9118A

Calibration Furnace

Users Manual

September 2012 Rev. 1, 2/2014

© 2012-2014 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship for one year from the date of purchase. This warranty does not

cover fuses, disposable batteries, or damage from accident, neglect, misuse, alteration, contamination, or abnormal conditions of operation

or handling. Resellers are not authorized to extend any other warranty on Fluke’s behalf. To obtain service during the warranty period,

contact your nearest Fluke authorized service center to obtain return authorization information, then send the product to that Service Center

with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE

EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR

LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries do not allow the exclusion or limitation of an implied

warranty or of incidental or consequential damages, this limitation of liability may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Table of Contents

Title Page

Introduction .................................................................................................................... 1

How to Contact Fluke .................................................................................................... 1

Safety Information .......................................................................................................... 1

Installation ..................................................................................................................... 6

Unpack and Inspection ............................................................................................. 6

Placement ................................................................................................................. 6

Dry-Out Period .......................................................................................................... 6

How to Move the Product .......................................................................................... 7

Product Components ..................................................................................................... 7

Front-Panel Controls ................................................................................................. 10

Rear-Panel Connections ........................................................................................... 12

Probe Installation ...................................................................................................... 17

The Isothermal Block ................................................................................................ 20

Connect to Mains Power ........................................................................................... 21

How to Turn On the Product .......................................................................................... 21

How to Turn Off the Product .......................................................................................... 22

Display ........................................................................................................................... 23

Setup ............................................................................................................................. 23

Set the Language ...................................................................................................... 23

Set Display Contrast ................................................................................................. 23

i

9118A

Users Manual

Operation ....................................................................................................................... 24

How to Set Parameters in the Product ...................................................................... 25

Value List ............................................................................................................. 25

Set Number Value ................................................................................................ 25

Softkey Menus .......................................................................................................... 26

Temperature (TEMP) Setup Menu ............................................................................ 29

Scan Rate ............................................................................................................ 29

Cutout ................................................................................................................... 29

Program (PROG) Menu ............................................................................................ 29

RAMP/SOAK Menu .............................................................................................. 29

RUN PROG Function ........................................................................................... 30

Calibration (CALIB) Menu ......................................................................................... 30

Calibration (CAL) Points Menu ............................................................................. 30

PID Setup Menu ................................................................................................... 31

Furnace Setup Menu ................................................................................................. 31

System Menu ............................................................................................................ 31

Display (DISP) Menu ............................................................................................ 31

Communications (COMM) Setup Menu ................................................................ 31

Password Setup Menu ......................................................................................... 32

System Information (INFO) Menu ......................................................................... 32

Adjust Furnace Temperature .................................................................................... 32

Set the Furnace Temperature with a Preset ......................................................... 32

Set the Furnace Temperature Manually ............................................................... 33

How to Stop the Furnace Heat Cycle ........................................................................ 33

Change a Preset Temperature .................................................................................. 33

Probe Insertion .............................................................................................................. 34

Cutouts .......................................................................................................................... 34

Soft Cutout ................................................................................................................ 34

Hard Cutout ............................................................................................................... 35

Chassis Thermostat Cutout ....................................................................................... 35

Fan Fault Cutout ....................................................................................................... 35

TC or Heater Fault Cutout ......................................................................................... 35

Remote Operation ......................................................................................................... 35

Digital Communication Interface ............................................................................... 36

ii

Contents (continued)

How to Configure the Digital Interface ...................................................................... 37

Input Terminators ...................................................................................................... 37

SCPI Commands ...................................................................................................... 37

Commands by Function or Group ........................................................................ 37

Alphabetic List of Commands ........................................................................................ 42

Maintenance .................................................................................................................. 59

Cutout Test ............................................................................................................... 60

How to Clean the Product ......................................................................................... 60

Furnace Calibration ................................................................................................... 60

Calibration Terminology ....................................................................................... 61

Environment Conditions ....................................................................................... 61

Calibration Equipment .......................................................................................... 61

Calibration ............................................................................................................ 61

Calibration Procedure for Tube Furnace ........................................................................ 64

Calibration procedure for 9118A-ITB (with Isothermal Block) ................................... 70

Calibration Equipment Setup .................................................................................... 70

Stability Test ......................................................................................................... 73

Accuracy Test ...................................................................................................... 73

Accuracy Adjustment ........................................................................................... 74

Axial Uniformity .................................................................................................... 74

Specifications for 9118A and 9118A-ITB ....................................................................... 78

General Specifications .............................................................................................. 78

Accuracy Specifications ............................................................................................ 79

Radial Uniformity ....................................................................................................... 79

Axial Uniformity ......................................................................................................... 79

Temperature Stability ................................................................................................ 79

Heating Time (23 °C to 1200 °C) .............................................................................. 80

Cooling Time (1200 °C to 300 °C) ............................................................................ 80

iii

9118A

Users Manual

iv

List of Tables

Table Title Page

1. Symbols ................................................................................................................................ 5

2. Front-Panel Controls ............................................................................................................. 11

3. Rear-Panel Connections ....................................................................................................... 13

4. Display Elements .................................................................................................................. 23

5. Commands by Function or Group ......................................................................................... 38

6. Calibration Equipment........................................................................................................... 61

7. Furnace Calibration Tests and Adjustments ......................................................................... 63

8. Stability Test Data ................................................................................................................. 66

9. Axial Uniformity Test ............................................................................................................. 67

10. Skew Correction Values ........................................................................................................ 67

11. SKEW Parameter ................................................................................................................. 67

12. Zone Correction Values ........................................................................................................ 68

13. ZONE Parameter .................................................................................................................. 68

14. Accuracy Parameter ............................................................................................................. 69

15. Stability Test Data with Isothermal Block .............................................................................. 73

16. Accuracy Parameter for Isothermal Block ............................................................................. 74

17. Axial Uniformity Test with Isothermal Block .......................................................................... 75

18. Skew Correction Values for Isothermal Block ....................................................................... 76

19. SKEW Parameter for Isothermal Block ................................................................................. 76

20. Zone Correction Values For Isothermal Block ...................................................................... 77

21. Zone Parameter for Isothermal Block ................................................................................... 77

v

9118A

Users Manual

vi

List of Figures

Figure Title Page

1. Calibration Tube Furnace ..................................................................................................... 8

2. Front View with Isothermal Block .......................................................................................... 9

3. Rear View with Isothermal Block .......................................................................................... 9

4. Front-Panel Controls ............................................................................................................. 10

5. Rear-Panel Connections ....................................................................................................... 12

6. Rear View of 9118A Thermocouple Calibration Furnace with Isothermal Block ................... 14

7. Short Tube and Long Tube Insertion .................................................................................... 15

8. Rear Plug Insertion ............................................................................................................... 15

9. Attach the Rear Shield .......................................................................................................... 16

10. Attach the Support Bracket ................................................................................................... 16

11. Front Plug Insertion .............................................................................................................. 17

12. Probe Installation A ............................................................................................................... 18

13. Probe Installation B ............................................................................................................... 19

14. Insert Alignment .................................................................................................................... 20

15. Power-Up Screen ................................................................................................................. 21

16. Main Screen .......................................................................................................................... 22

17. Preset Selection .................................................................................................................... 25

18. SETPOINT Temperature ...................................................................................................... 25

19. Softkey Menu Tree ............................................................................................................... 27

20. Menu Softkey Displays ......................................................................................................... 28

vii

9118A

Users Manual

21. Preset Selection .................................................................................................................... 32

22. Change Preset Temperature ................................................................................................. 33

23. RS-232 Cable Connections................................................................................................... 36

24. Tube Furnace Calibration Flow Chart ................................................................................... 62

25. Test Equipment Connections ................................................................................................ 65

26. Calibration Equipment Setup ................................................................................................ 71

27. Calibration Procedure for Furnace with Thermo Block .......................................................... 72

viii

Introduction

Warning

To prevent possible electrical shock, fire, or

personal injury, read all safety information

before you use the Product.

The Product is used to calibrate Platinum Resistance

Thermometers (PRTs), fiber optic sensors, and

thermocouples to a maximum temperature of 1200 °C.

How to Contact Fluke

To contact Fluke Calibration, call one of these telephone

numbers:

• Technical Support USA: 1-877-355-3225

• Calibration/Repair USA: 1-877-355-3225

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31-40-2675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• China: +86-400-810-3435

• Brazil: +55-11-3759-7600

• Anywhere in the world: +1-425-446-6110

To see product information and download the latest

manual supplements, visit Fluke Calibration’s website at

www.flukecal.com.

