Page 1

P3031 & P3032

Pneumatic Deadweight Tester

PN 3963385

November

© 2010 Fluke Corporation. All rights reserved. Printed in USA. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit register.fluke.com

Page 3

Table of Contents

Chapter Title Page

1 General Information ............................................................................ 1-1

Introduction........................................................................................................ 1-1

How to Contact Fluke ........................................................................................ 1-1

Safety Information ............................................................................................. 1-1

Safety Summary ............................................................................................ 1-1

Compressed Gas ............................................................................................ 1-2

Heavy Weights .............................................................................................. 1-2

Personal Protective Equipment...................................................................... 1-2

Symbols Used in this Manual ............................................................................ 1-2

Operating Principle ............................................................................................ 1-2

Operating & Storage Specification .................................................................... 1-3

Environmental Corrections ................................................................................ 1-3

Gravity........................................................................................................... 1-3

Temperature and Air Density ........................................................................ 1-4

Fluid Head ..................................................................................................... 1-4

2 Preparation .......................................................................................... 2-1

Preparation ......................................................................................................... 2-1

Connection to External Pressure Supply............................................................ 2-1

Connections ....................................................................................................... 2-1

Test Port Insert................................................................................................... 2-4

PCU Priming...................................................................................................... 2-5

3 Operation ............................................................................................. 3-1

Introduction........................................................................................................ 3-1

4 Calibration in Different Pressure Units ............................................. 4-1

Introduction........................................................................................................ 4-1

Conversion Weights ...................................................................................... 4-1

Software......................................................................................................... 4-1

5 Maintenance & Servicing.................................................................... 5-1

i

Page 4

P3031 & P3032

Users Manual

Introduction........................................................................................................ 5-1

PCU Assembly................................................................................................... 5-1

Piston Disassembly........................................................................................ 5-1

Piston Cleaning.............................................................................................. 5-1

Piston Reassembly......................................................................................... 5-2

Replacement PCU Assembly ........................................................................ 5-2

Draining PCU Fluid ........................................................................................... 5-3

Top Plate Removal............................................................................................. 5-5

Screw Press ........................................................................................................ 5-6

6 Fault Finding........................................................................................ 6-1

Poor PCU Spin/Sensitivity................................................................................. 6-1

General .......................................................................................................... 6-1

System Will Not Pressurize ............................................................................... 6-1

High Piston Fall-Rate......................................................................................... 6-1

7 Storage & Transportation ................................................................... 7-1

Instrument — Storage........................................................................................ 7-1

Instrument — Transportation............................................................................. 7-1

Weights .............................................................................................................. 7-1

8 Ancillary Equipment............................................................................ 8-1

Dirt/Moisture Trap, P5532................................................................................. 8-1

Angle Adapter, P5543........................................................................................ 8-2

Pointer Remover/Punch, P5551......................................................................... 8-2

ii

Page 5

List of Tables

Table Title Page

1-1. Symbols.................................................................................................................. 1-2

1-2. Temperature and Humidity Ranges for the DWT .................................................. 1-3

2-1. Test Port Insert - Parts List..................................................................................... 2-5

5-1. PCU Assembly - Parts List..................................................................................... 5-3

5-2. PCU Housing Assembly - Parts List ...................................................................... 5-5

5-3. Screw Press Assembly - Parts List......................................................................... 5-7

iii

Page 6

P3031 & P3032

Users Manual

iv

Page 7

List of Figures

Figure Title Page

2-1. Screw on Gauge Adapter........................................................................................ 2-2

2-2. Making Pressure Connections................................................................................ 2-3

2-3. Do Not Over-Tighten ............................................................................................. 2-3

2-4. Adjust Gauge Position............................................................................................ 2-3

2-5. Tighten Gauge........................................................................................................ 2-4

2-6. Do Not Over-Tighten ............................................................................................. 2-4

2-7. Test Port Insert ....................................................................................................... 2-4

2-8. Sectional View - PCU Housing.............................................................................. 2-5

3-1. Float Height Indicator Post .................................................................................... 3-1

3-2. Weight Rotation ..................................................................................................... 3-2

5-1. PCU Assembly ....................................................................................................... 5-3

5-2. PCU Housing Assembly ........................................................................................ 5-4

5-3. Screw Press Assembly ........................................................................................... 5-7

8-1. Dirt/Moisture Trap ................................................................................................. 8-1

8-2. Angle Adapter ........................................................................................................ 8-2

8-3. Pointer Remover/Punch.......................................................................................... 8-2

v

Page 8

P3031 & P3032

Users Manual

vi

Page 9

Introduction

This manual covers the operation and maintenance of the P3031 and P3032 Pneumatic

Deadweight Testers (DWT).

