FLY SERVICE SUPPORT

FS404 SERVICE MANUAL

1

FLY SERVICE SUPPORT

TABLE OF CONTENTS

INTRODUCTION………………………………………………………………………

Chapter 1 EXPLODED VIEW AND COMPONENT DISPOSAL…………………

EXPLODED DIAGRAM…………………………………………………………….

DISASSEMBLY AND ASSEMBLY ………………………………………………………..

SERVICE TOOLS…………………………………………………………………….

DISASSEMBLE……………………………………………………………………….

ASSEMBLY……………………………………………………………………………

Chapter 2 ACTUALL BOARD……………………………………………………….

SIDE A…………….…………………………………………..……………………………….

SIDE B……………………….………………………………………………………………..

Chapter 3 CIRCUIT INTRODUCTION………………………………………………

Chapter 4 TROUBLESHOOTING……..………………………………………..…..

Chapter 5 UPGRADE SOFTWARE INTRODUCTION…………..……………….

INTRODUCTION

The purpose of this document is to help service workshop technicians to service products.

This service manual must be used only by authorized service suppliers. The content of it is

confidential. Please note that provides other guidance documents for service suppliers.

Follow these regularly and comply with the given instructions. while every effort has been

made to ensure the accuracy of this document, some errors may exist. please keep in mind

also that this documentation is continuously being updated and modified, so always watch

out for the newest version.

CAUTIONS

Please refer to the phone’s user’s guide for instructions relating to operation, care, and

maintenance, which include important safety information.

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti-static workstation and that an anti-static wrist

strap is worn.

3. Use only approved components as specified in the parts list.

4. Ensure all components, modules, screws, and insulators are correctly re-fitted after

servicing and alignment.

5. Ensure all cables and wires are repositioned correctly.

Electrostatic discharge can easily damage the sensitive components of electronic

products. Therefore, every service supplier must observe the precautions which

mentioned above.

2

FLY SERVICE SUPPORT

GENERAL REPAIR INFORMATION

1. Make sure your testing equipment is functioning properly before beginning repair work.

2. before starting repairs you must observe ESD precautions such as being in your ESD

protected area and connecting your wristband.

3. use gloves to avoid corrosion and fingerprints.

4. cover windows and displays with a protective film to avoid dust and scratches5. use a

lint-free cloth to clean the LCD.

6. when cleaning the pads use a soft cloth\ESD brush and isopropanol. Do not use a glass

fiber pencil: this scratches the surface and will corrosion.

7. non-faulty mechanical parts(except shielding lids and bent parts or soldered

components). May be reused if they are not soldered.

8. when removing the shielding lids make sure to replace them with new ones, otherwise

the high-frequency leakage can affect the device

9. always use the original spare parts.

10. check the soldering joints of the parts concerned with regard to the fault symptom. And

resolder them if necessary.

11. remove excess soldering flux after repair.

12. observe the torque requirements when assembling the unit.

13. please aware that some malfunctions may be software related and solved by an update

