Page 1

FLYBOX

®

1

®

Flybox

Fuel L-P

Omnia57 Fuel L-P - Installation and User Manual,

(Omnia57 family)

Safety Instructions and Warning Booklet

Rev. 1.0

Page 2

Installation and User Manual, Safety

Instructions and Warning Booklet

This product is not TSO’d and cannot be installed into

traditional FAA Part 23 and similarly Type-Certificate Aircraft

Document A2019FUEL L-P

Revision#1.0, 02/2019

For firmware version 1.0

Page 3

SECTIONS

INTRODUCTION

IMPORTANT NOTICE AND WARNINGS

INDEX

OMNIA57 FAMILY SYSTEM OVERVIEW

MECHANICAL INSTALLATION

ELECTRICAL INSTALLATION

INSTRUMENT SETTINGS

OPERATING INSTRUCTIONS

TECHNICAL SPECIFICATIONS

WARRANTY

DISCLAIMER

Page 4

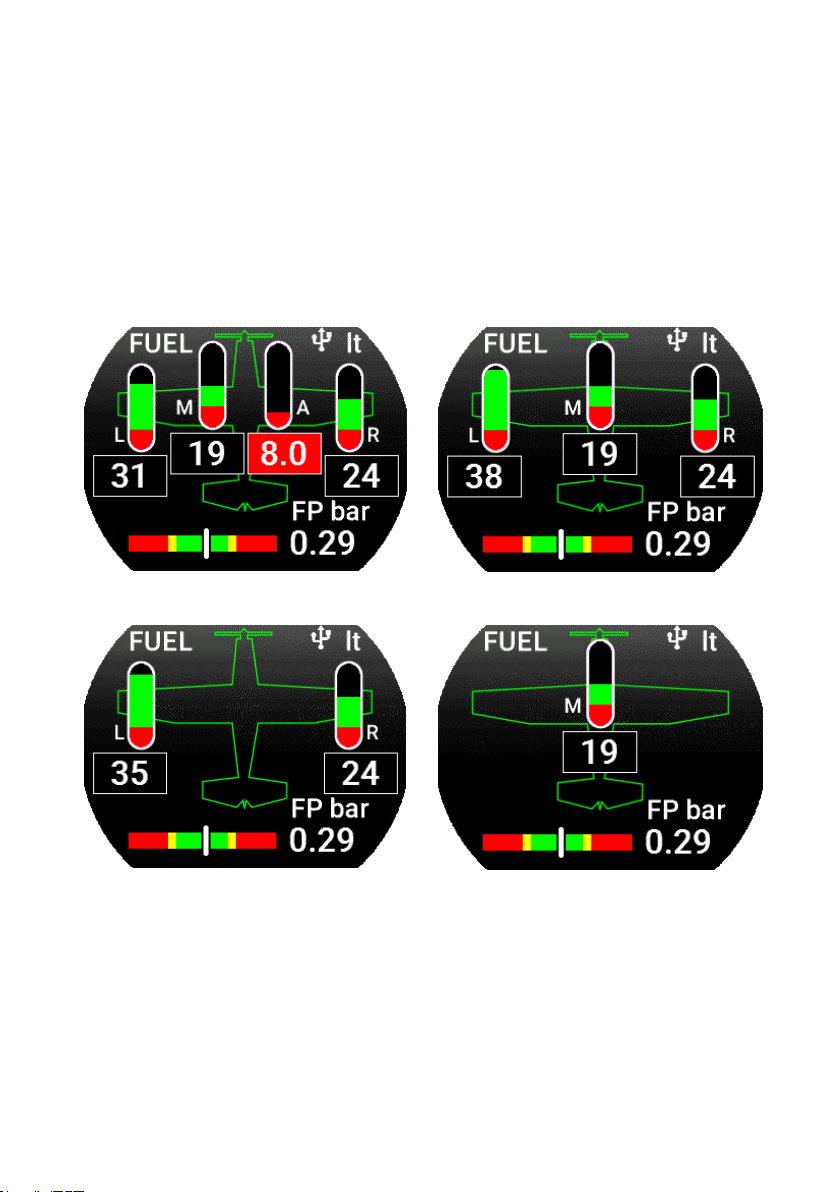

Examples of different configurations

Page 5

®

Introduction

Thank you for purchasing a Flybox® Omnia57

instrument.

Our intent in developing the Omnia57 instrument family

was to create a light and compact product, powerful and

easy to install and use.

The Omnia57 instrument family is equipped with a

state-of-the-art highly visible display, a powerful 32 bit

microcontroller and the latest generation of solid state

sensors to ensure reliability and accuracy over time.

The owner has the possibility to keep the instrument

software up-to-date by downloading the latest available

revision from the www.flyboxavionics.it website and

installing it using a USB pen drive.

We are confident our products will be satisfactory and

will make your flying experience a pleasant one.

FLYBOX

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 6

FLYBOX

®

Symbols used in the Installation and User Manual,

Safety Instructions and Warning Booklet

NOTE: Used to highlight important information.

CAUTION: Used to warn the user, it indicates a

potentially hazardous situation or improper use of the

product.

WARNING: Used to indicate a dangerous situation that

can cause personal injury or death if the instruction is

disregarded.

Important notices & warnings

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 7

®

Important notices & warnings

WARNING: These instructions must be provided to users

before use, and retained for ready reference by the user.

The user must read, understand (or have explained) and

heed all instructions and warnings supplied with this product

and with those products intended for use in association with

it. Always keep a copy of the Installation and User Manual,

Safety Instructions and Warning Booklet on the aircraft. In

case of change of ownership, the Installation and User

Manual, Safety Instructions and Warning Booklet must be

delivered together with all of the other papers.

WARNING: Read the Installation and User Manual, Safety

Instructions and Warning Booklet before installing the device

on your aircraft and follow the procedure described therein.

WARNING: This device is intended to be installed on

NON-TYPE CERTIFIED AIRCRAFT ONLY, as it does NOT

require any air operator’s certificate. Refer to your national

aviation authorities to check if this device can be installed on

your aircraft.

FLYBOX

WARNING: It is the owner’s responsibility to test this device

before operating the aircraft and to make sure nobody is

using it unless properly instructed and authorized to do so.

WARNING: Once the installation process is completed, it is

extremely important to test the device before taking off to

make sure it works properly. Therefore, we strongly suggest

to double check all of the electronic instruments available on

the aircraft and to turn them on to verify they function correctly.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 8

FLYBOX

®

WARNING: This device is operated through a software which

from time to time can be updated and/or subject to change.

Please, always refer to the Installation and User Manual,

Safety Instructions and Warning Booklet for the last updated

version of the software available at www.flyboxavionics.it

WARNING: It is the responsibility of the installer to properly

install the device on the aircraft. In case of calibration, or any

technical or functional customization of the device, the

responsibility lies with the individual who carried out such

operation.

FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY

OR DEATH.

WARNING: If this product is not used correctly, or it is

Important notices & warnings

subjected to additions or alterations, the effectiveness

of this device may be considerably reduced.

WARNING: Alterations, additions, or repairs not performed

by the instrument manufacturer or by a person or organization

authorized by the manufacturer shall negate any warranty.

WARNING: Do NOT rely on the Omnia57 Fuel L-P device

ONLY to determine the level of the fuel available in the tanks.

WARNING: The unit isn’t waterproof. Serious damage could

occur if the unit is exposed to water or spray jets.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 9

®

Important notices & warnings

NOTE: The consumer decides of his own free will if the

purchased product is suitable and safe for his need. If the

consumer does not agree with the notices contained in this

Installation and user Manual, Safety Instructions and Warning

Booklet, do not install this instrument in his aircraft.

NOTE: Flybox Avionics reserves the right to change or

improve its products as well as terms, conditions, and notices

under which their products are offered without prior notice.

NOTE: The Installation and User Manual, Safety Instructions

and Warning Booklet will be updated annually if needed.

