FLYGT P7030, P7035, P7040 Installation, Operation And Maintenance Manual

Installation, Operation

and Maintenance

Manual

Flygt P7030, P7035, P7040

Table of Contents

Introduction and Safety.........................................................................................................................3

Introduction..........................................................................................................................................3

Safety.....................................................................................................................................................3

Safety terminology and symbols....................................................................................................3

Environmental safety........................................................................................................................4

User safety.........................................................................................................................................5

Product warranty...............................................................................................................................6

Transportation and Storage..................................................................................................................7

Inspect the delivery.............................................................................................................................7

Inspect the package.........................................................................................................................7

Inspect the unit..................................................................................................................................7

Transportation guidelines..................................................................................................................7

Precautions........................................................................................................................................7

Position and fastening......................................................................................................................7

Lifting..................................................................................................................................................7

Temperature ranges for transportation, handling and storage....................................................8

Handling at freezing temperature..................................................................................................8

Unit in as-delivered condition.........................................................................................................8

Lifting the unit out of liquid.............................................................................................................8

Storage guidelines..............................................................................................................................9

Storage location................................................................................................................................9

Long-term storage............................................................................................................................9

Table of Contents

Product Description.............................................................................................................................10

Pump Design.....................................................................................................................................10

Intended Use...................................................................................................................................10

Parts....................................................................................................................................................11

The monitoring equipment..............................................................................................................12

The data plate....................................................................................................................................12

Approvals...........................................................................................................................................13

Product approvals for hazardous locations.................................................................................13

EN approval plate...........................................................................................................................13

IEC approval plate..........................................................................................................................14

FM approval plate..........................................................................................................................14

Product denomination......................................................................................................................14

Installation.............................................................................................................................................16

Fasteners............................................................................................................................................16

Requirements for the cable handling system................................................................................16

Install the pump.................................................................................................................................16

Make the electrical connections......................................................................................................20

General precautions.......................................................................................................................20

Requirements..................................................................................................................................20

Cables..............................................................................................................................................20

Earthing (Grounding).....................................................................................................................21

Cable entry parts............................................................................................................................21

Connect the motor cable to the pump........................................................................................21

Connect the motor cable to the starter and monitoring equipment.......................................22

Power cable phase sequence.......................................................................................................23

Cable charts....................................................................................................................................23

Cable bending radius, weight and diameter..............................................................................30

Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual 1

Table of Contents

Check the impeller rotation.............................................................................................................32

Operation..............................................................................................................................................33

Precautions.........................................................................................................................................33

Distance to wet areas........................................................................................................................33

Noise level..........................................................................................................................................33

Start the pump...................................................................................................................................33

Maintenance.........................................................................................................................................35

Precautions.........................................................................................................................................35

Torque values....................................................................................................................................35

Changing the coolant.......................................................................................................................36

Empty the coolant..........................................................................................................................36

Fill with coolant...............................................................................................................................37

Preparing for work on the hydraulic end.......................................................................................38

Remove the entrance cover..........................................................................................................38

Attach the assembly and dismantling stand...............................................................................39

Replacing the propeller....................................................................................................................40

Measure the clearance...................................................................................................................41

Remove the propeller....................................................................................................................42

Install the propeller........................................................................................................................43

Replace the bell mouth....................................................................................................................45

Replace the zinc anodes...................................................................................................................46

Service the pump..............................................................................................................................47

Inspection........................................................................................................................................47

Major overhaul................................................................................................................................49

Service in case of alarm.................................................................................................................49

Troubleshooting...................................................................................................................................50

Introduction.......................................................................................................................................50

The pump does not start..................................................................................................................50

The pump does not stop when a level sensor is used.................................................................51

The pump starts-stops-starts in rapid sequence...........................................................................51

The pump runs but the motor protection trips.............................................................................52

The pump delivers too little or no water........................................................................................52

Technical Reference............................................................................................................................54

Product overview...............................................................................................................................54

Materials.............................................................................................................................................54

Mounting-related data......................................................................................................................55

Operational data...............................................................................................................................56

Application limits............................................................................................................................56

Motor Data......................................................................................................................................56

The monitoring equipment...........................................................................................................56

P7030 Motor rating and performance, 50 Hz...................................................................................57

Low voltage........................................................................................................................................57

P7030 Motor rating and performance, 60 Hz...................................................................................58

Low voltage........................................................................................................................................58

2 Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual

Introduction and Safety

Introduction

Purpose of this manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the product. Improper use of the

product can cause personal injury and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the location of the

unit.