How to Contact Fluke

To order accessories, receive operating assistance, or get the location of the nearest Fluke

distributor or Service Center, call:

Chapter 1

General Information

• Technical Support USA: 1-800-99-FLUKE (1-800-993-5853)

• Calibration/Repair USA: 1-888-99-FLUKE (1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31-402-675-200

• China: +86-400-810-3435

• Japan: +81-3-3434-0181

• Singapore: +65-738-5655

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com

To register your product, visit http://register.fluke.com

To view, print, or download the latest manual supplement, visit

http://us.fluke.com/usen/support/manuals

Safety Information

Safety Summary

The following are general safety precautions that are not related to any specific

procedures and do not appear elsewhere in this publication. These are recommended

precautions that personnel must understand and apply during equipment operation and

maintenance to ensure safety and health and protection of property.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

.

.

.

W Warning

1-1

Page 10

P3031 & P3032

Users Manual

Compressed Gas

Heavy Weights

Personal Protective Equipment

Symbols Used in this Manual

Use of compressed gas can create an environment of propelled foreign matter. Pressure

system safety precautions apply to all ranges of pressure. Care must be taken during

testing to ensure that all hydraulic connections are properly and tightly made prior to

applying pressure. Personnel must wear eye protection to prevent injury.

Lifting and movement of heavy weights can create an environment of strain and impact

hazards. Care must be taken during testing to ensure that weight masses are lifted in a

manner that avoids over-reaching or twisting, and that the masses are not dropped.

Personnel must wear reinforced safety shoes to prevent injury.

Wear eye protection and reinforced safety shoes approved for the materials and tools

being used.

In this manual, a Warning identifies conditions and actions that pose a hazard to the user.

A Caution identifies conditions and actions that may damage the Pneumatic Deadweight

Tester or the equipment under test.

Symbols used on the DWT and in this manual are explained in Table 1-1.

Symbol Description

B AC (Alternating Current)

J Earth Ground

W Important Information: refer to manual

~

Operating Principle

Deadweight Testers are the primary standard for pressure measurement. Utilizing the

well-proven Piston-Gauge system, consisting of a vertically mounted, precision lapped

Piston and Cylinder assembly, accurately calibrated weight masses (Force) are loaded on

the piston (Area), which rises freely within its cylinder. These weights balance the

upward force created by the pressure within the system.

Each weight is marked with the tester serial number, and the pressure measured when

placed on a correctly spinning and floating piston. The total pressure measured is the

summation of the weights plus the piston weight carrier assembly.

Table 1-1. Symbols

Do not dispose of this product as unsorted

municipal waste. Go to Fluke’s website for

recycling information.

PRESSURE =

FORCE

AREA

1-2

When the gas pressure within the system balances the combined downward force of the

piston and weights, the piston and weights will float freely and the system is in

equilibrium.

Page 11

General Information

Operating & Storage Specification 1

The design of a Piston/Cylinder Unit (PCU) fitted to a deadweight tester allows for a very

small clearance gap between the piston and cylinder. This is required to allow the gas to

pass between the components, providing a lubricating film, and preventing

metal-to-metal contact.

Operating & Storage Specification

Temperature and relative humidity ranges for operation and storage of the deadweight

tester are listed in Table 1-2.

Table 1-2. Temperature and Humidity Ranges for the DWT

Operation Storage

Temperature

Relative Humidity

(Non-Condensing)

18 °C to 28 °C

64 °F to 82 °F

20 % to 75 % 0 % to 90 %

Environmental Corrections

The DWT has been calibrated to the Gravity, Temperature and Air Density stated on the

certificate.

Equations and factors are given on the certificate to adjust for any variations in these

environmental conditions.

Gravity

Gravity varies greatly with geographic location, and so will the deadweight tester reading.

Due to the significant change in gravity throughout the world (0.5%), ensure that the

tester has either been manufactured to your local gravity, or that you have applied the

correction from the calibrated gravity.

Example:

Deadweight Tester calibrated gravity 980.665 cm/s²

(980.665 cm/s² is the International

Standard Gravity)

10 °C to 50 °C

50 °F to 122 °F

Gravity at site 981.235 cm/s²

Indicated Pressure 250 psi

235.981

250

xPRESSURETRUE =

665.980

psiPRESSURETRUE 1453.250=

The ability to determine the local gravity value will depend on the data available in the

country that the instrument is to be used in. Some countries have geographic/geological

survey/mapping organizations that have the data readily available. If not, the countries’

National Standards Laboratory may be able to recommend a source of suitable

information.

1-3

Page 12

P3031 & P3032

Users Manual

Temperature and Air Density

Temperature and Air Density variations are less significant than gravity.

Variations should be corrected for when maximum accuracy is required.

Temperature variation example:

Deadweight Tester calibrated temperature 20 °C

Operating temperature 24 °C

Percentage change per °C 0.002%

Indicated Pressure 250 psi

Fluid Head

The piston assembly is liquid-lubricated in this particular model of deadweight tester;

therefore variance in the fluid level within the piston chamber will have an effect on the

pressure within the system.

The deadweight tester has been manufactured to an average fluid height relative to the

bottom of the piston in its mid-operating position.

The change in pressure as a result of variations in the relative fluid level, during normal

operation, will not exceed:

The fluid level is not visible in operation; therefore the exact height cannot be ascertained.

However, to ensure best accuracy, fill the chamber to its upper limit and then operate. In

this condition, the fluid level will be 4.5 mm above the calculated average.

