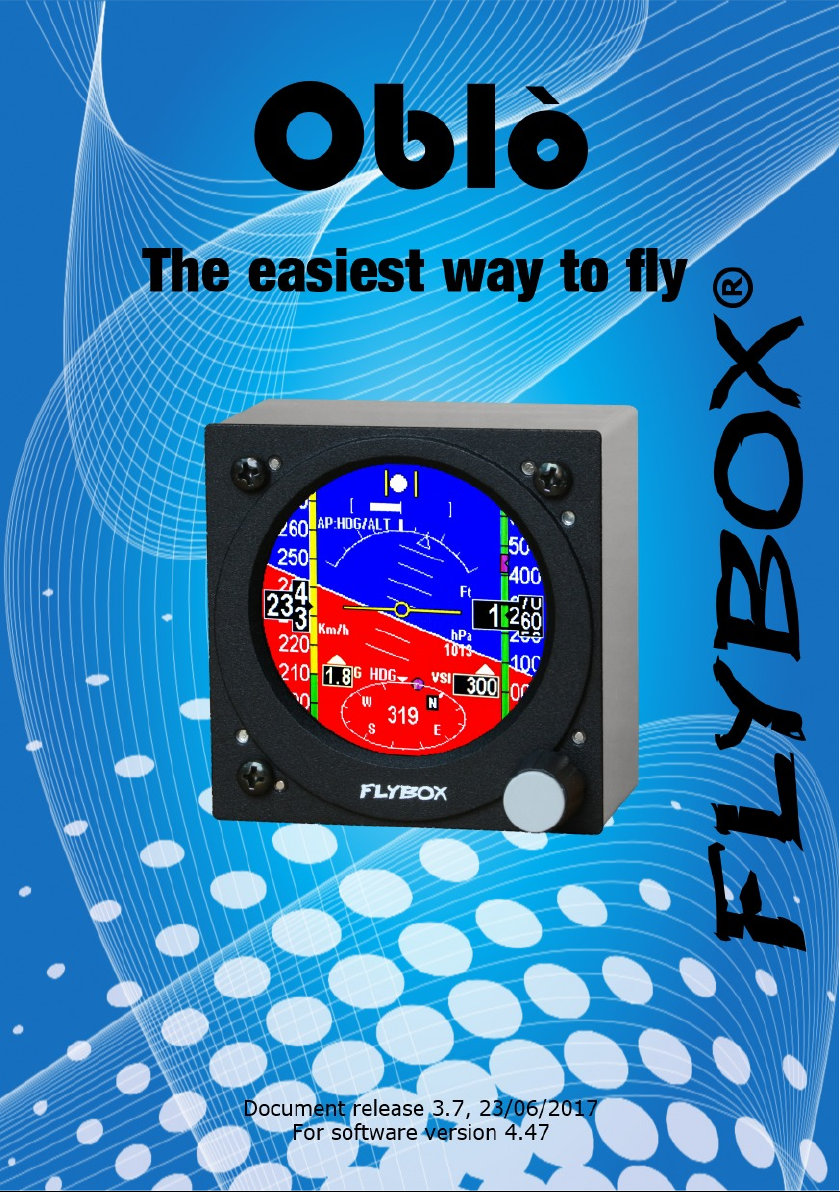

Page 1

Page 2

Page intentionally left blank

Page 3

SECTIONS

STANDARD OBLÒ INSTALLATION

INSTRUMENT CONFIGURATION

OBLÒ-A/P INSTALLATION

OBLÒ-REP INSTALLATION

USING THE OBLÒ

AUTOPILOT SYSTEM

AUTOPILOT OPERATION

USE OF THE OBLÒ-REP

TECHNICAL SPECIFICATIONS

Page 4

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Introduction

Thank you for purchasing a Flybox® product.

We hope it provides many years of service to you,

becoming a useful instrument for easy and immediate

consultation. Developing Oblò our intent was to create

a compact and lightweight attitude indicator / EFIS,

easy to install and to use. Oblò is equipped with

state-of-the-art highly visible display and the latest

generation of solid state inertial sensors to ensure

reliability and accuracy over time.

SYMBOLS USED IN THE MANUAL

NOTE: Used to highlight important informations.

CAUTION: Used to warn the user and indicate a potentially

hazardous situation or improper use of the product.

WARNING: Used to indicate a dangerous situation that can

cause personal injury or death if the instruction is

disregarded.

Rev.3.7

Page 5

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Flybox

NOTE: Keep this manual in the aircraft.

This document must accompany the instrument in the event

of change of ownership.

NOTE: This device is intended for installation onto non type

certified aircraft only, because it has no aviation certifications.

Refer to your local aviation authorities to check if this device

may be installed in your aircraft.

CAUTION: Read entirely this manual before installing the

instrument in your aircraft, and follow the installation and

operating instructions described here.

CAUTION: The pilot must understand the operation of this

instrument prior to flight, and must not allow anyone to use

it without knowing the operation. Don't use this instrument

in flight until you are sure of the correct operating of the same.

Important notices & warnings

CAUTION: This instrument cannot be used under any

circumstances to conduct flights in IMC conditions.

CAUTION: When the installation is finished you must do a

test, prior to flight, switching on all the possible source of

electric noise and checking the properly operation of this

instrument.

CAUTION: Using this instrument over the maximum

allowable ranges can cause malfunction or wrong indications.

Rev.3.7

Page 6

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Important notices & warnings

CAUTION: The software of this instrument can be subject to

change, update, addition or removal of functions, so also the

operating mode of the instrument can be subject to change.

Always refer to the installation and operating manual updated

with the software version used in your instrument. To

obtain updated software and manuals, please visit

www.flyboxavionics.it.

WARNING: Responsibility for installation lies entirely with the

installer. Responsibility for operations lies entirely with the

operator. Responsibility for any calibration, alarms

thresholds and activations, every customizable instruments

thresholds or any other settings lies with the person

performing these modifications.

WARNING: Do not solely rely on the Oblò to determine the

primary flight informations. Always compare the informations

provided with other primary flight instruments to recognize

eventual malfunction.

IMPORTANT: If you do not agree with the notices above

do not install the Oblò in your aircraft, but return the

product for a refund.

Microel s.r.l. reserves the right to change or improve its

products. Information in this document is subject to changes

without notice.

Rev.3.7

Page 7

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Index

INDEX

SECTION 1 - Standard Oblò installation

1.1 - Mechanical installation …….…………………………….. 12

1.2 - Electrical and pneumatic installation ……..………….….. 17

General wiring hints ………………..……………….….. 20

Optional accessories available …….….…………….…... 20

1.3 - Altitude serial out for transponder …………….…………. 21

1.4 - Primary actions after installation ………………...………. 23

SECTION 2 - Oblò-A/P installation

2.1 - Mechanical installation ..…................................................. 25

Oblò-A/P installation ………...…….…............................ 25

ACU control unit installation .………............................... 25

Servo/s installation ……………….…............................... 28

2.2 - Electrical installation …...................................................... 30

SECTION 3 - Oblò-REP (repeater) installation

3.1 - Oblò-REP (repeater) installation …..................................... 37

3.1.1 - Electrical installation Oblò standard–>Oblò-REP ........... 38

3.1.2 - Electrical installation Oblò-A/P–>Oblò-REP …….......... 39

SECTION 4 - Instrument configuration

4.1 - Main menu configuration ..………...................................... 41

Zero pitch .……….…….…………................................... 42

TRK/HDG ……….…….…………................................... 42

Light ………….….…….…………................................... 42

G-meter reset ...….…….………….................................... 42

4.2 - Setup menu configuration ………....................................... 43

T.R.I. (Turn rate indicator) ………..........................….…. 43

Ball (Slip indicator) ………………................................... 44

I

Rev.3.7

Page 8

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Index

Roll ……….….………….……….................................… 44

Pitch …….….………….……..…..................................… 45

ASI (Airspeed) ….….………...……….........................… 46

ALT/VSI (Vertical scale indicator) ...............................… 47

Autopilot …….….……..……..….................................… 48

G-meter …….………….……..….................................… 48

GPS ….….….………….……..….................................… 49

HSI ….….….………….……..…..............................….… 50

Compass ……………….……..….................................… 50

ADI ….….….………….……..….................................… 51

Config …..….………….……..….................................… 51

About ……….………….……..….................................… 52

FW Upgrade ..………….……..….................................… 52

4.3 - Magnetic calibration ….…………...................................... 53

SECTION 5 - Using the Oblò

5.1 - Using the Oblò ………………..…….…....….……........... 56

5.1.1 Attitude indicator page ……..…...…...........................… 57

5.1.2 HSI page …………………..….….............................… 64

5.1.3 Drum altimeter page ..…..…..….................................… 66

SECTION 6 - Autopilot system

6.1 - Autopilot system ..….….….……………............................ 67

Requirements …….…….……..….................................… 67

Autopilot overview ………………................................… 68

Remote disengage button …….….................................… 70

6.2 - Autopilot system configuration ………….......................... 71

6.2.1 - Servo/s calibration ……………..….………................ 72

6.2.2 - Communications check ……….……………............... 78

6.2.3 - Remote button operation check …………...…............ 79

6.2.4 - Servo torque check ……………..….….…….............. 80

II

Rev.3.7

Page 9

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

6.3 - Autopilot setup menu ……………….....……..................... 81

6.3.1 - “Min Spd” and “Max Spd” parameters setting …........ 82

6.3.2 - Roll servo setup ……………...….….….…………..... 84

6.3.3 - Pitch servo setup ……………………….…………..... 87

6.3.4 - Remote button setup ……………..….….…………..... 91

6.4 - Flight based test and configuration .….……....................... 93

6.4.1 - Autopilot setup - Roll axis (Flight based) ………....... 95

6.4.2 - Autopilot setup - Pitch axis (Flight based) ….……..... 99

SECTION 7 - Autopilot operation

7.1 - Autopilot operation ………….…….………....................... 102

7.2 - How to engage and disengage the autopilot …………........ 105

7.3 - Details of operation ….………………...….…................… 108

7.4 - Autopilot related alarms ………………….......................... 114

7.5 - Important notices - safety checks ..…………...................... 117

7.6 - Autopilot activation procedure ….….………..................... 118

SECTION 8 - Use of the Oblò-REP (optional)

8.1 - Use of the Oblò-REP .….……….…………...................… 121

Index

SECTION 9 - Technical specifications

9.1 - Technical specifications ………….…………...........…..… 123

APPENDIX “A” - Altimeter calibration …..……..……………. 124

APPENDIX “B” - Detail of optional wirings …….……………. 126

APPENDIX “C” - Detail of optional GPS module..……………. 128

WARRANTY ……….………………….………………………. 130

Revision history ……….………………………..………………. 131

III

Rev.3.7

Page 10

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Page intentionally left blank

