FLYGT 3085 Installation, Operation And Maintenance Manual

Installation, Operation,

and Maintenance Manual

Flygt 3085

Table of Contents

1 Introduction and Safety..............................................................................................................3

1.1 Introduction.......................................................................................................................... 3

1.2 Safety terminology and symbols........................................................................................3

1.3 User safety.............................................................................................................................4

1.4 Ex-approved products.........................................................................................................4

1.5 Special hazards.....................................................................................................................5

1.6 Protecting the environment................................................................................................6

1.7 Spare parts............................................................................................................................6

1.8 Warranty................................................................................................................................6

2 Transportation and Storage...................................................................................................... 7

2.1 Inspect the delivery..............................................................................................................7

2.1.1 Inspect the package..................................................................................................... 7

2.1.2 Inspect the unit..............................................................................................................7

2.2 Transportation guidelines...................................................................................................7

2.2.1 Lifting..............................................................................................................................7

2.3 Temperature ranges for transportation, handling and storage.....................................8

2.4 Storage guidelines...............................................................................................................8

Table of Contents

3 Product Description................................................................................................................. 10

3.1 Pump design...................................................................................................................... 10

3.2 Monitoring equipment......................................................................................................12

3.3 The data plate.................................................................................................................... 12

3.4 Approvals............................................................................................................................14

3.5 Product denomination...................................................................................................... 15

4 Installation................................................................................................................................. 17

4.1 Install the pump................................................................................................................. 17

4.1.1 Install with P-installation.............................................................................................18

4.1.2 Install with S-installation.............................................................................................19

4.1.3 Install with T/Z-installation......................................................................................... 20

4.1.4 Install with F-installation.............................................................................................21

4.1.5 Install with H-installation............................................................................................ 22

4.1.6 Install with X-installation.............................................................................................22

4.2 Make the electrical connections...................................................................................... 23

4.2.1 Prepare the SUBCAB® cables....................................................................................25

4.2.2 Connect the motor cable to the pump.................................................................... 26

4.2.3 Connect the motor cable to the starter and monitoring equipment...................27

4.2.4 Cable charts.................................................................................................................28

4.3 T-installation: Bleed air before starting pump............................................................... 35

4.4 Check the impeller rotation..............................................................................................36

5 Operation.................................................................................................................................. 38

5.1 Estimate zinc anode replacement intervals....................................................................38

5.2 Start the pump....................................................................................................................39

6 Maintenance..............................................................................................................................40

6.1 Torque values.....................................................................................................................40

6.2 Change the oil....................................................................................................................41

6.3 Service the pump...............................................................................................................43

Flygt 3085 Installation, Operation, and Maintenance Manual 1

Table of Contents

6.3.1 Inspection.................................................................................................................... 43

6.3.2 Major overhaul............................................................................................................ 44

6.3.3 Service in case of alarm..............................................................................................44

6.4 Replace the impeller......................................................................................................... 44

6.4.1 Replace the C-, D-, or L-impeller.............................................................................. 45

6.4.2 Replace the F-impeller...............................................................................................49

6.4.3 Replace the M-impeller..............................................................................................54

6.4.4 Replacing the Adaptive N-impeller..........................................................................57

7 Troubleshooting....................................................................................................................... 63

7.1 The pump does not start...................................................................................................63

7.2 The pump does not stop when a level sensor is used..................................................64

7.3 The pump starts-stops-starts in rapid sequence............................................................64

7.4 The pump runs but the motor protection trips..............................................................65

7.5 The pump delivers too little or no water.........................................................................66

8 Technical Reference.................................................................................................................67

8.1 Motor data.......................................................................................................................... 67

2 Flygt 3085 Installation, Operation, and Maintenance Manual

1 Introduction and Safety

1.1 Introduction

Purpose of the manual

The purpose of this manual is to provide necessary information for working with the unit.

Read this manual carefully before starting work.

Read and keep the manual

Save this manual for future reference, and keep it readily available at the location of the

unit.

Intended use

WARNING:

Operating, installing, or maintaining the unit in any way that is not covered in this manual

could cause death, serious personal injury, or damage to the equipment and the

surroundings. This includes any modification to the equipment or use of parts not

provided by Xylem. If there is a question regarding the intended use of the equipment,

please contact a Xylem representative before proceeding.

1 Introduction and Safety

Other manuals

See also the safety requirements and information in the original manufacturer's manuals

for any other equipment furnished separately for use in this system.

1.2 Safety terminology and symbols

About safety messages

It is extremely important that you read, understand, and follow the safety messages and

regulations carefully before handling the product. They are published to help prevent

these hazards:

• Personal accidents and health problems

• Damage to the product and its surroundings

• Product malfunction

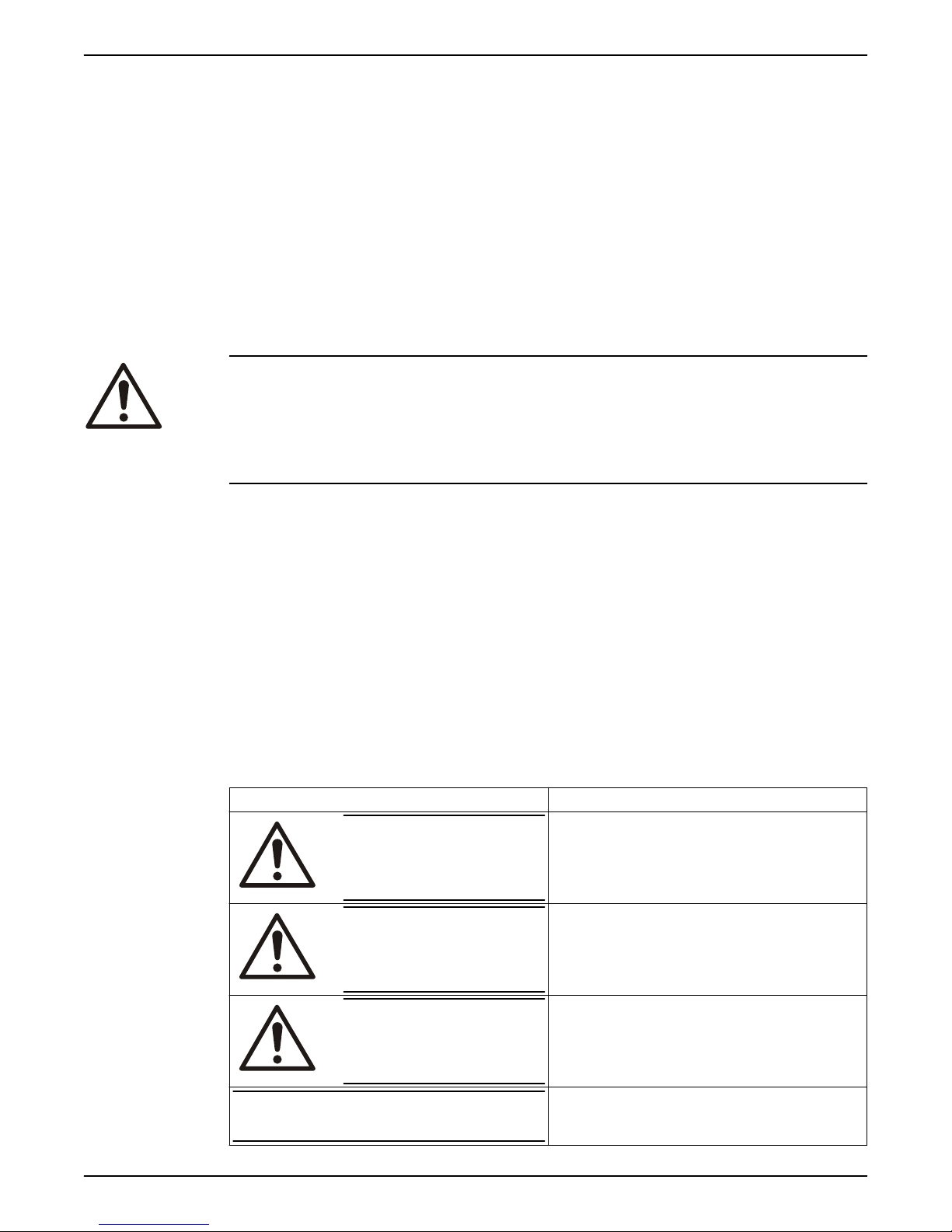

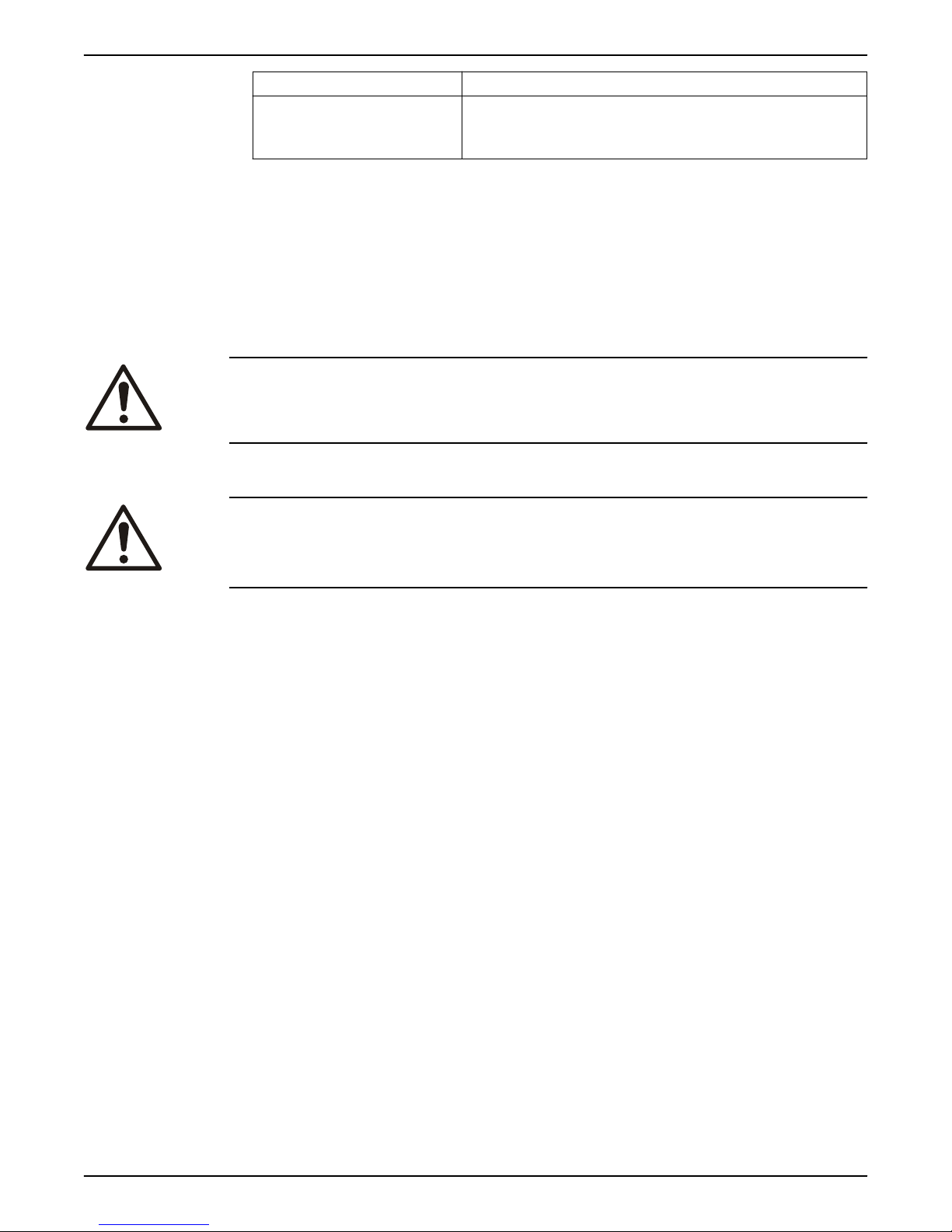

Hazard levels

Hazard level Indication

DANGER:

WARNING:

A hazardous situation which, if not avoided, will result in

death or serious injury

A hazardous situation which, if not avoided, could result

in death or serious injury

NOTICE:

Flygt 3085 Installation, Operation, and Maintenance Manual 3

CAUTION:

A hazardous situation which, if not avoided, could result

in minor or moderate injury

Notices are used when there is a risk of equipment

damage or decreased performance, but not personal

injury.

