Page 1

Electronic Flap Controller

Flybox

®

EFC-P

Revision# 3.1 17/7/2015

For firmware version 1.5

Page 2

Page intentionally left blank

Page 3

SECTIONS

MECHANICAL INSTALLATION

TRANSDUCER & ACTUATOR INSTALLATION

ELECTRICAL INSTALLATION

USE OF THE INSTRUMENT

TECHNICAL SPECIFICATIONS

Page 4

EFC-P - User’s manual

®

Introduction

FLYBOX

Thank you for purchasing a Flybox® product. We hope

it fully satisfy you and makes your flights pleasant and

secure.

Developing EFC-P, our intent was to create a compact

and lightweight flap controller, easy to install and use.

SYMBOLS USED IN THE MANUAL

NOTE: Used to highlight important informations.

CAUTION: Used to warn the user and indicate a potentially

hazardous situation or improper use of the product.

WARNING: Used to indicate a dangerous situation that can

cause personal injury or death if the instruction is

disregarded.

Rev. 3.1

Page 5

EFC-P - User’s manual

FLYBOX

®

NOTE: Although the EFC-P has been heavily tested to

ensure the maximum safety in every condition, the correct

operation depends also by installation and wiring, that must

be accurately made and verified reading completely this

manual.

NOTE: Keep this manual in the aircraft.

This document must accompany the instrument in the event

of change of ownership.

NOTE: This device is intended for installation onto non type

certified aircraft only, because it has no aviation certifications.

Refer to your local aviation authorities to check if this device

may be installed in your aircraft.

CAUTION: Read entirely this manual before installing the

instrument in your aircraft, and follow the installation and

operating instructions described here.

Important notices & warnings

CAUTION: The pilot must understand the operation of this

instrument prior to flight, and must not allow anyone to use

it without knowing the operation. Don't use this instrument

in flight until you are sure of the correct operating of the same.

CAUTION: When the installation is finished you must do a

test, prior to flight, switching on all the possible source of

electric noise and checking the properly operation of this

instrument.

CAUTION: Using this instrument over the maximum

allowable ranges can cause malfunction or wrong indications.

Rev. 3.1

Page 6

EFC-P - User’s manual

®

Important notices & warnings

WARNING: the EFC-P must be turned off in case of start

with booster. open the corresponding breaker before starting.

warranty shall not apply for damage to the EFC-P for this

reason.

WARNING: The EFC-P is attached directly to the flaps

actuator: the non-respect of the notices above or a damage

to the EFC-P may result in unexpected movements of the

flaps. In this situation you must immediately disable the

EFC-P by turning the switch in the “MANUAL” position (see

chap.4.4 “Use in MANUAL mode”).

WARNING: Responsibility for installation lies entirely with the

installer. Responsibility for operations lies entirely with the

operator.

FLYBOX

IMPORTANT: If you do not agree with the notices above

do not install this instrument in your aircraft, but return

the product for a refund.

Microel s.r.l. reserves the right to change or improve its

products. Information in this document is subject to changes

without notice.

