Page 1

MDA-550/MDA-510

Motor Drive Analyzer

Users Manual

September 2018

©2018 Fluke Corporation. All rights reserved.

All product names are trademarks of their respective companies.

Specifications are subject to change without notice.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and service. The warranty period is three years and begins

on the date of shipment. Parts, product repairs, and services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of a

Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in Fluke's opinion, has been misused, altered, neglected,

contaminated, or damaged by accident or abnormal conditions of operation or handling. Fluke warrants that software will operate substantially in accordance with its

functional specifications for 90 days and that it has been properly recorded on non-defective media. Fluke does not warrant that software will be error free or operate

without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to extend a greater or different

warranty on behalf of Fluke. Warranty support is available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the applicable

international price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when product purchased in one country is submitted for

repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair, or replacement of a defective product which is returned

to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return authorization information, then send the product to that service

center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following warranty repair,

the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that failure was caused by neglect, misuse, contamination,

alteration, accident, or abnormal condition of operation or handling, including overvoltage failures caused by use outside the product’s specified rating, or normal

wear and tear of mechanical components, Fluke will provide an estimate of repair costs and obtain authorization before commencing the work. Following repair, the

product will be returned to the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR

ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR

THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential damages, the

limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other decisionmaker of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

ООО «Флюк СИАЙЭС»

125167, г. Москва, Ленинградский

проспект дом 37,

корпус 9, подъезд 4, 1 этаж

Page 3

Table of Contents

Title Page

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How to Contact Fluke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safe Use of Li-ion Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

In The Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Input Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Navigation and User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Motor Drive Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Voltage and Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Voltage Unbalance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Current Unbalance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Harmonics (MDA-550 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Motor Drive DC-Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Voltage DC Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Voltage AC Ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

i

Page 4

MDA-550/MDA-510

Users Manual

Motor Drive Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Motor Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Motor Shaft (MDA-550 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FlukeView 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Measurements Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Voltage and Current (Filtered) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Voltage Modulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Phase-Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Phase-Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Phase DC- or DC+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Spectrum (MDA-550 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Voltage Unbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Current Unbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ii

Page 5

Introduction

The MDA-550/MDA-510 Motor Drive Analyzer (the Product

or test tool) is an extension of the ScopeMeter

190 Series II with additional functionality and accessories

that test inverter type motor drives. Inverter type motor

drives are known as variable frequency drives or variable

speed drives and use pulse width modulation to control ac

motor speed and torque. The test tool supports motor drives

with signal levels up to 1000 V to ground.

For Motor Drive Analysis, the test tool provides:

• Key motor drive parameters

Includes measurement of voltage, current, dc link

voltage level and ac ripple, voltage and current

unbalance, harmonics (MDA-550), and voltage

modulation.

• Extended harmonics

Identifies the effects of low and high order harmonics on

the electrical power system.

• Guided measurements

Guidance for motor drive input, dc bus, drive output,

motor input, and shaft measurements (MDA-550).

• Simplified measurement setup

Graphically shows how to connect and then

automatically triggers according to the selected test

procedure.

®

Test Tool

• Reports

Use for troubleshooting and collaborative work with

others.

• Additional electrical parameters

Full 500 MHz oscilloscope capability is available for the

complete range of electrical and electronic

measurement on industrial systems.

This manual describes the functions of the Motor Drive

Analyzer that are available when you select the Motor Drive

Analyzer key. The functionality and specification for the

Scope and Recorder modes are described in the

®

ScopeMeter

Test Tool 190 Series II Users Manual.

The TrendPlot function in the Recorder mode plots a graph

of selected Motor Drive readings over time.

Replace all references to the Meter key in the Users Manual

with the Motor Drive Analyzer key. It is not possible to show

large readings as described in the section Making

Automatic Meter Measurements (for models 190-xx4).

However, it is possible to show readings together with the

waveform as described in the section Making Automatic

Scope Measurements.

The Motor Drive Analyzer is based on the ScopeMeter test

tool model 190-504. All references to models 190-xx2 can

be ignored.

The BC190/830 is the model number for the power adapter

that complies with new regulations.

1

Page 6

MDA-550/MDA-510

Users Manual

The accessory set that is included for the Motor Drive

Analyzer is different than the ScopeMeter

Series II. See In The Box in this manual.

For User Manual corrections, download the latest manual

supplement at http://us.fluke.com/usen/support/manuals

®

Test Tool 190

.

How to Contact Fluke

To contact Fluke, use one of these telephone numbers:

• USA: 1-800-760-4523

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• China: +86-400-921-0835

• Brazil: +55-11-3530-8901

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com

To register your Product, visit http

To view, print, or download the latest manual supplement,

visit http://us.fluke.com/usen/support/manuals

://register.fluke.com.

.

.

Safety Information

A Warning identifies hazardous conditions and procedures

that are dangerous to the user. A Caution identifies

conditions and procedures that can cause damage to the

Product or the equipment under test.

XW Warning

To prevent possible electrical shock, fire, or

personal injury:

• Read all safety information before you use

the Product.

• Carefully read all instructions.

• Do not alter the Product and use only as

specified, or the protection supplied by the

Product can be compromised.

• Use only the Fluke power supply, model

BC190 (Power Adapter).

• Before use, check that the

selected/indicated range on the BC190

matches the local line power voltage and

frequency.

• For the BC190 Power Adapter only use line

cords that comply with the local safety

regulations.

• Use only insulated voltage probes, test

leads, and adapters supplied with the

product, or indicated by Fluke as suitable

for the MDA-550/MDA-510 Motor Drive

Analyzer or Fluke 190 II ScopeMeter series.

2

Page 7

Motor Drive Analyzer

Safety Information

• Before use, inspect voltage probes, test

leads and accessories for mechanical

damage and replace when damaged.

• Remove all probes, test leads and

accessories that are not in use.

• Always connect the power adapter first to

the ac outlet before connecting it to the

product.

• Do not touch voltages >30 V ac rms, 42 V

ac peak, or 60 V dc.

• Do not connect the ground spring (see

Figure 1 in the ScopeMeter Test Tool 190

Series II Users Manual) to voltages higher

than 42 V peak (30 Vrms) from earth

ground.

• Do not apply more than the rated voltage,

between the terminals or between each

terminal and earth ground.

• Do not apply input voltages above the

rating of the instrument. Use caution when

using 1:1 test leads because the probe tip

voltage will transmit directly to the product.

• Do not use exposed metal BNC connectors.

Fluke offers cables with plastic, safety

designed BNC connectors suitable for the

Motor Drive Analyzer. See Optional

Accessories in the Users Manual.

• Do not insert metal objects into

connectors.

• Do not wear loose-fitting clothing or

jewelry and keep long hair tied back when

near rotating machinery. Use approved eye

protection and approved personalprotective equipment where necessary.

• Use the Product only as specified, or the

protection supplied by the Product can be

compromised.