1 Introduction and Safety

Special symbols

Some hazard categories have specific symbols, as shown in the following table.

Electrical Hazard Permanent-magnet hazard

Electrical Hazard:

1.3 User safety

All regulations, codes, and health and safety directives must be observed.

The site

• Observe lockout/tagout procedures before starting work on the product, such as

transportation, installation, maintenance, or service.

• Pay attention to the risks presented by gas and vapors in the work area.

• Always be aware of the area surrounding the equipment, and any hazards posed by

the site or nearby equipment.

Qualified personnel

This product must be installed, operated, and maintained by qualified personnel only.

Protective equipment and safety devices

• Use personal protective equipment as needed. Examples of personal protective

equipment include, but are not limited to, hard hats, safety goggles, protective gloves

and shoes, and breathing equipment.

• Make sure that all safety features on the product are functioning and in use at all times

when the unit is being operated.

CAUTION:

1.4 Ex-approved products

Follow these special handling instructions if you have an Ex-approved unit.

Personnel requirements

These are the personnel requirements for Ex-approved products in potentially explosive

atmospheres:

• All work on the product must be carried out by

authorized mechanics. Special rules apply to installations in explosive atmospheres.

• All users must know about the risks of electric current and the chemical and physical

characteristics of the gas, the vapor, or both present in hazardous areas.

• Any maintenance for Ex-approved products must conform to international and national

standards (for example, IEC/EN 60079-17).

Xylem disclaims all responsibility for work done by untrained and unauthorized personnel.

Product and product handling requirements

These are the product and product handling requirements for Ex-approved products in

potentially explosive atmospheres:

• Only use the product in accordance with the approved motor data.

• The Ex-approved product must never run dry during normal operation. Dry running

during service and inspection is only permitted outside the classified area.

• Before you start work on the product, make sure that the product and the control

panel are isolated from the power supply and the control circuit, so they cannot be

energized.

• Do not open the product while it is energized or in an explosive gas atmosphere.

• Make sure that thermal contacts are connected to a protection circuit according to the

approval classification of the product, and that they are in use.

certified electricians and Xylem

4 Flygt 3085 Installation, Operation, and Maintenance Manual

• Intrinsically safe circuits are normally required for the automatic level-control system by

the level regulator if mounted in zone 0.

• The yield stress of fasteners must be in accordance with the approval drawing and the

product specification.

• Do not modify the equipment without approval from an Ex-approved Xylem

representative.

• Only use parts that are provided by an Ex-approved Xylem representative.

• The thermal detectors fitted to the stator windings shall be connected into the motor

control circuit in such a manner as to disconnect the supply to the motor in order to

prevent the Temperature Class T3.

• The width of flameproof joints is more than the values specified in the tables of the IEC

60079–1 standard.

• The gap of flameproof joints is less than the values specified in Table 1 of the IEC

60079–1 standard.

• The equipment must be submerged during normal operation.

Guidelines for compliance

Compliance is fulfilled only when you operate the unit within its intended use. Do not

change the conditions of the service without the approval of an Ex-approved Xylem

representative. When you install or maintain explosion proof products, always comply

with the directive and applicable standards (for example, IEC/EN 60079–14).

1 Introduction and Safety

Minimum permitted liquid level

See the dimensional drawings of the product for the minimum permitted liquid level

according to the approval for explosion proof products. If the information is missing on

the dimensional drawing, the product must be fully submerged. Level-sensing equipment

must be installed if the product can be operated at less than the minimum submersion

depth.

Monitoring equipment

For additional safety, use condition-monitoring devices. Condition-monitoring devices

include but are not limited to the following:

• Level indicators

• Temperature detectors

1.5 Special hazards

Biological hazards

The product is designed for use in liquids that can be hazardous to your health. Observe

these rules when you work with the product:

• Make sure that all personnel who may come into contact with biological hazards are

vaccinated against diseases to which they may be exposed.

• Observe strict personal cleanliness.

WARNING: Biological Hazard

Infection risk. Rinse the unit thoroughly with clean water before working on it.

Wash the skin and eyes

Follow these procedures for chemicals or hazardous fluids that have come into contact

with your eyes or your skin:

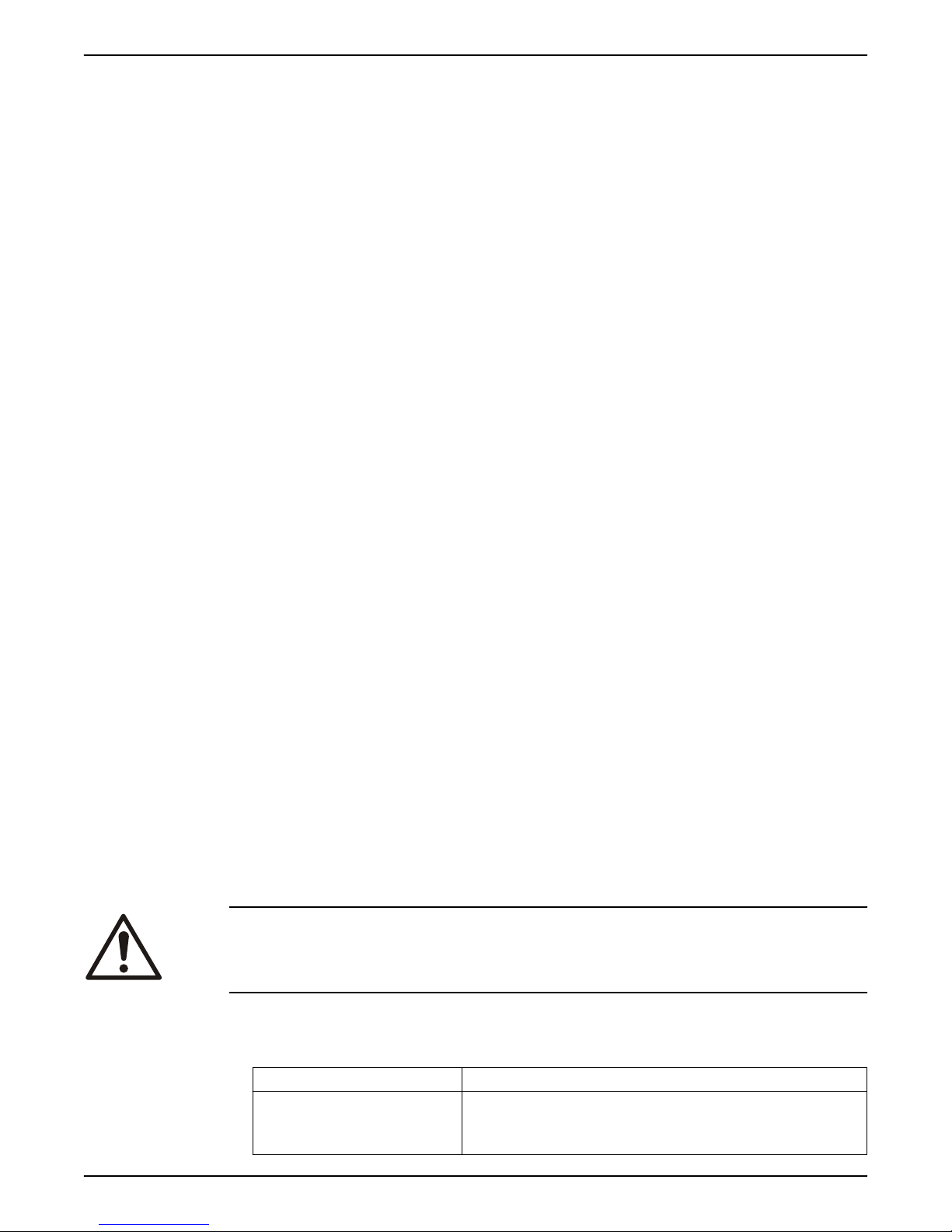

Condition Action

Chemicals or hazardous fluids in

eyes

Flygt 3085 Installation, Operation, and Maintenance Manual 5

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

1 Introduction and Safety

Condition Action

Chemicals or hazardous fluids on

skin

1.6 Protecting the environment

Emissions and waste disposal

Observe the local regulations and codes regarding:

• Reporting of emissions to the appropriate authorities

• Sorting, recycling and disposal of solid or liquid waste

• Clean-up of spills

Exceptional sites

CAUTION: Radiation Hazard

Do NOT send the product to Xylem if it has been exposed to nuclear radiation, unless

Xylem has been informed and appropriate actions have been agreed upon.

1.7 Spare parts

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. Seek medical attention, if necessary.

1.8 Warranty

CAUTION:

Only use the manufacturer’s original spare parts to replace any worn or faulty

components. The use of unsuitable spare parts may cause malfunctions, damage, and

injuries as well as void the warranty.

For information about warranty, see the sales contract.

6 Flygt 3085 Installation, Operation, and Maintenance Manual

2 Transportation and Storage

2 Transportation and Storage

2.1 Inspect the delivery

2.1.1 Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the

distributor.

2.1.2 Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact the local sales representative if there is any issue.

2.2 Transportation guidelines

Precautions

DANGER: Crush Hazard

Moving parts can entangle or crush. Always disconnect and lock out power before

servicing to prevent unexpected startup. Failure to do so could result in death or serious

injury.

Position and fastening

The unit can be transported either horizontally or vertically. Make sure that the unit is

securely fastened during transportation, and cannot roll or fall over.

2.2.1 Lifting

Always inspect the lifting equipment and tackle before starting any work.