10

Rev.3.7

Page 11

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

INSTALLATION

SECTION

11

Rev.3.7

Page 12

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Standard Oblò installation

1.1 MECHANICAL INSTALLATION

Mechanical installation

SECTION 1

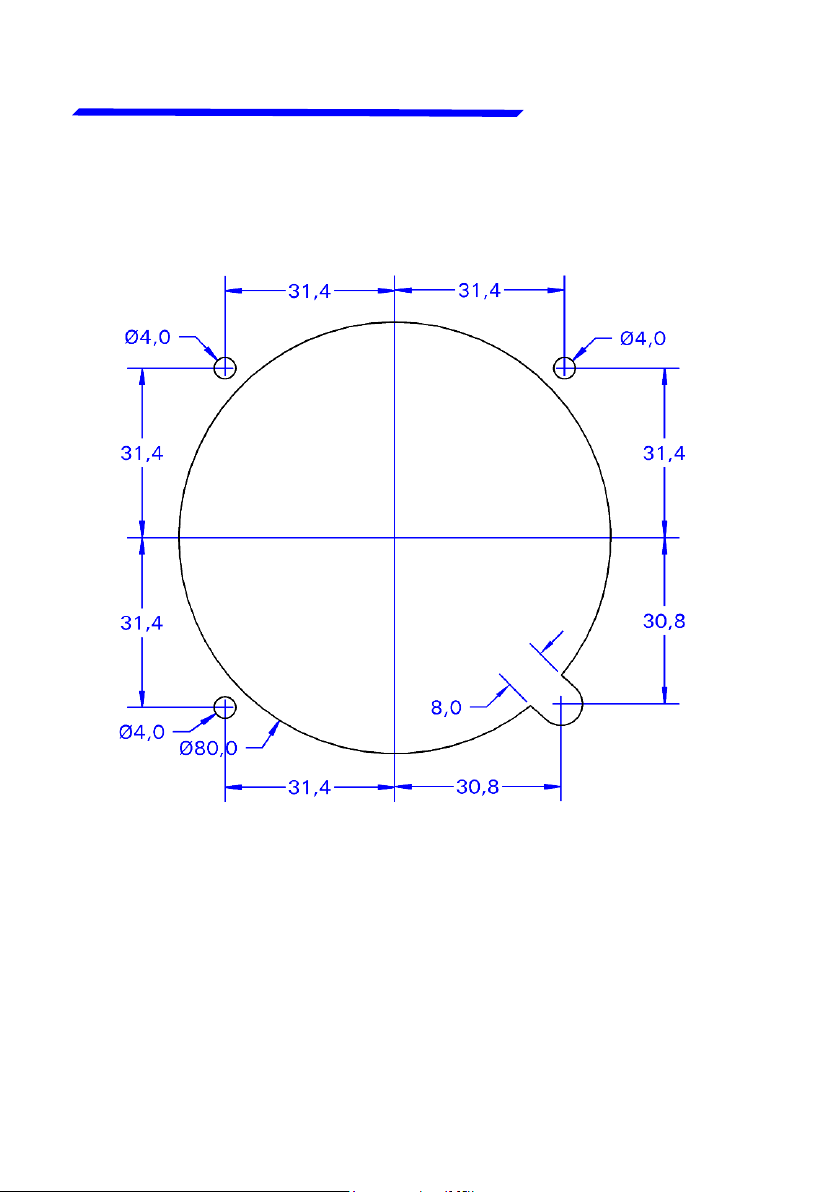

Oblò fits in a standard 3 1/8” (80 mm) cutouts. On the

1)

panel it's necessary to make the cutout for the knob on

the lower right hole.

The installation location must be carefully chosen since

2)

Oblò contains magnetic sensors for the compass

indication. Given that a location without magnetic

interference can be difficult or impossible to find, it’s

recommended to install the instrument in the top row of

the instrument panel, to limit the interference of cables,

switches and breakers that are usually found at the

bottom.

Do not install near any magnetic sources (wires that

carry large amount of current, magnets/electromagnets,

electric motors, airplane parts or metal parts that may

have residual magnetic field). As a general rule keep a

minimum distance of 30cm, but 60cm or more are

recommended.

To test if the location where you intend to install it is

appropriate, turn on all the electrical loads (in particular

radio and strobe lights) and move a handheld compass

around the area making sure that the compass needle

is stable (should not cycles back and forth) and is

approximately indicating the magnetic North.

Small deviations from the North can be compensated

with the magnetic calibration (see chap.4.3)

12

Rev.3.7

Page 13

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

During use the instrument become warm so it's

3)

necessary to have some air circulation inside the

instruments room, to avoid that the temperature

increase over the operating limits.

Avoid placing in hot locations (for example near heater

4)

vents).

Find a location where the display will always be

5)

completely visible.

Standard Oblò installation

Mechanical installation

13

Rev.3.7

Page 14

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Standard Oblò installation

Mechanical installation

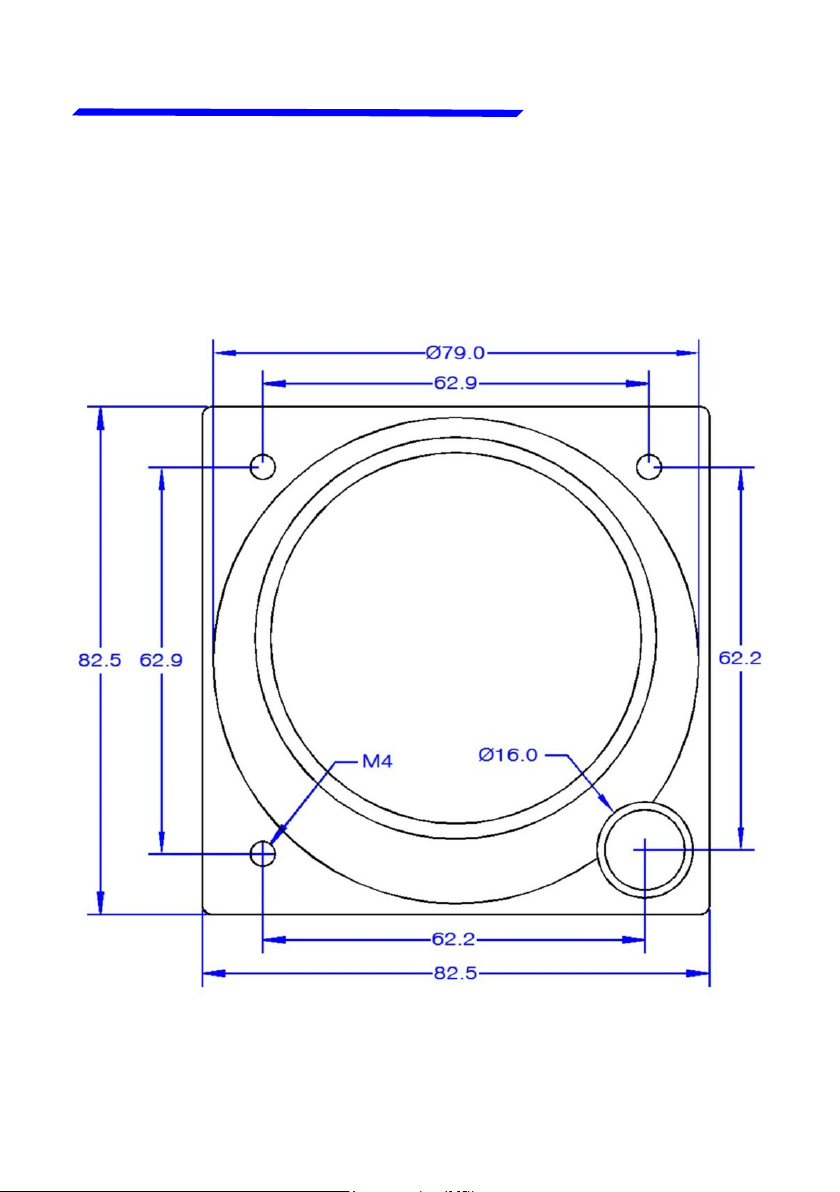

Front view

Flybox

14

Rev.3.7

Page 15

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

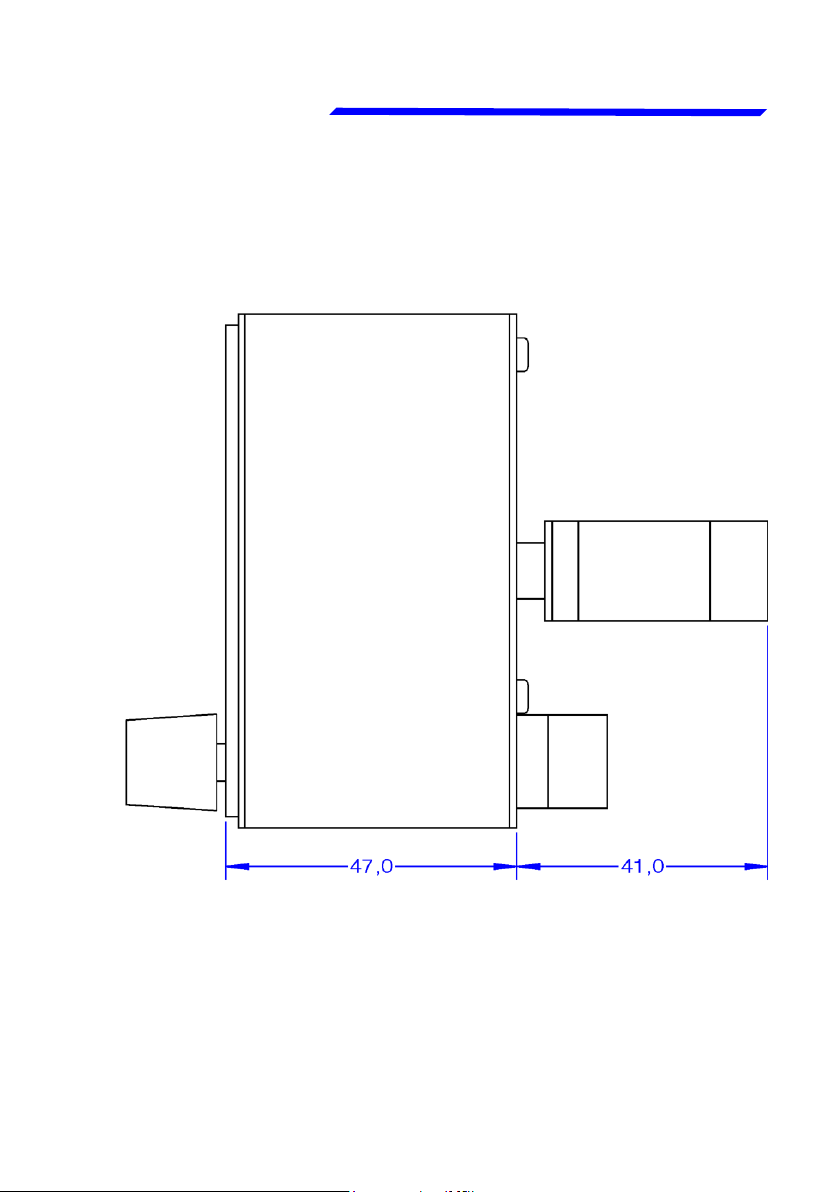

Side view

Standard Oblò installation

Mechanical installation

15

Rev.3.7

Page 16

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Standard Oblò installation

Mechanical installation

Panel cut-out

Flybox

- All dimensions are in millimeters.