All changes or updates will be published on our website

www.flyboxavionics.com in the "support" section.

FLYBOX

NOTE: Upon receipt of the instrument it is advisable to register

on our website www.flyboxavionics.it in the "product

registration" section.

The Registration data will be used only to send important news

or information about available firmware updates or to

communicate safety information about the instrument.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 10

FLYBOX

®

i

Index

INDEX

SECTION 1 - Omnia57 Family System overview..………… 1

1.1 - Construction Features …….…………………………..…. 1

1.2 - Ergonomics………...…...………….……………………. 1

1.3 - Interconnection Ability ………...…...…………..……….. 2

1.4 - Easy Software Update ………...…...………….…………. 3

1.5 - Easy Datalog Saving ………...…...………….…………… 3

1.6 - Interfaces ……..…...…...………….……………………… 4

SECTION 2 - Mechanical installation….……………………… 5

2.1 - Mechanical Dimensions……………..….………………… 5

2.2 - Fuel Level Sensors Installation………..………………….. 7

2.3 - Important Considerations..………..………………….….. 8

SECTION 3 - Electrical Installation.…...…….….….….……… 10

3.1 - Rear Panel Connections…………..…….….………..…… 10

3.2 - 22 Pole Female Connector Wiring……………………… 11

3.3 - 22 Pole Connector Table……………………………….… 12

3.4 - Sensors Electrical Connections….…..…..…..…....……… 13

3.5 - CAN bus Connection Wiring.………….………………… 14

3.6 - CAN Bus Connector Tables……………………………… 15

SECTION 4 - Instrument settings……….………….…………. 16

4.1 - Minimum Settings Before First Use.…..….….…….…… 16

4.2 - Panel Indicators And Commands…..…….………….…. 17

4.3 - Setup Menu Navigation……….…….…..…….………… 18

4.4 - Main Setup Menu… ………………………….………… 19

4.4.1 - Gauges Submenu…….. …………………….………… 21

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 11

®

ii

Index

FLYBOX

4.4.2 - Televels Submenu…….. …………………….………… 22

4.4.3 - Main Tank Submenu……….……….…………………… 24

4.4.4 - Main Tank Calibration..…………………………………. 26

4.5 - Fuel Pressure Submenu.….…….……….…………….…… 35

4.6 - Backlight Submenu….………….………………………… 39

4.7 - Fuel Level Sensors Checking.…………………………… 42

SECTION 5 - Operating Instructions……….…………………… 43

5.1 - Firmware Upgrade..……………..…..….….…….………. 43

5.2 - Backup/Restore……………….…..…….………….….…. 46

5.3 - Use Of The Instrument……….…….…..…….……………. 48

5.4 - Logger…..………. ………………………….……………. 50

TECHNICAL SPECIFICATIONS…………………………… 51

WARRANTY…………………………………………………… 53

CLEANING…………………………………………………….. 51

TERM OF USE AND DISCLAIMER………………………… 54

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 12

FLYBOX

®

1

Omnia57 Family System Overview

OMNIA57 FAMILY SYSTEM OVERVIEW

The Omnia57 instrument family has many innovative

features, common to all models as described below.

1.1 CONSTRUCTION FEATURES

Omnia57 instrument family is built from solid aluminum

alloy, CNC milled and powder coated to last a long time

over the years always showing a new appearance.

1.2 ERGONOMICS

- Large 2.4 inch TFT display, 320x240 Pixels, 1000 nits,

antiglare surface, sunlight readable, wide temperature

range.

- A high quality knob encoder with push button for easy

access to all features.

- Backlight auto dimming feature with one optional sensor

for all the Omnia57 installed in the panel.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 13

®

2

Omnia57 Family System Overview

FLYBOX

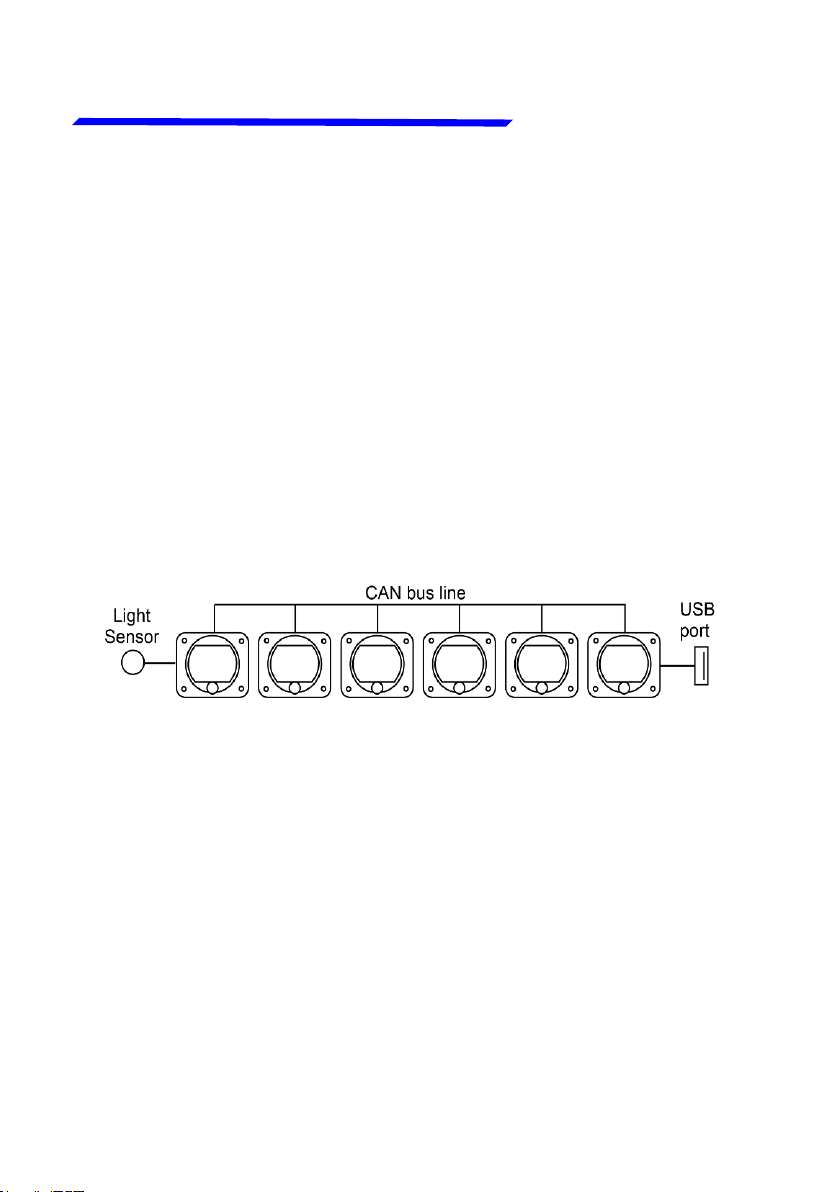

1.3 INTERCONNECTION ABILITY

All the instruments of the Omnia57 family can be

connected together to form a communication network,

making some data exchange operations simpler.

The software update of a Omnia57 instrument connected

in group takes place through the CAN bus communication

with the instrument that has the USB pen drive connected.

This means that the USB connection is made to a single

instrument, and the information will be forwarded via CAN

bus to or from all the others in the group.

Up to 16 Omnia57 can be connected together through

the CAN 1 bus.

The configuration data and the data logger of the

interconnected instruments are saved or restored via CAN

bus on the same USB pen drive. A single brightness sensor

can provide information to all the connected instruments

to automatically adjust the backlight intensity.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 14

FLYBOX

®

3

Omnia57 Family System Overview

1.4 EASY SOFTWARE UPDATE

The user can download any new firmware, when available,

from Flybox website, connect a USB pen drive to the

instrument and freely update it with the last features.

With one USB connection only, it will be possible to update

every instrument installed in the panel. If more Omnia57

are installed and properly connected, they will search for

the right firmware through the CAN bus.

