PG9000™

Piston Gauge

Operation and Maintenance Manual

© 1998-2010 Fluke Calibration

Warning

To prevent possible electrical shock, fire, or personal injury:

Read all safety Information before you use the product.

Use the product only as specified, or the protection supplied by the

product can be compromised.

High-pressure liquids and gases are potentially hazardous. Energy stored

in these liquids and gases can be released unexpectedly and with extreme

force. High-pressure systems should be assembled and operated only by

personnel who have been instructed in proper safety practices.

Use only the main power cord and connector approved for the voltage and

plug configuration in your country and rated for the product.

Make sure the ground conductor in the main power cord is connected to a

protective earth ground. Disruption of the protective earth could put

voltage on the chassis that could cause death.

Replace the main power cord if the insulation is damaged or if the

insulation shows signs of wear.

Do not put the product where access to the main power cord is blocked.

Do not use and disable the product if it is damaged.

Use this product indoors only.

© 1998 - 2010 Fluke Calibration All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written p ermission of Fl uke Cali bratio n, 4 765

East Beautiful Lane, Phoenix, Arizona 85044-5318 USA.

Fluke Calibration makes sincere efforts to ensure the accuracy and quality of its published materials; however, no warranty,

expressed or implied, is provided. Fluke Calibration disclaims any responsibility or liability for any direct or indirect damages

resulting from the use of the information in this manual or products described in it. Mention of any product or brand does not

constitute an endorsement by Fluke Calibration of that product or brand. This manual was originally composed in English and was

subsequently translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the

English version and other language versions, the English version predominates.

Fluke Calibration, DH, DHI, PG9000, PG9607, CalTool and COMPASS are trademarks, registered and otherwise, of Fluke

Corporation.

Swagelok is a registered trademark of the Swagelok Company.

Krytox is a registered trademark of the Dupont de Nemours Company.

Products described in this manual are manufactured unde r international patents and one or more of the following

U.S. patents: 6,701,791, 5,142,483, 5,257,640, 5,331,838, 5,445,035. Other U.S. and international patents pending.

Document No. 3782240

100820

Printed in the USA

© 1998-2010 Fluke Calibration

Table of Contents

Table of Contents ................................................................. III

Tables .................................................................................. V

Figures ................................................................................ VI

About This Manual ............................................................... VII

1. Introduction ..................................................................... 1

1.1 Product Overview ................................................................................................................................... 1

1.2 Specifications ......................................................................................................................................... 2

1.2.1 General Specifications ............................................................................................................................. 2

1.2.1.1 AMH Automated Mass Handler (Optional) .............................................................................................. 3

1.2.1.2 Embedded Features ............................................................................................................................... 3

1.2.1.3 Ambient and Instrument Condition Measurements ................................................................................. 4

1.2.2 Piston-Cylinder Assembly (PC-9607-5) ................................................................................................... 5

1.2.3 Mass Sets ................................................................................................................................................. 5

1.2.4 Pressure Measurements (PG9607) .......................................................................................................... 5

1.3 Front and Rear Panels ........................................................................................................................... 6

1.3.1 Terminal Front and Rear Panels .............................................................................................................. 6

1.3.1.1 PG Terminal Front Panel ........................................................................................................................ 6

1.3.1.2 PG Terminal Rear Panel ........................................................................................................................ 6

1.3.2 Remote Electronics Module Rear Panel ................................................................................................. 7

1.3.3 Base Rear Panel ....................................................................................................................................... 8

2. Installation ....................................................................... 9

2.1 Unpacking And Inspection .................................................................................................................... 9

2.1.1 Removing From Packaging ..................................................................................................................... 9

2.1.1.1 Platform ................................................................................................................................................. 9

2.1.1.2 Manual Mass Set ................................................................................................................................... 9

2.1.1.3 Piston-Cylinder Assembly (PG9607) .................................................................................................... 10

2.1.1.4 Vacuum Reference Hardware (Optional) .............................................................................................. 10

2.1.1.5 AMH Automated Mass Handler (Optional) ............................................................................................ 10

2.1.1.6 AMH Mass Set (Optional) ..................................................................................................................... 10

2.1.2 Inspecting Contents ............................................................................................................................... 11

2.1.2.1 Platform ............................................................................................................................................... 11

2.1.2.2 Mass Set .............................................................................................................................................. 12

2.1.2.3 Piston-cylinder Assembly ..................................................................................................................... 13

2.1.2.4 Vacuum Reference (Optional) .............................................................................................................. 14

2.1.2.5 Automated Mass Handler (Optional) ..................................................................................................... 15

2.2 Site Requirements ................................................................................................................................ 15

2.3 Setup ..................................................................................................................................................... 17

2.3.1 Preparing for Operation ......................................................................................................................... 17

2.3.1.1 Setting Up the Platform ........................................................................................................................ 17

2.3.1.2 System Pressure Interconnections ....................................................................................................... 17

2.3.1.3 Setting Up A Manual Mass Set ............................................................................................................. 18

2.3.1.4 Setting Up An AMH Automated Mass Handler (Optional) ..................................................................... 19

2.3.1.5 Setting Up an AMH Mass Set ............................................................................................................... 20

2.3.1.6 Setting Up Vacuum Reference Hardware (Optional) ............................................................................. 22

2.3.2 Installing and Removing a PG9607 Piston-Cylinder Assembly ........................................................... 23

2.4 Power Up And Verification .................................................................................................................. 26

2.4.1 Powe r Up ................................................................................................................................................ 26

2.4.2 Check That On-board Piston-Cylinder Module And Mass Set Information Are Correct .................... 26

2.4.3 Set Local Gravity Value ......................................................................................................................... 26

2.4.4 Setup Pressure Equation Variable Input Sources ................................................................................ 26

2.4.5 Check Proper Operation Of Ambient Condition Measurements ......................................................... 27

2.4.6 Apply Pressure To The Piston-Cylinder Module .................................................................................. 27

2.4.7 Check Proper Behavior Of Motorized Piston Rotation ........................................................................ 28

Page III © 1998-2010 Fluke Calibration

TABLE OF CONTENTS

2.4.8 Check Proper Operation Of Piston Behavior Measurements .............................................................. 28

2.4.9 Verify Vacuum Reference ...................................................................................................................... 28

2.4.10 AMH Start Up/Verificati on ...................................................................................................................... 29

2.4.11 Check Automated Pressure Generation (If Present) ............................................................................ 30

2.4.12 Check/Set Security Level ....................................................................................................................... 30

2.4.13 Additional Precautions to Take Before Making Pressure Measurements .......................................... 31

2.5 Short Term Storage .............................................................................................................................. 31

3. General Operation ........................................................... 33

3.1 Fundamental Operating Principles ..................................................................................................... 33

3.2 Keypad Layout And Protocol .............................................................................................................. 34

3.3 Sounds .................................................................................................................................................. 35

3.4 Pressure Ready/Not Ready Indication ................................................................................................ 35

3.4.1 Piston Position Ready/Not Ready ......................................................................................................... 36

3.4.2 Piston Rotation Ready/Not Ready ......................................................................................................... 36

3.4.3 Vacuum Reference Ready/Not Ready ................................................................................................... 37

3.5 Piston Position ..................................................................................................................................... 37

3.6 Manual Mass Loading .......................................................................................................................... 38

3.7 AMH Mass Loading .............................................................................................................................. 40

3.7.1 Operating Principals .............................................................................................................................. 40