16

Rev.3.7

Page 17

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Standard Oblò installation

Electrical installation

1.2 ELECTRICAL AND PNEUMATIC

INSTALLATION

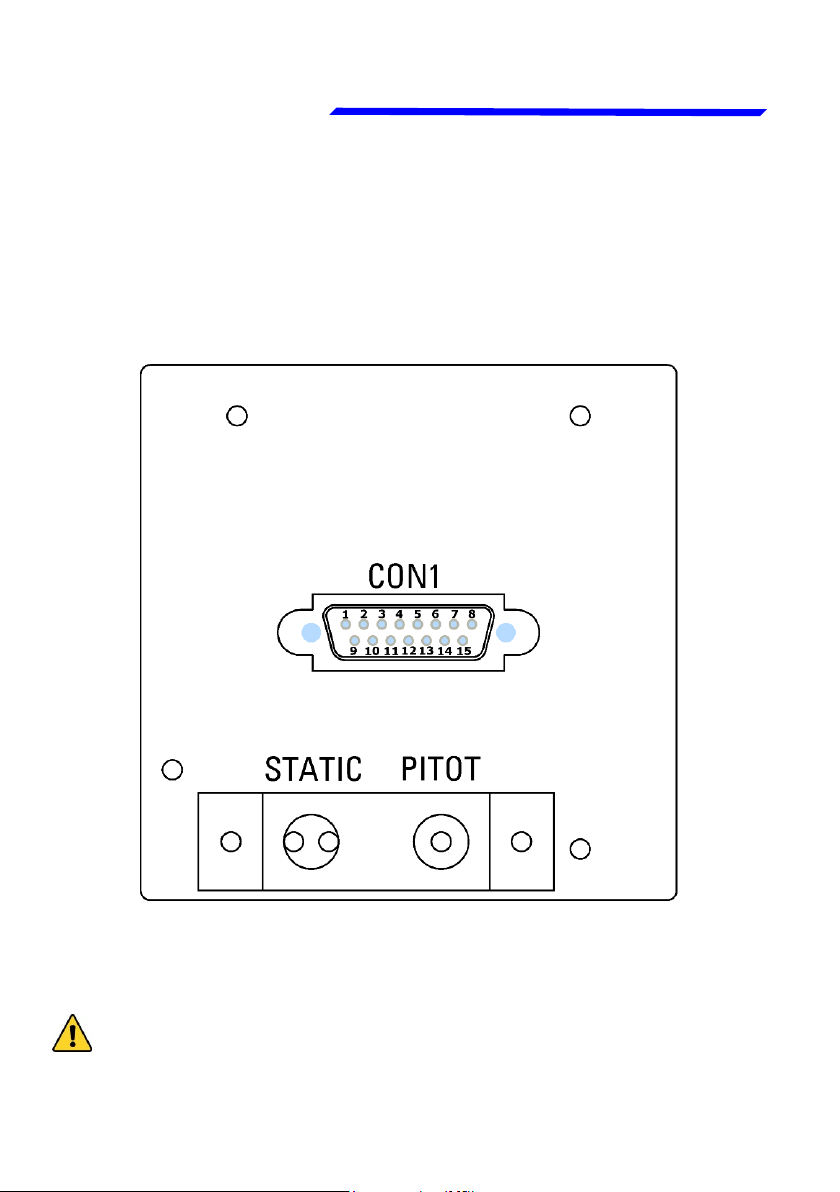

On the backpanel of the Oblò there is a 15 poles D-sub

plug connector, supplied with the corresponding 15-pole

receptacle, one static and one pitot port.

Use 1/8” NPT male fittings to connect the static

pressure (STATIC) and the dynamic pressure

(PITOT).

CAUTION: Don't blow air inside the fittings.

17

Rev.3.7

Page 18

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Standard Oblò installation

Electrical installation

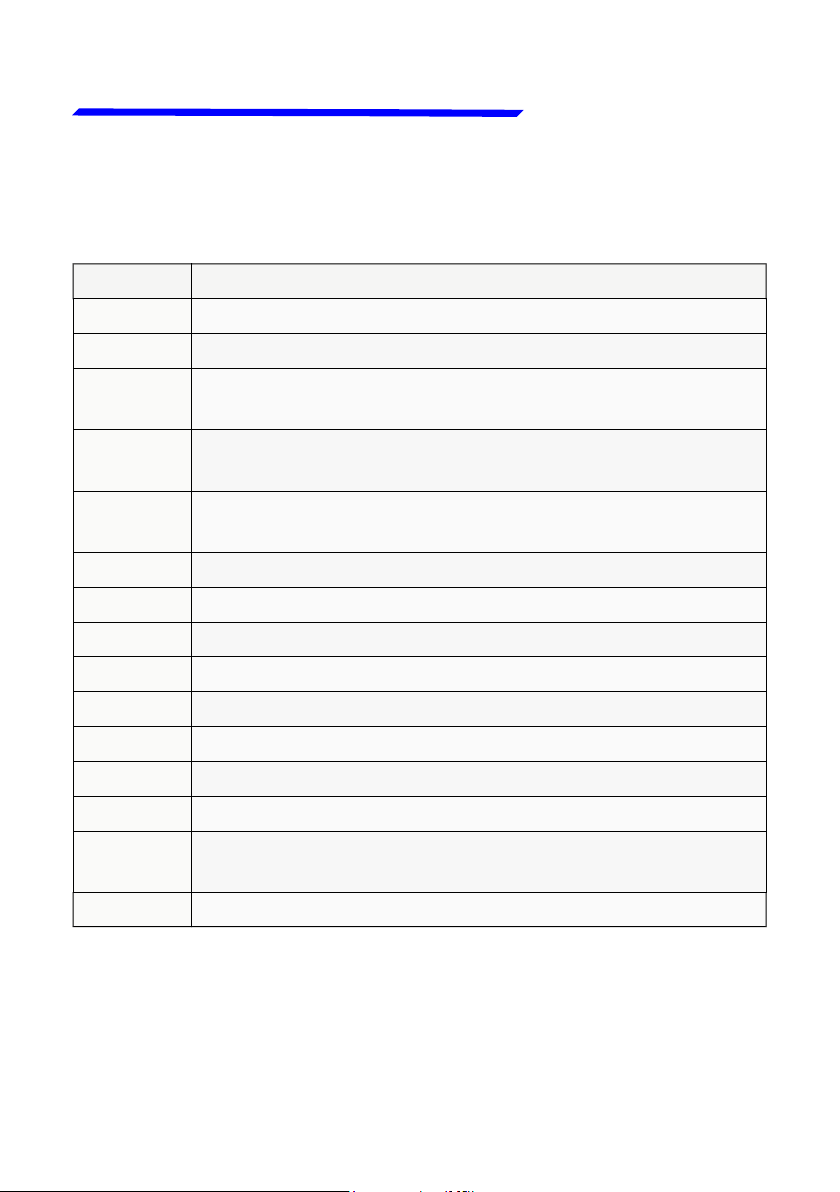

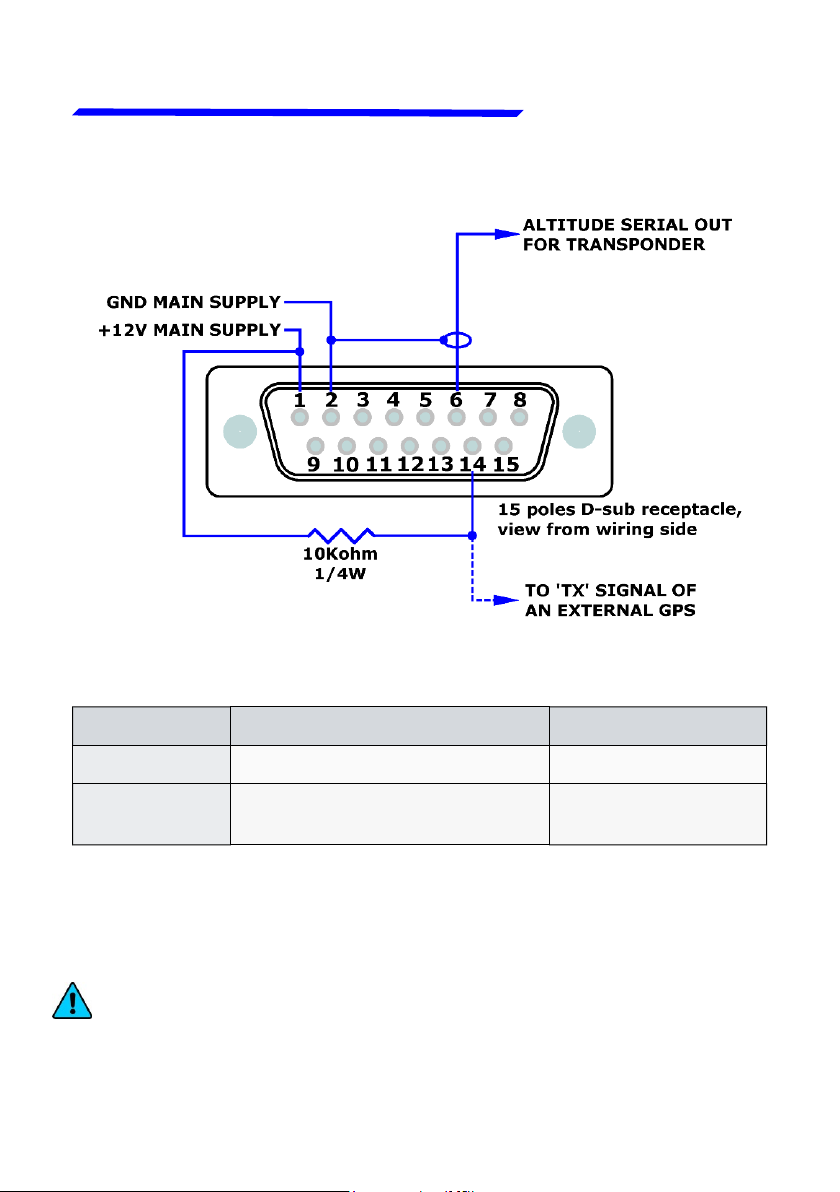

CON1 connector pinout

PIN# Description

1 +12V Main supply

2 GND Main supply

Flybox

3

4

5

6 Transponder altitude serial out (see chap.1.3)

7 Autopilot remote button (see chap.2.2)

8 Not used

9 USB-VCC

10 USB-D+

11 USB-D-

12 USB-GND

13 Low-level intercom audio out (see chap.2.2)

14 GPS input (connect to TX signal of an external GPS)

15 Not used

CAN H signal for autopilot control unit connection

(see chap.2.2)

CAN L signal for autopilot control unit connection

(see chap.2.2)

Open-collector alarm-out (active low) max 400mA /

5W (see chap.2.2)

18

Rev.3.7

Page 19

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Standard Oblò installation

Electrical installation

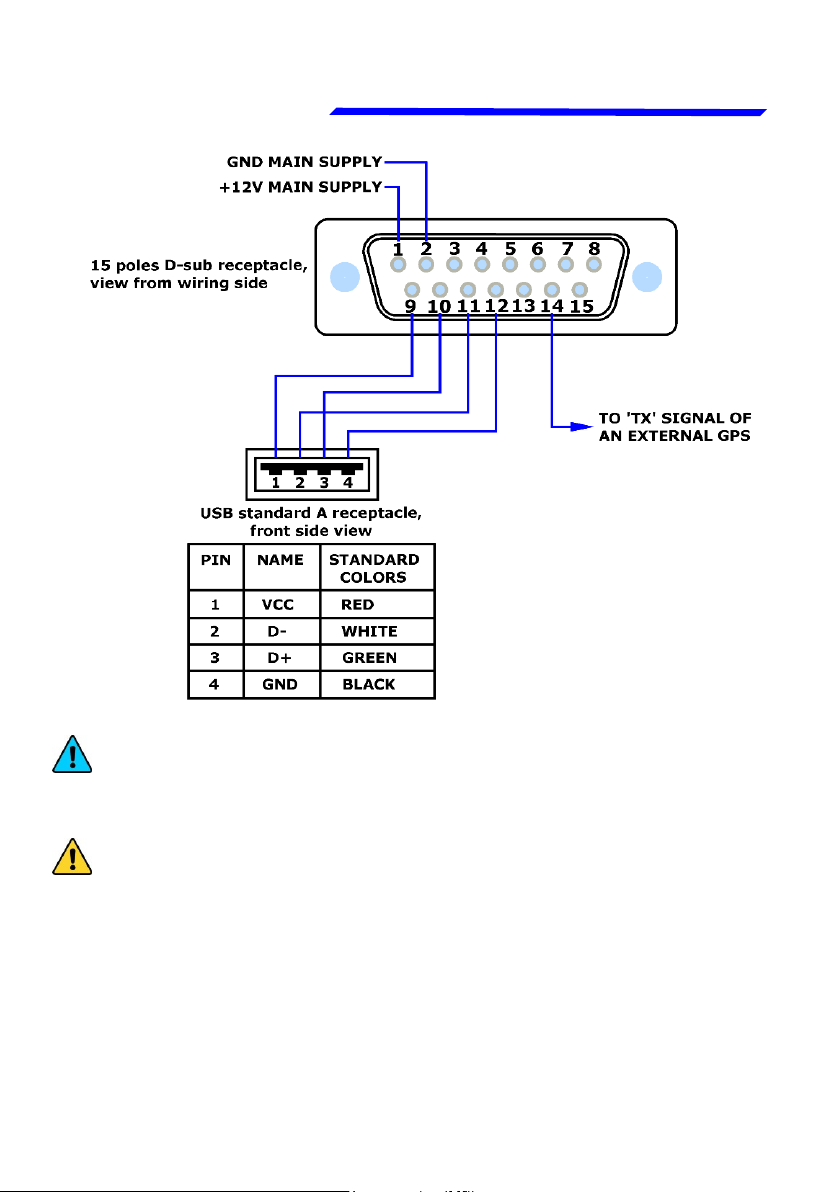

NOTE: Connections of pin#9-10-11-12 to a USB connector

is used for software upgrades and for datalogger function (in

development).