1.5 EASY DATALOG SAVING

Easy logging of the data for debug purpose. If needed,

each Omnia57 unit can save a last flight log on the USB

pen drive. The user can then send the log via e-mail to

Flybox support for a help/support request.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 15

®

4

Omnia57 Family System Overview

FLYBOX

1.6 INTERFACES

All the Omnia57 instruments have the following common

interfaces:

2 separate CAN BUS: they can be used to connect the

Omnia57 instruments together, to interface them with

other Flybox instruments or with external devices like

Engines ECUs or new devices that will be possibly

developed in the future.

2 RS232 serial ports: used to connect the Omnia57

instruments to an external GPS (when applicable). This

feature appears in some models only.

1 Sensor Light Input: if connected, it allows the automatic

light intensity adjustment, one sensor for all the

instruments.

2 Power outputs for sensors: one 12 V 500mA@60°C

and the other 5 V 350 mA@60°C, both protected from

short circuit.

If the current on one of the

outputs is too high, a caution

message will appear.

1 Alarm output: all the Omnia57 instruments can activate

an external warning device like a lamp or a small relay

through this NPN transistor output.

Caution!

High current PIN 2

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 16

FLYBOX

®

5

Omnia57 Family System Overview

MECHANICAL INSTALLATION

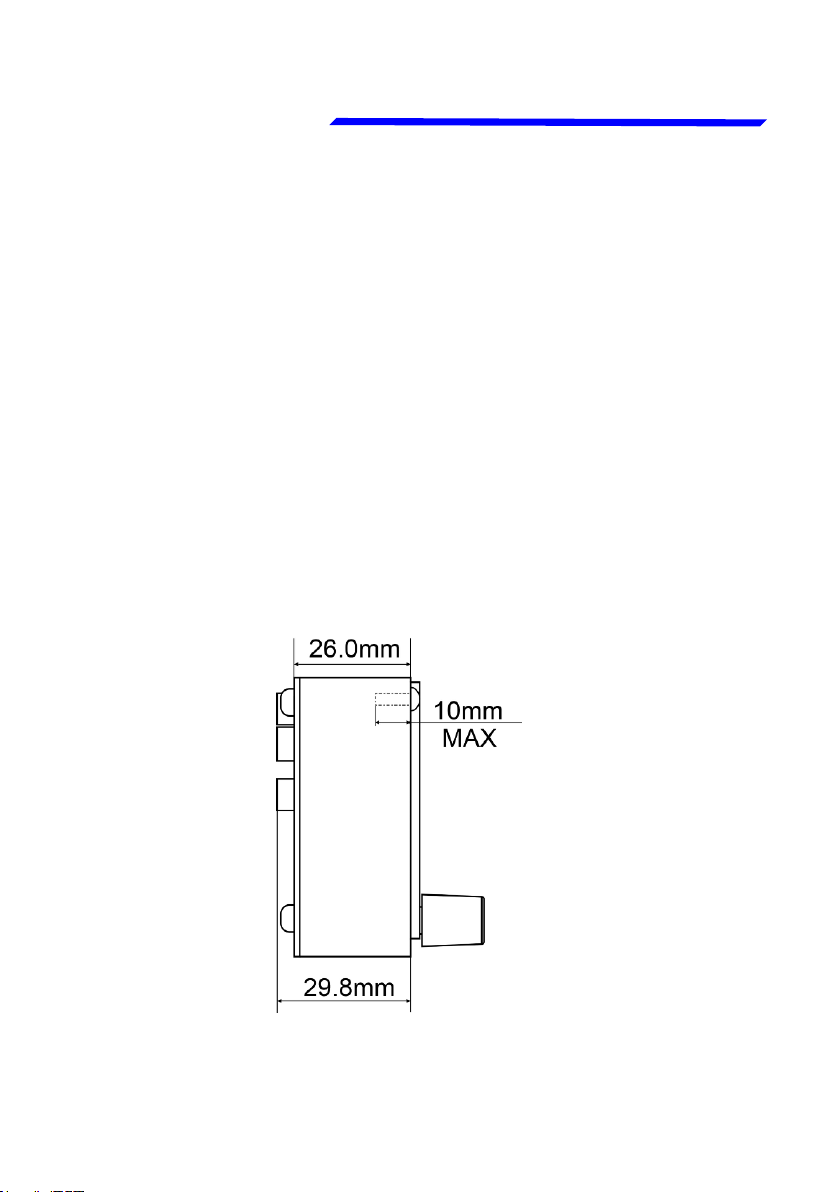

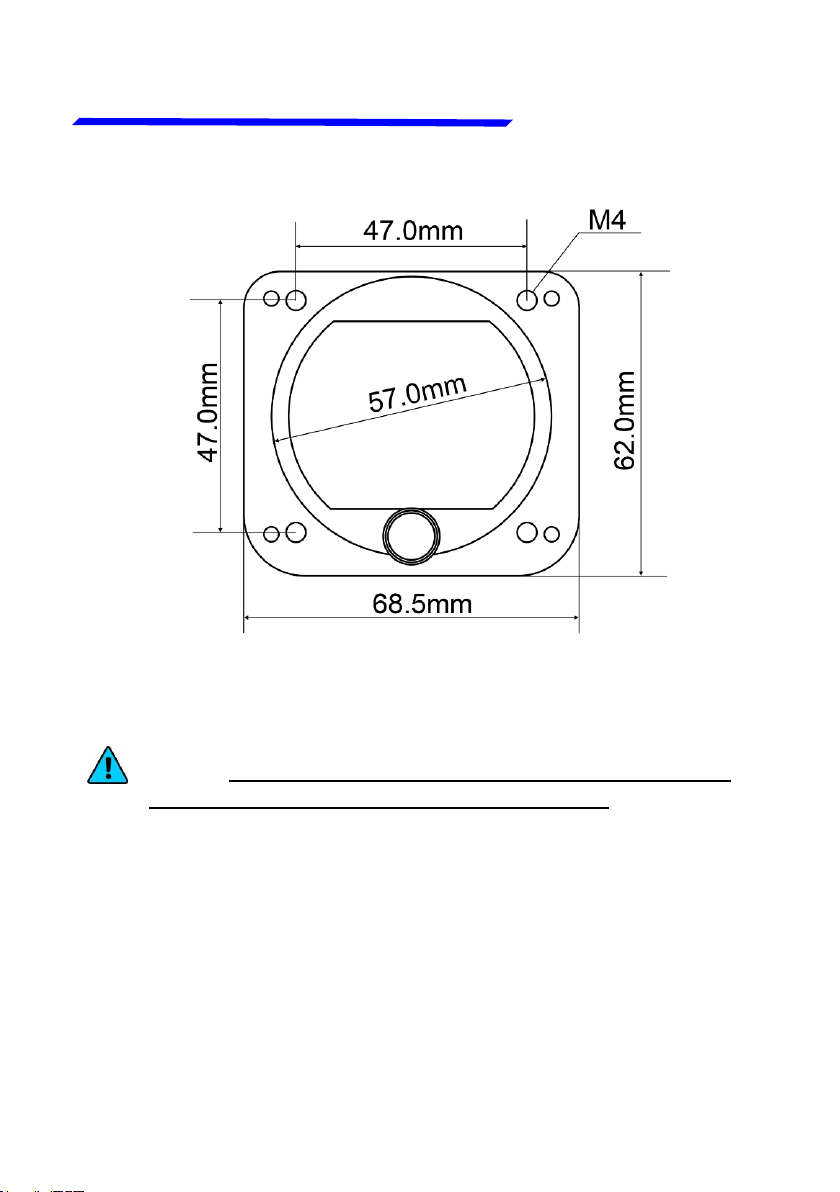

2.1 MECHANICAL DIMENSIONS

The Omnia57 Fuel L-P instrument fits in a standard 2

¼” (57 mm) panel cutout; it's recommended to choose a

position that permits optimal display visibility. It's furnished

with four M4 screws to install it to the panel, if you use

other screws consider that the maximum thread length

inside the instrument body is 10mm (see the picture below).