3.7.2 AMH Operation ....................................................................................................................................... 42

3.7.2.1 Installing an AMH Mass Handler on the PG9000 Platform .................................................................... 43

3.7.2.2 Removing a Mass Handler from the PG9000 Platform ......................................................................... 45

3.7.2.3 AMH Mass to Pressure or Pressure to Mass Operation ............................................................................ 45

3.7.2.4 Direct Control of AMH Functions .......................................................................................................... 46

3.7.2.5 Making and Breaking Reference Vacuum with AMH ............................................................................. 46

3.7.2.6 Accessing the PG9000 Piston-Cylinder Module with AMH .................................................................... 46

3.7.2.7 AMH Indicator LED .............................................................................................................................. 47

3.7.2.8 AMH Error Messages ........................................................................................................................... 47

3.8 Controlled Clearance Pressure (PG9607)........................................................................................... 49

3.9 Main Run Screen .................................................................................................................................. 50

3.10 General Function/Menu Flow Chart .................................................................................................... 51

3.11 Direct Function Keys............................................................................................................................ 51

3.11.1 Direct Function Keys Summary ............................................................................................................ 51

3.11.2 [P-C] ........................................................................................................................................................ 52

3.11.3 [UNIT] ...................................................................................................................................................... 53

3.11.3.1 Customizing Pressure Units Available Under the UNIT Function .......................................................... 54

3.11.4 [MODE] .................................................................................................................................................... 55

3.11.4.1 Differential Measurement Mode ............................................................................................................ 56

3.11.5 [SYSTEM] ................................................................................................................................................ 63

3.11.5.1 First System Run Screen...................................................................................................................... 64

3.11.5.2 Second System Run Screen ................................................................................................................ 64

3.11.5.3 Third System Run Screen .................................................................................................................... 65

3.11.6 [AMBIENT] .............................................................................................................................................. 66

3.11.7 [HEAD] .................................................................................................................................................... 67

3.11.8 [ROTATE] ................................................................................................................................................ 69

3.11.8.1 <2Pre-Decel> ....................................................................................................................................... 70

3.11.9 [GEN] (Optional) ..................................................................................................................................... 71

3.11.9.1 <2target>.............................................................................................................................................. 73

3.11.9.2 <3raise> ............................................................................................................................................... 73

3.11.9.3 <4UL> .................................................................................................................................................. 73

3.11.9.4 <5tol> ................................................................................................................................................... 73

3.11.9.5 <6refloat> ............................................................................................................................................. 74

3.11.10 [RES] ....................................................................................................................................................... 74

3.11.11 [ENTER/SET P] From Run Screen ......................................................................................................... 76

3.11.11.1 [ENTER/SET P] In Pressure To Mass Mode ........................................................................................ 77

3.11.11.2 [ENTER/SET P] In Mass To Pressure Mode ........................................................................................ 78

3.11.11.3 Commands for zero pressure, ending a test ......................................................................................... 79

3.11.12 [P OR M] ................................................................................................................................................... 79

3.11.13 [ ] and [ ], [←] .................................................................................................................................. 80

3.12 [SETUP] Menu ....................................................................................................................................... 81

3.12.1 <1select> ................................................................................................................................................ 82

3.12.2 <2view> ................................................................................................................................................... 83

3.12.3 <3edit> .................................................................................................................................................... 84

3.13 [SPECIAL] Menu ................................................................................................................................... 86

3.13.1 <1PC/MS> ............................................................................................................................................... 87

3.13.1.1 Create a Piston-Cylinder Module .......................................................................................................... 88

© 1998-2010 Fluke Calibration Page IV

TABLE OF CONTENTS

3.13.1.2 Edit a Piston-Cylinder Module .............................................................................................................. 90

3.13.1.3 View a Piston-Cylinder Module ............................................................................................................. 90

3.13.1.4 Delete a Piston-Cylinder Module .......................................................................................................... 91

3.13.1.5 Select The Active Piston-Cylinder Module ............................................................................................ 91

3.13.1.6 Add a Mass Set .................................................................................................................................... 92

3.13.1.7 Edit a Mass Set .................................................................................................................................... 96

3.13.1.8 View a Mass Set .................................................................................................................................. 96

3.13.1.9 Delete a Mass Set ................................................................................................................................ 96

3.13.1.10 Select Mass Set ................................................................................................................................... 96

3.13.1.11 Add a Mass Loading Bell ...................................................................................................................... 97

3.13.1.12 Edit a Mass Loading Bell ...................................................................................................................... 98

3.13.1.13 View a Mass Loading Bell .................................................................................................................... 98

3.13.1.14 Delete A Mass Loading Bell ................................................................................................................. 99

3.13.1.15 Select A Mass Loading Bell .................................................................................................................. 99

3.13.2 <2presU> ................................................................................................................................................ 99

3.13.3 <3head> .................................................................................................................................................. 99

3.13.3.1 <3head>, <1fluid> ...............................................................................................................................100

3.13.3.2 <3head>, <2unit> ................................................................................................................................101

3.13.3.3 <3head>, <3atm> ................................................................................................................................101

3.13.3.4 <3head>, <4piston> ............................................................................................................................101

3.13.4 <4prefs> .................................................................................................................................................102

3.13.4.1 <4prefs>, <1ScrSvr> ...........................................................................................................................102

3.13.4.2 <4prefs>, <2sound> ............................................................................................................................102

3.13.4.3 <4prefs>, <3time> ...............................................................................................................................103

3.13.4.4 <4prefs>, <4ID> ..................................................................................................................................103

3.13.4.5 <4prefs>, <5level> ..............................................................................................................................104

3.13.5 <5remote> ..............................................................................................................................................106

3.13.5.1 COM1, COM2, COM3 and COM4 (RS232) .........................................................................................107

3.13.5.2 IEEE-488.............................................................................................................................................107

3.13.5.3 RS232 Self Test ..................................................................................................................................108

3.13.5.4 External Barometer (RPM) Communications (COM2) ..........................................................................108

3.13.5.5 External Vacuum Gauge Communications (COM2) .............................................................................110

3.13.6 <6gl> ......................................................................................................................................................112

3.13.7 <7cal>.....................................................................................................................................................113

3.13.8 <8AMH> .................................................................................................................................................113

3.13.8.1 <2control>, <1up/down> ......................................................................................................................114

3.13.8.2 <2control>, <2discreet> .......................................................................................................................114

3.13.8.3 <2control>, <3loadall> .........................................................................................................................114

3.13.8.4 <2control>, <4unloadall> .....................................................................................................................115

3.13.9 <9reset> .................................................................................................................................................115

3.13.9.1 <9reset>, <1sets> ...............................................................................................................................115

3.13.9.2 <9reset>, <2units> ..............................................................................................................................116

3.13.9.3 <9reset>, <3com> ...............................................................................................................................116

3.13.9.4 <9reset>, <4cal> .................................................................................................................................116

3.13.9.5 <9reset>, <5setups> ...........................................................................................................................117

3.13.9.6 <9reset>, <6all> ..................................................................................................................................117

4. Remote Operation ......................................................... 119

4.1 Overview ............................................................................................................................................. 119

4.2 Interfacing ........................................................................................................................................... 119

4.2.1 RS232 interface .....................................................................................................................................119

4.2.1.1 COM1 .................................................................................................................................................119

4.2.1.2 COM2, COM3 and COM4 ...................................................................................................................120

