Flyboard Pro Series User Manual

USER MANUAL

1

DESCRIPTION

Flyboard® is a WFC (Water Flight Device) allowing the user to move both below the surface of the water and in the air.

The supply hose (which is connected to the pump of the PWC) is attached to a Y shaped pipe which roots the water through two nozzles placed under the

user’s feet. This generates thrust and allows the user to move by tilting his feet.

Flyboard® is intuitive to use, but it is an extreme sport which requires to be practiced with vigilance.

Flyboard® is free to use for all recreational activities and flight initiations. Lucrative shows and demonstrations are the exclusivity of ZAPATA

RACING®.

Flyboard® is protected by international patents.

All rights reserved. Any reproduction, even partial of the product by any means whatsoever is prohibited.

95% of its parts are made in France.

SAFETY – RISKY BEHAVIOUR – GENERAL INFORMATION

It is recommended not to use Flyboard® under the age of 16 (no weight restriction).

It is forbidden and dangerous to practice Flyboard® when winds exceed 60 km/h and waves exceed 1 meter in height.

It is mandatory to follow an hour of training in a specialized fly center to understand the basics and the main security rules (please refer to the “ZR Spots”

section on www.zapata-racing.com.)

It is forbidden to use Flyboard® under the influence of alcohol, narcotics or drugs which could affect alertness.

MANDATORY EQUIPMENT:

- Life jacket with CE certification

- Wakeboard type helmet

- Neoprene shorts: the penetration of water through the orifices of the body during a fall or during contact with Flyboard® water jets may cause serious

internal injuries. Wearing a simple bathing suit is not an adequate protection.

IMPORTANT:

It is essential to comply with the navigation laws according to the country where Flyboard® is used.

Make sure the area where Flyboard® is practiced is cleared from any other watercraft such as boats, other PWC or other Flyboard® users as well as

swimmers, divers and other sea users.

Before lifting up to 2 meters or more, and before diving: make sure there is a minimum depth of 4 meters and that the water is clear enough to estimate the

depth and the reliefs.

It is strongly recommended not to take off, land or use Flyboard® near to any source of risk such as rocks, docks, beaches, boats, banks etc. Misuse of

Flyboard® can result in serious injuries.

Do not exceed your limits and avoid aggressive movements to reduce loss of control.

2

This is a high performance product, not a toy.

Do not reproduce tricks and risky behavior such as showed on TV or Internet (i.e. backflips). These are performed by professionals. You risk serious injury, put

your life in danger and risk to seriously damage the equipment if the tricks are not done perfectly.

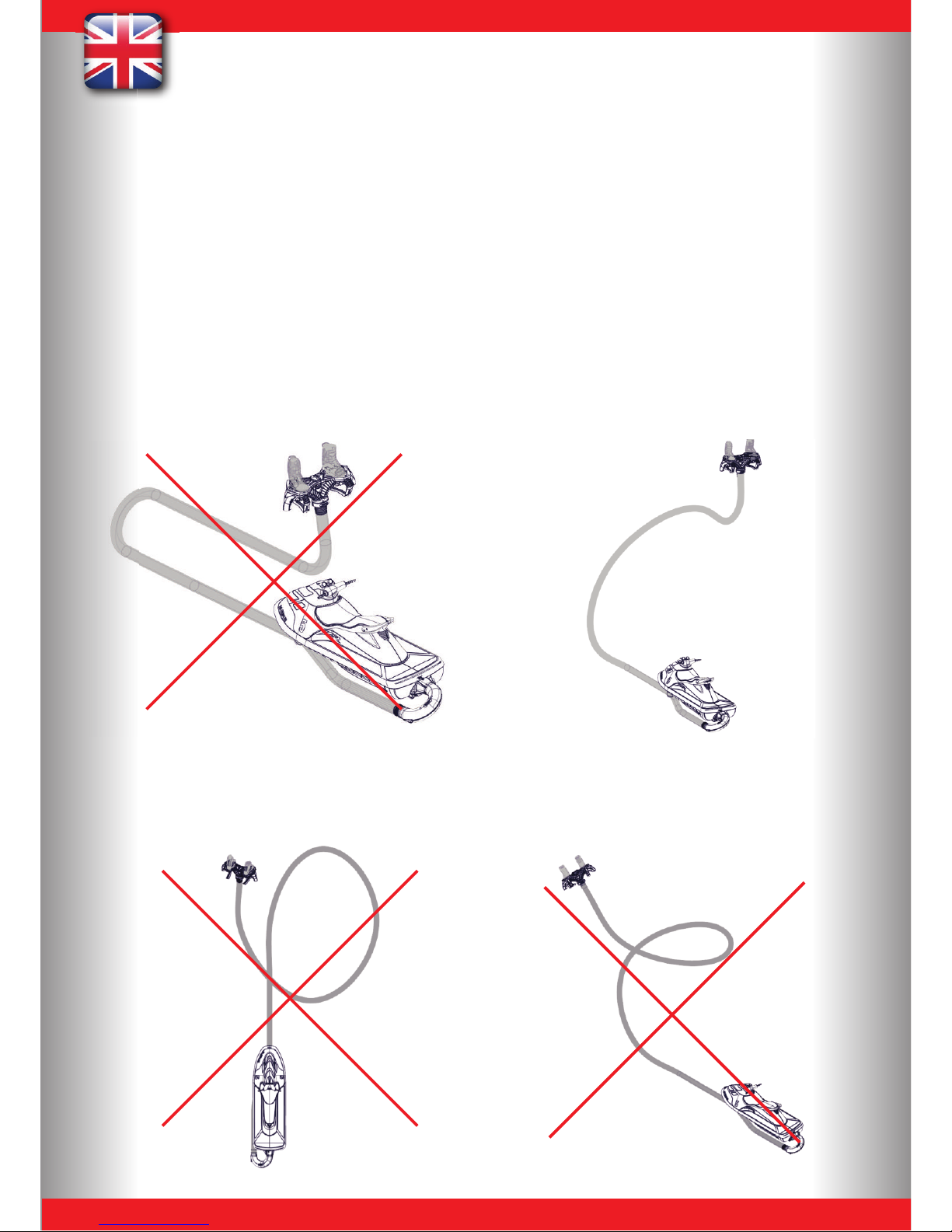

Ensure any trajectory taken opposite the PWC is not too tight, but keep a radius curvature of 4 meters minimum. An aggressive turn leads Flyboard® to over

break and makes the PWC take an abrupt turn with the possible cases:

- Fall of the Flyboard® user

- Fall of the PWC driver

- Breakage of the parts ref. FB02020 – FB02021 – FB02022

Damage the hose ref. FB02002 / ZR01002 / ZR01002-23 by either causing a separation between the inner and outer layer at the connection with the

strap causing an immediate or delayed tear of the hose (this does not apply to the X-Armor hose ref ZR01003 / ZR01003-23

Do not turn 360 in front of the watercraft as this may damage the hose ref. FB02002 / ZR01002 / ZR01002-23 by either causing a separation between

the inner and outer layer of the hose at the connection with the strap, or causing an immediate or delayed tear of the hose (this does not apply to the XArmor hose ref ZR01003 / ZR01003-23).

3

The Flyboard® user and the watercraft driver must be sure the distance between Flyboard® and the PWC is never less than 4 meters. When

Flyboard® is used by 2 persons (without electronic kit – optional, see page 58), the watercraft driver mustn’t exceed 6000 RPM. It is

recommended to use the learning key when using a watercraft over 250HP.

The Flyboard® user and the watercraft driver must be sure that Flyboard® user has sufficient stability and does not fall on his back before taking a

new step in height.

The Flyboard® user must always be positioned to move forward and never backward to limit falls on his back.

The Flyboard® user must constantly control his relative position to the PWC and be even more vigilant when he rises above 4 meters height. The

Flyboard® user must always check the presence of any objects, reefs, buoys, etc.