To register your product, visit http://flukecal.com/register-

product.

Safety Information

A Warning identifies conditions and procedures that are

dangerous to the user. A Caution identifies conditions and

procedures that can cause damage to the Product or the

equipment under test.

Warning

To prevent possible electrical shock, fire, or

personal injury:

• Read all safety information before you use the

Product.

• Carefully read all instructions.

1

9118A

Users Manual

• Use the Product only as specified, or the

protection supplied by the Product can be

compromised.

• Do not use the Product around explosive gas,

vapor, or in damp or wet environments.

• Use this Product indoors only.

• Use only the mains power cord and connector

approved for the voltage and plug

configuration in your country and rated for the

Product.

• Replace the mains power cord if the insulation

is damaged or if the insulation shows signs of

wear.

• Connect one end of the supplied ground wire

to the protective earth ground terminal on the

rear panel and the other end to an earth

ground.

• Make sure the ground conductor in the mains

power cord is connected to a protective earth

ground. Disruption of the protective earth

could put voltage on the chassis that could

cause death.

• Do not put the Product where access to the

mains power cord is blocked.

• Make sure that the Product is grounded before

use.

• Do not use an extension cord or adapter plug.

• Do not use the Product if it operates

incorrectly.

• Do not use the Product if it is damaged.

• Disable the Product if it is damaged.

• Make sure the power cord does not touch with

hot parts of the Product.

• Make sure that the space around the Product

meets minimum requirements.

• Do not keep the Product in operation and

unattended at high temperatures.

• Use caution when you install and remove

probes and inserts from the Product. They can

be hot.

• Do not put the Product on a flammable surface

and keep a fire extinguisher nearby.

• Do not set anything on top of the Product. Very

high temperatures can cause the ignition of

flammable materials.

• Do not remove the isothermal block and rear

plug at high temperatures. The isothermal

block and rear plug are the same temperature

as shown on the display.

• Do not lift or move the Product with the

isothermal block in place. The isothermal

block and rear plug may fall out of the

instrument.

2

Calibration Furnace

Safety Information

• Applicable personal protective equipment

must be worn when you move hot temperature

probes or do work near the furnace apertures.

• Do not use the Product for applications other

than calibration work.

• The Product must only be used by approved

personnel.

• Do not touch surfaces near the well access

port. They can be very hot.

• Do not touch the insulation material in the

Product. The insulation material can cause

mild mechanical irritation with skin, eyes, and

upper respiratory system. If it gets on your

skin, flush area and wash gently. Do not rub or

scratch exposed skin. If it gets into your eyes,

flush abundantly with water. Do not rub eyes. If

the nose and throat become irritated, move to

a dust-free area and blow nose. If symptoms

continue, get medical advice.

Caution

To prevent damage to the Product:

• Operate the Product at room temperature.

See specifications.

• Keep a minimum of 45 cm clearance from

the front, left, and right sides. Keep 150 cm

from the top of the Product.

• Do not put the Product in a corner or cause

a blockage behind the Product.

• Do not use fluids to clean out the well.

Fluids in the Product can cause damage.

• Do not put unwanted material into the

probe protection tube or hole of the insert.

Fluids in the Product can cause damage.

• Only change calibration constant values

from the factory set values when you

calibrate the Product. These values are

important in the safe operation of the

Product.

• Read and understand the operation before

you turn on the Product.

• Do not operate the Product in wet, oily,

dusty, or dirty environments.

• Make sure the probe handle temperature

does not go above its limit.

3

9118A

Users Manual

• Be careful with thermometer probes. Do

not drop, stress, or let them become too

hot.

• Do not operate the Product without the

control probes correctly connected and put

into the furnace. The furnace does not

operate correctly without the control

probes.

• Make sure the main probe and zone probe

are connected to the correct connector.

• Turn off the furnace when a mains supply

power fluctuation occurs. Turn on the

furnace only when the mains power is

stable.

• Make sure that all reference sensors used

with the furnace are specified for the

temperature range of the furnace.

• Do not disconnect the Product from the

mains while the furnace temperature is

above 80 °C.

• Do not attempt to push the block into the

furnace. The isothermal block expands as

the furnace heats due to thermal

expansion. It will extend beyond the front

of the furnace at high temperatures. This is

normal.

• Remove the isothermal block and rear plug

prior to transporting the furnace. The

ceramic furnace tube is fragile and can be

damaged by the block.

• To prevent the probe under test from

getting stuck in the isothermal block due to

different rates of thermal expansion, allow

a clearance of at least 0.4 mm between the

outer diameter of the probe and the hole of

the isothermal block.

• Never introduce any foreign material into

the probe hole of the isothermal block.

Fluids, etc. can leak into the Product and

cause damage.

• Minimize vibration in the calibration

environment.

• The furnace can be used with or without an

isothermal block installed. Unique

calibration parameters are necessary for

each mode of operation.

• Before operating the furnace, select the

appropriate mode of operation in the

calibration menu (see Furnace Setup

Menu). If necessary, a calibration for the

new mode of operation may be required.

4

Calibration Furnace

Safety Information

The symbols on the Product and in this manual are shown in Table 1.

Table 1. Symbols

Symbol Description Symbol Description

Risk of Danger. Important information. See

Manual.

Hazardous voltage. Risk of electric shock.

Caution. Hot surface. Protective Earth Ground

USB connection Conforms to European Union directives.

Conforms to relevant North American Safety

Standards.

This product complies with the WEEE Directive (2002/96/EC) marking requirements. The affixed label indicates

that you must not discard this electrical/electronic product in domestic household waste. Product Category: With

reference to the equipment types in the WEEE Directive Annex I, this product is classed as category 9 "Monitoring

and Control Instrumentation" product. Do not dispose of this product as unsorted municipal waste. Go to Fluke’s

website for recycling information.

Conforms to relevant Australian EMC standards.

5

9118A

Users Manual

Installation

The subsequent sections give you information on best

practices for Product installation.

Unpack and Inspection

Carefully unpack the Product and check for all parts. If

there is damage, tell the shipper immediately and make a

claim. The parts included are:

• 9118A Calibration Furnace

• Type-S Thermocouple, Long

• Type-S Thermocouple, Short

• Protection Tube, Long

• Protection Tube, Short

• TC Support Bracket

• L-Key, Hex 3 mm

• Button Head Screw, M5X12 (2 each)

• Getting Started Manual

• Users Manual CD-ROM

• Ground Wire

• Serial Cable

• Isothermal Block

• Rear Plug

• Rear Plug for backup

The last 3 items are only for the thermocouple calibration

furnace with isothermal block.

Placement

For best results, choose a location to setup the Product

where room temperature changes are minimum. To safely

remove heat, put the Product in a position with a minimum

of 45 cm of free air space around it.

Fluke Calibration recommends that you do a test for axial

uniformity and adjust if necessary after the Product is

installed. Temperature uniformity of the Product could be

affected by the environment where the Product operates or

by equipment or material placed inside or at the ends of

the central tube. Refer to the Calibration section of this

manual.

Dry-Out Period

Before initial use, after transport, or the Product has not

been energized for more than 10 days, turn on the Product

for a minimum of 2 hours.

If the Product is wet or was in a wet environment, remove

moisture before you turn on the Product.

• USB Cable

• Super Wool Insulator

• Calibration Certificate

6

Calibration Furnace

Product Components

How to Move the Product

Warning

To prevent personal injury, use proper

techniques to lift the Product.

When you lift the Product, bend your knees and lift with

your legs. Before you move the Product, let it cool to

ambient temperatures and remove the control and cutout

thermocouples and all objects in the furnace well. To

safely move the Product, two people are necessary. Put

one person in the front and one person at the rear of the

Product. Carefully put your hands under the Product and

lift in unison.

Caution

To prevent damage to the Product, remove the

isothermal block and rear plug prior to

transporting the furnace. The ceramic furnace

tube is fragile and can be damaged by the

block.

Product Components

As shown in Figure 1 the two primary components of the

Product are the furnace and the controller. Figures 2 and 3

show the thermocouple calibration furnace with the

isothermal block. The isothermal block shown in Figure 2

is made of aluminum-oxide and provides a constant and

accurate temperature environment for the sensor under

test. Four 6.7 mm diameter wells are provided.