If running at this level, reduce the pressure measurement by:

()

2420250 xxPRESSURETRUE −+=

002.0

250

100

psiPRESSURETRUE 98.249=

0.0055 psi / 0.00038 bar for oil-lubricated systems.

0.0118 psi / 0.00082 bar for Krytox GPL101 lubricated systems.

0.0055 psi / 0.00038 bar for oil.

0.0118 psi / 0.00082 bar for Krytox GPL101.

1-4

The change in fluid height per minute at maximum pressure for the initial 2 mm is

typically 0.01 mm, which equates to:

0.000012 psi / 0.0000008 bar for oil.

0.0000262 psi / 0.0000018 bar for Krytox GPL101.

The change in fluid height per minute at maximum pressure after the initial 2 mm will

reduce to typically 0.005 mm, which equates to:

0.000006 psi / 0.0000004 bar for oil-lubricated systems.

0.0000131 psi / 0.0000009 bar for Krytox GPL101 lubricated systems.

To ensure accuracy is maintained, the piston and weights must be kept clean and

undamaged.

Page 13

Preparation

The deadweight tester must be set up on a level, stable workbench or similar surface.

Level the tester using the four adjustable feet to the bubble level attached to the top plate.

Connection to External Pressure Supply

The connection port in the rear panel of the instrument is ¼ NPT. Pressure supply must

be both clean and dry — a compressed gas bottle (instrument quality nitrogen or air)

fitted with a pressure regulator is recommended. Factory (compressor) air lines should

only be used if a series of filters are fitted to ensure that the supply is clean and dry.

Chapter 2

Preparation

The external pressure supply must be regulated to either the maximum range of the

deadweight tester, or 10% above the maximum pressure required, whichever is the lower.

Great care must be taken when operating any pneumatic

deadweight tester, as any contamination present within the

system will result in degradation of performance, and eventual

IRREPARABLE DAMAGE to the PCUs.

Do not over-pressurize the deadweight tester.

To avoid damage to the instrument, the operator should ensure that any device under test

(DUT) is clean and dry before connecting it to the test port. If the DUT is of unknown

cleanliness, the Dirt/Moisture Trap, P5532, can be mounted to the test port of the

deadweight tester. This will prevent any dirt particles or moisture droplets present within

the DUT from passing into the deadweight tester system, (See Chapter 8, Ancillary

Equipment).

Connections

Fit the device under test (DUT) to the test port using the method described below:

Ensure that all devices are internally clean and free from

contamination before connecting to the tester.

Particle contamination can damage the sensitive piston

assemblies, valve seats and screw pump.

W Warning

W Caution

To avoid cross-contamination from other fluids, and protect the

system from particulates, we recommend the use of Liquid

Separator 5521M, (refer Chapter 9, Ancillary Equipment).

2-1

Page 14

P3031 & P3032

Users Manual

W Warning

DO NOT use Teflon/PTFE tape on these connections, as this

will prevent correct sealing. The Gauge Adapter sealing system

is designed for hand-tight sealing up to 20,000 psi / 1,400

bar-wrenches or similar tools are not required — over

tightening can cause damage to threads or sealing faces.

Before connection, ensure that there is an O-ring fitted to the

test port.

Check that the sealing face of the device to be fitted is clean

and undamaged, as scratches or dents can form leak-paths.

Note

The thread on the test port, and the lower part of the gauge adapters is LEFT-HANDED.

The following procedure details the correct method for mounting devices using these

adapters.

1. Screw the appropriate gauge adapter fully on to the instrument to be tested.

2-2

Figure 2-1. Screw on Gauge Adapter

2. Screw assembly down COUNTER-CLOCKWISE on to test port.

Note

Hand-tight is sufficient; ensure that the bottom face contacts the O-ring on

the test port.

gmg01.bmp

Page 15

Preparation

Connections 2

gmg02.bmp

Figure 2-2. Making Pressure Connections

gmg03.bmp

Figure 2-3. Do Not Over-Tighten

3. To adjust the position to face forward, hold the gauge adapter and turn the instrument

COUNTER-CLOCKWISE, so that it faces forward.

Figure 2-4. Adjust Gauge Position

4. Hold the instrument steady, while turning the gauge adapter

COUNTER-CLOCKWISE until it pulls down onto the O-ring.

gmg04.bmp

2-3

Page 16

P3031 & P3032

Users Manual

Test Port Insert

For devices with 1/8 BSP or NPT mounting threads, the diameter of the thread is very

close to the effective sealing diameter of the O-ring fitted to the test port.

This can make it difficult to achieve a good seal. When mounting these devices, use the

test port insert (stored in the spare seals container) as shown in Figure 2-7.

Figure 2-5. Tighten Gauge

Figure 2-6. Do Not Over-Tighten

1

2

gmg05.bmp

gmg06.bmp

2-4

3

Figure 2-7. Test Port Insert

gmg07.eps

Page 17

Preparation

PCU Priming 2

Table 2-1. Test Port Insert - Parts List

Item Description Part

1 O Ring 3865142

2 Test Port Insert 3919892

3 O Ring 3883397

To calibrate panel-mounted gauges with pressure connections in the rear, use an

Angle Adapter P5543, (see Chapter 8, Ancillary Equipment).

