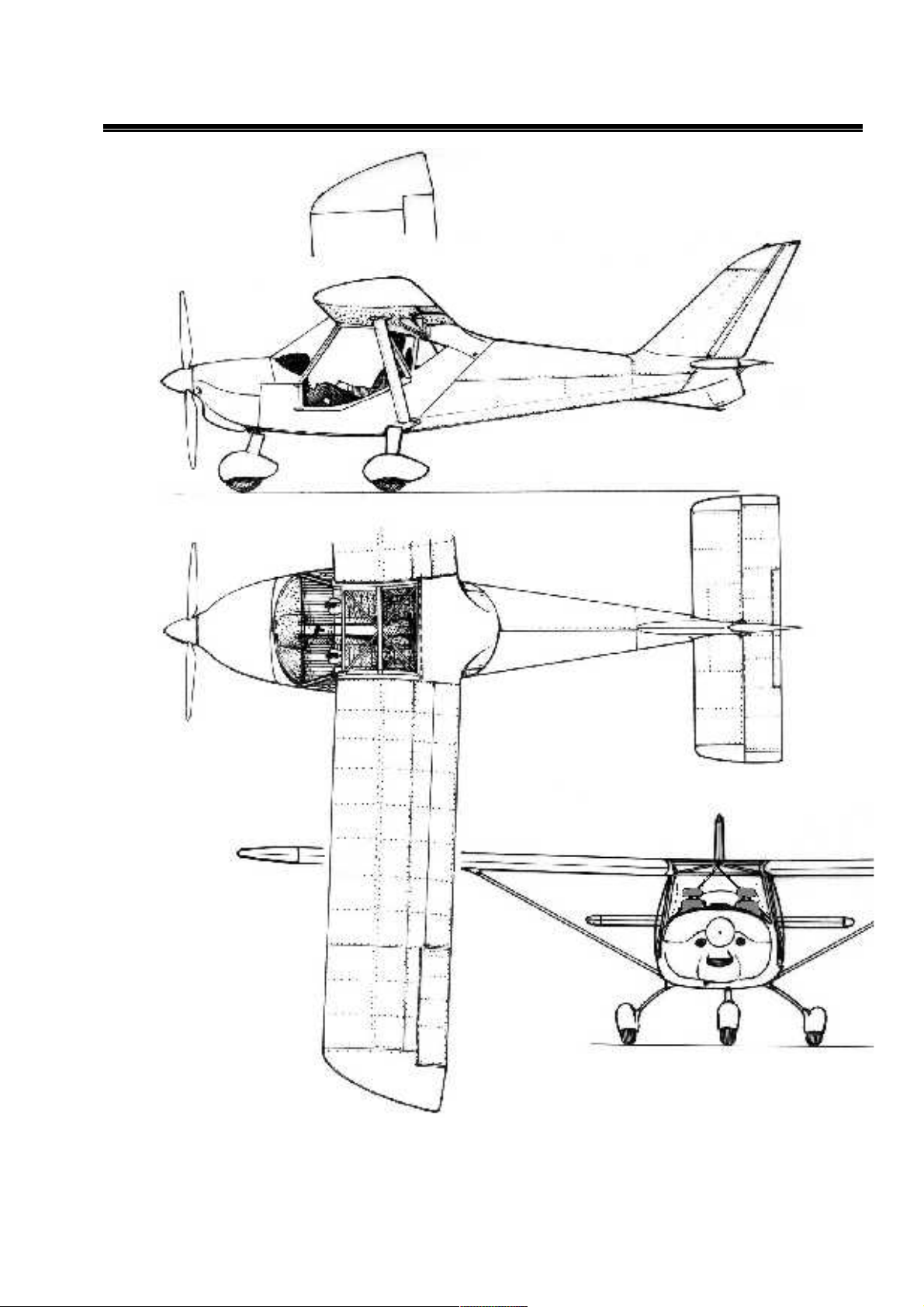

1.2.1.Airplane views

DIMENSIONS :

9

Aircraft maintenance manual MD3

RIDER

1.2.2. Three – view drawing

10

Aircraft maintenance manual MD3

RIDER

11

Aircraft maintenance manual MD3

RIDER

1.2.3.Basic dimensions

Wing span 9.0 m 28,5 ft

Length 5.9 m 19,3 ft

Height 2.3 m 7,5 ft

Wing area 9.9 m

2

106,6 sq ft

Forward swept wing: -3

1.2.4.Tires-inflation

Nose landing gear - 180 +20 kPa / 26,5 + 3 psi

Main landing gear - 180 +20 kPa / 26,5 + 3 psi

1.2.5.Weights

MD3 RIDER MD3 RIDER UL MD3 RIDER 914

Empty weight 295 kg / lb 276 kg / lb 297 kg / lb

Maximum take-off weight 450 kg / 992 lb 450 kg /992 lb 450 kg / 992 lb

Strength limit MTOW 480 kg / 480 kg / 480 kg /

Maximum load factor +4 / -2 (ultimate + 6 / -3)

1.2.6.Power plant

1.2.6.1.Engine ROTAX

912 S 912 UL 914 UL

Maximum power 100HP / 73,5 kW 80 HP / 59,6 kW 115 HP / 85,7 kW

Time limited max. 5 min. max. 5 min.