WARNING: Crush Hazard

1) Always lift the unit by its designated lifting points. 2) Use suitable lifting equipment and

ensure that the product is properly harnessed. 3) Wear personal protective equipment. 4)

Stay clear of cables and suspended loads.

NOTICE:

Never lift the unit by its cables or hose.

Lifting equipment

Lifting equipment is always required when handling the unit. It must fulfill the following

requirements:

• The minimum height (contact your local sales and service representative for

information) between the lifting hook and the floor must be sufficient to lift the unit.

• The lifting equipment must be able to hoist the unit straight up and down, preferably

without the need for resetting the lifting hook.

• The lifting equipment must be securely anchored and in good condition.

Flygt 3085 Installation, Operation, and Maintenance Manual 7

2 Transportation and Storage

• The lifting equipment must support the weight of the entire assembly and must only

be used by authorized personnel.

• Two sets of lifting equipment must be used to lift the unit for repair work.

• The lifting equipment must be dimensioned to lift the unit with any remaining pumped

media in it.

• The lifting equipment must not be oversized.

CAUTION: Crush Hazard

Over-dimensioned lifting equipment can lead to injury. A site-specific

risk analysis must be done.

2.3 Temperature ranges for transportation, handling and storage

Handling at freezing temperature

At temperatures below freezing, the product and all installation equipment, including the

lifting gear, must be handled with extreme care.

Make sure that the product is warmed up to a temperature above the freezing point

before starting up. Avoid rotating the impeller/propeller by hand at temperatures below

the freezing point. The recommended method to warm the unit up is to submerge it in the

liquid which will be pumped or mixed.

NOTICE:

Never use a naked flame to thaw the unit.

Unit in as-delivered condition

If the unit is still in the condition in which it left the factory - all packing materials are

undisturbed - then the acceptable temperature range during transportation, handling and

storage is: –50°C (–58ºF) to +60°C (+140ºF).

If the unit has been exposed to freezing temperatures, then allow it to reach the ambient

temperature of the sump before operating.

Lifting the unit out of liquid

The unit is normally protected from freezing while operating or immersed in liquid, but

the impeller/propeller and the shaft seal may freeze if the unit is lifted out of the liquid

into a surrounding temperature below freezing.

Units equipped with an internal cooling system are filled with a mixture of water and 30%

glycol. This mixture remains a flowing liquid at temperatures down to –13°C (9°F). Below –

13°C (9°F), the viscosity increases such that the glycol mixture will lose its flow properties.

However, the glycol-water mixture will not solidify completely and thus cannot harm the

product.

Follow these guidelines to avoid freezing damage:

1. Empty all pumped liquid, if applicable.

2. Check all liquids used for lubrication or cooling, both oil and water-glycol mixtures, for

the presence of unacceptable amounts of water. Change if needed.

2.4 Storage guidelines

Storage location

The product must be stored in a covered and dry location free from heat, dirt, and

vibrations.

NOTICE:

Protect the product against humidity, heat sources, and mechanical damage.

8 Flygt 3085 Installation, Operation, and Maintenance Manual

NOTICE:

Do not place heavy weights on the packed product.

Long-term storage

If the unit is stored more than six months, then the following apply:

• Before operating the unit after storage, it must be inspected with special attention to

the seals and the cable entry.

• The impeller/propeller must be rotated every other month to prevent the seals from

sticking together.

Packaging material stacking limit

If the packaging material has an indicated stacking limit, then it is valid for 23° C (73° F)

and 50% relative humidity. Depending on the material, other temperature and humidity

ranges can reduce the stacking limit.

2 Transportation and Storage

Flygt 3085 Installation, Operation, and Maintenance Manual 9

3 Product Description

3 Product Description

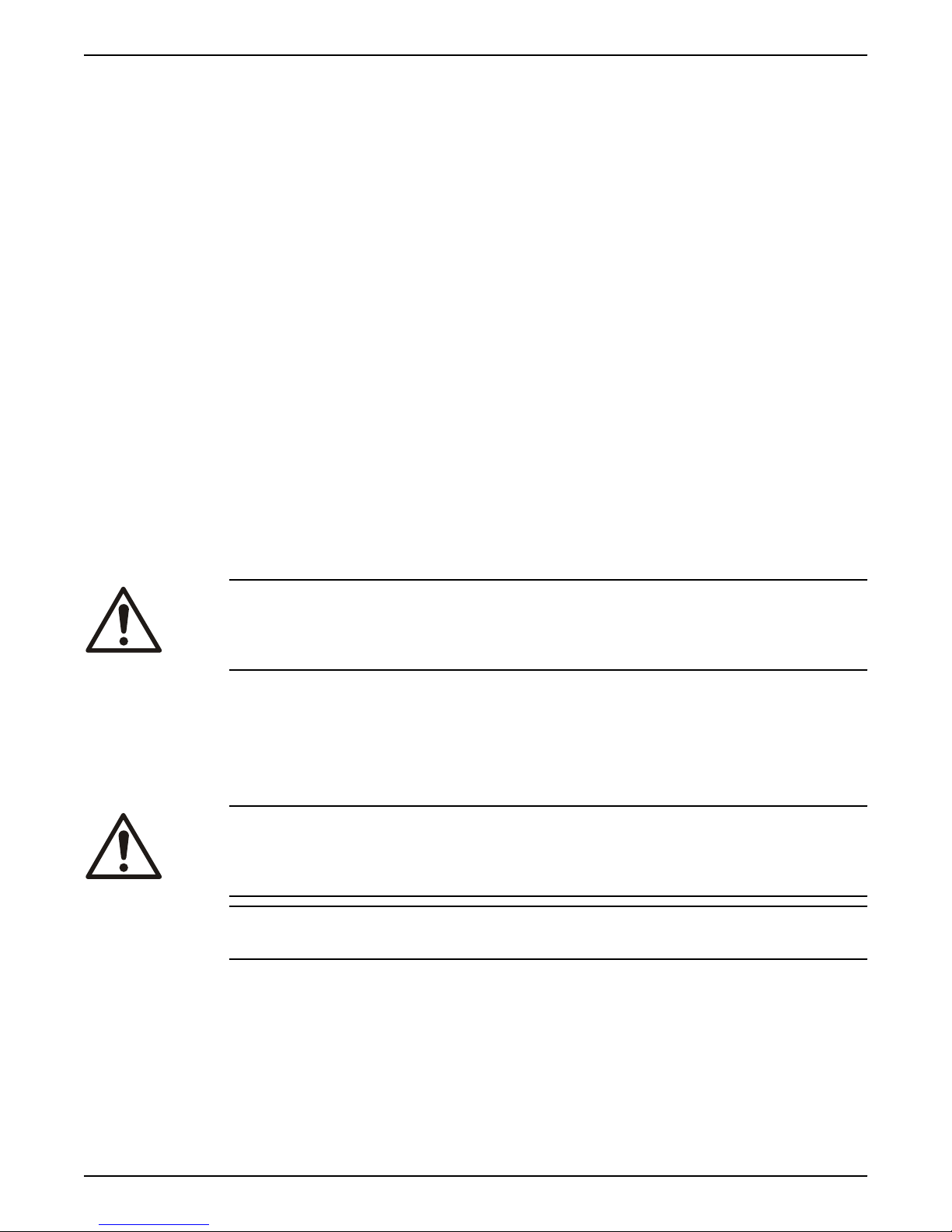

Products included

Pump

C-hydraulic

High Efficiency motor

(LSPM)

Explosion proof drive unit

Non-explosion proof drive unit

3085.092 X X X X X X

3085.160 X X

3085.172 X X

3085.183 X X X X X X

3085.190 X X

3085.760 X X *

3085.770 X X *

3085.800 X X X

3085.810 X X X

3085.820 X X X

3085.830 X X X

3085.891 X X

3085.900 X X X

3085.910 X X X

3085.960 X X X *

3085.970 X X X *

* Stainless steel Adaptive-N hydraulics

D-hydraulic

F-hydraulic

G-hydraulic

M-hydraulic

(Grinder)

N hydraulic

(Hard-Iron)

Adaptive-N hydraulic

Pump-specific information

For the specific weight, current, voltage, power ratings, and speed of the pump, see the

data plate of the pump.

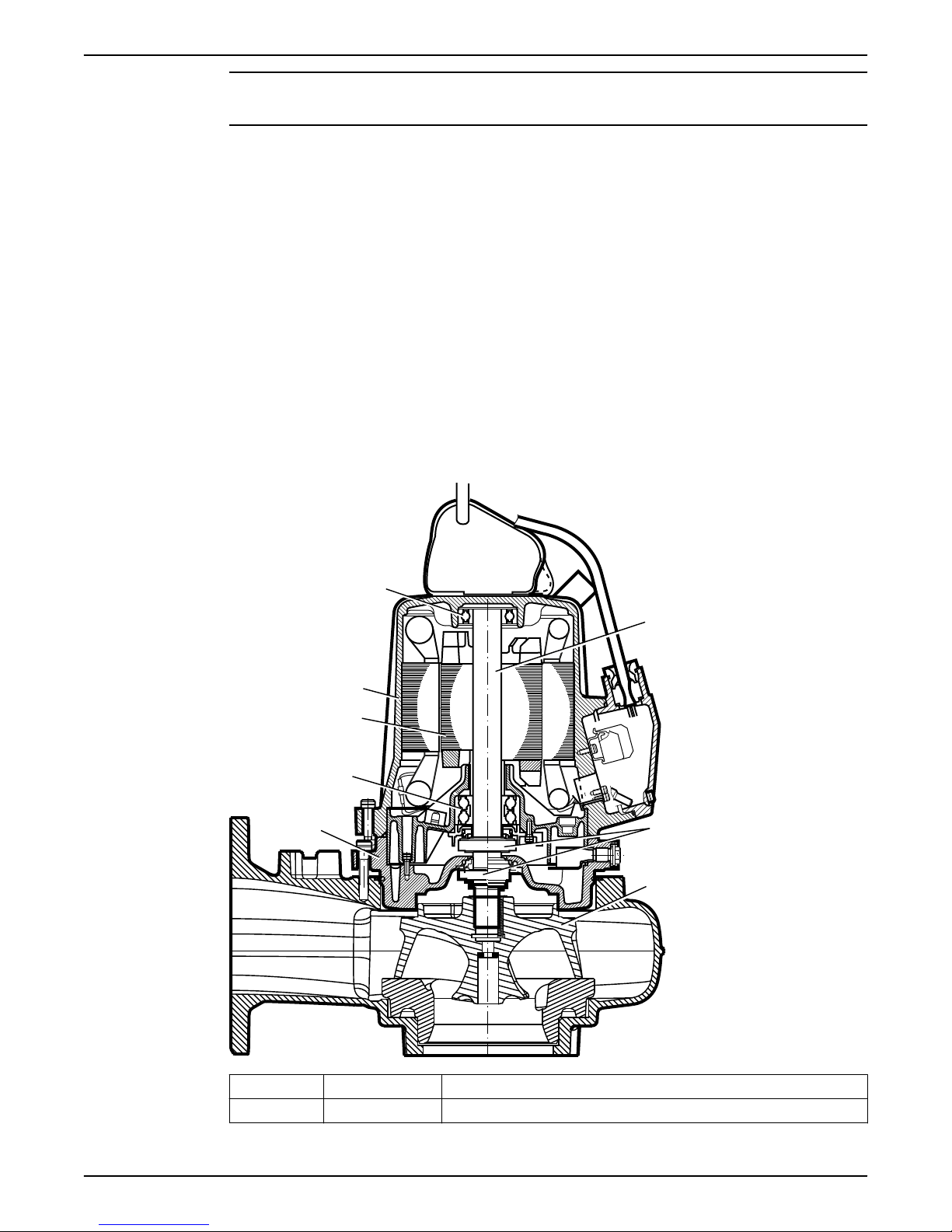

3.1 Pump design

The pump is submersible, and driven by an electric motor.