PCU Priming

If the instrument is to be primed for the first time after drainage for storage/transportation,

the following points apply:

1. Remove PCU assembly — see Chapter 5, PCU Assembly.

2. Remove filler plug.

3. Using the filler bottle, fill the chamber through the top port until the fluid level

reaches the PCU O-ring. Allow time for the fluid level to stabilize.

4. Continue this procedure until the fluid level reaches the bottom of the filler plug

port — DO NOT OVERFILL. If this occurs, wipe up any spills, and allow any

excess fluid to drain out of the port.

5. Replace the filler plug.

6. Replace the PCU assembly.

2

1

Figure 2-8. Sectional View - PCU Housing

gmg08.eps

2-5

Page 18

P3031 & P3032

Users Manual

2-6

Page 19

Introduction

There is a monitor gauge fitted to the instrument top plate, to serve as a guide to the

operator by indicating the approximate pressure in the system.

1. Ensure that both Inlet and Exhaust valves are closed.

2. Turn screw press out (counter-clockwise) to approximately half its travel.

3. Select the required weights and stack them on the piston assembly. The pressure

measured is the sum of the weights plus the piston/weight carrier.

Chapter 3

Operation

4. SLOWLY open and close inlet valve until piston floats with the bottom face of the

lowest weight is level with the groove in the indicator post. This is the PCU mid-float

position, which is the height at which all internal corrections have been made with

reference to the pressure datum (top of the test port).

WEIGHT

gmg09.eps

Figure 3-1. Float Height Indicator Post

5. If the piston is over-pressurized (piston against top travel limit) then reduce pressure

by SLOWLY opening and closing exhaust valve until the piston floats freely. The

screw press can be used for fine control — turn in (clockwise) to increase, and out to

decrease pressure.

3-1

Page 20

P3031 & P3032

Users Manual

Note

At low pressures, the piston may require lifting manually to overcome the

‘stick’ due to surface tension of the film of fluid that will develop between

the top of the cylinder and the underside of the weight carrier.

6. Gently rotate the weight stack clockwise, such that it is turning between

approximately 10 and 60 rpm. Avoid side-loads when turning the weights by placing

the palms of the hands on either side and “rolling” the stack by pulling in opposite

directions, see Figure 3-2. DO NOT rotate weights when the piston is against the

top or bottom limits of travel.

7. Allow a few moments for the system to stabilize before taking any readings,

especially after large changes in system pressure.

8. For the next higher calibration point, repeat from step 3 above.

9. To measure reducing pressures, remove the necessary weights, and by opening and

closing the Exhaust valve, SLOWLY reduce the system pressure until the piston

floats, then rotate clockwise as above.

10. Depressurize the system by SLOWLY opening the Exhaust valve, as sudden

depressurization will cause the weight stack to fall quickly, which may damage the

piston assembly.

11. Remove the weights from the piston.

12. The fluid level should be checked and maintained as required, periodically

(dependant upon use). Always ensure that the system is fully depressurized before

removing the filler plug. Remove the filler plug and introduce more fluid with the

filler bottle, until it reaches the bottom of the filler port, then replace plug.

Figure 3-2. Weight Rotation

gmg10.bmp

3-2

Page 21

Calibration in Different Pressure Units

Introduction

The deadweight tester can be used to calibrate in different pressure units in either of two

methods:

Conversion Weights

A set of Conversion Weights can be supplied, marked in the required pressure unit, and

adjusted to the correct mass for use with the existing piston(s).

The set includes (where applicable) a replacement low-pressure weight carrier table, and

a replacement high-pressure weight carrier ring. These items are simply exchanged for

the original items when using the conversion weights. Calibration is carried out as

described above, with logical pressure increments throughout the operating range,

avoiding the need to perform pressure unit conversion calculations.

Chapter 4

Software

PressCal software is available for use with deadweight testers, and will allow users to

apply all necessary corrections (e.g. local gravity, temperature, pressure head, etc.) to

enhance the pressure measurement accuracy of the instrument.

It will allow calibration in any of 12 different pressure units, using the existing weight set.

4-1

Page 22

P3031 & P3032

Users Manual

4-2

Page 23

Introduction

The piston / cylinder assembly is the most critical and sensitive

part of the deadweight tester. To maintain accuracy, the piston

must always slide freely in the cylinder, and the gas supply

must remain clean and dry.

The Figures on the following pages detail the components of each assembly, together

with the relevant part numbers. Where “SPEC” appears as a part number, this indicates

that this particular component varies with the specification of the deadweight tester, and

is usually associated with other components in an assembly for replacement purposes.

Chapter 5

Maintenance & Servicing

W Caution

A replacement seal kit is available for instruments covered by this manual,

part number 3874964.

PCU Assembly

Piston Disassembly

1. Hold the weight carrier (1), and lift the piston to its full extent. Unscrew cylinder

retainer (5), and lift out PCU assembly.