• Do not use the Product if it operates

incorrectly.

• Do not use the Product if it is altered or

damaged.

• Disable the Product if it is damaged.

• Keep fingers behind the finger guards on

the probes.

• Use only correct measurement category

(CAT), voltage, and amperage rated probes,

test leads, and adapters for the

measurement.

• Do not exceed the Measurement Category

(CAT) rating of the lowest rated individual

component of a product, probe, or

accessory.

• Do not use the Product around explosive

gas, vapor, or in damp or wet

environments.

• Measure a known voltage first to make sure

that the Product operates correctly.

3

Page 8

MDA-550/MDA-510

Users Manual

• Examine the case before you use the

product. Look for cracks or missing plastic.

Carefully look at the insulation around the

terminals.

• Do not work alone.

• Comply with local and national safety

codes. Use personal protective equipment

(approved rubber gloves, face protection,

and flame resistant clothes) to prevent

shock and arc blast injury where hazardous

live conductors are exposed.

• The battery door must be closed and

locked before you operate the product.

• Do not operate the Product with covers

removed or the case open. Hazardous

voltage exposure is possible.

• Remove the input signals before you clean

the Product.

• Use only specified replacement parts.

• Do not use test leads if they are damaged.

Examine the test leads for damaged

insulation, exposed metal, or if the wear

indicator shows. Check test lead

continuity.

Safe Use of Li-ion Battery Pack

The battery pack Fluke model BP291 (52 Wh) has been

tested in accordance with the UN Manual of Tests and

Criteria Part III Subsection 38.3 (ST/SG/AC.10/11/Rev.3) –

more commonly known as the UN 38.3 – tests, and have

been found to comply with the stated criteria. The battery

pack has additionally been tested according to IEC 62133.

Recommendations for safe storage of

battery pack:

• Do not store battery packs near heat or fire.

Do not store in sunlight.

• Do not remove a battery pack from its

original packaging until required for use.

• When possible, remove the battery pack

from the equipment when not in use.

• Fully charge the battery pack before

storing it for an extended period to avoid a

defect.

• After extended periods of storage, it may

be necessary to charge and discharge the

battery packs several times to obtain

maximum performance.

• Keep the battery pack out of the reach of

children and animals.

• Seek medical advise if a battery or part of it

has been swallowed.

4

Page 9

Safe Use of Li-ion Battery Pack

Motor Drive Analyzer

Recommendations for safe use of the battery

pack:

• The battery pack must be charged before

use. Use only Fluke approved power

adapters to charge the battery pack. Refer

to Users Manual for proper charging

instructions.

• Do not leave a battery on prolonged charge

when not in use.

• The battery pack gives the best

performance when operated at normal

room temperature 20 °C ±5 °C (68 °F ±9 °F).

• Do not put battery packs near heat or fire.

Do not put in sunlight.

• Do not subject battery packs to severe

impacts such as mechanical shock.

• Keep the battery pack clean and dry. Clean

dirty connectors with a dry, clean cloth

• Do not use any charger other than that

specifically provided for use with this

equipment.

• Do not use any battery which is not

designed or recommended by Fluke for use

with the Product.

• Take careful notice of correct placement of

the battery in the product or the External

Battery Charger.

• Do not short-circuit a battery pack. Do not

keep battery packs in a place where the

terminals can be shorted by metal objects

(e.g. coins, paper clips, pens or other).

• Never use a battery pack or charger

showing visible damage.

• Batteries contain hazardous chemicals that

can cause burns or explode. If exposure to

chemicals occurs, clean with water en get

medical aid. Repair the Product before use

if the battery leaks.

• Alteration of battery pack: there shall be no

attempt to open, modify, reform or repair a

battery pack, which appears to be

malfunctioning, or which has been

physically damaged.

• Do not disassemble or crush battery packs

• Use the battery only in the application for

which it is intended.

• Retain the original Product information for

future reference.

5

Page 10

MDA-550/MDA-510

Users Manual

Recommendations to safe transport of

battery packs:

• The battery pack must adequately be

protected against short-circuit or damage

during transport.

• Always consult the IATA guidelines

describing safe air transport of Li-ion

batteries.

• Check-in luggage: battery packs are only

allowed when installed in the Product.

• Hand carried luggage: a number of battery

packs as required for normal and individual

use is allowed.

• Always consult national/local guidelines

that are applicable for shipment by mail or

other transporters.

• A maximum of 3 battery packs may be

shipped by mail. The package must be

marked as follows: PACKAGE CONTAINS

LITHIUM-ION BATTERIES (NO LITHIUM

METAL).

Recommendations to safe disposal of a

battery pack:

• You must properly dispose of a failed

battery pack in accordance with local

regulations.

• Do not dispose of the battery as unsorted

municipal waste.

• Dispose in discharged condition and cover

the battery terminals with isolation tape.

6

Page 11

Symbols

Table 1 is a list of symbols used on the Product or in this manual.

Table 1. Symbols

Symbol Description Symbol Description

Motor Drive Analyzer

Symbols

W

X

~

Consult user documentation.

WARNING. RISK OF DANGER.

WARNING. HAZARDOUS VOLTAGE. Risk of

electric shock.

Earth

AC (Alternating Current)

Conforms to the Appliance Efficiency Regulation (California Code of Regulations, Title 20, Sections 1601 through 1608),

for small battery charging systems.

Measurement Category III is applicable to test and measuring circuits connected to the distribution part of the building’s

low-voltage MAINS installation.

Measurement Category IV is applicable to test and measuring circuits connected at the source of the building’s low-voltage

MAINS installation.

This product contains a Lithium-ion battery. Do not mix with the solid waste stream. Spent batteries should be disposed of

by a qualified recycler or hazardous materials handler per local regulations. Contact your authorized Fluke Service Center

for recycling information.

This product complies with the WEEE Directive marking requirements. The affixed label indicates that you must not discard

this electrical/electronic product in domestic household waste. Product Category: With reference to the equipment types in

the WEEE Directive Annex I, this product is classed as category 9 "Monitoring and Control Instrumentation" product. Do not

dispose of this product as unsorted municipal waste.

T

)

P

DC (Direct Current)

Double Insulated

Conforms to relevant Australian EMC standards.

Certified by CSA Group to North American safety

standards.

Conforms to European Union directives.

