Basic Troubleshooting Guide

LiFT Pack™ Advanced Lithium Battery

Table of Contents

Safety Precautions ........................................................................................................................................... 2

Introduction ..................................................................................................................................................... 3

Troubleshooting ............................................................................................................................................... 4

State of Charge Gauge and Device Trouble Codes (DTCs) ............................................................................... 4

Solid Red Light on SOC, No Power to Truck .................................................................................................... 4

No Lights on SOC, No Power to Truck ............................................................................................................ 4

Over Discharged ........................................................................................................................................... 5

Jumper Plug .............................................................................................................................................. 5

Charger Troubleshooting .............................................................................................................................. 5

Connecting to a LiFT Pack (Optional) ................................................................................................................. 6

Flux Connect – LiFT Pack ............................................................................................................................... 6

2

BTS

Safety Precautions

The LiFT Pack is a lithium-ion battery and is classified as Class 9 (miscellaneous) Hazardous Material. Precautions

to correctly handle the LiFT Pack include:

• The LiFT Pack should only be handled by experienced personnel familiar with the handling, storing

and installing industrial batteries.

• Only authorized technicians should open a LiFT Pack for servicing.

• Make sure the LiFT Pack is not plugged into a truck, charger, or wall socket when servicing the battery.

• Use Tools with insulated handles to prevent inadvertent shorts when working on a LiFT Pack.

• Remove metal watches and rings when working on a LiFT Pack

• Always use proper lifting techniques when installing or removing a LiFT Pack.

• Never recycle lithium-ion batteries with lead-acid batteries, please consult your local Crown branch

for more information on how to recycle a LiFT Pack.

For technical assistance on the LiFT Pack visit our support website at www.fluxpwr.com/support-main

Flux Power Support at:

FLUX Power

985 Poinsettia Ave, Suite A

Vista, CA 92081

Tel: 760-741-3589

Fax: 760-741-3535

Email: Support@FLUXpwr.com

Web: www.FLUXpwr.com

or, contact

3

BTS

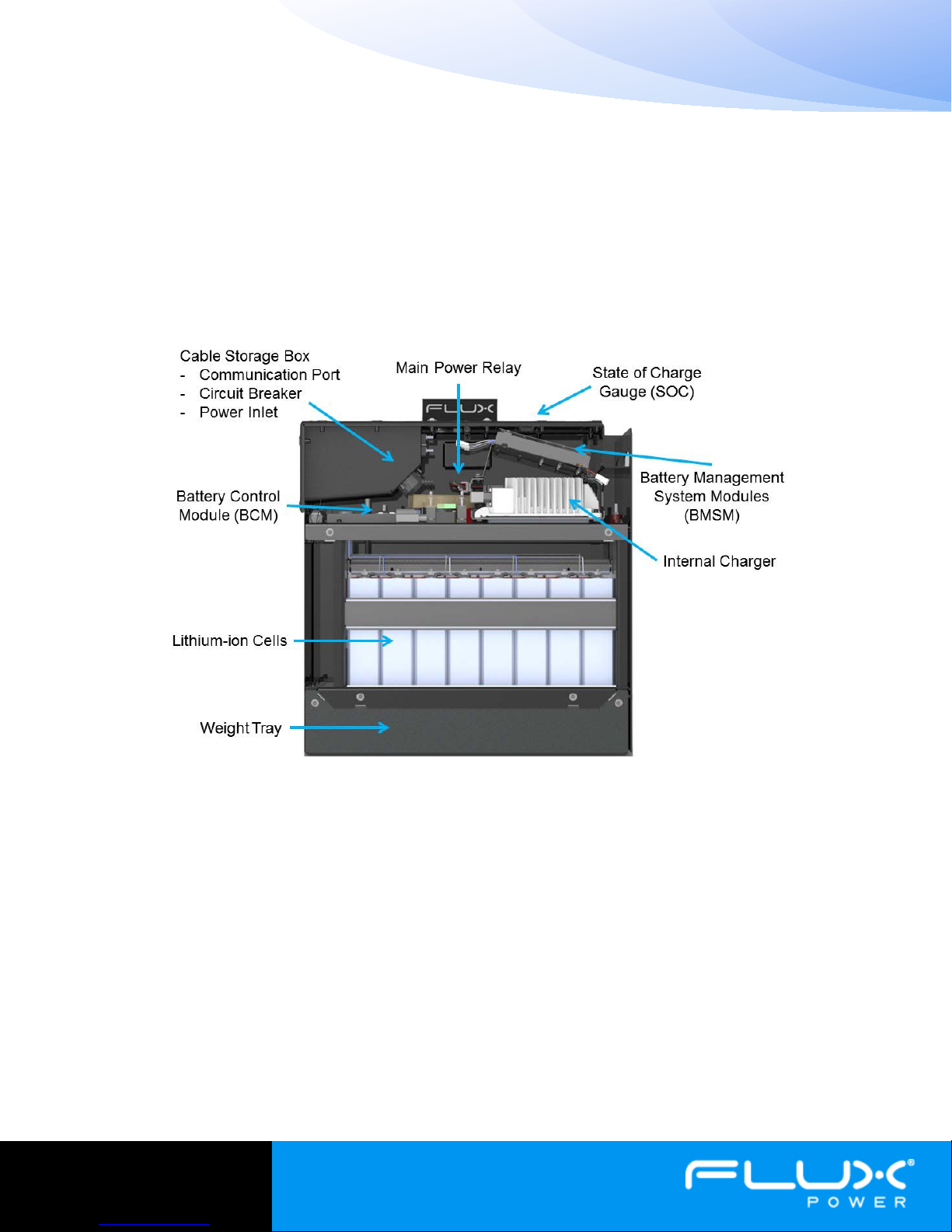

Figure 1: Diagram of a LiFT Pack S8 and it's major components.

Introduction

The LiFT Pack™ is a 24V industrial lithium-ion battery designed for class 3 Walkie Pallet Jacks. It includes advanced

electronics which optimize performance, store usage data, and prevent misuse during daily operation. The main

internal components are shown in figure 1 and illustrates the dramatic difference between a lead-acid battery and

a LiFT Pack. The case design allows the LiFT pack to fit into most walkie battery boxes and has mounting options

for Crown, Toyota, Raymond, Yale, Hyster and more. It is available in 72Ah, 100Ah, and 180Ah capacities and is

the only UL Listed lithium-ion battery currently available.

The main components in a LiFT Packs consist of 8 lithium-ion cells connected in series, a Battery Management

System (BMS) consisting of a Battery Control Module (BCM) and two Battery Management System Modules

(BMSMs), an internal charger, a protective relay, and protective fuses. Combined, these components provide a

robust, safe battery that protects the battery from electrical shorts, high temperatures, overcharge, and a number

of other scenarios.

This guide is intended to provide instruction and basic understanding on how to service a LiFT Pack. Included are

instructions on how to identify Device Trouble Codes (DTCs), replacing fuses, and other major components.

Finally there is a brief section on connecting to the battery using a computer to see a number of internal stats

including individual cell voltages, temperatures, and stored data.

4

BTS

Figure 2: SOC gauge showing Device

Troubleshooting

State of Charge Gauge and Device Trouble Codes (DTCs)

The first step in troubleshooting a LiFT Pack is observing the State of Charge gauge (SOC) on top of the battery.

Under normal operation, the gauge will have solid lights showing the LiFT Pack state of charge. If the pack is

charging, the lights will display a scrolling pattern. If a single LED is blinking it is a Device Trouble Code (DTC).

DTCs let the user or technician quickly assess why a LiFT Pack may be disrupting operation. The following list

details each DTC.

- LED 6: Low cell voltage imminent, charge battery to fix.

- LED 5: Current exceeded, >90A continuous will cause this

alert.

- LED 4: Over/Under temperature – If the battery gets too hot

and cuts power to the truck, it must cool by before it will reenable power to the truck.

- LED 3: Service required – All temperature sensors are

malfunctioning.

- LED 2: Unused.

- LED 1: Charge immediately – The battery is either empty, or a single

cell voltage is low. The pack may cut power to the truck if a cell is

too low.

Trouble Codes (DTCs)

Solid Red Light on SOC, No Power to Truck

If the SOC shows a solid red light and there is no power to the truck, it is in sleep mode and is protecting itself

from over discharge. To wake the pack up, first cycle the breaker. If this does not return power to the truck, the

pack must be plugged in to charge.

No Lights on SOC, No Power to Truck

If there are no lights on the LiFT Pack SOC, there are a few possible scenarios. Some which require you to remove

the lid. First Remove the LiFT pack from the truck, then unscrew the 16 top bolts to remove the top of the

battery. It should have enough slack in the battery leads to lay on the top edge of the battery.