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 17

®

6

Mechanical installation

FLYBOX

NOTE: For an installation without interference, consider

making a hole of at least 57.5 mm diameter

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 18

FLYBOX

®

7

Mechanical installation

2.2 FUEL LEVEL SENSORS INSTALLATION

Omnia57 Fuel L-P has 4 fuel level inputs that can be

connected to both resistive sensors (with max resistance

of 300 ohm) and capacitive sensors (with output voltage

range 0~5 Volt).

Resistive sensors can be of two types, both supported by

the device: resistive sensors that increase resistance as

you add fuel and resistive sensors that decrease

resistance as you add fuel. If you don't know what type of

sensors are installed please see chapter 4.7 “Fuel level

sensors checkings”.

It's also possible to install a mixed type of sensors (i.e. 2

resistive + 2 capacitive).

CAUTION: All fuel level sensors connected to the

Omnia57 Fuel L-P must not be connected to any other

instrument.

Disconnect any previously used instrument.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 19

®

8

Mechanical installation

FLYBOX

2.3 IMPORTANT CONSIDERATIONS

NOTE: Be advised that many fuel level sensors might not

be able to accurately measure the capacity of the tank and

that one of the following issues might occur (please, see

chapter 2.2 “Fuel level sensors installation”):

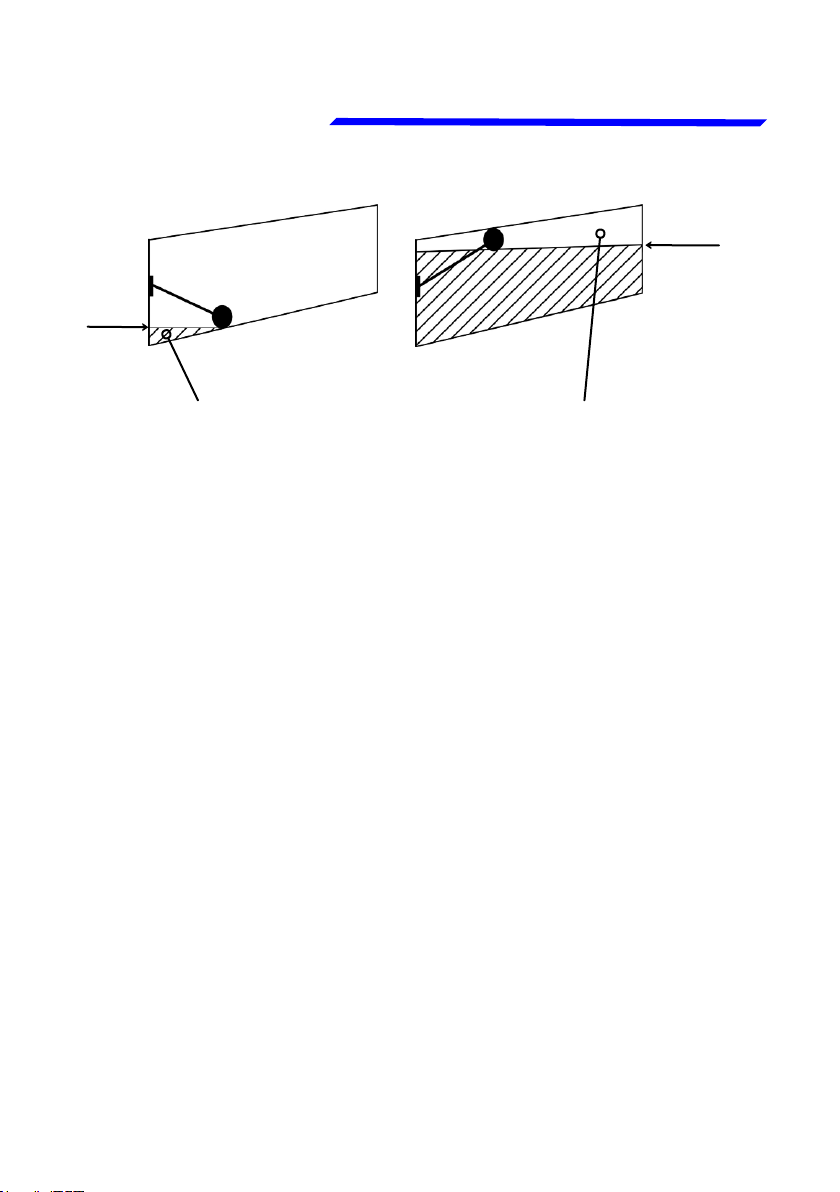

In the example of pic.1 of next page, a tank contains 7

litres but the fuel sensor cannot measure that lower part

of the tank, so Omnia57 Fuel L-P will display "0" (zero)

for a fuel level of 7 litres or less.

In the example of pic.2 of next page, a tank can hold 50

liters of fuel but at 35 liters the fuel sensor is at his upper

position, the maximum quantity that Omnia57 Fuel L-P

will display is 35 liters.

The first situation described above, or the second one, or

both, can occur very often, especially for tanks installed in

the wings due to the angle of dihedral.

NOTE: If your fuel sensor is not able to measure the fuel

level from empty to full, while planning your flights, you

may need to keep in mind the amount of fuel that the

instrument is unable to measure. Keep in mind that this

can happen even with an analog indicator, where the

sensor can not measure, the instrument can not give

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 20

FLYBOX

®

9

Pic.1

Pic.2

7 LT

Mechanical installation

35 LT

Not measurableNot measurable

It takes a considerable

amount of fuel before

the sensor starts moving

when adding fuel to an

empty tank.