Introduction and Safety

Safety

WARNING:

• The operator must be aware of safety precautions to prevent physical injury.

• Any pressure-containing device can explode, rupture, or discharge its contents if it is

over-pressurized. Take all necessary measures to avoid over-pressurization.

• Operating, installing, or maintaining the unit in any way that is not covered in this manual

could cause death, serious personal injury, or damage to the equipment. This includes

any modification to the equipment or use of parts not provided by Xylem. If there is a

question regarding the intended use of the equipment, please contact an Xylem

representative before proceeding.

• This manual clearly identifies accepted methods for disassembling units. These methods

must be adhered to. Trapped liquid can rapidly expand and result in a violent explosion

and injury. Never apply heat to impellers, propellers, or their retaining devices to aid in

their removal.

• Do not change the service application without the approval of an authorized Xylem

representative.

CAUTION:

You must observe the instructions contained in this manual. Failure to do so could result in

physical injury, damage, or delays.

Safety terminology and symbols

About safety messages

It is extremely important that you read, understand, and follow the safety messages and

regulations carefully before handling the product. They are published to help prevent

these hazards:

• Personal accidents and health problems

• Damage to the product

• Product malfunction

Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual 3

Introduction and Safety

Hazard levels

Hazard level Indication

Hazard categories

DANGER:

WARNING:

CAUTION:

NOTICE:

Hazard categories can either fall under hazard levels or let specific symbols replace the

ordinary hazard level symbols.

Electrical hazards are indicated by the following specific symbol:

A hazardous situation which, if not avoided, will result in

death or serious injury

A hazardous situation which, if not avoided, could result

in death or serious injury

A hazardous situation which, if not avoided, could result

in minor or moderate injury

• A potential situation which, if not avoided, could

result in undesirable conditions

• A practice not related to personal injury

Electrical Hazard:

These are examples of other categories that can occur. They fall under the ordinary hazard

levels and may use complementing symbols:

• Crush hazard

• Cutting hazard

• Arc flash hazard

Environmental safety

The work area

Always keep the station clean to avoid and/or discover emissions.

Waste and emissions regulations

Observe these safety regulations regarding waste and emissions:

• Appropriately dispose of all waste.

• Handle and dispose of the processed liquid in compliance with applicable

environmental regulations.

• Clean up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

4 Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual

Electrical installation

Recycling guidelines

User safety

General safety rules

Introduction and Safety

WARNING:

Do NOT send the product to the Xylem manufacturer if it has been contaminated by any

nuclear radiation. Inform Xylem so that accurate actions can take place.

For electrical installation recycling requirements, consult your local electric utility.

Always recycle according to these guidelines:

1. Follow local laws and regulations regarding recycling if the unit or parts are

accepted by an authorized recycling company.

2. If the first guideline is not applicable, then return the unit or parts to your Xylem

representative.

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc flash

hazards.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

Safety equipment

Use safety equipment according to the company regulations. Use this safety equipment

within the work area:

Electrical connections

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local regulations. For more information about

requirements, see sections dealing specifically with electrical connections.

Hazardous liquids

The product is designed for use in liquids that can be hazardous to your health. Observe

these rules when you work with the product:

• Hard hat

• Safety goggles, preferably with side shields

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• First-aid kit

• Safety devices

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific information

about safety devices in other chapters of this manual.

• Make sure that all personnel who work with biologically hazardous liquids are

vaccinated against diseases to which they may be exposed.

• Observe strict personal cleanliness.

Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual 5

Introduction and Safety

Wash the skin and eyes

Follow these procedures for chemicals or hazardous fluids that have come into contact

with your eyes or your skin:

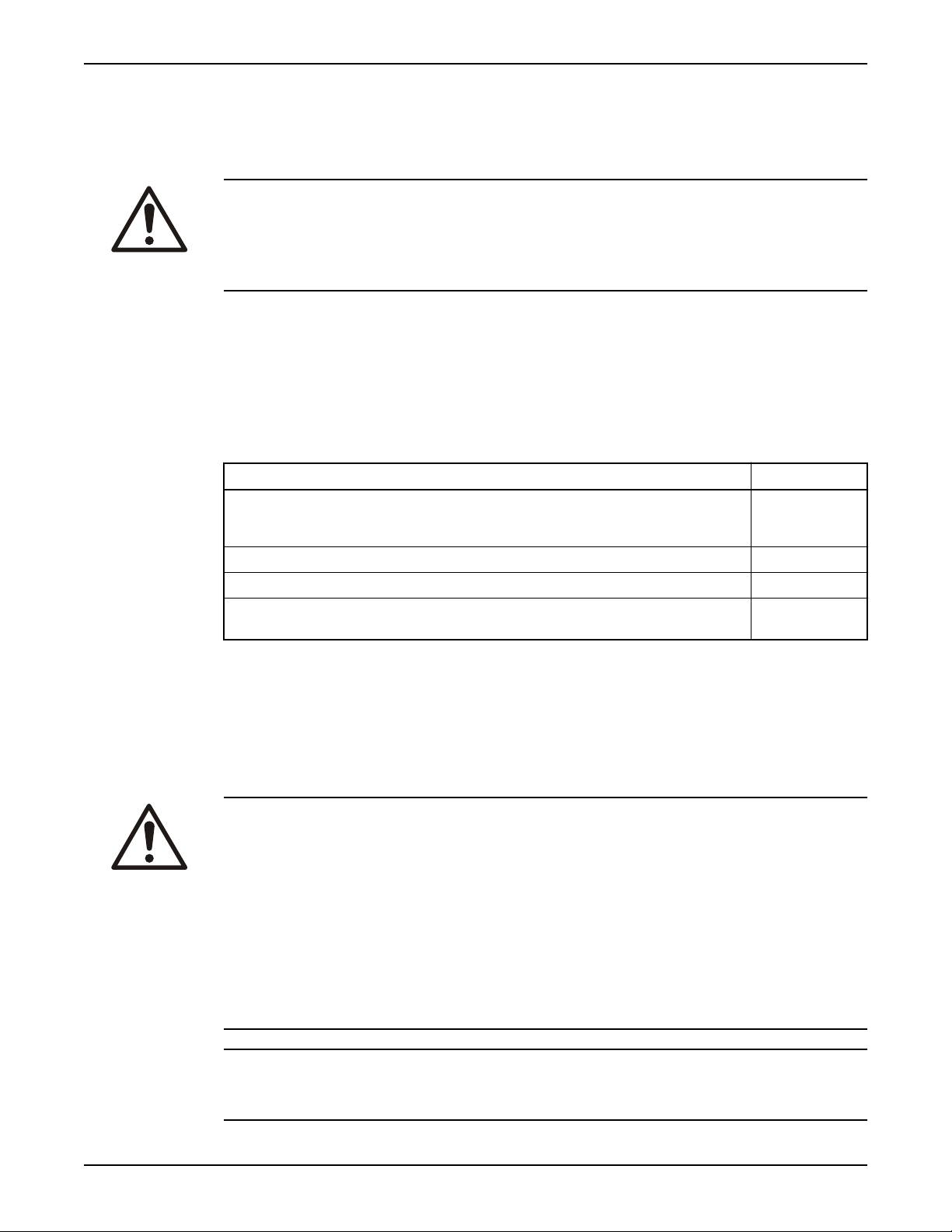

Condition Action

Product warranty

Coverage

Limitations

Chemicals or hazardous

fluids in eyes

Chemicals or hazardous

fluids on skin

Xylem undertakes to remedy defects in products from Xylem under these conditions:

• The faults are due to defects in design, materials, or workmanship.

• The faults are reported to an Xylem representative within the warranty period.

• The product is used only under the conditions described in this manual.