4.2.2 IEEE-488 (GPIB) .....................................................................................................................................120

4.3 Commands .......................................................................................................................................... 121

4.3.1 Command Syntax ..................................................................................................................................121

4.3.2 Command Summary .............................................................................................................................121

4.3.3 Error Messages .....................................................................................................................................123

4.3.3.1 AMH Errors .........................................................................................................................................124

4.3.4 Command descriptions ........................................................................................................................124

4.3.4.1 IEEE Std. 488.2 Common And Status Commands ..............................................................................124

4.3.4.2 PG9000 Commands ............................................................................................................................126

4.4 Status System ..................................................................................................................................... 151

4.4.1 Status Reporting System ......................................................................................................................151

4.4.1.1 Status Byte Register............................................................................................................................151

4.4.1.2 Standard Event Register .....................................................................................................................153

Page III © 1998-2010 Fluke Calibration

TABLE OF CONTENTS

5. Maintenance, Adjustments And Calibration ..................... 155

5.1 Introduction ........................................................................................................................................ 155

5.2 Platform ............................................................................................................................................... 156

5.2.1 Calibration/Adjustment Of On-board Measurement Funct ions ..........................................................156

5.2.1.1 Principles ............................................................................................................................................156

5.2.1.2 Barometric Pressure Sensor ...............................................................................................................156

5.2.1.3 Ambient Temperature sensor ..............................................................................................................157

5.2.1.4 Relative Humidity Sensor ....................................................................................................................158

5.2.1.5 Piston-Cylinder Module Temperature Sensors ....................................................................................158

5.2.1.6 Reference Vacuum Sensor (Optional) .................................................................................................160

5.2.2 Piston Position Detection Adjustment .................................................................................................160

5.2.3 Drive Belt Replacement ........................................................................................................................161

5.3 Piston-Cylinder Disassembly, Cleaning And Maintenance ............................................................ 162

5.3.1 Disassembly Of The PG9607 Piston Retaining Assembly ..................................................................163

5.3.1.1 Disassembly Procedure ......................................................................................................................163

5.3.1.2 Reassembly Procedure .......................................................................................................................164

5.3.2 Cleaning (Other Than PG9607) .............................................................................................................165

5.3.3 Cleaning (PG9607) ................................................................................................................................166

5.3.4 Recalibration .........................................................................................................................................167

5.3.4.1 Updating Piston-Cylinder Module Files ................................................................................................167

5.4 Mass Sets ............................................................................................................................................ 167

5.4.1 Cleaning .................................................................................................................................................167

5.4.2 Recalibration .........................................................................................................................................167

5.5 Reloading Embedded Software Into PG9000 Flash Memory .......................................................... 167

5.6 Disassembly And Reassembly Of PG9000 ....................................................................................... 168

5.6.1 Platform .................................................................................................................................................168

5.6.2 Terminal .................................................................................................................................................168

5.6.3 AMH Automated Mass Handler Removal .............................................................................................168

6. Troubleshooting............................................................ 169

6.1 Overview ............................................................................................................................................. 169

7. Appendix ...................................................................... 173

7.1 Conversion Of Numerical Values ...................................................................................................... 173

7.1.1 Pressure ................................................................................................................................................173

7.2 Defined Pressure Calculations .......................................................................................................... 173

7.2.1 Calculations ...........................................................................................................................................175

7.2.2 Fluid Heads ............................................................................................................................................176

7.2.2.1 Fluid Head Components ......................................................................................................................176

7.2.2.2 Overall Fluid Head Correction .............................................................................................................177

7.3 Glossary .............................................................................................................................................. 178

7.4 Limited Warranty And Limitation Of Liability ................................................................................... 180

© 1998-2010 Fluke Calibration Page IV

Tables

Table 1. PG9607 Parts List ........................................................................................................................ 11

Table 2. Manual Mass Set Parts List (excluding 80 and 100 kg) ............................................................... 12

Table 3. Manual Mass Set Parts List (80 and 100 kg) ............................................................................... 12

Table 4. AMH-100 Mass Set Parts List ...................................................................................................... 12

Table 5. Mass Set Compositions ............................................................................................................... 13

Table 6. 50 mm Gas Piston-Cylinder Ass embly Parts List ........................................................................ 13

Table 7. PG9000 Vacuum Reference Hardware ....................................................................................... 14

Table 8. AHM-100-VAC Parts List ............................................................................................................. 15

Table 9. Drive Air Pressure Requirement by Mass Set ............................................................................. 16

Table 10. AMH Errors ................................................................................................................................ 48

Table 11. Summary of PG9000 Direct Function Key Operations .............................................................. 52

Table 12. Pressure Units of Measure Available ......................................................................................... 55

Table 13. Valve Settings for Setting Differential Mode Static Pressure ..................................................... 59

Table 14. Valve Settings to Apply PG9000 Pressure to the RPM for Differential Mode Offsetting ........... 60

Table 15. Valve Settings for Operating in Differential Mode ...................................................................... 62

Table 16. SETUP File Choices, Factory Preferred Choice and Normal Value .......................................... 82

Table 17. Security Levels - Functions NOT Executed Per Function/Level .............................................. 105

Table 18. COM1, COM2, COM3 and COM4 Available Settings.............................................................. 107

Table 19. COM1 DB-9F Pin Designation ................................................................................................. 120

Table 20. COM2, COM3 and COM4 DB-9M Pin Designation ................................................................. 120

Table 21. Command Summary ................................................................................................................ 121

Table 22. Error Messages ........................................................................................................................ 123

Table 23. Status Byte Register ................................................................................................................ 151

Table 24. Standard Event Register .......................................................................................................... 153

Table 25. PG9000 Troubleshooting Checklist ......................................................................................... 169

Table 26. Pressure Unit of Measure Conversions ................................................................................... 173

Table 27. PG9000 Defined Pressure Calculation Variables .................................................................... 174

Table 28. Fluke Calibration Authorized Service Providers ...................................................................... 181

Page V © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL

Figures

Figure 1. PG Terminal Front Panel .............................................................................................................. 6

Figure 2. PG Terminal Rear Panel ............................................................................................................... 7

Figure 3. PG9000 Remote Electronics Module Rear Panel ....................................................................... 7

Figure 4. PG9000 Base Rear Panel (PG9607 shown) ................................................................................ 8

Figure 5. AMH Mass Set ............................................................................................................................ 21

Figure 6. PG9607 Piston-Cylinder Installation ........................................................................................... 25

Figure 7. Piston Gauge Operating Principle .............................................................................................. 33

Figure 8. PG9000 Keypad Layout .............................................................................................................. 34

Figure 9. Piston Stroke and Zones ............................................................................................................ 38

Figure 10. AMH Schematic/Operati ng Pri nc ip le ........................................................................................ 42

Figure 11. AMH Installation on PG9000 Platf or m ...................................................................................... 43

Figure 12. AMH Indicator location .............................................................................................................. 47

Figure 13. Run Screen Flow Chart ............................................................................................................ 51

Figure 14. Differential Mode Controller Schematic .................................................................................... 58

Figure 15. PG9000 Platform Reference Level Location ............................................................................. 68

Figure 16. Status Byte Register ............................................................................................................... 151

Figure 17. Piston Retainer Assem bl y ....................................................................................................... 164

Figure 18. Gas Operated, Gas Lubricated Piston-Cylinder Module Lubrication Chart ............................. 165

© 1998-2010 Fluke Calibration Page VI

About This Manual

This manual provides the user with the information n ecessary to operate the PG9000 Piston Gauge. It

also includes a great dea l of additional information provide d to help optimize PG9000 use and take f ull

advantage of its many features and functions.