Rev. 3.1

Page 7

EFC-P - User’s manual

FLYBOX

®

SECTION 1

Index

1.1

Mechanical installation

Rectangular panel version

2”¼ round panel version

SECTION 2

2.111Transducer installation

2.213Actuator installation

SECTION 3

3.1 Electrical installation

3.2 Wiring diagram for actuator with no

internal limit switches

3.3 Wiring diagram for actuator with

internal limit switches

3.4 Wiring diagram for actuator with

internal limit switches and external

wires

9

9

10

15

17

17

18

3.5 Wirings check

19

Rev. 3.1

Page 8

EFC-P - User’s manual

®

Index

SECTION 4

FLYBOX

4.1

4.2

4.3

4.4

4.5

Panel indicators and commands

Operation instructions

Use in AUTOMATIC mode

Use in MANUAL mode

Troubleshooting and

error code

SECTION 5

5.126Technical specifications

Warranty

20

21

23

24

25

27

Rev. 3.1

Page 9

EFC-P - User’s manual

FLYBOX

®

Mechanical installation

SECTION 1

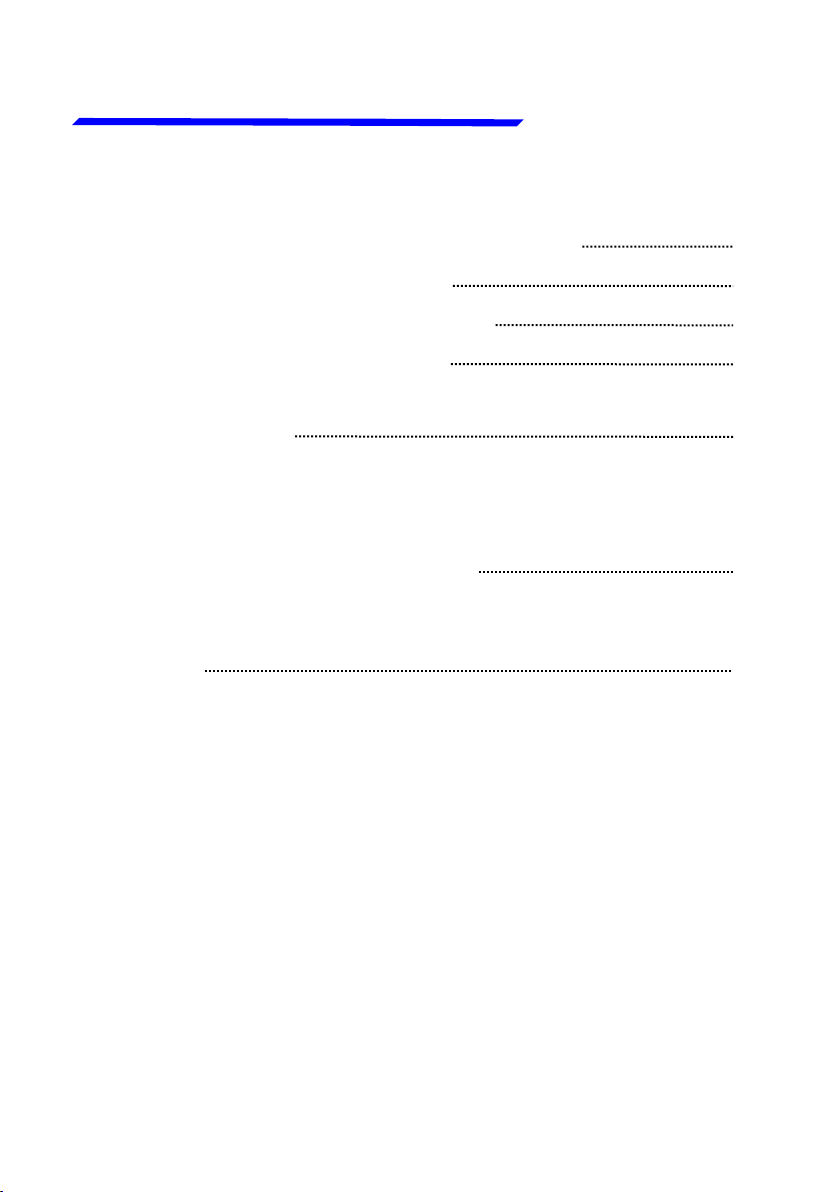

1.1 MECHANICAL INSTALLATION

Ractangular panel version (EFC-P)