CAUTION: The connection of the external GPS is highly

recommended to increase the accuracy of the attitude

indicator. It is also required for the tracking indication and for

the automatic correction of magnetic declination.

If you connect a GPS that is not powered by the aircraft bus

(for example battery-powered), connect together the ground

of the GPS and of the Oblò. If no external GPS is available

use the Flybox® GPS cod. 810010.

19

Rev.3.7

Page 20

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Standard Oblò installation

Electrical installation

GENERAL WIRING HINTS:

- Take care to properly insulate any exposed wire to

avoid short circuits.

- Insert a 1-Ampere circuit breaker to the power lead

(+12V).

- Use aeronautic cable for the wiring.

CAUTION: Voltage peaks on the supply line that

exceeds the operating limits (20V) can damage the

device.

OPTIONAL ACCESSORIES AVAILABLE:

- Ready to use wiring (ord. cod. 802000).

- GPS receiver module (ord. cod. 810010).

- USB flash drive, for eventual software upgrades.

- Backup battery system (ord.cod. 810020).

NOTE: Visit our web page

http://www.flyboxavionics.it/en/oblo.html for updated

prices and informations.

20

Rev.3.7

Page 21

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Standard Oblò installation

Electrical installation

1.3 ALTITUDE SERIAL OUT FOR

TRANSPONDER CONNECTION

If you use a transponder with serial input for

receiving the altitude data, it can be connected to

the Oblò by following this steps:

- To enable the transponder output it's required to

connect a 10Kohm resistor between pin#1 and pin#14

(whether or not it's connected the external GPS on

pin#14).

- Ensure there is a shared ground between the Oblò and

the transponder.

- Wire a serial transmit line, using shielded cable, from

the Oblò (pin#6 of the connector) to the respective

receive connection on the transponder. The serial out

of the Oblò is RS232 type, refer to the transponder

manual for its installation and configuration.

21

Rev.3.7

Page 22

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Standard Oblò installation

Electrical installation

Connection of altitude serial out for transponder:

The Oblò does not require any configuration, the altitude data is

transmitted once per second with the followig protocol:

Baud Rate Message formatting Example

9600 bps

The message contains the current pressure altitude, in feet, with

a fixed reference to 1013.25mB (29.92 inches mercury). The

resolution is 10 ft.

NOTE: If you use the ready-to-use wiring (ord. cod. 802000 or

802010), the 10 Kohm resistor between pin#1 and pin#14 is

already fitted inside the connector housing of the wiring.

22

Alt,space,five altitude digits,

carriage return

Rev.3.7

ALT 05200 [CR]

Page 23

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Standard Oblò installation

Pre-flight check

1.4 PRIMARY ACTIONS AFTER

INSTALLATION

WARNING: Do not fly until you have performed at

least the actions indicated below:

1) Airspeed bar thresholds setting: It's essential to set

the airspeed thresholds (bar colors) according to the

V-speeds of the aircraft on which you installed the

instrument, as explained in chapter 4.2, section “ASI”.

Flying without correctly set this thresholds may be very

dangerous because the airspeed bar indicate the colors

relative to the various V-speeds incorrectly. The default

factory settings are all preset to zero.

2) Magnetic calibration: The magnetic calibration after

the installation of your Oblò is an essential procedure

that you must perform before you fly. Not only the

heading, but also the attitude indicator depends on a

correct magnetic calibration. Without it there is no data

stored for the magnetic sensors and the attitude

indicator, that use this data also, may not work correctly.

The magnetic calibration it's a simple procedure that is

explained in chapter 4.3.

23

Rev.3.7

Page 24

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Standard Oblò installation

Pre-flight check

3) Instruments panel pitch adjust: For the proper

operation of the attitude indicator it's necessary to

compensate the inclination of the instruments panel

regards the longitudinal axis of the aircraft, as explained

in chap.4.2, “Pitch” parameter.

24

Rev.3.7

Page 25

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

OBLÒ-A/P INSTALLATION

Oblò-A/P installation

Mechanical installation

SECTION 2

2.1 MECHANICAL INSTALLATION

- Mechanical installation of Oblò A/P is identical to the

standard Oblò (see chap.1.1) with the addition of:

- Mechanical installation of ACU autopilot control unit.

- Mechanical installation of servo/s.

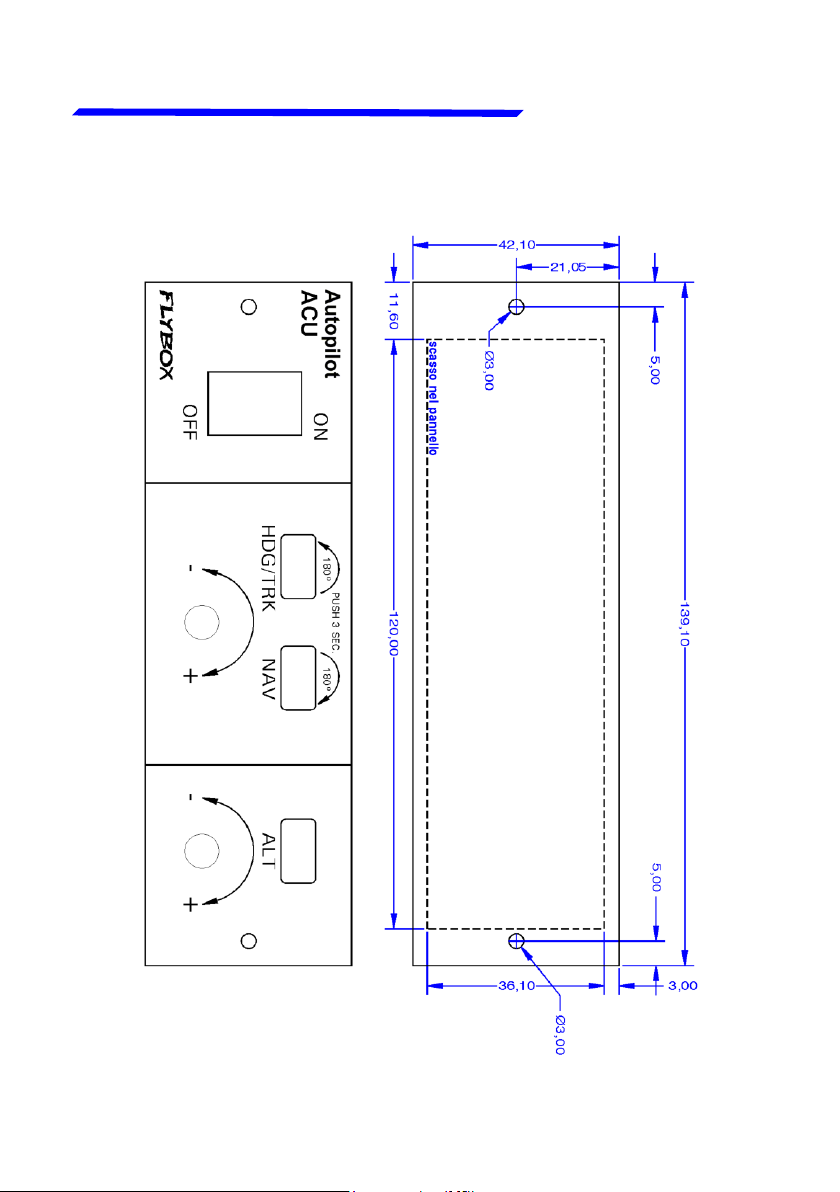

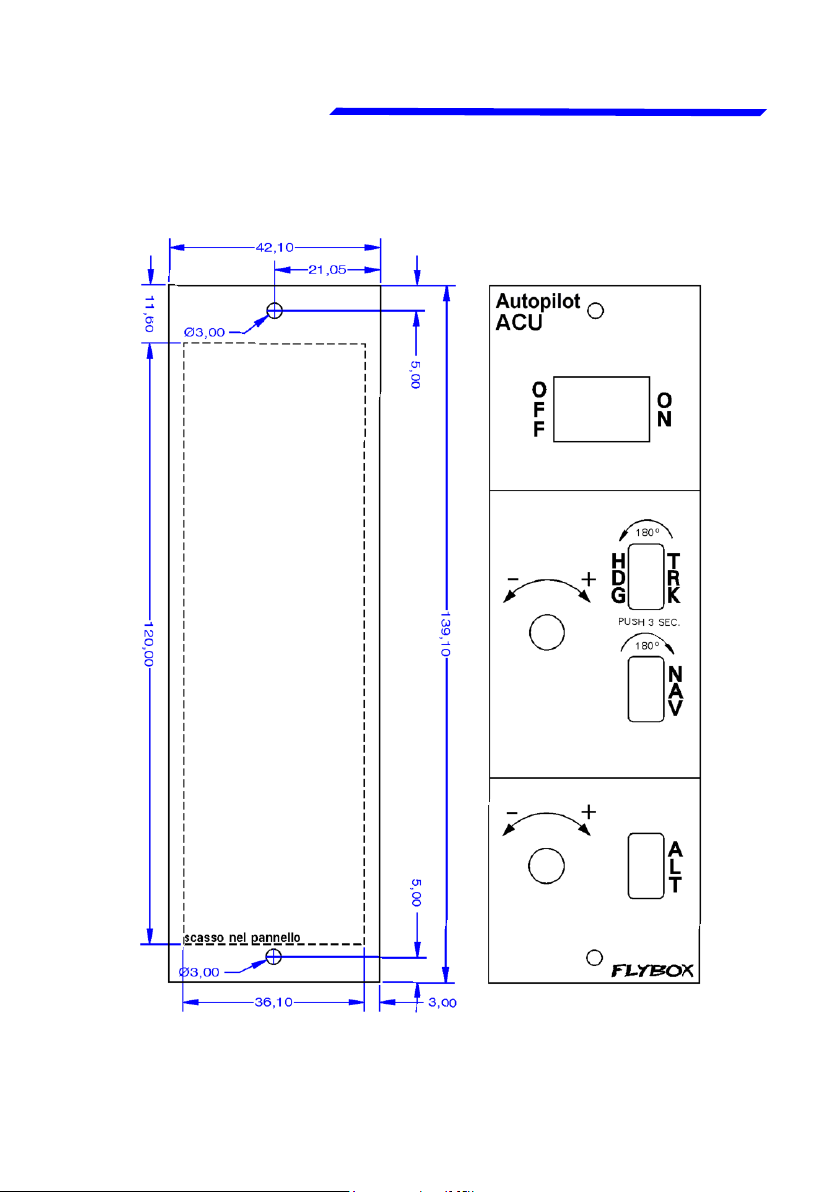

ACU AUTOPILOT CONTROL UNIT INSTALLATION

The ACU is available in two versions, for horizontal

or vertical mounting.

