Page 1

Revision 1.0, 18/7/2017

For firmware version 2.14

Flybox

®

Operating manual

Page 2

Page intentionally left blank

Page 3

SECTIONS

INSTRUMENT CONFIGURATION

OPERATING INSTRUCTIONS

TECHNICAL SPECIFICATIONS

Page 4

Flybox

VIGILUS - Operating manual

®

Rev. 1.0

Thank you for purchasing a Flybox® product. We hope

it fully satisfy you and makes your flights pleasant and

secure.

Developing Vigilus, our intent was to create a compact

but complete Engine Information System , easy to install

and use.

SYMBOLS USED IN THE MANUAL

NOTE: Used to highlight important informations.

CAUTION: Used to warn the user and indicate a potentially

hazardous situation or improper use of the product.

WARNING: Used to indicate a dangerous situation that can

cause personal injury or death if the instruction is

disregarded.

Page 5

VIGILUS - Operating manual

Flybox

Rev. 1.0

®

Important notices & warnings

NOTE: Keep this manual in the aircraft.

This document must accompany the instrument in the event

of change of ownership.

NOTE: This device is intended for installation onto non type

certified aircraft only, because it has no aviation certifications.

Refer to your local aviation authorities to check if this device

may be installed in your aircraft.

CAUTION: Read entirely this manual before installing the

instrument in your aircraft, and follow the installation and

operating instructions described here.

CAUTION: The pilot must understand the operation of this

instrument prior to flight, and must not allow anyone to use

it without knowing the operation. Don't use this instrument

in flight until you are sure of the correct operating of the same.

CAUTION: When the installation is finished you must do a

test, prior to flight, switching on all the possible source of

electric noise and checking the properly operation of this

instrument.

CAUTION: The software of this instrument can be subject to

change, update, addition or removal of functions, so also the

operating mode of the instrument can be subject to change.

Always refer to the installation and operating manual updated

with the software version used in your instrument. To

obtain updated manuals, please visit www.flyboxavionics.it.

Page 6

Flybox

VIGILUS - Operating manual

®

Rev. 1.0

Important notices & warnings

WARNING: Responsibility for installation lies entirely with the

installer. Responsibility for operations lies entirely with the

operator. Responsibility for any calibration, settings or any

other customization lies with the person performing these

operations.

WARNING: Do not solely rely on this instrument to determine

the primary engine informations. Always compare the

informations provided with other primary instruments to

recognize eventual malfunctions.

IMPORTANT: If you do not agree with the notices above

do not install this instrument in your aircraft, but return

the product for a refund.

Microel s.r.l. reserves the right to change or improve its

products. Information in this document is subject to changes

without notice.

WARNING: For safety reasons, the Vigilus operational

procedures must be learned on the ground.

WARNING: It’s up to the installer to check the correctness

of the settins for its engine, even using one of the Vigilus

preset, because engine manufacturers may change

parameters without notice. The engine preset of the Vigilus

are a help but needs to be checked by the installer.

Page 7

VIGILUS - Operating manual

Flybox

Rev. 1.0

®

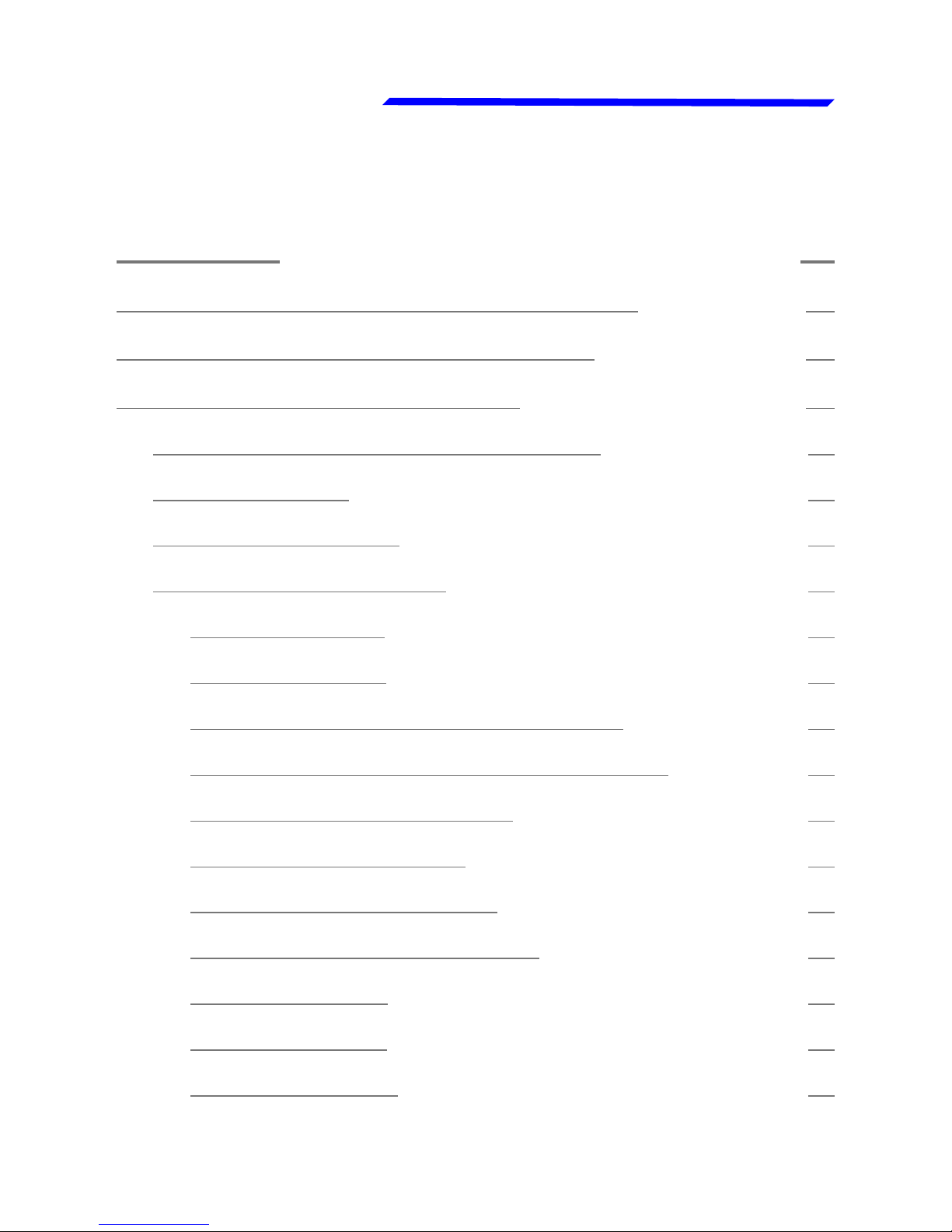

Contents

SECTION 1............................................................11

1.1 PRIMARY ACTIONS AFTER INSTALLATION....................11

1.2 PANEL INDICATORS AND COMMANDS.........................13

1.3 INSTRUMENT CONFIGURATION..................................14

1.3.1 ENTERING & BROWSING THE MENUs...........................14

1.3.2 MAIN MENU:.............................................................16

1.3.3 SETTINGS MENU:......................................................16

1.3.4 INSTRUMENTS MENU:................................................16

EGT SETUP MENU:........................................................17

CHT SETUP MENU:........................................................19

OAT (OUTSIDE AIR TEMP.) SETUP MENU:........................22

CAT (CARBURETOR AIR TEMP.) SETUP MENU:..................23

FUEL PRESSURE SETUP MENU:.......................................24

FUEL LEVEL SETUP MENU:.............................................26

OIL PRESSURE SETUP MENU:.........................................28

OIL TEMPERATURE SETUP MENU:...................................30

RPM SETUP MENU:........................................................32

MAP SETUP MENU:........................................................33

VOLT SETUP MENU:......................................................34

Page 8

Flybox

VIGILUS - Operating manual

®

Rev. 1.0

AMP SETUP MENU:........................................................36

GB T (GEARBOX TEMPERATURE) SETUP MENU:................37

ROTOR SETUP MENU:....................................................39

1.3.5 GLOBAL SETTINGS MENU:..........................................41

AIRCRAFT SETUP..........................................................41

GPS SETUP..................................................................43

SERIAL PORTS SETUP...................................................43

AUDIO SETTINGS.........................................................44

UNITS SETUP...............................................................45

PAGES SETUP...............................................................46

1.3.6 FUEL COMPUTER MENU:.............................................47

1.3.7 ABOUT MENU:...........................................................49

1.3.8 FIRMWARE UPGRADE MENU:.......................................50

1.3.9 BACKUP AND RESTORE MENU:....................................51

1.4 FUEL FLOW TRANSDUCER CALIBRATION.....................52

1.5 FUEL LEVEL SENSORS CALIBRATION...........................54

1.5.1 FUEL LEVEL SENSORS CHECKINGS..............................58

1.6 FUEL COMPUTER ACTIVATION....................................59

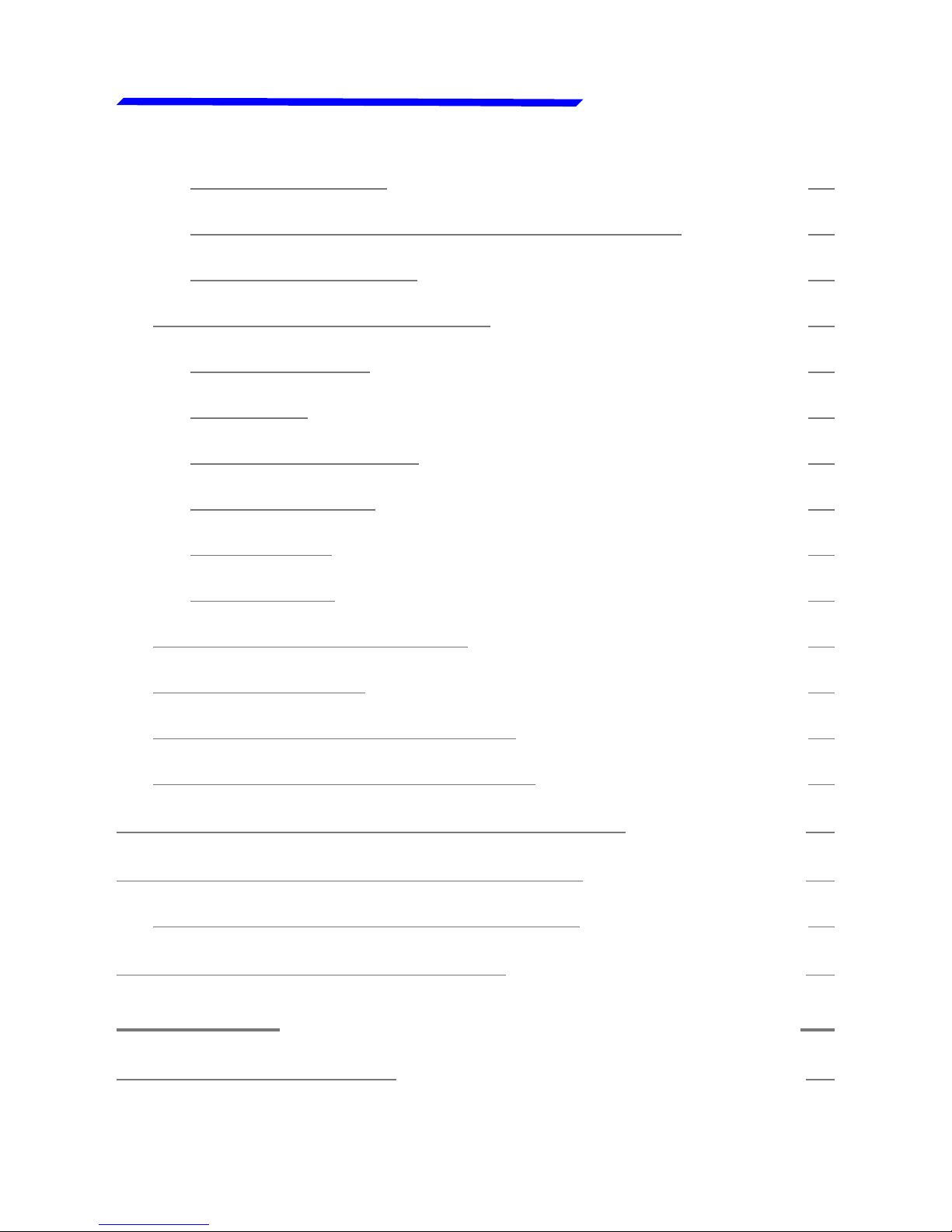

SECTION 2............................................................60

2.1 USING THE VIGILUS.................................................60

Page 9

VIGILUS - Operating manual

Flybox

Rev. 1.0

®

2.2 PAGE1: Main engine data page...................................61

2.2.1 TEMPERATURE PAGE..................................................68

2.3 PAGE2: Chronometer page........................................69

2.4 PAGE3: Fuel management page..................................71

2.5 PAGE4: Hourmeter page............................................75

SECTION 3............................................................77

3.1 ALARMS..................................................................77

3.2 SENSOR ALARMS......................................................78

SECTION 4............................................................79

4.1 DATALOGGER..........................................................79

SECTION 5............................................................84

5.1 VIGILUS DEFAULT CONFIGURATION TABLE..................84

TECHNICAL SPECIFICATIONS..........................................86

WARRANTY:..................................................................88

Page 10

Page intentionally left blank

Page 11

VIGILUS - Operating manual

Flybox

11

Rev. 1.0

®

SECTION 1

1.1 PRIMARY ACTIONS AFTER INSTALLATION

WARNING: Do not fly until you have performed at least

the actions indicated below:

1 - Select the engine type: the first parameter to setup is the

engine selection, because it reset all the parameters to the

default value. The engine selection can be made by entering in

the Main menu → Settings → Global Settings → Aircraft as

explained in chap.1.3.5.

