P5500 Series

Hydraulic and pneumatic

comparison test pumps, media

separators and accessories

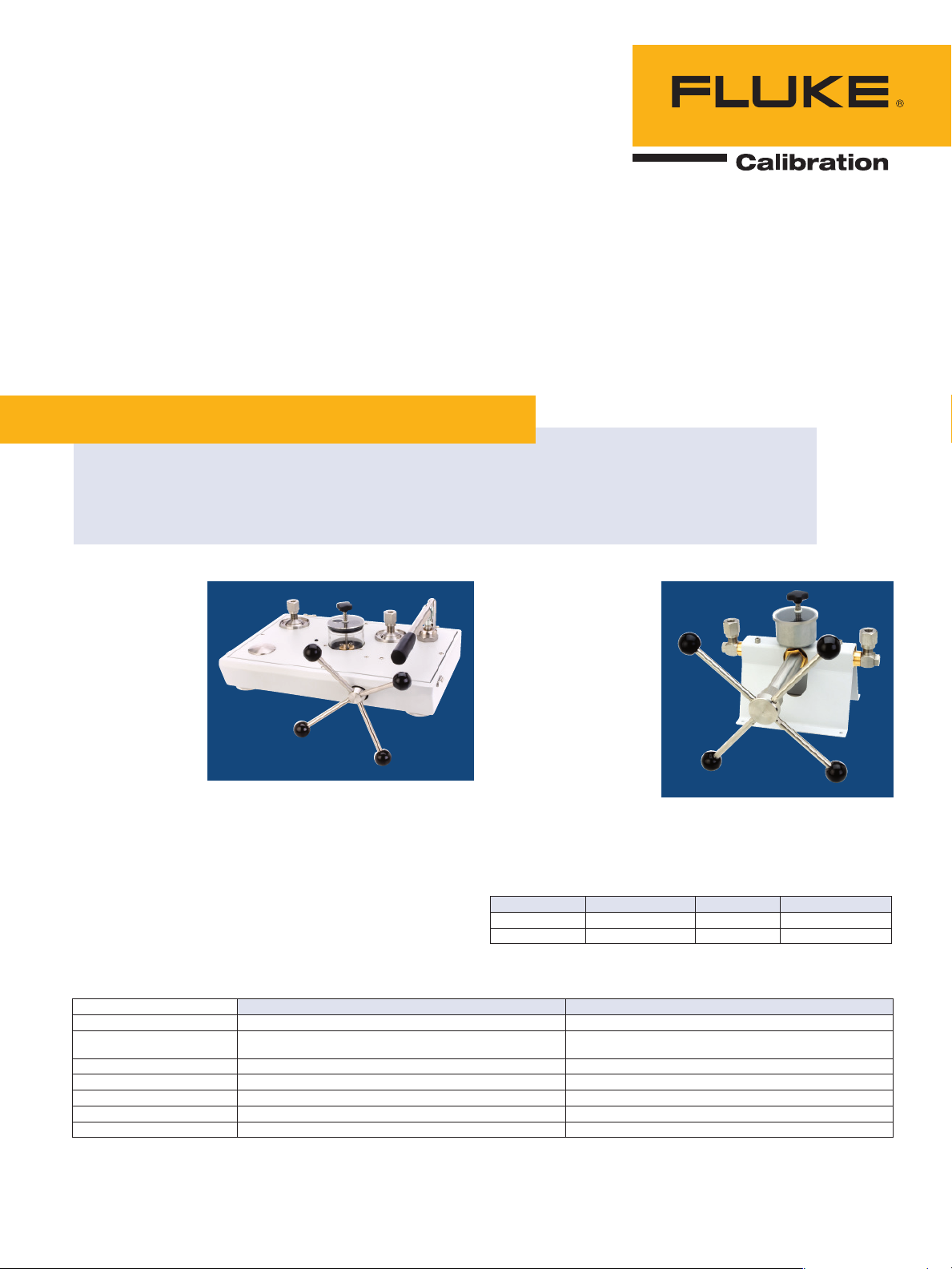

Hydraulic comparison test pumps

The Fluke Calibration Series of hydraulic test pumps are used for checking pressure measuring

instruments against master test gauges, indicators or transducers. These cost effective instruments,

which include several features from our popular line of hydraulic deadweight testers, are capable of

easily generating high pressures and provide precise control for important calibration requirements.