For 5800 rpm 5800 rpm

Without limit 95 HP / 69,0 kW 100 HP / 74,5 kW

For 5500 rpm 5800 rpm 5500 rpm

Cylinder volume 1352ccm 1211ccm 1211ccm

Compression ratio 10,5 : 1 9,0 : 1

Dry weight 56,6 kg 54 kg 61,1 kg

Ignition unit DUCATI double CDI

Carburetor 2 x BING 64-3

1.2.7.Operation fillings

Fuel 94 l automotive petrol SUPER - BA 96 in two 47 l integral wing fuel tanks

Gear box oil API-GL5 (0, 5 l )

12

Aircraft maintenance manual MD3

RIDER

1.2.8.Propellers

1.2.8.1.Standard:

WOODCOMP SR 200 B - wooden 3-blade on the ground adjustable

1.68 m

Optional: Klassic 160/3/R - composite on the ground adjustable 3-blade 1.6 m

Winglet 165/3/R - on the ground adjustable 3-blade 1.65 m

Varia 170/2R - composite in the flight variable pitch 2-blade 1.70 m

SR 2000 XA - in flight variable pitch wooden 1.70 m

13

Aircraft maintenance manual MD3

RIDER

1.3.Technical description of the plane

1.3.1.Technology

All-metal semi-monocoque airframe, primary glued and riveted from aluminum alloy sheets

by blind rivets.

1.3.2.General

The MD3 airframe is of semi-monocoque construction glued and riveted from aluminum alloy

sheets by blind rivets. Some non supporting parts are made from fiberglass.

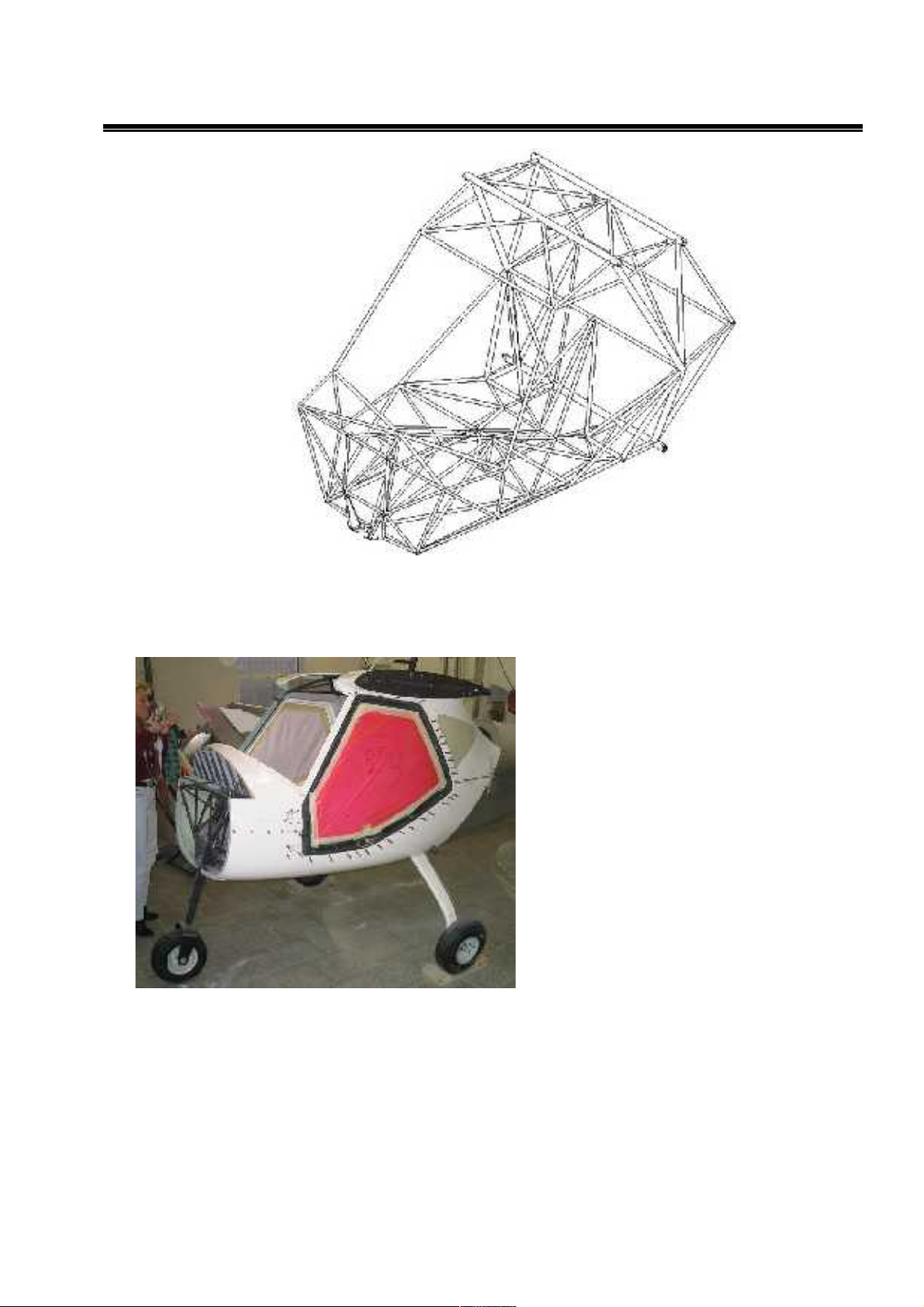

Fig.: MD3 Rider aircraft construction

14

Aircraft maintenance manual MD3

RIDER

1.3.3.Fuselage

1.3.3.1.Fuselage cockpit cage

FUSELAGE COCKPIT CAGE is welded from steel tubes. Its structure cover firewall,

engine mounting hinges and front wheel bracket in the front, wing struts and main gear

hinges on its sides and instrument panel frame and seats brackets, safety belts, arm-rest

and control levers hinges in the middle. On the rear part it has 4 rear fuselage part hinges.