• The monitoring equipment incorporated in the product is correctly connected and in

use.

• All service and repair work is done by Xylem-authorized personnel.

• Genuine Xylem parts are used.

• Only Ex-approved spare parts and accessories authorized by Xylem are used in Exapproved products.

The warranty does not cover defects caused by these situations:

• Deficient maintenance

• Improper installation

• Modifications or changes to the product and installation made without consulting

Xylem

• Incorrectly executed repair work

• Normal wear and tear

Xylem assumes no liability for these situations:

• Bodily injuries

• Material damages

• Economic losses

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. Seek medical attention, if necessary.

Warranty claim

Xylem products are high-quality products with expected reliable operation and long life.

However, should the need arise for a warranty claim, then contact your Xylem

representative.

Spare parts

Xylem guarantees that spare parts will be available for 15 years after the manufacture of

this product has been discontinued.

6 Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual

Transportation and Storage

Inspect the delivery

Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the

distributor.

Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact your sales representative if anything is out of order.

Transportation and Storage

Transportation guidelines

Precautions

WARNING:

• Stay clear of suspended loads.

• Observe accident prevention regulations in force.

Position and fastening

The unit can be transported either horizontally or vertically. Make sure that the unit is

securely fastened during transportation, and cannot roll or fall over.

Lifting

WARNING:

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods

and wear steel-toed shoes at all times.

• Lift and handle the product carefully, using suitable lifting equipment.

• The product must be securely harnessed for lifting and handling. Use eyebolts or lifting

lugs if available.

• Always lift the unit by its lifting handle. Never lift the unit by the motor cable or by the

hose.

• Do not attach sling ropes to shaft ends.

Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual 7

Transportation and Storage

Lifting equipment

Lifting equipment is always required when handling the unit. It must fulfill the following

requirements:

• The minimum height (contact Xylem for information) between the lifting hook and the

• The lifting equipment must be able to hoist the unit straight up and down, preferably

• The lifting equipment must be securely anchored and in good condition.

• The lifting equipment must support weight of the entire assembly and must only be

• Two sets of lifting equipment must be used to lift the unit for repair work.

• The lifting equipment must be dimensioned to lift the unit with any remaining pumped

• The lifting equipment must not be oversized.

floor must be sufficient to lift the unit.

without the need for resetting the lifting hook.

used by authorized personnel.

media in it.

NOTICE:

Oversized lifting equipment could cause damage if the unit should stick when being

lifted.

Temperature ranges for transportation, handling and storage

Handling at freezing temperature

At temperatures below freezing, the product and all installation equipment, including the

lifting gear, must be handled with extreme care.

Make sure that the product is warmed up to a temperature above the freezing point before

starting up. Avoid rotating the impeller/propeller by hand at temperatures below the

freezing point. The recommended method to warm the unit up is to submerge it in the

liquid which will be pumped or mixed.

NOTICE:

Never use a naked flame to thaw the unit.

Unit in as-delivered condition

If the unit is still in the condition in which it left the factory - all packing materials are

undisturbed - then the acceptable temperature range during transportation, handling and

storage is: –50°C (–58ºF) to +60°C (+140ºF).

If the unit has been exposed to freezing temperatures, then allow it to reach the ambient

temperature of the sump before operating.

Lifting the unit out of liquid

The unit is normally protected from freezing while operating or immersed in liquid, but the

impeller/propeller and the shaft seal may freeze if the unit is lifted out of the liquid into a

surrounding temperature below freezing.

Units equipped with an internal cooling system are filled with a mixture of water and 30%

glycol. This mixture remains a flowing liquid at temperatures down to –13°C (9°F). Below –

13°C (9°F), the viscosity increases such that the glycol mixture will lose its flow properties.

However, the glycol-water mixture will not solidify completely and thus cannot harm the

product.

Follow these guidelines to avoid freezing damage:

8 Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual

1. Empty all pumped liquid, if applicable.

2. Check all liquids used for lubrication or cooling, both oil and water-glycol mixtures, for

the presence of water. Change if needed.

Storage guidelines

Storage location

The product must be stored in a covered and dry location free from heat, dirt, and

vibrations.