2 - Tank level sensors: (if connected). It's indispensable to

perform the calibration for all the tank level sensors connected

to the Vigilus. Without performing calibration and settings no

indication will be furnished.

It is responsibility of the user to check during the first flights

and over time the goodness of the calibration and therefore

the instrument indications.

The verification can be done in any moment, for example b y

simply checking the quantity put to fill the tank: if you k n o w

that the tank filled contain 40 liters and the Vigilus i n d i c a t e

as remaining quantity 10.0 liter, you know that to fill the tank

you must put approximately 30 liters. Of course keeping in

mind that in ground the indications will be different that in

flight because of the flight's attitude. This problem is present

also in the traditional analog gauge indicators, but is more

difficult to detect because of the non-numeric indication.

Another verification is, in case of low remaining quantity (i.e.

4~5 liters), drain and measure it.

Page 12

Flybox

VIGILUS - Operating manual

12

®

Rev. 1.0

Primary actions after installation

3 - Fuel computer: (if installed). If it's installed the fuel flow

transducer, BEFORE rely on informations provided by the fuel

computer section you must:

- Verify that the K-factor set in the Vigilus is pertinent to the

installed fuel flow transducer (for the Flybox® TFTHP is 416400).

- Execute the fuel flow transducer calibration as explained in

chapter 1.4. Without calibration the fuel computer

informations may be wrong, even if the nominal K-factor is

correct for the fuel flow transducer used.

After calibration, the K-factor should have been calculated

automatically and at best for every single installation. You must

still check for some time if the remaining quantity indicated are

reliable compared to the refuelling performed. For example, if

the instrument indicate a remaining quantity of 35 liters and you

know that the tanks capacity is 80 liters, filling the tanks should

require approximately 45 liters; in case of much difference redo

the calibration.

Consider also that, during use, little errors accumulate and if

you never fill the tanks you never “reset” all these errors.

Page 13

VIGILUS - Operating manual

Flybox

13

Rev. 1.0

®

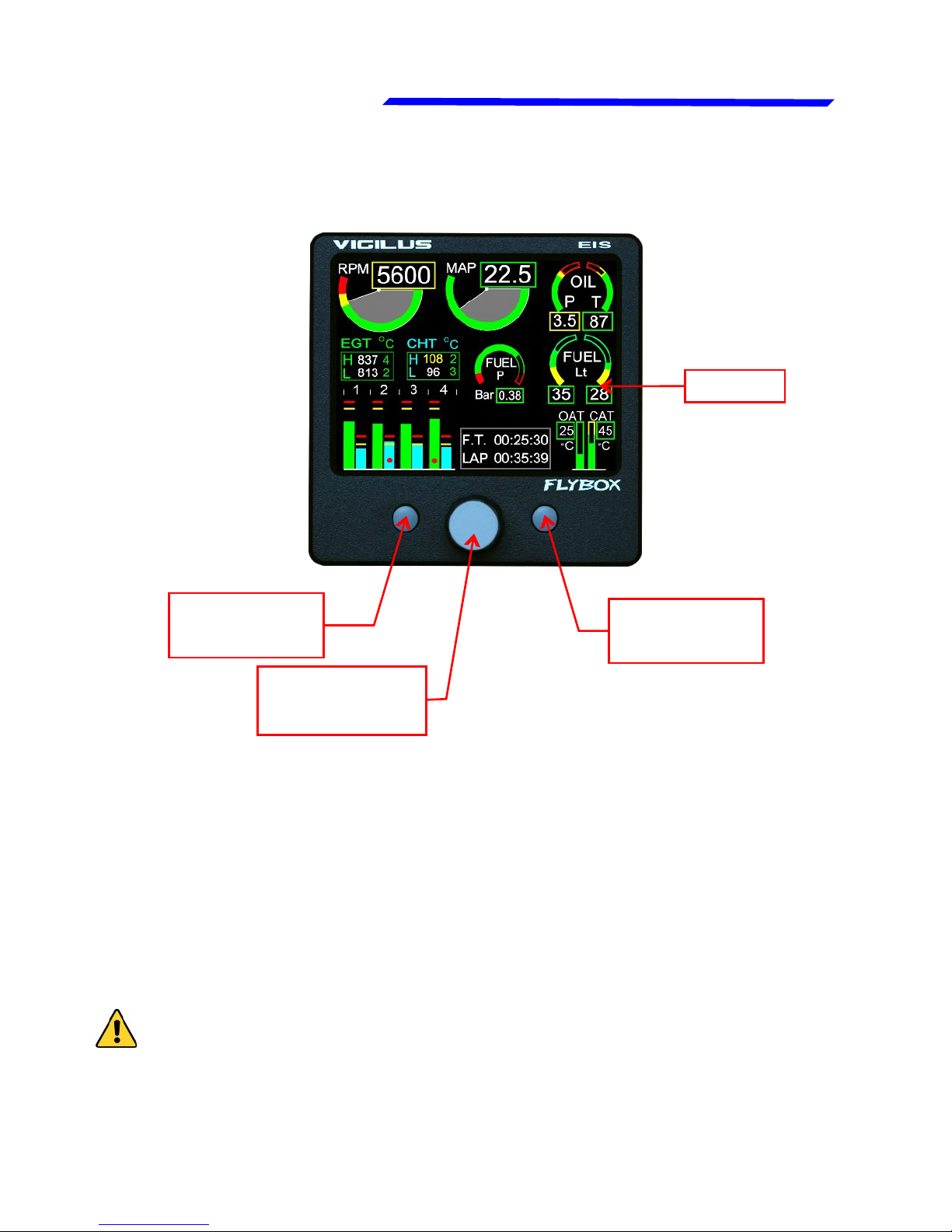

F1

pushbutton

Display

Knob with

pushbutton

1.2 PANEL INDICATORS AND COMMANDS

The knob with pushbutton can be rotated (for example to

increment or decrement a value) or pressed like a pushbutton

(for example to enter in a submenu).

Inside the menus it’s always indicated the meaning of the

pushbuttons (for example: exit, back, etc…)

● Display cleaning:

To clean the display use the supplied smooth cloth, slightly

moistened with cleaner. Use a cleaner that is specified as safe

for anti-reflective coatings.

CAUTION: Avoid any chemical cleaners or solvents that can

damage the display anti-reflective coating or plastic

components. Do not use cleaners containing ammonia.Do not

spray water or cleaner directly onto the display.

F2

pushbutton

Page 14

Flybox

VIGILUS - Operating manual

14

®

Rev. 1.0

1.3 INSTRUMENT CONFIGURATION

Before using the Vigilus you need to configure it; read

completely this chapter and follow step by step the

sections to completely configure all the sensors, alarms

and preferences available.

1.3.1 ENTERING & BROWSING THE MENUs

Press the knob for 1 second to enter in the main menu:

● Press the “EXIT”

pushbutton to exit the

menu.

● Rotate the knob to select

an item of the menu.

● Click the knob to enter in

the selected item.

For example, to change the display brightness:

● Rotate the knob to select

the “Brightness” item.

● Click the knob and the item

become highlighted in

flashing red: it means that

you can edit this value by

rotating the knob.

● Click again the knob to

store the new value for the

brightness OR press the

“ESC” pushbutton to exit

without saving the

changes.

Page 15

VIGILUS - Operating manual

Flybox

15

Rev. 1.0

®

Entering & browsing the menus

Instrument configuration

Also when inside a parameters page, the editing

philosophy is the same, for example:

On this example, by rotating

the knob you select the

parameter that you want to

edit (the selected

parameter is highligted in

red).

If you don’t want to store the new value press “Esc”

pushbutton to cancel the editing or press “Exit” pushbutton

to exit the menu and return to the main pages.

If you click the knob the

highlight become flashing

red to indicate that you are

editing that parameter.

Rotate the knob to change

the value and press the

knob to store the new value

Page 16

Flybox

VIGILUS - Operating manual

16

®

Rev. 1.0

Instrument configuration

● Brightness: display brightness adjustment (1=min. brightness,

16=max. brightness). Default value=16.

● Data Logger: enter in the datalogger menu (see section 4).

● Settings: enter in the settings menu (see next chapter).

1.3.2 MAIN MENU:

1.3.3 SETTINGS MENU:

1.3.4 INSTRUMENTS MENU:

On this menu you can set all the parameters for each available

measurement. On the right window there is a preview of the

thresolds for the selected item; click the knob to enter in a item.

Page 17

VIGILUS - Operating manual

Flybox

17

Rev. 1.0

®

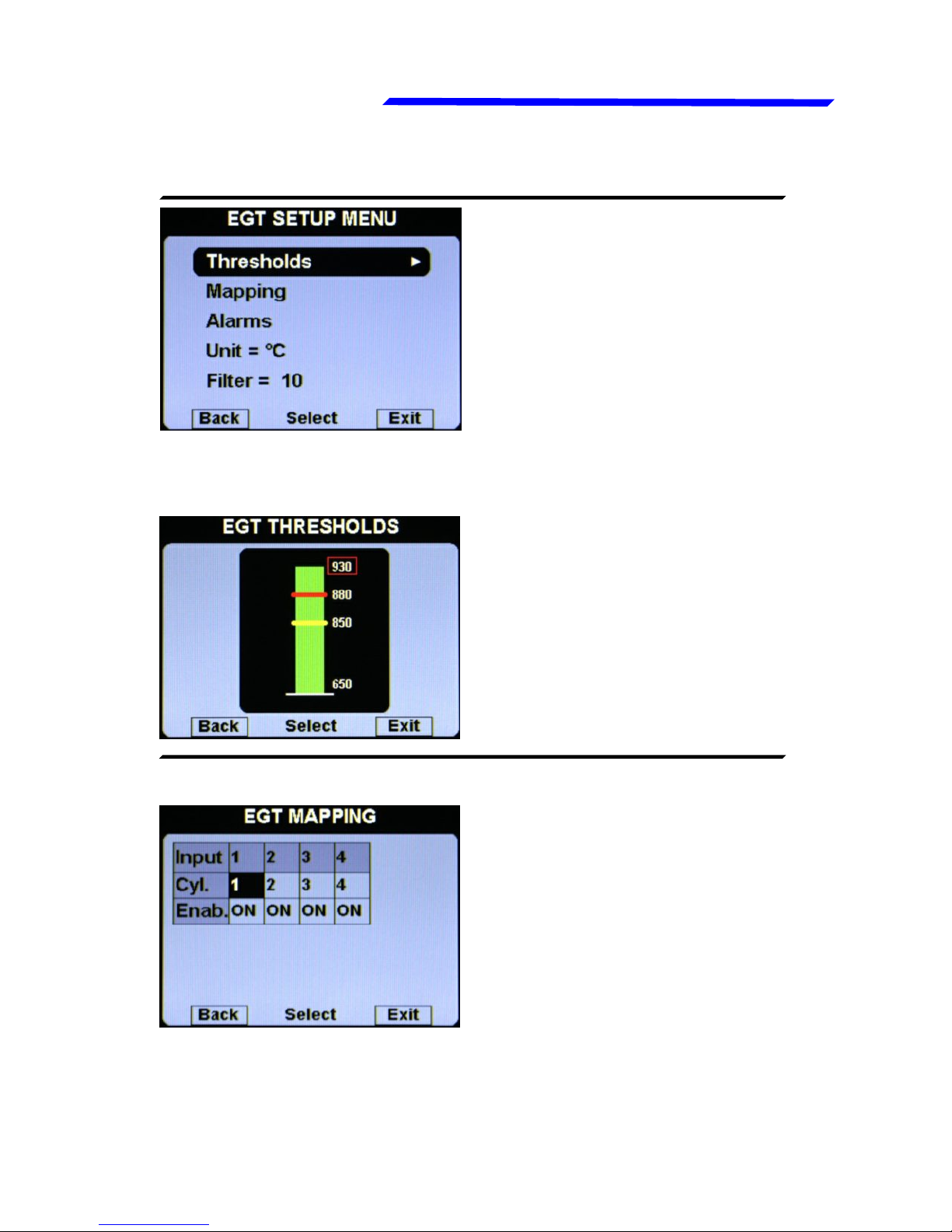

Egt setup menu

● Thresholds: set the

thresholds of the EGT bars:

min value (bottom of the bar),

yellow threshold, red

threshold and max value (top

of the bar).

● Mapping: although we

recommend to perform a

clean installation, with this

feature it’s possible to

reassign or disable the

different EGT inputs available

in the remote module: for

example you can assign the

input#1 of the remote module

EGT SETUP MENU:

● EGT THRESHOLDS SUBMENU:

● EGT MAPPING SUBMENU:

to the engine cylinder#3 and so on. You can also disable each

inputs, useful for example if a sensor fails and you don’t want

to display the indication for that sensor.