7

9118A

Users Manual

Furnace

Controller

8

Figure 1. Calibration Tube Furnace

gxs009.eps

Calibration Furnace

Product Components

Rear Plug

Thermal Block

Figure 2. Front View with Isothermal Block

gxs121.eps

gxs133.eps

Figure 3. Rear View with Isothermal Block

9

9118A

Users Manual

Front-Panel Controls

Figure 4 shows the front-panel controls of the Product and Table 2 is a list of control descriptions.

1

10

2

9

3

8

5

4

7

6

gxs007.eps

Figure 4. Front-Panel Controls

10

Calibration Furnace

Product Components

Table 2. Front-Panel Controls

Item Description Item Description

LCD Display Mains power switch

Set a temperature setpoint into the Product.

Sets the Product to show temperatures in Celsius or

Fahrenheit.

Moves through menus and adjusts numbers.

Furnace fuses

Used to set a value into the Product and choose a

menu.

Menu button shows the main menu in the display.

Exits the menu shown in the display and moves to the

previous menu.

Softkeys (F1 through F4) are used to select the function

that shows in the display above the softkey.

11

9118A

Users Manual

Rear-Panel Connections

Figure 5 shows the rear-panel connections of the Product and Table 3 is a list of connector descriptions.

N10140

MAIN TCZONE TC

BEFORE OPENING DISCONNECT MAINS.

230V 50/60Hz 20A

12

EARTH CONNECTION ESSENTIAL

BEFORE CONNECTING SUPPLY.

1

2

3 4 5 6

RS-232

Serial no.

FLUKE CORPORATION

www.flukecal.com

gxs008.eps

Figure 5. Rear-Panel Connections

Calibration Furnace

Product Components

Table 3. Rear-Panel Connections

Item Description Item Description

Mains power cord Main thermocouple input jack

Protective Earth Terminal USB connector

Zone thermocouple input jack RS-232 connector

13

9118A

Users Manual

Protection Tube and Support Bracket Installation (and Optional Isothermal Block)

Warning

To prevent personal injury, disconnect the

Product from mains power and when

applicable, allow to cool to 80 °C prior to

performing any maintenance or installation

work on the Product.

To install two protection tubes and a thermocouple (TC)

support bracket and optional isothermal block (9118AITB):

1. Remove the five socket-head screws and take down

the rear shield from unit. See Figure 6.

Rear Shield

Socket

Head Screw

Figure 6. Rear View of 9118A Thermocouple

Calibration Furnace with Isothermal Block

gxs124.eps

14

Calibration Furnace

Product Components

2. Insert the long and short protection tubes into flange

nuts and screw them into position.

• Long tube in the right side.

• Short tube in the left side. See Figure 7.

Short Tube

Long Tube

gxs125.eps

Figure 7. Short Tube and Long Tube Insertion

3. This step is only for the optional isothermal block

(9118A-ITB). Insert the rear plug carefully into position.

See Figure 8.

Rear Plug

gxs126.eps

Figure 8. Rear Plug Insertion

15

9118A

Users Manual

4. Attach the rear shield with the five socket-head

screws. See Figure 9.

Rear Shield

Socket

Head Screw

Figure 9. Attach the Rear Shield

gxs127.eps

5. Install the thermocouple support bracket on the rear

shield. See Figure 10.

Rear Shield

TC Support

Bracket

gxs128.eps

Figure 10. Attach the Support Bracket

16

Calibration Furnace

Product Components

6. This step is only for the optional isothermal block

(9118A-ITB). Insert the isothermal block into the

ceramic tube from the front side of the Product. See

Figure 6.

a. Make sure that the front plug is in contact with the

side of the ceramic tube.

b. The position of block must be as shown in Figure 11.

Right Position Wrong Position

Figure 11. Front Plug Insertion

gxs130.eps

Probe Installation

Note

When you put the temperature control probes into

their applicable protection tube (see steps 2 and 6

below), make sure the end surface of the probe

handle is aligned with the edge of the TC support

bracket. Failure to do so may cause the Product to

be out of calibration.

Two thermocouples are used as temperature control

probes. These probes are put into the rear of the furnace

and held in position with the TC support bracket.

To install the control probes:

1. Put the long probe into the MAIN TC tube on the rear

panel of the furnace.

2. Align the end surface of the thermocouple handle with

the front edge of the bracket. See Figures 12 and 13 .

3. Tighten the bracket screw to hold the thermocouple in

position.

4. Connect the cable of the long probe to the MAIN TC

connector on the rear panel.

17

9118A

Users Manual

Zone TC

Main TC

Support Bracket

N10140

BEFORE OPENING DISCONNECT MAINS.

230V 50/60Hz 20A

MAIN TCZONE TC

EARTH CONNECTION ESSENTIAL

BEFORE CONNECTING SUPPLY.

RS-232

Serial no.

FLUKE CORPORATION

www.flukecal.com

18

gxs131.eps

Figure 12. Probe Installation A

Calibration Furnace

Product Components

Zone TC Handle

Locking Screw

Main TC

Handle

Align these two surfaces

Support Bracket

gxs132.eps

Figure 13. Probe Installation B

19

9118A

Users Manual

Caution

To prevent damage to the thermocouple, do

not over tighten the screw.

To prevent contamination of the thermocouple,

always wear clean gloves when you handle the

thermocouples.

5. Put the short probe into the ZONE TC tube on the rear

panel of the furnace.

6. Align the end surface of the thermocouple handle with

the front edge of the bracket. See Figures 13 and 12.

7. Tighten the bracket screw to hold the thermocouple in

position.

8. Connect the cable of the short probe to the ZONE TC

connector on the rear panel.

The Isothermal Block

The Isothermal Block consists of:

• Front ceramic plug

• Four ceramic guide tubes

• Ceramic block

• Rear ceramic plug

accurate temperature environment for the sensor under

test. Four 6.7 mm diameter wells are provided.

To install the insert:

1. Carefully remove the isothermal block from the

packaging.

The well must be clear of any foreign objects such as

dirt or grit before the isothermal block is installed.

2. Carefully insert the isothermal block into the well from

the front of the furnace until the front plug contacts the

well.

3. Rotate the insert to the correct position, as shown in

Figure 14.

Right Position Wrong Position

Items 1-3 are fixed together by high temperature cement.

The isothermal block is intended to stabilize temperature

fluctuations and improve heat conduction between the

furnace and the sensor under test. The “block” is made of

aluminum-oxide and provides a relatively constant and

20

gxs130.eps

Figure 14. Insert Alignment

4. Insert the rear plug into the well from the rear of the

furnace until it contacts the tube.

Calibration Furnace

How to Turn On the Product

The fit between the block and the tube is typically

loose in order to accommodate thermal expansion.

Connect to Mains Power

Warning

For safe operation and maintenance of the

product, remove moisture from the Product

before you connect to mains power. Fluke

Calibration recommends the Product be put in

a low humidity temperature chamber at 50 °C

for 4 hours or more.

To prevent possible electrical shock or

personal injury, connect mains power cord

correctly and make sure the product is

grounded.

Be sure the power cord to the mains supply is wired

correctly. The power cord wires are color-coded as follows:

• Black: Line

• White: Neutral

• Green: Ground

Attach a separate safety ground wire between the

Protective Earth Terminal on the rear panel of the Product

and an earth ground conductor.

How to Turn On the Product

Push the “I” side of the power switch, on the front panel of

the Product. The screen shown in Figure 15 shows in the

display while the Product does a self test.

qrs001.bmp

Figure 15. Power-Up Screen

Connect the supplied ground wire between the protective

earth terminal on the rear panel and earth ground. Use the

2.5 meter power cord to connect the Product to a 230 V ac

outlet rated for 20 amps.

21

9118A

Users Manual

When the self test is complete and no errors are sensed,

the screen shown in Figure 16 shows in the display. The

Product is in a standby mode. You must set a setpoint

temperature to start control of the furnace. See the “Adjust

Furnace Temperature” section to learn how to start the

temperature control of the furnace.

qxs002.bmp

Figure 16. Main Screen

How to Turn Off the Product

Warning

To avoid personal injury, do not disconnect

the product from mains power if the furnace

temperature is greater than 80 °C.

Caution

To prevent possible damage to the Product,

disable the temperature control first and then

turn off power.

To turn off the Product:

1. Push .

2. Push the softkey under SAVE/DISABLE to disable the

heaters.