7

Page 12

MDA-550/MDA-510

Users Manual

In The Box

The test tool includes:

• MDA-550 or MDA-510 Motor Drive Analyzer

• 3 VPS 100:1 high voltage probe sets and alligator clips

• 1 VPS410 10:1 high frequency probe set

• Extension ground lead, 1 meter (only recommended to

connect to ground when using the ground lead that is

included with the VPS is not practical)

• i400s current clamp for MDA-510, 3 i400s current

clamps for MDA-550

• Battery Pack BP291 - 52 Wh (to be installed in the unit)

• Hang Strap

• BC190 Power Adapter

• Regional Power Cords

• Safety Information (Multi-Language)

• USB drive (with multi-language User Manuals and

FlukeView ScopeMeter PC Software)

• USB Interface Cable for PC Connection (USB A-to-mini

USB B)

• Soft Carry Case C1740

The MDA-550 includes a Shaft Voltage Test Set to make

the connection with a rotating shaft:

• set of 3 brushes

• probe holder

• two-piece extension rod

• magnetic base

Input Connections

The top of the test tool has four safety BNC signal inputs.

These isolated inputs allow independent floating

measurements with each input. See Figure 1.

!

ALL INPUTS ISOLATED

Figure 1. BNC Connectors

To make motor drive voltage and current measurements:

1. Connect the voltage probe to input A.

2. Connect the voltage probe tip to a phase.

3. For Phase-Phase measurements, connect the ground

lead to another phase that is used as a reference.

4. For Phase-Ground measurements, connect the ground

lead to ground.

5. For the current measurement, place the clamp around

one phase and connect the current probe to input B.

After measurement selection, an on-screen connection

diagram shows the connections for each measurement.

8

Page 13

Motor Drive Analyzer

Input Connections

To make motor drive 3-phase voltage unbalance

measurements:

1. Connect the red voltage probe to input A, the blue

voltage probe to input B, the gray voltage probe to

input C.

2. Connect the probe tip to a phase and the ground leads

of each voltage probe to another phase as shown in the

connection diagram on the screen after you select the

measurement.

3. For each phase, make sure that one probe tip and one

ground lead are connected.

To make motor drive 3-phase current unbalance

measurements:

1. Connect the current probes to the Inputs A, B and C.

2. Measure the current of each phase.

To make a motor shaft voltage measurement (MDA-550

only):

1. Connect the red VP-410 voltage probe to the input A.

2. Connect the ground lead of the voltage probe to

ground.

3. Connect a brush on top of the voltage probe.

4. Place the probe in probe holder.

5. Use the extension rod and magnetic base to keep the

probe in a fixed position and the brush in good contact

with the motor shaft.

Note

To maximize the benefit of independent isolated

floating inputs and to avoid problems caused by

improper use, see Chapter 6, Tips in the

ScopeMeter Test Tool 190 Series II Users

Manual.

For an accurate indication of the measured

signal, you must match the probe to the input

channel on the test tool.

When using probes that are not included with the

Product, see Calibrating the Voltage Probes in

the ScopeMeter Test Tool 190 Series II Users

Manual.

9

Page 14

MDA-550/MDA-510

MOTOR DRIVE

ANALYZER

ENTER

CLEAR

SCOPE

MOTOR DRIVE

ANALYZER

RECORDER

CURSOR

ZOOM

REPLAY

F1

F2

F3

F4

AUTO

MANUAL

A

B

C

D

TRIGGER

HOLD

RUN

USER

SAVE

TIME nss

MOVE

MOVE

RANGE

mV

V

MOTOR DRIVE

ANALYZER

ENTER

Users Manual

Navigation and User Interface

Push to display the Motor Drive Main Menu. This

menu is for the selection of measurements at different

locations of the motor drive system. See Figure 2.

From the submenus the specific measurement is selected

with .

Figure 2. Motor Drive Main Menu

The main menu items are:

• Drive Input

Use these functions to check drive input conditions.

Input voltage relates to the quality of the mains power

that feeds the drive. Input current depends on the

loading of the drive and the condition of the drive input

section.

• Drive DC-Bus

Use these functions to check the DC-bus of the drive.

DC-bus voltage relates to good drive input and load

conditions. DC-bus ripple relates to the drive input

circuit, capacitors, and output loading.

• Drive Output

Use these functions to check the drive output

conditions. The modulated output voltage varies with

the motor speed and load. The output current depends

on load and correct function of the motor. Unbalance

between the phases can cause or indicate problems.

The stress on the motor insulation can be determined

by measurement of the risetime of a fast modulation

pulse.

• Motor Input

Use these functions to check the motor input conditions.

The measurements are the same as Drive Output and

help to determine the influence of the cable. Incorrect

wiring between drive and motor can cause contact,

voltage drop, and reflection problems that can cause

performance drop or damage to the motor. The

measurements are stored separately when you select

Save to Report.

10

Page 15

• Motor Shaft Voltage (MDA-550 only)

ENTER

ENTER

Use this function to detect bearing grease flash-over

currents that can damage motor bearings. These

problems can be caused by high shaft voltages due to

fast high voltage switching of the drive output circuit. A

brush on the tip of a probe measures the rotating shaft

voltage.

After you select a measurement location, select the specific

measurement with .

Some measurements require another submenu to select

the measurement method. As an example, for voltage and

current measurement on the motor drive input, select if the

measurement is done between 2 phases or between phase

and ground.

After a selection is complete, a connection diagram shows

how to connect the voltage probes and current clamps. See

Figure 3.

Motor Drive Analyzer

Navigation and User Interface

Figure 3. Connection Diagram

Push or NEXT to show the actual

measurement.

11

Page 16

MDA-550/MDA-510

1

2

3

4

5

6

HOLD

RUN

Users Manual

Display

The display shows the waveforms as well as the

readings that correspond to the selected measurement.

See Figure 4.

Figure 4. Measurement Screen

BWL indicates that a bandwidth limiter (filter) is applied.

The filter is automatically selected for the specific

measurement.

AUTO indicates that the Connect-and-View algorithm is

applied. The algorithm lets the test tool display complex

signals automatically. 1/2 AUTO indicates that the algorithm

is partially adapted for optimal results in the selected

function.

HOLD shows on the display when you push

to

freeze the screen.

The Status Bar shows the vertical range/division for each

active channel, the time/division, and the trigger channel.

The softkeys correspond to the four function keys on the

Product. The labels and functions change according to the

menu that shows on the display.

Note

A warning message shows on the top left of the

display in Motor Drive Analysis mode to indicate

that bandwidth filters are automatically applied

on the input and that higher frequency

components of the signal are not measured.

12

Page 17

Motor Drive Analyzer

MOVE

mV

V

RANGE

TIMEsns

ZOOM

REPLAY

TRIGGER

CURSOR

HOLD

RUN

CLEAR

Navigation and User Interface

Keys

This section is an overview of the keypad functions:

Manually changes the view of the

waveform. Select the Input Channel

with these keys. The D channel is not

used in the Motor Drive Analyzer mode.

Change the view of the waveform on

the selected Input Channel.

Changes the time base.

Turn off a channel. Use the same key

again to return to the screen with the

motor drive button bar.

This key is disabled as special settings

apply for motor drive signals.

Use these keys the same as in Scope

mode. Use the same key again to

return to the screen with the motor drive

button bar.