Instrument configuration

Page 18

Flybox

VIGILUS - Operating manual

18

®

Rev. 1.0

Egt setup menu

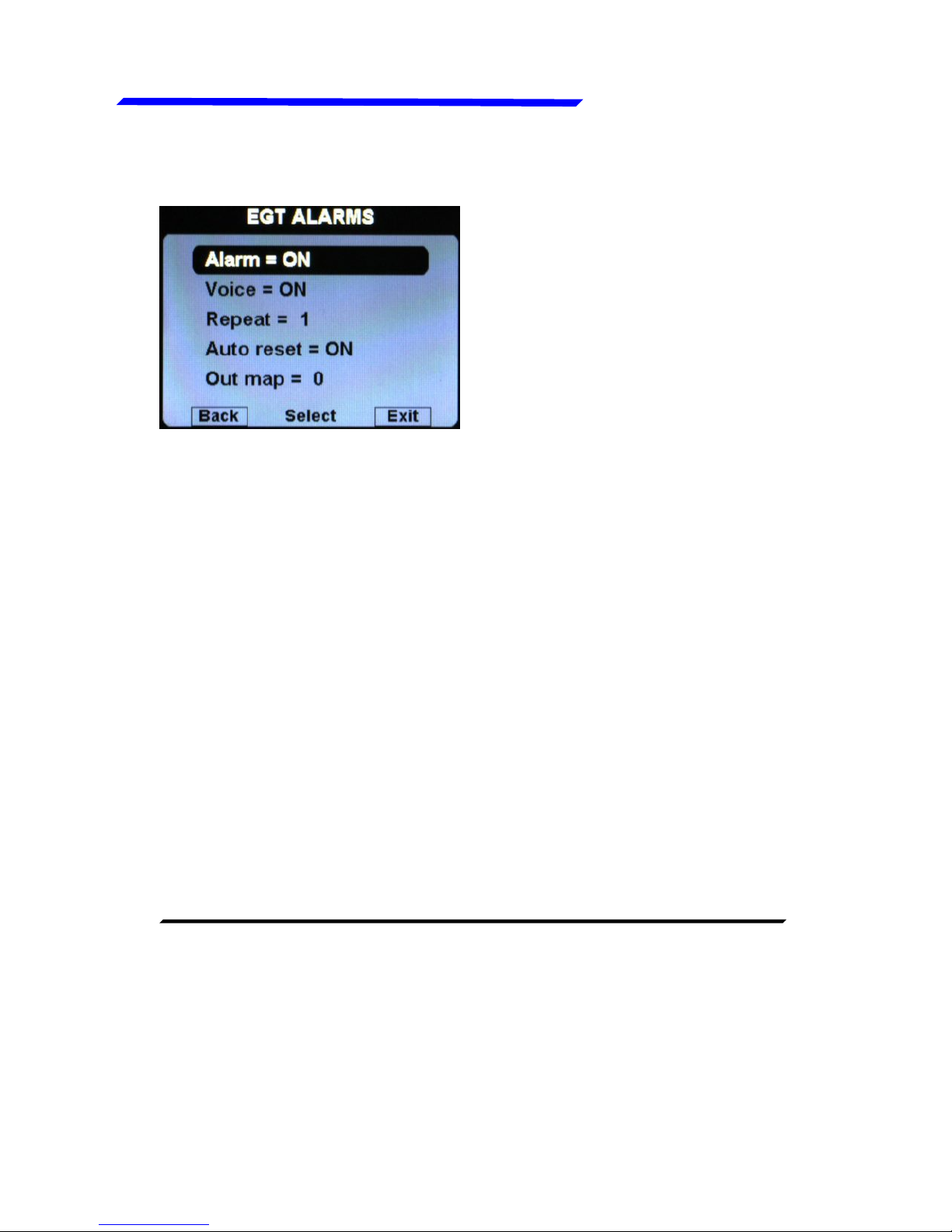

● Alarm = ON/OFF:

enable/disable the alarm

(alert indication on display)

that occurs when a EGT

measurement exceeds the

red threshold (default=ON).

● Voice = ON/OFF: enable/disable the audio alert notification on

EGT alarms (default=ON).

● Repeat: Set the number of times that the vocal alarm for the

EGT is repeated on the audio output (range:1~5, default=1).

● Auto reset = ON/OFF: if set to ON, if a alarm condition is

activated but the measurement that activated this alarm has

dropped below the alarm threshold, the Vigilus automatically

reset the alarm indication. If set to OFF, the user must manually

reset the alarm indication, even if the measurement that

activated this alarm has dropped below the alarm threshold

(default=ON).

● Out map: you can choose to enable one of the four outputs

available on the remote module when the alarm is activated,

useful for example to turn on an alarm light on the cockpit.

Set to zero to disable this function (default=0).

● Unit: °C / °F: Set the unit of measure for the EGT temperatures;

choose between °Celsius (°C) or °Fahrenheit (°F). Default=°C.

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=100).

● EGT ALARMS SUBMENU:

Instrument configuration

Page 19

VIGILUS - Operating manual

Flybox

19

Rev. 1.0

®

Cht setup menu

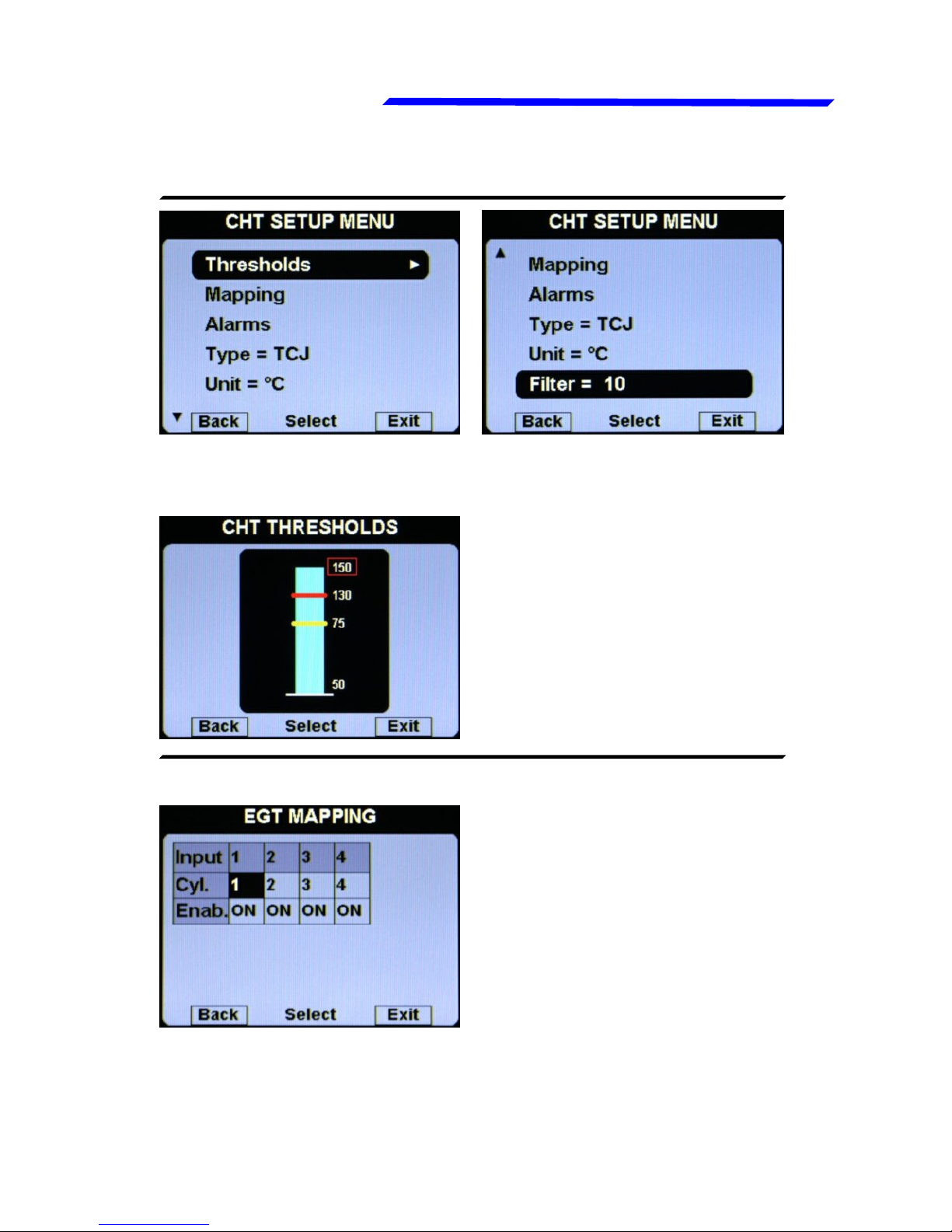

● Thresholds: set the

thresholds of the CHT bars:

min value (bottom of the bar),

yellow threshold, red

threshold and max value (top

of the bar).

● Mapping: although we

recommend to perform a

clean installation, with this

feature it’s possible to

reassign or disable the

different CHT inputs available

in the remote module: for

example you can assign the

input#1 of the remote module

● CHT THRESHOLDS SUBMENU:

● CHT MAPPING SUBMENU:

to the engine cylinder#3 and so on. You can also disable each

inputs, useful for example if a sensor fails and you don’t want

to display the indication for that sensor.

CHT SETUP MENU:

Instrument configuration

Page 20

Flybox

VIGILUS - Operating manual

20

®

Rev. 1.0

Cht setup menu

For example, for Rotax 912/914 engines the default situation

will be the following:

Since the Rotax engines are provided with two CHT sensors,

but the first is for the cylinder#2 and the second is for the

cylinder#3, this configuration make sure that the first input of

the remote module (where is connected the first sensor) is

referred to the cylinder#2, while the second input of the remote

module (where is connected the second sensor) is referred to

the cylinder#3; the third and fourth inputs are disabled (Enab.

= OFF).

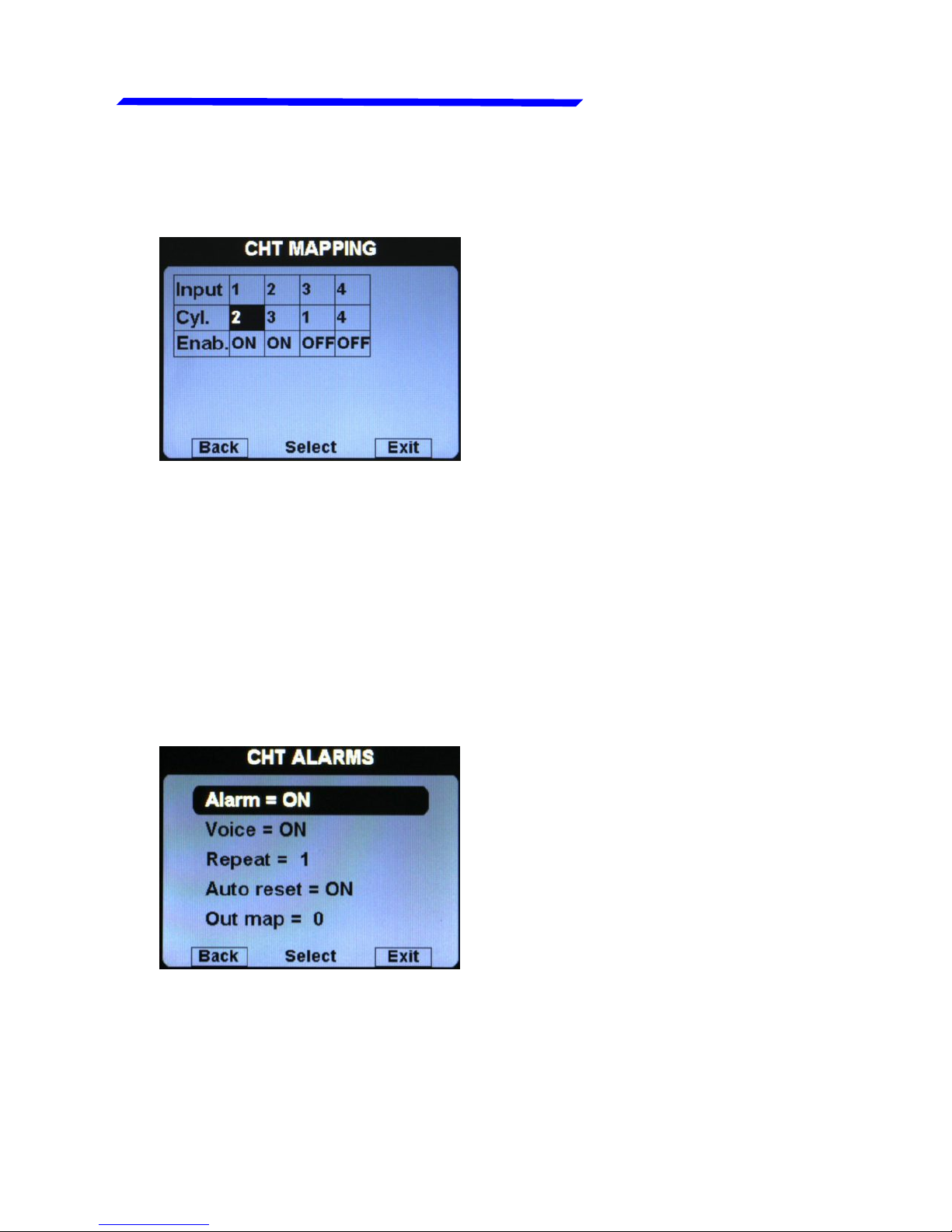

● Alarm = ON/OFF:

enable/disable the alarm

(alert indication on display)

that occurs when a CHT

measurement exceeds the

red threshold (default=ON).

