FLYGT MAS 711 Installation And Operation Manual

Installation and Operation

MAS 711

895115/10

Overview

Installation and Operation

MAS 711

Table of

Contents

This publication contains the following topics:

Topic

Preface ............................................................................................................... 7

General Safety Information ................................................................................... 9

Environment.................................................................................................. 10

User Safety and Health...................................................................................11

Warranty ....................................................................................................... 12

Warning Symbols ......................................................................................... 13

Product Description ........................................................................................... 15

System Components ..................................................................................... 16

Configurations............................................................................................... 19

Monitoring Alternatives with ITT Flygt Pumps .................................................. 20

Base Unit Indication....................................................................................... 21

Installation ......................................................................................................... 23

Installation Guideline ..................................................................................... 24

Connect the Unit ........................................................................................... 25

Connect to the Web Tool ............................................................................... 44

First Setup Using the Web Tool ...................................................................... 52

First Setup Using the Operator Panel.............................................................. 55

Use the Web Tool............................................................................................... 57

Use the Operator Panel...................................................................................... 59

Browse the Menus......................................................................................... 60

Menu System................................................................................................ 63

Settings with the Web Tool.................................................................................. 75

Change Password ........................................................................................ 76

Change the Display Language ....................................................................... 77

Set Unit Information....................................................................................... 79

Configure Communication (RS-485, Modbus) ................................................. 80

Make a Manual Setting of a Monitoring Channel ............................................. 82

Record Running Time and Number of Starts .................................................. 84

Compensate for Measurement Error due to Long Leads ................................. 86

Update the Internal Program .......................................................................... 90

Set Reload Time for Alarm and Quick Overview ............................................. 92

Make Settings for Alarm Distribution through E-mail ........................................ 93

Make Modem/PPP Settings ........................................................................... 94

Set Up MAS Network Overview ..................................................................... 96

Set Up MAS Relay Module............................................................................. 97

3

Overview

Settings with the Operator Panel ......................................................................... 99

Change the Display Language ...................................................................... 100

Log in and Change Password........................................................................101

Set Unit Information......................................................................................102

Retrieve Sensor Information from Pump Memory............................................103

Make a Manual Setting of a Monitoring Channel ............................................104

Record Running Time and Number of Starts .................................................105

Check and Change the IP Address................................................................107

Operation ......................................................................................................... 109

Handle Alarms ............................................................................................. 110

View Operation Data..................................................................................... 115

Handle Database Information and Parameters ...............................................126

Handle Pump Information and Service Functions............................................135

Copy Data To/From Pump Memory................................................................139

Trouble Shooting...............................................................................................143

Common Problems and Solutions..................................................................144

Event Messages and Actions ........................................................................ 146

Contact Information .......................................................................................... 149

4

,

Overview

5

Preface

Purpose The purpose of this manual is to give the reader an overview of how to install and set up

the MAS 711.

Recipient The manual is principally intended for ITT Flygt

• service departments

•customers.

and

Product

Documentation

The policy of the ITT Flygt documentation department is to develop as user friendly

product information as possible. Please inform us if this manual

• lacks information that would make the operation of the product easier

• contains information that is irrelevant to the operation of the product.

or

Abbreviations This table shows some of the abbreviations that may be found in this manual:

Abbreviation Meaning

APP Automatic Pump Pilot. Pump controller.

CAS Control And Status. Old pump monitoring system, replaced by MAS.

CLS Capacitive Leakage Sensor. Detects the presence of water in the

oil chamber.

FLS Flygt Leakage Sensor. Float switch for detection of liquid.

FMC Flygt Mactec Control. Pump controller.

MAS Monitoring And Status. Pump monitoring system.

MRM 01

PLC Programmable Logic Controller. General purpose programmable

MAS Relay Module

controller.

VIS10

Vibration sensor

Reference More information about the MAS 711 and how to handle it is available in the following

documents:

• Technical specification, MAS 711 Monitoring system.

• MAS Base unit, Modbus protocol (rev 1,2,3).

• PAN 311/312 User manual.

• MRM 01, Installation and User Manual.

7

Overview

General Safety Information

NOTE!

Table o f

Contents

It is extremely important that you read, understand and follow the warnings and safety

regulations carefully before handling an ITT Flygt product. They are published to

help prevent

• personal accidents and health problems

• damage to the unit

• product malfunction.

ITT Flygt assumes no liability for either bodily injuries, material damages or economic

losses beyond what is stated in this chapter.

This chapter contains the following topics:

Topic

Environment ...................................................................................................... 10

User Safety and Health........................................................................................11

Warranty............................................................................................................ 12

Warning Symbols .............................................................................................. 13

9

General Safety Information,

Environment

Environment

The unit must be installed in an environment that is

• sheltered

• well-ventilated,

• non-hazardous.

Temperature The unit must be used at a temperature within the minimum and maximum rate defined

in accompanying technical data.

Disturbance Ensure that equipment causing serious disturbance is suppressed in the best possible way.

and

10

General Safety Information,

User Safety and Health

User Safety and Health

Introduction All government regulations, local health and safety directives must be observed.

General

electricity

precautions

All danger due to electricity must be avoided. Electrical connections must always be

carried out in compliance with the

• connections shown in the product documentation that is delivered together with the

product,

• electrical regulations locally in force. Reference: For details, consult the regulations

of your local electricity supplier.

Ground the unit: Ground the unit before carrying out any other operation. The electric

pump motor and the panel must be connected to an efficient grounding system in

compliance with the electrical regulations locally in force.

Disconnect the power supply: Always disconnect the power supply before proceeding

to carry out any operation on the electrical or mechanical components of the unit or the

system. Isolate the power supply before opening the pump.

and

High Voltage! Check rated data: Before starting the installation work, check that the rated data of

the automatic control panel is suitable to the mains power supply and the rated data of

the pump.

Isolate power supply before troubleshooting: All trouble shooting must be carried out

with the power supply isolated. If not, the pump could start unexpectedly.

11

General Safety Information,

Warranty

Warranty

Introduction ITT Flygt undertakes to remedy faults in products sold by ITT Flygt if the fault is

• caused by defects in design, materials or workmanship,

• reported to ITT Flygt or ITT Flygt’s representative during the warranty period.