On the top welded cage carries wing hinges, prepared for its folding and brackets of

aileron and flap controls.

15

Aircraft maintenance manual MD3

RIDER

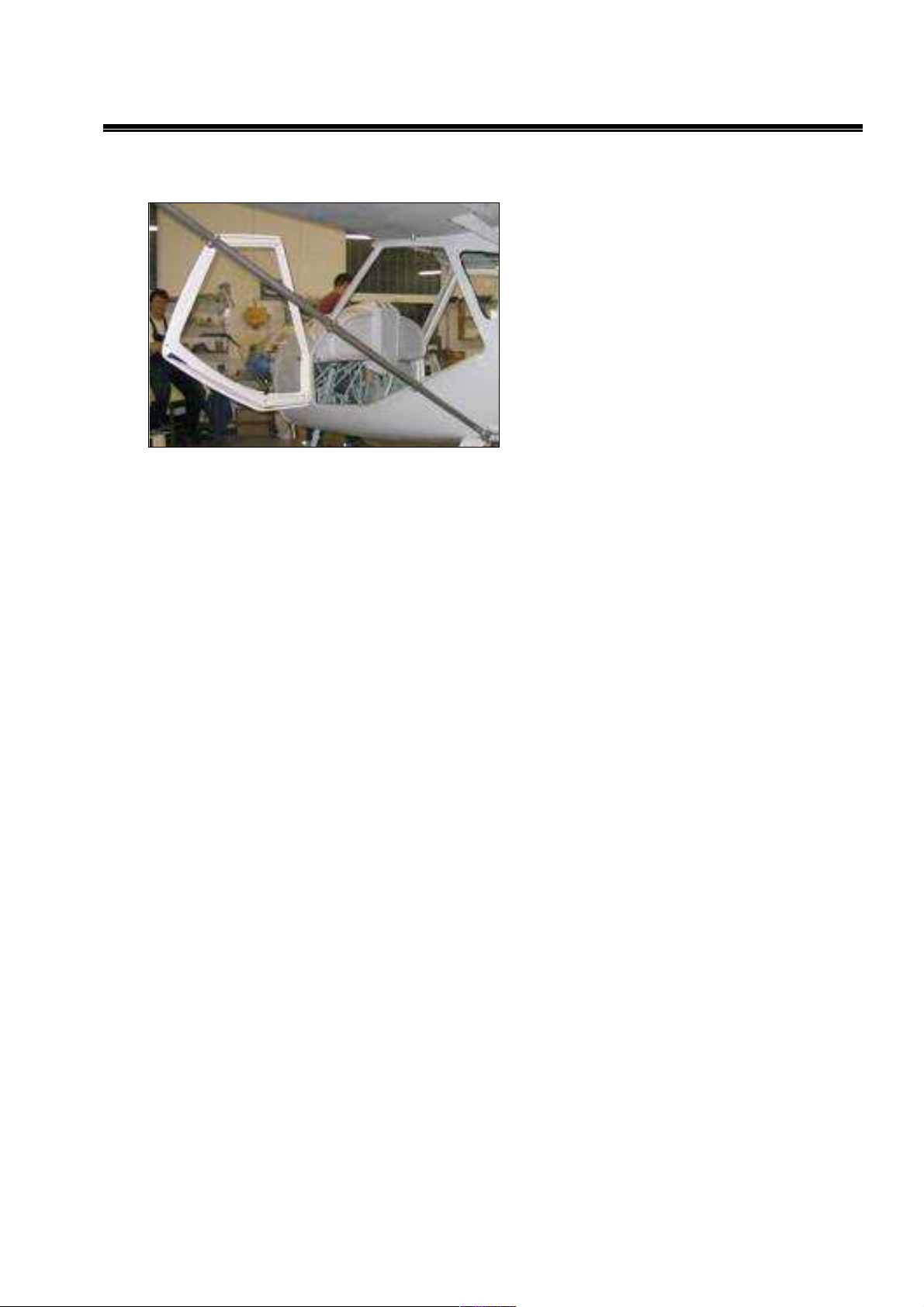

1.3.3.2.Cockpit Fairing

Cockpit fairing is produced from glass

fiber composite, glued on the tubes and

sheets of airframe and covers firewall,

instrument panel including air vents,

windshield frame in the front, conection

to the wings in the top and door frames

on the sides. In the rear COCKPIT

FAIRING is equipped by foldable cargo

compartment doors, needed to be

folded for wing folding too.

1.3.3.3.Rear fuselage part cone

Rear fuselage part cone is riveted from aluminum alloy sheets with integral fin and with

horizontal tail hinges on the rear “floor” and rudder hinges on the fin beam. Aluminum

alloy cone is finished by composite fairings with aerodynamically smooth transition

between horizontal and vertical areas and creates small bottom fin with tail-bump.