When falling into water, the Flyboard® user must always check the distance between him and the watercraft because the inertia may push the

PWC at a low speed in the user’s direction.

When falling into water, it is essential that the Flyboard® user or the watercraft driver releases the throttle as soon as possible and turns off the

engine. When the Flyboard® user is underwater (fall or dive) the watercraft driver must immediately releases the throttle and turn the engine off.

A minimum level in swimming is compulsory. Flyboard® should not be used by water phobic people.

When falling (especially on the back), the Flyboard® user can go up to a 2 meters depth underwater so he must anticipate an apnea of about 10

seconds during the fall and during immersion.

Never fly towards the watercraft.

Note : Flyboard® bearings will be stiffer than normal for the first 10 minutes of use.

USING FLYBOARD® FOR THE FIRST TIME

It is mandatory to follow an hour of training in a specialized fly center to understand the basics and the main security rules (please refer to the

”Rental Centers” section on www.flyboard.com.)

When flying a novice person the watercraft driver mustn’t exceed 4500 RPM. It is important not to accelerate if the user fails to take off because

the user may be propelled in the air when positioning his feet flat.

If the person fails to take off, it means his feet are not well positioned.

USING FLYBOARD® WITH EMK (OPTIONAL)

If the Flyboard® user uses the EMK for the first time, level 1 (learning mode) must be used first (only 1 LED lit) during 20 minutes at least. The

user must train at each level for 20 minutes minimum before advancing to the next level. At the exception of level 4 which should never be used

before 5 hours of training at level 3, and level 5 which should never be used before 10 hours of training at level 4.training at level 3, and level 5

which should never be used before 10 hours of training at level 4.

4

TYPE OF PWC

Any type of watercraft as long as is approved and certified by the authorities in the country where it is used.

- Power requirement: 100 HP

- Maximum power requirements: 300 HP

Adaptors for Sea Doo, Yamaha, Kawasaki and Honda PWCs are available within the distribution network.

It is extremely dangerous and not recommended to remove the PWC buoyancy elements.

ADAPTATION TO THE PWC

To connect Flyboard® on the watercraft:

a) Remove the steering and reverse systems.

b) Assemble the pump interface (ref. FB03A08) with the appropriate adapter (PWC brand and model specific).

Adaptors are necessary for to allow assembly between Flyboard® and the PWC. They are available through the distribution network, and

compatible with all main brands: Sea Doo, Yamaha, Kawasaki and Honda. As the adaptor is not included in the Flyboard® kit, please ensure your dealer

know which PWC brand and model you intend to use with Flyboard®.

Adapting Flyboard® on Sea Doo Spark:

A specific adaptation system is available for the use of Flyboard® with the Sea Doo Spark (2 or 3 seaters, with or without IBR, recommended for 90HP

version). Please refer to page 17 for complete assembly instructions.

WHERE TO PRACTICE FLYBOARD®?

Flyboard® can be used in both lakes and open seas when the minimum water depth of 4 meters is respected.

It is strictly forbidden to use the Flyboard® in confined spaces such as swimming pools etc...

Do not start the watercraft or use Flyboard® in insufficient water depths (less than 1 meter) with sandy bottom, it may damage Flyboard® bearings.

In the event of such use, check the operation of all bearings before further use to avoid breakage of the equipment.

Warning, it is the responsibility of the user to make sure there is sufficient depth in the stretch of water used.

5

MAINTENANCE – AFTER SALES SERVICE

WARNING: NEVER use hydrocarbons like acetone or petrol on polycarbonate parts (all see-through parts) as these products can seriously damage the

material.

To ensure adequate security, we recommend to:

• Check the all board’s screws are tight after 2 hours of use.

• Change the supply hose every 2 years.

• Change the plastic balls ref. FB02267 of Flyboard® deck ref. FB04B01 every year. Ensure to use silicone grease or Vaseline (no marine

grease or other product containing hydrocarbons that may damage the Flyboard® material).

• Change the clips ref. FB02046 of the Flyboard® deck ref. FB04B01 every year.

• Change the parts ref. FB04051, FB04070, FB04071, FB04087, FB04094 and FB03011 every year.

• Flyboard® should be rinsed with clean water after each use (hose, deck, bindings) and stored in a dry location away from direct sunlight

(this does not apply to the X-Armor hose ZR01003 / ZR01003-23).

• Do not pull the hose on the floor when full of water (this does not apply to the X-Armor hose ZR01003 / ZR01003-23).

• The hose should be rinsed, dried and rolled up after each use and stored away from direct sunlight (this does not apply

to the X-Armor hose ZR01003 / ZR01003-23).

WARRANTY

Flyboard® is covered by warranty against all manufacturing faults for 1 year following the date of purchase. You will be required

to provide your purchasing invoice.

ZAPATA RACING® will provide warranty cover on Flyboard® if used as described in this manual.

Warranty is limited to the operation and not the visual condition of the parts.

Warranty does not cover any part subject to wear and tear (i.e. plastic balls ref. FB02267, hose (ref. FB02002 / ZR01002 / ZR01002-23, etc.)

Flyboard® should be used in its original configuration. It is strictly forbidden and dangerous to modify, remove or add parts other than those provided

by ZAPATA RACING®.

Breakage of equipment caused by falls or violent/extreme use will not be covered by warranty. ZAPATA RACING® cannot be held responsible for such

usage of the product.