Limitations of validity: The warranty does not cover fault due to the following:

•Deficient maintenance

• Improper installation

•Improperuse

• Incorrectly executed repairs

• Normal wear and tear

and

Qualification

of personnel

All work on the product should be carried out by certified electricians or ITT

Flygt-authorized mechanics.

ITT Flygt disclaims all responsibility for work done by untrained, unauthorized personnel.

Usage The monitoring equipment incorporated in the product must be correctly connected and in

use.

Improper use may cause damage to the equipment and result in warranty cancellation.

Modification Modifications or changes to the product/installation should only be carried out after

consulting with ITT Flygt.

Spare parts Original spare parts and accessories authorized by ITT Flygt are essential for compliance.

The use of other parts can invalidate any claims for warranty or compensation.

Warranty claim For warranty claim, contact your ITT Flygt representative.

Support ITT Flygt only supports products that have been tested and approved. ITT Flygt will not

support unapproved equipment.

12

General Safety Information,

Warning Symbols

Warning Symbols

Symbols In the ITT Flygt documentation, admonitions are used together with the denomination.

The following items describes the safety levels of the admonition symbols in combination

with the denomination.

DANGER!

Risk of causing

• severe injury to people

•death,

• considerable damage to property

if the warning is ignored.

WARNING!

or

NOTE!

High Voltage

Possible risk of causing

• severe injury to people

•death,

• considerable damage to property

if the warning is ignored.

or

CAUTION!

Risk of causing

• injury to people,

• damage to property

if the warning is ignored.

Information that is important for the proper operation of the product, but is not a risk to

the safety of personnel.

Presence of a dangerous voltage.

or

13

Overview

Product Description

Table o f

Contents

This chapter contains the following topics:

Topic

System Components .......................................................................................... 16

Configurations ................................................................................................... 19

Monitoring Alternatives with ITT Flygt Pumps....................................................... 20

Base Unit Indication ........................................................................................... 21

15

Product Description ,

System Components

System Components

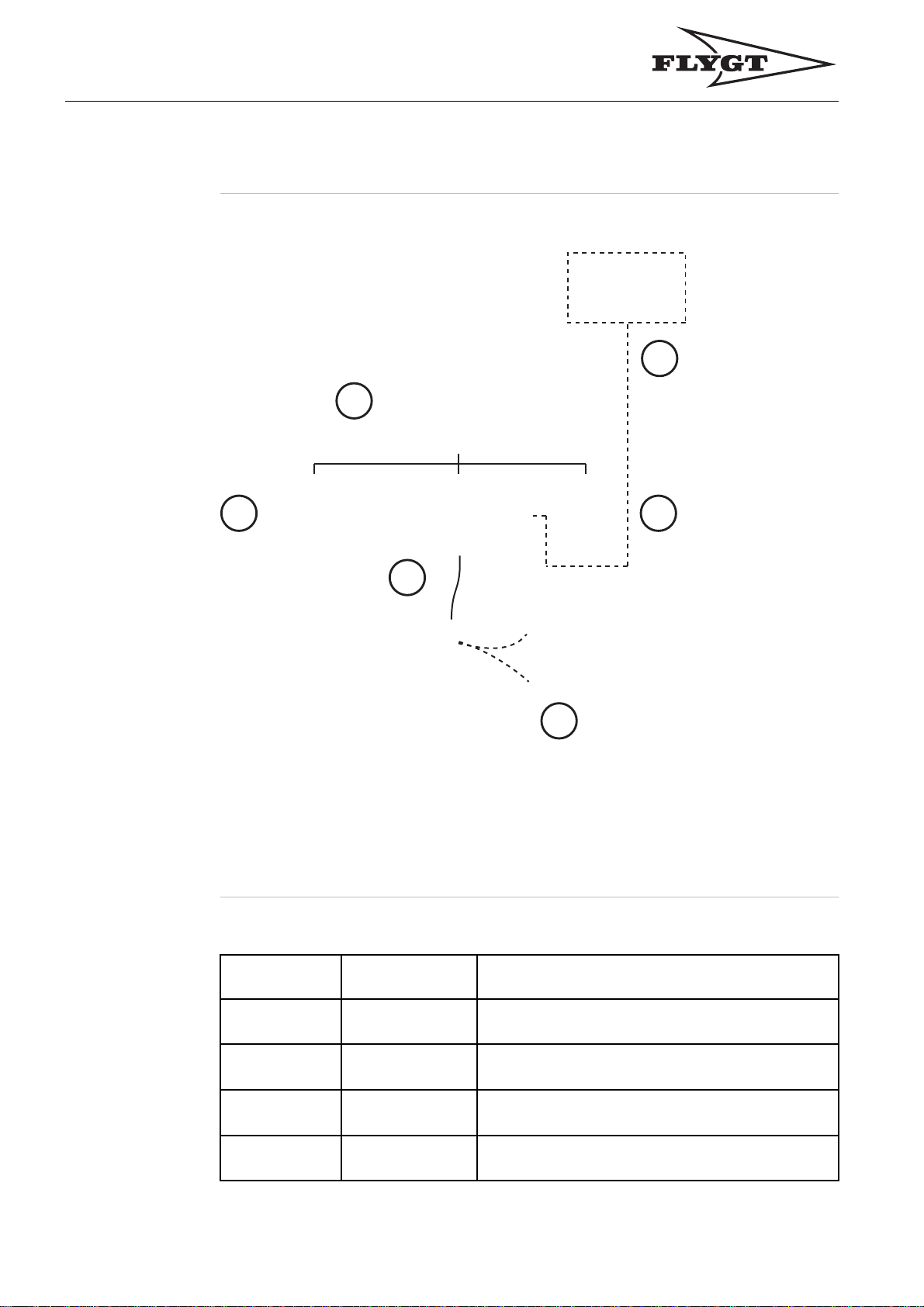

Illustration

5

1

Component

Description

4

2

This table describes the system components:

Number

Component

6

3

Description

16

1

2Baseunit

3 Pump memory

4 Power analyzer

Operator panel Front panel mounted module used for interaction

with the system.

Contains a powerful processor, memory and

terminals for sensor connections.

Mounted inside the pump and contains information

about the pump.

Optional unit, which measures power, current,

voltage and power factor.