Dimensions in millimeters

Panel cut-out

9

Rev. 3.1

Page 10

EFC-P - User’s manual

®

Mechanical installation

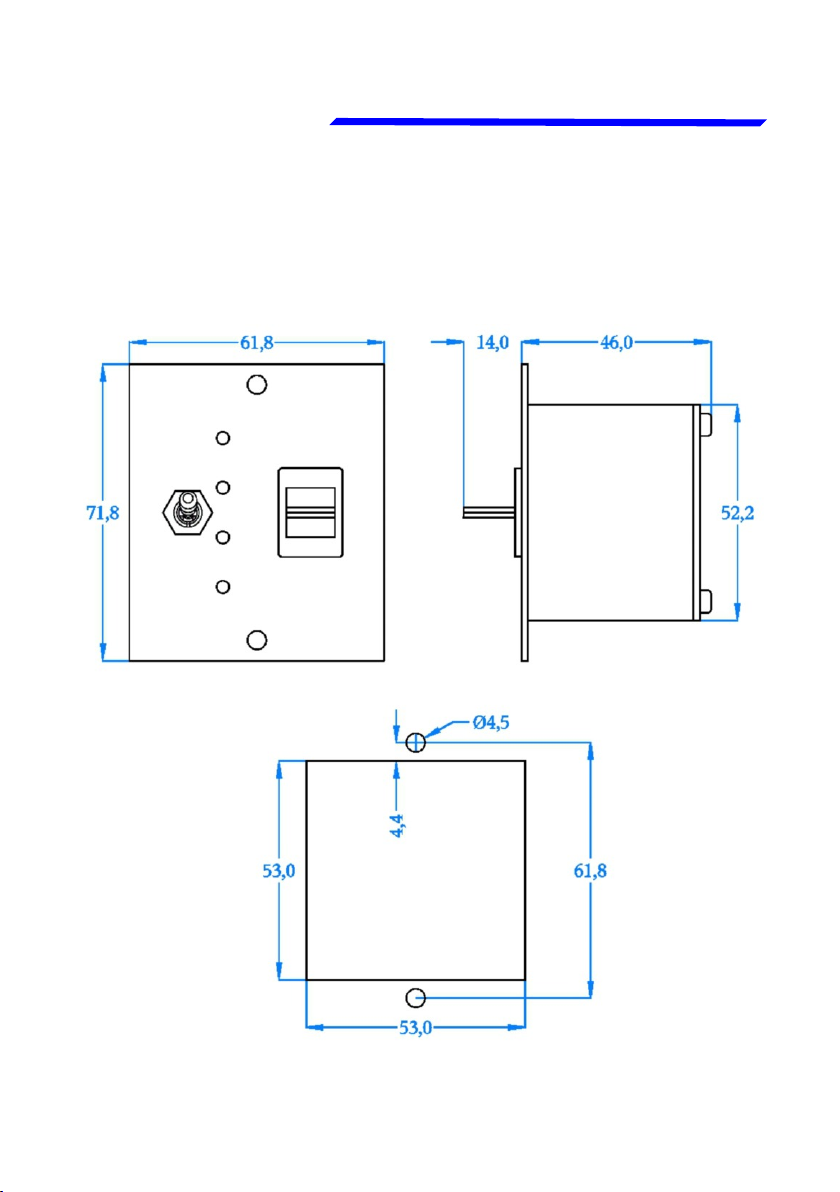

2”1/4 round panel version (EFC57-P)