For a list of pump version and corresponding motor type, see Motor data (page 67).

Intended use

The product is intended for moving wastewater, sludge, raw and clean water. Always

follow the limits that are given in Application limits (page 67). If there is a question

regarding the intended use of the equipment, please contact a local sales and service

representative before proceeding.

DANGER: Explosion/Fire Hazard

Special rules apply to installations in explosive or flammable atmospheres. Do not install

the product or any auxiliary equipment in an explosive zone unless it is rated explosionproof or intrinsically-safe. If the product is EN/ATEX-, MSHA- or FM-approved, then see

the specific EX information in the Safety chapter before taking any further actions.

10 Flygt 3085 Installation, Operation, and Maintenance Manual

NOTICE:

1

2

4

6

7

8

5

3

WS006127A

Do NOT use the unit in highly corrosive liquids.

Spare parts

• Modifications to the unit or installation should only be carried out after consulting with

Xylem.

• Original spare parts and accessories that are authorized by Xylem are essential for

compliance. The use of other parts can invalidate any claims for warranty or

compensation. For more information contact your Xylem representative.

Pressure class

LT Low head

MT Medium head

HT High head

SH Super high head

Experior® product concept

Experior® is a product concept including N-technology, Premium efficiency motor, and

the intelligent control SmartRun®.

Parts

3 Product Description

Position Denomination Description

1 Shaft The shaft is made of stainless steel, with an integrated rotor.

Flygt 3085 Installation, Operation, and Maintenance Manual 11

3 Product Description

Position Denomination Description

2 Impeller There are multiple types of impellers. For information about the pumps

3 Mechanical seals One inner and one outer seal in a combination of materials:

4 Oil housing The oil housing includes a coolant that lubricates and cools the seals; the

5 Main bearing The bearing consisting of a two-row angular contact ball bearing.

6 Motor

7 Stator housing The pump is cooled by the ambient liquid/air.

8 Support bearing The bearing consisting of a single-row ball bearing.

3.2 Monitoring equipment

The following applies to the monitoring equipment of the pump:

• The stator incorporates three thermal contacts connected in series that activate the

alarm and stops the pump at overtemperature

• The thermal contacts open at 125°C (257°F).

• Ex-approved pumps must have thermal contacts connected to the control panel.

• The sensors must be connected to either the MiniCAS II monitoring equipment or an

equivalent equipment.

• The monitoring equipment must be of a design that makes automatic restart

impossible.

• Information in the junction box shows if the pump is equipped with optional sensors.

impellers, see Parts List.

• Aluminium oxide Al2O

• Silicon carbide RSiC

• Corrosion-resistant cemented carbide WCCR

3

For information about the pumps mechanical seals, see Parts List.

housing acts as a buffer between the pumped fluid and the drive unit.

For information about the motor, see Motor data (page 67)..

Optional sensors

FLS is a miniature float switch for detection of liquid in the stator housing. Due to its

FLS

design it is best suited for pumps in a vertical position. The FLS sensor is installed in

the bottom of the stator housing.

CLS CLS is a sensor for detection of water in the oil housing. The sensor initiates an alarm

when the oil contains approximately 35% water. The sensor is installed in the bearing

housing/bearing holder with its sensing part in the oil housing. The CLS sensor is not

applicable to Ex-approved pumps.

NOTICE:

The CLS sensor body is made of glass. Handle the sensor with care.

One CLS and one FLS sensor can be used in the same pump, if they are connected in

parallel.

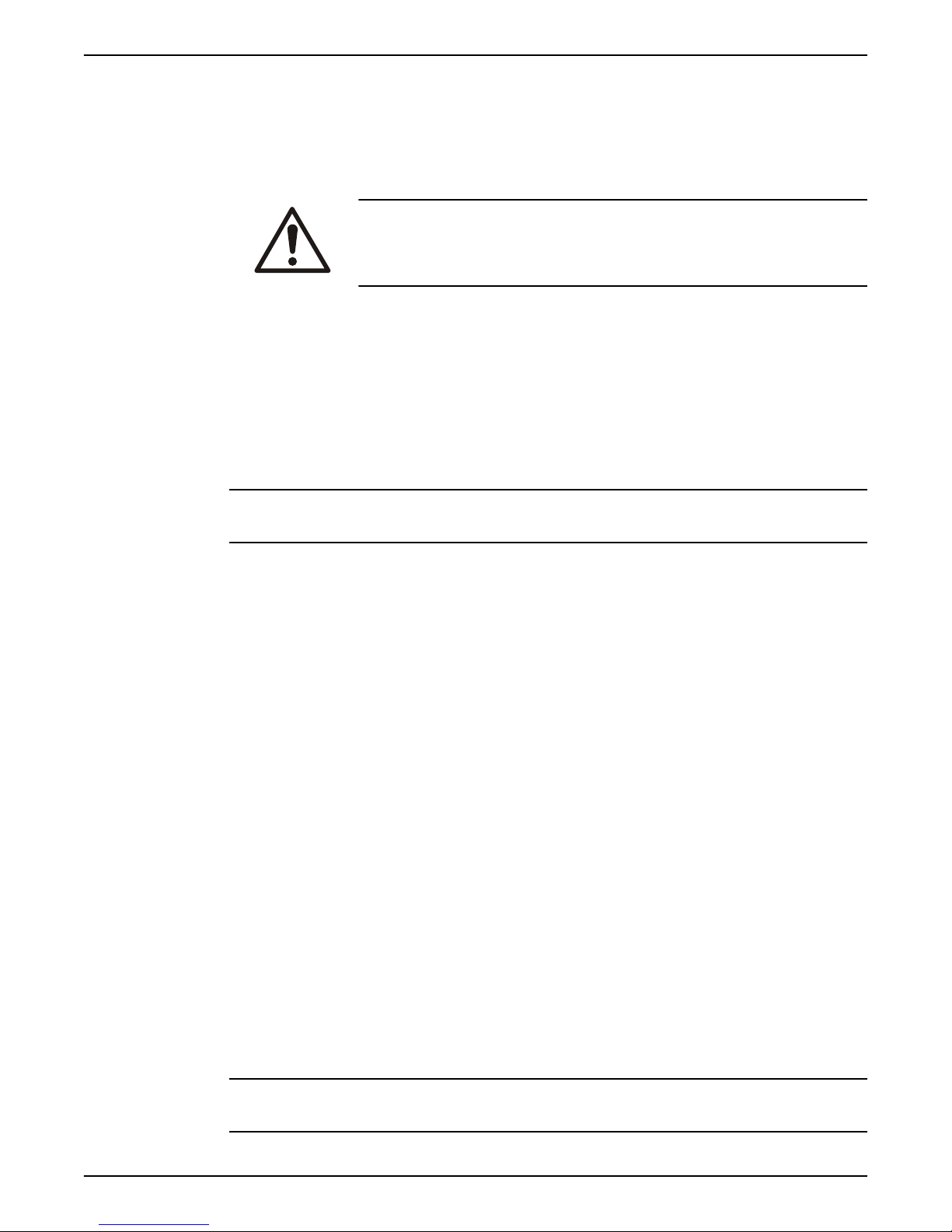

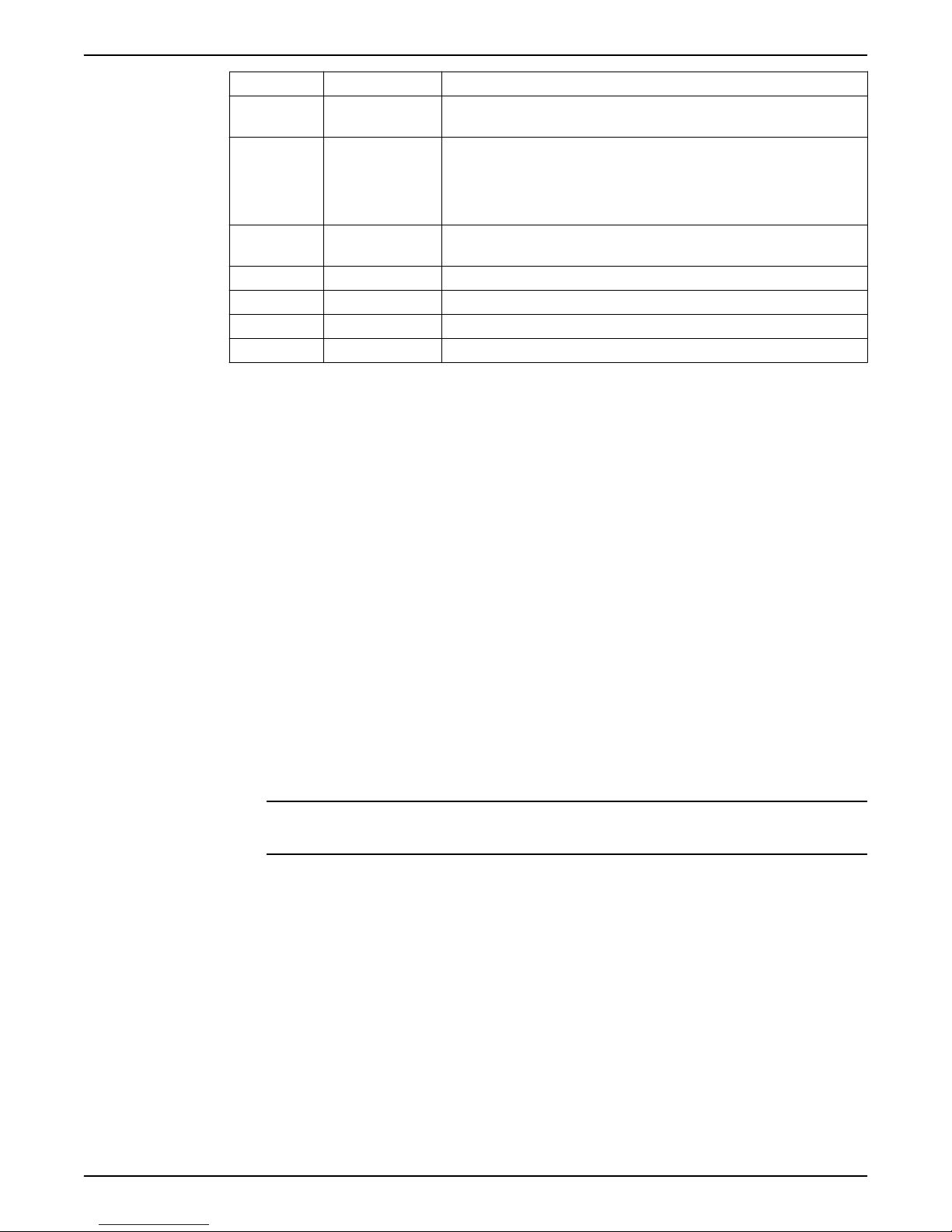

3.3 The data plate

The data plate is a metal label that is located on the main body of the products. The data

plate lists key product specifications. Specially approved products also have an approval

plate.