3

FLY SERVICE SUPPORT

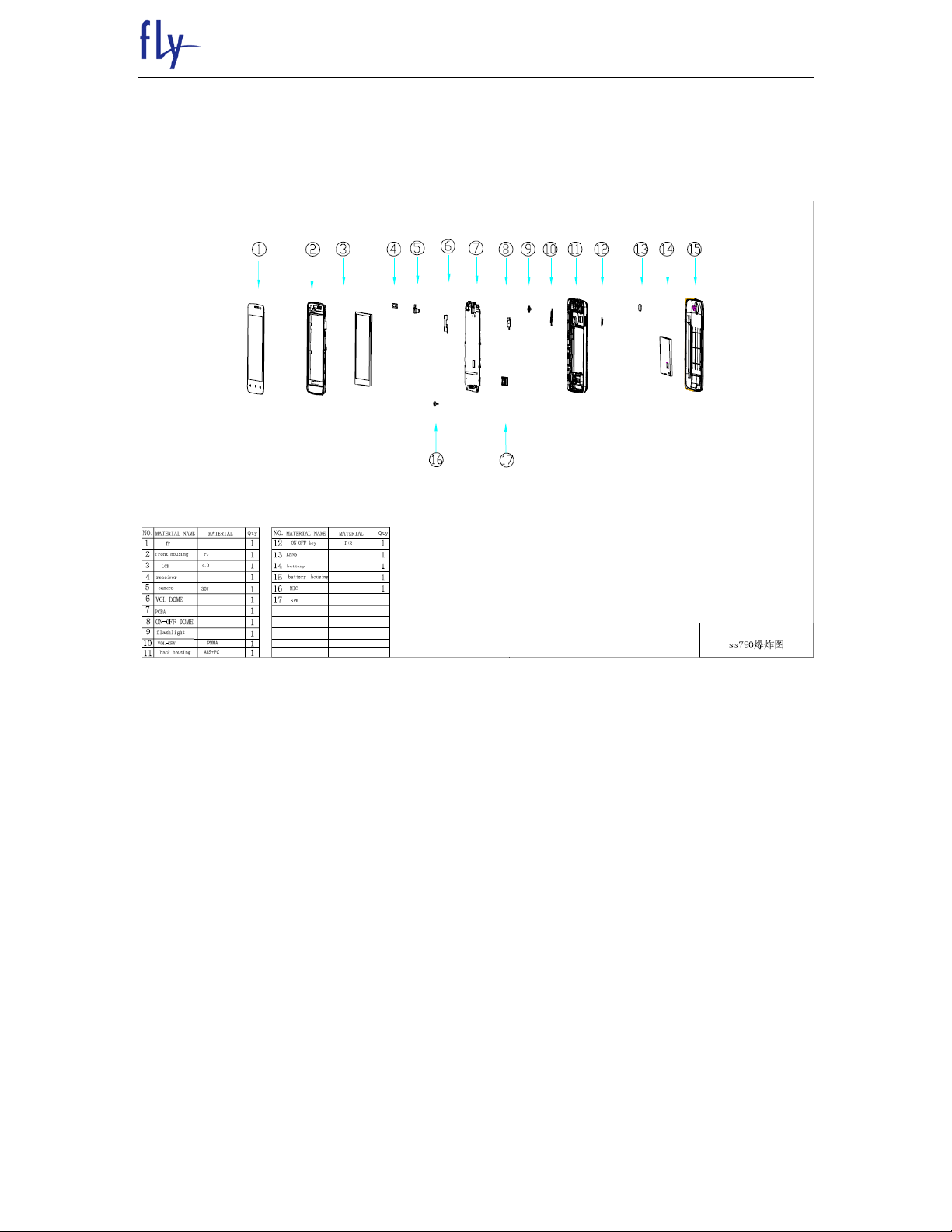

Chapter 1

EXPLODED VIEW AND COMPONENT DISPOSAL

1.1 EXPLODED

4

FLY SERVICE SUPPORT

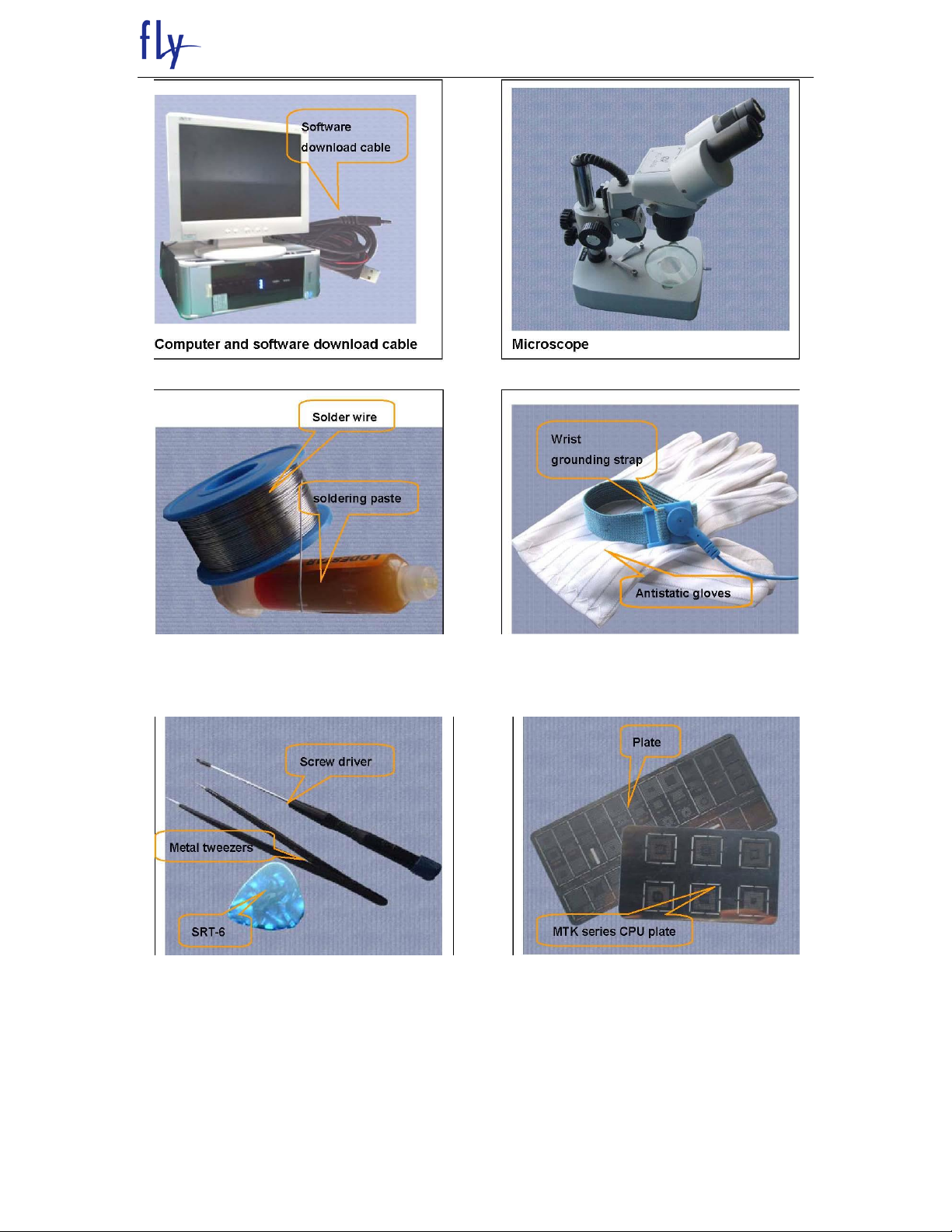

1.2 DISASSEMBLY AND ASSEMBLY

1.2.1 SERVICE TOOLS

5

FLY SERVICE SUPPORT