6

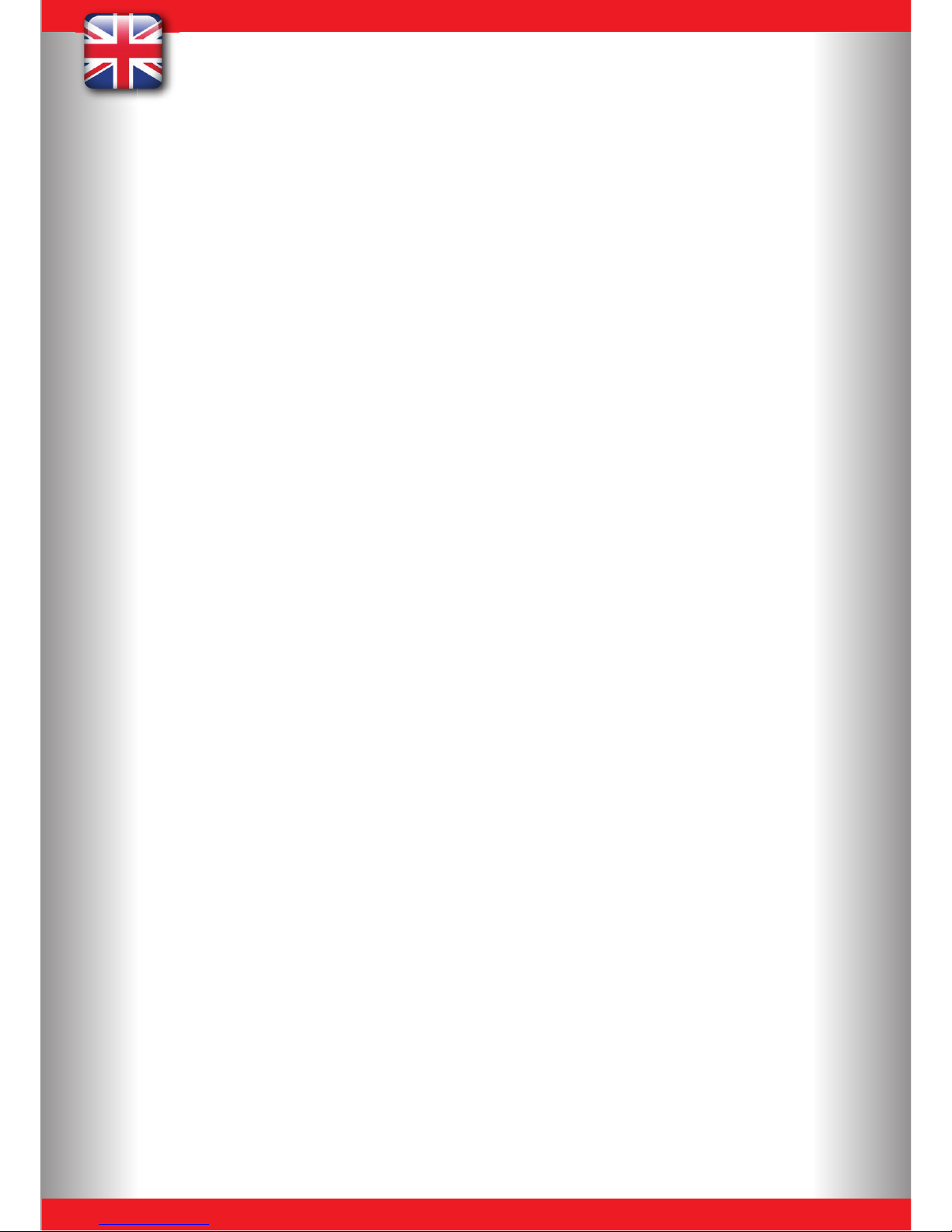

FLYBOARD® PRO SERIES

REF. QT DESIGNATION

FB04B01 1

FLYBOARD® DECK

FB03004 (S-M) 1

BINDINGS

FB03009(L-XL)

FB03A03 1

HOSE SWIVEL

FB02002 1

PRO RIDER HOSE

ZR01002 /-23

X-POWER HOSE

ZR01003 /-23

X-ARMOR HOSE

FB02020 1

HOSE STRAP

FB02022 1

FASTENING STRAP

FB03A08 1

PUMP INTERFACE

FB03A01 1

EQUIPPED U PIPE

FB02021 1

CARABINER

7

Installing the Flyboard® kit on the PWC:

Remove the steering and reverse systems.

Assemble the pump interface (ref. FB03A08, page 50) with the appropriate adapter (brand and model specific).

Adaptors are compulsory to allow assembly between Flyboard® and the PWC. They are available through the distribution

network, and compa-tible with all main brands: Sea Doo, Yamaha, Kawasaki and Honda. As the adaptor is not included in

the Flyboard® kit, please ensure your dealer know which PWC brand and model you intend to use with Flyboard®.

STEP 01 : ASSEMBLY OF THE PUMP

INTERFACE WITH THE ADAPTER

8

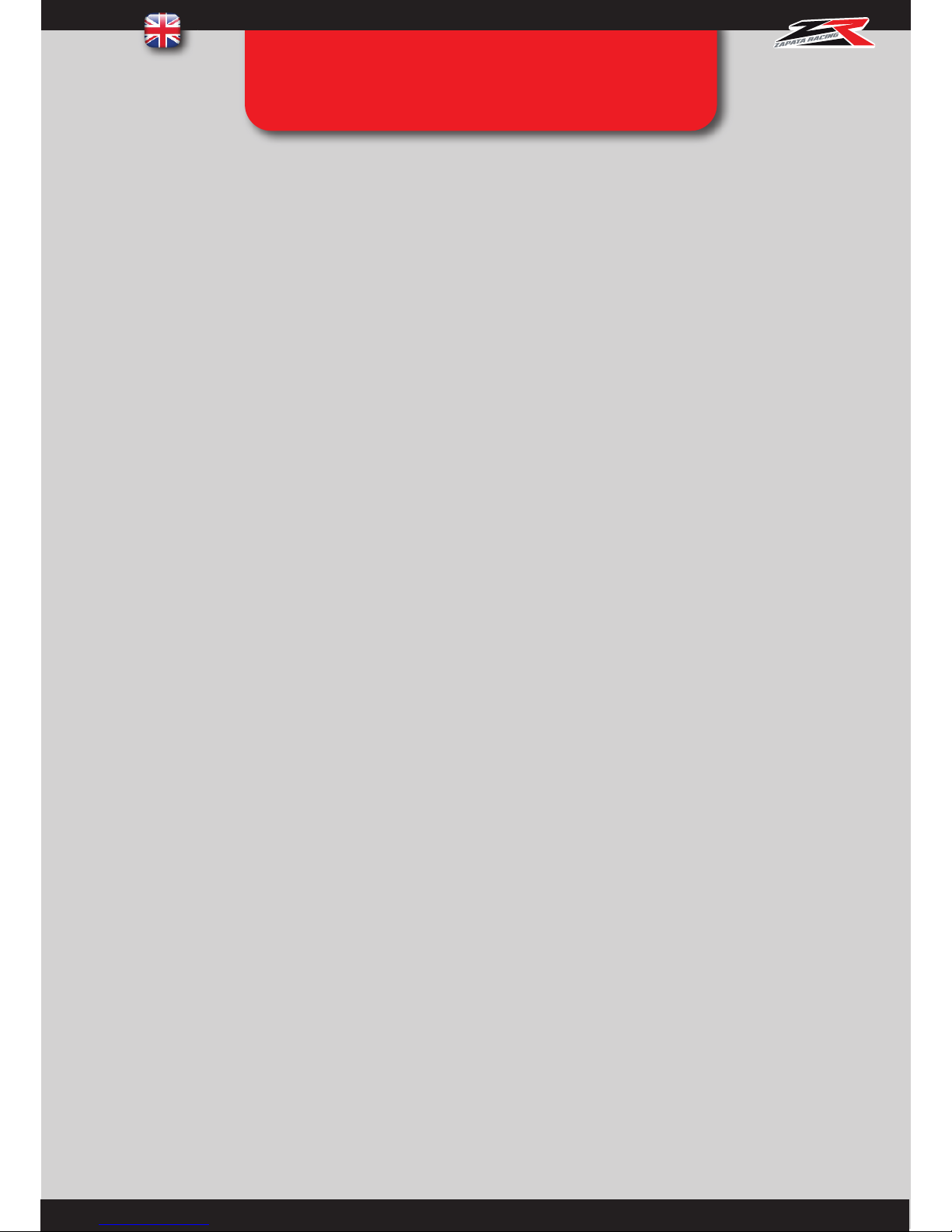

FB03KAF01: SEA DOO FLYBOARD® ADAPTER KIT

REF. QT DESIGNATION

FB03039 1

SPECIAL BARB

FB03049 1

BARB O-RING

FB02266 4

LUG STUG

FB02272 4

SPECIAL NUT 2012 +

FB02263 4

SPECIAL NUT

FB02200 4

SPECIAL RING 1

FB02201 4

CHC SCREW M8X30

FB02067 4

CHC SCREW M8X100

INSTRUCTIONS :

FB03039 : Plug the connector ref. FB03039 to the PWC’s Venturi after you have installed the O-ring ref. FB03049. FB03028 :