12 Flygt 3085 Installation, Operation, and Maintenance Manual

2

1312 14

22

21

20

17 18 1916159 10 11

8

7

6

5

4

3

1

23

24

WS006257A

1. Curve code or Propeller code

2. Serial number

3. Product number

4. Country of origin

5. Additional information

6. Phase; type of current; frequency

7. Rated voltage

8. Thermal protection

9. Thermal class

10.Rated shaft power

11.International standard

12.Degree of protection

13.Rated current

14.Rated speed

15.Maximum submergence

16.Direction of rotation: L=left, R=right

17.Duty class

18.Duty factor

19.Product weight

20.Locked rotor code letter

21.Power factor

22.Maximum ambient temperature

23.Read installation manual

24.Notified body, only for EN-approved Ex products

Figure 1: The data plate

3 Product Description

Flygt 3085 Installation, Operation, and Maintenance Manual 13

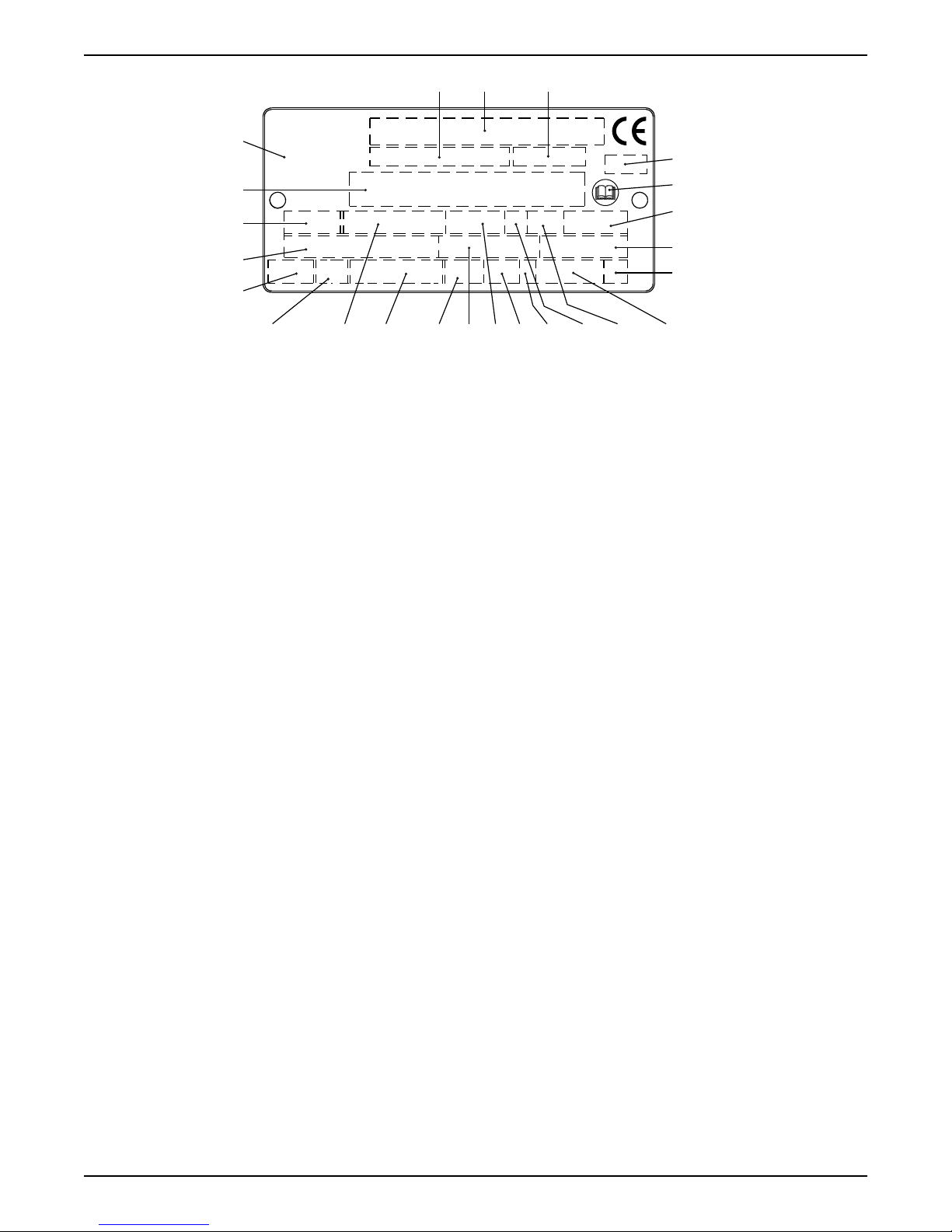

1 2 3

4

5

6 7

8

9 10

12

11

13

14

15

WS003972A

3 Product Description

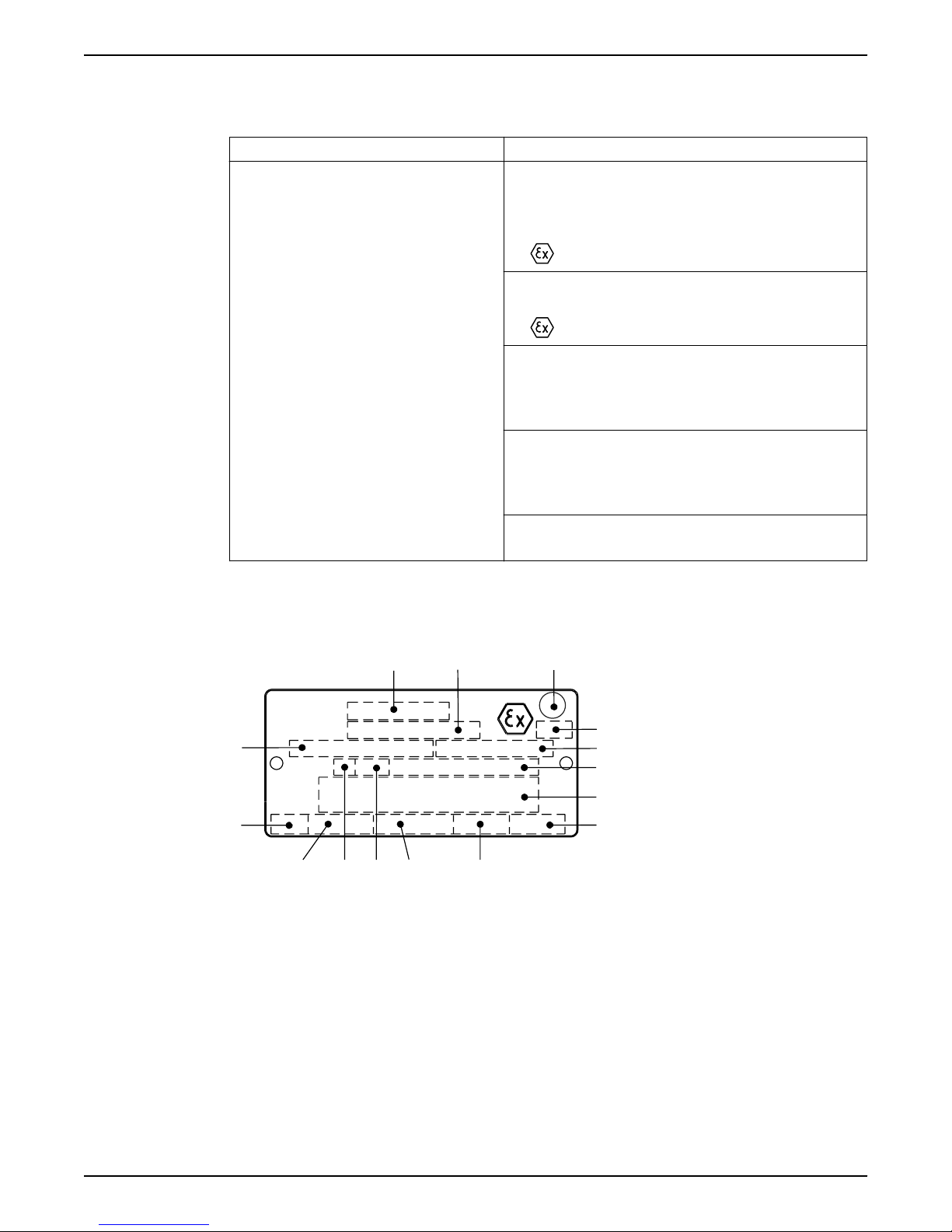

3.4 Approvals

Product approvals for hazardous locations

Pump Approval

• 3085.092

• 3085.190

• 3085.770

• 3085.810

• 3085.830

• 3085.891

• 3085.910

• 3085.970

European Norm (EN)

• ATEX Directive

• EN 60079-0:2009, EN 60079-1:2007, EN 13463-1:2009,

EN 13463-5:2011

•

II 2 G c Ex d IIB T4 Gb

EN approval for cable entry:

• Certificate number: INERIS 02ATEX9008 U

•

II 2 G Ex d IIC Gb or I M2 Ex d I Mb

IEC

• IECEx scheme

• IEC 60079-0, IEC 60079-1

• Ex d IIB T4

FM (FM Approvals)