● CHT ALARMS SUBMENU:

● Voice = ON/OFF: enable/disable the audio alert notification on

CHT alarms (default=ON).

● Repeat: Set the number of times that the vocal alarm for the

CHT is repeated on the audio output (range:1~5, default=1).

Instrument configuration

Page 21

VIGILUS - Operating manual

Flybox

21

Rev. 1.0

®

Cht setup menu

● Auto reset = ON/OFF: if set to ON, if a alarm condition is

activated but the measurement that activated this alarm has

dropped below the alarm threshold, the Vigilus automatically

reset the alarm indication. If set to OFF, the user must

manually reset the alarm indication, even if the measurement

that activated this alarm has dropped below the alarm threshold.

(default=ON)

● Out map: you can choose to enable one of the four outputs

available on the remote module when the alarm is activated,

useful for example to turn on an alarm light on the cockpit.

Set to zero to disable this function (default=0).

● Type: Select the type of CHT sensors installed:

TCJ: J-type thermocouples

P1K: PT1000 resistive sensors

ROX: standard ROTAX CHT sensors (default)

NOTE: It's not possible to mix different type of CHT

sensors (i.e. 2 Rotax + 2 thermocouples).

● Unit: °C / °F: Set the unit of measure for the CHT temperatures;

choose between °Celsius (°C) or °Fahrenheit (°F).Default=°C.

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=100).

Instrument configuration

Page 22

Flybox

VIGILUS - Operating manual

22

®

Rev. 1.0

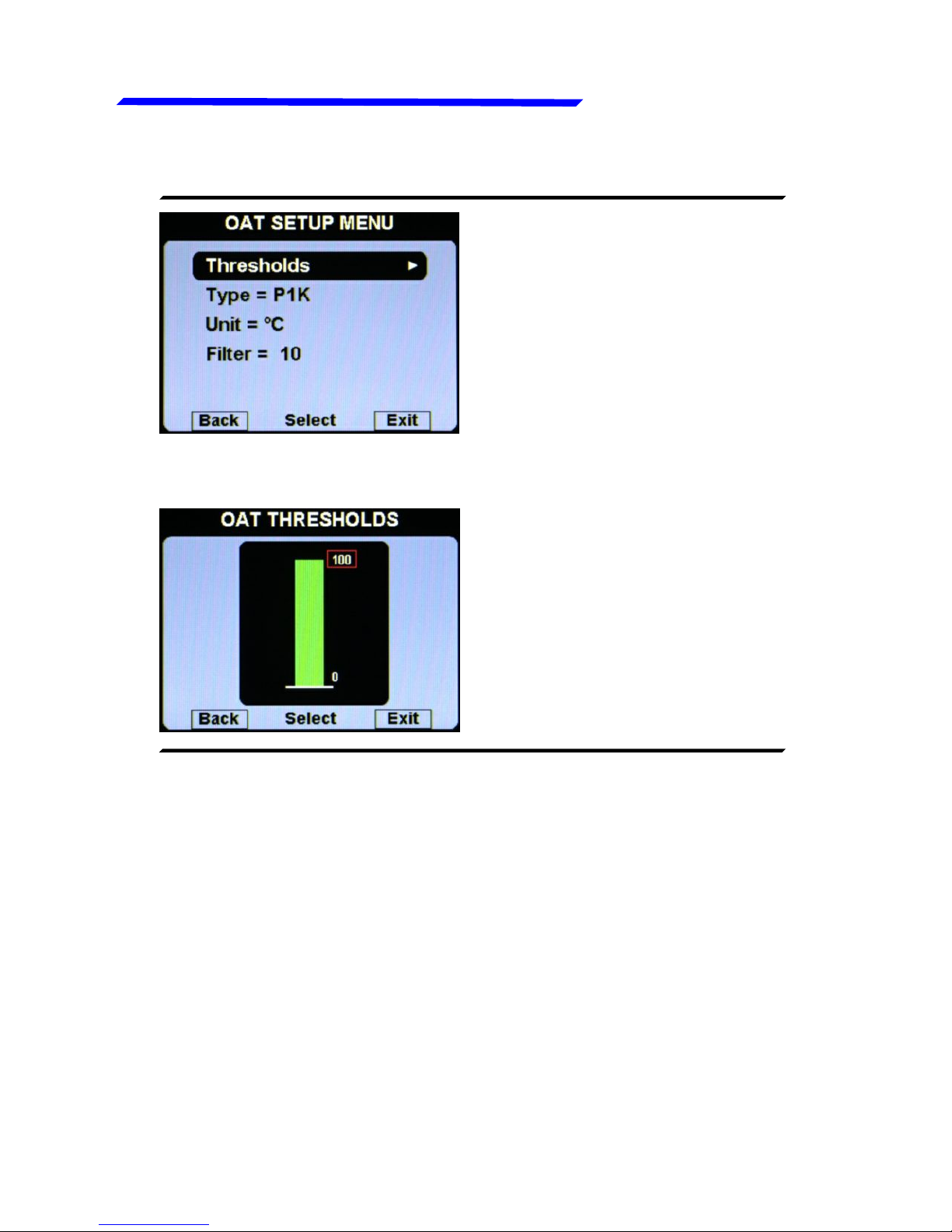

OAT setup menu

OAT (OUTSIDE AIR TEMP.) SETUP MENU:

● Thresholds: set the min

value (bottom of the bar) and

the max value (top of the bar).

● OAT THRESHOLDS SUBMENU:

● Type: Select the type of OAT sensor installed:

P1K: PT1000 resistive sensors (default).

NO: No sensor installed (disable the indication).

● Unit: °C / °F: Set the unit of measure for the OAT temperature;

choose between °Celsius (°C) or °Fahrenheit (°F).Default=°C.

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more fast

and unfiltered (but subject to fluctuations), an high value means

that the readings will be more slow and stable (range: 0~999,

default=100).

Instrument configuration

Page 23

VIGILUS - Operating manual

Flybox

23

Rev. 1.0

®

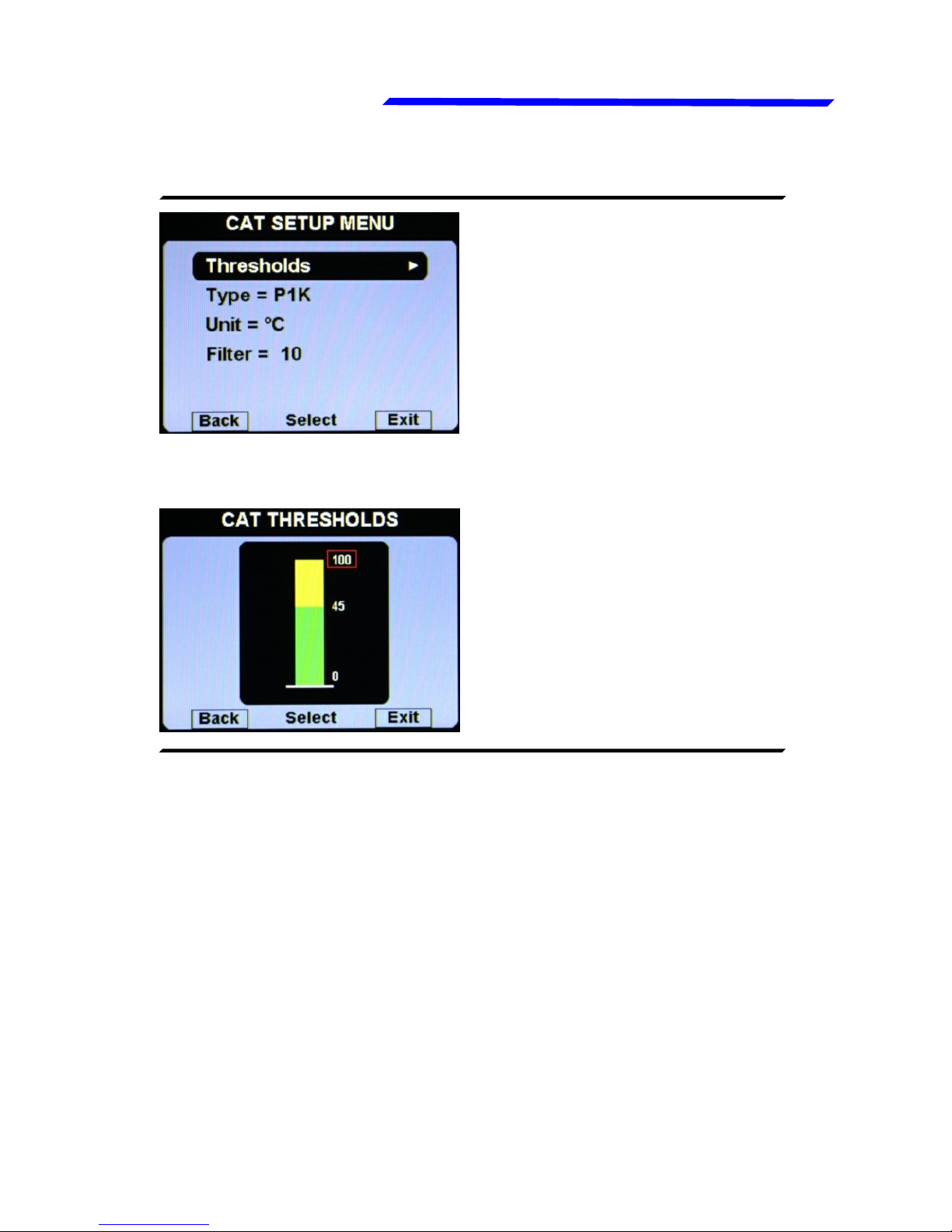

CAT setup menu

CAT (CARBURETOR AIR TEMP.) SETUP MENU:

● Thresholds: set the min

value (bottom of the bar), the

yellow threshold and the max

value (top of the bar).

● CAT THRESHOLDS SUBMENU:

● Type: Select the type of CAT sensor installed:

P1K: PT1000 resistive sensors (default).

NO: No sensor installed (disable the indication).

● Unit: °C / °F: Set the unit of measure for the CAT temperature;

choose between °Celsius (°C) or °Fahrenheit (°F).Default=°C.

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more fast

and unfiltered (but subject to fluctuations), an high value means

that the readings will be more slow and stable (range: 0~999,

default=100).

Instrument configuration

Page 24

Flybox

VIGILUS - Operating manual

24

®

Rev. 1.0

Fuel press. setup menu

FUEL PRESSURE SETUP MENU:

● Thresholds: set the min

value (bottom of the bar), the

low red threshold, the high

red threshold and the max

value (top of the bar).

● FUEL P. THRESHOLDS SUBMENU:

● Alarm = ON/OFF:

enable/disable the alarm

(alert indication on display)

that occurs when the oil

pressure is outside of the

green zone (either high or

low). Default=ON.

● FUEL P. ALARMS SUBMENU:

● Voice = ON/OFF: enable/disable the audio alert notification on

fuel pressure alarms (default=ON).

Instrument configuration

Page 25

VIGILUS - Operating manual

Flybox

25

Rev. 1.0

®

Fuel press. setup menu

● Repeat: Set the number of times that the vocal alarm for the

fuel pressure is repeated on the audio output (range:1~5,

default=1).

● Auto reset = ON/OFF: if set to ON, if a alarm condition is

activated but the measurement has returned in the green zone,

the Vigilus automatically reset the alarm indication. If set to

OFF, the user must manually reset the alarm indication, even

if the measurement has returned in the green zone (default=ON).

● Out map: you can choose to enable one of the four outputs

available on the remote module when the alarm is activated,

useful for example to turn on an alarm light on the cockpit.

Set to zero to disable this function (default=0).

● Sensor = ON/OFF: Set to ON if you have installed the fuel

pressure sensor, set to OFF if you have not installed it (the

indication will be disabled).Default=ON.

● Unit = Bar / Psi: Set the unit of measure for the fuel pressure

indication.Default=Bar.

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=100).