Connect the pipe ref. FB03028 to the connector ref. FB03039. FB02201 : Torque 28 N.m, use medium strength thread locking

fluid

FB02267 : Torque 20 N.m, use high strength thread locking fluid

9

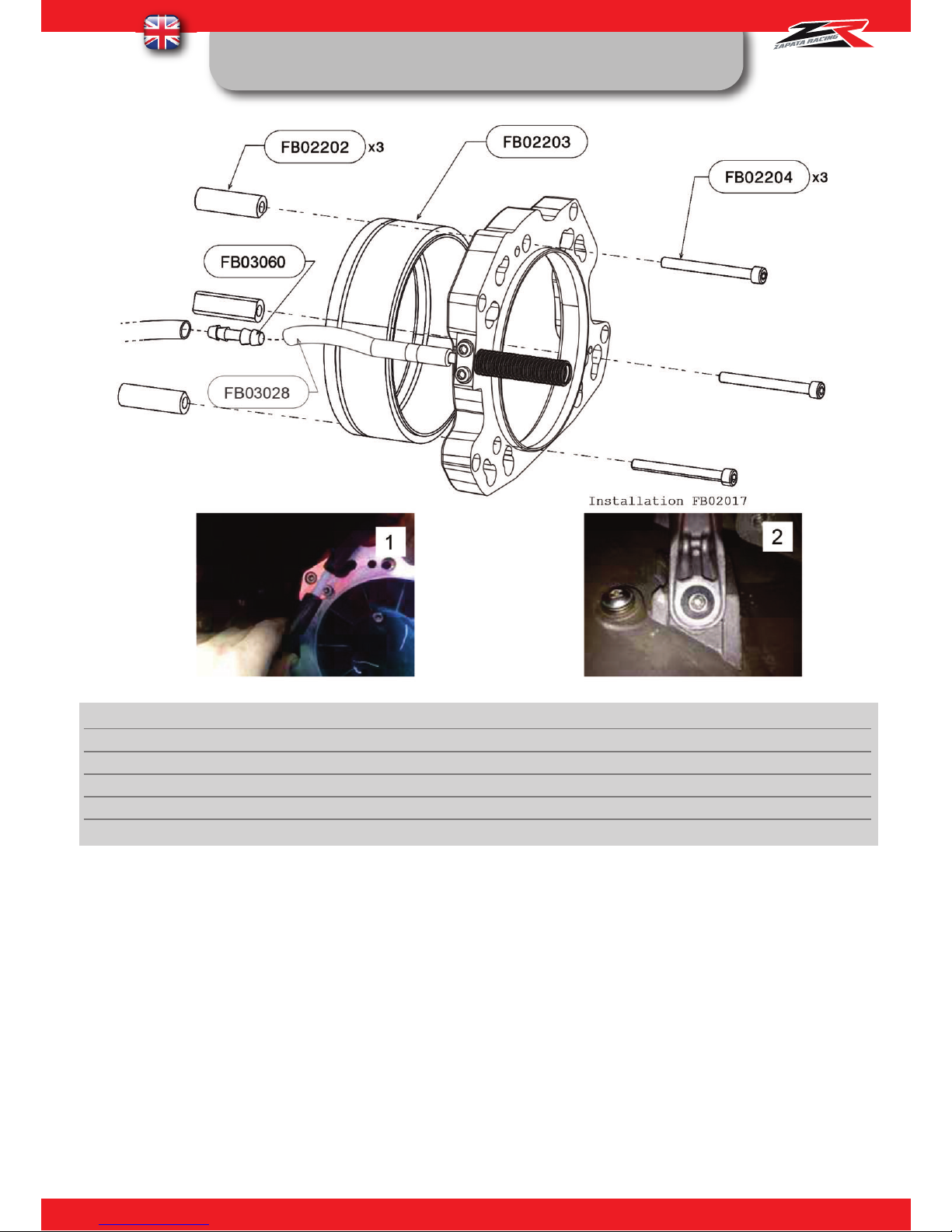

FB03KAF02: SEA DOO 2010 FLYBOARD® ADAPTER

KIT

REF. QT DESIGNATION

FB03060 1

MALE CONNECTOR Ø8

FB02017 2

FILLISTER HEAD SCREW M8X30

FB02202 3

SEADOO 2010 SPACER

FB02203 1

SEADOO 2010 PUMP ADAPTER

FB02204 3

CHC SCREW M8X80

INSTRUCTIONS :

FB03028 : Connect the Venturi pipe réf. FB03028 using the connector ref. FB03060 to the original PWC’s Venturi pipe

(see picture 1). FB02017 : Change the left and right back screws of the pump and replace them with the screws ref.

FB02017. Use high strength thread locking fluid; torque 30 N.m (see picture 1).

FB02204 : Torque: 28 N.m, use medium strength thread locking fluid.