• Explosion proof for use in Class I, Div. 1, Group C and D

• Dust ignition proof for use in Class II, Div. 1, Group E, F and G

• Suitable for use in Class III, Div. 1, Hazardous Locations

CSA Ex

• Explosion proof for use in Class I, Div. 1, Group C and D

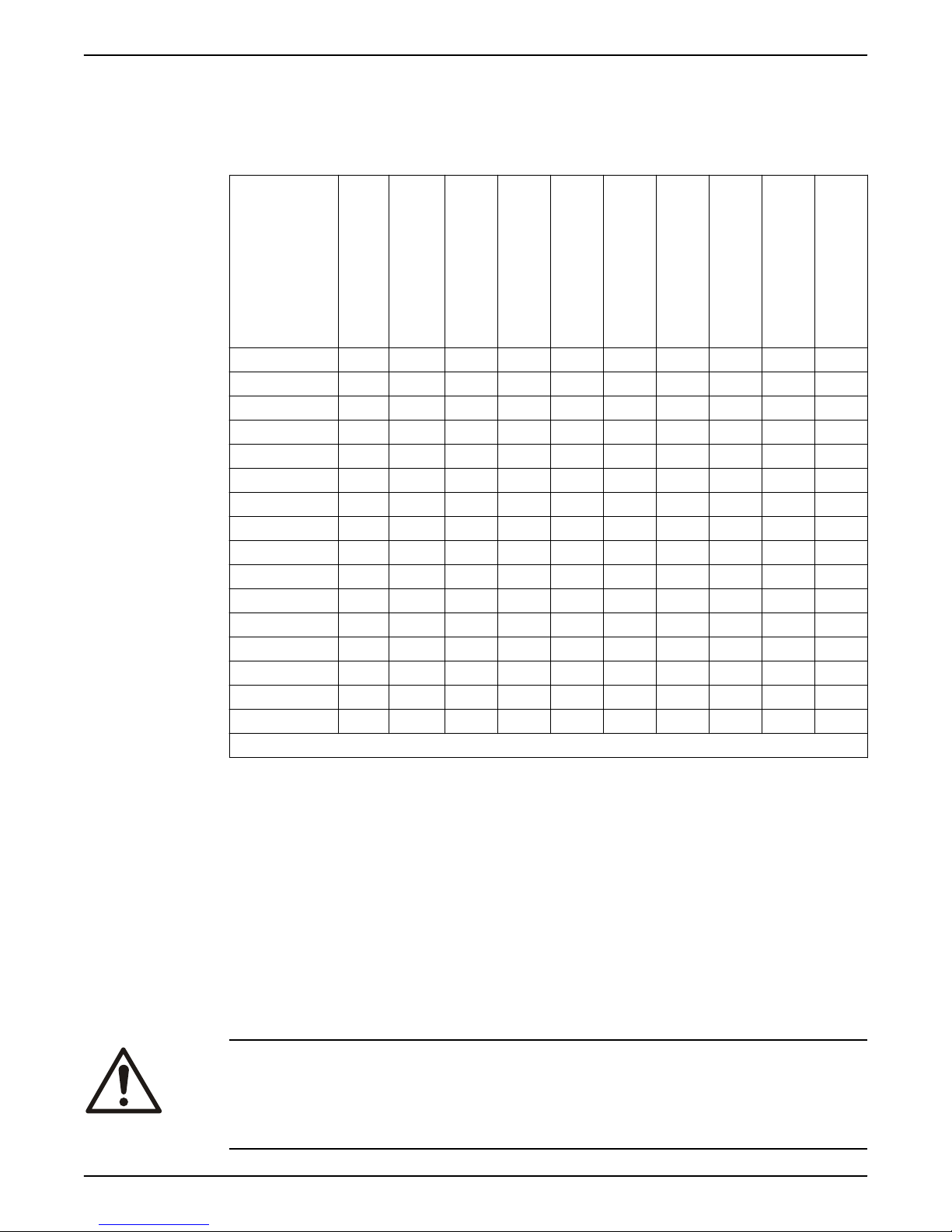

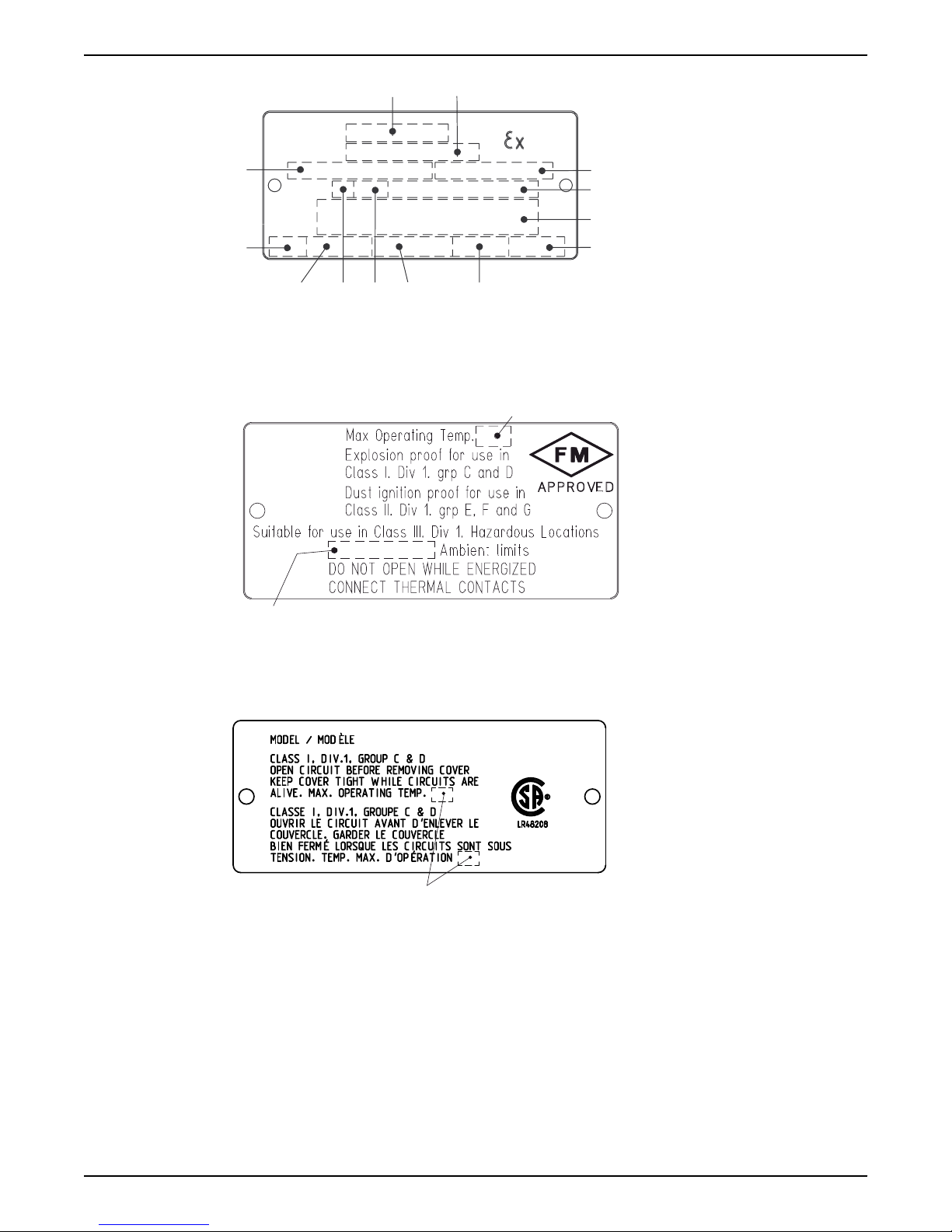

EN approval plate

IEC approval plate

This illustration describes the EN approval plate and the information that is contained in

its fields.

1. Approval

2. Approval authority and

Approval number

3. Approval for Class I

4. Approved for drive unit

5. Stall time

6. Starting current or Rated

current

7. Duty class

8. Duty factor

9. Input power

10.Rated speed

11.Controller

12.Additional information

13.Maximum ambient temperature

14.Serial number

15.ATEX marking

This illustration describes the IEC approval plate and the information that is contained in

fields.

its

International Norm; not for EU member countries.

14 Flygt 3085 Installation, Operation, and Maintenance Manual

WS001279B

21

876

3

4

5 9

10

11

12

13

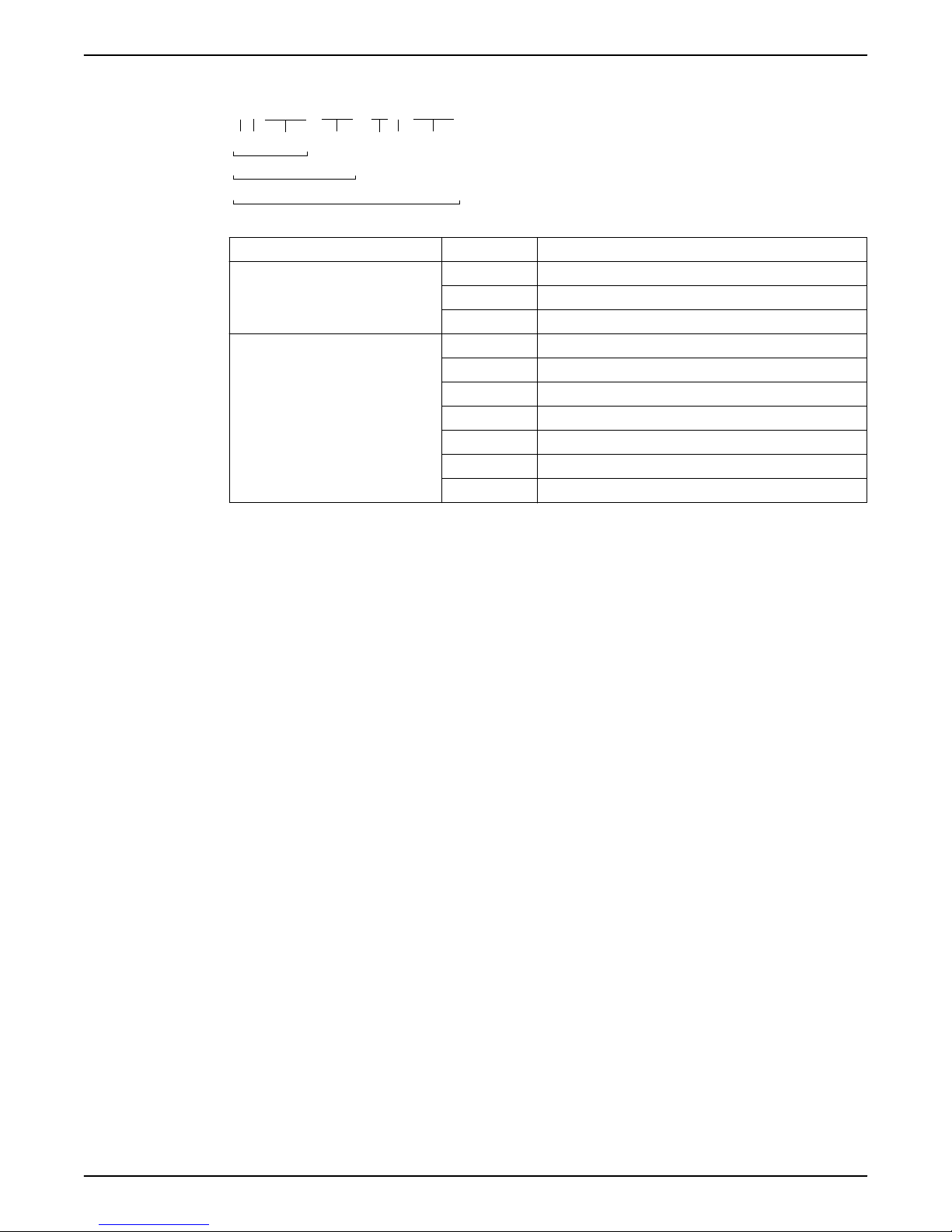

FM approval plate

1

2

WS003973A

1

WS009401A

3 Product Description

1. Approval

2. Approval authority and

Approval number

3. Approved for drive unit

4. Stall time

5. Starting current or Rated

current

6. Duty class

7. Duty factor

8. Input power

9. Rated speed

10.Controller

11.Additional information

12.Maximum ambient temperature

13.Serial number

This illustration describes the FM approval plate and the information that is contained in

its fields.