2. Unscrew set screw (2) two turns, and remove weight carrier (1).

3. Remove cylinder retainer, and carefully withdraw the piston from the cylinder.

Piston Cleaning

4. Use “non-fluffing”, non-abrasive, lint-free tissue or absorbent cloth. Hold the piston

by the larger “head” end, and rub the tissue back and forth along its length.

5. To remove all traces of contamination, the piston can be cleaned in a suitable solvent.

6. After removal from the solvent, using a NEW tissue, repeat the cleaning procedure in

step 4.

7. Place piston carefully on a NEW tissue where it will not be damaged while the

cylinder is cleaned.

Never touch the working surface of a clean piston with bare

fingers — the natural oil in your skin can cause the piston and

cylinder to stick.

W Caution

8. Wipe any dirt or moisture from the outside surfaces of the cylinder (3).

5-1

Page 24

P3031 & P3032

Users Manual

Piston Reassembly

9. Roll a NEW tissue into a tapered rod of appropriate size. Force the tissue through the

cylinder bore whilst rotating. Ensure that the tissue is a tight fit inside the bore so that

dirt and contamination is removed.

10. Repeat step 9, using a NEW tissue, but from the opposite end of the cylinder.

11. Immerse the cylinder in a suitable, clean solvent.

12. After removal from the solvent, using a NEW tissue, repeat the cleaning procedure in

step 9 & 10.

13. Holding the piston by the larger “head” end, dip the other end into a container of

clean operating fluid, and transfer to the bore in the underside of the cylinder.

Allow the fluid to run through the bore. Repeat this 2 or 3 times to ensure an even

film of fluid exists in the cylinder bore.

14. Carefully introduce the piston into the underside of the cylinder, and push gently

through (the piston will normally slide freely through due to its own weight).

15. NEVER FORCE THE PISTON INTO ITS CYLINDER OR DAMAGE WILL

RESULT.

16. If resistance is felt, re-clean piston, cylinder or both. If, after repeated cleaning, the

piston still will not slide freely within the cylinder, then permanent damage may have

occurred. In which case, the parts should be returned to the factory for evaluation or

replacement.

17. Place cylinder retainer over the piston, and locate on the stepped end of the cylinder.

18. Ensure that the weight carrier (1) is clean (especially the central mounting hole), and

locate on the recessed end of the piston. Secure with set screw — Do not over-tighten.

19. Carefully screw the assembly into the instrument, ensuring that the PCU seal inside

the housing is clean, undamaged, and correctly re-fitted.

Replacement PCU Assembly

The piston and cylinder assembly is a matched pair, which is

calibrated and adjusted to a calculated mass figure. If, for any

reason, the piston or cylinder becomes damaged, then the

entire assembly must be replaced. The replacement assembly

consists of the following components: Item numbers

1 through 4.