10

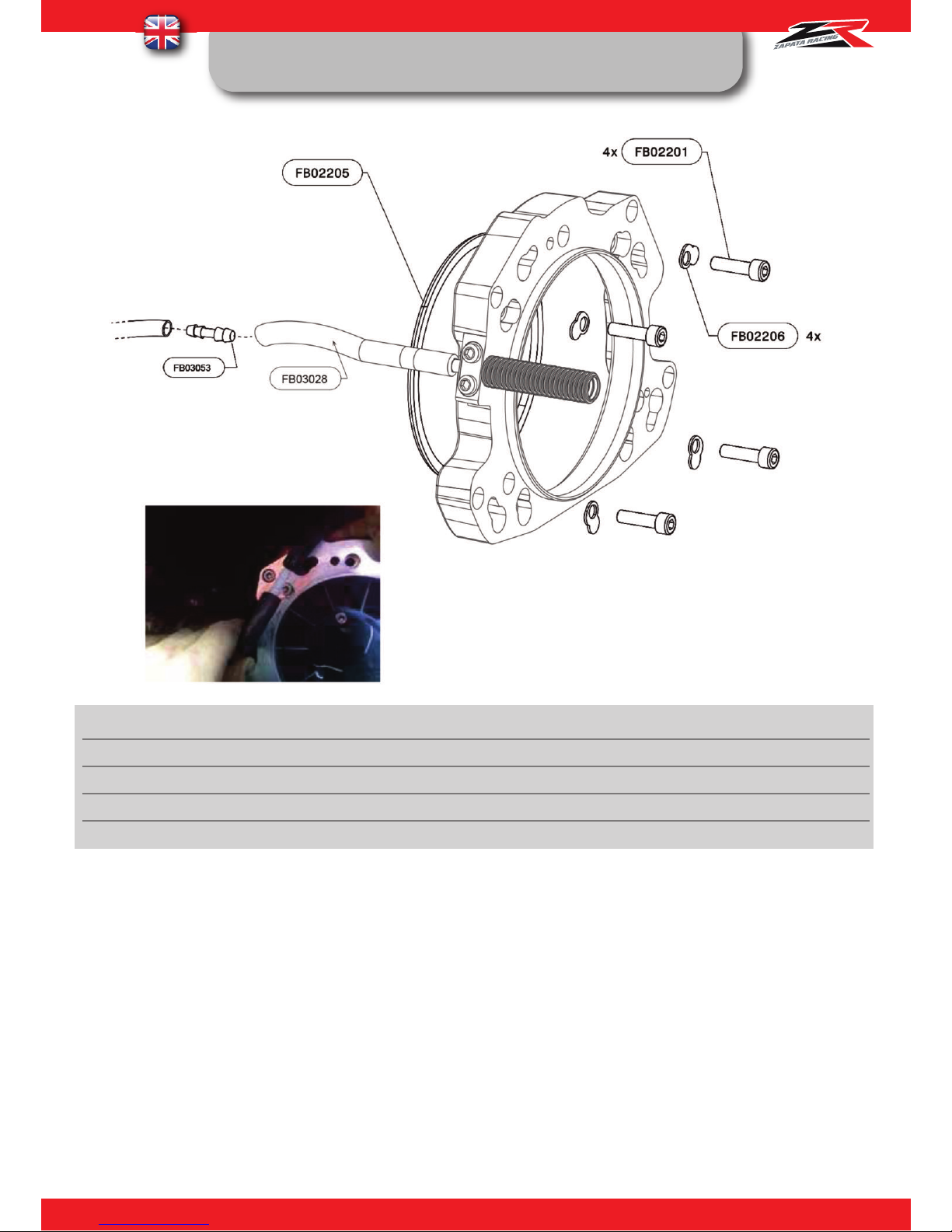

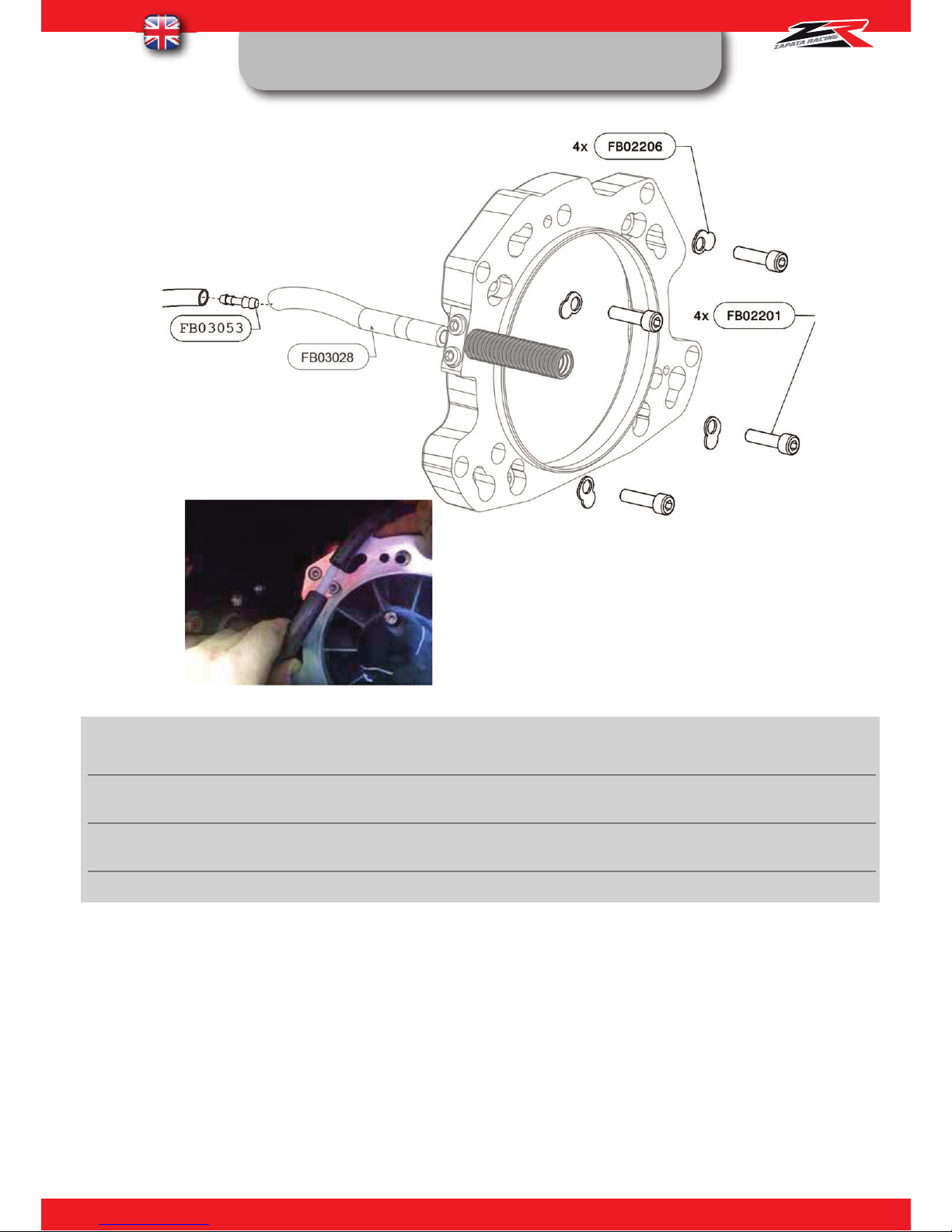

FB03KAF03: KAWASAKI 15F FLYBOARD® ADAPTER

KIT

REF. QT DESIGNATION

FB03053 1

MALE CONNECTOR Ø8/10

FB02205 1

KAWASAKI 15F PUMP ADAPTER

FB02201 4

CHC SCREW M8X30

FB02206 4

SPECIAL RING 2

INSTRUCTIONS :

FB03028 : Connect the Venturi pipe réf. FB03028 using the connector ref. FB03060 to the original PWC’s

Venturi pipe (see picture 1). FB02201 : Torque 28 N.m, use medium strength thread locking fluid.

11

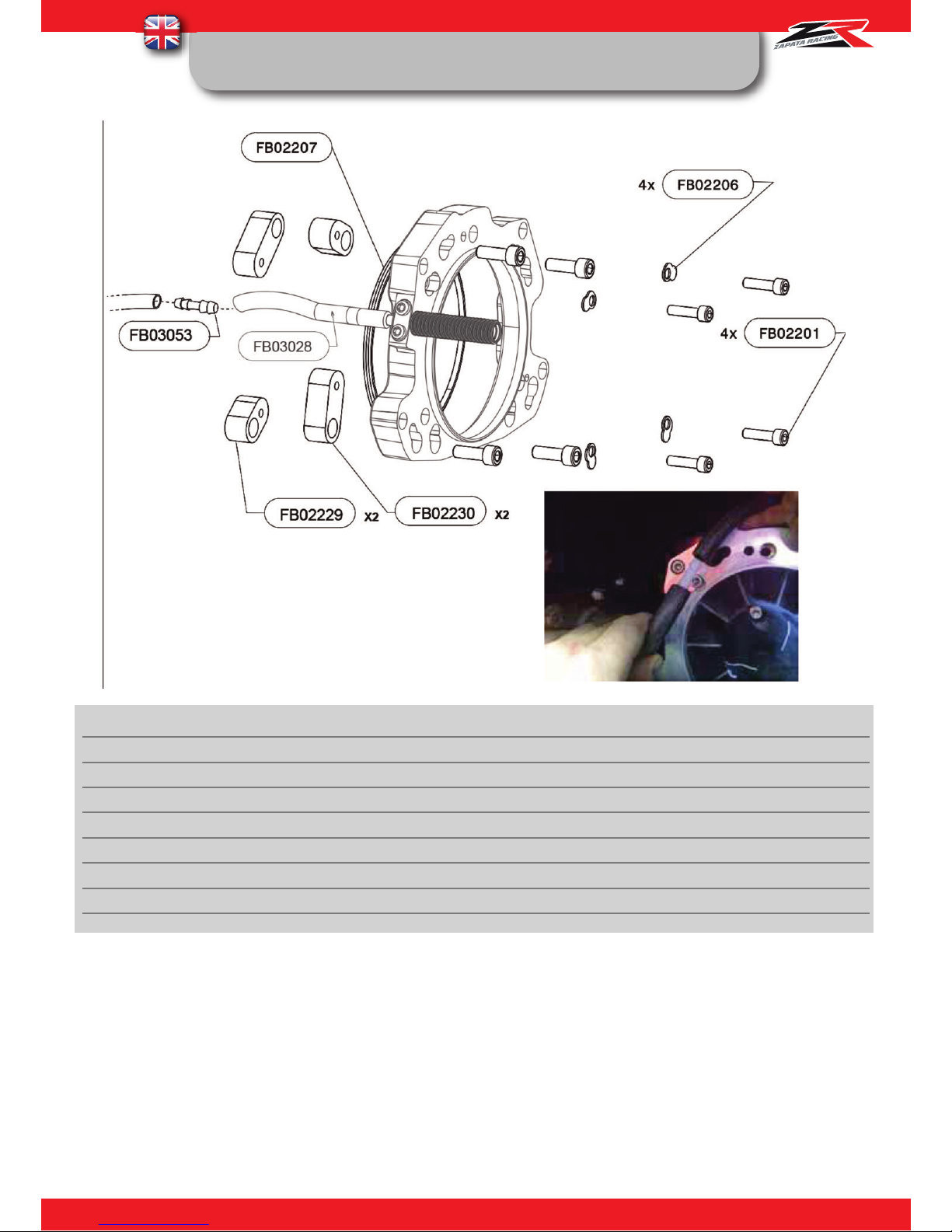

FB03KAF04: KAWASAKI ULTRA FLYBOARD® ADAPTER

KIT

REF. QT DESIGNATION

FB03053 1

MALE CONNECTOR Ø8/10

FB02229 2

REINFORCING

-

SMALL

FB02230 2

REINFORCING BOSS LARGE

FB02207 1

KAWASAKI ULTRA PUMP ADAPTER

FB02232 4

SCREW M10X30

FB02231 4

SCREW M8X150

FB02206 4

SPECIAL RING 2

FB02201 4

CHC SCREW M8X30

INSTRUCTIONS :

FB03028 : Connect the Venturi pipe réf. FB03028 using the connector ref. FB03060 to the original PWC’s Venturi pipe (see picture 1).