Instrument configuration

Page 26

Flybox

VIGILUS - Operating manual

26

®

Rev. 1.0

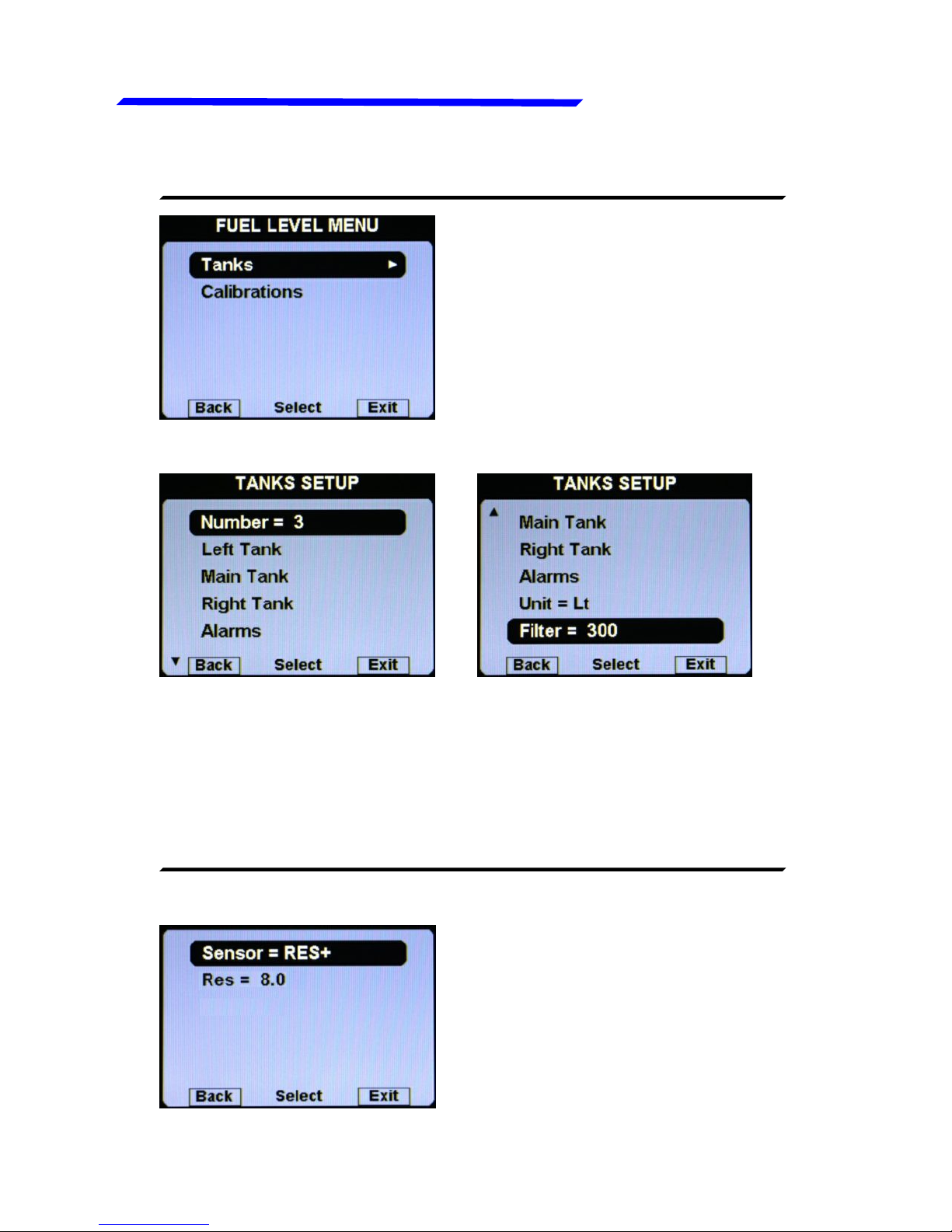

Fuel level setup menu

FUEL LEVEL SETUP MENU:

● TANKS SUBMENU:

● Number = 1/2/3: Set the number of fuel level sensors installed

and connected to the remote module.

If you have not connected any fuel level sensors, set to zero.

If you set one tank, it will be named “Main tank”.

If you set two tanks, they will be named “Left tank” and “Right

tank”. Default=2.

● LEFT/MAIN/RIGHT TANK SUBMENU:

Instrument configuration

Page 27

VIGILUS - Operating manual

Flybox

27

Rev. 1.0

®

Fuel level setup menu

● Sensor: Set the fuel level sensor type installed for the selected

tank:

“RES+” for resistive fuel sensors that increase resistance

as you add fuel (default).

“RES-” for resistive fuel sensors that decrease resistance

as you add fuel.

If you don't know what type of resistive sensors are

installed please see chapter 1.5.1 “Fuel level sensors

checkings”.

“CAP” for capacitive fuel sensors.

“DRES” for fuel sensors model “DRES”.

● Res: Set the amount of fuel below which is activated the alarm

of low fuel level for the selected tank (range:1~40 l, default=8l).

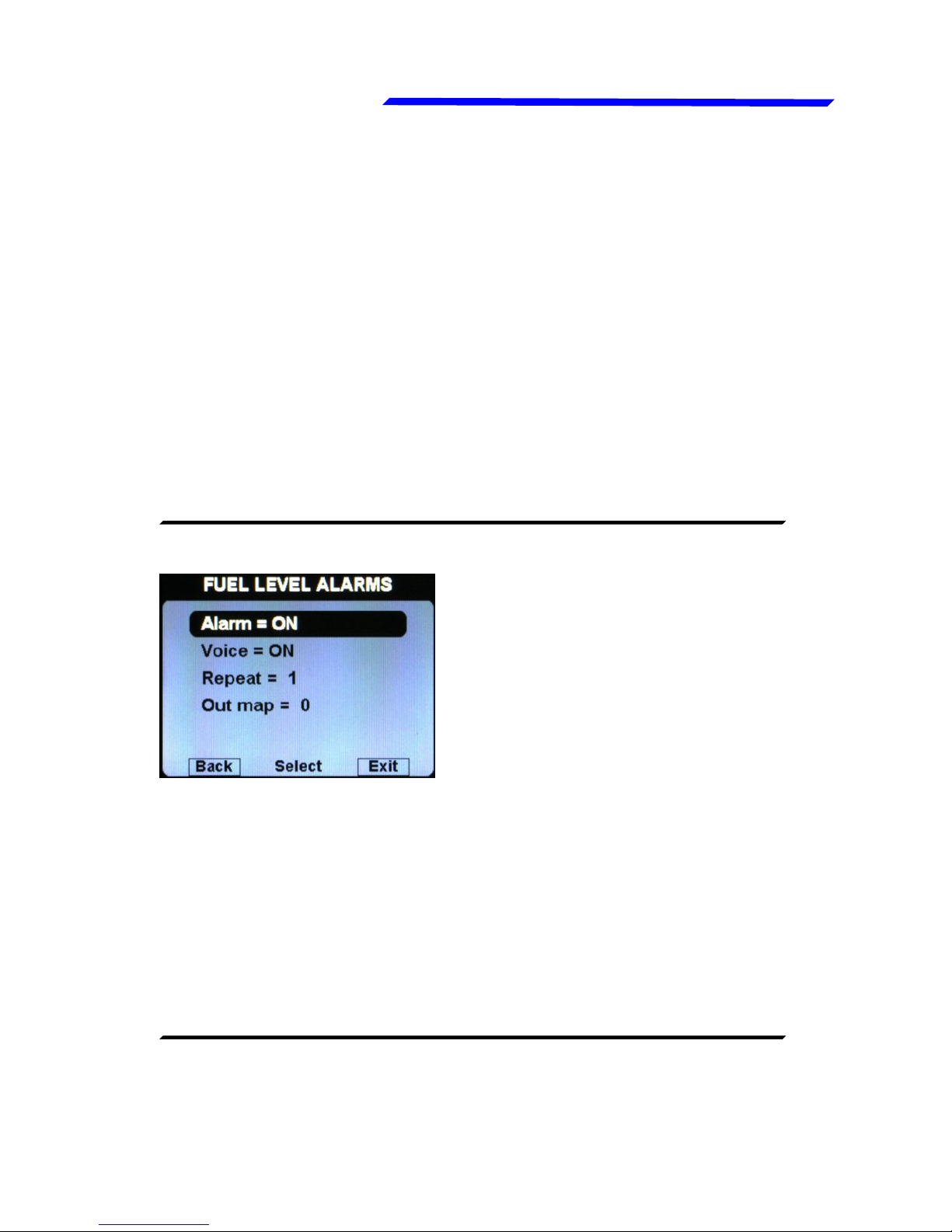

● FUEL LEVEL ALARMS SUBMENU:

Alarm = ON/OFF: enable/disable

the alarm (alert indication on

display) for the low fuel on any of

the available tanks (default=ON).

● Voice = ON/OFF: enable/disable the audio alert notification on

low fuel alarms (default=ON).

● Repeat: Set the number of times that the vocal alarm for the

fuel levels is repeated on the audio output (range:1~5,

default=1).

● Out map: you can choose to enable one of the four outputs

available on the remote module when the alarm is activated,

useful for example to turn on an alarm light on the cockpit.

Set to zero to disable this function (default=0).

● CALIBRATIONS SUBMENU:

Calibration of the fuel tanks (see chapter 1.5 "Fuel level sensors

calibration").

Instrument configuration

Page 28

Flybox

VIGILUS - Operating manual

28

®

Rev. 1.0

Oil press. setup menu

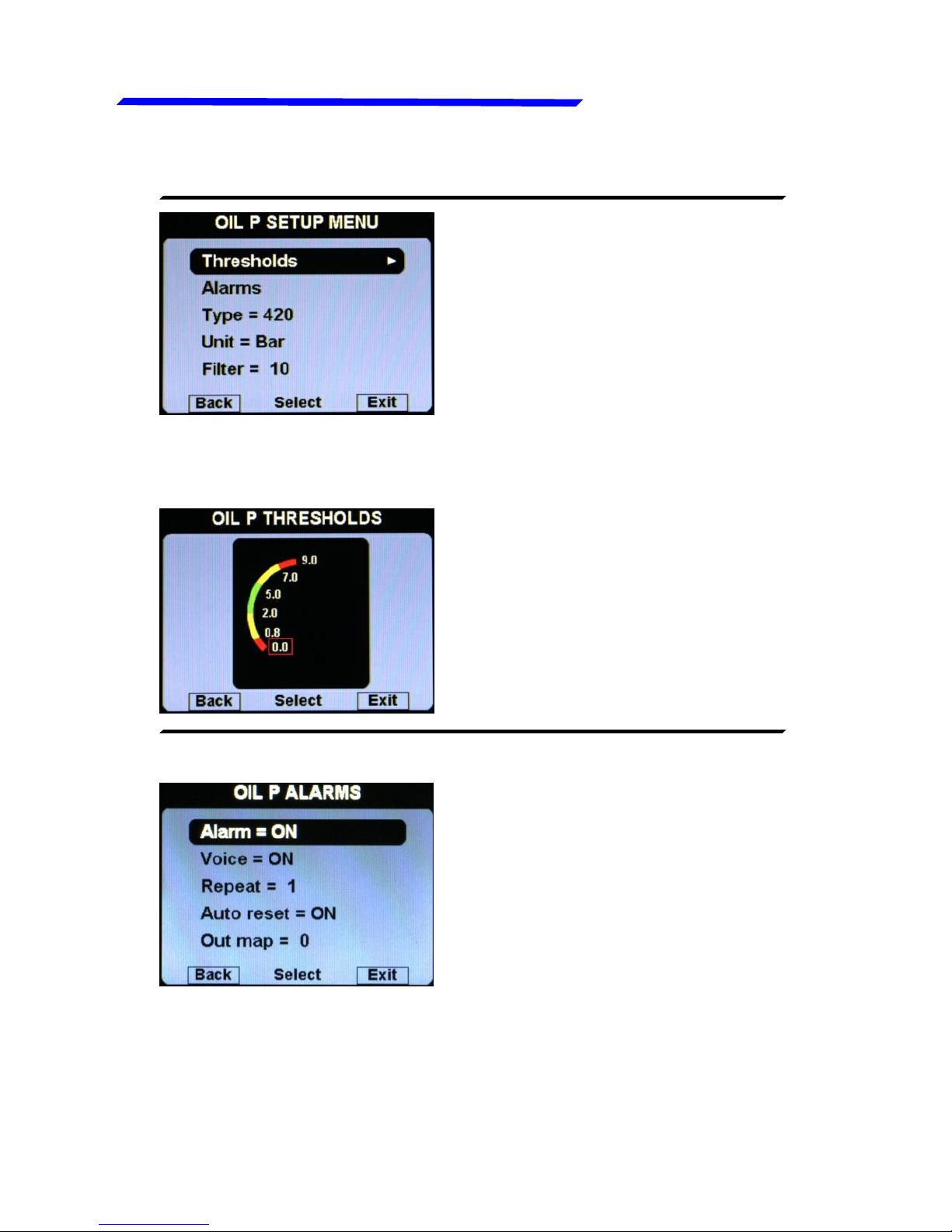

OIL PRESSURE SETUP MENU:

● Thresholds: set the min

value (bottom of the bar), the

low red threshold, the low

yellow threshold, the high

yellow threshold, the high red

threshold and the max value

(top of the bar).

● OIL P. THRESHOLDS SUBMENU:

● Alarm = ON/OFF:

enable/disable the alarm

(alert indication on display)

that occurs when the oil

pressure is too low (below the

low yellow threshold) or too

high (above the high red

threshold). Default=ON,

● OIL P. ALARMS SUBMENU:

● Voice = ON/OFF: enable/disable the audio alert notification on

oil pressure alarms (default=ON).

● Repeat: Set the number of times that the vocal alarm for the

oil press. is repeated on the audio output (range:1~5, default=1).

Instrument configuration

Page 29

VIGILUS - Operating manual

Flybox

29

Rev. 1.0

®

Oil press. setup menu

● Auto reset = ON/OFF: if set to ON, if a alarm condition is

activated but the measurement has returned in the safe zone,

the Vigilus automatically reset the alarm indication. If set to

OFF, the user must manually reset the alarm indication, even

if the measurement has returned in the safe zone (default=ON).

● Out map: you can choose to enable one of the four outputs

available on the remote module when the alarm is activated,

useful for example to turn on an alarm light on the cockpit.