W Caution

5-2

Page 25

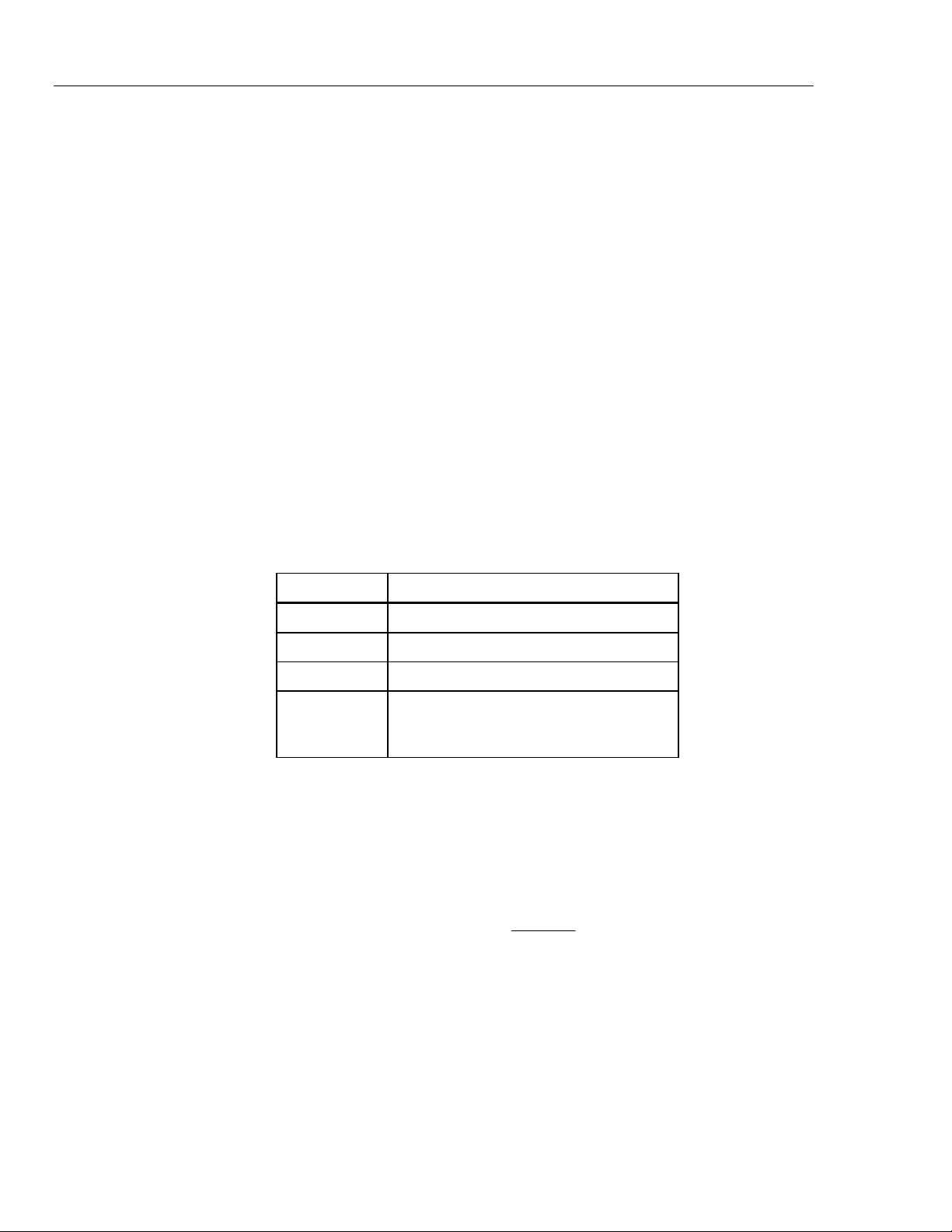

Maintenance & Servicing

Draining PCU Fluid 5

1

2

5

3

4

Item Description Part

1 Weight Carrier SPEC

2 Set Screw 3910313

3 Cylinder SPEC

4 Piston SPEC

5 Cylinder Retainer 3919216

Draining PCU Fluid

In order to prevent contamination of the pneumatic system, the PCU

lubricating fluid must be drained from the PCU housing before

commencing any maintenance procedures that involve moving the

instrument from the horizontal position. This includes packing the

instrument for storage or shipment.

Figure 5-1. PCU Assembly

Table 5-1. PCU Assembly - Parts List

Note

gmg11.eps

1. Depressurize the system by slowly opening the exhaust valve.

2. Disconnect any DUT from the test port.

3. Place absorbent cloth or tissue paper around the base of the PCU housing.

4. Unscrew drain plug at the lower, rear of the housing to release fluid.

5. To increase flow rate, unscrew filler plug at the upper left hand side of the housing.

5-3

Page 26

P3031 & P3032

Users Manual

6. To ensure all fluid is removed, unscrew cylinder retainer, and remove PCU assembly.

7. Unscrew 6 screws, and remove cylinder holder.

8. Carefully wipe all traces of fluid from inside the PCU housing.

9. Ensure that there is no particulate contamination inside the housing, then replace

cylinder holder and screws, ensuring that the o-ring is correctly re-fitted.