3. Push the “O” side of the power switch, on the front

panel of the Product.

22

Calibration Furnace

Display

Display

Table 4 is a list of display elements with descriptions.

Table 4. Display Elements

1

2

3

5

Item Description

Furnace temperature

Setpoint temperature

4

gxs006.eps

Setup

Set the Language

Text in the LCD display can be set to show in a different

language. To set the language:

1. Push .

2. Push the softkey below System Menu.

3. Push the softkey below Display Menu.

4. Push or to scroll through the languages.

5. When your language is shown in the display, push

.

To toggle between the set language and English, push

and at the same time.

Set Display Contrast

With the main screen shown in the display, push to

decrease display contrast. Push to increase display

contrast.

Heat/Cool Status

Stability Indicator

(

= stable, = unstable)

Softkey functions

23

9118A

Users Manual

Operation

Warning

For safe operation and maintenance of the

product:

• Energize the Product for a 2 hour dry-out

period before use, if the Product was:

o In transport

o In a humid or semi-humid storage

environment

o Not energized for more than 10 days

• Remove moisture from the Product before

you connect to mains power. Fluke

Calibration recommends the Product be

put in a low humidity temperature chamber

at 50 °C for 4 hours or more. While the

Product dries, do not assume the Product

complies with all safety standards.

• Put temperature probes you remove from

the Product on a heat resistant rack or

surface until they are safe to touch.

• Keep a minimum of 45 cm clearance from

the front, left, and right sides. Keep 150 cm

from the top of the Product.

Notes

In order for the Product to perform within

specification, the open ends of the furnace tube

(both front and rear) must be filled with a

temperature-resistant fiber ceramic insulating

material such as a Superwool Plus Blanket.

Fiber ceramic insulation contains a binding

material that will off-gas when first exposed to high

temperatures producing a harmless odor. Once

the binding material has off-gassed completely,

the odor will no longer persist with subsequent

uses of the furnace.

Warning

To avoid personal injury or skin irritation, wear

disposable latex gloves (or equivalent) when

handling fiber ceramic material.

The front-panel controls let you set the parameters of the

Product and monitor its performance. You can also set the

parameters of the communication interface. Four softkeys

are used to navigate through the menus of the Product.

The menus let you setup the Product and change system

parameters as necessary.

24

Calibration Furnace

Operation

How to Set Parameters in the Product

There are two methods to set a parameter in the Product.

You can set a parameter from a list of values or in the

case of numerical values, set a parameter with the cursor

keys.

Value List

An example where you select from a list of values is the

preset selection.

1. From the main screen, push .

2. Push the softkey below SELECT PRESET in the

display.

As shown in Figure 17, the number 1 is highlighted to

the right of PRESET:.

gxs111.eps

Figure 17. Preset Selection

4. Push when the correct preset number is shown

in the display.

This is the selection method for value lists.

Set Number Value

An example where you set a number is where you set the

setpoint temperature.

1. From the main screen, push .

2. Push .

As shown in Figure 18 the left most digit in the

SETPOINT temperature is highlighted.

SELECT

PRESET

Figure 18. SETPOINT Temperature

SAVE/

DISABLE

gxs110.eps

3. To change the preset number, push and to scroll

through the preset numbers.

25

9118A

Users Manual

3. Push or to increase or decrease the highlighted

digit.

4. Push to move the highlight to the next digit.

5. Do steps 3 and 4 again for each digit in the number.

6. After all digits are set, push .

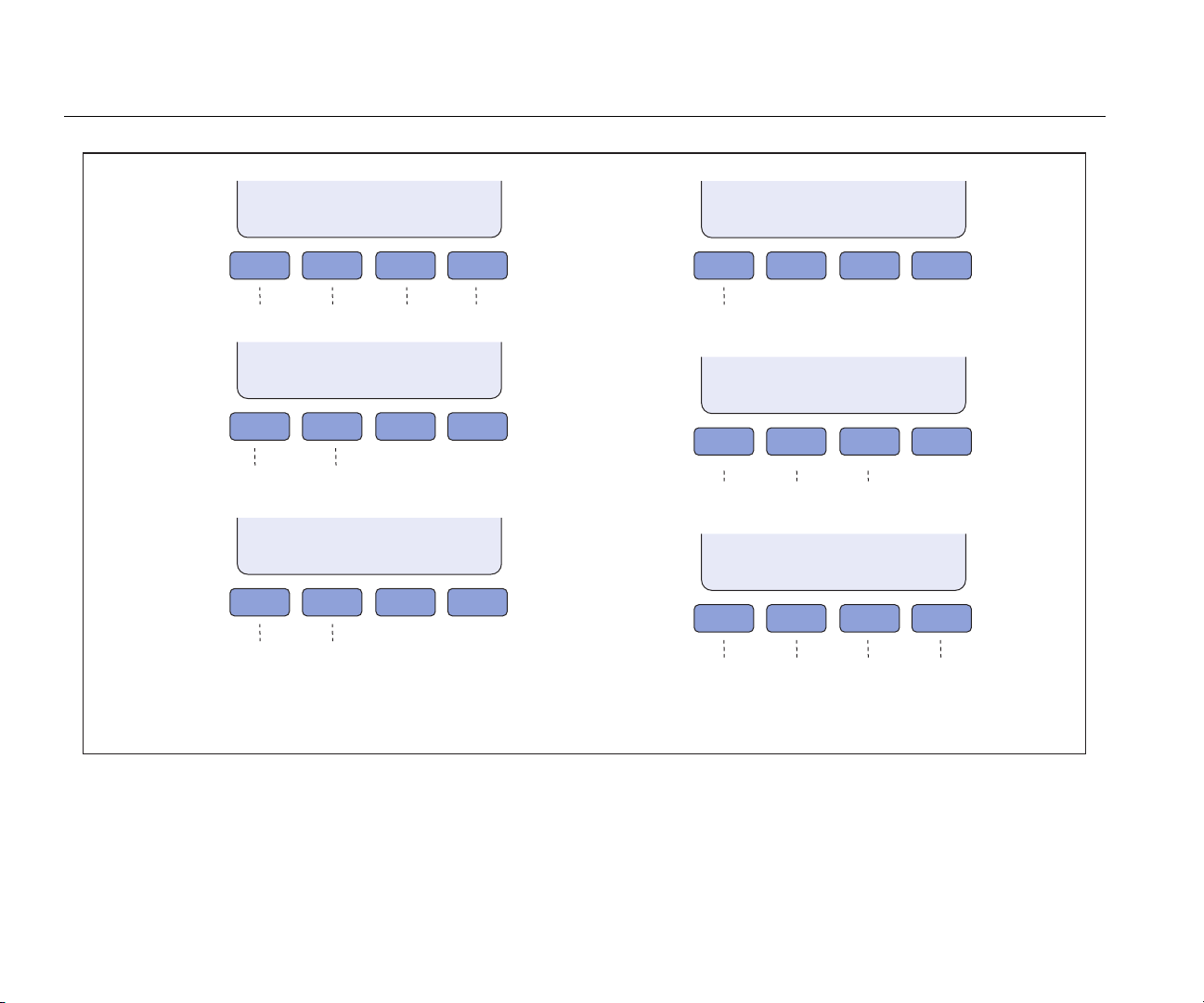

Softkey Menus

The softkeys are identified in Table 2. The softkeys are

used with the front-panel key. The functions of the

four softkeys are identified by label information shown

directly above each key.

A group of softkey labels is a menu. A group of connected

menus makes a menu tree. Figure 19 shows the menutree structure for the Product. Figure 20 shows each menu

in the menu tree.

26

Calibration Furnace

Operation

MENU

A

B

F

E

C

D

gxs003.eps

Figure 19. Softkey Menu Tree

27

9118A

Users Manual

TEMP

A

SETUP

PROG

MENU

CAL

MENU

F1 F2 F3 F4

To B To C To E To F

B

SETUP CUTOUT

F1 F2 F3 F4

Set

Set soft cutout

View hard cutout

RAMP/

SOAK

C

Scan Rate

RUN

PROG

F1 F2 F3 F4

Self Test

Set # of setpoints,

Status

set soak time

set # of cycles

set direction

To D

SYSTEM

MENU

SET

D

POINTS

F1 F2 F3 F4

Set up to

8 setpoints

CAL

E

POINTS

F1 F2 F3 F4

Set calibration

parameter

DISPLAY

F

MENU

F1 F2 F3 F4

Set language,

set decimal,

set audio

Figure 20. Menu Softkey Displays

PID

SETUP

Set control

parameter

COMM

SETUP

Set baud

rate, set

linefeed

FURNACE

SETUP

Set work

mode

PASSWORD

Set password,

set protection

SYSTEM

INFO

View model,

serial number,

firmware

version and

cal date

gxs004.eps

28

Calibration Furnace

Operation

Temperature (TEMP) Setup Menu

Push the softkey under TEMP SETUP to set the scan rate

and cutout parameters.