FLYBOX

Dimensions in millimeters

10

Rev. 3.1

Page 11

EFC-P - User’s manual

FLYBOX

®

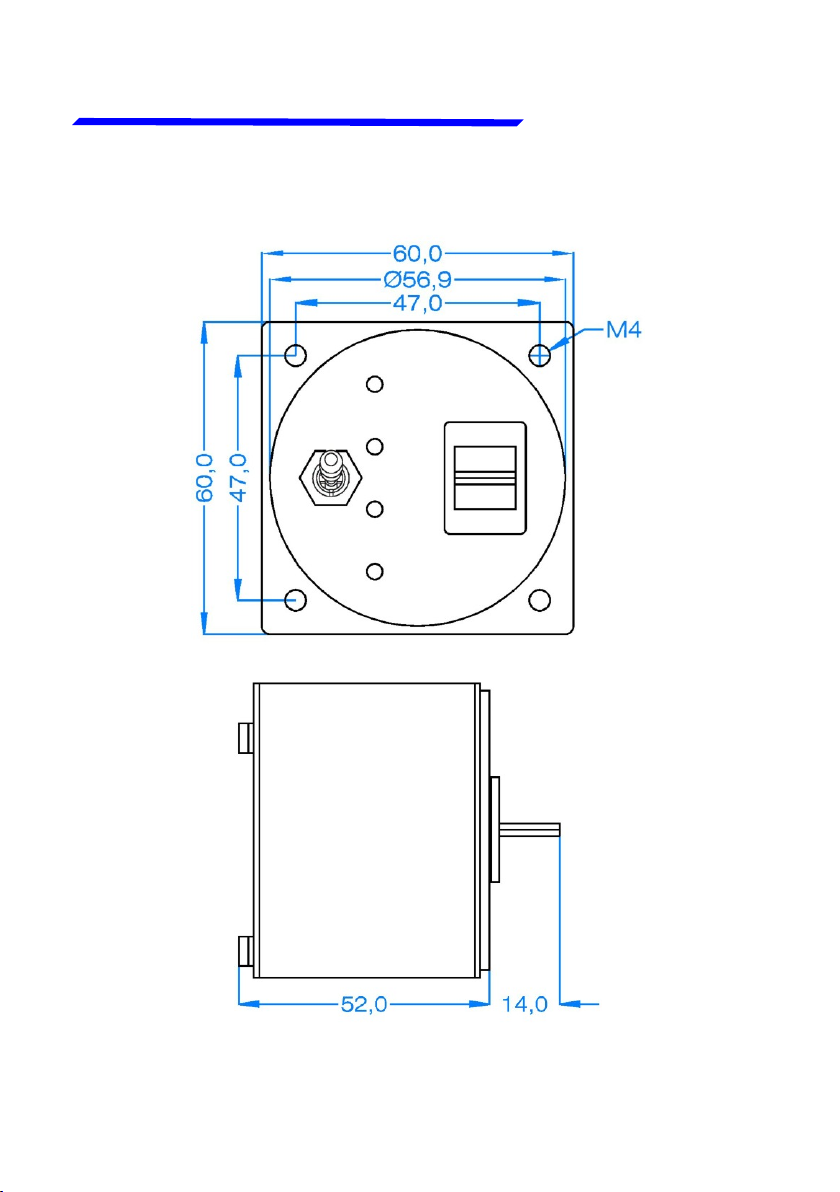

2.1 TRANSDUCER INSTALLATION

Transducer installation

SECTION 2

(only if using actuator without

integrated transducer)

The installation consists in the mechanical coupling

between the flaps actuator (motor) and the transducer

(potentiometer) which permits the EFC-P to know the

actual flaps position.

Example of mechanical installations actuator-transducer

Rev. 3.1

11

Page 12

EFC-P - User’s manual

®

Transducer installation

NOTE:

- The transducer's travel must be at least 10mm more

then the actuator's travel.

- The electrical resistance of the transducer must be

from 1 to 10 Kohm.

- The transducer must be centered over the actuator's

travel so that it isn't possible to exit from the limits, with

consequently damage to the position's transducer.

FLYBOX

12

Rev. 3.1

Page 13

EFC-P - User’s manual

FLYBOX

®

2.2 ACTUATOR INSTALLATION

If the actuator doesn't have any internal limit switches

it's necessary to install them externally.

To avoid the possibility of mechanical and electrical

damage, the actuator travel must match exactly with

the flaps travel: with the actuator completely retracted

(limit switch reached) the flaps must be completely

retracted (or completely extracted for inverse

mechanical coupling); with the actuator completely

extracted the flaps must be completely extracted (or

completely retracted for inverse mechanical coupling).

Adjust your actuator travel if it does not coincide with

the flaps travel, for example using an arm/lever with an

appropriate length.