Before using the m anual, tak e a m om ent to become familiar with the T able of Co ntents s tructur e. All first

time PG9000 users should read Sect ions 1 and 2. Section 3 provides a comprehensi ve description of

general PG9000 operating principles. Section 4 covers remote communication with an external

computer. Section 5 provides maintenance and calibration information. Section 6 is a quick

troubleshooting guide. Use the information in Section 6 to troubleshoot unexpected PG9000 behavior

based on the symptoms of that behavior.

Certain words and expressions have specific meaning as they pertain to PG9000s. The Glossary

(see Section 7) is useful as a quick referenc e for the definition of specific words and ex pressions as the y

are used in this manual.

Note

For those who “DON’T READ MANUALS”, go directly to section 2.3 to set up

the PG9000. Then go to section 2.4. This will get you running quickly with minimal

risk of causing damage to yourself or your PG9000. Then… when you have

questions or start to wonder about all the great features you might be missing, get

into the manual!

Manual Conventions

Caution

“Caution” is used in throughout the manual to identify conditions or actions that

could cause harm to the PG9000 or to the devices that are connected to the

PG9000.

Warning

“Warning” is used in throughout the manual to identify actions that could po se a

hazard to the user of the PG9000.

Note

“Note” is used throughout the manual to identify operating and applications advice

and additional explanations.

[ ] indicates direct function keys (e.g., [RANGE]).

< > indicates PG9607 screen displays (e.g., <1yes>)

Page VII © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL

Notes

© 1998-2010 Fluke Calibration Page VIII

1. Introduction

1.1 Product Overview

PG9000 Piston Gauges are reference level pressure standards that operate on the piston

gauge principle. Pressure is defined by balancing it against the force exerted by a known mass

accelerated by gravity on the effective area of a piston-cylinder.

A PG9000 piston gauge consists of the PG9000 Platform, a piston-cylinder module and a mass set.

Optional hardware for vacuum reference operation is available. An optional automated m ass handling

system is available as well. A PG9000 system typically also includes the m eans to generate and adjust

pressures and to interconnect the system components and a device being calibrated or tested. The

pressure generation component can be manual or autom ated. COMPASS

also be included to assist in executing test sequences, acquiring test data and producing test reports.

The PG9000 Platform consists of the PG9000 Base, Term inal and Remote Elec tronics Module. Local

user interface is through the keypad and display on the terminal. Remote communications and all on

board (built in) sensors are located inside or are connected to the Remote Electronics Module.

PG9000 is a fam ily of piston gauges with common presentation and f eatures. The f irst production model

of the PG9000 family is the PG9607.

®

for Pres sure software may

PG9607 operates up to a maximum pressure of 500 kPa and supports definition of pressure against

either atmosphere or vacuum reference using a gas operated, gas lubricated piston-cyli nder module

(PC-9607-5).

PG9607 was design ed to exploit a unique 50 m m diameter piston-c ylinder. With this piston-cylinder,

the piston is mounted in a fixed p osition in the m ounting post and the c ylinder f loats and is rotated. A

controlled clearance pr essure can be introduced into the mounting post allowing the pis ton diameter

and thus the gap between the piston and cylinder to be varied.

PG9607 is available o n a lim ited basis and, ge nerall y, is only of fered f or use in natio nal m easurement

institutes or other laboratories performing fundamental research in pressure metrology.

PG9000 platform, piston-c ylinder module, mass set and optional automated mass handling s ystem are

designed to max imize metr ological p erform ance and e ase of op eration. T he y include m any features that

enhance the fundamental precision and stability of pressure measurements as well as simplifying use and

reducing operator inf luence on the measurements. Ex tensive monitoring and controlling cap ability and

advanced local and remote user interfaces are integrated into the PG9000 Platform.

Operator interaction with PG9000 and its extensive capab ilities and peripherals is accomplished through

a single display and keypad on the PG Terminal or from a computer via a single standard RS232 or

IEEE-488 interface.

Page 1 © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL

PEM Fuse: 1A, 250V, 5x20mm, Slow blow

1.2 Specifications

1.2.1 General Specifications

Power Requirements

Operating Temperature Range

Operating Humidity Range

Weight

Instrument platform with no mass or

piston-cylinder loaded.

PG9607 (without vacuum hardware)

Remote Electronics Module

PG Terminal

Optional Vacuum Reference Hardware

Dimensions

PG9607 Base (without vacuum hardware)

PG9607 Base (with optional vacuum bell

jar and vacuum gauge connected)

Remote Electronics Module

PG Terminal

Microprocessors

Instrument Platform

PG Terminal

Communication Ports

RS232

IEEE-488

Fuses

Overall Pressure Range

Operating Media

Maximum Mass Load

50/60 Hz, 60 VA max. consumption.

100 to 240 VAC, operating altitude: <2000m

100 to 150 VAC, operating altitude: <5000m

15 to 35 °C

5 to 95% R.H., non-condensing

34 kg (74 lb)

1.9 kg (4 lb)

1.4 kg (3 lb)

16 kg (36 lb)

34.1 cm H x 54.3 cm W x 52.3 cm D (13.4 in x 21.4 in x 20.6 in)

(Height: top of piston-cylinder assembly)

56 cm H x 54.3 cm W x 52.3 cm D (22 in x 21.4 in x 20.6 in)

(Height: Top of bell jar)

10.2 cm H x 35.1 cm W x 19.6 cm D (4 in. 13.8 in. x 7.7 in.)

12 cm H x 15 cm W x 20 cm D (4.7 in. H x 5.9 in. W x 7.9 in. D)

Motorola 68302

Hitachi 64180

COM1: Host computer

COM2: Residual vacuum sensor (external)

COM3: Automated pressure generator/controller

COM4: Unused/spare or pass through

Host computer

Internal power supply Fuse: 3.15A, 250V

Gauge: 10.5 kPa to 500 kPa (1.5 to 72.5 psi)

Absolute: 10.5 kPa to 500 kPa (1.5 to 72.5 psi)

Differential: - 89.5 to 400 kPa (-13 to 58 psi) at

10.5 to 110 kPaa (1.5 to 16 psia) static pressure

Gas: nitrogen, hel i um, dry air (dewpoint ≤ -40 °C)

100 kg1

1

MS-AMH-100 mass set contains approximately 104.5 kg of mass.

Combined with the piston or cylinder and bell ass embly, total mass

loads may be up to 106 kg resulting in pressures of up to 530 kPa.

(76.9 psi)

Page 2 © 1998-2010 Fluke Calibration

1. INTRODUCTION

and are CE

Pressure Connections

Remote Electronics Module

CE Conformance

1.2.1.1 AMH Automated Mass Handler (Optional)

Power Requirements:

Operating Temperature:

Dimensions:

Power/Communications:

AMH Drive Air Supply:

AMH Vacuum Supply:

Pressure Connections:

CE conformance:

PG 9607 Base

AMH Drive

AMH Vent

Vacuum Bell Jar

Weight:

Available, must be specified

Pressure:

Vacuum:

Test port: : DH200

Controlled Clearance Pressure: DH200

Quick connector equivalent to Swagelok QM Series (QM2-B-200),

Use with DESO (double end shut off) type stem

Quick connector equivalent to Swagelok QM Series (QM2-B-200),

Use with SESO (single end shut off) type stem only.