Scan Rate

The SCAN RATE parameter sets the rate at which the

Product increases or decreases the temperature to a new

setpoint. The scan rate can be set between 0.1 °C to

80.0 °C/minute.

Note

The maximum scan rate is the natural rate the

Product heats and cools. This is less than the

maximum scan rate parameter value.

Cutout

In the cutout menu, there are two parameters: soft and

hard cutout. The Product has an adjustable cutout device

that turns off power to the heat source if the temperature is

higher than a set value.

Use the soft cutout parameter to cut out at the high

temperature limit of the probes under calibration. Fluke

Calibration recommends you set the cutout 5 °C to 10 °C

below the high temperature limit of the probe under test.

When the cutout opens, the Product shows CUTOUT in

the display, turns off power to the heater, and sets the

Product to cool. The Product stays in the cutout condition

until the temperature drops below the cutout temperature

and the Product is reset by the operator.

To reset the Product after the temperature drops below the

cutout value:

1. Push .

2. Push . If it is necessary to change the setpoint

temperature, use the cursor buttons to change the

value.

3. Push again.

The HARD CUTOUT parameter is set at the factory and is

not user settable. This menu selection only lets you see

the cutout value.

Program (PROG) Menu

Push the softkey under PROG to show the RAMP/SOAK

and RUN PROG menus.

RAMP/SOAK Menu

The RAMP/SOAK feature lets the user program setpoint

temperatures and set the time the Product holds the

temperature at each setpoint. The Product automatically

heats or cools to the programmed setpoint and holds that

temperature for the specified time.

The NO. SETPOINTS parameter is used to set the number

of different temperatures the ramp/soak function will use in

the program. You can set a maximum of eight temperature

setpoints.

29

9118A

Users Manual

The SOAK TIME parameter is used to set the number of

minutes each setpoint temperature is held before it

changes to the subsequent setpoint. Soak time starts

when the temperature is stable.

The NO. CYCLES parameter is used to set how many

times the setpoint sequence is to be done again.

The DIRECTION parameter is used to set how the

setpoints sequence before the sequence is done again.

When set to →, the Product does the setpoints in one

direction from 1 to 8. If set to , it does the setpoints from

1 to 8 and then back to 1 before the sequence is done

again.

RUN PROG Function

Use the RUN PROG function to start and stop the test set

up through the RAMP/SOAK menu. With the TEST

STATUS parameter highlighted, push or to change the

test status and push . When set to RUN, the furnace

uses the values set through the RAMP/SOAK menu to

control the furnace. When the furnace does all the values

in the RAMP/SOAK parameters, the status changes to

OFF. To stop a test, set the parameter to OFF.

Calibration (CALIB) Menu

Calibration (CAL) Points Menu

When you push the CAL POINTS softkey, the product

prompts you for a numeric password. You must know the

password before you can change a calibration point.

There are 12 calibration points: Zone 1 (300), Skew 1

(300), Temp 1 (300), Zone 2 (700), Skew 2 (700), Temp 2

(700), Zone 3 (1000), Skew 3 (1000), Temp 3 (1000),

Zone 4 (1200), Skew 4 (1200), and Temp 4 (1200).

The TEMP parameter adjusts the actual temperature at

the midpoint location for the applicable set-point

temperature, but does not change the temperature

gradient. The ZONE parameter increases or decreases the

temperatures in the outer areas of the access tube for an

applicable setpoint temperature. The curvature of the

temperature profile is adjusted, and does not have an

effect on the temperature at the midpoint location or the

slope of the temperature profile at the midpoint location.

The SKEW parameter adjusts the slope of the temperature

profile at the midpoint location for the applicable setpoint

temperature. This increases the temperature of one end of

the access tube and decreases the temperature of the

opposite end.

Note

Calibration parameters must be correct for the

Product to operate correctly.

The CALIB menu lets you get access to the calibration

points constants and the controller parameters.

30

Calibration Furnace

Operation

PID Setup Menu

The PID SETUP menu is used to set controller

parameters.

The TEMP PB parameter is the main proportional band

and the gain that the proportional-integral-derivative (PID)

controller uses for control.

The TEMP INT parameter lets you set the time the

controller uses for control. The time is in seconds.

The TEMP DER parameter lets you set the derivative time

the controller uses for control. The time is in seconds.

Furnace Setup Menu

To operate the Product with or without an isothermal

block.

1. From the calibration menu, push the Furnace Setup

softkey.

2. Enter the password.

3. Push .

4. Push or to scroll through the display status of

“YES” and “NO”. Select “YES” to set the Product to

work with the isothermal block installed. Select “NO” to

set the Product to work without the isothermal block

installed.

5. Push to save the selected mode.

Caution

The Product can be used with or without an

isothermal block installed. To prevent damage

to the Product, unique calibration parameters

are necessary for each mode of operation.

Before Product use, select the appropriate

mode of operation in the calibration menu.

When the mode of operation is changed,

calibration for the new mode of operation may

be required.

System Menu

The SYSTEM menu lets you get access to the display

menu to set the language, set the type of decimal

character, and turn off and turn on key audio. The

communication setup parameters, password, and system

information are also available through this menu.

Display (DISP) Menu

The LANGUAGE parameter is used to set the language

used in the display.

The DECIMAL parameter is used to set the decimal

character to a period or a comma.

The KEY AUDIO parameter is used to turn off and turn on

the audio feedback when a key is pushed.

Communications (COMM) Setup Menu

The BAUD RATE parameter lets you set the baud rate for

the RS-232 communications port.

31

9118A

Users Manual

The LINEFEED parameter turns on and turns off the line

feed character sent across the RS-232 communications

port.

Password Setup Menu

The PASSWORD menu lets you set the user password

and set the level of protection for specified parameters. A

password is necessary to access the password menu.

The USER PASSWORD parameter is used to set the

password for the system that is used to access some

menus. The password is a four-digit number where each

digit is a number from 1 to 9. The default password is

“1234”.

The PROTECTION parameter sets the level of password

protection in the Product. If set to HIGH, then a password

is necessary to access the Cutout menu, Ramp/Soak

menu, CALIB (Calibration) menu, and PROG menu. When

set to LOW, only CALIB and PROG menus are password

protected.

System Information (INFO) Menu

The SYSTEM INFO menu is a view only menu. This menu

shows the Product model number, serial number, firmware

version, and the calibration date.

Adjust Furnace Temperature

There are two methods to adjust the furnace temperature.

You can recall a preset temperature or set a temperature

setpoint manually. The term “setpoint” refers to the

temperature the furnace goes to and holds.

Set the Furnace Temperature with a Preset

The Product stores eight preset setpoint temperatures.

You can set each preset setpoint as necessary. To set the

setpoint to a preset temperature:

1. Push .

2. Push the softkey below SELECT PRESET.

3. Push or to move between presets (1 through 8). In

Figure 21, the temperature of the preset is shown in

the display.

gxs111.eps

Figure 21. Preset Selection

4. With a preset number highlighted, push .

Note

If the Product is in standby mode, you must push

again to start the furnace.

32

Calibration Furnace

Operation

Set the Furnace Temperature Manually

To adjust the furnace temperature manually:

1. Push .

2. Push .

3. Push to increase the temperature or push to

decrease the setpoint temperature.

Note

When you push the up or down key momentarily,

the setpoint temperature moves by one step. Push

and hold the key and the setpoint temperature

increases or decreases until the key is released.

4. Push to save the setpoint temperature and start

the furnace.

Note

After a maximum of 5 seconds, the furnace starts

to heat or cool to the setpoint temperature.

The actual temperature is the measured temperature in

the furnace and lags the setpoint temperature. The lag

interval is the time necessary to increase or decrease the

temperature of the center of the furnace.