- Required panel cutout: 120 x 36.1 mm.

- Outer dimensions: 139.1 x 42.1 mm.

- Screw the ACU to the instruments panel with two M3

screws.

25

Rev.3.7

Page 26

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Oblò-A/P installation

Horizontal installation (dimensions in millimeters)

Mechanical installation

Flybox

26

Rev.3.7

Page 27

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Mechanical installation

Vertical installation (dimensions in millimeters)

Oblò-A/P installation

27

Rev.3.7

Page 28

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Oblò-A/P installation

Mechanical installation

SERVO/S INSTALLATION :

The Flybox FX75 digital servos incorporates

important safety features:

It has a reliable disengaging system: situations like

severe turbolence or something other kind of anomaly

will not be a problem, because the pilot can take in any

case the immediate control of the plane.

When the autopilot isn't engaged, the internal gears are

completely disconnected, then at difference as some

servomotors the pilot will not feel no residual torque at

the command stick, giving a confortable flight.

In case of mechanical failure, the gear train is

engineered to be reversible: the pilot can overtop the

power of the brushless motor, it provides to the

servomotor a further safety level.

Flybox

The output torque is electronically adjustable, and in

case of forced action from the pilot on the command

stick, the disengage will be without the breaking of a

shear pin (unlike other servomotors on the market that

use that mechanical safety system that after the break,

needs a remediation action to work again).

28

Rev.3.7

Page 29

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

A software function disengage the autopilot if the pilot

override the servo for more than 1 seconds.

It's recommended to install also the remote disengage

button, to have an immediate way to disengage the

autopilot even in presence of strong turbulence.

For installation instructions refer to the installation

manual, which is included with each servo.

Oblò-A/P installation

Mechanical installation

WARNING: improper installation of servos can lead to

loss of control of the aircraft, resulting in damage to the

aircraft itself and injury or death of the occupants.

BE SURE TO CAREFULLY FOLLOW THE

INSTALLATION INSTRUCTIONS, AND CONSULT A

QUALIFIED INSTALLER.

29

Rev.3.7

Page 30

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Oblò-A/P installation

Electrical installation

Flybox

2.2 ELECTRICAL INSTALLATION

AUTOPILOT SYSTEM INSTALLATION:

• To install the autopilot system, in addition to perform

the standard installation as described in chap.1.2, you

must also perform the following wirings:

- Oblò ==> ACU control unit

- ACU control unit ==> servo/s

• The ACU control unit has two Molex minifit-jr

connectors:

- 1 four-pole connector (here called “CON4P”).

- 1 eight-pole connector (here called “CON8P”).

Included in the kit there are the corresponding socket

connectors (Molex P/N: 5556-04R for 4-poles connector

and 5556-08R for 8-poles connector) and the crimp

terminals (Molex P/N: 5556-TL).

Each servos is provided with a 10-poles Molex Microfit

connector (Molex 43025-1000) and the corresponding

crimp terminals (Molex 43030-0007).

30

Rev.3.7

Page 31

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

The electrical installation consists of the following

wirings:

Oblò-A/P installation

Electrical installation

- 12 Volt power supply: the power supply input is in the

ACU control unit and power also the connected servos.

Use wire with adequate sizing to minimize voltage drop

and avoid that the wire become warm (recommended

size: AWG18).

CAUTION: Power must be supplied through a breaker

connected exclusively to the ACU control unit, easily

accessible to the pilot and clearly identified as

“Autopilot”. If you have one servo only use a 4 Ampere

breaker, if you have two servos use a 7.5 Ampere

breaker.

Wirings between ACU control unit and Oblò instrument:

1)

the ACU is connected to the Oblò with a two-wires CAN

bus communication line. Use a two-pole twisted cable

or a two-pole with shield cable (shield connected to

ground in one point only). AWG24 wires should be

enough.

Rev.3.7

31

Page 32

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Oblò-A/P installation

Electrical installation

Wirings of the servos: each servo need to be connected

2)

to the ACU control unit with two wires for the power

supply (use AWG18 wires) and need to be connected

to the CAN bus communication line using a two-pole

twisted cable or a two-pole with shield cable (shield

connected to ground in one point only). AWG24 wires

should be enough.

CAUTION: Do not route this line in parallel with

transmitting antennas or other sources of known RF

interference. Do not route this line in parallel with

microphone cables or audio cables to avoid audible

noise in headphones.

Flybox

Wiring of the remote disengage button

3)

(RECOMMENDED): connect it between ground and

pin#7 of the Oblò connector. The type of the button must

be NORMALLY OPEN (NO).

CAUTION:

- Care should be taken to avoid that the wiring is

subjected to chafing or excessive flexing.

- Avoid if possible junctions, that with excessive vibration

may be subjected to fail or short-circuit.

32

Rev.3.7

Page 33

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

CONNECTIONS DETAIL FOR ACU CON4P CONNECTOR

CONNECTIONS DETAIL FOR ACU CON8P CONNECTOR

Socket view (from wire’s

insertion side)

Pin# Descriprion

1 CAN bus communication line: CAN-H signal

2 +12V main supply

3 CAN bus communication line: CAN-L signal

4 GND main supply

Oblò-A/P installation

Electrical installation

Socket view (from wire’s

insertion side)

Pin# Descriprion

1 GND for Pitch Servo

2 Not used

3 GND for Roll Servo

4 Not used

5 +12V for Pitch Servo

6 Not used

7 +12V for Roll Servo

8 Not used

Rev.3.7

33

Page 34

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Oblò-A/P installation

CONNECTIONS DETAIL FOR FX75 SERVO CONNECTOR

Electrical installation

Socket view (from wire’s insertion side)

Pin# Descriprion

1 +12V power supply

2 Not used

3 Not used

4 CAN bus communication line: CAN-L signal

5 CAN bus termination

6 GND power supply

7 Not used

8 Not used

9 CAN bus communication line: CAN-H signal

10 CAN bus termination

Flybox

34

Rev.3.7

Page 35

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Electrical connections for autopilot system

Oblò-A/P installation

Electrical installation

*NOTE: If you use the ready-to-use wiring (ord. cod. 802010), the 120 ohm resistor

between pin#3 and pin#4 is already fitted inside the connector housing of the wiring.

35

Rev.3.7

Page 36

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Oblò-A/P installation

Electrical installation

NOTE: The CAN bus termination (pin#5 connected with

pin#10) must be done only on the last servo of the CAN

bus line. If you install only one servo, the CAN line must

be terminated on that servo.

Flybox

36

Rev.3.7

Page 37

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Oblò-REP installation

Mechanical installation

SECTION 3

3.1 OBLÒ-REP (REPEATER) INSTALLATION

Dimensions & mechanical installation of Oblò-REP

are the same of standard Oblò (see chap.1.1)

Electrical installation is different and depends if the

Oblò-REP is connected to a standard Oblò or if it is

connected to a Oblò-A/P with autopilot control unit and

servos. See next pages for the appropriate wiring

diagrams.

37

Rev.3.7

Page 38

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Oblò-REP installation

Electrical installation

3.1.1 ELECTRICAL INSTALLATION OBLÒ-REP

CONNECTED TO A STANDARD OBLÒ

38

Rev.3.7

Page 39

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

3.1.2 ELECTRICAL INSTALLATION OBLÒ-REP

CONNECTED TO A OBLÒ-A/P WITH AUTOPILOT

NOTE: The Oblò-REP share the same CAN bus line of

the autopilot system. It can be connected at any point

of the CAN bus line but the length of the wiring that

connects the Oblò-REP must be maximum 1 meter.

39

Rev.3.7

Page 40

Oblò / Oblò-A/P(Autopilot) User’s manual

®

USE

SECTION

Flybox

40

Rev.3.7

Page 41

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Main menu configuration

Instrument configuration

SECTION 4

4.1 MAIN MENU CONFIGURATION

Before using your Oblò you need to configure it;

read completely this chapter and follow step by step

the sections to fully configure it according to your

preferences.

Navigation through the menu is very simple and quick

and is performed with the knob:

- Press the knob for 1 second to enter in the functions

menu. The menu automatically disappears if you don't

press or rotate the knob for 5 seconds.

- Rotate the knob to navigate through the menu items.

- Press the knob to enter in the selected item.

- The first item on every menu (“Exit” or “Back”) is used

to exit the current menu and go back to the previous.

Rev.3.7

41

Page 42

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Instrument configuration

Main menu configuration

•

EXIT: exit the menu and returns to the

main screen.

ZERO PITCH: use this function only in

•

flight because it reset the pitch to the

actual attitude. Use only when the aircraft

is in leveled flight and at constant speed,

never use it to reset the horizon during

other flight attitude.

TRK or HDG: switch between Heading/Tracking compass

indications. (Tracking available only if an external GPS is

connected).

LIGHT: display brightness adjustment (1=min. brightness,

19=max. brightness). Default value=19.

SETUP: enter in the setup menu.

G-METER RESET: Show/reset g-meter. Turning the knob to

highlight this item will display the maximum and minimum peaks

of vertical acceleration.

Press the knob if you want to reset the two peaks.

42

Rev.3.7

Page 43

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

4.2 SETUP MENU CONFIGURATION:

EXIT: exit the menu and returns to the main screen.

T.R.I.: (Turn rate indicator) Click the knob to enter the

turn rate indicator configuration.

Instrument configuration

Setup menu configuration

The available settings are:

- Scale: set the full scale, in degrees/seconds. Default

value=6°/s.

- Filter: filter setting. A low value means that the

readings will be more fast and unfiltered (but subject to

fluctuations), an high value means that the readings will

be more slow and stable. Default value=80.

Rev.3.7

43

Page 44

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Instrument configuration

Setup menu configuration

BALL: (Slip indicator) Click the knob to enter the slip

indicator configuration.

The available settings are:

- Scale: set the full scale, in milliG. Default

value=300mG.

- Filter: filter setting. A low value means that the

readings will be more fast and unfiltered (but subject to

fluctuations), an high value means that the readings will

be more slow and stable. Default value=80.

ROLL: Click the knob to enter the roll scale

configuration.

The available settings are:

- Arc mode: Set the roll indicator mode: set to 1 to

choose a stationary roll scale (while the arrow moves

to stay perpendicular to the horizon). Set to 2 to choose

to rotate the scale while the arrow stay fixed at the

center.

Default value=1.

44

Rev.3.7

Page 45

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

- Adjust:

adjustment of the roll to compensate misalignments due

to installation. On the ground, with wings of the plane

perfectly leveled, rotate slowly the knob until the number

at the bottom become zero, then press it to store this

value. Turn off and on the instrument after storing a new

inclination value.

Default value=0°

PITCH: Click the knob to enter the pitch axis

configuration.

The available setting is:

- Adjust: adjustment of the pitch to compensate the

inclination of the instruments panel regards the

longitudinal axis of the aircraft. This function must be

executed only once after installation, on the ground, in

leveled attitude.