It takes a considerable

amount of fuel before

the sensor starts moving

from the top when

draining fuel from a filled

up tank.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 21

®

10

Electrical installation

FLYBOX

ELECTRICAL INSTALLATION

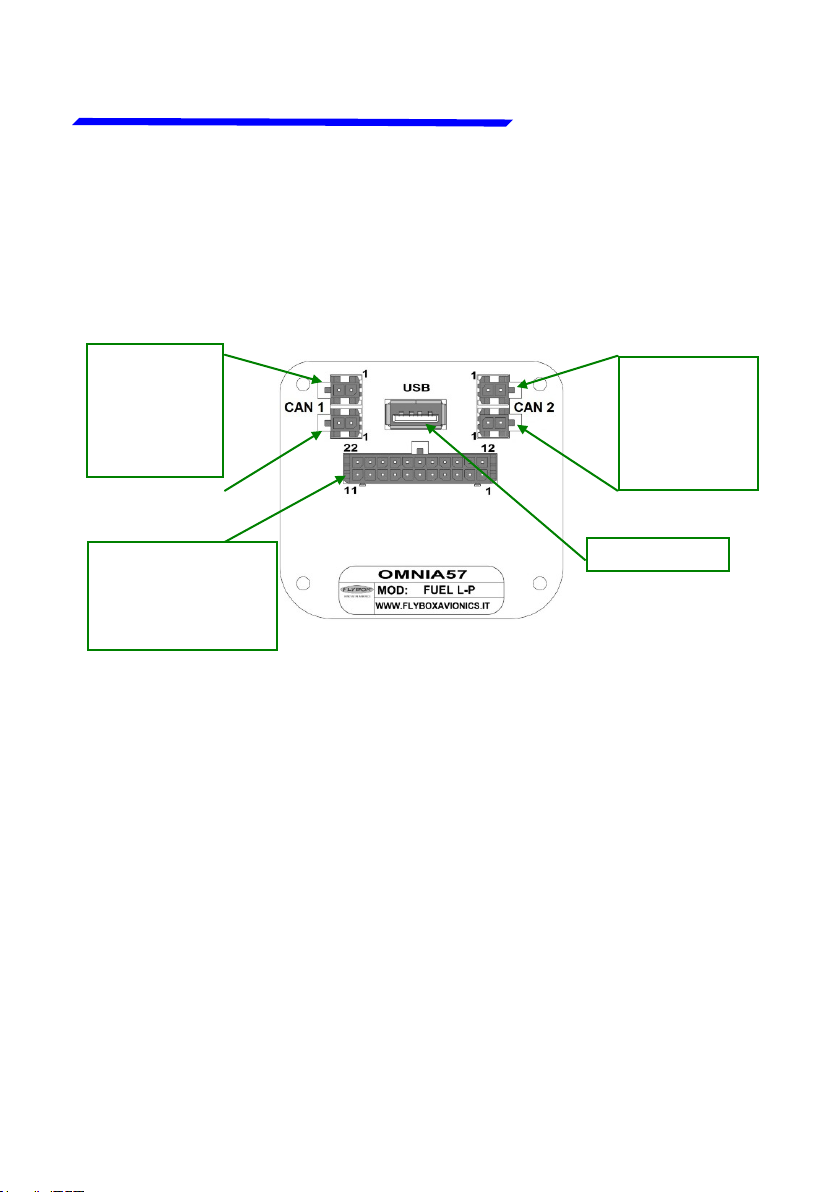

3.1 REAR PANEL CONNECTIONS

2 x 2 - p o l e

connectors,

Molex MicroFit for CAN 1

bus

22 pole female

connector, Molex

Micro-Fit. See the

table chapter 3.3

Upper

Lower

Upper

Lower

2 x 2 - p o l e

co n nectors,

Molex MicroFit for CAN 2

bus

USB 2.0 port

The required connectors and terminals are supplied with

the instrument.

The manufacturer’s codes are:

Molex P/N 43025-0200 (2 pole housing)

Molex P/N 43025-2200 (22 pole housing)

Molex P/N 43030-0007 (female crimp terminal)

The terminals can be crimped with:

- Flybox Professional Crimping Tool cod. 603000

- Molex tool P/N 63819-0000

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 22

FLYBOX

®

11

+ V Main Supply

GND Main Supply

+ Vout for sensors

Alarm OUT

+ 5V OUT for sensor

Ambient light sensor

+ 5V OUT

External switch

Left Tank Televel Input

Right Tank Televel Input

Main Tank Televel Input

Aux Tank Televel Input

Fuel Pressure Input

PIN 1

PIN 12

SPST switch, its use will be

implemented in future updates

Flybox ambient light sensor

code:105800 (sold separately)

Light

Sensor

PIN 2

PIN 13

PIN 3

PIN 14

PIN 5

PIN 15

PIN 16

PIN 6

PIN 17

PIN 7

Green

Blue

Electrical installation

3.2 - (22 POLE) FEMALE CONNECTOR WIRING

WARNING: Voltage peaks on the supply line exceeding

the operating limits can damage the device.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 23

®

12

Electrical installation

PIN

1

+V Main supply, 10-30Vdc, with a proper

breaker

2

Vout for sensors, it delivers the same

voltage supplied on the Pin 1, short

circuit protected and limited to 500mA

3

5V out for sensor, short circuit protected

and limited to 350mA

5

6

7

12

13

Alarm Out, NPN 300 mA (not protected)

14

15

16

17

FLYBOX

3.3 - (22 POLE) CONNECTOR TABLE

I/O Signal

I

O

O

I Left tank sensor input

I Main tank sensor input

I Fuel Pressure input

I GND main supply

O

I Ambient light sensor input

I External switch

I Right tank sensor input

I Aux tank sensor input

22

11

12

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Molex P/N 43025-2200

(22 pole housing). View

from wire insertion side.

1

Page 24

FLYBOX

®

13

+Vout for sensors

To Omnia57 Sensor Input

Capacitive

Fuel Sensor

To Omnia57 Sensor Input

Resistive

Fuel Sensor

FLYBOX Fuel

Pressure Sensor

To Omnia57 Fuel Pressure

Sensor Input

+Vout for sensors

White

Brown

Green

code: 601040 (sold separately)

Electrical installation

3.4 SENSORS ELECTRICAL CONNECTIONS

(see NOTE 1)

NOTE 1: use sensors which support the voltage supplied

to PIN 1 only.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

(see NOTE 1)

Rev. 1.0

Page 25

®

14

Electrical installation

FLYBOX

3.5 CAN BUS CONNECTION WIRING

Pin 2

Pin 1

120 Ohm

resistor

Molex P/N 43025-0200 (2 pole

housing). View from wire

insertion side

120 Ohm

resistor

CAN bus Wiring Information

The basic electrical architecture of a CAN bus consists of

a single twisted or shielded wire pair with a device

connected at each end. Each end must be terminated with

a 120 ohm resistor, Flybox code 105810. Up to 16

Omnia57 can be connected together through CAN 1 bus.

Ready-made termination resistors and wiring for

connecting several Omnia57 together are available in

different lengths: 25cm, 50cm, 100cm.

See the website www.flyboxavionics.it for details and how

to order.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 26

FLYBOX

®

15

3.6 - (2 POLE) CAN BUS CONNECTOR TABLES

PIN

1

2

PIN

1

2

PIN

1

2

PIN

1

2

I/O Signal

I/O

I/O

2 Pole CAN 1 Lower Connector

I/O Signal

I/O

I/O

2 Pole CAN 2 Upper Connector

I/O Signal

I/O

I/O

CAN 1 H Internally connected with the

Pin 1-CAN 1 H (Lower connector)

CAN 1 L Internally connected with the

Pin 2-CAN 1 L (Lower connector)

CAN 1 H Internally connected with the

Pin 1-CAN 1 H (Upper connector)

CAN 1 L Internally connected with the

Pin 2-CAN 1 L (Upper connector)

CAN 2 L Internally connected with the

Pin 1 CAN 2 L (Lower connector)

CAN 2 H Internally connected with the

Pin 2 CAN 2 H (Lower connector)

Electrical installation

2 Pole CAN 2 Lower Connector

I/O Signal

I/O

I/O

CAN 2 L Internally connected with the

Pin 1 CAN 2 L (Upper connector)

CAN 2 H Internally connected with the

Pin 2 CAN 2 H (Upper connector)

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 27

®

16

Instrument settings

FLYBOX

INSTRUMENT SETTINGS

4.1 MINIMUM SETTINGS BEFORE FIRST USE

CAUTION: Before using the Omnia57 Fuel L-P in flight

for the first time, you must set at least the following

parameters (as explained in the instructions on the

following pages):

● Set the unit of measure: US gallons or liters (set this

before all the other parameters).

● Enable the tanks installed in your aircraft only and let

disabled all the others tanks.

● Set all the “Reserve” value for the enabled tanks and

thresholds and alarm parameters for the fuel pressure

gauge, if enabled.

● Set the fuel sensor type for every enabled tanks

(resistive+ / resistive- / capacitive).

● Execute the calibration procedure for all the enabled

tanks.

● If a fuel pressure sensor is installed, set all the

paramters in the “Fuel Pressure” Submenu.

● Check if the indications are correct for all the enabled

tanks.

WARNING: In the absence of the above operations, or if

they are not performed correctly, you can not consider as

reliable the indications of the instrument.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 28

FLYBOX

®

17

Instrument settings

4.2 PANEL INDICATORS & COMMANDS

57 mm (2-1/4”) aluminium enclosure

320X240 pixels, high

brightness, sun

readable, color

M4 screws

Knob with pushbutton

The knob can be rotated to select the functions and

increment or decrement the values while pressing it to

confirm.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 29

®

18

Instrument settings

FLYBOX

4.3 SETUP MENU NAVIGATION

Navigation through the menus is very simple and fast using

the knob:

- Press the knob for 1 second to enter in the Setup Menu.

The menu automatically disappears if you don’t press or

rotate the knob for 5 seconds.