Freezes the screen (all readings and

waveforms) at any time.

Removes the button bar from the

screen. This is useful when the button

bar overlaps part of the waveform.

In the main menu the button bar shows the options for the

function keys:

Close Report

A report is a selection of screen bitmaps files. When you

save a measurement, use Save Report to save a screen

bitmap. When all the measurements are done, use Close

Report in the main menu to close the report. You must close

the report before you can start a new report. The report also

closes automatically when you turn off the Product.

Copy Report to USB

After a report is closed, you can save the report to a USB

drive (max 2 GB).

Delete Report

Delete a saved report.

Info

Use the Info screen to find explanations about the

selections and corresponding measurements, including tips

and tricks.

Probes

Select the probes to specify the type of voltage and current

probes. Make sure the clamp and the measurement

instrument are set to the proper range. Use the range select

switch on the clamp to adapt the setting if necessary. The

arrow on the top of the clamp must face towards the load of

the circuit. Connect the current clamp jaws around the

conductor to be measured.

13

Page 18

MDA-550/MDA-510

Users Manual

Motor Drive Input

The Motor Drive Input functions check the drive input

conditions. Input voltage relates to the quality of the mains

power that feeds the drive. Input current depends on the

loading of the drive and the condition of the drive input

section.

Voltage and Current

Voltage and Current measurements check for supply

voltage, current, and frequency at the Motor Drive input.

The measurement is done on one of the phases and for

3-phase systems can be repeated for the other phases.

Voltage measurements between two phases (PhasePhase) or between phase and ground (Phase-Ground) is

selected in the submenu.

The display shows the voltage waveform in red and the

current waveform in blue. The rms voltage, rms current and

frequency are displayed as readings in the top of the

display.

For displayed readings, use to change to the Volt

Peak readings or Current Peak readings: Peak-Peak,

Maximum Peak, Minimum Peak as well as the Crest Factor

(ratio between peak and rms value). This only changes the

readings. The voltage and current waveform continue to

show on the display with no change.

Tips:

• The test tool can compare the rms voltage against the

intended nominal voltage. The Vrms should be ±10 % of

the intended voltage.

• If the voltage is low:

• Check if the local circuit is overloaded.

• Check if the load of the circuit matches the current

rating of the circuit breaker. A high current load can

result in a low voltage on the drive input.

• Check the sizing of the conductor feeding the

circuit to see whether the cable size is within

specifications compared to local requirements.

• If the voltage is ±10 % of intended voltage, the

voltage level is not the problem during the

measurement period. Certain conditions can cause

the voltage to go outside of the acceptable limits

during other time periods.

• When the Motor Drive is on, the waveform does

not have a typical sinewave, for example, it can

look more like a camel hump shape. The current

readings and waveform shape can vary as the load

changes.

• Compare the measured frequency against the

specified frequency intended for that circuit.

Nominal frequency (typical 50 Hz or 60 Hz) should

be within 0.5 Hz of specification.

• When using a MDA-550, select Harmonics to

determine the harmonics related to the waveform

shape for both voltage and current (see Harmonics

section).

14

Page 19

Motor Drive Analyzer

Motor Drive Input

Voltage Unbalance

Voltage Unbalance checks for the difference between the

Phase-Phase voltages for 3-phase systems.

At the simplest level, all three phases of voltage should

always have the same magnitude. Expressing unbalance as

a percentage provides one number to describe the

situation. To calculate the unbalance value:

% unbalance = (maximum deviation from

average / average of three phases) x 100 %

While voltage unbalance at motor terminals can adversely

affect motor operation, it can also cause problems at the

input side of the drive. As little as 2 % to 3 % voltage

unbalance on the input to a motor drive can cause voltage

notching and excessive current to flow in one or more

phases. Voltage unbalance can also cause tripping of the

current overload fault protection on the motor drive.

Tips:

• The source of unbalance voltage could be poor

installation practices or loads that need to be correctly

optimized. Another common cause of voltage

unbalance is single-phase loads dropping in or out on

the same feed as the 3-phase motor drive. To minimize

or eliminate this problem, increase the kVA rating of the

transformer or provide a separate feed for the motor

drive.

• changes the readings that are displayed in the

top of the screen to the peak-peak values of each

phase as well as the highest Crest Factor (ratio

between peak and rms value) of one of the phases.

Current Unbalance

Current Unbalance checks for the difference between

current levels of the phases for 3-phase systems. To

calculate the unbalance value:

% unbalance = (maximum deviation from

average / average of three phases) x 100 %

Tips:

• Current unbalance should be <6 % and depends on

load current and circuit capacity. Excessive current

unbalance can point to or cause drive rectifier problems

that result in the motor overheating. Current unbalance

can be caused by voltage unbalance. For example, 1 %

of voltage unbalance can result in 3 % to 4 % of current

unbalance.

• changes the readings that are displayed in the

top of the screen to the peak-peak values of each

phase as well as the highest Crest Factor (ratio

between peak and rms value) of one of the phases.

Harmonics (MDA-550 only)

The MDA-550 provides harmonics analysis. Harmonics are

periodic distortions of the voltage and current sine wave.

Harmonics occur when multiples of the fundamental

waveform are superimposed over the fundamental. You can

consider the signal as a combination of various sine waves

with different frequencies. The contribution of each of these

components to the full signal is shown as a bar. For

example, a 5th harmonic is 300 Hz (5 x 60) for 60 Hz

systems or 250 Hz (5 x 50) for 50 Hz systems. The effect of

these harmonics is distortion of the voltage or current. The

sum of all distortions from the 2

harmonic divided by the fundamental component is

expressed as the Total Harmonic Distortion (THD).

nd

harmonic to the 50th

15

Page 20

MDA-550/MDA-510

ENTER

Users Manual

The readings in the top of the screen show the ac rms value

of the signal, the fundamental (H1) value, the frequency of

the fundamental and the THD value.

To view the reading for the harmonic component:

1. Select Harmonics.

2. Push Input to select the channel for the

harmonics display.

For Voltage and Current measurements, select A for

the Voltage harmonics on Channel A and select B for

the Current harmonics on Channel B.

For Unbalance measurements, select A, B, or C to

show the voltage or current harmonics for the selected

channel.

3. Push to vertically zoom in on the harmonics

display.

4. Push Scale Options to change the vertical

scale.

5. Use the to switch the vertical scale

between % of fundamental frequency and linear voltage

or current value.

6. In Scale Options, toggle between the TDD reading and

the THD reading for a current waveform.

TDD or Total Demand Distortion is the ratio of the rms

value of all the current harmonic components to the

maximum demand current entered as a value. This can

be useful when running at low load conditions. In that

case THD would be relatively high, but the harmonic

currents generated would be low, and the effect on the

supply system is negligible.

The distortion caused by the harmonics can affect the

operation of other electrical equipment on the same circuit.