Read the number printed on the bottom of the display

and copy the same value on this parameter by clicking

the knob and rotating it. For example if the number

printed on the bottom is -3.6° rotate the knob to the left

to set exactly -3.6°. If the number printed on the bottom

is +1.2° rotate the knob to the right to set exactly +1.2°.

Click the knob to store the value and turn off and on

again the instrument.

Default value=0°.

Instrument configuration

Setup menu configuration

45

Rev.3.7

Page 46

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Instrument configuration

Setup menu configuration

ASI: Click the knob to enter the airspeed indictor

configuration.

The available settings are:

- Vne-Vno-Vfe-Vs-Vs0: Set the speed setpoint for the

moving tape airspeed indicator. Default value=0 Km/h.

NOTE: Before setting these thresholds you must

choose the unit of measure (see next parameter).

Vne

Vno

Vfe

Vs

Vs0

(Velocity Never Exceed)

(Velocity Normal Operation), maximum structural

cruising speed.

(Velocity with Flaps Extended), maximum

airspeed at which you may extend the flaps, or fly

with them extended.

(Velocity of Stall), power off stalling speed with the

gear and flaps retracted.

(Velocity Stall 0), power off stalling speed with

gear and full flaps extended.

If you prefer the clean transition from white to green

zone set the same value on Vs and Vfe.

46

Rev.3.7

Page 47

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Instrument configuration

Setup menu configuration

- Unit: Set the unit of measure for the airspeed indicator

in kilometers per hour (Km/h), miles per hour (Mph) or

knots (Kts). Default value=Km/h.

- Filter: filter setting. A low value means that the readings

will be more fast and unfiltered (but subject to

fluctuations), an high value means that the readings will

be more slow and stable.

Default value=90.

ALT/VSI: Click the knob to enter the altimeter and

vertical speed indicator configuration.

The available settings are:

- Oxygen: Set the max altitude above which the altitude

tape turns red to indicate the hazardous condition.

Default value=12000 Ft.

- Alt unit: Set the unit of measure for the altimeter in

meters (Mt) or feets (Ft). Default value=Ft.

- Baro unit: Set the unit of measure for pressure

reference in hectoPascal (hPa) or inches of mercury

(inHg).

- Alt Filter: altimeter filter setting. A low value means

that the readings will be more fast and unfiltered (but

subject to fluctuations), an high value means that the

readings will be more slow and stable. Default value=90.

47

Rev.3.7

Page 48

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Instrument configuration

Setup menu configuration

- Vsi Filter: vertical speed indicator filter setting. A low

value means that the readings will be more fast and

unfiltered (but subject to fluctuations), an high value

means that the readings will be more slow and stable.

Default value=95.

AUTOPILOT:(Only for autopilot enabled Oblò) see 6.2

G-METER: Click the knob to enter the g-meter indicator

configuration.

The available settings are:

- Filter: filter setting. A low value means that the

readings will be more fast and unfiltered (but subject to

fluctuations), an high value means that the readings will

be more slow and stable.

Default value=50.

- Refresh:

with this parameter you can choose the display update

rate between 1 (1 display refresh per second) and 3 0

(30 display refresh per second).

Default value=2.

- Max: Show the maximum peak reached by the g-meter.

- Min: Show the minimum peak reached by the g-meter.

- Reset min/max: Click the knob after selecting this item

to reset the maximum and minimum peaks of the

g-meter.

48

Rev.3.7

Page 49

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

GPS: Click the knob to enter the external GPS

configuration (if connected).

The available settings are:

- Baud: Set the baud rate of the external GPS.

Default value=4800 bps.

- Utc: To check if the GPS is properly connected and the

baud rate is correct verify that this indication provides

the UTC time.

If it shows –:-- it means that the GPS is not connected

or setup correctly.

- Satellites: To check if the reception is good (and

therefore also to know if you have choosen a good

location where to install the GPS) read the number of

satellites indicated: the higher the number, the better

the reception. For a good reception at least 4 satellites

should be indicated.

Instrument configuration

Setup menu configuration

CAUTION: In case of communication problems between

GPS and Oblò check the following settings on the

external GPS:

- Baud rate/communication speed: must be set to the

same value as that set in the Oblò.

- Data protocol: must be set to NMEA.

- Enabled messages: must be enabled on the GPS the

$GPRMC e $GPGGA messages (standard messages

that every GPS should transmit). If you want to use the

HSI page or if you have installed the autopilot system

and you want to use the “navigation to a waypoint”

function, it must be enabled also the $GPRMB message.

49

Rev.3.7

Page 50

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Instrument configuration

XTE window

Setup menu configuration

HSI: Click the knob to enter the HSI (Horizontal Situation

Indicator) configuration menu.

The available settings are:

- XTE win.: Set the window amplitude of the cross track

error indicators (the XTE window is measured from the

two external dots). Default=1.0 Km.

- Unit: Set the unit of measure for the indications on the

HSI page. Choose between kilometers (KM), Nautical

miles (NM) or Miles (MI). Default=KM.

COMPASS: Click the knob to enter the compass

configuration. The available settings are:

- Auto H/T: YES/NO. Set to “YES” to enable tha automatic

switch between heading and tracking. In this mode if the

actual speed is below the speed set in the next parameter

the compass is set to heading; when the actual speed is

higher the compass is set to GPS tracking.

This feature is useful to automatically switch from magnetic

heading when you are in ground to GPS tracking, with wind

correction, when you are in flight. Default value=YES.

- Speed: Set the speed for the automatic switch between

heading and tracking (see previous item). Default value=60

Km/h.

- Calibration: Magnetic calibration. See next chapter.

- Mag.Dec.: Displays the magnetic declination of the actual

place (the indication appear only with the GPS connected).

50

Rev.3.7

Page 51

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

ADI: Click the knob to enter the attitude director indicator

setup. The available settings are:

- Mode: 1 / 2 / 3. There are three different display mode

of the indicator:

MODE 1 MODE 2 MODE 3

CONFIG: Click the knob to enter the configurations

menu. The available configurations are:

- Start page: Set the start page (on instrument turn-on).

Choose between the attitude indicator page (HOR), the

HSI page (HSI) or the drum altimeter page (ALT).

Default=HOR.

- Return delay: Set the auto return to the start page

after the time, in seconds, set here. Set to zero to disable

the auto return. Default=0.

Instrument configuration

Setup menu configuration

- Knob: Set the operating mode of the knob. Rotate the

knob to select the submenu called “Menu DN” and click

to enter. The available settings are:

- CCW: select this mode to set that by turning the knob

counter-clockwise you move down in the menus.

- CW: select this mode to set that by turning the knob

clockwise you move down in the menus.

51

Rev.3.7

Page 52

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Instrument configuration

Setup menu configuration

ABOUT: On this screen it’s possible to read current

software versions, useful to check if your Oblò is

updated to the latest version. The version number to

check is in the first row, indicated after the word “CORE”.

Check frequently our web site www.flyboxavionics.it to

see if there are any software updates.

NOTE: this manual is referred to the software version

indicated on the first page.

FW UPGRADE: Menu for USB software upgrade. If you

want to upgrade to a newer version, (see previous item

to check the actual software version) after selecting

this item keep pressed the knob for 2 seconds until the

following screen appears:

- Insert the USB flash drive on which you copied the

updated software and select if you want to upgrade the

Oblò (by selecting ”CORE”) or if you want to upgrade

the roll or pitch servo (by selecting “RSU” or “PSU”).

To upgrade all select “Upgrade All”.

If you have the Oblò standard without autopilot, you can

only upgrade the instrument itself by selecting the

“CORE” item.

52

Rev.3.7

Page 53

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Instrument configuration

4.3 MAGNETIC CALIBRATION

Oblò integrates the magnetic sensors for the heading

indication. The sensors are affected by all magnetic

fields present around them, which, if ignored, can lead

to considerable errors in the heading indication.

Magnetic fields are generated for example by ferro

magnetic materials (iron, ferrites), large electric current

in cables, electric motors; if possible it's recommended

to avoid installation of the instrument near these source

of magnetic fields.It's possible to compensate for weak

static magnetic fields by performing the calibration as

explained below. Please note that in particular cases

(presence of strong magnetic fields) may be insufficient

to perform this calibration; in this case the heading

provide incorrect or approximate indications and it's

necessary to install an external remote magnetometer

(in development).

CAUTION: Before using Oblò in flight it's necessary to

perform the magnetic calibration to obtain a correct

indication of the heading.

53

Rev.3.7

Page 54

Oblò / Oblò-A/P(Autopilot) User’s manual

®

Instrument configuration

Magnetic calibration

The calibration must be performed after the

installation is complete, by following this steps:

Turn on the engine and go in a place far from

1)

possible magnetic fields (metallic shed, concrete

floors with metal armatures, etc..) and where is

possible to execute more turn with the aircraft (on

the ground).

Turn on all the electric load usually used in flight.

2)

On the Oblò enter in the Setup-->Compass and

3)

select the “Calibration” item. Keep pressed the knob

for 3 seconds to enter in the calibration.

Flybox

Now the display show “PUSH TO START

4)

CALIBRATION”: briefly press the knob to start

calibration (if you want to cancel and return to the

previous menu keep pressed the knob for 3

seconds).

Wait the indication “MAKE A 420 DEGREE

5)

CLOCKWISE CIRCLE SLOWLY” on the display

then start, with the aircraft on ground, a

continuous slow circular movement toward right.

54

Rev.3.7

Page 55

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

In the center of the display appear a number that

6)

Instrument configuration

Magnetic calibration

indicate the rotation degrees, that starting from

zero increase during the rotation of the aircraft.

Continue the slow circular movement: the

calibration end automatically when the number

reach a value of 420 and the indication

“CALIBRATION DONE PUSH TO EXIT” appear

on the display.

Now you can press the knob to terminate the

calibration.

IMPORTANT: To complete the 420 degrees turn

required for the calibration you must take from 1 to 2

minutes.

After completing the calibration perform this check: with

7)

the Oblò displaying the heading turn the aircraft exactly

at North, South, West and East verifying the correct

indication on display. If external GPS is connected you

will automatically obtain the magnetic declination

correction.

55

Rev.3.7

Page 56

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Using the Oblò

SECTION 5

5.1 USING THE OBLO’

The Oblò is organized in 3 different pages:

• Attitude indicator page

• HSI (Horizontal Situation Indicator) page

• Drum altimeter page

By default, after power-on the Oblò shows the attitude

indicator page, but you can set your preferred start page

by going in the Setup menu → Config → Start page.

To switch between the pages you need to “fast rotate”

the knob: fast rotate the knob clockwise to switch from

attitude indicator page to HSI page and from HSI page

to drum altimeter page; fast rotate the knob

counterclockwise to go back in reverse order.

The “fast rotate” of the knob is thought to avoid

involuntary page change.

You can also set a time to automatically return to the

start page after you have switched to another page (See

Setup menu → Config → Return delay).

56

Rev.3.7

Page 57

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

5.1.1 ATTITUDE INDICATOR PAGE:

SLIP INDICATOR

TURN

RATE

AIRSPEED

G-METER

COMPASS

ATTITUDE

INDICATOR

ALTIMETER

PRESSURE

REFERENCE

VERTICAL SPEED

INDICATOR

COMPASS: Placed in the lower part of the screen, the

heading/tracking indication is represented with the numerical

indication at the center of the graphics. The four cardinal

points are shown as N , S , W , E.

- It can show the HEADING (magnetic compass, indicated

with “HDG”) or the TRACKING (Track of the GPS, indicated

with “TRK”, available only if an external GPS is connected).

- Note that after power-on the compass is set to heading and

can automatically switch to tracking above a certain speed

if you enable the “Auto H/T” function in the compass setup

menu (see chap.4.2).