- Rotate the knob to navigate through menus and

submenus items.

- The setup system is organized in menus and submenus;

a submenu is a term used to describe a menu that is

contained within another menu.

- Press the knob to enter in the selected item.

- The knob can be rotated to select the functions and

increment or decrement the values while pressing it to

confirm. To exit without changing while editing a number

or multiple choice, keep pressed the knob for 3 seconds.

- The first items on every menu are Exit or Back. “Exit” is

used to quit the Setup and go directly to the main screen,

“Back” is used to go back to the previous level.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 30

FLYBOX

®

19

Instrument settings

4.4 MAIN SETUP MENU

Exit: confirm to “exit” from the setup menu and go back to

the main screen.

Dimmer: adjust display brigtness from 1 (min brightness)

to 19 (max brightness). Default value=19. The adjustment

works both in Manual or in Automatic mode.

Gauges: select to set the 4 tanks gauge setup and the

fuel pressure gauge setup. Go to chapter 4.4.1 for a full

description.

Special: enter to restore the default settings. Caution:

This operation returns the instrument to the factory

settings. All settings, except calibration data, will be

erased. It will require double confirmation.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 31

®

20

Instrument settings

FLYBOX

Backlight: set the backlight in “Manual” or “Automatic”

mode. Go to chapter 4.6 for a full description.

Firmware Upgrade: enter to upgrade the firmware. Go to

chapter 5.1 for a full description.

Backup/Restore: enter to save and load settings. Go to

chapter 5.2 for a full description.

Logger: enable to save a flight session data. Go to chapter

5.4 for a full description.

About: enter to see instrument information.

About Page Example

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 32

FLYBOX

®

21

4.4.1 Gauges Submenu

Back: confirm to go back to previous menu.

Exit: confirm to go directly to the main screen.

Instrument settings

Televels: enter to setup the 4 fuel tank gauges. Go to

chapter 4.4.2 for a full description.

Fuel Pressure: enter to setup the Fuel Pressure gauge.

Go to chapter 4.5 for a full description.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 33

®

22

Instrument settings

4.4.2 Televels Submenu

CAUTION: The Unit

parameter must be selected

before calibration and then

must not be changed,

otherwise the calibrations

made will no longer be valid.

Back: confirm to go back to previous menu.

FLYBOX

Exit: confirm to go directly to the main screen.

Unit: set the unit of measure in liters (lt) or US

Gallons (gal). Default = lt.

Filter: set the fluctuation speed of the fuel level readings.

Default = 10

Min = 1 (faster)

Max = 100 (slower)

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 34

FLYBOX

®

23

Instrument settings

Qty Step: set the fuel quantity to add at each calibration

step. Range in liters: 1~20 with increment of 1; Range in

Gallons: 0.1~5.0 with increments of 0.1. The currently

selected unit of measurment is indicated in brackets after

the label as follows: Qty Step(lt) or Qty Step(gal).

Changing the unit of measure will reset the Qty Step value

if already set.

Choose a proper value considering the tank capacity and

how many calibration step you want to execute.

For example, with a 40 liters tank and "Qty Step" set to 4,

40/4 = 10 calibration steps will be required. The maximum

number of calibration steps is 50.

The “Qty Step” parameter is used for all the 4 tanks

calibration, don’t modify it once you have choosed a value.

The calibration ends when the tank is completely filled.

mV Step: minimum thresold to detect fuel sensors

movement. Default = 20. Don't modify this value.

Main Tank: set the Main Tank parameters. Go to chapter

4.4.3 for a full description.

Aux Tank: set the Aux Tank parameters.

Left Tank: set the Left Tank parameters.

Right Tank: set the Right Tank parameters.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 35

®

24

Instrument settings

FLYBOX

4.4.3 Main Tank Submenu

Back: go back to

previous menu.

Exit: confirm to go

directly to the main

screen.

Enable: select “Yes” to

enable this Tank, select

“No” to disable this Tank.

NOTE: Each time a new gauge is enabled this message

will appear to remind the installer that it is his responsibility

to make the correct settings before continuing.

Push and accept to

continue.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 36

FLYBOX

®

25

Instrument settings

Sender Type: set the proper fuel level sensor type

installed in the Main Tank.

The supported type can be:

RES+ for resistive fuel sensors that increase resistance

as you add fuel.

RES- for resistive fuel sensors that decrease resistance

as you add fuel.

CAP for capacitive with output between 0 and 5 volts.

If you don't know what type of sensors are installed, please

see chapter 4.7, Fuel level sensors checkings.

NOTE: It's also possible to install a mixed type of sensors

(i.e. 2 resistive + 2 capacitive).

Res: Set the value of the reserve at a level where the

instrument will give the alarm. When the remaining fuel

reaches this setpoint, the instrument activate the output

alarm (Range 0~calculated capacity after calibrated). An

alarm message will also appear on the screen; the

message can be reset by pressing the knob but the

background of the number remains red. To disable this

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 37

®

26

Instrument settings

Calibration: enter to calibrate the Fuel Sender of this

Tank. With the calibration process, Omnia57 F-P learns

the shape of your Tank and correct some errors like

non-linearity of the Fuel Sensor and tolerance. Go to

chapter 4.4.4 for a full description.

Alarms: select to set an alarm for this tank. Go to

chapter 4.4.5 for a full description.

FLYBOX

4.4.4 Main Tank Calibration

NOTE: if no calibrations have been made for this tank, a

message indicating that there are no calibration data will

appear.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 38

FLYBOX

®

27

Instrument settings

NOTE: Calibration must be performed with the aircraft in

flight attitude so you will need to raise or lower the tail

depending on whether it is, a taildragger or a tricycle.

Empty the tank so that only the unusable fuel remain in

the tank.

To reach the maximum accuracy in the calibration, It's

important that the fuel quantity is exactly measured.

A good practice to make the float stabilize on the fuel is

to give a shake to the plane. This can sometimes

overcome the friction of some floats that tend to be sticky.

Calibration is divided into several calibration steps, in each

step a predetermined amount of fuel (x liters) will be added

to the tank.

After confirming the calibration function, the screen above

will appears.

If this tank had already been calibrated before, turn the

knob to see all the values stored in the various steps. If it

has not yet been calibrated or if you want to repeat the

calibration process, press the knob to display the menu in

the following figure.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 39

®

28

Instrument settings

FLYBOX

Confirm Exit to exit calibration.

Confirm “Start” to start a new Calibration, this screen will

appear.

The tank currently calibrating

operation to

do

step still to

be performed

The fuel q.ty

a l r e a d y

added to the

tank at this

point of

calibration

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Electrical output

of the fuel level

sensor

Page 40

FLYBOX

®

29

Instrument settings

Step 1: Check that the tank is empty, wait for the mV

indication to be stable and confirm “done” before to

proceed to the next step.

At this step the actual

fuel is 0 lt.

After “Done” is confirmed, the microcontroller will calculate

the mV average value for few seconds, then the

screenshot below will appear. Now you are ready for the

next step.

In the example, the

“Qty Step” value is set

to 3 liters.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 41

®

30

Instrument settings

FLYBOX

Step 2: Now add the fuel indicated in the green field (it’s

the same quantity choosen in the “Qty Step” parameter).

Step 3: Wait for the new mV indication to be stable and

proceed to the next step by confirming “Done”. If there are

no problems in your system, what you’ll see is the following.

The microcontroller will calculate the average value for

few seconds, during which you will see the screenshot

above, before moving on to this screenshot of the next

page.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 42

FLYBOX

®

31

Instrument settings

Next steps: repeat step #2 and step #3 until tank is

completely filled. When the tank is filled: click on “DONE”

to confirm the last calibration step and then click on “END”

to end the calibration. You will be asked for a confirmation.

NOTE: A common problem for many fuel level sensors is

that they can't completely measure the tank capacity, so

one or both of this conditions can occur (see also chapter

2.2 “Fuel level sensors installation”):

- As you add fuel to an empty tank it takes a certain amount

of fuel before the fuel sensor starts moving from the bottom.