How to Stop the Furnace Heat Cycle

To stop the furnace heat cycle:

Change a Preset Temperature

You can set the temperature of the eight presets. To

change a preset temperature:

1. Push .

2. Push the softkey below SELECT PRESET.

3. Push or to scroll to the preset to change.

4. Push the softkey below EDIT PRESET. As shown in

Figure 22 the temperature of the selected preset is

highlighted in the display.

gxs112.eps

Figure 22. Change Preset Temperature

1. With the main screen in the display, push .

2. Push the softkey below SAVE/DISABLE.

The heat or cool procedure stops and the Product is set to

standby mode.

33

9118A

Users Manual

5. Push .

6. The highlight moves to the most significant digit of the

temperature.

7. Push or to change the digit.

8. Push to move the highlight to the next digit.

9. Do steps 7 and 8 again until all digits are set.

10. Push to set the preset value.

Note

If the preset you edited is not number 8, then the

highlight moves to the subsequent preset. You can

push to edit that preset. If the edited preset

is number 8, then the screen goes back to the

select preset screen.

Probe Insertion

Caution

To prevent possible damage to probes, make

sure all probes put into the furnace are rated

for the temperature range used in the

calibration procedure.

Note

Fluke Calibration recommends you use a metal

and/or ceramic fiber surface or container to set hot

probes on.

For the best stable temperature and minimum gradient, put

sample probes into the full depth of the holes in the

isothermal block or the center of the furnace tube if the

isothermal block is not installed. Variations in equipment,

probe dimension, and configuration can have an effect on

temperature stability and gradients.

Note

A solid (unstirred) mass, as in a furnace, can have

heat loss through the probe stem. The loss

changes between probes and temperatures.

Cutouts

The Product has five cutout functions: soft cutout, hard

cutout, chassis thermostat cutout, TC and heater cutout,

and fan fault cutout. Only the soft cutout can be set

through the user interface.

Soft Cutout

The soft cutout prevents damage to the Product and

temperature probes. Use the soft cutout to turn off power

to the furnace so the probes do not become too hot.

The temperature at which the soft cutout turns off power to

the furnace can be set through the user interface. See the

Temperature Setup Menu section to learn how to set the

soft cutout temperature. Set the cutout temperature to

±10 °C of the temperature limit of the equipment under

calibration.

34

Calibration Furnace

Remote Operation

When the soft cutout turns off power to the furnace,

CUTOUT shows in the display. The Product stays in this

condition until the temperature of the furnace goes below

the cutout temperature and the setpoint is set again.

Hard Cutout

The Hard Cutout disables the heaters if the control

thermocouples sense that the furnace temperature is

above a factory-set limit. It also cuts out if a control

thermocouple is open-circuit or disconnected.

The hard cutout temperature is set at the factory and can

be seen through the user interface. This is not a useraccessible parameter. When the hard cutout turns off

power to the furnace, the temperature must decrease a

few degrees below the hard cutout temperature to reset.

Chassis Thermostat Cutout

The Chassis Thermostat Cutout turns off power if the

chassis temperature is too hot. The power stays off until

the temperature of the chassis decreases a few degrees

below the cutout temperature. This is not a useraccessible adjustment.

Fan Fault Cutout

The Fan Fault Cutout turns off power to the furnace when

a fan fails. The furnace stays off until the fan is repaired.

probes opens. This cutout also turns off the furnace if it is

in the heat mode and the temperature of the furnace does

not increase. When this cutout turns off furnace power, TC

OR HEATER FAULT! shows in the display. The probe or

heater must be repaired or replaced to reset this cutout.

Remote Operation

Remote operation of the Product from a PC or computer is

done with commands through the remote interface. The

command set will let you set setpoint temperatures,

monitor furnace temperature, get measurement data, and

control furnace operation. This section contains the

procedures to set up, configure, and operate the Product

through the remote interface.

The Product is controlled with Standard Commands and

Programmable Instruments (SCPI) commands. The SCPI

command set and how the Product implements those

commands is included in the SCPI Commands section of

this manual.

TC or Heater Fault Cutout

The TC Fault Cutout turns off power to the furnace when

the product senses there is a problem with a control probe

or a heater. This protects the Product when a control

probe comes out of its socket or a wire in one of the

35

9118A

Users Manual

Digital Communication Interface

There is an RS-232C and USB interface on the rear panel

of the Product. See Figure 5. To prevent noise on the

signal wires, use a shielded low-resistance cable between

the Product and PC.

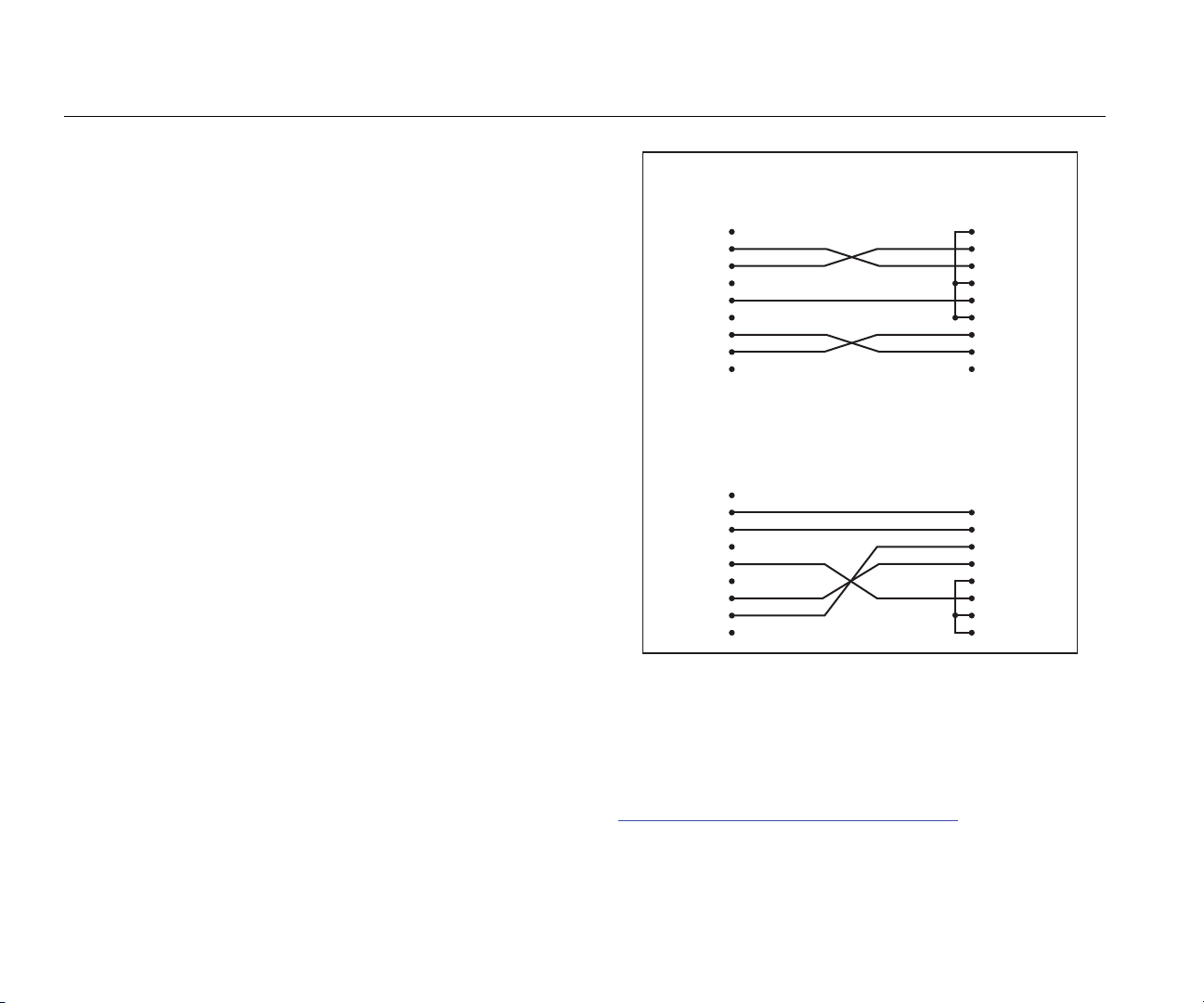

Figure 23 shows the cable connections that connects the

PC to the Product. The connections shown in the figure

are for a DB 9-pin connector and DB 25-pin connector on

the PC.