Solder wire, soldering paste Wrist grounding strap, Antistatic gloves

6

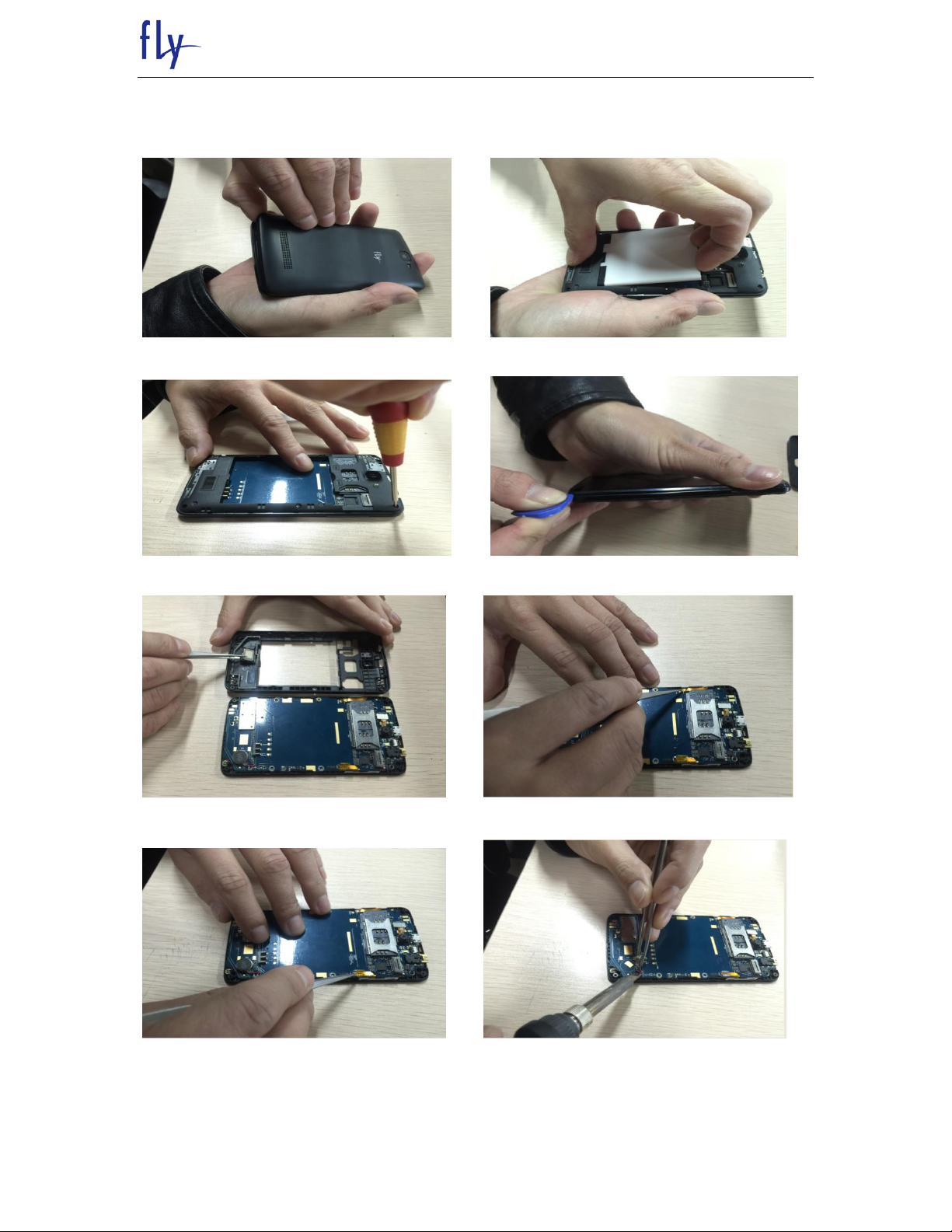

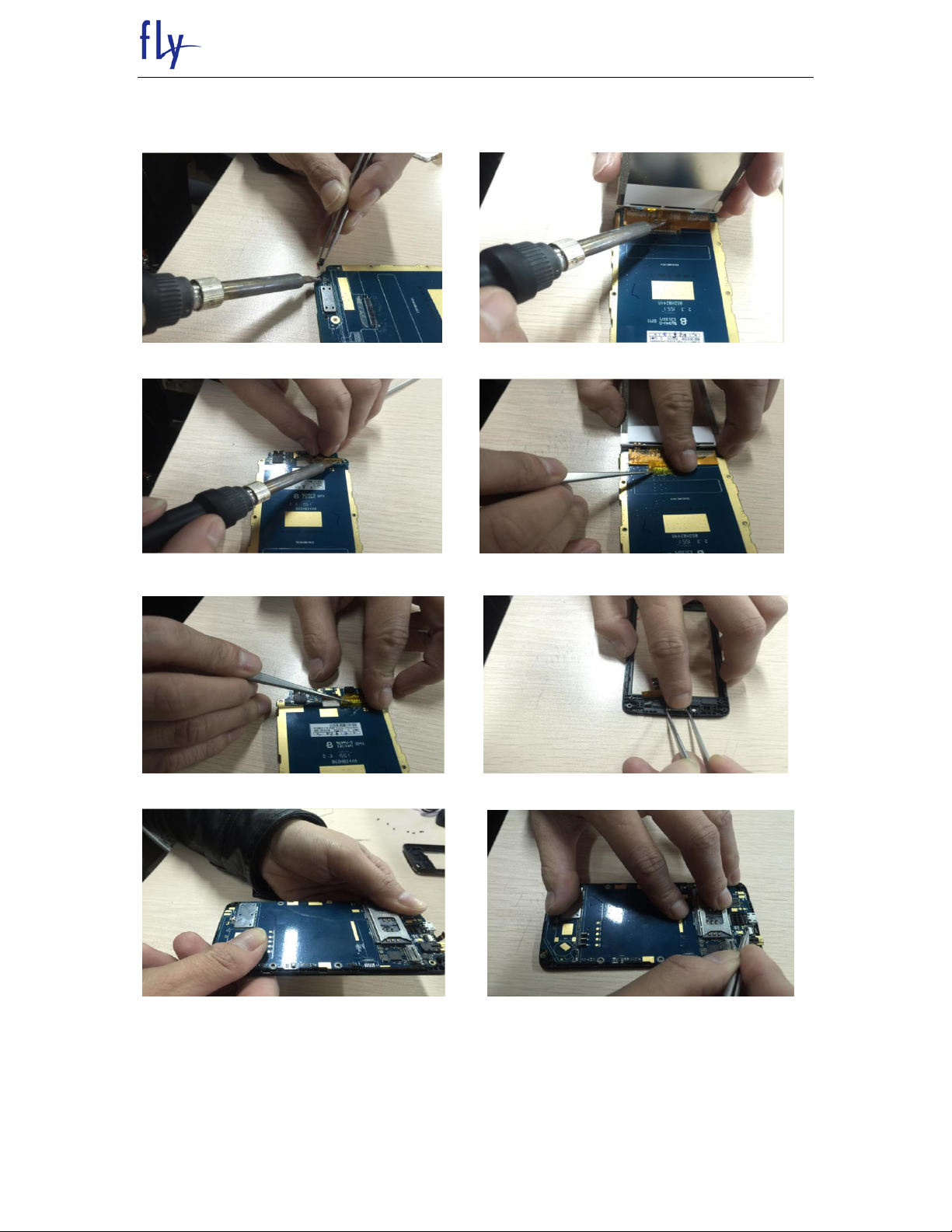

1.2.2 DISASSEMBLY

Remove battery cover Remove battery

FLY SERVICE SUPPORT

Remove 6 screws Remove back cover