FB02201 : Torque 28 N.m, use medium strength thread locking fluid.

12

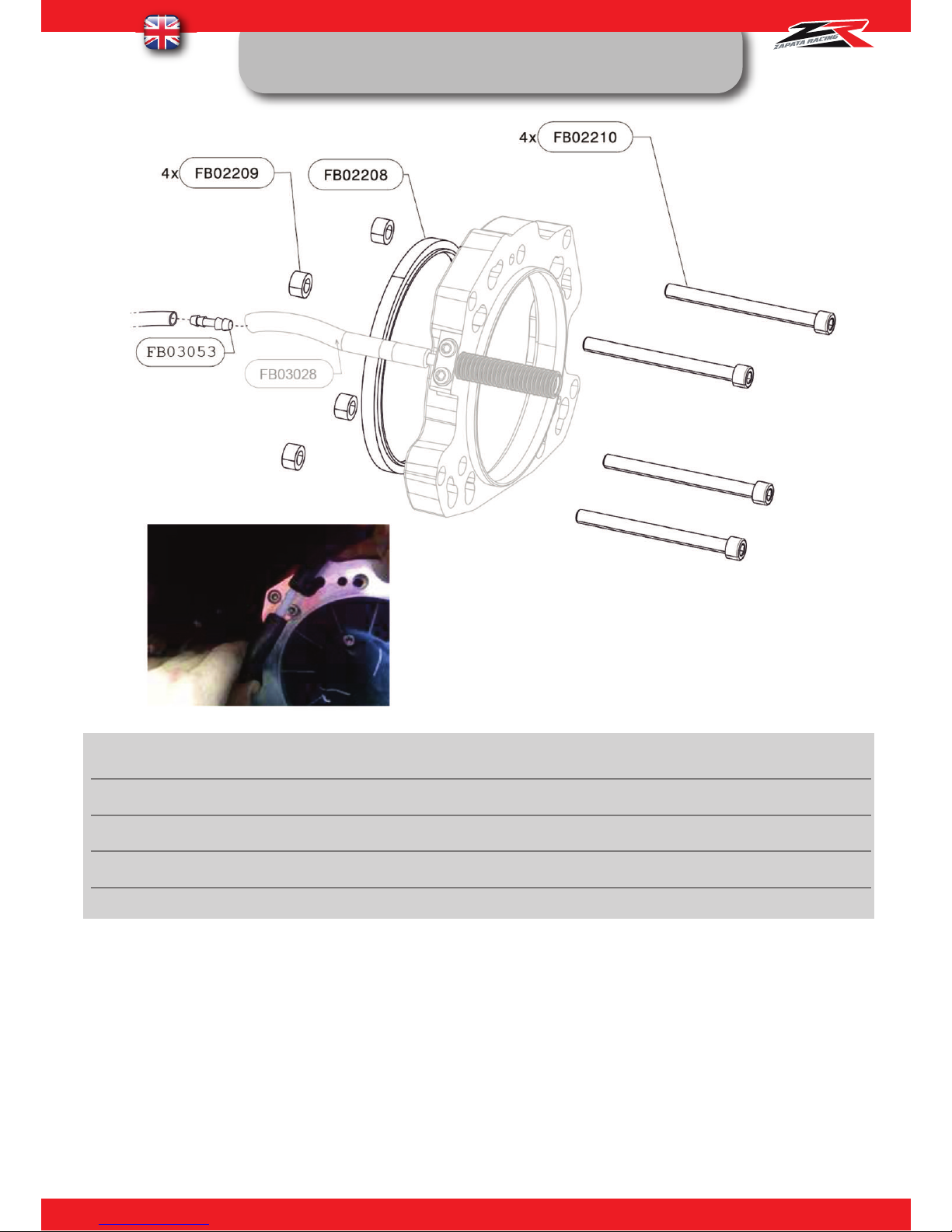

FB03KAF05: YAMAHA FLYBOARD® ADAPTER

KIT

REF. QT DESIGNATION

FB03053 1

MALE CONNECTOR Ø8/10

FB02209 4

YAMAHA PUMP SPACER

FB02208 1

YAMAHA PUMP ADAPTER

FB02210 4

SPECIAL SCREW M10X120

INSTRUCTIONS :

FB03028 : Connect the Venturi pipe réf. FB03028 using the connector ref. FB03060 to the original PWC’s

Venturi pipe (see picture 1). FB02210 : Torque 28 N.m, use medium strength thread locking fluid

13

FB03KAF06: HONDA FLYBOARD® ADAPTER KIT

REF. QT DESIGNATION

FB03053 1

MALE CONNECTOR Ø8/10

FB02206 4

SPECIAL RING 2

FB02201 4

8X30 SCREW

INSTRUCTIONS :

FB03028 : Connect the Venturi pipe réf. FB03028 using the connector ref. FB03060 to the original PWC’s

Venturi pipe (see picture 1). FB02201 : Torque 28 N.m, use medium strength thread locking fluid.