Product Description ,

System Components

Number

5

6 Relay Module

Component

Higher level

system

Possibility to connect to a higher level system

(APP/FMC or PLC) using Modbus.

Optional output unit containing four relays.

Enables communication for individual monitoring

channel alarms (A and/or B alarms) to specific

relays and LEDs on the relay module(s).

Description

Pump Memory The pump memory is an electronic unit mounted in the pump top, containing unique data

about the particular pump it is fitted in. By keeping records in the pump, data cannot be

lost or corrupted when the pump is serviced or moved. The information is used to simplify

installation, service and maintenance of the pump and the monitoring system.

Memory contents

The pump memory contains the following information:

• Data plate information, a fixed part and an editable part

• Pump sensor configuration and settings

• Running statistics

• Service notes

• Service interval

Power

Analyzer

Synchronization and backup

The base unit performs all measurements and data processing in the system. A subset of

all data is also stored in the pump memory. Updated measurement results, parameters or

text are first stored in the base unit and then copied to the pump memory. An automatic

synchronization (update) of the pump memory with the latest information from the base

unit takes place every second hour.

MAS 711 is pre-programmed for use with the optional Power analyzer PAN311/PAN312.

See PAN 311/312 User manual for more information about setup and connection.

The Power analyzer measures:

• Voltage in three phases and system voltage (phase voltage requires connection

“Three phase with neutral”)

• Current in three phases and system current

• Power in each phase and system power

• Power factor

• Energy consumption

Voltage and current unbalance are calculated by the base unit based on data from the

instrument.

MAS will automatically read a selection of registers in the Power analyzer over the

RS-485/Modbus serial data link Ext 2. In this way measured electrical quantities are

recorded and presented on the operator panel and the web tool.

17

Product Description ,

System Components

Higher Level

System

This communication port is dedicated for communication with a higher level system,

meaning for instance a Flygt APP/FMC pump controller or a PLC (Programmable Logical

Controller). The base unit acts as a slave in such a network.

A separate document (MAS Base unit, Modbus protocol) defines in detail how to set up

the communication with the base unit and contains registers used for reading parameters.

Relay Module MAS relay module (MRM 01) is an optional part of the monitoring system. One or more

relay modules (maximum number of 8 modules) can be connected to the base unit through

RS-485 Modbus. This will enable MAS to communicate individual alarms on the separate

monitoring channels (A and/or B alarms) to relays and LEDs on the relay module(s).

The pump sensors will be connected to the base unit and the base unit will monitor the

pump and detect unhealthy conditions. The individual alarms will be transmitted to LEDs

and relays on the MRM 01. The configuration of what alarm that will trigger which relay

on which module is done through the web tool. Sensor configuration, alarm limits and

additional settings are also done in the web tool. See MRM 01, Installation and User

Manual for more information about setup and connection.

Ingress

Protection

The base unit ingress protection is IP20, which means there is no protection against water.

Therefore, it should be mounted inside an electrical cabinet. The operator panel front has

an ingress protection of 65, which means it withstands a water splash or jet if mounted in a

panel or a cabinet door. The back of the operator panel is IP20.

18

Configurations

Product Description ,

Configurations

Configuration

Alternatives

Default

Configuration

for Retrofitof

CAS

Pump and

Application

Specific

Configuration

The system provides two alternative configurations useful for different situations:

• the base unit factory default configuration (for retrofitofCAS)

• a pump specificconfiguration brought by the pump memory.

Since MAS might be used as sparepart for its predecessor CAS or for retrofit (upgrade), it

is factory preset to fit as a CAS substitute. In this factory default configuration the following

monitoring channels are enabled:

• Stator temperature monitoring by means of thermal switches.

• Leakage sensor in the stator housing.

• Leakage sensor in the junction box.

• Main bearing temperature monitoring by means of a Pt100 sensor.

The pump memory which is fitted at the factory, contains information which must be loaded

into the base unit. This makes the system automatically configuredtoreflect the actual

setup of sensors in the particular pump. Default parameters, suitable for the pump such as

alarm limits are also transferred.

Application specific settings can be done either by using the operator panel or by

connecting a computer to the base unit and using the web tool.

or

19

Product Description ,

Monitoring Alternatives with ITT Flygt Pumps

Monitoring Alternatives with ITT Flygt Pumps

Large Pumps ITT Flygt standard monitoring (12-lead SubCab sensor cable)

Large pumps are equipped with a standard set of monitoring sensors to allow safe and

reliable operation. This standard includes large pump models

• 3231

• 3306–3800

• 7061–7121.

This alternative requires 12-lead SubCab sensor cable and includes the following sensors:

• Thermal switches for stator temperature monitoring (3 in series) or PTC-thermistors.

• Leakage sensor in the stator housing.

• Leakage sensor in the junction box.

• Analog temperature sensor (Pt100) for main bearing temperature monitoring.

• Analog temperature sensor (Pt100) for stator winding temperature in one phase.

• Pump memory.

Optional monitoring (24-lead SubCab sensor cable)

Midrange

Pumps

Additional monitoring functions require the use of a 24-lead SubCab sensor cable. The

following options are available:

• Vibration sensor VIS 10.

• Analog temperature sensor (Pt100) for stator winding temperature in phases 2 and 3.

• Leakage sensor in the oil housing (CLS).

• Analog temperature sensor (Pt100) for support bearing temperature monitoring.

Optional monitoring, alternative 1 (12-lead SubCab sensor cable)

The following options are available with midrange pumps (3153, 3171, 3202 and 3301)

and require the use of a 12-lead sensor cable:

• Thermal switches for stator temperature monitoring (3 in series) or PTC-thermistors.

• Leakage sensor in the inspection chamber.

• Leakage sensor in the junction box.

• Analog temperature sensor (Pt100) for main bearing temperature monitoring.

• Analog temperature sensor (Pt100) for stator winding temperature in one phase.

• Pump memory.

Optional monitoring, alternative 2 (12-lead SubCab sensor cable)

Alternative 2 is the same as alternative 1 above but the Leakage sensor in the junction box

is replaced by a Vibration sensor (not available with 3153).