- As you drain fuel to a filled tank it takes a certain amount

of fuel before the fuel sensor starts moving from the top.

NOTE: This is not a problem of the instrument but a

situation that can occur if the sensor travel does not cover

the entire fuel travel from botton to top.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 43

®

32

Instrument settings

FLYBOX

If one of these conditions occurs during the calibration,

Omnia57 F-P notices that the fuel sensor doesn't produce

an electrical change and asks the user if fuel is already

added for that calibration step:

If you are sure to have already added the fuel, confirm on

“YES” otherwise click on “NO” to go back to previous

calibration step.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 44

FLYBOX

®

33

4.4.5 Alarms:

NOTE: Consider that all fuel additions that will not give

any sensor movement will not be counted.

Follow the instructions given for the Main Tank setup

Chapter 4.4.3 for the other fuel tanks, Aux Tank, Left

Tank, Right Tank.

Instrument settings

Back: go back to previous menu.

Exit: confirm to go directly to the main screen.

Warning: select “Yes” to enable or select “No” to

disable the “Res” alarm output.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 45

®

34

Instrument settings

FLYBOX

Act delay: Select a delay in seconds before the alarm is

triggered. When the reserve value is reached, the alarm

output will be activated after the set time. This option can

be useful to avoid continuous alarms when the fuel reaches

quantities close to the set reserve value.

Default = 0s

Min = 0s (faster)

Max =10s (slower)

The alarm is only triggered if the Warning parameter is set

to "Yes". The alarm event triggers both the flashing

message on the screen and the alarm output. Both can be

reset by pressing the knob but the rectangle behind

number remains in red.

After resetting with the knobBefore resetting

(the example shows a setting of only one tank)

Follow the instructions given for the Main Tank alarm

setup for the other fuel tanks, Aux Tank, Left Tank, Right

Tank.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 46

FLYBOX

®

35

4.5 Fuel Pressure submenu

Back: go back to previous menu.

Instrument settings

Exit: confirm to go directly to the main screen.

Enable: set “Yes” if the Fuel Pressure sensor is installed,

“No” if it isn’t installed.

Filter: set the fluctuation speed of the Fuel Pressure

readings.

Default = 20

Min = 1 (faster)

Max = 100 (slower)

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 47

®

36

Instrument settings

FLYBOX

Source: select here the source for the Fuel Pressure

readings; the available sources are:

SENS, to read the data from a Fuel Pressure sensor if

connected. Optional Flybox code: 601040

912iS, to read the data from the Rotax 912iS CAN bus.

915iS, to read the data from the Rotax 915iS CAN bus.

Unit: Select “bar” or “psi”, default is “bar”

Thresholds: set all the thresholds for the Fuel Pressure

gauge.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 48

FLYBOX

®

37

Instrument settings

Rotate the knob to highlight the threshold you want to

change, push and change the value, push again to confirm.

Default thresholds are at 0.

NOTE: Start to change the maximum thresholds and then,

gradually, the lower thresholds.

NOTE: To make a colored portion disappear, give the

same value to the low and high thresholds of that color.

Alarms: enter to go in the Fuel Pressure Alarm menu.

Back: go back to previous menu.

Exit: confirm to go directly to the main screen.

Up Wrn: select “Yes” to enable or select “No” to disable

the High threshold alarm output.

Low Wrn: select “Yes” to enable or select “No” to

disable the Low threshold alarm output.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 49

®

38

Instrument settings

FLYBOX

Act delay: Select a delay in seconds before the alarm is

triggered. When the Low or the High thresholds are

reached, the alarm output will be activated after the set

time. This option can be useful to avoid continuous alarms

when the fuel pressure is stationary at values close to the

set threshold.

Default = 0s

Min = 0s (faster)

Max = 10s (slower)

The alarm is only triggered if the Warning parameter is set

to "Yes". The alarm event triggers both the flashing

message on the screen and the alarm output. Both can be

reset by pressing the knob but the rectangle behind

number remains in red.

Before resetting

After resetting with the knob

(the example shows a setting of only one tank)

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 50

FLYBOX

®

39

4.6 Backlight Submenu

Back: go back to previous menu.

Exit: confirm to go directly to the main screen.

Mode: select to chose from “Manual” and “Auto”. When in

“Manual” mode, the brightness can be changed with the

dimmer function from the main menu, from 1 (min

brightness) to 19 (max brightness). Default value=19.

Selecting “Auto” new parameters will appear in the list:

Instrument settings

Source: set how the instrument reads the ambient

brightness. Choose "Sens" to read the brightness from the

sensor connected to the instrument itself or "CAN" to read

the ambient brightness from the CAN bus if the brightness

sensor is connected to another Omnia57 instrument

connected in cluster.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 51

®

40

Instrument settings

FLYBOX

Delay (s): It introduces a delay to the variation of the

backlight, it can be useful to avoid continuous changes in

brightness when the sensor is hit by light and shadow

alternately.

Default= 2 s

Min= 0 s (faster)

Max= 30 s (slower)

Filter (s): The filter slows down the response to changes

in external brightness, it raises the value to slow down,

lowers it to speed them up.

Default = 2 s

Min = 0s (faster)

Max 30s (slower)

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 52

FLYBOX

®

41

Instrument settings

This function assigns the amount of light read by the

sensor to the target brightness (Level 15 = 15% brightness).

Once all 4 points have an assigned value, the brightness

will change according to the amount of light read,

interpolating it between the segments that are created.

Level 15: 4

Level 30: 8

Level 60: 17

Level 100: 35

Defaults values

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 53

®

42

Instrument settings

FLYBOX

4.7 FUEL LEVEL SENSORS CHECKINGS

To setup the Omnia57 Fuel L-P correctly, you need to

know what type of fuel level sensors are installed in your

aicraft. The resistive sensors can be of two types:

● Sensors that increase resistance as the fuel level

increase.

● Sensors that decrease resistance as the fuel level

increase.

If you don't know what type of resistive sensors are

installed in your aircraft, follow this procedure:

● Empty the tank that you want to check.

● Enter in the calibration for that tank

● From the screen that appears annotate the numerical

value indicated in the field mV

● Add a certain amount of fuel to the tank and check if

the numerical indication increases or decreases: if

increases then the sensors installed increase the

resistance as you add fuel (RES+), if it decreases the

sensors decrease the resistance as you add fuel (RES-).

To exit from the calibration screen turn select and confirm

“Abort” and then “Exit”.

Repeat the procedure for any other unknown sensors

installed.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 54

FLYBOX

®

43

5.1 FIRMWARE UPGRADE

OPERATING INSTRUCTIONS

The Omnia57 Fuel L-P software can be easily updated

with new versions, when available. To check if a new

software version is available, see www.flyboxavionics.it

under support > software page.

Download the new version and after unpacking it, copy it

to a USB stick, possibly free from other files.

To update the instrument it is necessary to connect the

USB stick to the instrument you want to update or to any

other instrument of the Omnia57 series installed and

clustered via the CAN bus, following the procedure below:

- connect the usb stick to the instrument

- From the main menu of the instrument you want to

upgrade select “Firmware Upgrade”.

Operating Instructions

If the USB stick is not yet plugged-in, a message advising

you to insert it will appear:

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 55

®

44

Operating Instructions

FLYBOX

If already plugged-in, a message indicating the file and

the version will appear:

Select and confirm the

software you want to

write, the following

screen will appear:

In case you are installing

a version prior to the

installed one, a different

message will inform that

you are downgrading

and not upgrading the

software. Confirm “Yes”

to proceed, “No” to exit

without writing any

software.

(DEV. NAME) is the name of the instrument being update.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 56

FLYBOX

®

45

Operating Instructions

Wait until this message will appear and then remove the

USB stick. The instrument will reboot with the new software.