Remove speaker Remove Insulating paper

Remove Insulating paper Remove Vibrater

7

FLY SERVICE SUPPORT

Remove NO/OFF FPC insulated Remove volume FPC insulated

Separate After camera Separate TP-FPC

Remove PCBA 3 screws Take out THE PCBA

The LCD protective film paste Separate the LCD

8

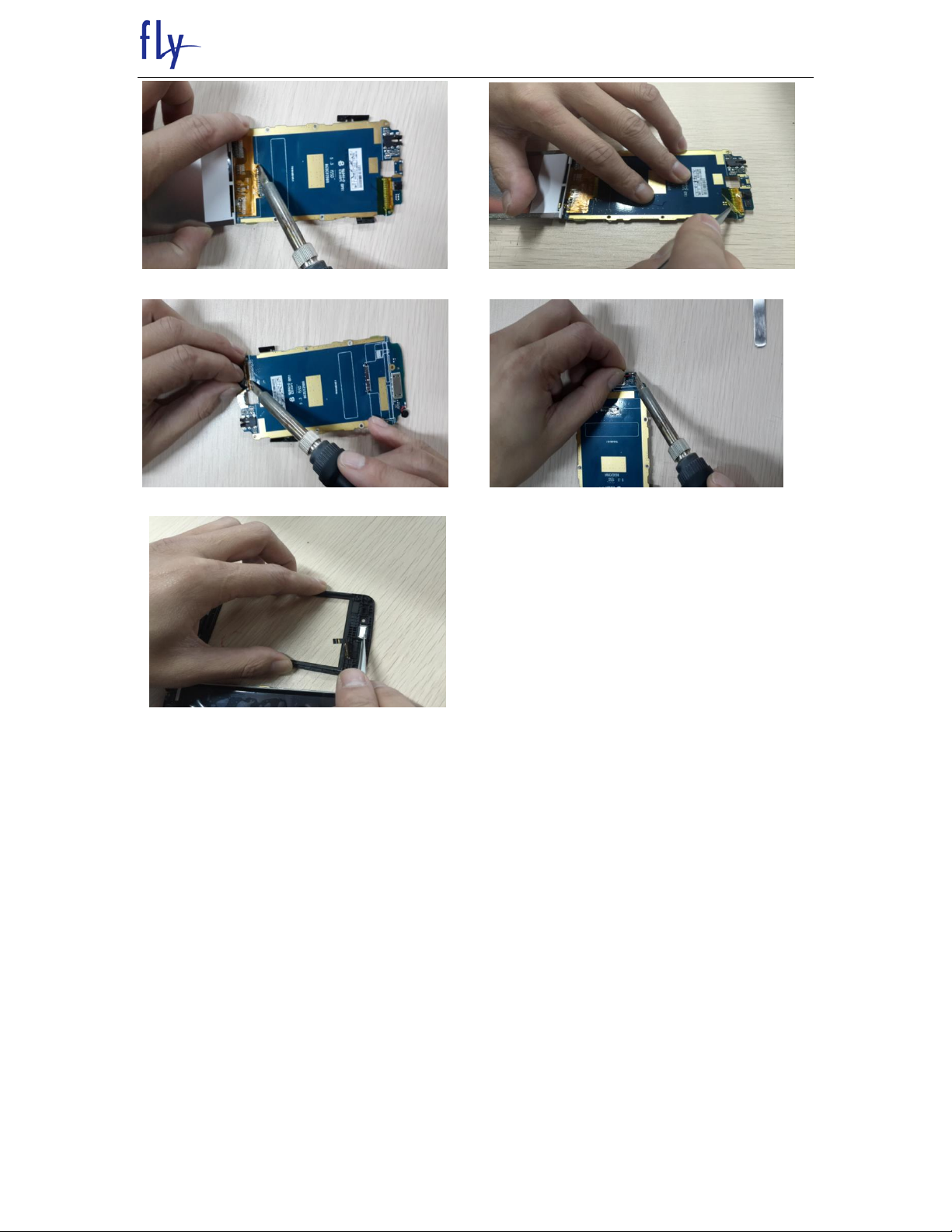

FLY SERVICE SUPPORT

Use the soldering iron Separate LCD Separate Before camera

Use the soldering iron Separate camera Use the soldering iron Separate MIC

Separate The Receiver

9

FLY SERVICE SUPPORT