NOTICE:

• Protect the product against humidity, heat sources, and mechanical damage.

• Do not place heavy weights on the packed product.

Long-term storage

If the unit is stored more than 6 months, the following apply:

• Before operating the unit after storage, it must be inspected with special attention to

the seals and the cable entry.

• The impeller/propeller must be rotated every other month to prevent the seals from

sticking together.

Transportation and Storage

Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual 9

Product Description

Product Description

Pump Design

Intended Use

The product is intended for moving wastewater, sludge, raw and clean water. Always

follow the limits that are given in Application limits (page 56). If there is a question

regarding the intended use of the equipment, please contact a Xylem representative

before proceeding.

WARNING:

In explosive or flammable environments, only use Ex- or MSHA-approved pumps.

NOTICE:

Do NOT use the pump in highly corrosive liquids.

10 Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual

Parts

1

2

3

8

7

6

5

4

12

11

10

9

13

WS003673A

15

7

9

14

14

13

Product Description

Figure 1: Section view, top view and exploded view of hydraulic parts.

Position Part Description

1 Terminal board

2 Support bearing Two-row ball bearing

3 Shaft Stainless steel, with an integrated rotor

4 Rotor

5 Main bearings Two-row angular contact ball bearing in O-arrangement

6 Seal housing Contains inner and outer mechanical seals. Includes a coolant that lubricates

and cools the seals; the housing acts as a buffer between the pumped fluid

and the electric motor

7 Propeller

8 Seal ring

9 Bell mouth With integrated relief groove

Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual 11

2

1312 14

22

21

20

17 18 1916159 10 11

8

7

6

5

4

3

1

23

24

Product Description

Position Part Description

10 Pump housing

11 Stator Equipped with temperature sensors in windings

12 Electrical lead-through

unit

13 Cable entry

14 Lifting handle

15 Guide vanes

Spare part requirements

The following applies when servicing or repairing the pump:

• Modifications to the unit or installation should only be carried out after consulting with

Xylem.

• Original spare parts and accessories authorized by Xylem are essential for compliance.

The use of other parts can invalidate any claims for warranty or compensation. For

more information contact your Xylem representative.