Set to zero to disable this function (default=0).

● Type: set the type of oil pressure sensor installed:

NO: not installed (disable the indication).

RES: ROTAX Resistive (engine before 2008/05).

420: ROTAX 956413 or Flybox® 602000 (default).

JAB: standard JABIRU sensor.

● Unit = Bar / Psi: Set the unit of measure for the oil pressure

indication (default=bar).

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=100).

Instrument configuration

Page 30

Flybox

VIGILUS - Operating manual

30

®

Rev. 1.0

Oil temp. setup menu

OIL TEMPERATURE SETUP MENU:

● Thresholds: set the min

value (bottom of the bar), the

low yellow threshold, the high

yellow threshold, the high red

threshold and the max value

(top of the bar).

● OIL T. THRESHOLDS SUBMENU:

● Alarm = ON/OFF:

enable/disable the alarm

(alert indication on display)

that occurs when the oil

temp. is too low (below the

low yellow threshold, only in

flight) or too high (above the

high red threshold).

Default=ON.

● OIL T. ALARMS SUBMENU:

● Voice = ON/OFF: enable/disable the audio alert notification on

oil temp. alarms (default=ON).

Instrument configuration

Page 31

VIGILUS - Operating manual

Flybox

31

Rev. 1.0

®

Oil temp. setup menu

● Repeat: Set the number of times that the vocal alarm for the

oil temp. is repeated on the audio output (range:1~5, default=1).

● Auto reset = ON/OFF: if set to ON, if a alarm condition is

activated but the measurement has returned in the safe zone,

the Vigilus automatically reset the alarm indication. If set to

OFF, the user must manually reset the alarm indication, even

if the measurement has returned in the safe zone (default=ON).

● Out map: you can choose to enable one of the four outputs

available on the remote module when the alarm is activated,

useful for example to turn on an alarm light on the cockpit.

Set to zero to disable this function (default=0).

● Type: set the type of oil temperature sensor installed:

NO: not installed (disable the indication).

ROX: standard ROTAX oil temperature sensor (default) .

JAB: standard JABIRU sensor.

P1K: PT1000 resistive sensor.

● Clearance: setpoint to allow warming the oil before takeoff

(used for the “WARMUP/READY” status indicator).

Range:0~999°C, default=50°C.

● Unit: °C / °F: Set the unit of measure for the oil temperature;

choose between °Celsius (°C) or °Fahrenheit (°F).Default=°C.

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=100).

Instrument configuration

Page 32

Flybox

VIGILUS - Operating manual

32

®

Rev. 1.0

RPM setup menu

RPM SETUP MENU:

● Thresholds: set the min

value (bottom of the bar), the

yellow threshold, the red

threshold and the max value

(top of the bar).

● RPM THRESHOLDS SUBMENU:

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable

(range:0~100, default=30).

● Flight: set the RPM required to start the flight timer (the flight

timer start automatically when the engine's RPM meets or

exceeds this parameter for 30 seconds). Range:0~9990,

default=4000.

● Trigger: set the electrical threshold for the RPM input. The

number on the right is the actual reading of the RPM, to check

immediately while modifying the trigger value.

For signal amplitude of 0~5 Volt set a value of 20.

For signal amplitude of 0~12 Volt set a value of 27.

Instrument configuration

Page 33

VIGILUS - Operating manual

Flybox

33

Rev. 1.0

®

RPM setup menu

MAP SETUP MENU:

● Thresholds: set the min value (bottom of the bar), the yellow

threshold, the red threshold and the max value (top of the bar).

If you don’t want the yellow and red zone, set the same value

on all the three upper thresholds.

● MAP THRESHOLDS SUBMENU:

● MAP Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=200).

For Rotax 912 engine tipically this parameter should not be

changed, let the default value (19). Min-Max range is 0~31.

● Alarm repeat: Set the number of times that the vocal alarm for

the engine overspeed is repeated on the audio output

(range:1~5, default=1).

Instrument configuration

Page 34

Flybox

VIGILUS - Operating manual

34

®

Rev. 1.0

Volt setup menu

VOLT SETUP MENU:

● Thresholds: set the min

value (bottom of the bar), the

low red threshold, the high

red threshold and the max

value (top of the bar).

● VOLT THRESHOLDS SUBMENU:

● Alarm = ON/OFF:

enable/disable the alarm

(alert indication on display)

that occurs when the voltage

is too low (below the low red

threshold) or too high (above

the high red

threshold).Default=ON.

● VOLT ALARMS SUBMENU:

● Voice = ON/OFF: enable/disable the audio alert notification on

high or low voltage alarms (default=ON).

● Repeat: Set the number of times that the vocal alarm for the

high or low voltage is repeated on the audio output (range:1~5,

default=1).

Instrument configuration

Page 35

VIGILUS - Operating manual

Flybox

35

Rev. 1.0

®

Volt setup menu

● Auto reset = ON/OFF: if set to ON, if a alarm condition is

activated but the measurement has returned in the safe zone,

the Vigilus automatically reset the alarm indication. If set to

OFF, the user must manually reset the alarm indication, even

if the measurement has returned in the safe zone (default=ON).

● Out map: you can choose to enable one of the four outputs

available on the remote module when the alarm is activated,

useful for example to turn on an alarm light on the cockpit.

Set to zero to disable this function (default=0).

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=100).

Instrument configuration

Page 36

Flybox

VIGILUS - Operating manual

36

®

Rev. 1.0

AMP setup menu

AMP SETUP MENU:

● Thresholds: set the min

value (negative bottom of the

bar) and the max value (top

positive of the bar).

● AMP THRESHOLDS SUBMENU:

● AMP Sensor = ON/OFF: Set to ON if you have installed the

current sensor, set to OFF if you have not installed it (the

indication will be disabled). Default=ON.

● AMP Offset: Calibration of battery current sensor. See “Current

sensor” section in chapter 2.4 of the installation manual for

explanation.

● AMP Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=10).

Instrument configuration

Page 37

VIGILUS - Operating manual

Flybox

37

Rev. 1.0

®

GB T setup menu

Instrument configuration

GB T (GEARBOX TEMPERATURE) SETUP MENU:

● Thresholds: set the min

value (bottom of the bar), the

yellow threshold, the red

threshold and the max value

(top of the bar).

● GEARBOX THRESHOLDS SUBMENU:

● Alarm = ON/OFF:

enable/disable the alarm

(alert indication on display)

that occurs when the gearbox

temp. is too high (above the

red threshold). Default=ON.

● GEARBOX ALARMS SUBMENU:

● Voice = ON/OFF: enable/disable the audio alert notification on

gearbox temp. alarms (default=ON).

Page 38

Flybox

VIGILUS - Operating manual

38

®

Rev. 1.0

GB T setup menu

Instrument configuration

● Repeat: Set the number of times that the vocal alarm for the

gearbox temp. is repeated on the audio output (range:1~5,

default=1).

● Auto reset = ON/OFF: if set to ON, if a alarm condition is

activated but the measurement has returned in the safe zone,

the Vigilus automatically reset the alarm indication. If set to

OFF, the user must manually reset the alarm indication, even

if the measurement has returned in the safe zone (default=ON).

● Out map: you can choose to enable one of the four outputs

available on the remote module when the alarm is activated,

useful for example to turn on an alarm light on the cockpit.

● Type: set the type of oil temperature sensor installed:

N1K: NT1000 resistive sensor (default).

P1K: PT1000 resistive sensor.

ROX: ROTAX oil temperature sensor.

● Unit: °C / °F: Set the unit of measure for the oil temperature;

choose between °Celsius (°C) or °Fahrenheit (°F).Default=°C.

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=100).

Page 39

VIGILUS - Operating manual

Flybox

39

Rev. 1.0

®

ROTOR setup menu

Instrument configuration

ROTOR SETUP MENU:

● Thresholds: set the min

value (bottom of the bar), the

low yellow threshold, the

green threshold, the high

yellow threshold, the red

threshold and the max value

(top of the bar).

● ROTOR THRESHOLDS SUBMENU:

● Alarm = ON/OFF:

enable/disable the alarm

(alert indication on display)

that occurs when the rotor is

on a red zone. Default=ON.

● ROTOR ALARMS SUBMENU:

● Voice = ON/OFF: enable/disable the audio alert notification on

rotor alarms (default=ON).

Page 40

Flybox

VIGILUS - Operating manual

40

®

Rev. 1.0

ROTOR setup menu

Instrument configuration

● Repeat: Set the number of times that the vocal alarm for the

rotor is repeated on the audio output (range:1~5, default=1).

● Auto reset = ON/OFF: if set to ON, if a alarm condition is

activated but the measurement has returned in the safe zone,

the Vigilus automatically reset the alarm indication. If set to

OFF, the user must manually reset the alarm indication, even

if the measurement has returned in the safe zone (default=ON).

● Out map: you can choose to enable one of the four outputs

available on the remote module when the alarm is activated,

useful for example to turn on an alarm light on the cockpit.

Set to zero to disable this function (default=0).

● 100% RPM: set the number of rotor rpm that corresponds to

the 100% of the rotor speed.

NOTE: The default is zero, so you are forced to set the

correct value for your helicopter to enable the indication.

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=100).

Page 41

VIGILUS - Operating manual

Flybox

41

Rev. 1.0

®

1.3.5 GLOBAL SETTINGS MENU:

AIRCRAFT SETUP

● Type = PLANE/HELICOPTER: Select if the Vigilus is installed

in a plane or in a helicopter.

● Eng.: Select the engine installed in your aircraft:

Rotax 912

Rotax 914

Rotax 912iS

EPAPower

Generic

By choosing one of the engine presets (Rotax 912, Rotax 914,

Rotax 912iS, EPAPower), the Vigilus set all its parameters to

the default value for the selected engine.

Instrument configuration

Page 42

Flybox

VIGILUS - Operating manual

42

®

Rev. 1.0

Global settings menu

CAUTION: Even if the Vigilus presets all the parameters for

the selected engine, it’s up to the installer to check the

compliance of all the settings and thresholds to the engine

specifications.

By choosing “Generic” you must manually select the engine

type (aspired or injection) and the number of cylinder. After

selecting the “Generic” setup, you must manually set also all

the other Vigilus parameters and thresholds according to your

engine specifications.

NOTE: Since the engine selections reset all the parameters,

you should set this as the first thing and never change it

anymore, unless you want to reset all the parameters to the

default value.

● Cyl. Position: Choose the cylinders position, to have a correct

indication in the graphical temperatures page.

Front of the

engine

Instrument configuration

Page 43

VIGILUS - Operating manual

Flybox

43

Rev. 1.0

®

Global settings menu

GPS SETUP

● Active = ON/OFF: Enable or disable the GPS. If enabled, the

Vigilus use the GPS to indicate the time on the chronometer

page. If disabled no time is shown in the chronometer page

(default=OFF).

● Time = UTC / LOCAL: Set if you want to see the time in the

UTC time zone (default setting) or in your local zone. If local is

selected, you should set also the:

● UTC: set the offset between your local time and the UTC time.

SERIAL PORTS SETUP

● COM1 Setup: Enter in the COM1 submenu to choose the

● Baud Rate: This serial port is used to connect an external GPS

so the baud rate should be set at the same value set in the

external GPS (default=4800 bps).

● COM2 Setup: COM2 serial port actually not used.

Instrument configuration

Page 44

Flybox

VIGILUS - Operating manual

44

®

Rev. 1.0

Global settings menu

AUDIO SETTINGS

● Volume: Set the volume for the vocal alarm on the audio output

(range: 0~110, default=103). Set to zero to mute the audio

output.

Instrument configuration

Page 45

VIGILUS - Operating manual

Flybox

45

Rev. 1.0

®

Global settings menu

UNITS SETUP

● Temp.: Set the unit of measure for all the temperatures; choose

between °Celsius (°C) or °Fahrenheit (°F). Default=°C

● Press.: Set the unit of measure for all the pressure indications

(except MAP that it’s always indicated in InHg); choose between

Bar or Psi. Default=Bar.

● Fuel: Set the unit of measure for the fuel quantities. Choose

between liters (Lt) or US Gallons (Gal). Default=lt.

This menu globally set the units of measure for all the available

indications.

NOTE: When you change the units of measure on this menu,

all the single units of measure of each indications will be

changed accordingly, so if you have already set different units

of measure for each indications on the Instruments submenus,

they will be overwritten.

Instrument configuration

Page 46

Flybox

VIGILUS - Operating manual

46

®

Rev. 1.0

Global settings menu

PAGES SETUP

Set, for each of the three information pages available in the

Vigilus (Chronometer page, Fuel Computer page and Hour

meter page), the auto return time on the main engine data page:

The time is in seconds: if you set 10, after 10 seconds of

showing the selected page, Vigilus will return automatically to

show the main engine data page.

To disable the auto return for the selected page, set the value

to zero. Default=0.

Instrument configuration

Page 47

VIGILUS - Operating manual

Flybox

47

Rev. 1.0

®

1.3.6 FUEL COMPUTER MENU:

● Fuel Computer = YES/NO: Enable or disable the fuel computer

page.

● GPS Enabled = YES/NO: Enable or disable the GPS for the

two indications that require it (RANGE and RESERVE); you

must correctly connect the GPS to use this features. Default=NO.