Other loads such as motors and transformers can overheat,

have shortened life, and ultimately fail due to the presence

of harmonics.

Tips:

• Voltage and current harmonics are closely related, but

the percentage levels are usually very different. Voltage

are a low number and current harmonics are a higher

number.

• Voltage THD exceeding 6 % on any phase can require

more investigation. Harmonics can be reduced by

modification to the drive, installation of harmonic filters,

or other solutions for harmonic mitigation. When

installing a filter, the harmonics measurement can be

done before and after the installation to verify the

performance of the filter.

• Scale Options show the higher frequency components

by selecting 2 kHz to 9 kHz or 9 kHz to 150 kHz as the

horizontal scale. The horizontal scale shows

frequencies instead of harmonics numbers.

• The frequency components are calculated using an FFT

algorithm based on the acquired waveform. The

horizontal scale is linear as the values are not related to

the fundamental frequency.

• Use these frequency ranges to determine to what

extent a drive (for example, with an active front end)

that operates on the same input power is affecting the

input section of the drive under test with high frequency

components. This also can influence filters on the input

of the drive.

16

Page 21

Motor Drive Analyzer

Motor Drive DC-Bus

Motor Drive DC-Bus

The Motor Drive DC-Bus functions check the intermediate

circuit of the motor drive.

XW Warning

To prevent possible electrical shock, fire, or

personal injury, be aware that the voltage

that is present on the dc bus outputs

remains on these outputs after the motor

drive is turned off. The amount of time

depends on the internal impedance.

Voltage DC Level

The Voltage DC Level checks the value and stability of the

internal DC-bus of the drive and influence of braking or

power feedback (if supported by the drive).

The readings show the dc level, as well as, the peak and

peak-peak value. Use Voltage AC Ripple for a closer look at

the ac component.

The dc bus voltage should be about 1.414 times the rms

line voltage, except when controlled rectifiers (IGBT) are

used in the input section. A dc voltage that is too low can

trip the drive. Low voltage can be caused by low input mains

voltage or distorted input voltage by flat topping.

Tips:

• Use the RECORD function to check the dc voltage

stability over time and detect slow fluctuations. The test

tool continuously records the digital readings of the

measurements and displays these as a graph.

• The TrendPlot graph rolls from right to left like a paper

chart recorder. Observe that the recorded time from

start appears at the bottom of the screen. The present

reading appears on top of the screen.

•See Using the Record Functions chapter in the

ScopeMeter

more information.

®

Test Tool 190 Series II User Manual for

Voltage AC Ripple

The Voltage AC Ripple function detects rapid fluctuations

and ac components on the dc-bus.

Tips:

• A slight ripple can be visible and is load dependent. If

the peaks of ripple have a different repetitive level, one

of the rectifiers could be malfunctioning.

• Ripple voltages >40 V can be caused by malfunctioning

capacitors or the drive rating is too small for the

connected motor and load.

17

Page 22

MDA-550/MDA-510

Users Manual

Motor Drive Output

The Motor Drive Output functions check the drive output

conditions. The modulated output voltage varies with the

motor speed and load. The output current depends on load

and correct function of the motor. Unbalance between the

phases can cause or indicate problems. The stress on the

motor insulation can be determined by measurement of the

risetime of a fast modulation pulse.

Voltage and Current (Filtered)

Voltage and Current (Filtered) are measurements of the

voltage, current, and frequency at one of the phases of the

motor drive output. The measurement is done with a 10 kHz

bandwidth filter so that a sinewave shaped voltage

waveform shows instead of the pulse width modulated

signal.

The voltage measurement is done between two phases

(Phase-Phase). The current measurement is done on a

single phase. Repeat the measurement for the other

phases.

The display shows the voltage waveform in red and the

current waveform in blue. The PWM voltage, rms current,

frequency, and Volt/Hz factor (ratio between voltage and

frequency) show as readings at the top of the display. The

PWM voltage shows and not the rms voltage, as PWM

voltage represents the effective voltage of the switching

output based on the average value of samples over a whole

number of periods of the fundamental frequency.

changes the readings on the display to Volt Peak

readings or Current Peak readings: Peak-Peak, Maximum

Peak, Minimum Peak, and Crest Factor (ratio between peak

and RMS value).

Tips:

• Use the V/Hz ratio to check if the ratio is within specified

limits for the motor.

• If V/Hz is too high the motor will overheat and if V/Hz is

too low the motor will lose torque.

Note

The peak voltage readings here are the peak of

the effective voltage and not the peaks of the

actual PWM voltage. Use the Voltage Modulation

function to measure PWM voltage.

• The Voltage and Current (filtered) function detects

motor overloading. Stable Hz with unstable V readings

points to dc bus problems. Unstable Hz with stable V

readings points to IGBT problems. Unstable Hz and

unstable V readings points to speed control circuits.

• Check the output voltage on the motor drive with the

nameplate rating. The current must be within the

specified Full Load Amps for the motor. Consider the

motor service factor that specifies the percentage of

overloading the motor can handle for short periods of

time.

• If the output current is too high, the motor can run hot. A

10-degree temperature rise can equal 50 % decrease in

stator insulation life.

18

Page 23

Motor Drive Analyzer

mV

V

RANGE

MOVE

TIMEsns

Motor Drive Output

Voltage Modulation

Use voltage modulation to display the modulated output

signal.The submenu has selection for what reference is

used for the measurement.

Phase-Phase

Phase-Phase shows the modulated signal between

2 phases. The PWM voltage, voltage peak-peak, frequency,

and volt/frequency ratio show as readings in the top of the

display. PWM voltage shows on the display but not the rms

voltage. PWM voltage represents the effective voltage of

the switching output based on the average value of samples

over a whole number of periods of the fundamental

frequency.

adjusts the zoom level (1, 2, or 3) of the waveform

as well as the corresponding readings.

For Zoom 2, the test tool selects a time base that shows the

pulses in more detail and the readings change to Volt Peak

Max, Volt Peak Min, and delta voltage between the upper

and lower levels.

BURST (positive or negative) selects either the

positive part of the modulated signal or the negative part of

the modulated signal. This selection also applies when you

change to Zoom 3.

For Zoom 3, the test tool selects a time base that shows the

edge of pulse of the modulation signal. A pulse with a high

peak is selected automatically to find the highest dV/dt

value.

The readings change to Volt Peak Max, dV/dt, risetime, and

overshoot percentage when Peak is selected as Risetime

with . The risetime measurement is based on the

IEC 60034-17 method that uses the 10 % and 90 % values

of the peak of pulse. This peak value is used as dt in the

dV/dt reading and the Peak Voltage as dV. Make sure that

the slope that is automatically selected is indeed the pulse

of the PWM signal and not of an interference. The start of

the slope must be around the 0-level.