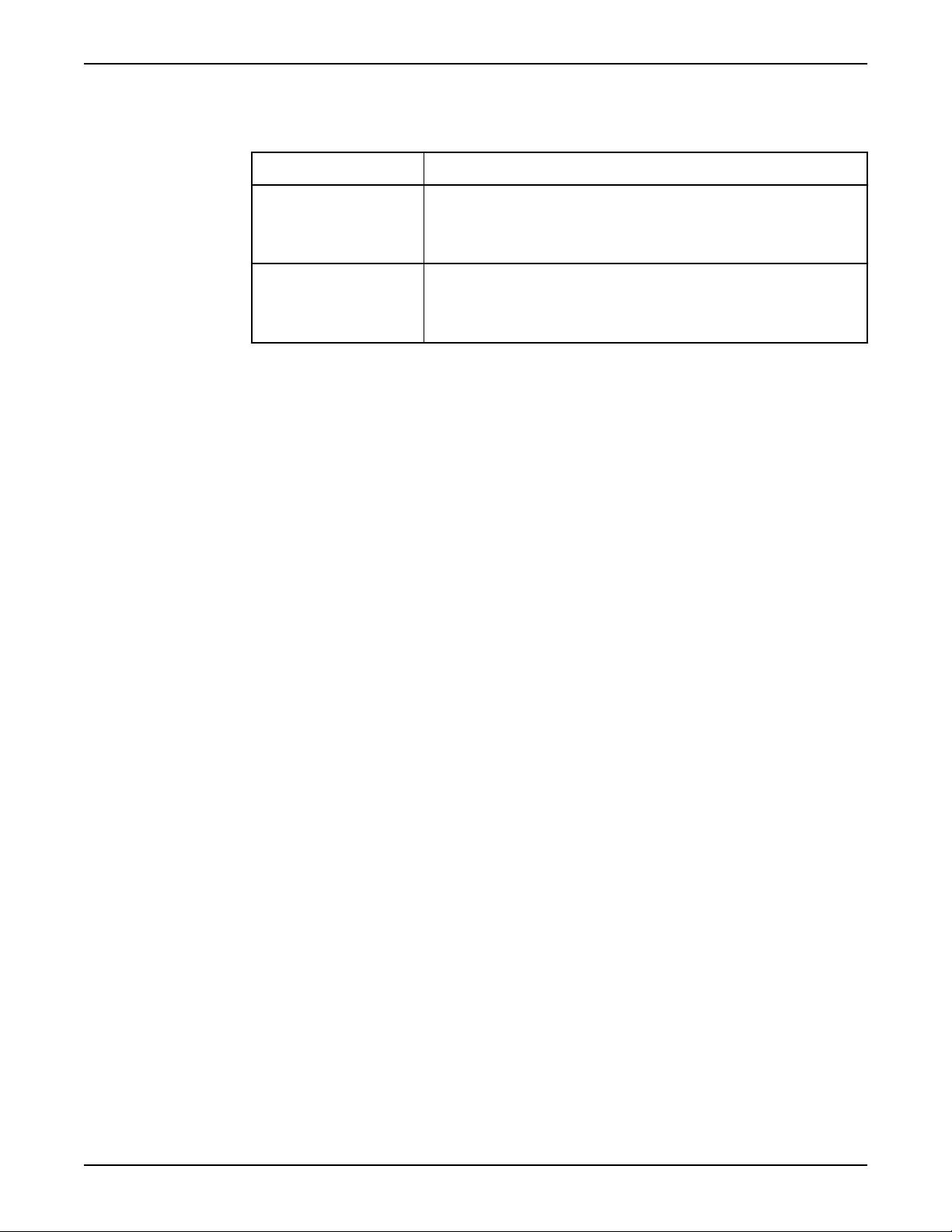

The monitoring equipment

MiniCAS II

The table below shows the parameters which can be tracked with the MiniCAS II

monitoring system.

Parameter Sensor Standard or optional

Stator winding temperature One of the following choices:

Standard

• 3 thermal switches (standard), or

• 3 PTC-thermistors (optional)

Leakage in the inspection chamber Float Switch Leakage Sensor (FLS) Standard

Leakage in the junction box Float Switch Leakage Sensor (FLS) Optional

The data plate

The data plate is a metal label located on the main body of the products. The data plate

lists key product specifications. Specially approved products also have an approval plate.

12 Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual

1. Curve code/Propeller code

2. Serial number, see Product denomination (page 14)

3. Product number

4. Country of origin

5. Additional information

6. Phase; type of current; frequency

7. Rated voltage

8. Thermal protection

9. Thermal class

10. Rated shaft power

11. International standard

12. Degree of protection

13. Rated current

14. Rated speed

15. Maximum submergence

16. Direction of rotation: L=left, R=right

17. Duty class

18. Duty factor

19. Product weight

20. Locked rotor code letter

21. Power factor

22. Maximum ambient temperature

23. Read installation manual

24. Notified body. Only for EN-approved Ex-products

Figure 2: The data plate

Approvals

Product approvals for hazardous locations

Pump Approval

Product Description

EN approval plate

7030.090 European Norm (EN)

• ATEX Directive

• EN 60079-0, EN 60079-1, EN 1127-1

•

II 2 G Ex d IIB T3

IEC

• IECEx scheme

• IEC 60079–0, IEC 60079–1

• Ex d IIB T3

EN approval for cable entry:

• Certificate number: INERIS 02ATEX9008 U

•

II 2 G Ex d IIC or I M2 Ex d I

Factory Mutural (FM)

• Class I. Div 1. Group C and D

• Dust ignition proof for use in Class II. Div 1. Group E, F and G

• Suitable for use in Class III. Div 1. Hazardous Locations

This illustration describes the EN approval plate and the information contained in its fields.

Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual 13

1 2 3

4

5

6 7

8

9 10

12

11

13

14

15

WS003972A

WS001279B

21

876

3

4

5 9

10

11

12

13

1

2

WS003973A

Product Description

IEC approval plate

1. Approval

2. Approval authority +

approval number

3. Approval for Class I

4. Approved drive unit

5. Stall time

6. Starting current/Rated

current

7. Duty class

8. Duty factor

9. Input power

10. Rated speed

11. Controller

12. Additional information

13. Maximum ambient

temperature

14. Serial number

15. ATEX marking

This illustration describes the IEC approval plate and the information contained in its fields.

International Norm; not for EU member countries.

1. Approval

2. Approval authority +

approval number

3. Approved for drive unit

4. Stall time

5. Starting current/Rated

current

6. Duty class

7. Duty factor

8. Input power

9. Rated speed

10. Controller

11. Additional information

12. Max. ambient temperature

13. Serial number

FM approval plate

This illustration describes the FM approval plate and the information contained in its fields.

1. Temperature class

2. Maximum ambient

temperature

Product denomination

14 Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual

Sales denomination

1

NP 3085

2 3

3085.183

1 2

NP

1

NP 3085.183 - 951 0163

2 3 4

Product code

Serial number

Product Description

The sales denomination consists of the four-digit sales code and two letters that indicate

the hydraulic end and type of installation.

This is an example of a sales denomination, and an explanation of its parts.

1. Hydraulic part

2. Installation type

3. Sales code

The product code consists of nine characters divided into two parts.

This is an example of a product code, and an explanation of its parts.

1. Sales denomination

2. Version

The serial number is used for identification of an individual product, and is divided into

four parts.

This is an example of a serial number, and an explanation of its parts.

1. Product code

2. Production year

3. Production cycle

4. Running number

Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual 15

Installation

Installation

Fasteners

WARNING:

• Only use fasteners of the proper size and material.

• Replace all corroded fasteners.

• Make sure that all fasteners are properly tightened and that there are no missing

fasteners.

Requirements for the cable handling system

When the pump is installed in a discharge tube, it is critically important that a proper cable

support and protection system is used, especially with long power cables and closed

discharge tubes.

Checklist

This table shows the requirements to be fulfilled by the cable handling system.

Requirement Check

Cables must be supported in such a way, so that they do not come in contact with any hard

surface which could abrade the cable sheathing. Examples of surfaces include pump and tube

components, lifting cables or wires and any other hardware.

Cables should be bundled together, using components that will not cut or abrade the cables.

Proper strain relief and support at prescribed intervals should be provided.

Spring-controlled tensioning and an integrated guide wire system is recommended for long

cables, to protect the cable from movement which can cause damage.

Install the pump

Consult the nearest Xylem representative regarding the following topics:

• Sizing of the pump, piping station, and access frame

• Choice of auxiliary equipment

• Other aspects of installation

WARNING:

• Note that special rules apply to installation in explosive atmospheres.

• Do not install the starter equipment in an explosive zone unless it is explosion-proof

rated.

• Check the explosion risk before welding or using electric hand tools.

• Provide a suitable barrier around the work area, e.g. a guard rail.

• Before installing the pump, check that the cable and cable entry have not been

damaged during transportation.

• A certified electrician must supervise all electrical work. Comply with all local codes and

regulations.

• Make sure that the unit cannot roll or fall over and injure people or damage property.

NOTICE:

• Do not run the pump dry.

• Never force piping to make a connection with a pump.