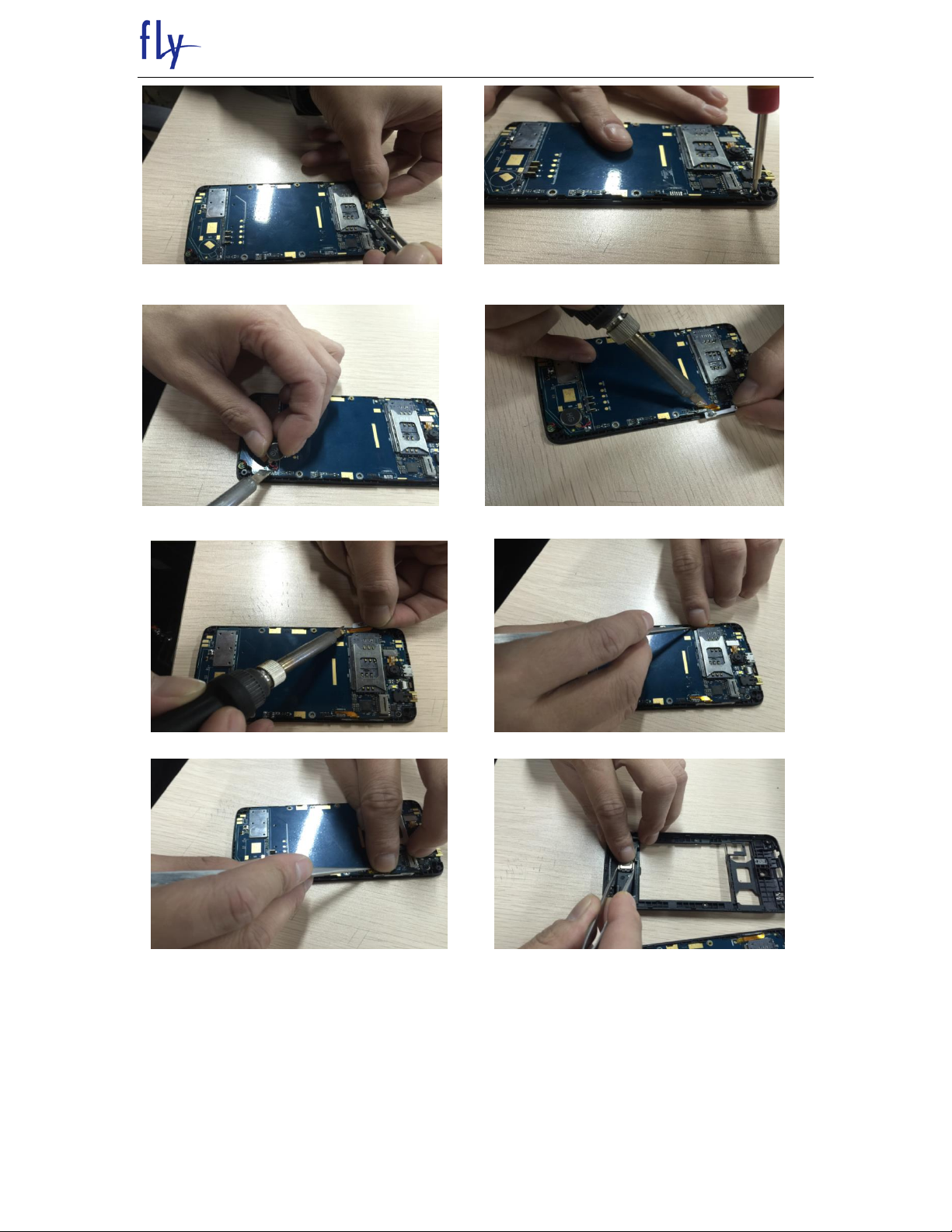

1.2.3 Assembly

Use the soldering iron Assemble MIC Use the soldering iron Assemble LCD

Use the soldering iron Assemble CAM Insulating paper

Insulating paper Assemble Receiver

Assemble PCBA Assemble TP-FPC

10

FLY SERVICE SUPPORT

Assemble After camera Assemble inside 3 screws

Use the soldering iron Assemble vibrator Use the soldering iron Assemble VolFPC

Use the soldering iron Assemble ON/OFF FPC Insulating paper

Insulating paper Assemble Speaker

11

Loading...

Loading...