14

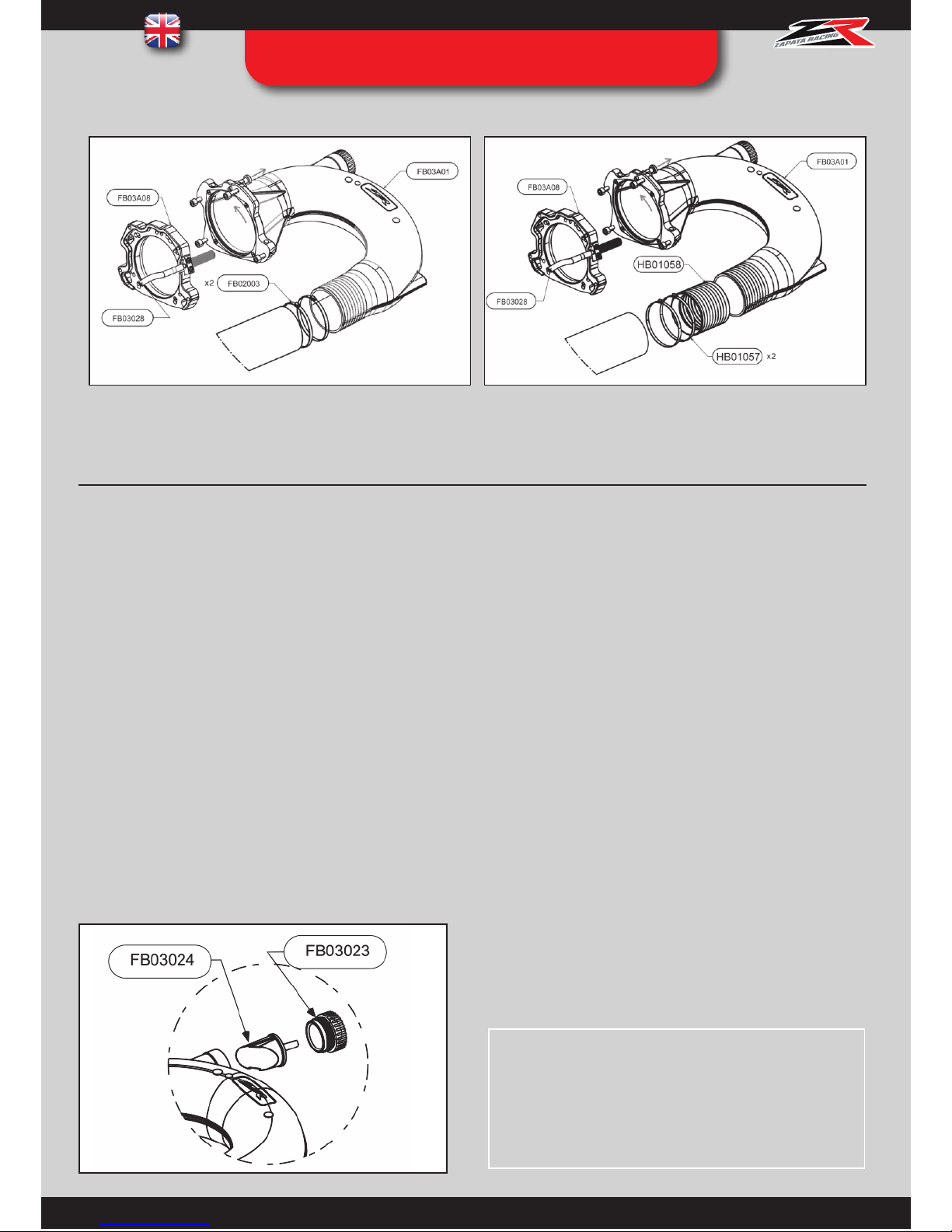

STEP 02 : PWC CONNECTION

ASSEMBLY

Standard version X-Power version

Assembly with Pro Rider and X-Armor hoses

(FB02002/ZR01003/ZR01003-23)

Assembly with X-Power hose

(ZR01002/ZR01002-23)

INSTRUCTIONS :

FB03A01: Pull and turn the index pin ref. FB02014 to keep it in open position. Slot the U-Pipe ref. FB03A01 in the

matching holes of the pump interface ref. FB03A08, turn it and lock the system with the index pin ref. FB02014.

NOTE: Grease the link between the parts ref. FB03A08 and FB03A01 every 5 uses to aid assembly.

FB02003: Slip the clamps ref. FB02003 over the hose.

Slip the hose over the u-pipe ref. FB03A01 until all

teeth are covered. Tighten the clamps with a size 13

key: torque 18 N/m

HB01057: Open the red cuff ref. HB01050 and place it

on the teeth of the u-pipe FB03A01. Slip the clamps ref.

HB01057 over the X-Power hose (ZR01002/

ZR01002-23). Slip the hose over the red cuff ref.

HB01050 until all teeth are covered. Tighten the clamps

with a size 13 key : torque 18 N/m

PWC in propulsion mode

Unscrew the nozzle FB03023

Remove the cap FB03024

Screw the nozzle FB03023

15

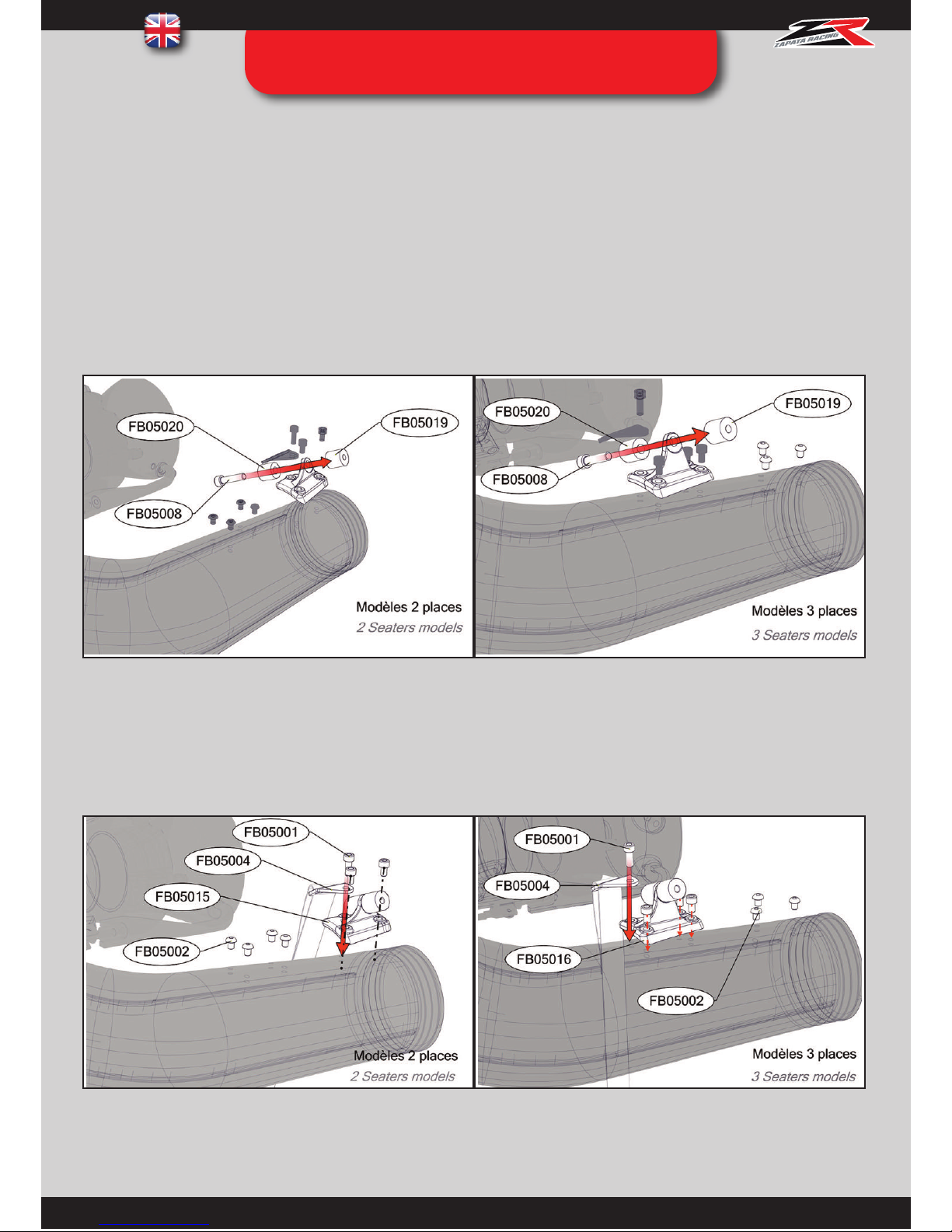

STEP 02BIS : PWC CONNECTION

ASSEMBLY WITH SEA DOO SPARK

Use the mount that is relevant to your model of the Sea Doo Spark and assemble the stop cylinders ref. FB05019 and

FB05020 with the screw ref. FB05008 and a size 6 Allen key.

Assemble the mount ref. FB05015 or FB05016 using the screws ref. FB05001 on the relevant space of the U-pipe

using a size 5 Allen key, making sure that the strap holder (ref. FB05004) is assembled in the process.

2. Assembly of the mount

The assembly system compatible with Sea Doo Spark can be assembled to the 2 and 3 seaters models, with and without

IBR. We recommend 90HP.

1 Assembly of the stop cylinders on the relevant mount

You will find two mounts for assembly of the stops ref. FB05019 and FB05020. The mount ref. FB05015 has 3 holes and

will be used with 2 sea-ters models, and the mount ref. FB05016 has 4 holes and will be used with 3 seaters models.