Fig.:Fuselage cockpit cage

16

Aircraft maintenance manual MD3

RIDER

1.3.3.4.Side Canopy doors

Side Canopy doors from carbon fiber with

integral 3D shaped plexiglas windows on

its full surface enables great view and

easy access. Doors are hinged on the

front hinges and locked in 2 points on the

top and bottom rear corners, equipped by

classic outside handles with key locks,

and lever handles from the inside in the

bottom frame.

17

Aircraft maintenance manual MD3

RIDER

1.3.4.

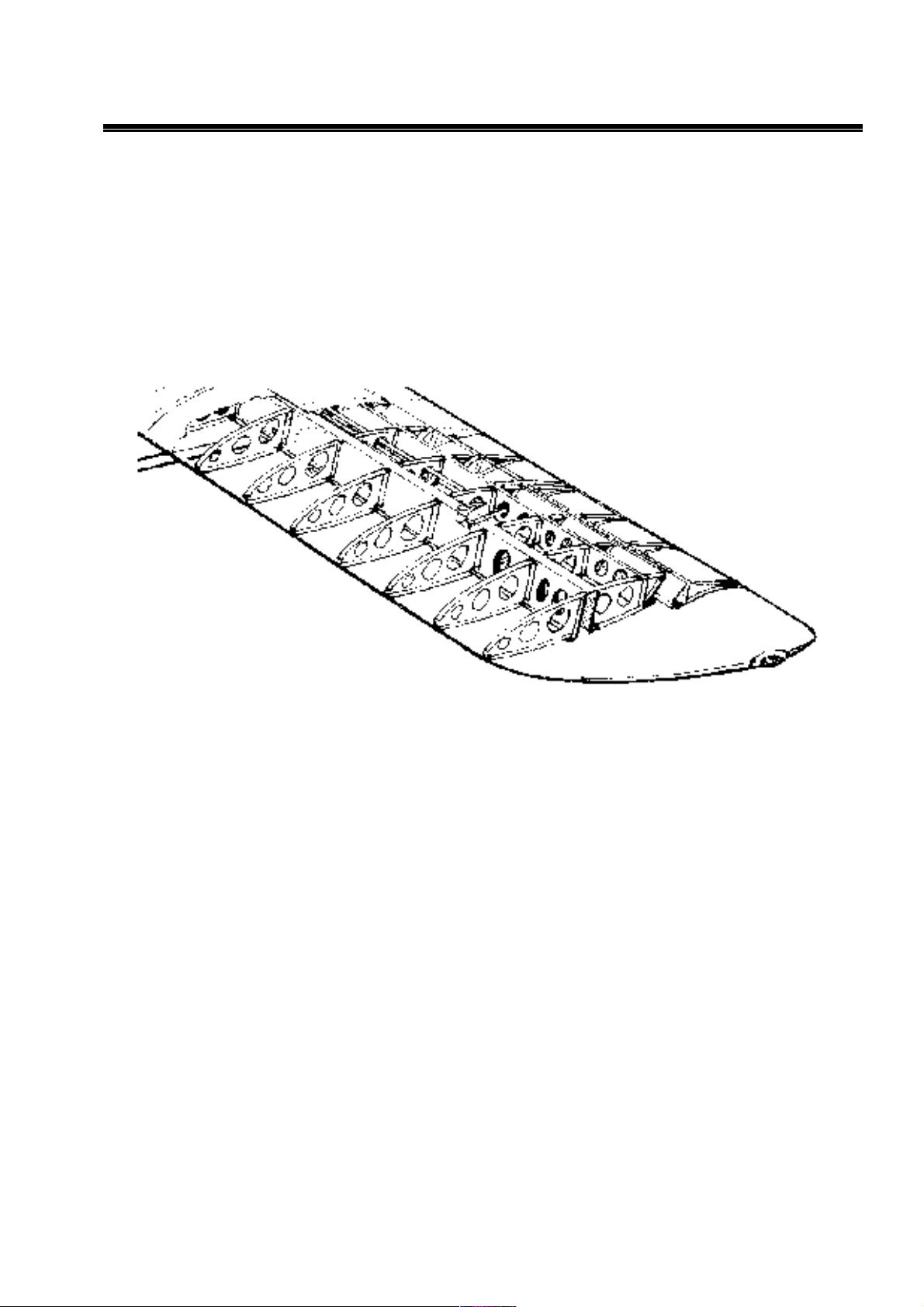

1.3.5.Wing

ALL METAL WINGS with simple aerodynamically shaped strut and efficient MS(1)-0313

airfoil with OMEGA-beam pressed ribs and integral fuel tanks 92 liters. Ailerons and large

flaps with 15o, 30o and 38o deflection are hinged on rear help-beam. Large aerodynamically

shaped wingtips increase wing efficiency. There is possibility to tilt wings backward to tail.