LEVEL selects the readings for Delta Voltage,

dV/dt, risetime, and overshoot percentage. The risetime

measurement is based on the NEMA MG1 Part 30.1

method that uses the 10 % and 90 % values of the voltage

level. This value is used as dt in the dV/dt reading and the

level voltage as dV.

To change the view of the waveform manually in any of the

Zoom modes:

1. Push or .

2. To change the time base, use the key.

3. Use the voltage, time, and dV/dt reading to see if the

steepness of the switching impulses is within the motor

insulation specification.

Tips:

• High voltage peaks can damage the motor insulation

and drive output circuit and cause the drive to trip.

Overshoot higher than 50 % of nominal voltage can be

problematic.

19

Page 24

MDA-550/MDA-510

Users Manual

• Measure on the motor input to check the pulses on the

input of the motor and the influence of the cable.

• When installing a filter, do the dV/dt measurement

before and after the installation to verify the

performance of the filter.

Phase-Ground

When you connect the reference lead to ground, the test

tool shows switching pulses for each phase. Typically, a

sinewave shows on top of the modulated signal as the

ground level is not the star point of the 3-phase system. Due

to the fluctuations in signal level to ground, a stable signal is

not always automatically shown in all zoom modes.

Compared to the Phase-Phase measurement, the carrier

frequency shows as the reading when you select Zoom 2,

as the waveform shows the switching of one phase, as

compared to the mix of two phases switching in PhasePhase.

Zoom 3 shows the same parameters as Phase-Phase and

can be high voltage peaks to ground that could damage the

motor insulation. The Phase-Ground signal can damage

different parts of the insulation. When filters are applied,

higher peaks can be visible when measuring Phase-Ground

compared to Phase-Phase.

Tips:

• Make sure that the slope that is automatically selected

is the pulse of the PWM signal and not of an

interference. The start of the slope must be around the

0-level.

• When a drive has a dc bus with intermediate 0-level

(middle point of DC+ and DC-) that can be accessed

with a reference lead, the same measurement can be

applied.

Phase DC- or DC+

The measurements with a dc positive or negative bus signal

as reference is the same as for Phase-Phase but with an

offset relative to the dc level. The Phase dc measurement is

also used to measure switch frequency, identify IGBT

problems, or to check if the signal is floating up and down to

indicate a system grounding problem.

Spectrum (MDA-550 only)

The MDA-550 includes spectrum analysis in voltage

modulation mode. In this mode, no hardware filter is

enabled. This function shows the spectral content of the

motor drive output voltage waveform. It performs an FFT

(Fast Fourier Transform) to transform the amplitude

waveform from the time domain into the frequency domain.

The switching frequency shows as high peaks. For phasephase measurement, 2x the switching frequency shows as

it is the combination of two phases switching. For PhaseGround measurements, only the switching frequency of the

drive shows as a peak in the spectrum.

Voltage Unbalance

The Voltage Unbalance checks for a difference between the

Phase-Phase voltages for 3-phase systems. The unbalance

value is calculated by dividing the maximum rms voltage

deviation of one of the phases and the average rms voltage

of all phases.

Voltage unbalance at motor terminals can adversely affect

motor operation and can also cause tripping of the current

overload fault protection on the motor drive.

changes the readings that show at the top of the

screen to the peak-peak values of each phase as well as

the highest Crest Factor (ratio between peak and rms value)

of one of the phases.

20

Page 25

Motor Drive Analyzer

Magnetic

probe holder

Voltage probe

Motor Input

Current Unbalance

Current Unbalance checks for a difference between current

levels of the phases in 3-phase systems.

The value is calculated by dividing the maximum rms

current deviation of one of the phases and the average rms

current of all phases. Current unbalance should be <6 %

and depends on load current and circuit capacity.

Make sure the phase currents are equal. If one of the

phases shows a failure, it can cause the motor to run hot,

not start after stopping, and loose efficiency. A phase failure

can be due to motor drive output malfunction or bad

connection between motor drive and motor and can cause

motor overheating.

changes the readings that show in the top of the

screen to the peak-peak values of each phase as well as

the highest Crest Factor (ratio between peak and rms value)

of one of the phases.

Motor Input

The functions for motor input are identical to motor drive

output, except that the phase-dc bus measurements are left

out for voltage modulation, as it is not practical to use the dc

bus as reference on the motor input.

Use the motor input functions to do the same

measurements and check the influence of the cable

between the motor drive and the motor and then document

the measurements separately in a report. The voltage

modulation measurements are useful to show voltage

peaks that are too high when the cabling is not properly

matched.

Motor Shaft (MDA-550 only)

The Motor Shaft function detects bearing flash-over that can

damage motor bearings. The measurement requires a

connection to the rotating shaft of the motor. For this

measurement, brushes are included as accessories.

Alternatively, you can use a stranded wire probe. Fluke

recommends the VP410 10:1 Voltage Probe. See Figure 5.

Figure 5. Motor Shaft Test Setup

W Caution

For safety, stop the motor.

To set up:

1. Remove the black protective cap and black insulation

sleeve from the probe tip.

2. Place the brush on top of the voltage probe.

3. Turn the screw to tighten the brush on the probe.

21

Page 26

MDA-550/MDA-510

Users Manual

4. Place the probe in the magnetic probe holder. Extend

the probe holder with the included two-piece extension

rod.

Note

Use the probe holder to keep the probe in a fixed

position and the brush in contact with the motor

shaft.

5. Make sure that it is possible to make good electric

contact with the shaft before you do the measurement.

6. Use one of the ground leads to contact the motor

chassis that is the reference ground.

When it is not possible to connect near the shaft, an

extension cord with 4 mm connections on both ends is

included for extending the connection to the ground

lead. The measurement can be done on the driven and

the non-driven end of the motor.

7. Turn on the motor.

8. Do the measurement after the motor warms up to

normal operating temperature.

With this function you can determine the number of flashovers that occur between shaft and motor chassis, also

referred to as electrical discharge machining. When motor

shaft voltages exceed the bearing grease insulation

capability, flash-over currents occur and cause pitting and

grooving of the bearing races.

Tips:

• Under direct 50/60 Hz mains operation, the shaft

voltage is normally <1 V.

• Due to the fast edges of the switching voltage from a

motor drive, the shaft voltage for a motor powered by a

motor drive can be much higher. High Voltage can

cause large breakdown currents across the grease

barrier causing damage to the bearings.

• Normal, unavoidable shaft voltage due to asymmetry in

the air-gap magnetic field result in peak voltages <5 V

and slower than 100 ns, which, in general, are not

damaging.

• Voltage discharges of >15 V and transition times faster

than 50 ns can point to grease flash-over currents that

can damage bearings. However, no fixed values can be

given that can be considered damaging for the motor,

as there are many factors that influence this value.