Technical Data

Model P5515

• Built-in pump

for large

volume applications and

system priming

• High quality

screw press for

fine pressure

control

• Acrylic reservoir for

Model P5514

• Bench mount design

• Screw press for

fine pressure

adjustments

• Test connections

can be made

without the need

for PTFE tape or

wrenches

• Operates with a

wide range of fluids

visibility of fluid level and quality

• Test port adapters which require no PTFE tape or

wrenches

• Built-in drain plug for removal of old fluid

• Sturdy carrying case with lid

• Operational with a wide range of fluids

The standard O-ring seals are Viton. Ethylene

Propylene seals are available for use with certain

aggressive fluids.

Model O-ring Model O-ring

P5515-140M Viton P5514-70M Viton

P5515-140M-EP Ethylene Propylene P5514-70M-EP Ethylene Propylene

Hydraulic comparison test pumps

Pressure range 0 psi to 20 000 psi (1 400 bar) 0 psi to 10 000 psi (700 bar)

Test port adapters M20 X 1.5, M14 X 1.5, 1/8, 1/4, 3/8, and 1/2 NPT and BSP

Weight 16 kg (36 lb) 5 kg (11 lb)

Dimensions (W x D x H) 440 mm x 300 mm x 215 mm (17.5 in x 12 in x 8.5 in) 279.4 mm x 279.4 mm x 254 mm (11 in x 11 in x 10 in)

Reservoir volume 150 cm

Screw press displacement 5.5 cm

Priming Pump displacement 4.7 cm

Model P5515 Model P5514

(plus 1 additional 1/4 NPT adapter)

3

(9.2 in3) 75 cm3 (4.6 in3)

3

(0.34 in3) 20 cm3 (1.2 in3)

3

(0.293 in) per stroke

M20 X 1.5, M14 X 1.5, 1/8, 1/4, 3/8, and 1/2 NPT and BSP

(plus 1 additional 1/4 NPT adapter)

Pneumatic comparison test pumps

These pneumatic comparison test pumps are designed for testing pressure measuring instruments

against master test instruments. These cost effective instruments provide precise control for important calibration requirements and include many features found in our popular line of pneumatic

deadweight testers.

Model P5510

• Dual pressure/

vacuum capability

• Bench mount design

• Built-in handpump

as pressure/vacuum

source

• High quality needle

valve for fine control

• Test port adapters which require

no PTFE tape or

wrenches

Model P5513

• High pressure

pneumatic

operation

• Screw press for

fine pressure

adjustments

• High quality

needle valves

for fine control

• Test port

adapters which

require no PTFE tape or wrenches

• Sturdy carrying case with lid

Note: P5513 requires a pressure source, such as a nitrogen bottle, for operation.

Pneumatic comparison test pumps

Pressure range 0 psi to 300 psi (20 bar) 0 psi to 3 000 psi (210 bar)

Vacuum range 0 in to 24 in Hg (800 mbar)

Test port adapters M20 X 1.5, M14 X 1.5, 1/8, 1/4, 3/8, and 1/2 NPT and BSP

Weight 3.5 kg (7.5 lb) 8 kg (17 lb)

Dimensions (W x D x H) 240 mm x 330 mm x 180 mm (9.5 in x 13 in x 7 in) 440 mm x 300 mm x 215 mm (17.5 in x 12 in x 8.5 in)

Model P5510-2M Model P5513-20M

(plus 1 additional 1/4 NPT adapter)

M20 X 1.5, M14 X 1.5, 1/8, 1/4, 3/8, and 1/2 NPT and BSP

(plus 1 additional 1/4 NPT adapter)

Gas supply connection 1/4 NPT female

2 Fluke Calibration P5500 Series Hydraulic and pneumatic comparison test pumps, media separators and accessories

Media separators

Liquid/liquid and liquid/gas media separators are

provided as a barrier between the deadweight tester

operating fluid and that of the device under test.

Liquid to liquid

Model P5521/5522

These liquid-to-liquid separators connect directly to the test

port of a hydraulic deadweight

tester or comparison test pump.

A flexible diaphragm separates

the fluids, protecting the calibrator from contamination and

allows calibration of the device

in its specific working fluid.

Dirt/moisture traps

Dirt/moisture traps provide an effective barrier against the transfer of moisture and dirt

from an instrument under test to the sensitive piston/cylinder assembly of a pneumatic

deadweight tester. Unexpected particle

contamination or fluid inside the device under

test will be prevented from entering the

deadweight system, avoiding downtime for

maintenance or repair. Designed for operation

in the vertical position these traps are simple

to dismantle and easy to clean.