1.3.5.1.Ailerons

40% 1:1,5 differential ailerons are connected to upper side of airfoil with piano-hinge and

and driven through control lever riveted to root rib

1.3.5.2.Flaps

Fowler flaps are connected to wing over three arms and are electrically driven (BETAKOM

system) over tube in two points root and middle arm section. They have three positions 15°

(start) 30° (landing) and 38° (short landing)

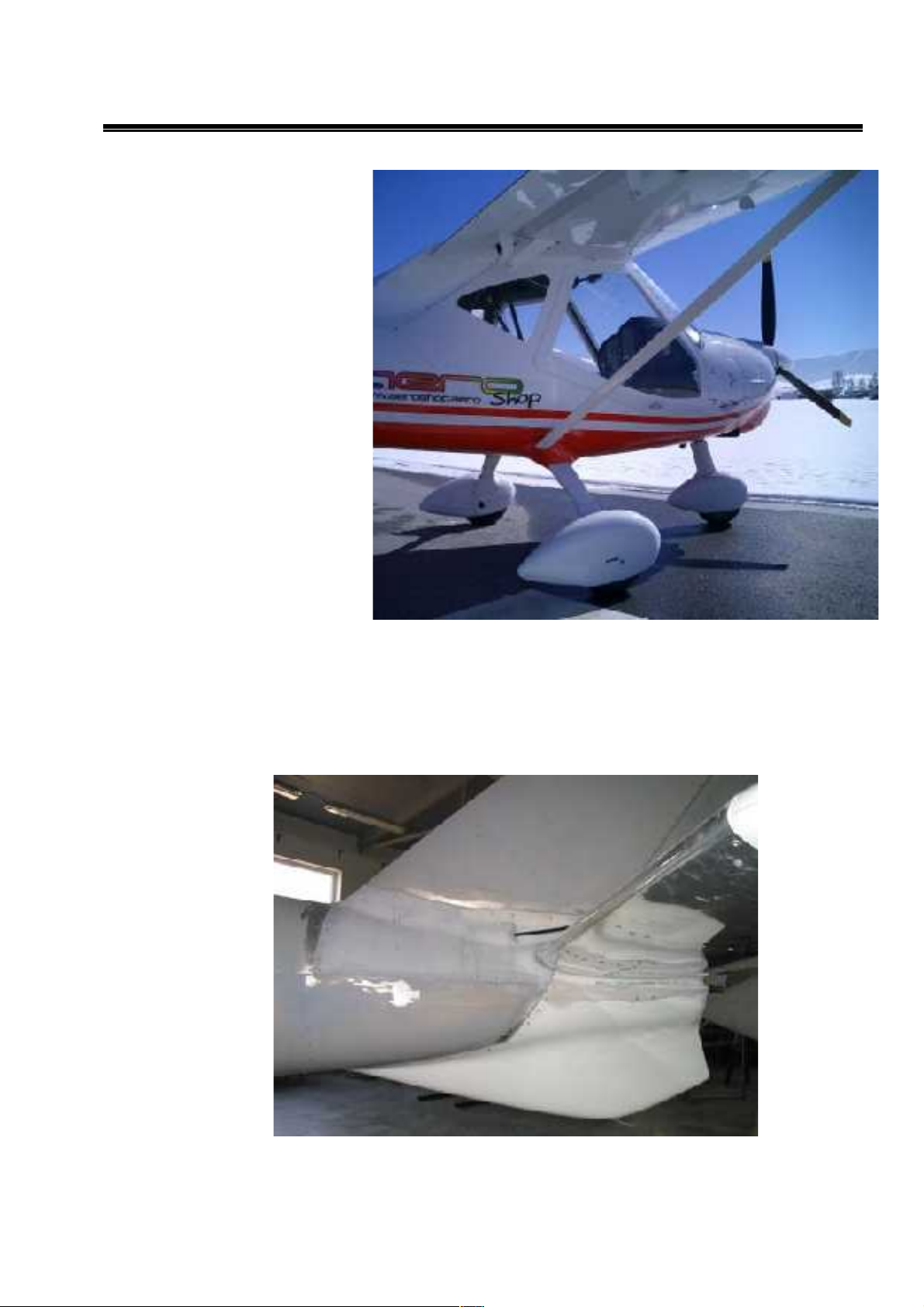

Fig.: Left wing

18

Aircraft maintenance manual MD3

RIDER

Fig.: Flaps in landing position

19

Aircraft maintenance manual MD3

RIDER

1.3.6.Tail

Classic-type all-metal TAIL has

symmetrical NACA 12%

profile. Horizontal Tail Unit

(HTU) consists of stabilizer

and elevator with trim tab. The

semi monocoque construction

consists of duralumin ribs,

spars and skin. Construction is

riveted by blind rivets and

glued by Efimastic PU50.

Trapezoidal Vertical Tail Unit

(VTU) consists of fin and

rudder. The rudder is attached

on the fin by two hinges. The

frame of VTU is composed of

metal sheet spar and

duralumin skin.(riveted and

glued by Efimastic PU50)

1.3.6.1.Stabilizer

Classic-type all-metal horizontal

tail glued by Emfimastic PU50 and riveted by blind rivets from aluminum alloy sheets and

pressed ribs and bended beams has symmetrical 12% airfoil NACA 0012. Stabilizer is

connected to fuselage over 2+2 connection points on auxiliary front and main rear spar.

Joint brackets on fuselage are riveted with solid rivets.