1. Temperature class

2. Maximum ambient temperature

CSA approval plate

This illustration describes the CSA approval plate and the information that is contained in

its fields.

1. Temperature class

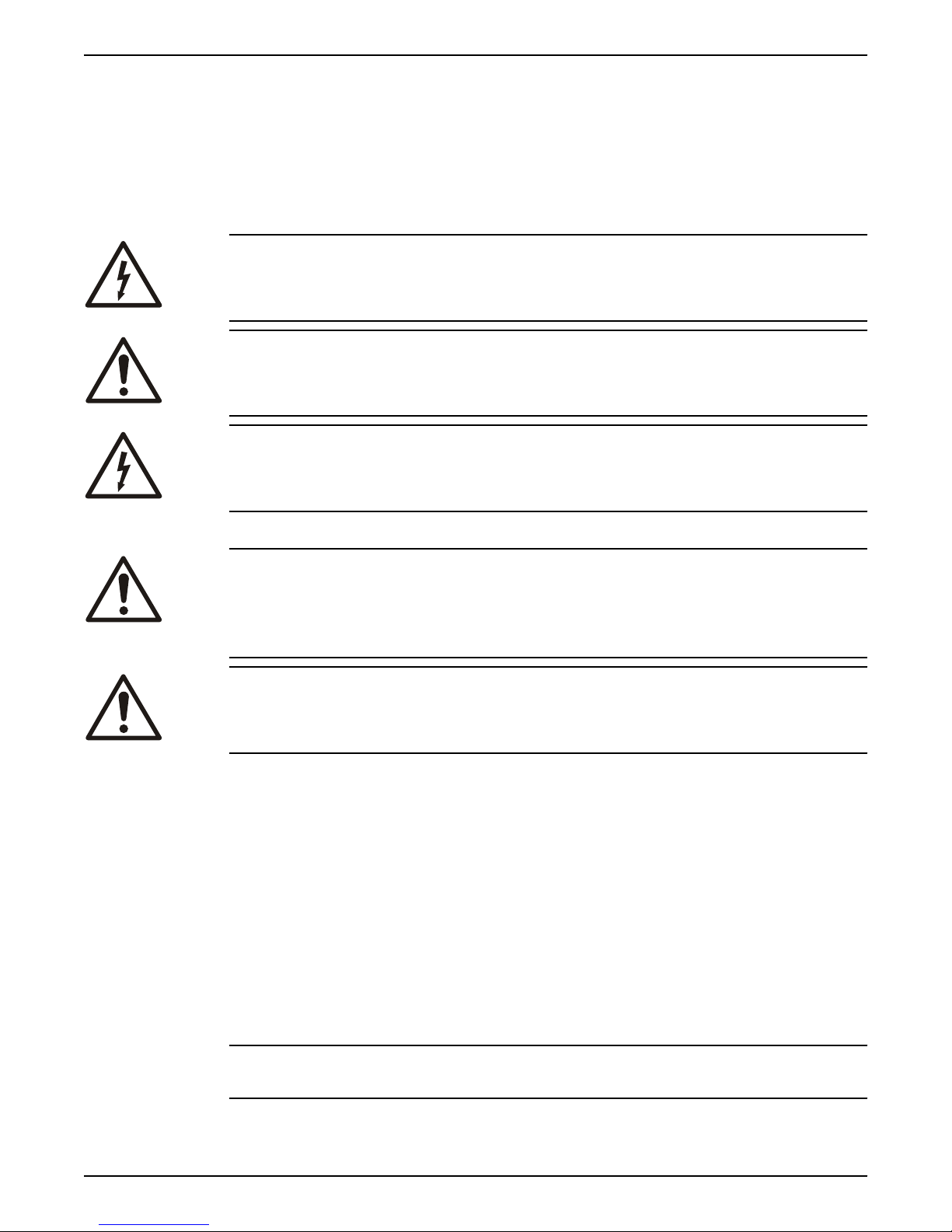

3.5 Product denomination

Reading instruction

In this section, code characters are illustrated accordingly:

X = letter

Y = digit

The different types of codes are marked up with a, b and c. Code parameters are marked

up with numbers.

Flygt 3085 Installation, Operation, and Maintenance Manual 15

XXYYYY YYY YYY YYYY

1

2

3

4

5

6

7

a

b

c

WS006265B

.

3 Product Description

Codes and parameters

Type of Callout Number Indication

Type of code a Sales denomination

Parameter 1 Hydraulic end

b Product code

c Serial number

2 Type of installation

3 Sales code

4 Version

5 Production year

6 Production cycle

7 Running number

16 Flygt 3085 Installation, Operation, and Maintenance Manual

4 Installation

4.1 Install the pump

Before starting work, make sure that the safety instructions in the chapter Introduction and

Safety (page 3) have been read and understood.

DANGER: Electrical Hazard

Before starting work on the unit, make sure that the unit and the control panel are isolated

from the power supply and cannot be energized. This applies to the control circuit as well.

DANGER: Inhalation Hazard

Before entering the work area, make sure that the atmosphere contains sufficient oxygen

and no toxic gases.

WARNING: Electrical Hazard

The permanent-magnet motor generates voltage when the shaft rotates, even if power

sources are disconnected. Never perform any electrical work if the shaft could rotate.

4 Installation

Hazardous atmospheres

DANGER: Explosion/Fire Hazard

Special rules apply to installations in explosive or flammable atmospheres. Do not install

the product or any auxiliary equipment in an explosive zone unless it is rated explosionproof or intrinsically-safe. If the product is EN/ATEX-, MSHA- or FM-approved, then see

the specific EX information in the Safety chapter before taking any further actions.

WARNING: Explosion/Fire Hazard

Do not install CSA-approved products in locations that are classified as hazardous in the

National Electric Code(TM), ANSI/NFPA 70-2005.

General requirements

These requirements apply:

• Use the pump dimensional drawing in order to ensure proper installation.

Before installing the pump, do the following:

• Provide a suitable barrier around the work area, for example, a guard rail.

• Make sure that equipment is in place so that the unit cannot roll or fall over during the

• Check the explosion risk before you weld or use electric hand tools.

• Check that the cable and cable entry have not been damaged during transport.

• Always remove all debris and waste material from the sump, inlet piping, and

• If the unit has a permanent magnet motor, then ensure that you have read and

installation process.

discharge connection, before you install the pump.

understood all safety instructions regarding permanent magnet motors.

NOTICE:

Do not run the pump dry.

Flygt 3085 Installation, Operation, and Maintenance Manual 17

WS006259A

4 Installation

NOTICE:

Never force piping to make a connection with a pump.

Authority regulation

Vent the tank of a sewage station in accordance with local plumbing codes.

Fasteners

• Only use fasteners of the proper size and material.

• Replace all corroded fasteners.

• Make sure that all fasteners are properly tightened and that there are no missing

fasteners.