Note

DH200 and DH500 are gland and collar t ype fittings for

1/4 in. (6.35 mm) coned and left hand threaded tubes.

DH200 is equivalent to AE SF250C, HIP LF4, etc.

DH500 is equivalent to AE F250C, HIP HF4, etc.

ATM port: 10-32 UNF

3x KF40, 1x KF50 (top)

All PG9000 models conform to CE requirements

marked.

15 VDC @ 2 A, 30 W max. consumption

15 to 35 ºC

41 cm H x 41 cm W x 36 cm D (16.3 in. x 16.1 in. x 14.1 in.)

12 kg (25 lbs)

Custom 8 pin connector

550 kPa (80 psi), ± 10%, minimal flow

At least 50 kPa (7.5 pi) under atmosphere, minimal flow

Quick connector DESO (double end shut off) type stem

Quick connector SESO (single end shut off) type stem

1.2.1.2 Embedded Features

• Local control with 2 x 20 vacuum fluorescent display and 4 x 4 function

driven keypad.

• Real time (1 second upda te rate) display and measurem ent of ambient

(pressure, temperature, humidity) and instrument (piston-cylinder

temperature, piston posit ion, piston drop rate, pis ton rotation rate, pisto n

rotation decay rate, reference vacuum) conditions.

• Real time (1 second update rate) mass-to-pressure and pressure-to-

mass calculations taking into consideration all environmental and

operational variables.

• Full gas and liquid f luid head corrections includ ing DUT head correctio n

and piston position h ead co rr ection. Barom eter he ad c orrection included

for atmosphere reference operation (gauge mode).

• Adjustable mass loading resolution (0.01 g to 0.1 kg).

• Audible prompts of instrument status (piston movement, Ready/Not

Ready indication) with override capability.

• Integrated automated mass handling option (AMH-100-VAC).

• Interfacing and automatic exploitation of external barometer via RS232.

• Interfacing and autom atic exploitation of an y external vacuum gauge via

RS232.

• Automated differential mode to define low differential pressures at

various static pressures between vacuum and two atmospheres.

• Storage and one step activation of metrological data on up to 18 piston-

cylinder modules, (3) mass sets and (3) mass loading bells.

Page 3 © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL

• Continuous pressure Ready/Not Ready indication based on measured

conditions.

• Motorized, intelligent piston drive system based measur ed rotation rate

with operator alert and manual override.

• Integrated autom ated pressure control with standard Fluke Calibration

pressure controllers.

• Full RS232 and IEEE-488 c ommunications wit h multi-level com mands to

set and read all instrument functions.

1.2.1.3 Ambient and Instrument Condition Measurements

Temperature

Range

Resolution

Measurement Uncertainty

Barometric Pressure

with Internal Sensor

Range

Resolution

Measurement Uncertainty

Relative Humidity

Measurement Uncertainty

Piston Position

Measurement Uncertainty

Piston Rotation

(Rate and deceleration)

1

Range

Resolution

Range

Resolution

Range

Resolution

Ambient

0 to 40

0.1

± 1

70 to 110 kPa

10 Pa

± 140 Pa

Barometric pressure can also be read automatically with any

RS232 device such as a DH Intruments RPM.

5 to 95 % RH

1 % RH

± 10 % RH

± 4.5 mm

0.1 mm

± 0.2 mm

2 to 99 rpm

1 rpm

1

Piston Cylinder Module

o

C 0 to 40 oC

o

C 0.01 o C

o

C ± 0.1 o C

Vacuum (Optional)

Range

Resolution

Measurement Uncertainty

1

PG9000 uses a Fluke Hart Scientific 2626-S temperature and humidity probe specified and factory

calibrated to deliver ±0.25 ˚ C uncertainty on temperature and ±3% on relative humidity. PG9000

performance requirements and factory calibration services require only the specifications listed above

to meet stated product uncertainties.

© 1998-2010 Fluke Calibration Page 4

0 to 13 Pa

0.01 Pa

± 0.05 Pa + 0.5 % of reading

1. INTRODUCTION

1.2.2 Piston-Cylinder Assembly (PC-9607-5)

The piston is mounted in a fixed position on the mounting post. The cylinder floats and

is rotated.

Piston Material:

Cylinder Material:

Nominal Diameter:

Nominal Area:

Mounting System:

Typical Drop Rate:

Tungsten carbide

Tungsten carbide

50 mm

2 000 mm

Free deformation with controlled clearance pres sure (CCP) available on

inside of piston.

< 0.25 mm/min at 500 kPa (Full mass load)

2

1.2.3 Mass Sets

Masses > 50g

Material

Finish

Adjustment Tolerance

Uncertainty of Measured Values

Masses < 50g

304L non-magnetic stainless steel

Electropolished

± 20 ppm of nominal value (manual mass sets, AMH

automated mass handler mass sets do not have fixed

adjustment tolerances)

± 5 ppm or 1 mg, whichever is greater

± 1 mg

1.2.4 Pressure Measurements (PG9607)

Note

For uncertainty in piston-cylind er effective area and typical measurem ent

uncertainty in pressure defined by the piston gauge, see the pistoncylinder calibration report and current revision of Fluke Calibration

Technical Note 0180TN12.

The piston is mounted in a fixed position on the mounting post. The cylinder floats and

is rotated.

All masses are delivered in molded, reusable, transit cases with custom inserts.

Sensitivity1:

1

Sensitivity: The smallest variation in input detectable in output.

2

Reproducibility: The root sum square of the stability of effective area and stability of the

Reproducibility

AMH-100 mass set for 1 year. Refer to Fluke Calibration Technical Note 0180TN12

0.005 Pa + 0.5 ppm

2

:

± 2 ppm + 0.05 Pa

.

Page 5 © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL

1.3 Front and Rear Panels

1.3.1 Terminal Front and Rear Panels

1.3.1.1 PG Terminal Front Panel

The front panel ass embly provides a 2 x 20 vacuum fluorescent display and a

4 x 4 membrane keypad for local user interface. The terminal front panel assembly

is the same for all PG9000 models.

Fluorescent display

Keypad

Figure 1. PG Terminal Front Panel

1.3.1.2 PG Terminal Rear Panel

The rear panel assembly provides the communications connection to the

PG9000 Remote Elec tronics Module. The terminal r ear panel assembly is the

same for all PG9000 models.

© 1998-2010 Fluke Calibration Page 6

1. INTRODUCTION

Power switch

Connector for 25 pin cable to PG

COM 2 (RS232) – External

Component

PG DRIVER – 15 pin Cable to

COM 4 (RS232) – Pass Through

COM 1 (RS232) – Remote Host

TERMINAL

Fuse

Power receptacle

Figure 2. PG Terminal Rear Panel

Remote Electronics Module

Cooling fan

1.3.2 Remote Electronics Module Rear Panel

The PG9000 Remote Electronics Modu le houses all working electr onics (processor, sensor

and communications) for the PG9000 in addition to sensors for ambient conditions

(temperature, pressure and humidity).