10. Carefully re-fit PCU assembly, and secure with cylinder retainer.

1

2

3

4

5

8

7

8

8

6

5-4

Figure 5-2. PCU Housing Assembly

gmg12.eps

Page 27

Maintenance & Servicing

Top Plate Removal 5

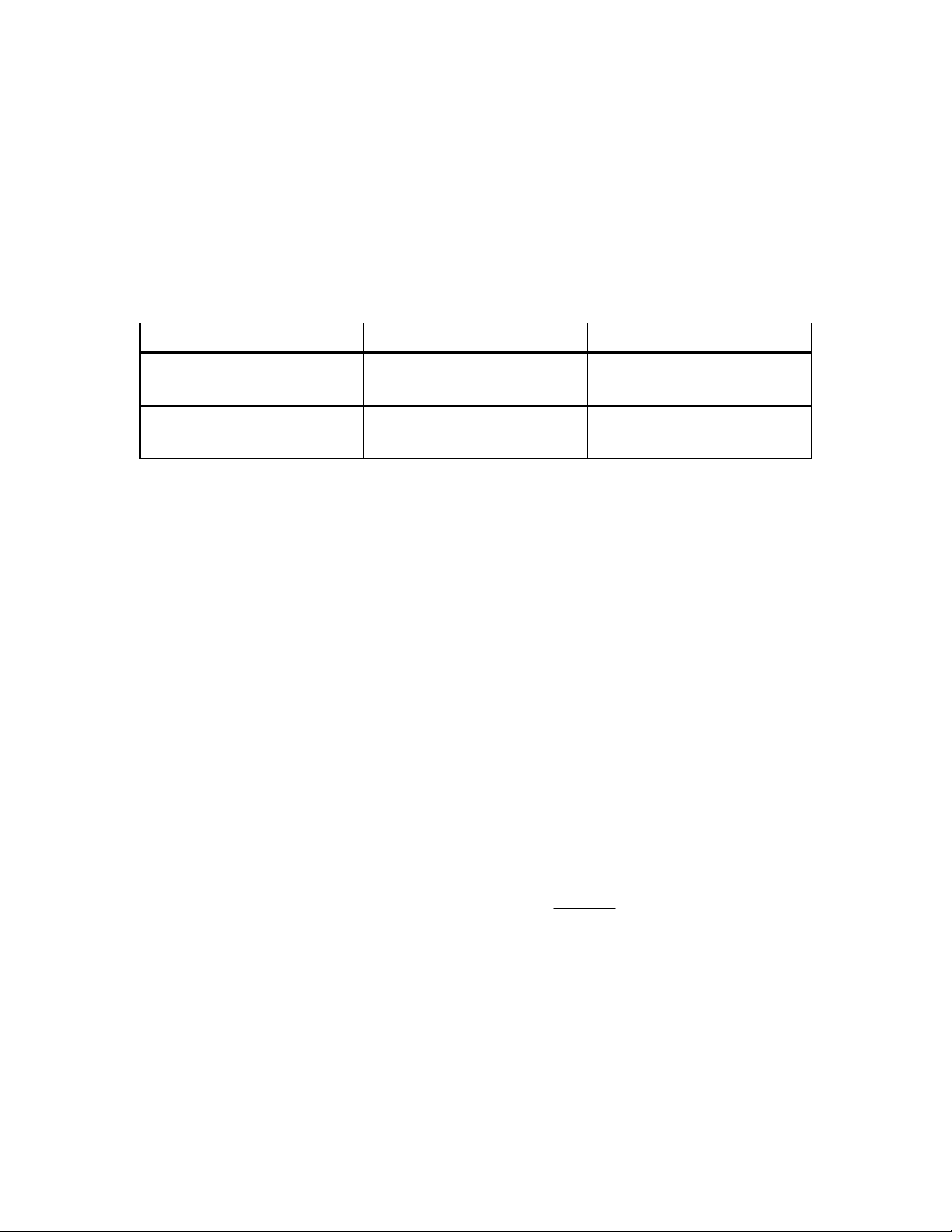

Table 5-2. PCU Housing Assembly - Parts List

Item Description Part

1 O-ring 3867582

2 Screw 3910035

3 Cylinder Holder 3919202

4 O-ring 3867594

5 PCU Housing 3867582

6 Filler Plug 3919233

7 Drain Plug 3919233

8 O-ring 3867575

Top Plate Removal

Note

In order to perform maintenance procedures on the pneumatic system, the

Top Plate Assembly must first be removed from the instrument case.

1. Depressurize the system by slowly opening the Exhaust valve.

2. Disconnect any DUT from the test port.

3. Drain the PCU lubricating fluid as described above in Chapter 5, Draining PCU Fluid.

4. Remove the capstan spokes from the screw press hub.

5. Remove the 4 screws from the instrument top plate, (1 at the mid-point of each edge).

W Caution

The top plate will be connected to the instrument case by the

tubing that runs to the external supply manifold, so care must

be taken when lifting the plate to avoid damage to these

connections.

6. Hold the top plate assembly by the test port, and tilt the plate so that the rear edge is

lifted, but the front edge remains in contact with the instrument case.

7. Slide the top plate towards the rear until the screw press hub is clear of the front lip

of the instrument case.

8. Carefully lift the top plate to reveal the inlet connection from the external supply

manifold (mounted on the rear panel of the case).

9. Disconnect the tubing, and lift the top plate clear of the case.

W Caution

When handling the top plate assembly, it is good practice to

remove the piston assemblies to avoid accidental damage.

Note

Replacement is simply the reverse of the above procedure.

5-5

Page 28

P3031 & P3032

Users Manual

Screw Press

1. Unscrew the large union nut (just behind the inner hub) of the screw press assembly.

2. Withdraw the lead screw assembly from the barrel (5), taking care not to drop the

rambler assembly (9).

3. The white, anti-extrusion ring (8) is a PTFE spiral, and can be removed by

“unwinding” it from the rambler.

4. When removing the rambler seal (7), take care not to use any tool that may have a

sharp edge that will scratch the surfaces of the rambler, otherwise it may leak when

reassembled.

5. The replacement rambler seal can be eased over the front of the rambler, and into the

groove.

6. Similarly, the new anti-extrusion ring can be “wound” into the groove in the rambler,

behind the rambler seal.

7. If it is necessary to remove the barrel (5), the locknut (4) must be loosened

approximately ½ turn. The barrel can then be unscrewed from the test station (2).

Note

It is often easier to remove the barrel support bracket (6) to allow greater

movement, (remove the 2 screws from the upper side of the top plate).

8. Before re-fitting the barrel, ensure that the barrel seal (3) is correctly located in the

counter-bore in the front of the barrel. Screw the barrel fully in to the test station, and

secure with the locknut.

9. Re-align the barrel support bracket (if removed), and secure through the top plate

with the 2 screws.

10. Ensure that the rambler assembly is correctly located on the end of the lead screw

assembly. Carefully introduce the rambler into the open end of the barrel; making

sure that it does not tilt when entering the barrel.