Optional monitoring (25-lead sensor cable)

20

The following additional monitoring functions require the use of a 25-lead sensor cable:

• Vibration sensor VIS 10 and Leakage sensor in the junction box at the same time.

• Analog temperature sensor (Pt100) for stator winding temperature in phases 2 and 3.

• Analog temperature sensor (Pt100) for support bearing temperature monitoring.

Product Description ,

Base Unit Indication

Base Unit Indication

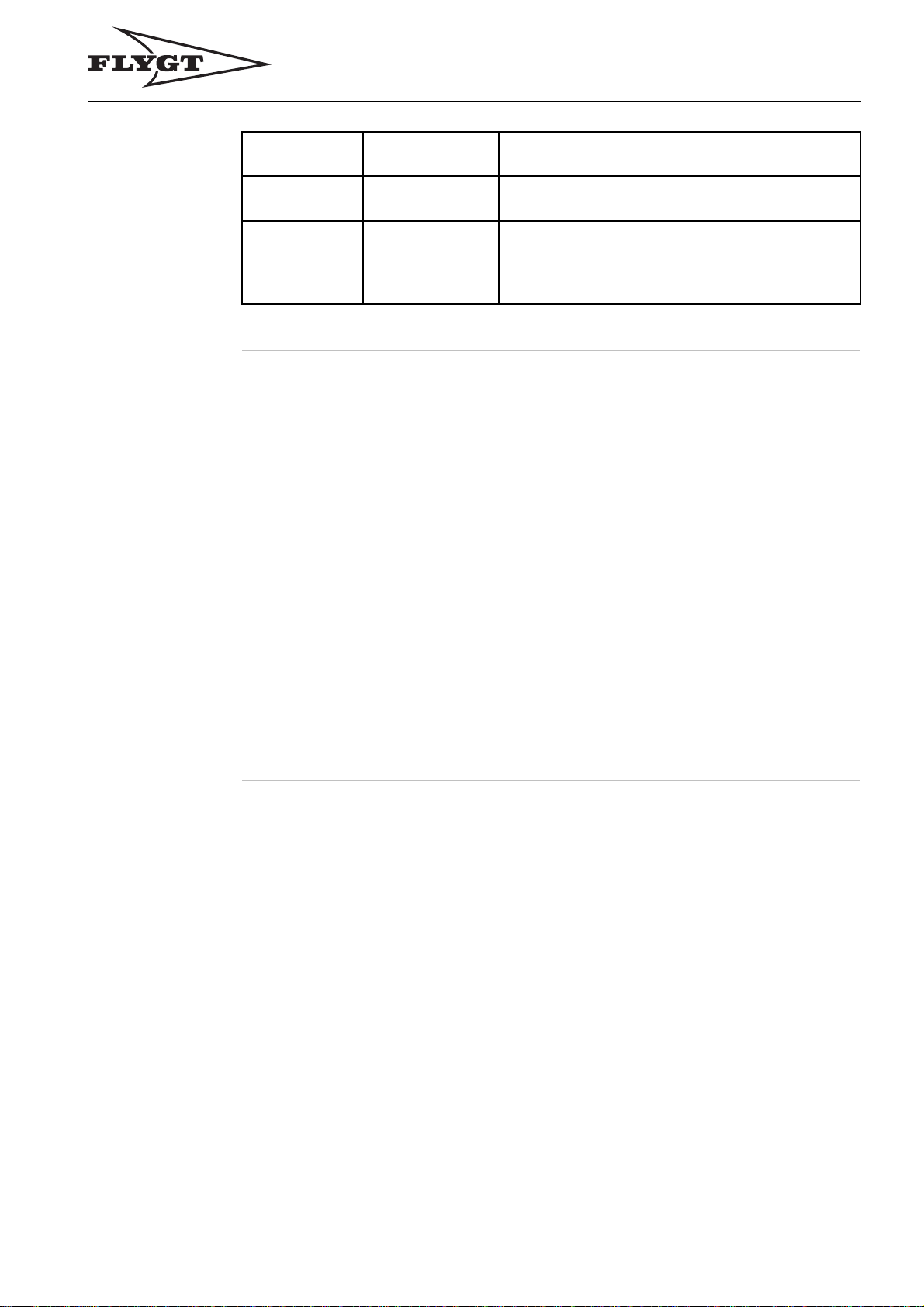

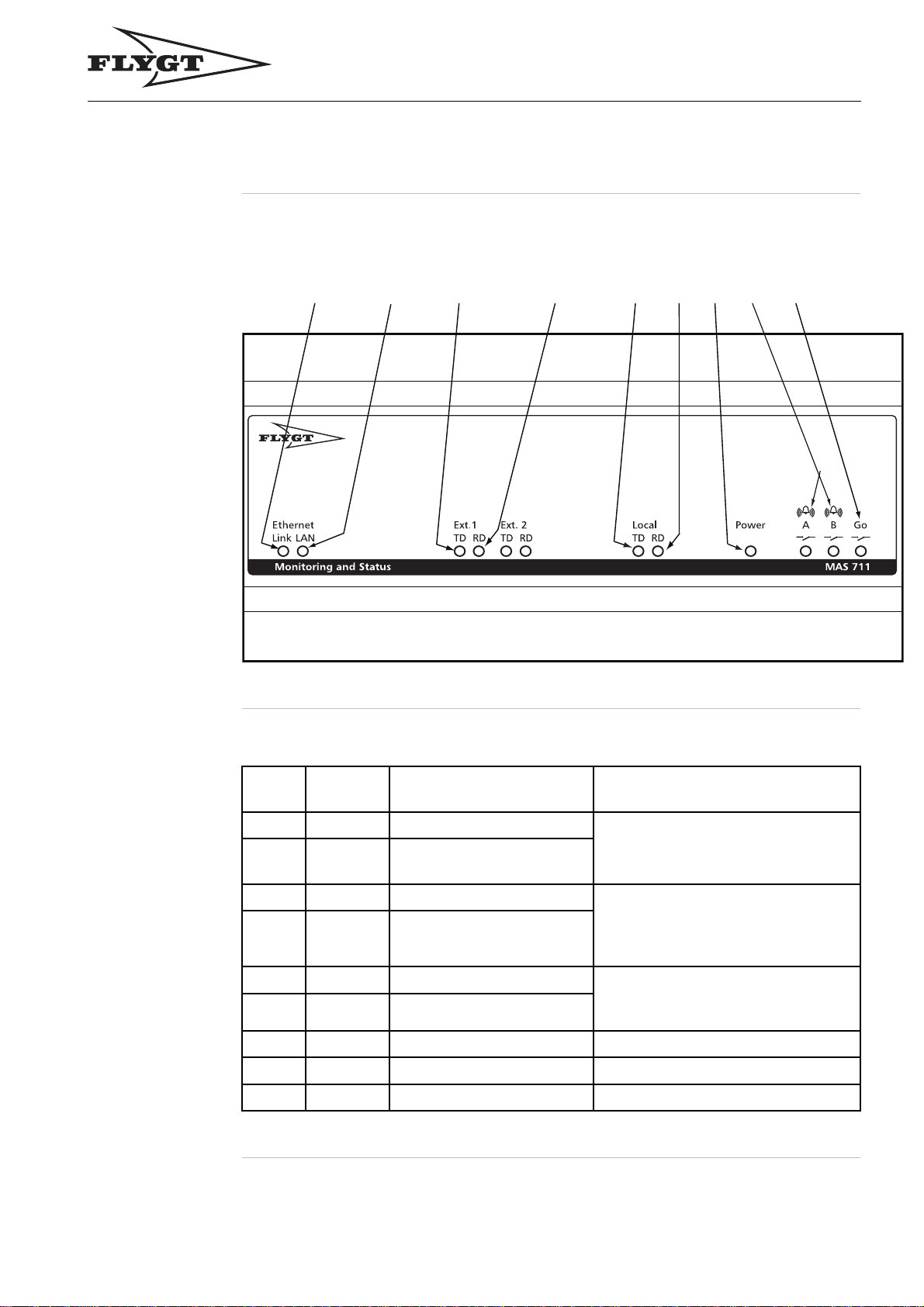

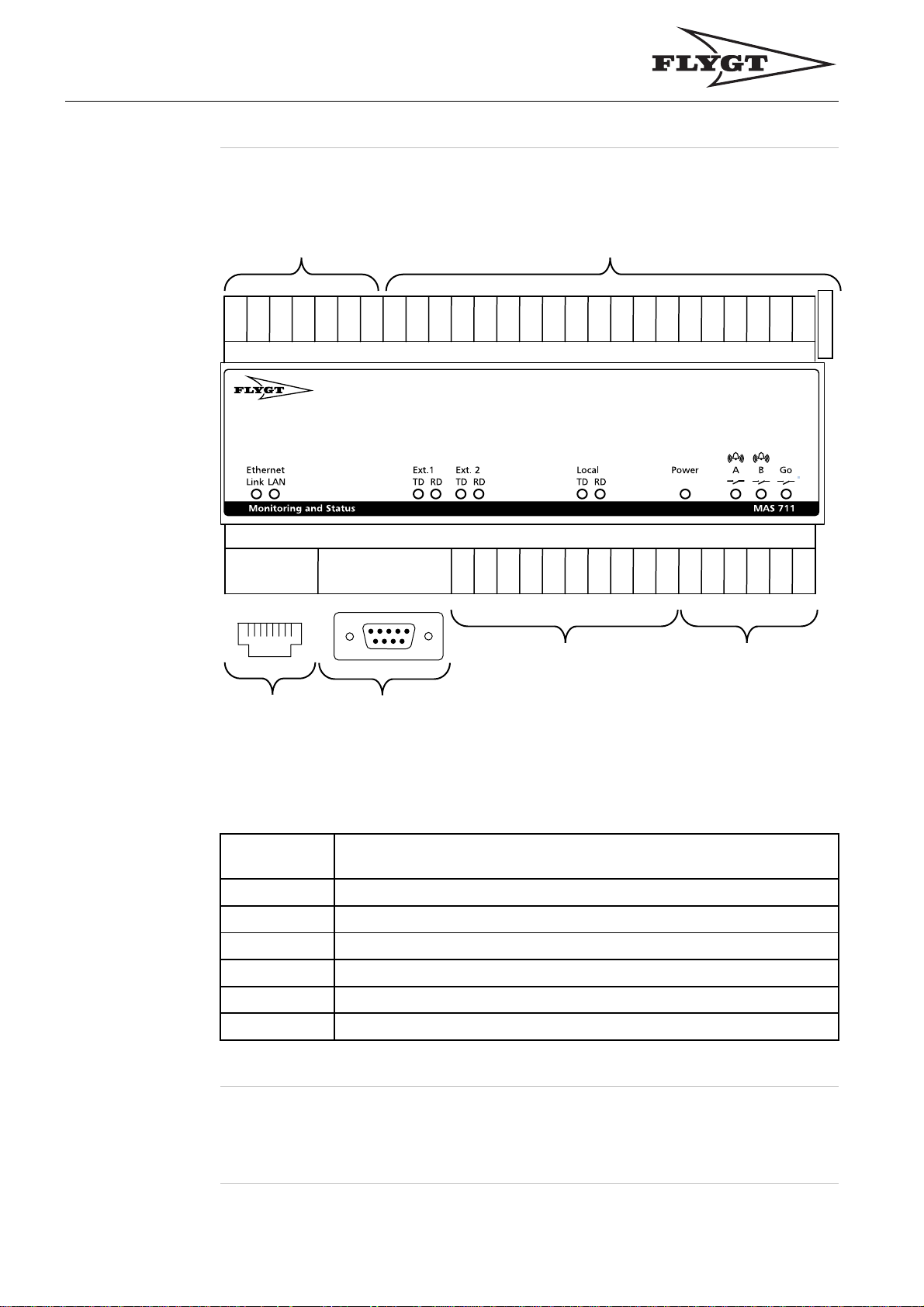

Illustration Light emitting diodes (LEDs) in the front are used for communication and relay indication.

This is an illustration of the base unit LEDs:

123 4

5

697

8

LED Indication

Description

This table describes what the base unit LEDs indicate:

Number

1 Link Ethernet connection status

2 LAN Data communication

3 TD Transmit data

4 RD Receive data

5

6 RD Receive data

7

8

9

LED

name

TD Transmit data

Power Light = Power on Power indication

A/B

Go Green light = OK

Description Type

Ethernet. Connection to LAN or PC

for web access.

indication

Ext. 1/Ext. 2. RS–485/Modbus

communication with APP/FMC

or PLC (Ext. 1) and with Power

analyzer (Ext. 2).