Barometer, External Vacuum

Gauge and Pass through

Communication

COM 3 (RS232) – Automated

Pressure Generation/Control

PG Base

ATM Connection (Barometer)

Mounting Post PRT Connector to

PG Remote Electronics Module

TH Probe Connector

Figure 3. PG9000 Remote Electronics Module Rear Panel

Communications

IEEE-488 – Remote Host

Communications

AMH Connection

Connector for 25 pin Cable to PG

Page 7 © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL

1.3.3 Base Rear Panel

The PG9000 Platform rear panel provides the communications connection to the PG Remote

Electronics Module, test and controlled clearance pressure connections as well as (optional)

AMH Automated Mass Handler connections.

PG Driver – to PG Remote

Electronics Module

AMH Connection

AMH Vent Port

Controlled Clearance Pressure

Port – PG9607 Only

TEST Pressure Port

AMH Drive Pressure Port

PRT Connector – to Remote

Electronics Module

Figure 4. PG9000 Base Rear Panel (PG9607 show n)

© 1998-2010 Fluke Calibration Page 8

2. Installation

2.1 Unpacking And Inspection

2.1.1 Removing From Packaging

A typical PG9000 system includes the PG9000 Platform ( see Section 2.1.1.1), a mass set (see

Section 2.1.1.2), a piston-cylinder assembly (see Section 2.1.1.3) and oth er access ories suc h as

vacuum reference hardware (see Section 2.1.1.4), an AMH automated mass handler (see

Section 2.1.1.5) and/or pressure generation and control components (see the accessory

Operation and Maintenance Manual or Instruction Sheet).

2.1.1.1 Platform

The PG9000 Platform c onsists of the PG9000 Base, R emote Electronic s Module,

Terminal and inter connect a ccessories . The Base is shipped in a custom woode n

crate. The Platf orm compone nts are shipp ed in a reusab le, molded shi pping and

storage case. The cables an d accessories ar e shipped i n a corrugated c ontainer

with other PG9000 accessories including operating instructions and calibration

reports.

Open the PG9000 Base shipping crate (71 cm x 71 cm x 56 cm).

Carefully lift the PG9000 B ase from its position in the lower pack ing insert.

Note the orientation s o that the sam e orientation will b e used when PG90 00

is repacked.

Warning

The PG9000 Base has a mass of 34 kg (74 lb). It is

recommended to remove it from the packaging with two people

on opposite sides of the shipping container. Removing or

lifting with only one person may cause injury.

Open the PG9000 molded, reusable recalibration transit case and the

accessories corrugated shipping container.

Remove the PG Terminal, Remote Electronics Module and Temperature-

Humidity Probe from the recalibration transit case and the Platform

accessories from the shipping container. Inspect and inventory the

accessories (see Section 2.1.2.1).

Reinstall the pack ing insert s into the s hippin g and s torage cas es and store in

a safe place.

2.1.1.2 Manual Mass Set

Caution

The stability over time of PG9000 pressure measurements is a

function of the stability of the masses loaded on the cylinder.

Precautions should be taken in handling the masses to

minimize influences that may change their mass. This includes

always wearing protective gloves when handling the masses to

avoid contaminating them with body oils and perspiration.

Protective gloves are provided in the accesso ry kits of PG9000

Platforms.

Page 9 © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL

The mass set accessories are shipped in a separate corrugated container.

Open the corrugated container and inspect and inventory the accessories.

The PG9000 masses are shipped in reusable, molded shipping and

storage cases. The PG9000 masses should be removed from their shipping

cases and inventoried w hen setting up the PG9000 system (see Section 2.1.1.2

for mass set content detail).

The PG9000 manual mass bell ships in a separate corrugated container.

The mass loading bell is a metrological element that is part of

the mass set. Like all of the masses, it is preferable not to

handle it with bare hands. Protective gloves are provided in the

accessory kit of each PG9000 Platform.

2.1.1.3 Piston-Cylinder Assembly (PG9607)

The PG9607 piston-cylinder assembly is shipped in a molded plastic case with

custom pol yethylene ins erts that accom modates 2 Acetal bullet c ases. The p iston

and the cylind er are separat e; each is packed i n its own bullet cas e. Do not handle

either of t hese elements with bare hands. Use the gloves that are in the PG9000

accessory kit or use the lint free wipes. See Section 2.1.2.3 for details.

Never handle the piston or cylinder with bare hands. Oil and

acids from bare skin can damage the crit ical surfa ces (polished

appearance).

Caution

Caution

2.1.1.4 Vacuum Reference Hardware (Optional)

The optional PG9000 Vacuum Reference Hardware includes the vacuum Bell

Jar, reference vacuum sensor with power supply and interconnect cables and

fittings necessary for vacuum operation.

The PG9000 Bell Jar is pack ed in a large wooden crate (66 cm x 66cm x 71 cm ).

The vacuum refer ence sensor, power supply and assoc iated fittings and cables

are packed in a reusable molded Vacuum Measurement Kit transit case.

Remaining fittings and adaptors are shipped in the PG9000 accessories

corrugated container (see Section 2.1.2.4).

2.1.1.5 AMH Automated Mass Handler (Optional)

AMH-100-VAC is delivered in a corrugated container with foam cut outs to hold

items in place. Accessories are bagged together and packaged in a separate

corrugated container with other PG9000 system accessories.

Remove all parts from the shipping boxes. See Section 2.1.2.5 for more detail.

2.1.1.6 AMH Mass Set (Optional)

PG9000 AMH masses are shipped in reusable, molded shipping and storage

cases. One of the cas es contains the binar y masses, binar y mass car rier, mass

bell and lifting shaft/trim mass tra y. The other cases c ontain the m ain masses of

10 kg (see Section 0 for mass set content detail). Each mass is packed in a

sealed plastic bag and then plac ed in a protective s hipping insert. The PG9000

AMH masses should be re moved from their shipping c as es and in ve ntori ed w he n

setting up the PG9000 system (see Section 2.1.1.2 for mass set content detail).

© 1998-2010 Fluke Calibration Page 10

2. INSTALLATION

Caution

The stability over time of PG9000 pressu re meas urement s is a funct ion of

the stability of the masses loaded on the piston. Precautions should be

taken in handling the masses to minimize influences that may change their

mass. This includes always wearing protectiv e gloves when handling the

masses to avoid contaminating them with body oils and perspiration.

Protective gloves are provid ed in the accessory kits of PG9000 Platforms.

2.1.2 Inspecting Contents

Inspect all parts for damage. If damage is noted, report it to your Shipping & Receiving

Department and the delivering carrier for appropriate action.

Inspect for any miss ing components or access ories referring to Tables 1-8. S ho uld any items

be missing, contact Fluke Calibration or your local Fluke Calibration representative.

A parts list of item s supplied is prov ided in Sectio n 2.1.2.1 for PG9000 Platform, Section 2.1.2.2

for mass sets, Section 2.1.2.3 for Piston-Cylinder Assemblies, Section 2.1.2.4 for (optional)

vacuum reference hardware and Section 2.1.2.5 for (optional) Automat ed Ma ss Handl er .

2.1.2.1 Platform

Each PG9000 Platform is delivered complete with access ories as listed by part

number in Table 1.