Liquid to gas

interface

Model P5523

For high pressure pneumatic

calibrations this

unit interfaces with

hydraulic deadweight

testers providing a rateless liquid-to gas separation. Driven

by a pneumatic pressure source (nitrogen bottle) and

controlled by needle valves, high pressure gas is balanced

against the liquid in a hydraulic deadweight tester through

a series of fluid traps.

Note: since fluid mist may be transferred during operation we do not recommend this

device for oxygen- safe instruments using an oil operated deadweight tester.

Media separators/interfaces

Liquid to liquid

Pressure range Model P5521:

Test port adapters Uses adapters supplied with

Weight 3.5 kg (7.5 lb) 11 kg (24 lb)

Dimensions (W x H)

Calibrator connection 3/8 BSP male

Gas supply connection 1/4 NPT female

Body material Aluminum bronze

Diaphragm 5521- Viton

Reservoir material Hard-anodized aluminum

Model P5521/5522

0 psi to 10 000 psi (700 bar)

Model P5522:

0 psi to 7 000 psi (480 bar) for

Skydrol and other aggressive fluids

calibrator

100 mm x 150 mm

(4 in x 6 in)

(mating adapter supplied)

®

5522-Ethylene

Propylene

Liquid to gas

Model P5523

0 psi to 3 000 psi (210 bar)

Uses adapters supplied with

calibrator

(W x D x H)

440 mm x 300 mm x 215 mm

(17.5 in x 12 in x 8.5 in)

Model P5531

Designed to mount directly

on the deadweight tester and

featuring an acrylic chamber

for visibility of contaminates

this unit utilizes the standard

test port adapters for easy

instrument connections.

Model P5532

This high pressure version is

provided with an aluminum

central chamber for safety

and utilizes the standard test

port adapters.

Dirt/moisture traps

Pressure range 0 psi to 500 psi (35 bar) 0 psi to 3 000 psi (210 bar)

Body material Stainless steel Stainless steel

Chamber material Acrylic Aluminum

O-Rings Nitrile Nitrile

Test port

connection

Deadweight

connection

Model P5531 Model P5532

As supplied with

calibrator

3/8 in BSP male

(mating adapter

supplied)

As supplied with

calibrator

3/8 in BSP male

(mating adapter

supplied)

3 Fluke Calibration P5500 Series Hydraulic and pneumatic comparison test pumps, media separators and accessories

Accessories

P5544-STD Two gauge stand

This adapter mounts directly to the test

port of the calibrator and allows for the

calibration of two instruments at the

same time or the connection of a reference test instrument. Maximum working

pressure is 10 000 psi (700 bar).

Adapter sets

P5540 Metric: M14 x 1.5, M20 x 1.5, 1/8 in and 1/4 in BSP

P5541 BSP: 1/8 in, 1/4 in, 3/8 in and 1/2 in BSP

P5542 NPT: 1/8 in, 1/4 in, 3/8 in and 1/2 in NPT

PK-P3000-ADPTR-SD: M14 x 1.5, M20 x 1.5, 1/8, 14/, 3/8,

and 1/2 in BSP and NPT

Model P5543 Angle adapter

To calibrate gauges with the pressure

connection on the rear (e.g. panel

mount gauges) In their correct operating

position, an angle adaptor should be used.

The angle adapter uses the standard

gauge adapters and positions the gauges

at 90°. The maximum working pressure

of this Unit is 10 000 psi (700 bar).

Model P5551 Pointer remover/punch

This tool is designed to quickly remove and consistently

refit the pointer of a pressure gauge.

Accessories

Body material Brass and stainless steel Stainless steel

O-Rings Nitrile Nitrile

Test port adapters M14 x 1.5, M20 x 1.5, 1/8, 14/, 3/8, and

Calibrator connection 1/2 in BSP male (mating adapter supplied) 3/8 in BSP male (mating adapter supplied)

4 Fluke Calibration P5500 Series Hydraulic and pneumatic comparison test pumps,

media separators and accessories

Model 5544 Model 5543

1/2 in BSP and NPT

As supplied with calibrator

Fluke Calibration.

Precision, performance, confidence.

Fluke Calibration

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (877) 355-3225 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.flukecal.com

©2010-2012 Fluke Calibration.

Specifications subject to change without notice.

Printed in U.S.A. 8/2012 3833524B D-EN-N

Modification of this document is not permitted

without written permission from Fluke Calibration.

™

Loading...

Loading...