Local. RS–485/Modbus

communication with operator

panel and pump memory.

A = Pump stop, B = Warning Alarm relay indication

Pump contactor interlock relay

21

Overview

Installation

Table o f

Contents

This chapter contains the following topics:

Topic

Installation Guideline .......................................................................................... 24

Connect the Unit ................................................................................................ 25

General Instruction ........................................................................................ 26

Wiring, Supply and Additional Inputs/Outputs .................................................. 28

Wiring, Modbus Communication ..................................................................... 29

Wiring, Relay Outputs.................................................................................... 32

Wiring, Large Pumps, SubCab 12–lead Sensor Cable ..................................... 32

Wiring, Large Pumps, SubCab 24–lead Sensor Cable ..................................... 35

Wiring, Midrange Pumps, SubCab 12–lead Sensor Cable, Alternative 1............ 37

Wiring, Midrange Pumps, SubCab 12–lead Sensor Cable, Alternative 2............ 39

Wiring, Midrange Pumps, 25–lead Sensor Cable ............................................. 41

Connect to the Web Tool .................................................................................... 44

General Instruction ........................................................................................ 44

Make a Direct Connection ............................................................................. 44

Make a LAN Connection ............................................................................... 46

Make a Modem Connection ........................................................................... 50

First Setup Using the Web Tool........................................................................... 52

First Setup Using the Operator Panel .................................................................. 55

23

Installation,

Installation Guideline

Installation Guideline

Guideline This guideline gives an overview of the installation procedure. All steps are described

in detail in the separate sections in the

as an outline.

Follow these steps to make a complete installation and setup:

Installation

chapter. This guideline only serves

Step

1

2

3

4

5

Action

Read the entire chapter

Comment: This is important to prevent injuries to personnel and damages to

the product.

Connect the unit.

Ifyouchoosetousethe

• webtool,gotostep4.

• operator panel, go to step 5.

• Connect to the web tool.

• Makethesetupusingthewebtool.

Result: Thesystemisnowreadytobeused.

Make the setup using the operator panel.

Result: Thesystemisnowreadytobeused.

General Safety Information

.

24

Connect the Unit

Installation,

Connect the Unit

Topics in this

Section

This section contains the following topics:

• General Instruction

• Wiring, Supply and Additional Inputs/Outputs

• Wiring, Modbus Communication

• Wiring, Relay Outputs

• Wiring, Large Pumps, SubCab 12–lead Sensor Cable

• Wiring, Large Pumps, SubCab 24–lead Sensor Cable

• Wiring, Midrange Pumps, SubCab 12–lead Sensor Cable, Alternative 1

• Wiring, Midrange Pumps, SubCab 12–lead Sensor Cable, Alternative 2

• Wiring, Midrange Pumps, SubCab 25–lead Sensor Cable

25

Installation,

General Instruction

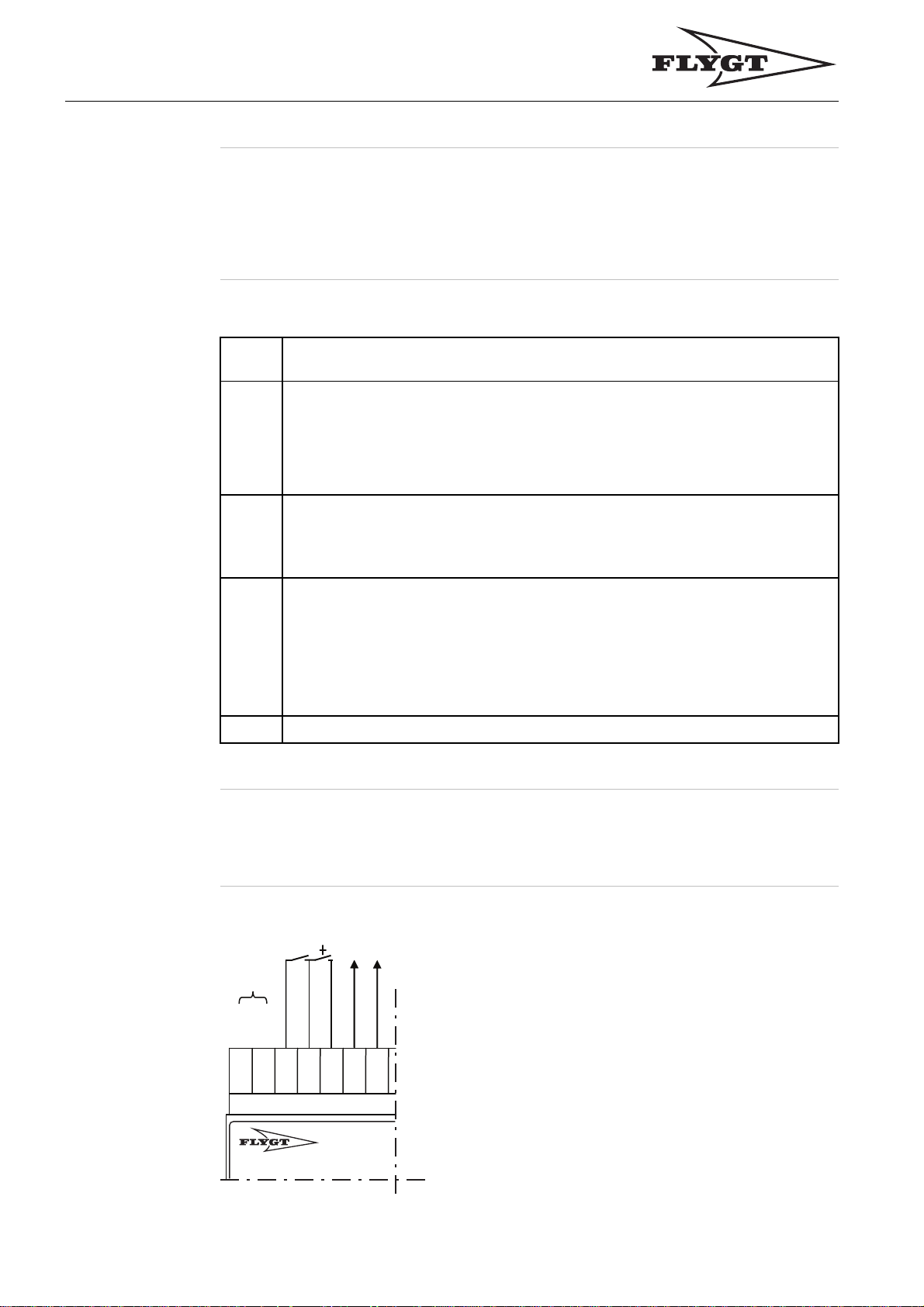

Base Unit

Termi nal Block

12

26

2524232221201918171615

141312

11

10

9

8

7

6

5

4

3

2

1

123

4-567-8

8

123456789

1

42

414039383736353433323130292827

56

34

Terminal block section description

This table describes the main sections of the base unit terminal block:

Section

number

1

2

3

4

5

Description

Supply and additional inputs/outputs

Sensor terminals

Ethernet port (RJ–45)

Serial port (RS–232)

Modbus communication (RS–485)

6 Relay outputs

General Instruction

26

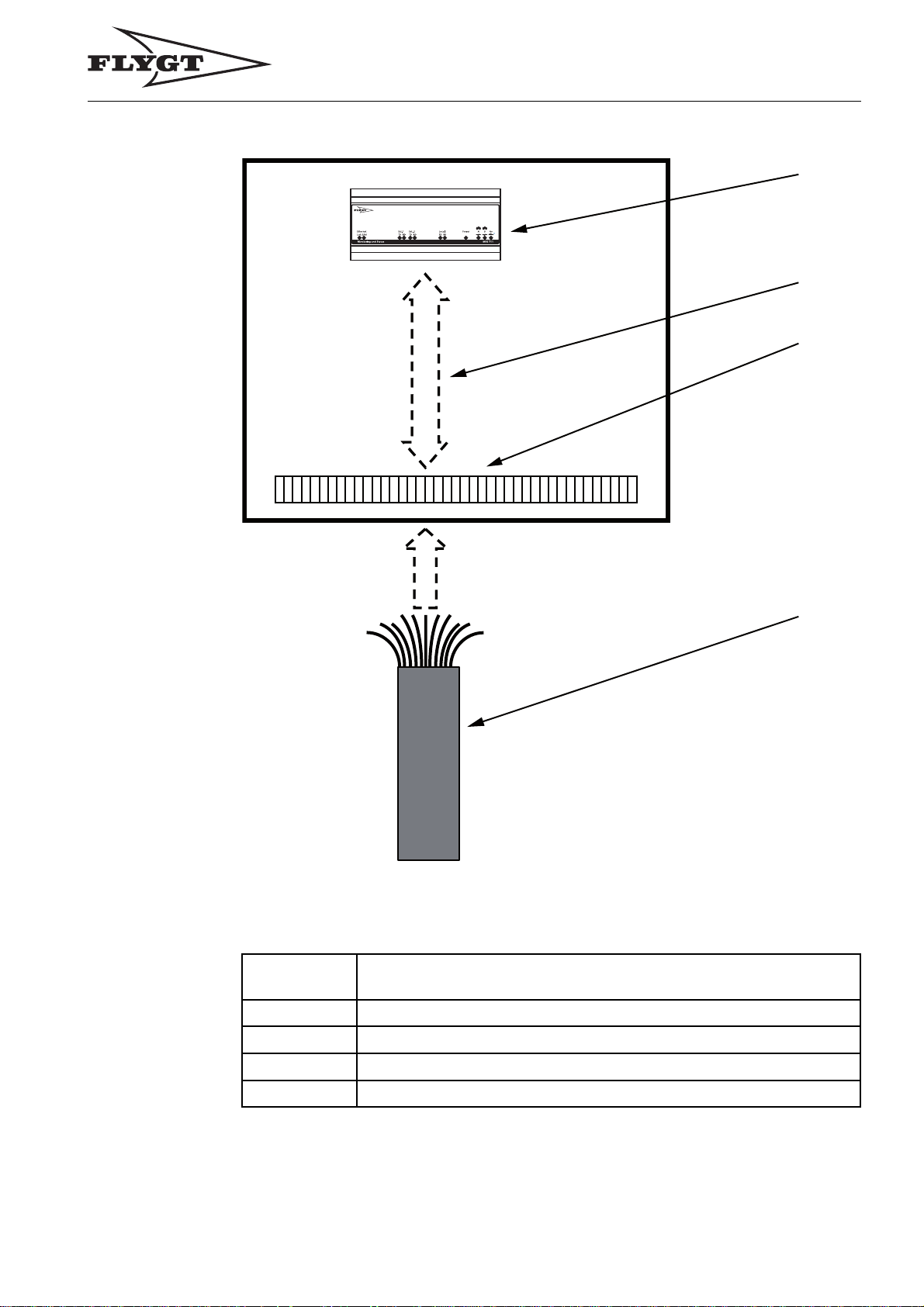

Main Parts

when

Connecting

the Unit

Installation,

General Instruction

1

2

3

Description

This table describes the main parts when connecting the unit:

Section

number

1 Base unit terminal block

2

Description

Cabinet cables

4

3

4

Cabinet connection block

Sensor cable

27

Installation,

Wiring, Supply and Additional Inputs/Outputs

Wiring

diagrams

Use the following wiring diagrams when connecting the unit:

• The wiring diagram of the cabinet.

• The applicable

Wiring

sections below.

Instruction Follow the steps below to connect the unit:

Step

1

Check which number on the cabinet connection block that is connected to

which number on the base unit terminal block. This information is found in the

wiring diagram of the cabinet.

Note! The numbers of the base unit terminal block do

numbers of the cabinet connection block.