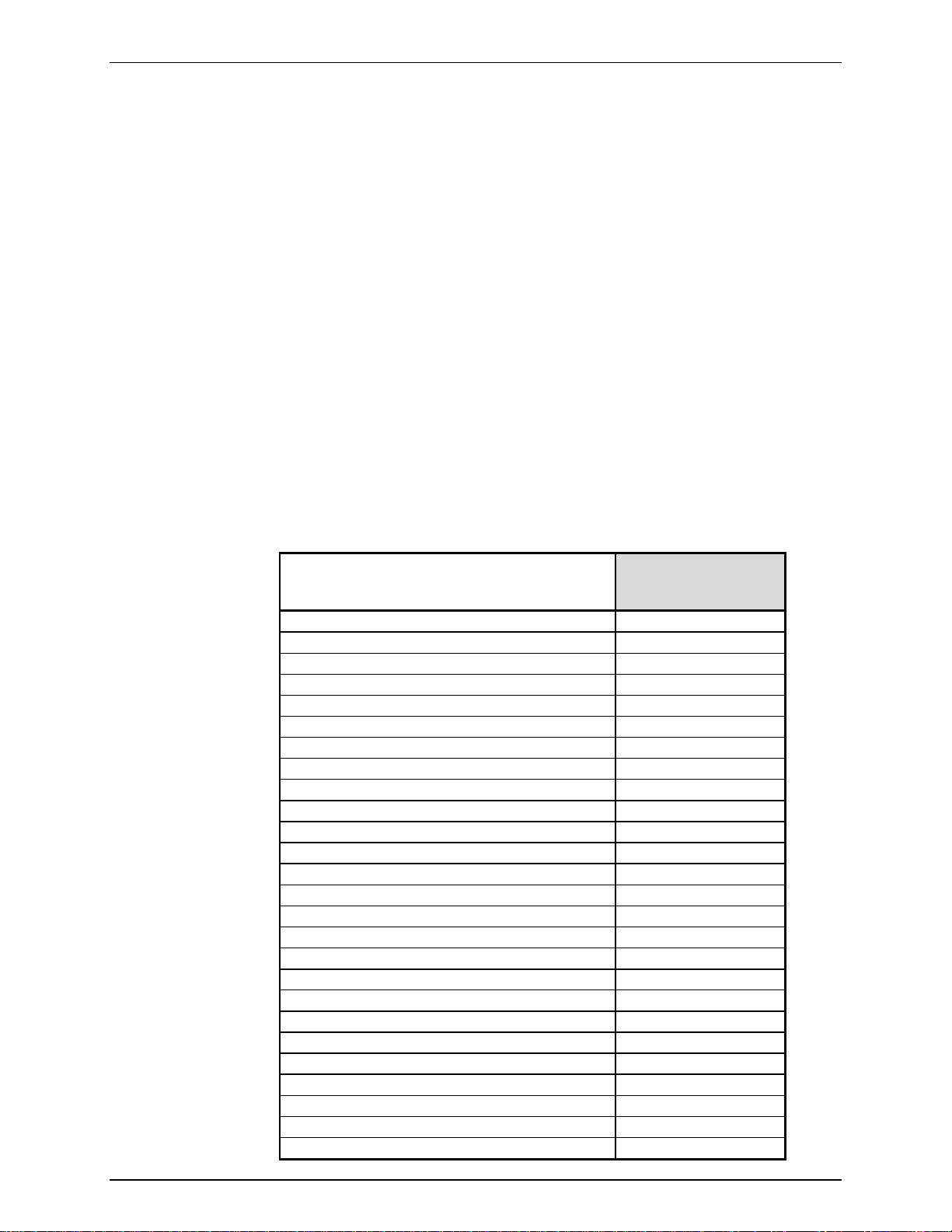

Table 1. PG9607 Parts List

PG9607

PLATFORM

3821488

Base

Terminal

Remote Electronics Module

Transit case for recalibration items

Accessory Kit 3841024

ADPT, DH200 M X 1/8 in. swage 3069062

(2) NIP, SS, DH200, 2.75" 3068377

(2) ADPT, SS, DH200 F X 1/8 in. NPT F 3068547

ADPT, SS, DH200 M X 1/4 in. swage 3069081

Tee, SS, 1/4 in. swage 3138683

Union, SS, 1/4 in. swage x 1/8 in. swage 3135076

ADPT, SS, 1/4 in. swage x 1/8 in. NPT F 3141914

ADPT, SS, 1/8 in. NPT M x 1/8 in swage 3068564

ADPT, 10-32UNF x 1/8 in. Swage 3141516

1/8” tubing, PFA, 2 m 3232357

(2) 1/4 in. tubing, SS, 10 cm 3853024

1/4 in. tubing, SS, 20 cm 3853036

1/4 in. tubing, SS, 50 cm 3853049

1/8 in. tubing, SS, 30 cm 3852995

1/8 in. tubing, SS, 150 cm 3853008

(2) O-ring, Viton, brown, 2-029 3144730

O-ring, Viton, brown, 2-019 3134945

(2) O-ring, Buna, 2-242 3135041

Allen wrench, 2.5 mm 3136044

Allen wrench, 3 mm 3135703

Allen wrench, 5 mm 3136098

3789373

3789710

3789425

3841097

Page 11 © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL

Krytox GPL205/6 0.5 oz

2493420

Gift kit with gloves 3123777

Terminal to Platform Cable (DB25M – DB25F) 3068724

PRT Cable, PG Platform 3778220

TH Probe Cable 3837033

Driver Cable, PG Platform 3068683

Power Cable – US 3133781

Power Cable – UK 3153005

Documentation

Calibrati on Report (PG)

Technical Dat a

Manual

Document ation CD

3152121

3152139

3782240

3139043

2.1.2.2 Mass Set

PG9000 m ass sets are compos ed of different c ombinations of ind ividual mas ses

and accessories depending on the specific mass set ordered (see Tables 2 - 5).

Table 2. Manual Mass Set Parts List (excluding 80 and 100 kg)

DESCRIPTION PART NO.

Mass Set Refer to Table 5

Reusable Molded Transit Case with Foam Inserts

35 kg set

40 kg set

45 kg set

55 kg set

Mass Set Storage Tray and Spindle 3147461 and 3148764

Dust Covers 3138017 and 3138130

Calibration Report 3152121

3068969

1 ea.

1 ea.

1 ea.

1 ea.

Table 3. Manual Mass Set Parts List (80 and 100 kg)

3068991

1 ea.

1 ea.

1 ea.

2 ea.

DESCRIPTION PART NO.

Mass Set Refer to Table 5

Reusable Molded Transit Case with Foam Inserts

80 kg set

100 kg set

Mass Set Storage Tray and Spindle 3147461 and 3148764

Dust Covers 3138017 and 3138127

Calibration Report 3152121

3068969

1 ea.

1 ea.

3068984

2 ea.

3 ea.

Table 4. AMH-100 Mass Set Parts List

DESCRIPTION PART NO.

Mass Set Refer to Table 5

Reusable Molded Transit Case with Foam Inserts

40 kg set (MS-AMH-40)

60 kg set (MS-AMH-60)

80 kg set (MS-AMH-80)

100 kg set (MS-AMH-100)

Calibration Report 3152121

3123990

1 ea.

1 ea.

1 ea.

1 ea.

3068984

1 ea.

2 ea.

2 ea.

3 ea.