1.3.6.2.Elevator

The same technology rectangular shape elevator (with pressed 2024T3 aluminum alloy ribs and

skin) is connected with stabilizer through on the airfoil (rear beam) top fixed piano hinge and

has electrically controlled integral TRIM-TAB as a standard.

1.3.6.3.Fin

Fin with symmetrical 12% airfoil NACA 0012 is integral part of Rear fuselage part structure.

Rudder is hinged in two hinges and controlled from bottom - by control cables.

In the top of fin-tip there is located bracket for optional tail strobe light placing.

1.3.6.4.Rudder

The rudder is the trapezoidal shape and formed with a duralumin spar and skin and

attached with two hinges at the fin.

Rudder upper tip is formed with fiberglass cover.

Fig.: Aircraft tail

20

Aircraft maintenance manual MD3

RIDER

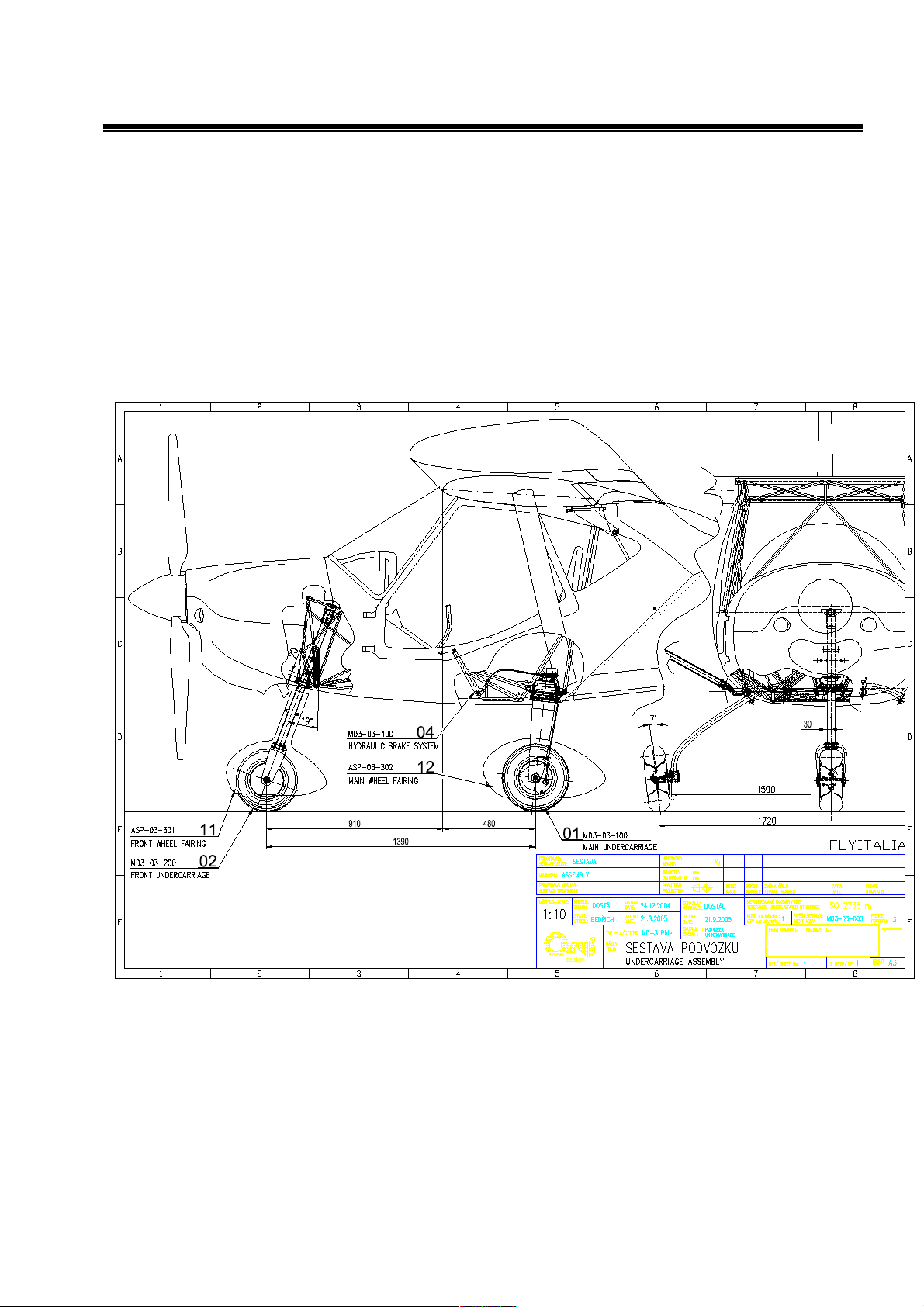

1.4.Landing gear

1.4.1.General description

The aircraft is equipped with fixed, tricycle landing gear.

The nose wheel is steerable, composite main gear is equipped with hydraulic brakes.

MD3-03-000

Fig.:Tricycle landing gear

21

Aircraft maintenance manual MD3

RIDER

1.4.2.The main landing gear

The main landing gear consists of right and left composite legs which are fixed in two

brackets inside fuselage welded cage. The legs are formed from fiberglass springs. The

main wheels 14x4” are equipped with hydraulic disc brakes (Aerospol) controlled by leveler

on the central column.