2

Connect the wires to the base unit according to the following sections below:

• Wiring, Supply and Additional Inputs/Outputs

• Wiring, Modbus communication

• Wiring, Relay Outputs

3

Identify the applicable sensor configuration and connect the sensor cable to

the cabinet connection block according to the applicable section below:

• Wiring, Large Pumps, SubCab 12–lead Sensor Cable

• Wiring, Large Pumps, SubCab 24–lead Sensor Cable

• Wiring, Midrange Pumps, SubCab 12–lead Sensor Cable, Alternative 1

• Wiring, Midrange Pumps, SubCab 12–lead Sensor Cable, Alternative 2

• Wiring, Midrange Pumps, SubCab 25–lead Sensor Cable

Action

not

have to match the

4 Turn on the voltage to the unit.

Wiring, Supply and Additional Inputs/Outputs

Illustration This is an illustration of section 1 of the base unit terminal block:

/Gnd

–

+

26

2524232221

Gnd

+

20

28

Installation,

Wiring, Modbus Communication

Termi nal

Description

This table describes the terminals for supply and additional inputs/outputs:

Term ina l

number

20

21

22

23

24

25

26

Type Description

+

Ground Configurable output, ground

+

Ground RUN/reset, common ground

+

+

–/ground Supply, ground

Configurable output, 4-20 mA

Reset input

RUN input

Supply, 24 V AC/DC

Wiring, Modbus Communication

Illustration This is an illustration of section 5 of the base unit terminal block:

29

Installation,

Wiring, Modbus Communication

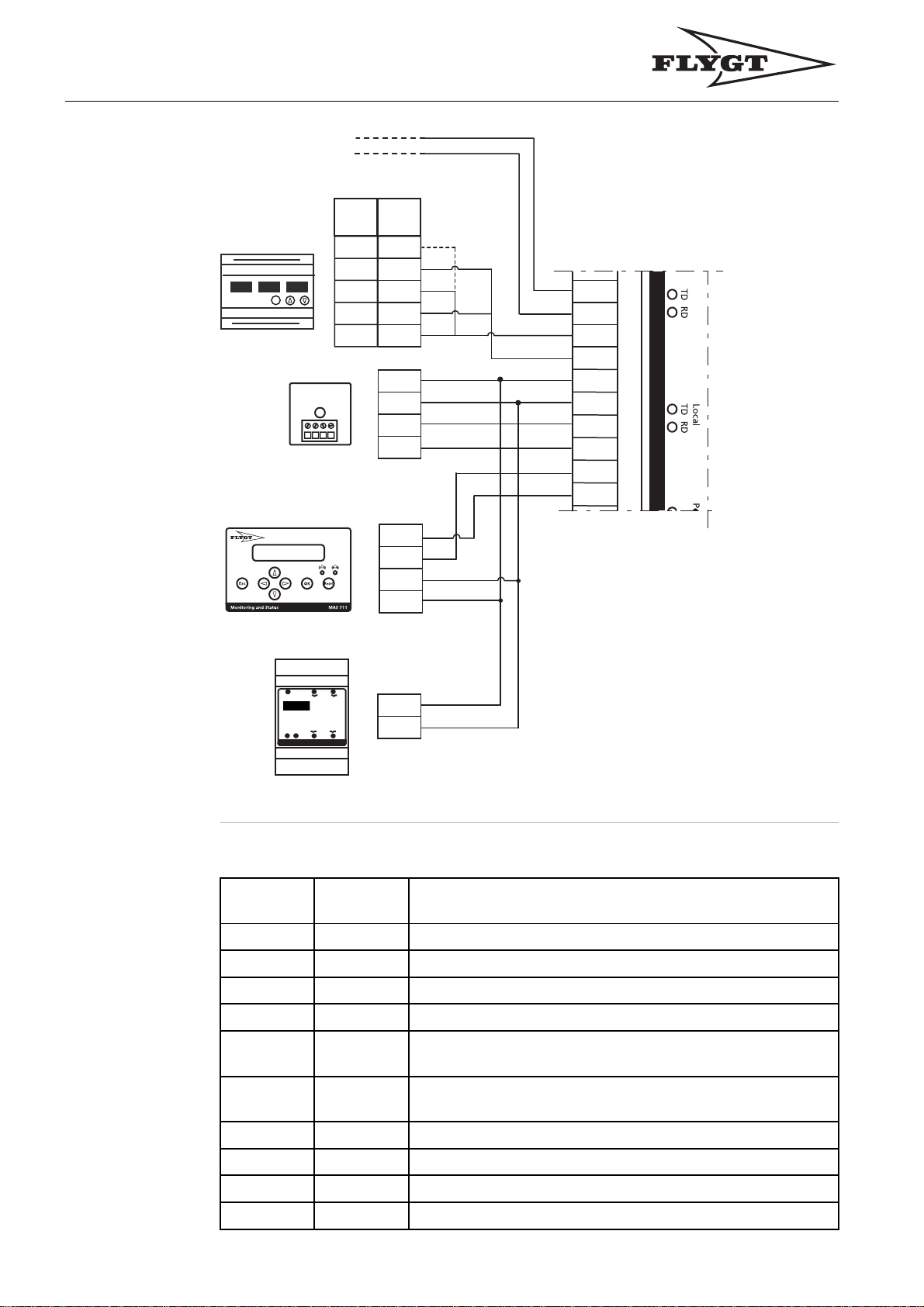

FMC

PLC

.

.

.

PAN

311

11

12

S

13

14

15

PAN

312

7

8

9

10

11

74

75

76

77

42

41

40

39

38

37

36

35

34

33

Ext.2

Base Unit

Termi nal

Description

+

-

A

B

Power

R1

R2

Local

R3 R4

TD RD

Relay mod u le MR M 0 1

This table describes the Modbus communication terminals (RS-485) of the base unit:

Terminal

Type Description

number

33

34

35

+

Ground Supply to Operator panel, ground

+

11

12

Supply to Operator panel, 12 V DC

Supply to Pump memory, 12 V DC

30

36

Ground Supply to Pump memory, ground

37 Local, A

38 Local, B

39 Ext 2, A

40 Ext 2, B

41 Ext 1, A

42 Ext 1, B

RS-485, Operator panel, Pump memory and Relay Module

(Modbus master)

RS-485, Operator panel, Pump memory and Relay Module

(Modbus master)

RS-485, Power Analyzer (Modbus master)

RS-485, Power Analyzer (Modbus master)

RS-485, Central system (Modbus slave)

RS-485, Central system (Modbus slave)

Loading...

Loading...