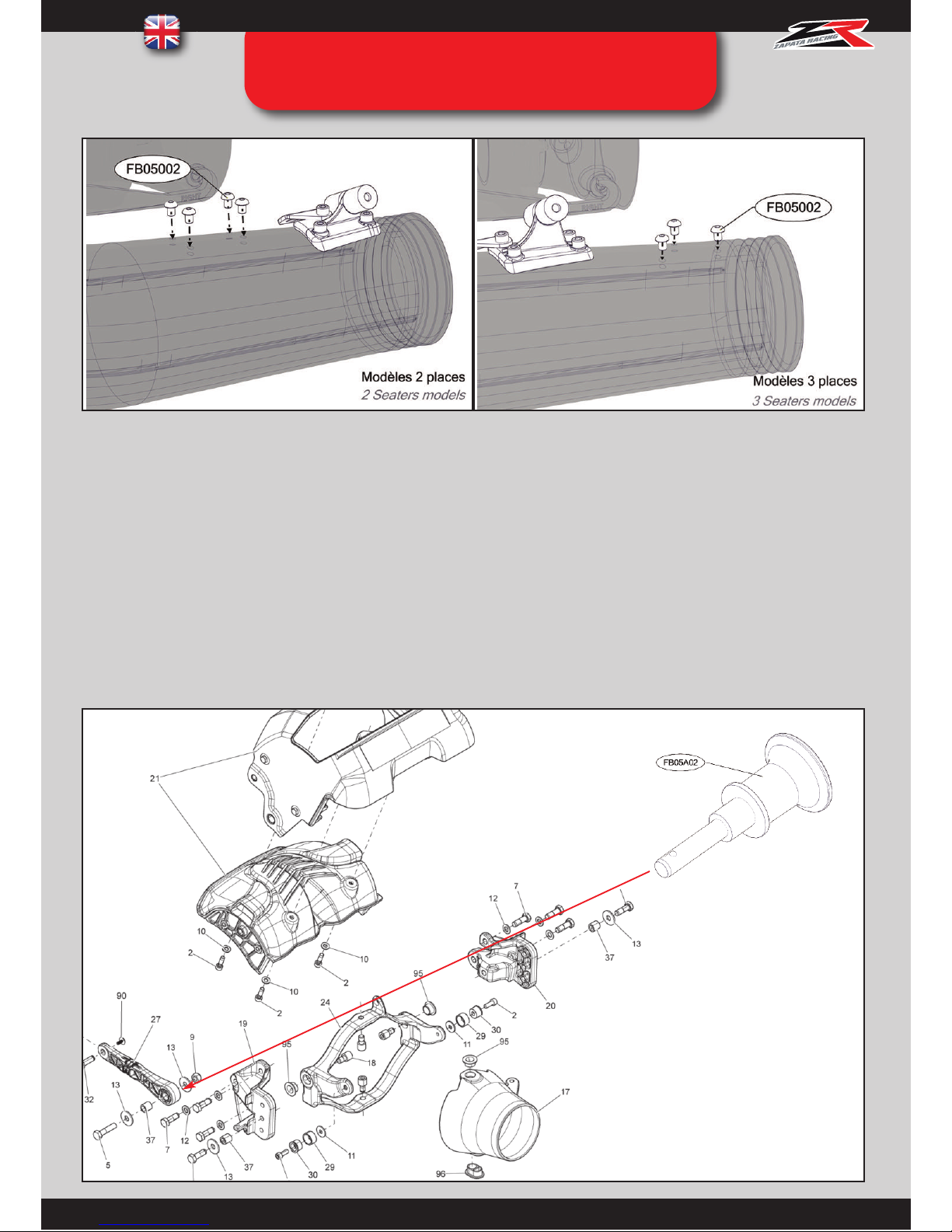

16

STEP 02BIS : PWC CONNECTION

ASSEMBLY WITH SEA DOO SPARK

Plug in the space left empty with the screws ref. FB05002 and a size 4 Allen key to avoid water leakage (leading to a loss

of power).

3.PWC Modifications

a. IBR Models : Quick assembly / unassembly of IBR

Remove the M8 screw from the IBR cover with size 13 key. This will stop the cover from coming down automatically when

the U-Pipe will be in place.

17

Replace the screw with the index pin ref. FB05A02 and place it inside the cover as shown above, in order to keep the IBR

working. The index pin can be inserted or removed to activate or deactivate the IBR depending on the user’s wish to use his

PWC with Flyboard® (index pin removed) or not (index pin inserted in the cover).

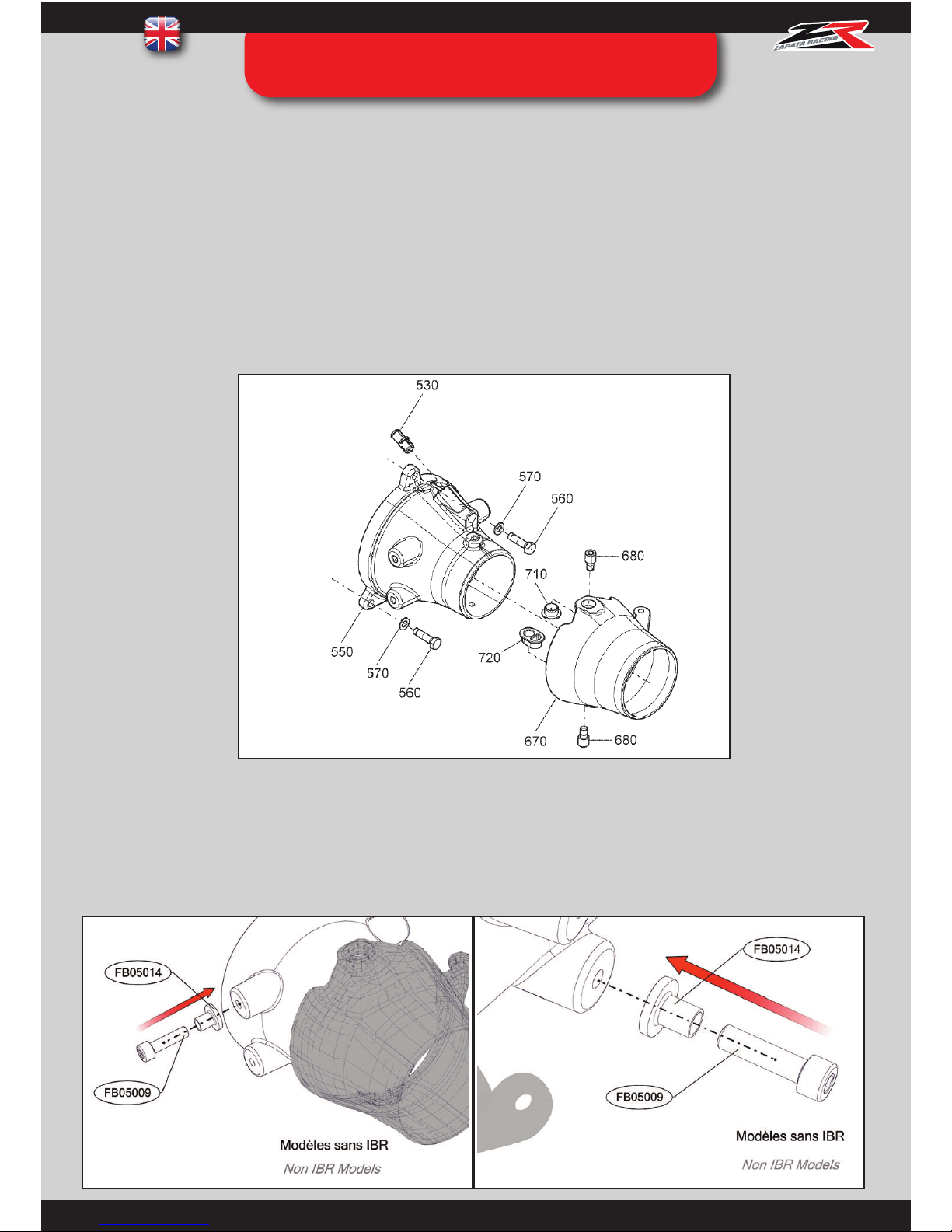

We will only use the top left and bottom right slots. Screw the bolts ref. FB05009 in the yellow slots.

b. Non IBR Models : attachment to the original nozzle

Localize the PWC’s fixed nozzle, especially the slots in yellow :

STEP 02BIS : PWC CONNECTION

ASSEMBLY WITH SEA DOO SPARK

Loading...

Loading...