Fig.:Fixing of the main landing gear leg

22

Aircraft maintenance manual MD3

RIDER

MD3-03-100

1.4.3.Nose wheel landing gear

Steerable nose landing gear consists of front landing gear leg. Rubber cable shock

absorbing unit and suspension stop. The nose leg is made from steel tube. Fork is from

carbon fibers. Two rods are used for the leg steering by the control pedals. Wheel 13x4”.

Fig.:Main landing gear

23

Aircraft maintenance manual MD3

RIDER

Fig.:Front landing gear leg with

avional fork

Fig.:Rubber rope suspension unit

24

Aircraft maintenance manual MD3

RIDER

1.4.4.Wheel brakes

Both wheels on the main landing gear are equipped with hydraulic disc brakes. The brake

system consists of the brake handle in the middle column, hydraulic brake master cylinder,

plastic hoses, brake caliper with hydraulic brake cylinder, brake pads and the brake discs.

MD3-03-400

9

ᄅ FLYITALIA

P2

31

6

DETAIL II

8

41

12

1

DETAIL I

51

D

7

61

52

42

C

19

9

32

3

C

D

2

15

B

II

C - C

19

B

B - B

D - D

13

13

10

18

2

3

1 2 3

25

Aircraft maintenance manual MD3

RIDER

MD3-03-400

ᄅ FLYITALIA

5

6

4

Fig.: Brake system

1. brake handle

2. plastic hoses

3. hydraulic master cylinder

4. brake caliper with brake cylinder

5. brake pads

6. brake disc

26

Aircraft maintenance manual MD3

RIDER

1.4.5.Wheel fairings

All landing gear wheels

can be optionally equipped

by composite wheel

fairings.

1.5.Auxiliary tail skid

Auxiliary tail skid protects tail of aircraft from inadvertent damage during tail down landing

conditions. ATS is made from aluminum alloy pressed U profiles and covered by fiberglass

formed cover – with shape of auxiliary bottom fin.

Fig.: Auxiliary tail skid

27

Aircraft maintenance manual MD3

RIDER

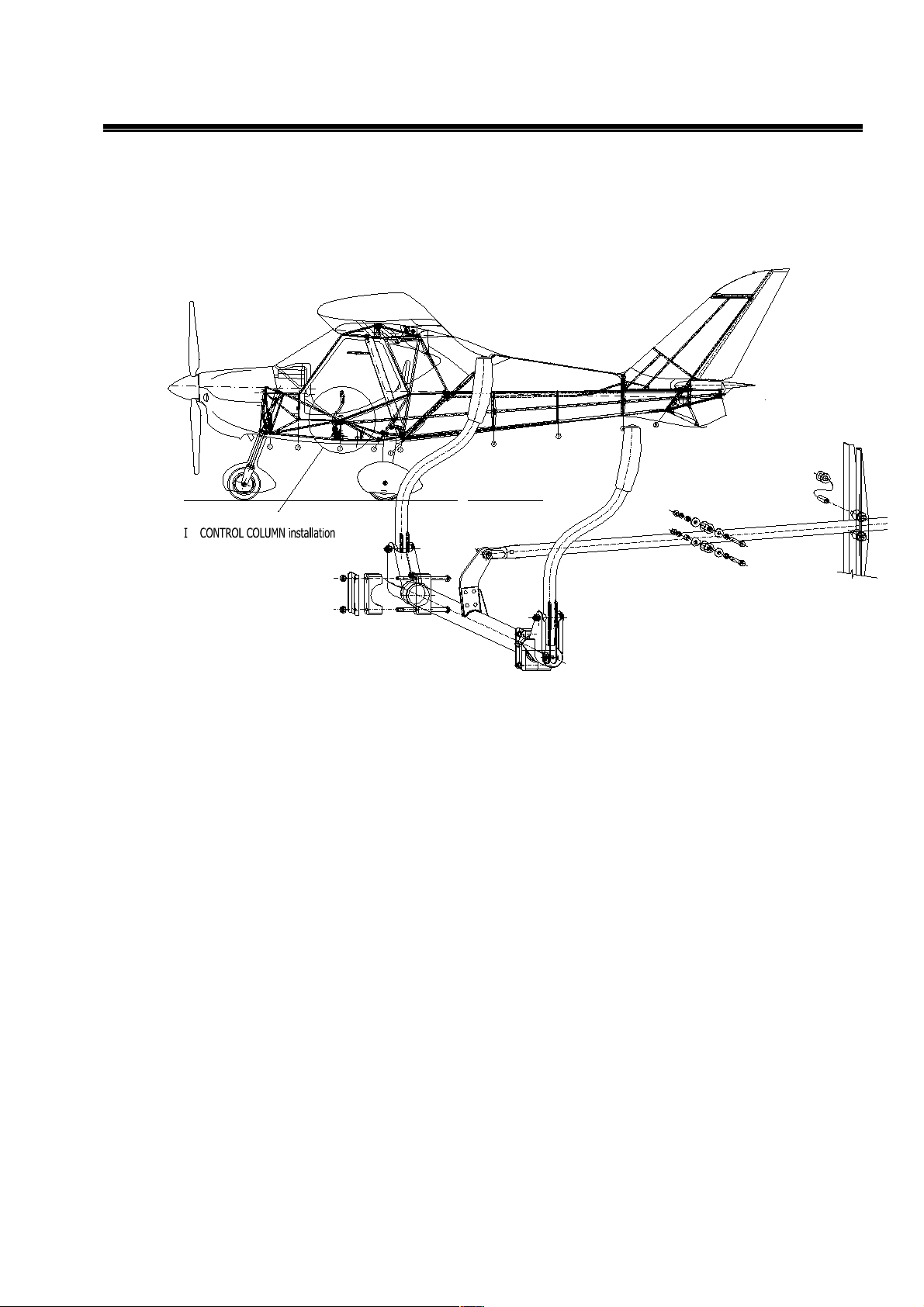

1.6.Three-axis control

Full dual control, with classic joysticks between pilot legs and pedals full controllable for both

pilots..Flap handle, trim handle, throttle and choke are placed on the central column.