Actuator installation

If the condition above indicated is not satisfied the

actuator is not protected against possible overtravel

during flap extension and retraction, therefore a pilot

that drive the flaps manually (for example using

“Manual” mode of the EFC-P) can cause mechanical

damage if he don't stop exactly when the flaps have

reached the up and down positions.

Rev. 3.1

13

Page 14

EFC-P - User’s manual

®

Actuator installation

Correct installation: actuator travel exactly match flaps

travel.

FLYBOX

IMPORTANT NOTES ON USING ACTUATORS WITH

INTEGRATED TRANSDUCER:

- The electrical resistance of the transducer must be from 1

to 10 Kohm.

- Choose a model that use the maximum electrical

resistance range. For example if you choose an actuator

with 10 Kohm transducer, verify that the stroke that you are

going to use provide at least a variation of half the

transducer's resistance, i.e. 5 Kohm.

14

Rev. 3.1

Page 15

EFC-P - User’s manual

FLYBOX

®

Electrical installation

SECTION 3

3.1 ELECTRICAL INSTALLATION

In the backpanel there is a 10-poles plug connector (model:

MOLEX Mini-Fit JR.); the corresponding socket connector is

delivered with your EFC-P.

Backpanel plug

Socket view (from wire'insertion side)

15

Rev. 3.1

Page 16

EFC-P - User’s manual

®

Electrical installation

Connector pinout:

1 – Motor out (-)

2 – Power input (+12V)

3 - Positive voltage (+5V) for the position's transducer

4 – Position's transducer signal

5 – Ground for the position's transducer

6 – Motor out (+)

7 – Power input (GND)

8 – “DOWN” limit switch

9 – Limit switches common connection

10 – “UP” limit switch

NOTE: Insert a breaker to the power lead (+12V);

choose a correct amperage depending on the actuator

installed.

FLYBOX

Use avionic cable.

It’s recommendend to use shielded cable (2

poles+shield) for the motor output (pin#1 & 6),

connecting the shield of the cable to ground on the

EFC-P side and leaves disconnected the shield on the

actuator side.

WARNING: Voltage peaks higher than 15 Volt on the

supply line can damage the device.

WARNING: The EFC-P must be turned off in case of

start with booster. Open the corresponding breaker

before starting.

16

Rev. 3.1

Page 17

EFC-P - User’s manual

FLYBOX

®

Electrical installation

3.2 WIRING DIAGRAM FOR ACTUATOR WITH

NO INTERNAL LIMIT SWITCHES

If the actuator used has no internal limit switches you must

install them externally and follow the wiring diagram below.

The UP and DOWN switches must be normally closed; diodes

max current must be at least 3 Ampere.

Pay attention to the UP and DOWN limit switches mechanical

and electrical installation, because a wrong connection can

prevent the EFC-P from turn off the actuator before the

mechanical stop, with possible damage to the actuator itself.

Wiring diagram for actuator with no internal limit switches

3.3 WIRING DIAGRAM FOR ACTUATOR WITH

INTERNAL LIMIT SWITCHES

If the actuator used has integrated limit switches and wiring

(no external wires) use the wiring diagram above, connecting

pin #1 and #6 of the EFC-P connector directly to the actuator.

17

Rev. 3.1

Page 18

EFC-P - User’s manual

®

Electrical installation

FLYBOX

3.4 WIRING DIAGRAM FOR ACTUATOR WITH

INTERNAL LIMIT SWITCHES AND

EXTERNAL WIRES

If the actuator used has 3 wires for the limit switches

connection, probably one wire is the common contact for the

limit switches, so the wiring diagram to the EFC-P is the

following:

Wiring diagram for actuator with internal limit switches and external wires.

Note that the common contact of the limit switches is connected to pin

#9.