11. Push the lead screw assembly fully in to the barrel, ensuring that the key in the nut

locates correctly in the slot in the barrel.

12. Re-tighten the barrel union nut.

W Caution

If the lead screw assembly shows signs of excessive wear, then

it is very likely that the associated components have worn also,

therefore the screw press assembly is available as a spare

part — see diagrams for part numbers.

5-6

Page 29

Maintenance & Servicing

Screw Press 5

2

11

4

5

6

gmg13.eps

1

7

8

9

3

10

Figure 5-3. Screw Press Assembly

Table 5-3. Screw Press Assembly - Parts List

Item Description Part

1 Tee 3867771

2 Test Port 3921414

3 O-ring 3864922

4 Barrel Locknut 3921438

5 Barrel 3921450

6 Barrel Support 3921492

7 O-ring 3867566

8 Anti-Extrusion Ring 3919118

9 Rambler 3919129

10 Ball 3917855

11 Lead Screw Assembly 3885994

5-7

Page 30

P3031 & P3032

Users Manual

5-8

Page 31

Poor PCU Spin/Sensitivity

General

If the piston is not free, do not rotate, as damage may occur — dismantle and clean the

assembly as described in Chapter 5, PCU Assembly.

To check the freedom of the PCU, open the Exhaust valve and hold the weight carrier.

Lift the piston vertically, gently up and down. It should slide freely within the cylinder, if

any resistance is detected, it must be cleaned immediately.

Chapter 6

Fault Finding

If the spin/sensitivity of a recently cleaned PCU deteriorates quickly, then it is likely that

the lubricating fluid within the PCU housing has become contaminated. This must be

drained out, and the PCU housing thoroughly cleaned and re-primed with clean fluid

before further calibration is carried out.

System Will Not Pressurize

1. Ensure that Inlet and Exhaust valves are closed

2. Ensure for missing or dirty seal in test port.

3. Ensure that the sealing face of the DUT is not dented or scratched, and is correctly

contacting the seal in the test port.

4. Ensure that the external supply is correctly connected and functioning correctly.

5. Ensure that the DUT is not leaking.

6. Check for correct fluid level in the PCU housing.

High Piston Fall-Rate

The piston will always fall slowly due to the small leak between piston and cylinder. This

fall rate will never be so fast that a stable reading cannot be made. If the fall rate is large:

1. Perform all checks in the System Will Not Pressurize section.

2. If the fluid has recently been topped-up, or the PCU has been removed, trapped air

may be bleeding past the piston. Continue to pressurize and the fall-rate will stabilize

when the trapped air has bled away.

6-1

Page 32

P3031 & P3032

Users Manual

6-2

Page 33

Instrument — Storage

1. Shut-off external gas supply, and depressurize system by slowly opening both Inlet

and Exhaust valves.

2. Disconnect external gas supply.

3. Refit instrument lid, ensuring that the hinges are correctly engaged, and secure with

toggle clips at the sides.

4. The instrument should be kept horizontal at all times.

Chapter 7

Storage & Transportation

Instrument — Transportation

To prevent system contamination during shipment/transportation of this instrument, the

fluid in the PCU housing MUST be drained — see Chapter 5, Draining PCU Fluid.

Weights

1. Starting with the largest increments first, stack all appropriate weights in the wooden

weight case.

2. Pass the threaded rod of the weight clamp assembly down through the center of the

weight stack, and locate in the base of the weight box.

3. Secure the weights by screwing the clamp assembly in clockwise, ensuring that the

stepped rim of the clamping disc locates correctly in the center of the weight stack.

4. Close lid and secure with catches at front.

W Warning

The weight set is HEAVY (can be up to 80 lbs/36 kg per

individual box) so care must be taken when moving it. Both

handles must be used when lifting the set for stability, and we

recommend that it be carried between two people.

7-1

Page 34

P3031 & P3032

Users Manual

7-2

Page 35

Dirt/Moisture Trap, P5532

If there is any doubt that the instrument to be tested is not internally clean, then the

addition of the P5532 Dirt/Moisture Trap will protect the deadweight tester from

contamination and possible damage. Any particles or moisture present within the DUT

will fall and be trapped in the aluminum chamber, which can be periodically inspected by

the operator.

The top connection reproduces the test port on the deadweight tester, allowing the

standard gauge adapters to be used.

Chapter 8

Ancillary Equipment

Figure 8-1. Dirt/Moisture Trap

gmg14.bmp

8-1

Page 36

P3031 & P3032

Users Manual

Angle Adapter, P5543

To calibrate gauges with the pressure connection on the rear (e.g. panel-mount gauges) in

their correct position, an angle adapter should be used. The angle adapter fits directly

onto the test station, converting it through 90 degrees, allowing the standard adapters to

be used.

Figure 8-2. Angle Adapter

Pointer Remover/Punch, P5551

To remove and refit the pointer of a pressure gauge, use this tool. This tool has a

spring-loaded plunger to quickly and consistently refit the pointer.

gmg15.bmp

8-2

Figure 8-3. Pointer Remover/Punch

gmg16.bmp

Loading...

Loading...