After selecting the Motor Shaft Voltage measurement, the

display shows the voltage waveform. The voltage

peak-peak reading shows at the top of the display. Select

EVENTS ON to view the discharge event and

count the amount of discharge events. Only the discharge

events show. The readings at the top of the display show

the Volt Peak-Peak, dV/dt, and falltime or risetime as well

as the number of events/second. Expect about 20 seconds

before the number of events/second shows on the display.

22

Use DEFINE EVENTS to define what is

considered a discharge event.

In this screen, select the maximum voltage change and

maximum rise or fall time that will be counted and displayed

as an event.

Page 27

Motor Drive Analyzer

HOLD

RUN

REPLAY

MOTOR DRIVE

ANALYZER

REPLAY

Replay

Tips:

• No waveform is visible when no events are detected.

• If excessive shaft voltage is measured, check that the

voltage discharges can be reduced by adapting the

cabling, grounding, drive parameters, or lubricant. If this

is not possible or does not help, use the shaft grounding

devices or the isolated shaft.

• If a bearing runs hot or is noisy and high shaft voltages

are measured, bearing flash-over currents can be the

primary source of excessive bearing wear.

• Check other sources of bearing wear, such as, coupling

misalignment or looseness.

Replay

The test tool automatically stores the 100 most recent

screens:

1. Push or to freeze memory contents.

2. Use the functions in the REPLAY menu to step back

through the stored screens to find the screen of interest.

You can use this feature to see previous measurements,

such as the last shaft voltage discharge waveforms.

To save a replay screen to a report:

1. Push the twice.

Report

The MDA-500 Series simplifies the process of gathering

data and writing test reports with a built-in report generator.

At each test point or measurement there is the option to

create, update, or modify a report:

1. Push SAVE TO REPORT to save the screen

as a .png file.

2. Enter a name for the drive that is measured.

The test tool uses the drive name as the name of a

directory and automatically creates names for the .png

files based on the selected measurement.

3. When all measurements on a drive are done, push

CLOSE REPORT in the Main Motor Drive

menu.

4. The next time you push SAVE TO REPORT,

enter a new name for the report.

5. After a report is closed, push COPY REPORT

TO USB to save a report to a USB drive.

The USB drive included with the test tool has 2 GB of

memory and is the maximum memory size supported

by the test tool.

6. Push DELETE REPORTS to remove saved

reports and free up the internal memory.

2. Push SAVE TO REPORT.

3. Push to return to the Replay screen.

23

Page 28

MDA-550/MDA-510

SAVE

ENTER

ENTER

Users Manual

When the test tool is turned off, an active Report is closed

automatically.

For copying or deleting stored reports:

1. Push .

2. FILE OPTIONS.

3. Use to highlight COPY to copy to USB, MOVE

to USB and delete, RENAME to rename the report

name or DELETE to delete the report.

4. Push .

5. Use to highlight the report.

6. Push to confirm.

Successive saved screens are represented by the last 2

digits in the filename. As an example, when SAVE TO

REPORT is selected for the second time in the Motor Drive

Output, Voltage Modulation, Phase-Phase mode, the

filename is OUVMPP02.PNG.

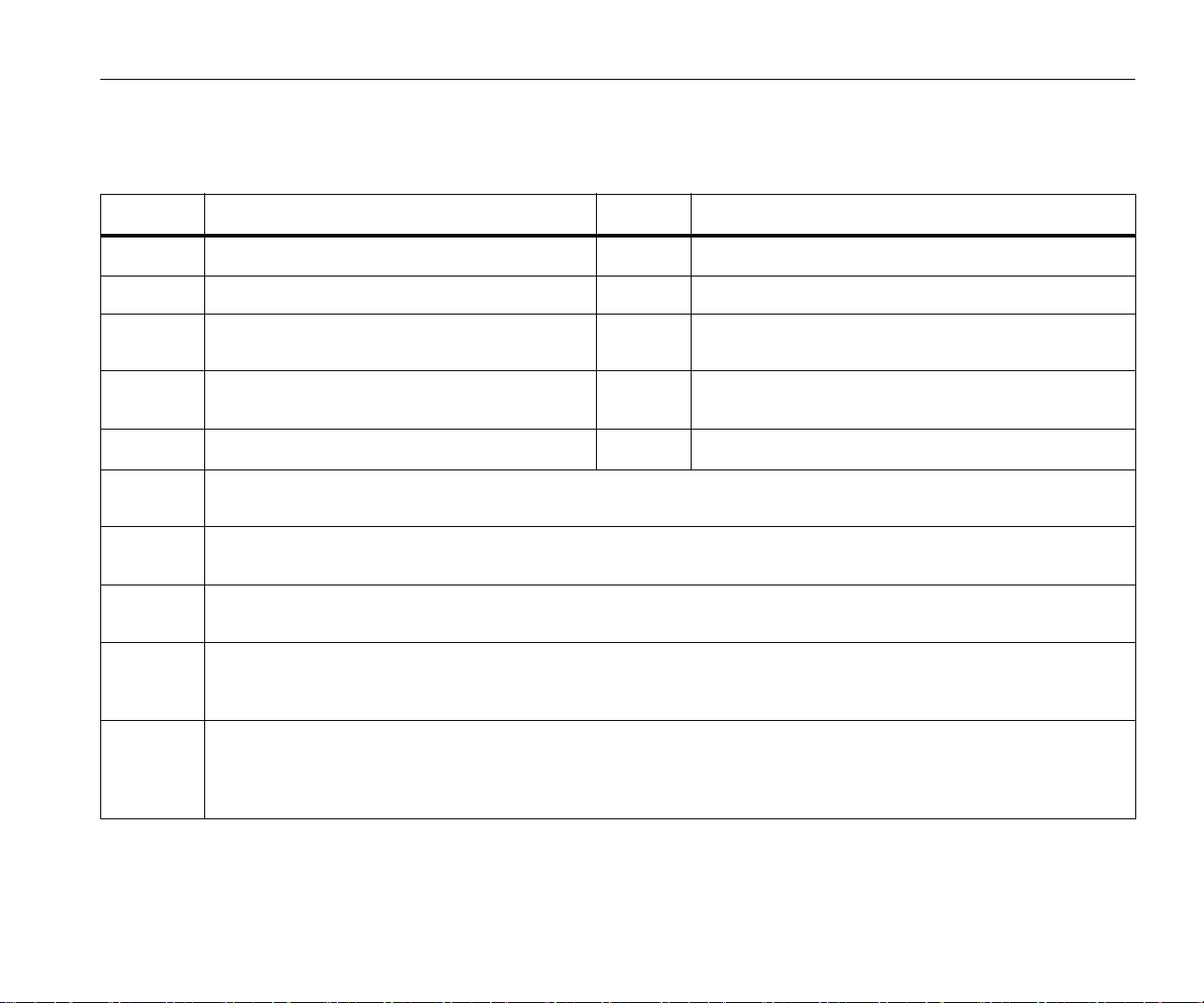

Table 2 shows the filenames that correspond to the

selected function.