● Main view = YES/NO: Enable or disable the indication of the

estimated remaining fuel on the main engine data page. Please

note that if enabled, it replace the fuel level indications (so if it’s

enabled, on the main engine data page you will have the

estimated remainind fuel calculated by the fuel computer, NOT

the fuel level read by the fuel level sensors). Default=NO.

● Fuel Unit: Set the unit of measure for the fuel quantities.

Choose between liters (Lt) or US Gallons (Gal). Default=Lt.

● Space Unit: Set the unit of measure for the distances. Choose

between kilometers (km) or nautical miles (NM). Default=Km.

● Tank Cap.: Set the tank capacity (if there are more than one

tank set the total capacity of the tanks). Default value is set to

zero to force the user the first time to set the capacity.

● Sensor N.: Set the number of fuel flow transducers installed.

Actually only one fuel flow transducer is supported.

Instrument configuration

Page 48

Flybox

VIGILUS - Operating manual

48

®

Rev. 1.0

Fuel computer menu

● K factor: Set the fuel flow transducer's K-factor, if installed. The

K-factor of a fuel flow transducer is the number of electric pulses

for 1 gallon of fuel consumption. If you have the K-factor in liters,

multiply the value by 3.78 before entering it. Default value is

416400 (nominal k-factor of Flybox® TFTHP flow transducer).

NOTE: For the Rotax 912iS engine the fuel flow is read by the

ECU so this parameter isn’t used.

● Filter: This parameter affect the readings and the gauges

displayed: a low value means that the readings will be more

fast and unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable (range:

0~999, default=100).

● Calibration: Calibration of the K-factor of the fuel flow

transducer, if installed. Refer to chapter 1.4 “Fuel flow

transducer calibration”.

NOTE: It's recommended to execute the K factor calibration

as soon as possible to have the maximum accuracy in the

fuel flow measurements.

● ALARMS SUBMENU:

● Remain. Alm = ON/OFF: Enable or disable the alarm on

remaining fuel quantity (default=ON).

● Remain. Q.ty: Set the fuel quantity for the “Remain. Alm”. When

the remaining fuel of the Fuel Computer is below this setpoint

the alarm is activated (range: 0.1~99.9 lt, default=30.0 lt).

● Remain. Rep: Set the number of times that the vocal alarm for

the remaining fuel quantity is repeated on the audio output

(range:1~5, default=1).

Instrument configuration

Page 49

VIGILUS - Operating manual

Flybox

49

Rev. 1.0

®

Fuel computer menu

● Endurance Alm = ON/OFF: Enable or disable the alarm on

endurance (default=ON).

● Min Time: Set the minimum time, in minutes, for the “Endurance

Alm”. When the endurance indication of the Fuel Computer is

below this setpoint the alarm is activated (range: 0~999 min,

default=30 min).

● Endurance Rep: Set the number of times that the vocal alarm

for the endurance is repeated on the audio output (range:1~5,

default=1).

● Balance Alm = ON/OFF: Enable or disable the alarm for tanks

balance (default=ON).

● Bal. Q.ty: Set the fuel quantity for the “Balance Alm”. If the

“Balance Alm” is enabled, the Vigilus will activate an alarm

every time the quantity of fuel used equals this value, showing

“TANK BALANCE” on the display.

This function is useful to keep balanced two wing tanks,

switching from one to the other after using a certain quantity

of fuel (range: 0.1~99.9 lt, default=10.0 lt).

● Balance Rep: Set the number of times that the vocal alarm for

the tanks balance is repeated on the audio output (range:1~5,

default=1).

1.3.7 ABOUT MENU:

On this screen it’s possible to read current firmware versions,

useful to check if your Vigilus and remote module are updated

to the latest versions.

NOTE: This manual is referred to the Vigilus firmware version

indicated on the first page.

Instrument configuration

Page 50

Flybox

VIGILUS - Operating manual

50

®

Rev. 1.0

On this example you can see that

the remote module needs to be

upgraded from version 3.6 to

version 3.9.

4- Select if you want to upgrade the Vigilus or the Remote

module and then click the knob to start the upgrade.

5- Wait until the firmware upgrade is completed then turn off the

power and remove the flash drive.

NOTE: Before the firmware upgrade the Vigilus automatically

perform a backup of the settings on the USB flash drive. If there

is already a backup file on the USB flash drive, it will be

overwritten so before upgrading the firmware move it in another

location if you want to keep it. The backup function is explained

in the next chapter.

1.3.8 FIRMWARE UPGRADE MENU:

This menu is used for upgrading the firmware versions of the

Vigilus and the connected remote module, using a USB flash

drive.

If you have received the upgrade files for the Vigilus and/or

remote module, copy them in a USB flash drive.

You can then check or upgrade by following this procedure:

1- From the settings setup menu, select “Firmware upgrade”.

2- Insert the USB flash drive with the upgrade files in the USB

receptacle on the Vigilus harness.

3- From the screen that appears, you can check if your Vigilus

and remote module needs an upgrade:

Instrument configuration

Page 51

VIGILUS - Operating manual

Flybox

51

Rev. 1.0

®

1.3.9 BACKUP AND RESTORE MENU:

This menu is used to save or

restore all the settings and

calibrations on your Vigilus.

● Backup: Insert a USB flash drive in the USB receptacle on the

Vigilus harness and then click the knob on this item to save all

the settings on the USB flash drive. The filename of the backup

is “Backup.vig”.

NOTE: It’s recommended to perform the backup right after

finishing to set the instrument and copy the “Backup.vig” file

in a safe place to have the opportunity to recall the settings if

needed.

● Restore: Insert the USB flash drive where you have previously

performed the backup (or manually copy the backup file

“Backup.vig” in a USB flash drive) and then click the knob on

this item to restore all the settings on the Vigilus.

NOTE: All current parameters will be overwritten after the

restore.

Instrument configuration

Page 52

Flybox

VIGILUS - Operating manual

52

®

Rev. 1.0

To increase accuracy in the fuel flow measurement you must

calibrate the transducer by following this steps.

NOTE: it's recommended to perform the calibration right after

installing the Vigilus+Remote module and repeat it once a year.

1- With the aircraft in level attitude, fill the tank/s of fuel; note

that in the step #4 it's required to refill the tank/s at the

exact level reached here.

2- Turn-on the Vigilus and select “FILLED” when asked for

the fuel quantity.

3- Burn at least 3/4 of fuel in the tank/s: a greater amount of

burned fuel will increase the accuracy, and you can do

this step in more flights: at the start of each flights you

must not add fuel in the tank/s and you must select “NO

REFUEL” when asked after turning on the Vigilus.

4- Fill the tank/s with the exact same level reached in the

step #1, accurately measuring the quantity of fuel added

in the tank/s.

5- Turn on the Vigilus and select “NO REFUEL” (even

though you have refilled it’s required to select “NO

REFUEL”).

6- Enter in the Main menu → Settings → Fuel Computer →

Calibration; the following screen will appears:

1.4 FUEL FLOW TRANSDUCER CALIBRATION

Instrument configuration

Page 53

VIGILUS - Operating manual

Flybox

53

Rev. 1.0

®

Fuel flow transducer calibration

7- Now you must insert in the “FUEL FILLED” the exact

quantity of fuel that you have added and measured in step

#4; probably it doesn't correspond exactly to the “FUEL

USED” because this is the measurement from the

transducer not yet calibrated and it’s showed for reference

only. To insert the value rotate the knob and press

“ENTER” to confirm. To exit without saving, press “ESC”.

8- When you confirm by pressing “ENTER” the display will

briefly shows the newly calculated K-factor and return to

the Fuel computer menu. The transducer is now

calibrated and the K-factor is automatically stored in

memory; you can safely exit the setup menu or turn off the

Vigilus.

NOTE: it's recommended to annotate the K-factor value

so that if you inadvertently modify it it's possible to

manually reenter the value without doing again the

calibration (however the fuel flow transducer calibration

may be repeated in any moment).

Instrument configuration

Page 54

Flybox

VIGILUS - Operating manual

54

®

Rev. 1.0

Before using the fuel level indications it's necessary to calibrate

all the aircraft fuel tanks by following the procedure explained

in this chapter.

The calibration is divided in more calibration steps, in each step

you will fill the tanks with predetermined fuel quantity; the

calibration ends when the tank is completely filled.

The parameters available in the calibration menu are:

● Cal Steps: With this parameter it's possible to choose the fuel

quantity to add at each calibration step. Choose a proper value

considering the tanks capacity and how many calibration steps

you want to execute.

For example with a 40 liters tank and “Calibration fuel step”

set to 2 it's required 40 / 2 = 20 calibration steps. Consider

also that the maximum number of calibration steps that is

possible to store in memory for every tank is 50.

The “Cal. steps” parameter is used for all the tanks

calibrations, don’t modify it once you have choosed a value

(range:1~100 lt, default=2 lt).

● mV Steps: Minimum thresold to detect fuel sensor movements

(default = 20, don't modify this value).

● DRES Filter: Filter for DRES sensors only. Not used for the

other sensor types.

1.5 FUEL LEVEL SENSORS CALIBRATION

Instrument configuration

Page 55

VIGILUS - Operating manual

Flybox

55

Rev. 1.0

®

Fuel level sensors calibration

● Left Tank / Main Tank / Right Tank: Choose which tank you

want to calibrate. For example if you select the left tank this

screen will appears:

If you’ve never performed the

calibration before for the selected

tank, you will see the “Calibration

never done!” indication.

● Press the “START” button to start the calibration; the display

will shows this screen:

START OF THE CALIBRATION:

(2) Calibration step

to be performed

(3) Electrical output

of the fuel level

sensor

(1) Action to be

performed

● Step#01 (EMPTY TANK): Drain the tank such that only the

unusable fuel remain in the tank. Wait until the indication (3)

is stable and then click the knob [NEXT] to confirm and go to

the next step.

● Step#02: Add to the tank the indicated fuel quantity (it's the

same quantity choosed with the “Cal. steps” parameter), on this

example it's required to add 2 liters of fuel:

Instrument configuration

Page 56

Flybox

VIGILUS - Operating manual

56

®

Rev. 1.0

Fuel level sensors calibration

Action to be

performed: Add 2

liters of fuel

Wait until the indication is stable and click the knob [NEXT] to

confirm and go to the next step.

NOTE: to reach the maximum accuracy in the calibration it's

important that the fuel quantity is exactly measured.

● Next steps: repeat the above step (add the same amount of

fuel then click the knob [NEXT] to confirm) until the tank is

completely filled.

● When the tank is filled: click the knob [NEXT] to confirm the

last calibration step and then click the “END” button to end the

calibration (when asked on display “Confirm calibration end?”

Click the “YES” button and then click the “CLOSE” button).

● The calibration for the selected tank is now completed. If

you reenter in the tank menu that you have just finished to

calibrate, you can see a calibration summary:

To exit from this screen, click the

“ESC” button.

It's recommended to perform a

backup operation after finishing

the calibrations (see chap.1.3.9)

Instrument configuration

Page 57

VIGILUS - Operating manual

Flybox

57

Rev. 1.0

®

Fuel level sensors calibration

NOTE: A common problem for many fuel level sensors is that

they can't completely measure the tank capacity, so one or both

of this conditions can occur (see also “Fuel level sensors”

section on chap.2.4 of the installation manual):

- As you add fuel to an empty tank it takes a certain amount

of fuel before the fuel sensor start to move from the

bottom.

- As you drain fuel to a filled tank it takes a certain amount

of fuel before the fuel sensor start to move from the top.

If one of this conditions occurs during the calibration, the Vigilus

notice that the fuel sensor doesn't produce an electrical change

and ask the user if fuel was really already added for that

calibration step:

If you are sure to have already added the fuel click on “YES”

otherwise click on “NO” to go back to the previous calibration

step.

Please note that the amount of fuel that is not measurable,

it will not be counted, so for example if your tank have a

capacity of 40 liters but only 30 is measurable by the fuel level

sensor, after the calibration you will see 30 liters when the tank

is full.

Instrument configuration

Page 58

Flybox

VIGILUS - Operating manual

58

®

Rev. 1.0

Fuel level sensors calibration

1.5.1 FUEL LEVEL SENSORS CHECKINGS

To configure correctly the fuel level indicators, you need to know

what type of fuel level sensors are installed in your aicraft. The

resistive sensors can be of two types:

● Sensors that increase resistance as the fuel level increase

● Sensors that decrease resistance as the fuel level increase

If you don't know what type of resistive sensors are installed in

your aircraft, follow this procedure:

- Empty the tank that you want to check.

- On the Vigilus enter in the calibration for that tank (Main

menu → Instruments → Fuel L → Calibrations →

Left/Right/Main Tank ).

- From the screen that appear click on “START” button

- Annotate the numerical value (mV):

- Add a certain amount of fuel in the tank and check if the

numerical indication increase or decrease: if increase then

the sensors installed increase the resistance as you add

fuel (RES+), if decrease the sensors decrease the

resistance as you add fuel (RES-).

To exit from the calibration screen click on “ABORT”.

Repeat the procedure for any other unknown sensors installed.

Instrument configuration

Page 59

VIGILUS - Operating manual

Flybox

59

Rev. 1.0

®

1.6 FUEL COMPUTER ACTIVATION

If you have purchased the optional fuel computer key for your

Vigilus, follow this procedure to activate it:

● Enter in the main menu → Settings → Password.

● Insert the password “301293”, rotating the knob to change

the digit and pressing it to confirm.