Instrument

Connector

(DB 9-Pin)

1 NC

2 RxD

3 TxD

4 ND

5 GND

6 NC

7 RTS

8 CTS

9 NC

Instrument

Connector

(DB 9-Pin)

1 NC

2 RxD

3 TxD

4 ND

5 GND

6 NC

7 RTS

8 CTS

9 NC

Computer (DTE)

Connector

(DB 9-Pin)

Computer (DTE)

Connector

(DB 25-Pin)

Figure 23. RS-232 Cable Connections

1 DCD

2 RxD

3 TxD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 NC

1 DCD

2 RxD

3 TxD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 NC

gxs005.eps

36

To use the USB interface for remote operation, you must

install a driver on the PC. The driver is found on the 9118A

CD-ROM.

To get an up-to-date USB driver, go to

http://www.ftdichip.com/Drivers/VCP.thm.

Calibration Furnace

Remote Operation

How to Configure the Digital Interface

To control the Product with a PC, you must set the

parameters of the digital interface in the Product. To set

the interface parameters:

1. Push .

2. Push the softkey below SYSTEM MENU.

3. Push the softkey below COMM SETUP.

4. Set the RS-232 parameters to the values as the

parameter values for the PC interface.

Input Terminators

An input terminator is a character sent by the PC that

identifies the end of a string. When the Product receives

an input terminator, it does the command preceding the

terminator character.

Applicable terminators are:

• LF (Line Feed)

• CR (Carriage Return)

• CR LF (Carriage Return/Line Feed)

In some instances, a terminator is automatically sent at the

end of an output string from the PC.

SCPI Commands

This section gives all SCPI commands recognized by the

Product with their description and syntax rules.

Commands by Function or Group

Table 5 is a list of commands grouped by Calibration, Main

Screen, Program, Setup, System, and Temperature.

37

9118A

Users Manual

Table 5. Commands by Function or Group

Group Screen Parameter Command Password Group Read/Write

Calibration – Controller TEMP PB SOUR:LCON:PBAN Unconditional R/W

TEMP INT SOUR:LCON:INT Unconditional R/W

TEMP DER SOUR:LCON:DER Unconditional

Calibration – Heat Source TEMP 1 SOUR:SENS:CAL:PAR1 Unconditional R/W

TEMP 2 SOUR:SENS:CAL:PAR2 Unconditional R/W

TEMP 3 SOUR:SENS:CAL:PAR3 Unconditional R/W

TEMP 4 SOUR:SENS:CAL:PAR4 Unconditional R/W

GRAD 1 SOUR:SENS:CAL:ZONE1 Unconditional R/W

GRAD 2 SOUR:SENS:CAL:ZONE2 Unconditional R/W

GRAD 3 SOUR:SENS:CAL:ZONE3 Unconditional R/W

GRAD 4 SOUR:SENS:CAL:ZONE4 Unconditional R/W

SKEW 1 SOUR:SENS:CAL:SKEW1 Unconditional R/W

SKEW 2 SOUR:SENS:CAL:SKEW2 Unconditional R/W

SKEW 3 SOUR:SENS:CAL:SKEW3 Unconditional R/W

SKEW 4 SOUR:SENS:CAL:SKEW4 Unconditional R/W

Calibration Furnace THERMAL BLOCK SYST:CONF:BLC Unconditional R/W

R/W

38

Calibration Furnace

Remote Operation

Table 5. Commands by Function or Group (cont.)

Group Screen Parameter Command Password Group Read/Write

Main Screen (none) SOUR:SENS:DATA N/A R

SETPT SOUR:SPO N/A R/W

HEAT % OUTP1:DATA N/A R

(none) OUTP2:DATA N/A R

ENABLE OUTP1:STAT N/A R/W

Program – Run TEST STATUS PROG:STAT N/A R/W

Program - Setup TEST ID PROG:IDEN N/A R/W

Ramp & Soak RAMP/SOAK SETUP PROG:SEQ:CAT N/A R

SETPOINT n PROG:SEQ:PAR SPOn Conditional R/W

SOAK TIME PROG:SEQ:PAR DWEL Conditional R/W

SETPOINTS PROG:SEQ:PAR POIN Conditional R/W

NO CYCLES PROG:SEQ:PAR CYCL Conditional R/W

DIRECTION PROG:SEQ:PAR DIR Conditional R/W

SETPOINT 1 SOUR:LIST:SPO1 N/A R/W

SETPOINT 2 SOUR:LIST:SPO2 N/A R/W

SETPOINT 3 SOUR:LIST:SPO3 N/A R/W

SETPOINT 4 SOUR:LIST:SPO4 N/A R/W

39

9118A

Users Manual

Table 5. Commands by Function or Group (cont.)

Group Screen Parameter Command Password Group Read/Write

Ramp & Soak (cont.) SETPOINT 5 SOUR:LIST:SPO5 N/A R/W

SETPOINT 6 SOUR:LIST:SPO6 N/A R/W

SETPOINT 7 SOUR:LIST:SPO7 N/A R/W

SETPOINT 8 SOUR:LIST:SPO8 N/A R/W

Setup – Communications BAUD RATE SYST:COMM:SER:BAUD N/A R/W

LINEFEED SYST:COMM:SER:LIN N/A R/W

Setup – Display LANGUAGE SYST:LANG N/A R/W

DECIMAL SYST:DEC:FORM N/A R/W

KEY AUDIO SYST:BEEP:KEYB N/A R/W

Setup – Password PASSWORD (Disable) SYST:PASS:CDIS Unconditional W

PASSWORD (Enable) SYST:PASS:CEN Unconditional W

Status (none) SYST:PASS:CEN:STAT N/A R

USER PASSWORD SYST:PASS:NEW Unconditional W

PROTECTION SYST:PASS:PROT N/A R/W

Setup – Date/Time DATE SYST:DATE Unconditional R/W

System – Setup °C/°F UNIT:TEMP N/A R/W

Heat Enable (none) OUTP:STAT N/A R/W

(none) SYST:KLOC Conditional R/W

40

Calibration Furnace

Remote Operation

Table 5. Commands by Function or Group (cont.)

Group Screen Parameter Command Password Group Read/Write

System – Information (none) SYST:ERR N/A R

(all) *IDN N/A R

(none) *CLS N/A W

(none) *OPT N/A R

FW VER SYST:CODE:VERS N/A R

Temperature – Cutout HARD CUTOUT SOUR:PROT:HCUT N/A R

SOFT CUTOUT SOUR:PROT:SCUT:LEV Conditional R/W

Reset (none) SOUR:PROT:CLEA N/A W

Trip State (none) SOUR:PROT:TRIP N/A R

Temperature – Setup SCAN RATE SOUR:RATE N/A R/W

Monitor Temperature CJC Temperature SOUR:SENS:DATA N/A R

Monitor TC SOUR:SENS:DATA N/A R

41

9118A

Users Manual

Alphabetic List of Commands

In this section, commands are shown alphabetically. Each command is shown with it long and short form. For each command

there is a description, one or more examples, and a parameter range when applicable.

Note

In this section, square brackets ([ ]) show optional keywords or parameters. Braces ({ }) enclose parameters inside a

command string. Triangle brackets (< >) show that you must replace the parameter with a value. Some commands

use upper and lower case letters. You must use all the uppercase letters in a command. The lowercase letters are

optional. The “|” is used as a separator between optional parameter values in a command.

All commands used with the Product are sequential. Each command is completed before a subsequent command is

processed.

All commands that are not recognized by the Product cause an error message to show in the error queue. A command can be

rejected with an error if the command is misspelled, has incorrect syntax, and/or has invalid parameters.

*CLS

Clears all status registers.

Example: *CLS

Response: None

*IDN?

Gets manufacturer, model number, serial number and firmware version of the product.

Example: *IDN?

Response: FLUKE,9118A,0,4.03

*OPT?

Gets product configuration or reference functionality.

Example: *OPT?

Response: 1 Reference hardware is enabled. (0 = disabled)

42

Calibration Furnace

Alphabetic List of Commands

OUTPut:STATus <n>

Sets or gets the main heat output on or off.

Parameters: n = ON or 1 Turn on main heat.

OFF or 0 Turn off main heat.

Example: OUTP:STAT 1 Turn on main heat.

OUTPut:STATus?

Gets the main heat output on or off.

Example: OUTP:STAT?

Response: 0 Main heat output is off. (1 = on)

OUTP[n]:DATA?