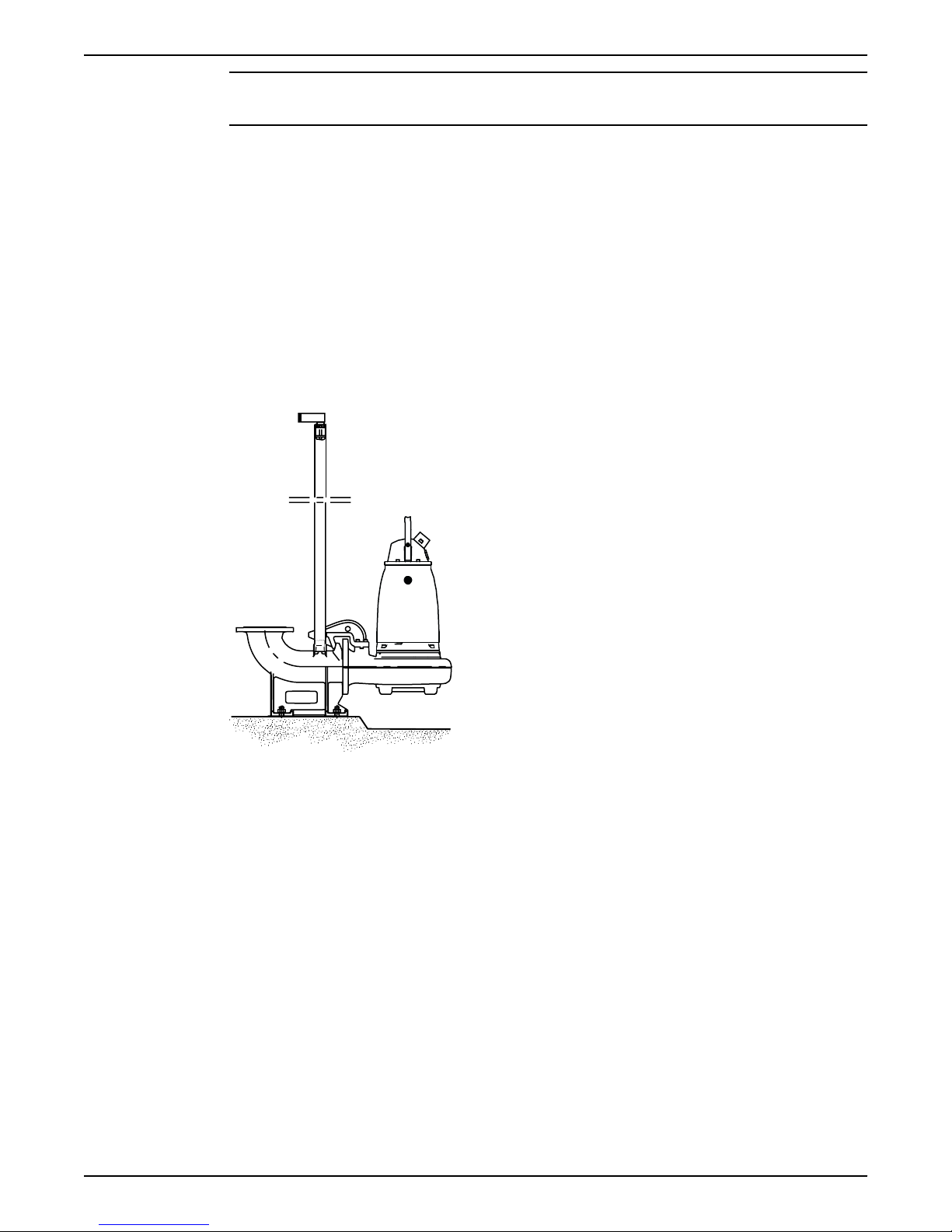

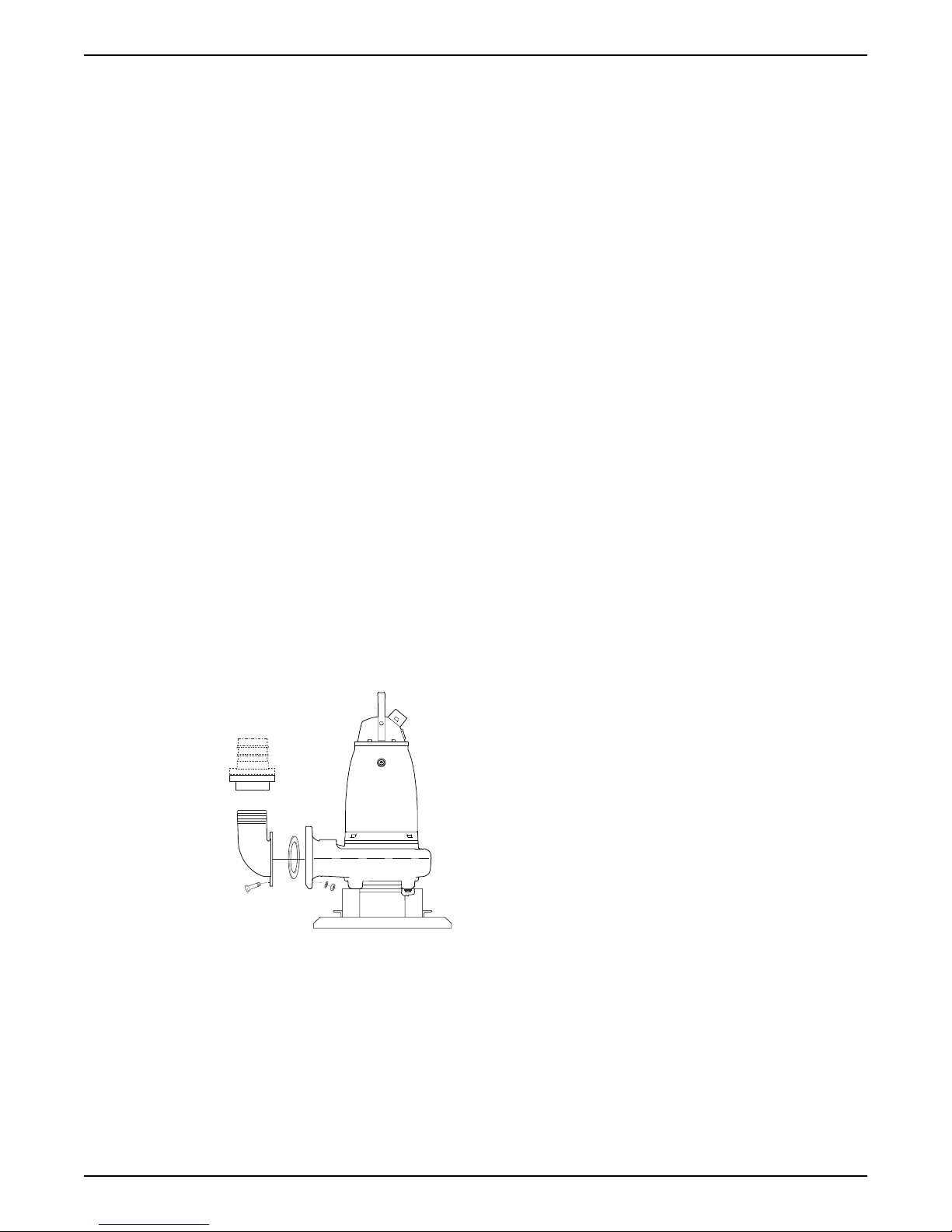

4.1.1 Install with P-installation

In the P-installation, the pump is installed on a stationary discharge connection, and

operates either completely or partially submerged in the pumped liquid. These

requirements and instructions only apply when the installation is made according to the

dimensional drawing.

Figure 2: P-installation

These items are required:

• Guide bars

• Guide bar bracket for attaching the guide equipment to the access frame or to the

upper part of the sump

• Cable holder for holding the cable

• Access frame (with covers) to which the upper guide bar bracket and cable holder can

be attached

• Discharge connection for connecting the pump to the discharge line

The discharge connection has a flange which fits the pump housing flange and a

bracket for attaching the guide equipment.

• Fasteners for the discharge connection

• Anchor bolts

1. Install the access frame:

a) Place the access frame in position and align it horizontally.

b) Grout the frame in place.

2. Grout the anchor bolts in place.

18 Flygt 3085 Installation, Operation, and Maintenance Manual

WS006270A

4 Installation

Be careful when you align and position the discharge connection in relation to the

access frame.

3. Place the discharge connection in position, and tighten the nuts.

4. Install the guide bars:

a) Secure the guide bars in the bracket.

b) Check that the guide bars are placed vertically. Use a level or a plumb line.

5. Connect the discharge pipe to the discharge connection.

6. Lower the pump along the guide bars.

When it reaches the bottom position, the pump automatically connects to the

discharge connection.

7. Secure the motor cable:

a) Fasten the permanent lifting device to the pump and to the access frame. For

example, you can use a stainless-steel lifting chain with shackles.

b) Fasten the cable to the cable holder.

Make sure that the cable cannot be sucked into the pump inlet or that it is neither

sharply bent, or pinched. Support straps are required for deep installations.

c) Connect the motor cable and the starter and monitoring equipment according to

the separate instructions.

Make sure that the impeller rotation is correct. For more information, see Check the

impeller rotation (page 36).

Clean all debris from the sump before starting the pump.

4.1.2 Install with S-installation

In the S-installation, the pump is transportable and intended to operate either completely

or partially submerged in the pumped liquid. The pump is equipped with a connection for

hose or pipe and stands on a base stand.

These requirements and instructions only apply when the installation is made according

to the dimensional drawing. For information about the different installation types, see

Parts List.

Figure 3: S-installation

1. Run the cable so that it has no sharp bends. Make sure that it is not pinched, and

cannot be sucked into the pump inlet.

2. Connect the discharge line.

3. Lower the pump into the sump.

4. Place the pump on the base and make sure it cannot fall over or sink.

Flygt 3085 Installation, Operation, and Maintenance Manual 19

WS008385A

WS006273A

1

WS008403B

2

3

1

2

3

4

4 Installation

Alternatively, the pump can be suspended with a lifting chain just above the sump

bottom. Make sure that the pump cannot rotate at start-up or during operation.

5. Connect the motor cable and the starter and monitoring equipment according to the

separate instructions.

Make sure that the impeller rotation is correct. For more information, see Check the

impeller rotation (page 36).

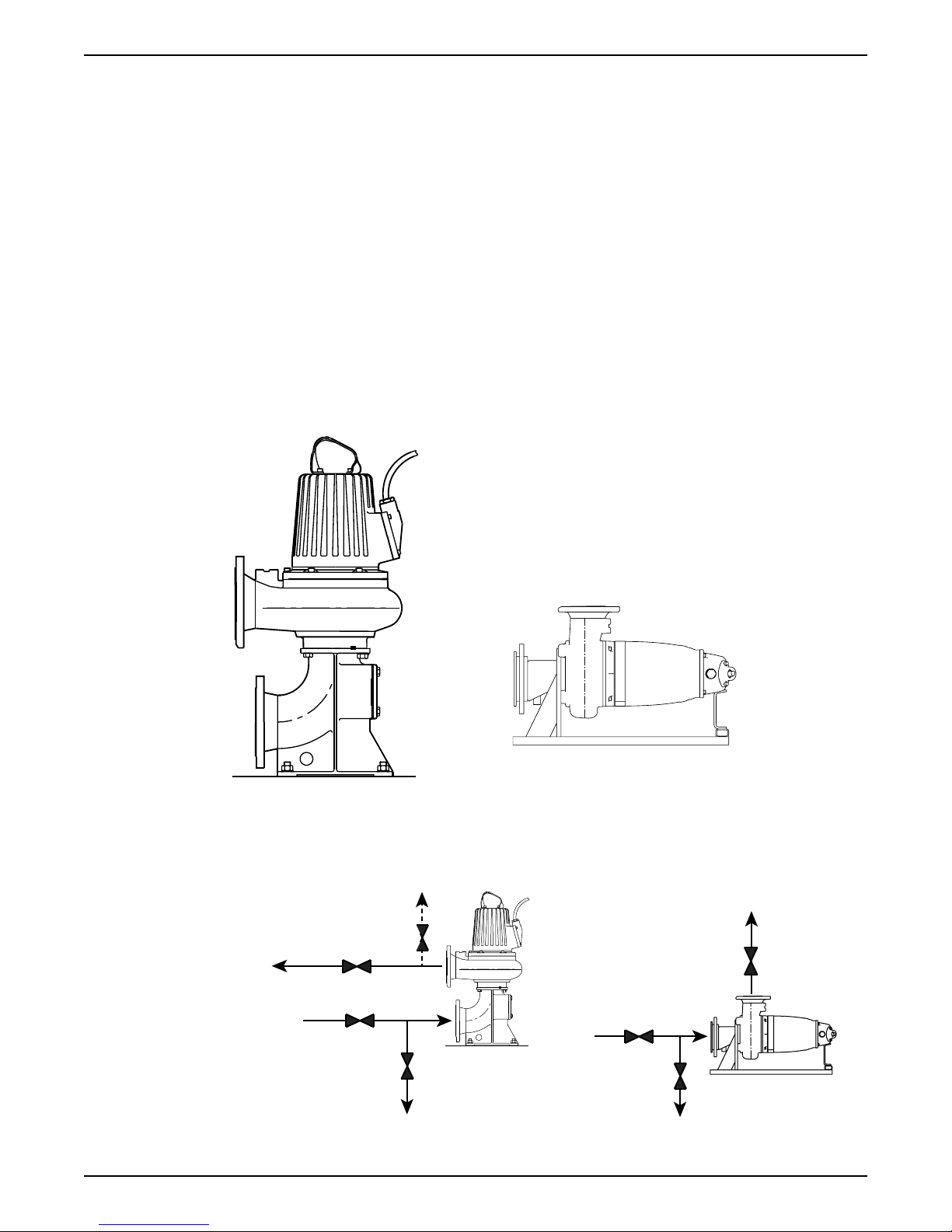

4.1.3 Install with T/Z-installation

This installation is not applicable for these versions:

• .172

• .891

In the T-installation, the pump is installed in a vertical position in a dry well next to the wet

sump. These requirements and instructions only apply when the installation is made

according to the dimensional drawing.

In the Z-installation, the pump is installed in a horizontal position on a support stand in a

dry well next to the wet sump. The following requirements and instructions are for Zinstallations that comply to the dimensional drawing.

Figure 4: T-installation

These items are required:

• Anchor bolts for anchoring the pump to a base.

• Shut-off valves that allow you to remove the pump from service

20 Flygt 3085 Installation, Operation, and Maintenance Manual

Figure 5: Z-installation

Loading...

Loading...