● Write down the ID code that appears and communicate it to

your Flybox® dealer.

● After you have received the “KEY” code from your Flybox®

dealer you can reenter in this password and insert the

received key (rotate the knob to change the digit and press

it to confirm).

● If the code is correct the Vigilus shows on display “FUEL

COMPUTER ENABLED”.

● Press the “ESC” pushbutton to exit.

WRITE DOWN HERE THE ACTIVATION DATA:

S/N: __________ (serial number on the back of the Vigilus)

ID: _______________

KEY: _______________

Instrument configuration

Page 60

Flybox

VIGILUS - Operating manual

60

®

Rev. 1.0

SECTION 2

2.1 USING THE VIGILUS

The Vigilus is organized in 4 monitoring pages:

● Page1: Main engine data page and temperature page

● Page2: Chronometer page

● Page3: Fuel management page

● Page4: Hourmeter page

After power-on the Vigilus shows the main engine data page

(Page1).

To switch between the four pages rotate the knob; when you

are on Page 2,3 or 4 the Vigilus can return automatically to

display Page1 after a set time. To enable this function, see

chap.1.3.5, section “Pages setup”.

NOTE: in this manual is presented the full version of the pages

but your Vigilus may differ depending on the optionals and

sensors installed in your aircraft.

Page 61

VIGILUS - Operating manual

Flybox

61

Rev. 1.0

®

2.2 PAGE1: Main engine data page

RPM

MAP

OIL PRESSURE

OIL TEMPERATURE

HIGHEST &

LOWEST

EGT / CHT

EGT / CHT

BARS

STATUS

INDICATOR

FLIGHT TIME &

LAP TIME

AIRBOX /

CARBURETOR

AIR TEMP.

OUTSIDE

AIR TEMP.

FUEL

PRESSURE

TANKS

FUEL

LEVEL

PLANE VERSION:

Page 62

Flybox

VIGILUS - Operating manual

62

®

Rev. 1.0

Main engine data page

HELICOPTER VERSION:

ENGINE

RPM

MAP

OIL PRESSURE

OIL TEMPERATURE

HIGHEST &

LOWEST

EGT / CHT

EGT / CHT

BARS

STATUS

INDICATOR

FLIGHT TIME &

LAP TIME

AIRBOX /

CARBURETOR

AIR TEMP.

OUTSIDE

AIR TEMP.

ROTOR %

TANK FUEL

LEVEL

GEARBOX

TEMPERATURE

FUEL

PRESSURE

Page 63

VIGILUS - Operating manual

Flybox

63

Rev. 1.0

®

On this page all the important engine data is clearly displayed

in both graphical and numerical indications. The green, yellow

and red zones of the various gauges is completely customizable

as explained in chap.1.3.4 “Instruments menu”; when a

measurement is on a yellow or red zone the corresponding

numerical indication change color to yellow or red; when in red

zone the corresponding gauge is also blinking.

The available indications are:

● Tachometer with both graphical and numerical indication.

● MAP with both graphical and numerical indication, in inches

of mercury.

● Oil pressure with both graphical and numerical indication in

BAR or PSI, depending on what unit of measure you have

choosen in the settings.

● Oil temperature with both graphical and numerical indication

in°Celsius or °Farhenheit, depending on what unit of measure

you have choosen in the settings.

● Fuel pressure with both graphical and numerical indication

in BAR or PSI, depending on what unit of measure you h a v e

cho osen in the settings.

● Tanks fuel level: The fuel level indications here are obtained

by reading the fuel level sensors installed in your aircraft and

connected to the Vigilus. The indications are approximated, do

not solely rely on the Vigilus to determine the fuel available in

the tanks but always refer to primary instrument installed in your

aircraft.

Main engine data page

Page 64

Flybox

VIGILUS - Operating manual

64

®

Rev. 1.0

Main engine data page

CAUTION: Before using the fuel level indications you must

be sure to have already set the following parameters:

- Set the unit of measure: US gallons or liters (set this before

all the other parameters). See parameter “Unit” on menu

Settings → Instruments → Fuel L → Tanks.

- Set the number of tanks used (see parameter “Number” on

menu Settings → Instruments → Fuel L → Tanks).

- Set the type of level sensors installed (see parameter “Sensor”

on menu Settings → Instruments → Fuel L → Tanks →

Left/Main/Right tank).

- Execute the calibration for each used tanks (see chap.1.5).

● Highest & lowest EGT / CHT: on this window you can read

the numerical indication of the highest (denoted by “H”) and

lowest (denoted by “L”) EGT and CHT, with also the indication

of what cylinder is referred:

● EGT / CHT bars: graphical representation of the EGT and CHT

temperature of every cylinder; the EGT are the green bars, the

CHT are the light blue bars. The highest EGT and CHT are

indicated by a red dot over the bars.

● OAT: outside air temperature, with both graphical and

numerical indication in°Celsius or °Farhenheit, depending on

what unit of measure you have choosen in the settings.

● CAT: Airbox/carburetor air temperature, with both graphical

and numerical indication in°Celsius or °Farhenheit, depending

on what unit of measure you have choosen in the settings.

Page 65

VIGILUS - Operating manual

Flybox

65

Rev. 1.0

®

Main engine data page

● Status indicator: This is a useful indicator that you should

check before takeoff.

When the essential measurements are not in a safe area the

indicator shows “WARMUP” in red background; the

measurements taken in consideration are the oil pressure

(must be in green zone), the oil temperature (must be warmer

than “Clearance” parameter), the fuel pressure (must be in

green zone), the CAT (must be in green zone) and all the

CHTs (must be in green zone).

When all the measures becomes in its safe zone the indicator

change state to “READY” in green background, that

automatically disappear 30 seconds after take-off.

● Flight time: The flight timer starts automatically when the

engine meets or exceeds for 30 seconds the value set in the

“Flight” parameter (see chap.1.3.4, section “RPM setup menu”)

and it stops automatically when the engine is turned off (0000

RPM).

● Lap time: The lap time starts at the same time of the flight time

explained above but it can be reset during flight (see chap.2.3).

● ROTOR % (helicopter version only): Shows the rotor %, with

both graphical and numerical indication.

● Gearbox temperature (helicopter version only): with both

graphical and numerical indication in°Celsius or °Farhenheit,

depending on what unit of measure you have choosen in the

settings.

Page 66

Flybox

VIGILUS - Operating manual

66

®

Rev. 1.0

Main engine data page

VARIANT FOR ROTAX 912iS:

The engine page for the Rotax 912iS version is slightly different

from the aspirated version; the differences are:

1 - WT (Water temperature) instead of CHT (Cylinder head

temperature): 912iS have only one sensor for the water/coolant

temperature.

2 - MT (Manifold temperature) instead of CAT (carburetor

temperature).

3 - TP: Throttle position 0~100%

4 - The STATUS INDICATOR became a smaller circular version

to save space for the throttle position gauge. The function of

the status indicator remain the same:

When the essential measurements are not in a safe area the

indicator shows “WU” in red background; the measurements

taken in consideration are the oil pressure (must be in green

zone), the oil temperature (must be warmer than “Clearance”

parameter), the fuel pressure (must be in green zone), the MT

(must be in green zone) and the WT (must be in green zone).

When all the measures becomes in its safe zone the indicator

change state to “RD” in green background, that automatically

disappear 30 seconds after take-off.

5 - ECU STATUS: This status indicate if the Vigilus is

communicating properly with the two ECUs (A and B) of the

Rotax 912iS engine.

If the communication is ok with both A and B ECUs the two

indications are in green [A B].

If the communication is missing with one of the ECUs the

relative indication is in red ( for example [A B] or [A B] ).

Page 67

VIGILUS - Operating manual

Flybox

67

Rev. 1.0

®

Main engine data page

WATER/COOLANT

TEMPERATURE

ECU

STATUS

STATUS

INDICATOR

THROTTLE

POSITION

MANIFOLD

TEMPERATURE

Page1 - Variant for Rotax 912iS

Page 68

Flybox

VIGILUS - Operating manual

68

®

Rev. 1.0

Main engine data page

2.2.1 TEMPERATURE PAGE

By pressing the F1 pushbutton (the left pushbutton) you can

switch between the main engine data page and the temperature

page. This page shows, with a graphical representation of the

engine, the temperatures of CHT, EGT, Oil and the difference

between warmer and colder CHT and EGT.

Cylinder 1

temperatures

Cylinder 3

temperatures

Cylinder 4

temperatures

Cylinder 2

temperatures

Difference

between warmer

and colder EGT

Difference

between warmer

and colder CHT

NOTE: you can customize the cylinders position by going in the

menu → Settings → Global settings → Aircraft → Cyl. Position.

Page 69

VIGILUS - Operating manual

Flybox

69

Rev. 1.0

®

2.3 PAGE2: Chronometer page

CLOCK

The information available on this page are:

● Clock: Shows the time, if a GPS is connected and enabled on

the Vigilus. To enable the GPS and set the time zone, go in the

menu → Settings → Global Settings → GPS.

● Flight time: The flight timer starts automatically when the

engine meets or exceeds for 30 seconds the value set in the

“Flight” parameter (see chap.1.3.4, section “RPM setup menu”)

and it stops automatically when the engine is turned off (0000

RPM).

● Lap time: The lap time starts at the same time of the flight time

explained above but it can be reset during flight by pressing the

“RESTART” button (right button).

FLIGHT TIME

LAP TIME

AMPEROMETER

VOLTMETER

Page 70

Flybox

VIGILUS - Operating manual

70

®

Rev. 1.0

Chronometer page

● Voltmeter: Shows the battery voltage (the voltage is measured

on the power supply line of the remote module).

● Amperometer: Shows the battery current, if the optional Flybox

current sensor is installed. The current shown here may have

different meaning depending on where you installed the current

sensor (refer to “Current Sensor” section on chap.2.4 of the

installation manual).

Page 71

VIGILUS - Operating manual

Flybox

71

Rev. 1.0

®

2.4 PAGE3: Fuel management page

● Fuel levels section:

The fuel level indications are obtained by reading the fuel level

sensors installed in your aircraft and connected to the remote

module of the Vigilus. The indications are approximated, do not

solely rely on the Vigilus indications to determine the fuel

available in the tanks, but always refer to primary instrument

installed in your aircraft.

Before using the fuel llevels section you must be sure to have

already set the following parameters:

- Set the unit of measure: USgallons or liters (set this before all

the other parameters). See parameter “Unit” on menu Settings

→ Instruments → Fuel L → Tanks.

Fuel levels

section

Fuel flow

Burned

fuel

Range (need GPS)

Endurance

Reserve (need GPS)

Remaining fuel

Fuel

computer

section

Page 72

Flybox

VIGILUS - Operating manual

72

®

Rev. 1.0

Fuel management page

- Activate only the number of tanks used (see parameter

“Number” on menu Settings → Instruments → Fuel L → Tanks).

- Set the type of level sensors installed (see parameter “Sensor”

on menu Settings → Instruments → Fuel L → Tanks →

Left/Right/Main Tank).

- Execute the calibration for each used tanks (see chap.1.5).

● Fuel Computer section:

Before using the fuel computer section you must be sure to have

already set the following parameters:

- Set the unit of measure: USgallons or liters (set this before all

the other parameters). See parameter “Fuel unit” on menu

Settings → Fuel Computer.

- Set the unit of measure: kilometers or nautical miles. See

parameter “Space unit” on menu Settings → Fuel Computer.

- Set the total tank/s capacity. See parameter “Tank Cap.” on

menu Settings → Fuel Computer.

- Set the K-factor. The K-factor of a fuel flow transducer is the

number of electric pulses for 1 gallon of fuel consumption (if you

have K-factor in liters you must multiply this value by 3.78 before

set k-factor in the Vigilus). If you use Flybox® TFTHP fuel flow

transducer, set the k-factor to 416400.

It's recommended also to execute the K-factor calibration as

soon as possible to have the maximum accuracy (refer to

chapter 1.4 “Fuel flow transducer calibration”).

Everytime after powering-on, the Vigilus ask if you have

refuelled the tank; you must choose one of the 3 options

available (rotate the knob to select and press to confirm):

Page 73

VIGILUS - Operating manual

Flybox

73

Rev. 1.0

®

Fuel management page

NO REFUEL: Select this option if you have not refuelled the

tank.

ADD FUEL: Select this option if you have added fuel to the tank

(on the next screen that appears you can insert the exact

amount of fuel added).

FILLED: Select this option if you have filled the tank; the display

will show the quantity that has been added to reach the full level.

Before using this option you must have already set the tank/s

capacity in the fuel computer setup.

If you press “ESC” pushbuttons no change are made, but the

next time that you reach the fuel management page it ask again

until you choose one of the three options.

NOTE: If you need to correct a wrong fuel quantity add, select

“ADD FUEL” and insert a negative value.

Now the fuel computer is ready to operate; the available

indications are:

● FUEL FLOW: According to the selected unit of measure the

flow is indicated in liters per hour (Lt/h) or gallons per hour (Gl/h).

● REMAINING FUEL: Display the fuel remaining in the tank/s.

According to the selected unit of measure the quantity is

indicated in liters (Lt) or gallons (Gal).

WARNING: The remaining fuel displayed here is not a

measurement of the fuel in the tank, but it is calculated from

the initial quantity entered by the user and the burned quantity