Gets the duty cycle of a heater duty cycle in percent.

Parameters: n 1 to 3 1 = main heater output (default), 2 = zone heater output, 3 = balance heater output.

Example: OUTP:DATA?

Response: 18.0 Main heater output duty cycle is 18 %.

Example: OUTP2:DATA?

Response: 57.0 Zone heater output duty cycle is 57.0 %.

PROGram:IDEN [quoted string]

Sets the program identifier.

Parameters: string = 1 to 12 characters (0 - 9, A – Z, ‘-‘). Default = “0”

Example: IDEN? “TEST-1”

43

9118A

Users Manual

PROGram:IDEN? <quoted string>

Gets the program identifier.

Example: IDEN?

Response: TEST-1

PROGram:SEQ:CAT?

Gets a parameters list for ramp and soak tests.

Example: PROG:SEQ:CAT?

Response: “SPOn”,”DWELL”,”DIR”,”POIN”,”CYCL”

PROGram:SEQ:PAR <Par>[, n]

Set a parameter in the ramp/soak test.

Parameters: Par = SPO[x] x = 1 to 8 setpoint number. Default = 1. n = 300.00 to 1200.00. Default = 300.00.

DWEL 1 to 100 seconds of soak time. Default = 15.

POIN 1 to 8 setpoints in the ramp/soak test. Default = 8.

CYCL 1 to 999 times the ramp/soak test is to be repeated. Default = 1.

DIR 0 or 1. Sets the direction of how the setpoints will be done in the test. See DIRECTION

in the Ramp/Soak Menu section. 0 = Up. 1 = Up then Down. Default = 0.

Example: To make a ramp/soak test with 3 setpoint temperatures of 450 °, 1145 °, and 825 ° that soak for 20 minutes:

PROG:SEQ:PAR POIN,3 Sets three temperature setpoints for the test.

PROG:SEQ:PAR SPO1,450.00 Sets setpoint #1 to 450.00 degrees.

PROG:SEQ:PAR SPO2,1145.00 Sets setpoint #2 to 1145.00 degrees

PROG:SET:PAR SPO3,825 Sets setpoint #3 to 825.00 degrees

PROG:SET:PAR DWEL,20 Sets soak time to 20 minutes.

44

Calibration Furnace

Alphabetic List of Commands

PROGram:SEQ:PAR? <Par>

Get a parameter from the ramp/soak test.

Parameters: Par = SPO[x] x = 1 to 8 setpoint number. Default = 1. Gets setpoint temperature for the setpoint

number.

DWEL Gets soak time

POIN Gets the number of setpoints in the ramp/soak test.

CYCL Gets the number of times the ramp/soak test is to be repeated.

DIR Gets the direction of how the setpoints will be done in the test. See DIRECTION in the

Ramp/Soak Menu section.

Example: PROG:SEQ:PAR? SPO2 Gets the setpoint temperature for setpoint number 2.

PROGram:STATus <n>

Sets the execution state for the selected program.

Parameters: n = RUN or 1 Start the selected program.

OFF or 0 Stop the selected program. (Default)

Example: PROG:STAT 1 Starts the selected program.

PROGram:STATus?

Sets or gets the execution state for the selected program.

Example: PROG:STAT?

Response: 0 The selected program is stopped.

45

9118A

Users Manual

SOURce:LCON:DER <n>

Sets the main control derivative time in seconds.

Note

This command has password protection. Use the SYST:PASS:CEN command first before you use this command to

set this value.

Parameters: n 0.0 to 99.9 seconds.

Example: SOUR:LCON:DER 5

SOURce:LCON:DER?

Gets the main control derivative time in seconds.

Example: SOUR:LCON:DER?

Response: 1.5 The main zone derivative time is 1.5 seconds.

SOURce:LCON:INT <n>

Sets the main control loop integral time in seconds.

Note

This command has password protection. Use the SYST:PASS:CEN command first before you use this command to

set this value.

Parameter: n = 10.0 to 999.9 seconds.

Example: SOUR:LCON:INIT 10

SOURce:LCON:INT?

Gets the main control loop integral time in seconds.

Example: SOUR:LCON:INIT?

Response: 20.0 The main control loop integral time is 20.0 seconds.

46

Calibration Furnace

Alphabetic List of Commands

SOURce:LCON:PBAN <n>

Sets the main control proportional band in °C which the PID controller uses for main zone control.

Parameters: n = 1.0 to 199.9 °C

Example: SOUR:LCON:PBAN 7

SOURce:LCON:PBAN?

Gets the main control proportional band in °C which the PID controller uses for main zone control.

Example: SOUR:LCON:PBAN?

Response: 1.5 The main control loop proportional band is 1.5 °C.

SOURce:LIST:SPO<i> <n>

Sets the temperature value for a preset setpoint in the RAMP/SOAK menu.

Parameters: i = Setpoint number (1 to 8)

n = Setpoint temperature.

Example: SOUR:LIST:SPO6 700.00 Sets setpoint number 6 to 700.00 degrees.

SOURce:LIST:SPO<i>?

Gets the temperature value for a preset setpoint in the RAMP/SOAK menu.

Example: SOUR:LIST:SPO4?

Response: 400.0 The setpoint temperature for setpoint 4 is 400.0 degrees.

SOURce:PROT:HCUT?

Gets the hard cutout temperature setpoint in °C or °F.

Example: SOUR:PROT:HCUT?

Response: 140 The hard cutout temperature is set to 140 °C.

47

9118A

Users Manual

SOURce:PROT:CLEA

Resets the cutout to enable the Product.

Example: SOUR:PROT:CLEA

Response: None

If the furnace goes above the maximum temperature, the cutout circuit will trip. The Product does not heat or cool until the

cutout condition is cleared.

SOURce:PROT:SCUT:LEV <n>

Sets the soft cutout temperature.

Note

This command has password protection. Use the SYST:PASS:CEN command first before you use this command to

set this value.

Parameters: n = 25.00 to 1240.00 degrees.

Example: SOUR:PROT:SCUT:LEV 450 Sets the soft cutout to 450 degrees.

SOURce:PROT:SCUT:LEV?

Gets the soft cutout temperature.

Example: SOUR:PROT:SCUT:LEV?

Response: 1000 Soft cutout temperature is set to 1000 degrees.

SOURce:PROT:TRIP?

Gets the cutout trip state.

Example: SOUR:PROT:TRIP?

Response: 0 Cutout not tripped (1 = cutout tripped).

48

Calibration Furnace

Alphabetic List of Commands

SOURce:RATE <n>

Sets the control temperature rate of change (scan rate) in °C or °F per minute.

Parameters: n = 0.10 to 500.00 degrees per minute. Default = 100.00

Example: SOUR:RATE 1.26 Sets the scan rate to 1.26 degrees per minute.

SOURce:RATE?

Gets the control temperature rate of change (scan rate) in °C or °F per minute.

Example: SOUR:RATE?

Response: 0.531 The scan rate is set to 0.531 degrees per minute. The response to this command starts out high and

decreases as the temperature gets nearer to the setpoint temperature.

SOURce:SENS:CAL:ZONE <x> <n>

Sets the axial gradient adjustment parameter.

Note

This command has password protection. Use the SYST:PASS:CEN command first before you use this command to

set this value.

Parameters: x = 1 to 4 (1 = ZONE1, 2 = ZONE2, 3 = ZONE3, 4 = ZONE4)

n = -10.0 to 10.0 as a temperature offset in °C.

Example: SOUR:SENS:CAL:ZONE2 0.08

SOURce:SENS:CAL:ZONE <x>?

Gets the axial gradient adjustment parameter.

Example: SOUR:SENS:CAL:ZONE2?

Response: 0.05 Axial gradient adjustment is 0.05.

49

9118A

Users Manual

SOURce:SENS:CAL:PAR<x> [n]

Sets a control temperature calibration parameter.

Note

This command has password protection. Use the SYST:PASS:CEN command first before you use this command to

set this value.

Parameters: x = 1 to 3 (1 = PAR1 = TEMP 1, 2 = PAR2 = TEMP 2, 3 = PAR3 = TEMP 3, 4 = TEMP 4)

n = -50.00 to +50.00 (Default = 0.000)

Example: SOUR:SENS:CAL:PAR2 0.02 Set the calibration parameter to 0.02 for main control.

SOURce:SENS:CAL:PAR<x>?