- It's however possible to manually switch between the two

indications: keep pressed the knob for 1 second and in the

menu that appear choose “HDG” or “TRK”.

57

Rev.3.7

Page 58

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Using the Oblò

Attitude indicator page

• The HEADING is valid either stationary or moving and

during aircraft turns the indicator is fluid and continuous.

It compensate for aircraft attitude so that the indication

is valid also with pitch or roll inclination. If external GPS

is connected you will automatically obtain the magnetic

declination correction.

• The TRACKING is read from external GPS receiver

and is usually updated once per second, so in case of

fast turns it may not have a continuous and fluid

indication. Provided that GPS receiver have a good

satellites reception, the tracking indication is very

accurate and compensated from wind.

NOTE: The GPS tracking is not valid when stationary

or for speed below 20 km/h.

58

Rev.3.7

Page 59

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

TURN RATE: Graphical indications of the turn rate. To

set the full scale go in the Setup menu-->T.R.I.-->Scale

(see chap.4.2).

AIR SPEED: The Air speed is represented with both

tape and numeric indicator. The unit of measure can be

km/h, Mp/h or knots. The range of measure is from 30

to 650 km/h (16~350 knots or 18~403 mph). Below air

speed of 30 km/h the indication remain fixed to zero.

To set the unit of measure and the speed thresold that

define the coloured zone go in the Setup menu-->ASI

(see chap.4.2).

ATTITUDE INDICATOR: With 360° continuous

operation in both pitch and roll. Above and below the

horizon line, major pitch marks are shown for every 10°,

up to +/- 40°. Minor pitch marks are shown for every 5°.

Using the Oblò

Attitude indicator page

The roll scale show inclinations from -60 to +60°; mark

lines are shown for the following inclination:

0° - 10° - 20° - 30° - 45° - 60°.

59

Rev.3.7

Page 60

Oblò / Oblò-A/P(Autopilot) User’s manual

®

-60°

-45°

-30°

-20°

-10°

10°

20°

30°

45°

60°

Using the Oblò

Attitude indicator page

Horizon zero

Flybox

Roll scale zero

The colors used for the attitude indicator are brown for

the ground and sky blue for the sky. The zero is

represented by the yellow line.

60

Rev.3.7

Page 61

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

IMPORTANT NOTES ON USING ATTITUDE

INDICATOR:

The attitude indicator may loose accuracy during the

flight for the following causes:

Using the Oblò

Attitude indicator page

- During uncoordinated, accentuated or acrobatics

maneuvers.

- Rapid temperature changes or temperature outside

the operating limit (-20°C~+70°C).

• Never use the attitude indicator as a reference for flight

manoeuvres.

• Never use the attitude indicator as a reference in

absence of visibility.

NOTE: This instrument is not certified.

61

Rev.3.7

Page 62

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Using the Oblò

Attitude indicator page

SLIP INDICATOR: It's a graphic indication of the lateral

accelerations.

ALTIMETER: It include both a tape indicator and a

numeric indicator. The unit of measure can be feets or

meters, the range of measure is -1000~25000 feets

(-300~ +7600 m). On the tape indicator the thousands

digits are shown every 500 (i.e. 1500,2000, etc..) while

the numeric indications is always displayed completely.

- To change the PRESSURE REFERENCE click the

knob and then rotate it to change the numerical value;

click again to store the new reference.

VERTICAL SPEED INDICATOR: Displays the

numerical indication (absolute value). The unit of

measure is meters per second if altimeter is set in

meters or feet per minute if the altimeter is set in feet.

The arrow pointing up indicate an ascent (positive

value), the arrow pointing down indicate a descent

(negative value).

G-METER: Indicate the vertical acceleration in g; it

display also an upward arrow during positive

accelerations or a downward arrow during negative

accelerations.

The g-meter has a memory for storing the maximum and

minimum acceleration peaks: to see them entern in the

function menu by pressing the knob for 1 second and

then select the item “G-meter reset”.

62

Rev.3.7

Page 63

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

CAUTION: If the instrument's internal temperature

exceeds the maximum allowed (70°C) it appears to

display the message “SENSOR TEMPERATURE OUT

OF HIGH LIMIT”. High temperatures can be reached for

example if the aircraft is parked in the sun without any

instruments panel protection. In this case to decrease

the temperature it's sufficient to ventilate the instruments

panel.

If the temperature exceeds the minimum allowed (-20°C)

it appears to display the message “SENSOR

TEMPERATURE OUT OF LOW LIMIT”. In both cases

the data provided by the instrument may be not reliable.

It's possible to check the instrument's internal

temperature on the “About” menu (“Int. Temp” item).

Using the Oblò

Attitude indicator page

63

Rev.3.7

Page 64

Oblò / Oblò-A/P(Autopilot) User’s manual

®

5.1.2 HSI PAGE:

ACTUAL HEADING

OR TRACKING

Flybox

COMPASS BUG

COURSE

POINTER

DESTINATION

WAYPOINT ID

GROUND SPEED

COURSE

DISTANCE TO GO

CROSS TRACK

ERROR

The HSI (Horizontal Situation Indicator) page reduces pilot

workload by providing heading/tracking, course reference,

course deviation and other navigation aid. In order to work,

the HSI page needs that the Oblò is connected to an external

GPS navigation system, in which a flight plane, route or

GOTO has been set.

The available indications are the followings:

● ACTUAL HEADING OR TRACKING: It can shows the

HEADING (magnetic compass, indicated with “HDG”) or

the TRACKING (Track of the GPS, indicated with “TRK”).

Note that after power-on the compass is set to heading

and can automatically switch to tracking above a certain

speed if you enable the “Auto H/T” function in the

compass setup menu (see chap.4.2).

COURSE

DEVIATION

INDICATOR

TIME TO GO

64

Rev.3.7

Page 65

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Using the Oblò

HSI page

During the flight is possible to manually switch between

the heading or the tracking: keep pressed the knob for 1

second and in the menu that appear choose “HDG” or “TRK”.

● COMPASS BUG: The compass bug can be freely moved by

the pilot by clicking the knob and rotating to select a new

heading/tracking. If it’s installed the optional autopilot system

and you start a navigation on it, the bug will be coupled to

the autopilot.

● COURSE POINTER: This pointer indicates the currently

selected course (it is automatically programmed by the GPS

route).

● COURSE DEVIATION INDICATOR: The CDI indicates how

far to the left or right you are from the selected course. A

series of "dots" provides a linear indication of how far the

aircraft is "off course". To set the full scale of the dots, go in

the setup menu → HSI → XTE win parameter.

● DESTINATION WAYPOINT ID: It shows the name of the

destination waypoint, if transmitted by the GPS navigator. If

no information is received this field is left blank.

● DISTANCE TO GO: It shows the distance from your aircraft’s

position to the next waypoint (in kilometers (KM), Nautical

miles (NM) or Miles (MI), depending on what you have set

on the HSI setup menu).

● TIME TO GO: It shows the time needed to reach the next

waypoint.

● GROUND SPEED: It shows the ground speed (this data is

received from the GPS).

● COURSE: It shows the course to mantain to reach the

waypoint.

65

Rev.3.7

Page 66

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

● CROSS TRACK ERROR: It shows the numerical indication

of the deviation from the selected course (in kilometers (KM),

Nautical miles (NM) or Miles (MI), depending on what you

have set on the HSI setup menu).

5.1.3 DRUM ALTIMETER PAGE:

PRESSURE

REFERENCE

(hPa)

PRESSURE

REFERENCE

(InHg)

This page simulates the graphic of a traditional drum altimeter.

To change the PRESSURE REFERENCE click the knob and

then rotate it to change the numerical value; click again to

store the new reference. The settable pressure reference is

the one corresponding to the unit of measure setted on the

Setup menu → ALT/VSI → Baro unit.

66

Rev.3.7

Page 67

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Autopilot system

SECTION 6

6.1 AUTOPILOT SYSTEM

REQUIREMENTS:

The following components are required for the autopilot

to function:

- Flybox® Oblò-A/P instrument or Oblò with autopilot

function enabled (see chap.7.6).

NOTE: Upgrade your Oblò to the latest version before

using the autopilot function (check web site

http://www.flyboxavionics.it/en/software-updates.html)

- Autopilot Control Unit (Flybox® ACU).

- 1 Flybox® FX75 digital servo for roll control.

- 1 Flybox® FX75 digital servo for pitch control.

67

Rev.3.7

Page 68

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Autopilot system

Autopilot overview

AUTOPILOT OVERVIEW:

The autopilot system can use 1 or 2 servos, that need

to be connected to the control stick for roll and pitch

control.

The available functions are:

Horizontal navigation (roll axis control):

- Magnetic heading hold.

- GPS tracking hold.

- Track to a waypoint (GOTO function, require an

external GPS with NMEA messages $GPRMC

$GPRMB $GPGGA).

- Track a flight plane (require an external GPS with

NMEA messages $GPRMC $GPRMB $GPGGA).

Automatic course reversal (180°).

Vertical navigation (pitch axis control):

- Altitude hold.

- Altitude change.

68

Rev.3.7

Page 69

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

HDG/TRK knob for

heading/tracking

setting

Autopilot system

Autopilot overview

ON/OFF

switch

ON led indicator

“HDG/TRK” button with led

(led on when autopilot is

engaged in HDG/TRK mode)

“NAV” button with led

(led on when autopilot is

engaged in NAV mode)

ALT knob for

altitude setting

“ALT” button with led

(led on when autopilot is

engaged in ALT mode)

- Use the ON/OFF switch to turn on and off the autopilot

control unit.

- Press the “HDG/TRK” button to engage/disengage the

autopilot in heading or GPS tracking mode.

- Rotate the “HDG/TRK” knob to adjust the

heading/tracking bug. Press the knob to center the bug

to the actual heading or GPS tracking.

- Press the “ALT” button to engage/disengage the

autopilot in altitude hold mode.

- Rotate the “ALT” knob to adjust the altimeter bug.

Press the knob to center the bug to the actual altitude.

- Press the “NAV” button to engage/disengage the

autopilot in flight plane or goto navigation.

69

Rev.3.7

Page 70

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Autopilot system

Autopilot overview

REMOTE DISENGAGE BUTTON:

It's recommended to install also the remote disengage

button, that operate in this way:

- With autopilot engaged: push shortly to disengage.

- With autopilot disengaged: push for 2 seconds to

engage it. This function must be enabled from menu:

Setup → Autopilot → Remote button → HtoE enable

(see chap.6.3.4).

- With autopilot engaged: keep pressed for more than 2

seconds to activate the Control Wheel Steering (CWS)

mode: it's possible to fly the aircraft to a new

heading/traking or altitude and then release the button

to let the autopilot acquire and mantain the new

values. This function must be enabled from menu:

Setup → Autopilot → Remote button → CWS enable

(see chap.6.3.4).

70

Rev.3.7

Page 71

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Autopilot configuration

6.2 AUTOPILOT SYSTEM CONFIGURATION

After the physical installation of the autopilot system it's

required to check the connections and configure the

parameters, as explained in the following two chapters.

The operations that you will perform in sequence are

the following:

Ground based test and configuration:

- Servos calibration (chap.6.2.1)

- Communications check (chap.6.2.2)

- Remote button operation check (chap.6.2.3)

- Servos torque check (chap.6.2.4)

- “Min speed” and “Max speed” parameters setting (chap.6.3.1)

- Roll servo setup (chap.6.3.2)

- Pitch servo setup (chap.6.3.3)

- Remote button setup (chap.6.3.4)

Flight based test and configuration:

- Autopilot setup – roll axis (chap.6.4.1)

- Autopilot setup – pitch axis (chap.6.4.2)

71

Rev.3.7

Page 72

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

6.2.1 SERVO/S CALIBRATION

Autopilot configuration

The servo/s calibrations is GROUND BASED.