Fig.:Dual control system

28

Aircraft maintenance manual MD3

RIDER

1.6.1.Elevator control

Elevator is controlled by joysticks, fixed in control column through one rod only guided in rod pulleys

fixed in metal brackets in welded cage and rear fuselage cone and connected directly with elevator

lever.

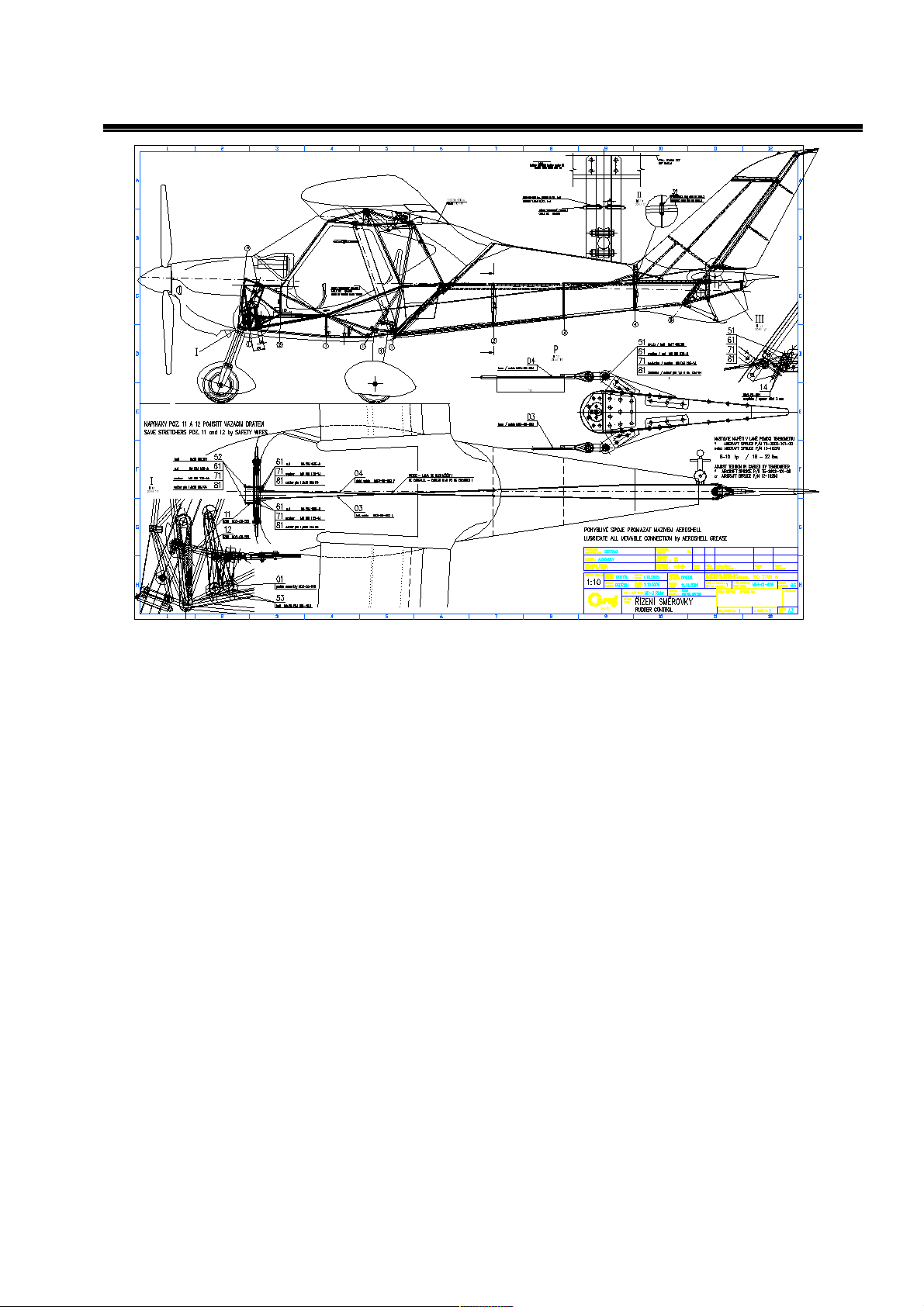

1.6.2.Rudder control

Rudder is controlled by wires in plastic slide tubes and connected through front undercarriage leg

control levers. Stretchers are located in the front – accessible from the cockpit.

29

Aircraft maintenance manual MD3

RIDER

MD3-09-500

ᄅ FLYITALIA

B

B

31

21

B - B

31

30

Loading...

Loading...