1 Storage Mode – The pack may be in storage mode. Check the breaker in the cable storage box on the lid

of the battery. Cycle the breaker by firmly pressing the red button in (OFF), and then folding in the yellow

tab on the side of the breaker (ON). If this does not revive the battery, continue to step 2.

2 Failed Breaker – Check the breaker in the closed position for continuity. The top must be removed to

access the back of the breaker where the posts are located. Check these for continuity.

3 Blown Fuse – There are two fuses inside the LiFT Pack, the main fuse (200A), and the inline blade fuse

(3A). The fuse locations are shown in figure 3. Check the fuses for continuity and replace if blown.

4 Over Discharged – LiFT Packs contain advanced electronics which draw power from the battery. These

systems slowly drain the battery, and if not charged regularly, will drain the pack. If a pack drains below

4V, the electronics shut down and the contactors opens. To revive the pack, follow the procedure in the

Over Discharged section (page 5).

5

BTS

200A Main Fuse with Nomex Cover

3A Blade Fuse

Upper Electronics

Charger Underneath

Figure 4: A Jumper Plug. It is used to

revive an over

Figure 5: Delta-Q lightning bolt and error code

display

Figure 3: Pack internals viewed from above. Note the fuse locations and charger location.

Over Discharged

Jumper Plug

The Jumper Plug (part number 150002-13) is a small plug designed to revive an

over discharged LiFT Pack. If you do not have a Jumper Plug, contact Flux Power

customer support to obtain one. To revive a battery using a Jumper Plug,

Deck with Internal

1) insert the plug firmly into the data port located in the cable storage box.

2) Close the circuit breaker located in the cable storage box.

3) Plug the battery into a standard wall socket and wait 15-45 minutes.

The battery will trickle charge until the electronics boot up and begin charging

normally. Once the SOC lights scroll and indicate the pack is charging, the Jumper

Plug should be removed. If the pack SOC does not scroll there may be an issue with the internal charger. Go to

Charger Troubleshooting if this is the case.

NOTE: If the Jumper Plug is left in the data port, the battery will not allow truck operation.

-discharged LiFT Pack.

Charger Troubleshooting

If the pack revives, but does not show a scrolling pattern on the SOC, it is

possible the charger has malfunctioned. To check the charger, look through

the large hole between the BMSMs located on top of the charger. A lightning

bolt and display are visible on the far end of the charger as shown in figure 5.

The display will show one of the following error codes related to the charger

issue.

F - codes meaning that an internal fault condition has caused charging to stop.

E - codes meaning that an external error condition has caused charging to stop.

P - code meaning that the charger programming mode is active.

USB - code meaning that the USB interface is active, and the USB flash drive

should not be removed.

seen through the upper electronics deck.

6

BTS

Connecting to a LiFT Pack (Optional)

A simple and effective way to troubleshoot a LiFT Pack battery, is by connecting to the BMS using a computer.

The BMS records and reports important information, and allows you to download data, see battery statistics, and

troubleshoot more effectively.

To connect to the battery you will need a Windows PC and a Flux Power Connection Package containing a

peakCAN dongle, Flux Connect software, and a JST-Deutsch connection cable. To obtain a Flux Power Connection

Package contact Flux Power customer support.

To connect your computer to a LiFT Pack first install the peakCAN drivers on the included usb stick. Next install

Flux Connect – LiFT Pack. This software is also available online at www.fluxpwr.com/support-main.

Flux Connect – LiFT Pack

Once you have successfully installed the software, connect your computer to the LiFT Pack data port, located in

the cable storage box. A red light should illuminate on the peakCAN dongle. If you do not see a red light, restart

your computer and try again.

Open FluxConnect and click RUN. Figure 6 shows the FluxConnect home page. The fields shown are defined

below.

1. Current (+ is charge current, - is discharge current)

2. BCM Temperature – Temperature of the BCM board

3. BMSM Temperatures – Temperature of the BMSM boards

4. Cell Voltages

5. Cell Temperatures

6. Pack Voltage

7. Main Contactor Status – Provides power to the battery leads

8. Charge Contactor Status – Provides power to the internal charger.

If you want to know more refer to the in depth software guide. To obtain the software guide contact Flux Power

technical support.

7

BTS

2

3

3

4

5

6

7

8

Flux Power is a registered trademark of Flux Power Inc.

990814v1.1

Figure 6: FluxConnect allows users to log into the battery and see the a number of important details.

If you have any questions or concerns, please contact Flux Power technical support or visit www.fluxpwr.com.

Loading...

Loading...