18

Rev. 3.1

Page 19

EFC-P - User’s manual

FLYBOX

®

Electrical installation

3.5 WIRINGS CHECK

FIRST CHECK:

When finished all the wirings turn the Auto/Manual switch in

Manual position and check the flaps movement with the

UP/DOWN switch: press in “DOWN” position and check that

the flaps go down, press in “UP” position and check that the

flaps go up. If directions are reversed swap the two actuators

wire (pin 1 and 6 on the EFC-P connector).

SECOND CHECK:

The wiring between the transducer and the EFC-P connector

(pins 3-5) depends on the actuator-transducer mechanical

coupling (i.e. flaps down-->transducer's shaft extracted or

flaps down-->transducer's shaft retracted).

To check if the wirings are ok measure the voltage between

ground (pin#7) and pin #4 of the EFC-P connector:

with the flaps completely down the voltage must be to its

maximum value, with the flaps completely up the voltage

must be to its minimum. If this doesn't occur, or if the EFC-P

does not work correctly, swap the two wires on pins #3 and

#5 of the EFC-P connector.

19

Rev. 3.1

Page 20

EFC-P - User’s manual

®

Panel indicators & commands

FLYBOX

SECTION 4

4.1 PANEL INDICATORS AND COMMANDS

LED 1

LED 2

A/M switch

(Auto/Manual)

LED 3

LED 4

NOTE: The Auto/Manual switch has a safety lock to

avoid accidental operation: it must first pulled on the

outside and then moved to the desired position.

U/D switch

(Up/Down)

20

Rev. 3.1

Page 21

EFC-P - User’s manual

FLYBOX

®

Operation instructions

4.2 OPERATION INSTRUCTIONS

The EFC-P can work in two modes: Automatic or Manual.

For normal operations use the “Automatic” mode; the

“Manual” mode must be used only in case of emergency or

failure of the EFC-P.

NOTE: Before using the device for the first time you must

program the four position that the EFC-P store in memory

and use in Automatic mode. Follow this steps to perform the

programming:

● With the device powered off turn the A/M switch in the

“Automatic” position, then press and hold the U/D switch

in the “UP” position..

● Power on the EFC-P and wait 10 seconds until the LED1

and the LED4 come on steady.

● Release the U/D switch (LED1 and LED4 start flashing).

NOTE: The EFC-P doesn't enter in the programming

mode if a limit switch is open (UP or DOWN limit switch);

if this occour you must turn in “Manual” mode and move

the flaps until the limit switch will de-activate, then repeat

the programming sequence from the beginning.

21

Rev. 3.1

Page 22

EFC-P - User’s manual

®

Operation instructions

● Make this sequence using the U/D switch: 2 click in the

UP position, 2 click in the DOWN position and 1 click in

UP; if the sequence is correct the EFC-P enters in

programming mode and the LED2/LED3 briefly flash.

● Now the first led is flashing indicating that you can adjust

the flaps in the desired position (using the U/D switch).

To store the position, briefly move the A/M switch in

“Manual” and then return in “Automatic”.

● Now the second led is flashing and you can adjust and

then store the second position in the same way explained

in the previous step (U/D switch to adjust then A/M

switch to store the position). Repeat again the step for

the third and fourth position.The EFC-P will automatically

exit from the programming mode and become operative

once the last position is correctly stored in memory.

FLYBOX

NOTE: If the EFC-P is powered on the first time without enter

in the programming mode the four LED will simultaneously

flash.

The positions remains stored in memory also without

power supply.

22

Rev. 3.1

Page 23

EFC-P - User’s manual

FLYBOX

®

Use in AUTOMATIC mode

4.3 USE IN AUTOMATIC MODE

In AUTOMATIC mode you can move the flaps choosing one

of the four stored position; the maximum travel of the motor

is defined by the two limit switches UP and DOWN.