16 Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual

WS001675A

Installation

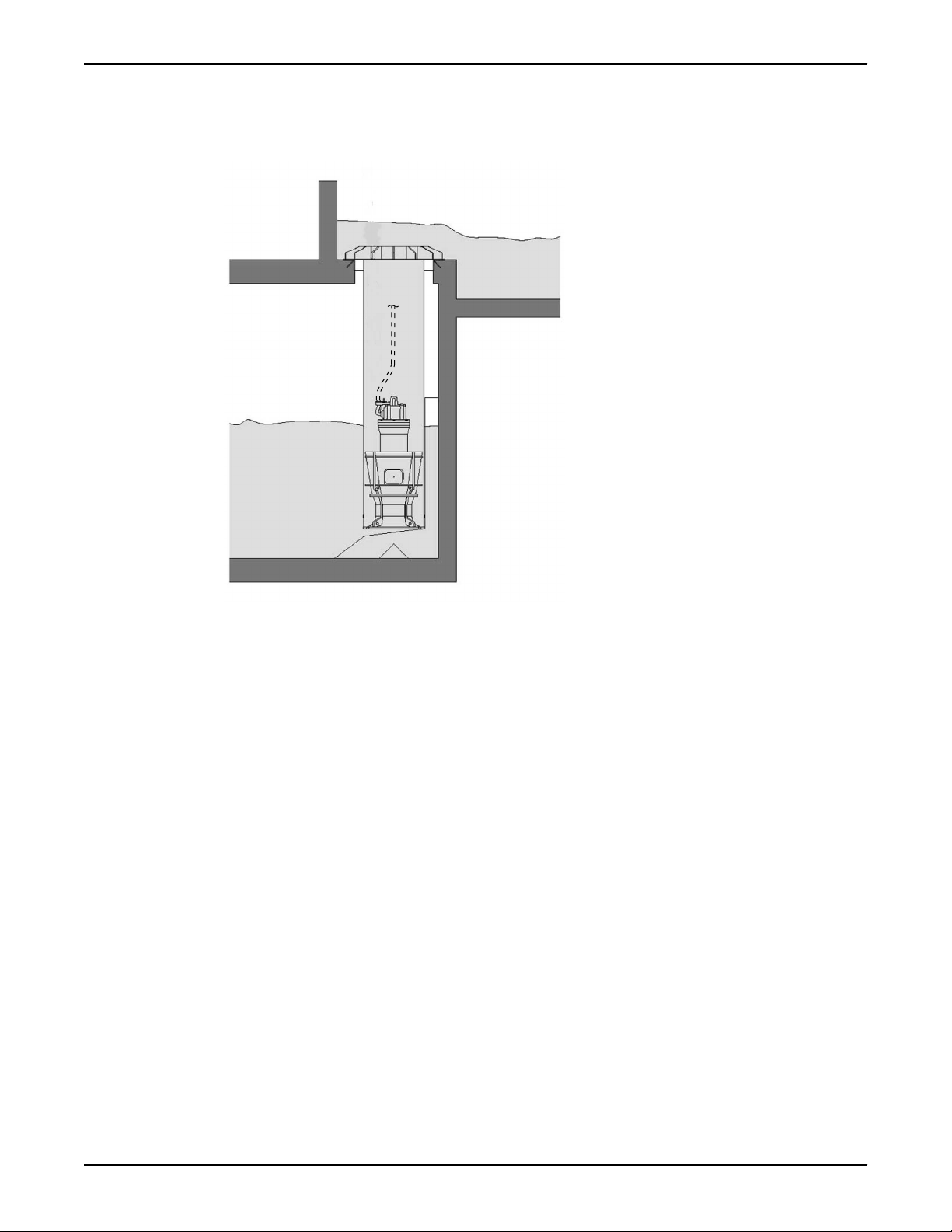

The pump is usually installed in a vertical discharge tube on a pump seat, which is

incorporated in the lower end of the tube. No anchoring is required because the weight of

the pump is sufficient to keep it in place. The pumps are equipped with anti-rotation

devices.

Figure 3: Pump in discharge tube (generic propeller pump shown)

When the pump is installed in a discharge tube, the following must be considered:

• A suitable cable support and protection system must be used.

Before installation, check the following:

• The propeller must rotate in the correct direction.

If the rotation is not in the correct direction, then the pump may lift and start rotating

inside the tube. This can seriously damage the equipment.

• The rubber seal ring underneath the pump is in place.

• There is no damage to, or debris on, the pump seat.

• There is no large construction debris under the pump tube (at the pump intake). If

debris is present then there is a risk that it can get sucked into the pump and cause

propeller damage.

• The pump control is set to turn the pump off at or above the minimum operating water

level for this pump installation.

1. After cable preparation, lower the pump into the pump column.

Make sure that the pump does not tilt on the stop vanes, which are at the bottom of the

column.

Flygt P7030, P7035, P7040 Installation, Operation and Maintenance Manual 17

Loading...

Loading...