Note: if the USB stick is installed on a device other than

the one you are updating, the following messages will

appear on the 2 devices:

Device is being

Update

Remote device

where the USB is

connected

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 57

®

46

Operating Instructions

5.2 Backup / Restore

All set parameters and calibrations made in the instrument

can be saved in a backup file. This can be useful if you

need to restore all the parameters in a new instrument, for

example in case of replacement, or if you need help from

the instrument manufacturer. In this case, simply send the

backup file saved on the USB stick to the Flybox support

service. To backup or restore the parameters it is

necessary to connect a USB stick to the instrument you

want to backup/restore or to any other instrument of the

Omnia57 series installed and clustered via the CAN bus.

From the main menu of the instrument you want to backup

or restore the parameters, choose “Backup/Restore”. If the

USB stick is not plugged-in yet , a message advising you

to insert it will appear

FLYBOX

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 58

FLYBOX

®

47

Operating Instructions

Select “Backup” and push the knob to write the file on the

USB stick. When the file is written, this message will appear:

Select “Restore” and push the knob to load the previously

saved parameters into the instrument.

Push the knob to reboot, the new parameters are now

loaded in the instrument.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 59

®

48

Operating Instructions

FLYBOX

5.3 USE OF THE INSTRUMENT

When switched-ON, the display will immediately show the

main page with the enabled gauges.

NOTE: The first time you switch-ON the Omnia57 F-P,

there will not be enabled tanks. You need to enable and

calibrate the tanks as explained in chapter 4.4.3.

The fuel pressure gauge will not be enabled too, so if you

have the fuel pressure sensor installed, enable it as

explained in the chapter 4.5.

The example below refers to the installation comprising of

four tanks and the fuel pressure gauge; if your aircraft has

less than 4 tanks, the indication of the display might be

different. The tanks are named:

L (left), M (main), A (auxiliary), R (right).

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 60

FLYBOX

®

49

Operating Instructions

When the fuel in a single tank drops below the relative

reserve setpoint (see chapter 4.1), Omnia57 F-P activates

an alarm warning as explained in the chapter 4.4.5.

Pushing the knob will reset the alarm but note that the

rectangle behind number remains in red.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 61

®

50

Operating Instructions

5.4 Logger

USB Icon

The Logger can be useful for storing flight data on the USB

stick, for example to ask for assistance in case of problems.

The data will be stored at 1 second samples and written

on a file with some information of the instrument that

generated them.

When the USB flash drive is plugged-in to the device to

be logged or to any other instrument of the Omnia57 series

installed and clustered via the CAN bus, a white icon will

appear on the display indicating that the flash drive is

connected.

FLYBOX

To activate the Logger choose “Yes” from the Main

Menu>Logger. The icon will turn green when the file is

being written and red when the Logger is enabled but the

USB stick is not connected.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 62

FLYBOX

®

51

Technical specifications

TECHNICAL SPECIFICATIONS

● Graphic TFT LCD with backlight and coated glass,

dimensions 29x18mm.

● Standard mounting 2 1/4” (57mm).

● Powder painted aluminium case.

● Dimensions: 60 x 60 x 40 mm.

● Weight: 140g.

● 4 fuel level sensors input for resistive (300 ohm max)

or capacitive (0~5 Volt) sensors.

● Supply voltage: 10 ~ 30 V=.

● Supply current: 60mA.

● Open-collector alarm output (max 300mA, active

low). This output can also be used to send a tone in

the intercom, using the Flybox optional device code

105899.

● Operating temperature range: -20 ~ +70°C.

● Humidity: 90% max (without condensation).

● Communication through 2 CAN bus.

● USB port: for USB 2.0

CLEANING

The screen is very sensitive to some cleaning materials

and should be cleaned with a clean, damp cloth only.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 63

FLYBOX

®

52

Page Intentionally Left Blank

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 64

FLYBOX

®

53

One Year Warranty:

Product support and warranty information can be found at www.flyboxavionics.it.

Flybox® warrants this Product to be free from defects in materials and workmanship

for 12 months from date of delivery. The inactivity of the Products determined by periods

of repair does not involve the extension of the warranty period.

This warranty covers only defects in material and workmanship found in the products

under normal use and service when the product has been properly installed and

maintained. This warranty does not cover failures due to abuse, misuse, accident,

improper maintenence, failures to follow improper instructions or due to unauthorized

alterations or repairs or use with equipments with which the Products is not intended

to be used. Flybox®, after verification of the complaint and confirmation that the defect

is covered by warranty, at its sole discretion, will either replace or repair the Products

at no costs for the customer. Alterations, additions, or repairs not performed by the

manufactuter shall negate any warranty. This warranty doesn’t cover cosmetic or

incidental damages. Shipping costs, taxes, custom fee, any other duties and any costs

incurred while removing, reinstalling or troubleshooting the Products, shall be at

customer’s charge.

TO THE EXTENT PERMITTED BY LAW, THE WARRANTIES AND REMEDIES

CONTAINED HEREIN ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES

EXPRESS, IMPLIED, OR STATUTORY, INCLUDING ANY LIABILITY ARISING UNDER

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, WHICH MAY VARY BASED ON YOUR JURISDICTION.

TO THE EXTENT PERMITTED BY LAW, IN NO EVENT SHALL UPRIGHT BE LIABLE

FOR ANY INCIDENTAL, SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

WHETHER RESULTING FROM THE USE, MISUSE, OR INABILITY TO USE THIS

PRODUCT. SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY

NOT APPLY TO YOU.

Warranty

Out of warranty repairs

Products that can not be repaired under warranty as out of the

maximum term or that do not work for reasons that would have

been covered by warranty, can be repaired at a flat rate as

described on the site. For out-of-warranty eligible damages, the

repair must be assessed for each individual case.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 65

FLYBOX

®

54

Disclaimer

Term of Use and Disclaimer

Limitation of Liability

In no event shall MICROEL s.r.l. be liable for any direct, indirect,

punitive, incidental, special consequential damages whatsoever

arising out of or connected with the use or misuse of its products.

Entire Obligation

The TERM OF USE, WARRANTY AND DISCLAIMER document

states the entire obligation of MICROEL S.r.l. with respect to the

products. If any part of this disclaimer is determined to be void, invalid,

unenforceable or illegal, including, but not limited to the warranty

disclaimers and liability disclaimers and liability limitations set forth

above, then the invalid or unenforceable provision will be deemed

superseded by a valid, enforceable provision that most closely

matches the intent of the original provision and the remainder of the

agreement shall remain in full force and effect.

General

This disclaimer statement is governed by the laws of ITALY. You

hereby consent to the exclusive jurisdiction and venue of the Courts

of competent jurisdiction, ITALY, in all disputes arising out of or relating

to the use of this product. Use of this product is unauthorized in any

jurisdiction that does not give effect to all provisions of these terms

and conditions, including without limitation this paragraph.

Omnia57 Fuel L-P - Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 1.0

Page 66

Date

Revision Description

02/2019 1.0 First release

Flybox® reserves the right to change the terms,

conditions, and notices under which their products are

offered without prior notice”.

WARNING: All photos, data, drawings, instruments layouts, technical solutions

and data representation you find in this document or watching at FLYBOX®

instruments working and/or you can access by means of any other media,

including web sites, are sole property of MICROEL s.r.l., cannot be copied or

imitate without a written permission of MICROEL s.r.l. itself and are protected

by law, even by means of extended international copyright and/or specific

patents deposited. Any infringement of this statement and of MICROEL s.r.l.

intellectual property will be prosecuted.

©2019 Microel s.r.l. – all rights reserved.

Page 67

Flybox® is a registred brand of Microel s.r.l.- Italy

www.flyboxavionics.it

MICROEL s.r.l.

Via Mortara 192-194

27038 Robbio (PV) - ITALY

Tel +39-0384-670602 - Fax +39-0384-671830

Page 68

Loading...

Loading...