© 1998-2010 Fluke Calibration Page 12

2. INSTALLATION

Table 5. Mass Set Compositions

DESIGNATION PART #

MS-7002-35 3069861 35 - 5 2 1 1 2 1 1 (4) MS-7002-40 3070021 40 - 6 2 1 1 2 1 1 (4) MS-7002-45 3069980 45 - 7 2 1 1 2 1 1 (4) MS-7002-55 3069877 55 - 9 2 1 1 2 1 1 (4) MS-7002-80 3070000 80 6 1 2 1 1 2 1 1 (9) -

MS-7002-100 3070017 100 8 1 2 1 1 2 1 1 (9) -

TOTAL

MASS (kg)

10

5

kg

kg 2 kg 1 kg

DESIGNATION PART # NOMINAL

TOTAL

10

NOMINAL

MASS (kg)

MS-AMH-40 3071528 40 3 1 - 1 1 1 1 1 1 1

MS-AMH-60 3071519 60 5 1 - 1 1 1 1 1 1 1

MS-AMH-80 3071504 80 7 1 - 1 1 1 1 1 1 1

MS-AMH-100 3071440 100 9 1 - 1 1 1 1 1 1 1

All mass sets also inclu de a trim m ass se t of 50 g to 0.01 g (t ota l 100 g)

kg

6.4

kg

MASS SET COMPOSITION

0.5

kg

MASS SET COMPOSITION

6.2

3.2

kg

1.6

kg

kg

0.2

kg

0.8

kg

0.1

kg

0.4

kg

MAKE-UP

MASS

(kg)

0.2

0.1

kg

kg

BELL, SHAFT,

BINARY MASS

Note

The mass loading bell and piston make up part of the total mass

load. The mass loading bell for loading manual mass sets is

ordered and shipped separatel y. The mass loading bell for AMH

mass sets is delivered with the mass set.

CARRIER

(3 PARTS)

2.1.2.3 Piston-cylinder Assembly

Table 6. 50 mm Gas Piston-Cylinder Assembly Parts List

5 kPa/kg

PC-9607-5

Piston-cylinder kit

Piston-cylinder 3782004

Piston-cyli nder cas e (w/ 2 bullet cases) 3781999

Accessory Kit

(2) O-rings, brown, Viton (2-015) 3134923

Documentation

Calibration report

Caution

Never handle the piston or cylinder with bare hands. Oil and

acids from bare skin can damage the c ritical surfa ces (polished

appearance).

3782028

3118500

3152121

Page 13 © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL

2.1.2.4 Vacuum Reference (Optional)

Table 7. PG9000 Vacuum Reference Hardware

Vacuum Measurement Kit 3840203

CDG Power Supply 3142866

CDG Cable, 10 ft. 3142875

RS232 Cable, 10 ft. 3142882

KF40 Centering Rng with Viton O-ring 3140217

KF40 Clamp 3140221

KF40 to KF16 Reducer 3142990

KF16 Elbow 3836205

CDG with manual valve – assembled with centering

ring and clamp 3841484

(2) KF16 Centering Ring with Viton O-ring 3134540

(2) KF16 Clamp 3138978

Transit Case for Vacuum Measurement Kit 3841085

Bell Jar 3478417

Bell Jar Gasket 3788743

Vacuum Vent Valve and Fittings 3841060

(2) KF40 Clamp 3140221

KF40 Blank Off Cap 3140671

KF40 Centering Ring with SS Screen 3142830

KF40 Centering Ring with Viton O-ring 3140217

KF40 to KF16 Reducer 3142990

KF16 Clamp 3138978

Vent Valve, KF10 3139838

KF10/16 Centering Ring, Viton, with Viton O-ring 3133103

KF50 Blank Off Cap 3836143

KF50 Centering Ring 3836162

KF50 Clamp 3836170

PG9000 Vacuum

Reference Hardware

3821513

Caution

The vacuum sensor (CDG) is assembled to an isolation valve in

order to store and/or transport in an evacuated condition. In

order to assure performance within specifications, open the

valve only when the pressure in the attached vacuum chamber

is below 500 Pa and close the valve before increasing the

chamber pressure from vacuum.

© 1998-2010 Fluke Calibration Page 14

2. INSTALLATION

2.1.2.5 Automated Mass Handler (Optional)

Table 8. AHM-100-VAC Parts List

DESCRIPTION PART #

1 ea. AHM-100-VAC Automated Mass Handler 3821508

Accessory kit including: 3841402

1 ea. Power/Comm Cable 3843744

2 m 1/8 in. PFA tubing 3232357

2 m 1/4 in. PFA tubing 3232378

2 m 3/8 in. PFA tubing 3232445

1 ea. 3/8 i n. Tee 3843090

1 ea. Reducer, 1/4 in. Swage x 3/8 in. Swage 3843104

1 ea. 3/8 in. Port Connector 3843119

1 ea. ADPT, 1/8 in. Swage x 1/4 in. NPTM 3135780

1 ea. Quick Connect or Stem, 1/8 in. Swage DESO (red band) 3123691

1 ea. Quick Connect or Assy, with valve, AMH VAC Port (blue band) 3121719

4 ea. Cable Ti e, Hook and Loop 2008964

1 ea. 3 mm Hex Wrench 3141776

2.2 Site Requirements

The exact PG9000 system inst allation is affected b y the elements other than th e PG9000 Pl atform that

make up the PG9000 system.

When selecting and preparing a site to set up the PG9000 system, the following should be considered:

• Ambient conditions: T o achieve optimum m etrological performance, am bient conditions should be

controlled and maintained within the following:

♦ Temperature: 19 to 26 °C, minimize rate of change of temperature.

♦ Relative Humidity: 5 to 95 %RH (non-condensing).

♦ Ambient Pressure: Minimize external influences that will cause barometric instability.

♦ Air Currents: Do not insta ll the PG9000 Pl atform under a so urce of vertic al air c urrents s uch as an

overhead air conditioning duct. These can blow on the mass load and add unquantified forces.

♦ Vibration: Minimize local vibr ation. Excessive vibration will red uce the stabilit y of the pressures

defined by PG9000 (vibrati on affects the floating pisto n). Excessiv e high frequen cy vibration, f or

example from a vacuum pump on the same table as the PG9000, may affect piston sensitivity.

• Bench stability: Up to 100 k g may be loaded and unloaded onto the PG9000 Platform. The bench

on which the PG9000 sits should not deflect significantly under the mass load changes . This can be

verified by setting the PG9000 Platf orm on the benc h, leveling it, loadin g and unload ing the com plete

mass set while observing whether the level setting changes.

• Location of other components: Plan the space r equired and a convenient l ayout for the complete

PG9000 system including the PG Terminal, PG Remote Electronics Module, mass set, pressure

generation/control com pon ent(s) , test i nstrum ent c onnec tion an d com puter (if pres ent). If us ing a DH

Intruments PPC or MPC to generate/control pressur e, see its Operation and Maintenance Manual

for information on installing it. If a DH Intruments interconnect ions kit is being used to interc onnect

the components, see its instruction sheet.

• Electrical and pressure supplies: Plan t he supply of electr ical power to the PG Terminal and to th e

pressure generation/control component(s), if needed. If using a DH Intruments PPC or MPC to

generate/c ontrol pressure, s ee its Operation and Ma intenance Manua l for information on the pr essures

source(s) it nee ds a nd h ow t o conn ec t them . Gas s up plied to a P C-9000 piston-cylinder module m ust be

clean and dry (instrument grade minimum, high purity preferred) to avoid contaminating the piston-cylinder

gap.

• Reference vacuum supply: Plan for the vacuum connection to the optional bell jar and AMH

automated mass handler and the location of the reference vacuum pump.

Page 15 © 1998-2010 Fluke Calibration

PG9000™ OPERATION AND MAINTENANCE MANUAL