The LEDs show the status of the flaps:

LED on: indicate the current position of the flaps

LED flashing: indicate the position that the flaps are reaching

-EXAMPLE OF USE-

The flaps are in the first position (LED1 on, all other LEDs

off):

to move the flaps in the third position press two times the U/D

switch in the DOWN position; the flaps start moving and the

third LED is flashing, indicating the position that the flaps are

reaching.

When the flaps reaches the second position the first LED turn

off while the second turn on; when they reaches the third

position the second LED turn off and the third turn on. The

flaps have reached the selected position and the EFC-P

return to steady state, waiting for another command.

Pressing the U/D switch in the UP position for more than 1

second move automatically the flaps to the first position

(regardless of the current position).

23

Rev. 3.1

Page 24

EFC-P - User’s manual

®

Use in MANUAL mode

FLYBOX

4.4 USE IN MANUAL MODE

In this mode the flaps position are not fixed between the four

programmed positions but the movement are continuous;

however it's recommended to use the MANUAL mode only

in case of device's electronic failure, because this mode

bypass the internal electronic circuits and connect directly

the motor to the U/D switch.

To control the flaps simply use the U/D switch: press and hold

in a position (UP or DOWN) and release when the motor have

reached the desired position.

24

Rev. 3.1

Page 25

EFC-P - User’s manual

FLYBOX

®

Troubleshooting and error code

4.5 TROUBLESHOOTING AND ERROR CODE

● All the four LEDs flashing: no positions' programming

have been made (see chap. 4.2)

● LED1 and LED2 flashing: it means that the EFC-P try

to move the motor but there is no feedback from the

transducer: can be a wrong connections on the motor's

wiring or on the transducer's wiring.

To exit from this condition you must turn off the device

and remove the cause of failure.

● LED1 and LED3 flashing: it means that the connection

motor/transducer are not correct; maybe the motor's

wire reversal or a wrong tranducer wiring.

To exit from this condition you must turn off the device

and remove the cause of failure.

● LED2 and LED4 flashing: it means that the EFC-P has

detected an over-current condition. Check that wirings

of the actuator motor have no short circuits or check

that the actuator is working correctly.

25

Rev. 3.1

Page 26

EFC-P - User’s manual

®

Technical specifications

FLYBOX

SECTION 5

5.1 TECHNICAL SPECIFICATIONS

● Frontpanel dimensions:

61.8 x 71.8 mm (rectangular panel version).

60.0 x 60.0 mm (2”1/4 round panel version).

● Depth:

46 mm (rectangular panel version).

52 mm (2”1/4 round panel version).

● Weight: 125 g.

● Power requirements: 12 ~ 20 V=, 80 mA.

● Maximum current supplied to the motor: 7 Ampere.

● Operating temperature range: -20 ~ +70 °C.

● Relative humidity: 10% ~ 90% without condensation.

26

Rev. 3.1

Page 27

EFC-P - User’s manual

FLYBOX

®

WARRANTY:

This product is warranted to be free from defects for a

period of 12 months from the user invoice date.

The warranty only cover the manufacture's defects; shall

not apply to product that has been improper installed,

misused or incorrect maintenance, repaired or altered

by non-qualified person.

Date

06/2011 2.8 First release

11/2014 3.0 Layout update

7/2015 3.1 Updated chap.4.2

WARNING: All photos, data, drawings, instruments layouts, technical solutions and

data representation you find in this document or watching at FLYBOX® instruments

working and/or you can access by means of any other media, including web sites,

are sole property of MICROEL s.r.l., cannot be copied or imitate without a written

permission of MICROEL s.r.l. itself and are protected by law, even by means of

extended international copyright and/or specific patents deposited. Any infringement

of this statement and of MICROEL s.r.l. intellectual property will be prosecuted.

Revision Description

©2015 Microel s.r.l. – all rights reserved.

Rev. 3.1

27

Page 28

MICROEL s.r.l.

Via Mortara 192-194

27038 Robbio (PV) - ITALY

Tel +39-0384-670602 - Fax +39-0384-671830

www.flyboxavionics.it

Loading...

Loading...