The calibration procedure is mandatory: if you try to

engage the autopilot without first calibrate the servo, the

Oblò will show the error message “AUTOPILOT

DISENGAGE! ROLL/PITCH SERVO CALIB”.

THE CALIBRATION MUST ALSO BE REPEATED IN

THE EVENT OF ANY CHANGES TO MECHANICAL

INSTALLATION OF THE SERVO/S.

NOTE: The “neutral position” terms used in the

following explanation means the center of the servo

arm travel relative to the position of the limiting

bracket:

72

Rev.3.7

Page 73

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

To begin the calibration procedure:

- Press for 1 second the knob to enter in the function

menu.

- Rotate the knob to select the “Setup” menu and click

to enter.

- Rotate the knob to select the “Autopilot” menu and click

to enter.

- Rotate the knob to select the “Servo(s) calib”.

- Press the knob for 3 seconds until the display shows

the word “IDENTIFICATION”. If instead it was already

made a previous calibration, the display shows the data

of the previous calibration as in example below:

Autopilot configuration

Servo/s calibration

NOTE: If appears the message “NO SERVO(S)

FOUND” it means that the servos are not properly

connected.

73

Rev.3.7

Page 74

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Autopilot configuration

Servo/s calibration

- Press the knob to start the calibration and follow the

onscreen instructions; for example if you have installed

the servos on both roll and pitch axis the complete

procedure will be as follows:

● Step#1: center the control stick in neutral position and

then click the knob to go to the next step.

● Step#2: position the control stick to the left limit (without

forcing), paying attention to not move it in the pitch axis

during the motion. After doing so, the calibration

automatically switch to the next step:

● Step#3: center the control stick in neutral position and

then click the knob to go to the next step.

● Step#4: position the control stick to the forward limit

(without forcing), paying attention to not move it in the

roll axis during the motion. After doing so, the calibration

automatically switch to the next step or, if you have not

installed the pitch servo, click the knob to go to the

next step.

● Step#5: center the control stick in neutral position and

then click the knob to go to the next step.

74

Rev.3.7

Page 75

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

● Step#6: position the control stick to the left limit (without

forcing).

Click the knob or the remote button to store the position

and go to the next step.

● Step#7: position the control stick to the right limit (without

forcing). Click the knob or the remote button to store the

position and go to the next step.

NOTE: If appears the message “BAD MECHANICAL

INSTALLATION! NOT ENOUGH SERVO TRAVEL” it

means that the servo is not correctly installed, as the travel

of the servo arm is too small to function properly. In this

case you should modify the mechanical installation, for

example by using an outer hole of the servo arm.

Autopilot configuration

Servo/s calibration

● Step#8: position the control stick to the forward limit

(without forcing).

Click the knob or the remote button to store the position

and go to the next step.

● Step#9: position the control stick to the backward limit

(without forcing). Click the knob or the remote button to

store the position and end the calibration.

75

Rev.3.7

Page 76

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Autopilot configuration

Servo/s calibration

NOTE: If appears the message “BAD MECHANICAL

INSTALLATION! NOT ENOUGH SERVO TRAVEL” it

means that the servo is not correctly installed, as the travel

of the servo arm is too small to function properly. In this

case you should modify the mechanical installation, for

example by using an outer hole of the servo arm.

At the end of the calibration procedure the display

briefly shows the confirmation message “Servo Calib

Done”.

To exit the calibration menu keep pressed the knob

for 3 seconds.

76

Rev.3.7

Page 77

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

SERVO/S CALIBRATION CHECK

WARNING: Once finished the calibration you must

execute this check (ground based):

- With the Oblò and ACU control unit turned on, insert

the autopilot on roll axis by pressing the “ H D G / T R K ”

button on the ACU. Rotate clockwise the HDG/TRK

knob (so that the heading bug is at the right of the actual

heading) and check that the flight control move as to

turn the aircraft right.

Rotate counter clockwise the HDG/TRK knob (so that

the heading bug is at the left of the actual heading) and

check that the flight control move as to turn the aircraft

left.

Check also that the servo pitch does not move.

Autopilot configuration

Servo/s calibration

- Engage the autopilot on pitch axis by pressing the

“ALT” button on the ACU. Using the ALT knob set the

altitude bug to a higher value than the actual altitude

and check that the flight control move as to increase the

aircraft altitude; set the altitude bug to a lower value than

the actual altitude and check that the flight control move

as to decrease the aircraft altitude.

If movement direction of one or both servos is

reversed it means that the calibration is wrong, so

NEVER ENGAGE THE AUTOPILOT IN FLIGHT but

repeat the servos calibration procedure and check

again.

Rev.3.7

77

Page 78

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

6.2.2 COMMUNICATIONS CHECK

Autopilot configuration

This check must be performed GROUND BASED.

- Turn on Oblò instrument only.

- Turn on ACU control unit and check that appear

“AP:OFF” in the top left corner of the display.

If no message appear means that there is a

communication problem between Oblò and ACU control

unit: check again the electrical wirings.

- Press the “HDG/TRK” button on the ACU panel and

verify that the message “AP:OFF” become “AP:HDG”.

If the message remains “AP:OFF” it means that there is

a communication problem between ACU control unit and

servo/s: check again the electrical wirings.

78

Rev.3.7

Page 79

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Autopilot configuration

6.2.3 REMOTE BUTTON OPERATION CHECK

This check must be performed GROUND BASED.

- Engage the autopilot by pressing the “HDG/TRK”

button on the ACU (check the message “AP:HDG” on

the Oblò display).

- Press the remote disengage button and check that the

message “AP:HDG” become “AP:OFF”.

If the message remains “AP:HDG” it means that there

is a problem with the remote button: check the electrical

wiring and the correct functionality of the button itself.

79

Rev.3.7

Page 80

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

6.2.4 SERVO TORQUE CHECK

Autopilot configuration

This check must be performed GROUND BASED.

- Engage the autopilot by pressing the “HDG/TRK”

button on the ACU (check the message “AP:HDG” on

the Oblò display).

- Force the control stick to the left or right limit, so that

you override the servo force and after 1 seconds the

autopilot disengages automatically (check the message

“AP:OFF” on display).

- Engage the autopilot by pressing the “ALT” button on

the ACU (check the message “AP:ALT” on the Oblò

display).

- Force the control stick to the forward or backward limit,

so that you override the servo force and after 1 seconds

the autopilot disengages automatically (check the

message “AP:OFF” on display).

At this stage you should check also the override

force: it must be strong enough to give a fairly good

control authority to the servos, but not so strong as

to be difficult to override with the control stick. See

chap.6.3.2 for roll servo torque setup and chap.6.3.3

for pitch servo torque setup.

80

Rev.3.7

Page 81

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

6.3 AUTOPILOT SETUP MENU

The parameters configuration is performed on the Oblò

instrument.

During the configuration it's required to turn on also

the ACU control unit but without engaging the

autopilot (so on the ACU control unit turn on the

ON/OFF switch and don't press any other button).

All the configurable

parameters are on the

Oblò menu, accessible in

this way:

- Press for 1 second the

knob to enter in the

function menu.

Autopilot configuration

- Rotate the knob to select the “Setup” menu and click

to enter.

- Rotate the knob to select the “Autopilot” menu and click

to enter.

Rev.3.7

81

Page 82

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Autopilot configuration

Autopilot setup menù

6.3.1 “MINSPD” AND “MAXSPD”

PARAMETERS SETTING

This settings must be performed GROUND BASED.

The autopilot system measures the airspeed and allows

the pilot to set the minimum and maximum operating

speed to ensure that the aircraft is in safe conditions

when the autopilot is engaged.

MIN SPD: Select the minimum airspeed at which the

autopilot will fly the aircraft. The unit of measure is the

same set for the ASI (see Setup menu → ASI → Unit).

The autopilot cannot be engaged at airspeed below Min

Spd, with the exception of 0 to allow ground testing.

With autopilot engaged, if the airspeed drops below the

minimum, it enters to an airspeed hold mode, to restore

and maintain approximately the minimum airspeed.

Set Min Spd to be at least 20% above the Vfe of your

aircraft. The Vfe speed must be set in the Oblò

according to the specifications of your aircraft (to set the

Vfe, see Setup menu → ASI → Vfe).

82

Rev.3.7

Page 83

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

MAX SPD: Select the maximum airspeed at which the

autopilot will fly the aircraft. The unit of measure is the

same set for the ASI (see Setup menu → ASI → Unit).

With autopilot engaged, if the airspeed rises above the

maximum, it enters to an airspeed hold mode, to restore

and maintain approximately the maximum airspeed.

The choice of the Max Spd value must be made

according to the characteristics of your aircraft, it should

be below the Vne speed of your aircraft but above the

normal cruise speed. The Vne speed must be set in the

Oblò according to the specifications of your aircraft (to

set the Vfe, see Setup menu → ASI → Vne).

Max Spd parameter cannot be set to a value above 95%

of Vne, so you should first check the correctness of the

ASI speed settings.

Autopilot configuration

Autopilot setup menù

83

Rev.3.7

Page 84

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

6.3.2 ROLL SERVO SETUP

Autopilot configuration

Autopilot setup menù

This settings must be performed GROUND BASED.

This settings can be performed inside the “ROLL

SERVO” menu, that can be reached in this way:

- Press for 1 second the knob to enter in the function

menu.

- Rotate the knob to select the “Setup” menu and click

to enter.

- Rotate the knob to select the “Autopilot” menu and click

to enter.

- Rotate the knob to select the “Roll servo” menu and

click to enter.

84

Rev.3.7

Page 85

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

“GAIN” PARAMETER CHECK

This check must be performed GROUND BASED.

GAIN: This parameter specify how fast or slow the

autopilot responds to deviations between commanded

and actual heading/tracking.

For now check only that the parameter is at the default

value (10), because it will be set in flight as explained

later in chap.6.4.1.

The min-max range is: 1~40.

“TORQUE” PARAMETER SETTING

This settings must be performed GROUND BASED.

TORQUE: Set the desired torque, that is the force of the

servo when engaged.

Autopilot configuration

Autopilot setup menù

To set a correct value, keep in mind that the torque must

be strong enough to give a fairly good control authority

to the servos, but not so strong as to be difficult to

override with the control stick.

To test the torque after setting a new value, perform the

“Servo torque check” as explained in chap.6.2.4.

The min-max range is: 1~40, when the autopilot system

detects for the first time that the servo is set as a roll

servo, it set the default value to 10.

85

Rev.3.7

Page 86

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

Autopilot configuration

Autopilot setup menù

“TURN RATE” PARAMETER SETTING

This settings must be performed GROUND BASED.

TURN RATE: Select your desired target rate of turn

when autopilot is engaged. The unit of measure is

degrees per second and the range min-max is from

0.5°/s to 3.0°/s.

When selecting your desired turn rate consider that the

autopilot may slightly exceed the turn rate target during

regulation.

“MAX BANK” PARAMETER SETTING

This settings must be performed GROUND BASED.

MAX BANK: This parameter specifies a maximum bank

angle which the autopilot will not exceed during turns.

Set an appropriate bank limit, the min-max range is:

5~30 degrees.

86

Rev.3.7

Page 87

Oblò / Oblò-A/P(Autopilot) User’s manual

Flybox

®

6.3.3 PITCH SERVO SETUP

This settings must be performed GROUND BASED.

This settings can be performed inside the “PITCH

SERVO” menu, that can be reached in this way:

- Press for 1 second the knob to enter in the function

menu.