FlukeView 2

Refer to the section Connecting to a Computer in the Fluke

190 Series II Users Manual for information about how to

connect the USB cable to a computer.

The setup program of the FlukeView 2 for ScopeMeter Test

Tools is available on the USB drive included with the

Product.

After installation:

1. Start the FlukeView 2 software.

2. Push HELP to access the documentation for the

program.

24

Page 29

Motor Drive Analyzer

Measurements Overview

Measurements Overview

Table 2 is a list of the measurements you can do with the

test tool.

Table 2. Measurement and Analysis Combinations

Test Point Subgroup Reading 1 Reading 2 Reading 3 Reading 4 Report Filename

Motor Drive Input

Voltage and Current

V-A-Hz V AC+DC A AC+DC Hz

Phase-Phase

A Peak A Peak max A Peak min A pk-to-pk Crest Factor

V-A-Hz V AC+DC A AC+DC Hz

Phase-Ground

A Peak A Peak max A Peak min A pk-to-pk Crest Factor

Unbalance V AC+DC V AC+DC V AC+DC Unbalance

Voltage Unbalance

Peak V pk-to-pk V pk-to-pk V pk-to-pk max Crest Factor

Unbalance A AC+DC A AC+DC A AC+DC Unbalance

Current Unbalance

Peak A pk-to-pk A pk-to-pk A pk-to-pk max Crest Factor

Motor Drive DC Bus

DC V DC V pk-to-pk V Peak max DCVCF

Ripple V AC V pk-to-pk Hz DCVRPL

INVCFPV Peak V Peak max V Peak min V pk-to-pk Crest Factor

INVCFGV Peak V Peak max V Peak min V pk-to-pk Crest Factor

INVUNB

INCUNB

25

Page 30

MDA-550/MDA-510

Users Manual

Table 2. Measurement and Analysis Combinations (cont.)

Test Point Subgroup Reading 1 Reading 2 Reading 3 Reading 4 Report Filename

Motor Drive Output

V-A-Hz V PWM A AC+DC Hz V/Hz

Voltage and Current

(Filtered)

A Peak A Peak max A Peak min A pk-to-pk Crest Factor

Unbalance V PWM V PWM V PWM Unbalance

Voltage Unbalance

Peak V pk-to-pk V pk-to-pk V pk-to-pk max Crest Factor

OUVCFV Peak V Peak max V Peak min V pk-to-pk Crest Factor

OUVUNB

Current Unbalance

Voltage Modulation

Phase-Phase

Phase-Ground

26

Unbalance A AC+DC A AC+DC A AC+DC Unbalance

OUCUNB

Peak A pk-to-pk A pk-to-pk A pk-to-pk max Crest Factor

Zoom 1 V PWM V pk-to-pk Hz V/Hz

Zoom 2 V Peak max V Peak min Delta V

OUVMPP

Zoom 3 PEAK V Peak max Delta V/s Risetime Peak Overshoot

Zoom 3 LEVEL Delta V Delta V/s Risetime Level Overshoot

Zoom 1 V PWM V pk-to-pk V Peak max V Peak min

Zoom 2 V Peak max V Peak min Delta V Hz

OUVMPG

Zoom 3 PEAK V Peak max Delta V/s Risetime Peak Overshoot

Zoom 3 LEVEL Delta V Delta V/s Risetime Level Overshoot

Page 31

Motor Drive Analyzer

Measurements Overview

Table 2. Measurement and Analysis Combinations (cont.)

Test Point Subgroup Reading 1 Reading 2 Reading 3 Reading 4 Report Filename

Zoom 1 V PWM V pk-to-pk V Peak max V Peak min

Zoom 2 V Peak max V Peak min Delta V Hz

Phase-DC +

Zoom 3 PEAK V Peak max Delta V/s Risetime Peak Overshoot

Zoom 3 LEVEL Delta V Delta V/s Risetime Level Overshoot

Zoom 1 V PWM V pk-to-pk V Peak max V Peak min

Zoom 2 V Peak max V Peak min Delta V Hz

Phase-DC -

Zoom 3 PEAK V Peak max Delta V/s Risetime Peak Overshoot

Zoom 3 LEVEL Delta V Delta V/s Risetime Level Overshoot

Motor Input

V-A-Hz V PWM A AC+DC Hz V/Hz

Voltage and Current

(Filtered)

A Peak A Peak max A Peak min A pk-to-pk Crest Factor

OUVMDC+

OUVMDC-

MIVCFV Peak V Peak max V Peak min V pk-to-pk Crest Factor

Voltage Unbalance

Current Unbalance

Unbalance V PWM V PWM V PWM Unbalance

MIVUNB

Peak V pk-to-pk V pk-to-pk V pk-to-pk max Crest Factor

Unbalance A AC+DC A AC+DC A AC+DC Unbalance

MICUNB

Peak A pk-to-pk A pk-to-pk A pk-to-pk max Crest Factor

27

Page 32

MDA-550/MDA-510

Users Manual

Table 2. Measurement and Analysis Combinations (cont.)

Test Point Subgroup Reading 1 Reading 2 Reading 3 Reading 4 Report Filename

Voltage Modulation

Zoom 1 V PWM V pk-to-pk Hz V/Hz

Zoom 2 V Peak max V Peak min Delta V

Phase-Phase

Zoom 3 PEAK V Peak max Delta V/s Risetime Peak Overshoot

Zoom 3 LEVEL Delta V Delta V/s Risetime Level Overshoot

Zoom 1 V PWM V pk-to-pk V Peak max V Peak min

MIVMPP

Phase-Ground

Zoom 2 V Peak max V Peak min Delta V Hz

Zoom 3 PEAK V Peak max Delta V/s Risetime Peak Overshoot

Zoom 3 LEVEL Delta V Delta V/s Risetime Level Overshoot

MDA-550 Only

Motor Shaft

Events off V pk-to-pk

Shaft Voltage

Events on Delta V

Motor Drive Input, Output, and Motor Input

Voltage V AC+DC

Harmonics

Current V AC+DC

28

Rise/Fall

time

V

fundamental

A

fundamental

Delta V/s Events/s

Hz

fundamental

Hz

fundamental

%THD

%THD/TDD

MIVMPG

SHAFTV

Page 33

Motor Drive Analyzer

Specifications

Specifications

DC Voltage (V DC)

Maximum voltage with 10:1 or 100:1 probe.............. 1000 V

Maximum resolution with 10:1 or 100:1 probe..........1 mV

Full scale reading...................................................... 999 counts

Accuracy at 4 s to 10 us/div......................................±(3 % + 6 counts)

AC voltage (V AC)

Maximum voltage with 10:1 or 100:1 probe.............. 1000 V

Maximum resolution with 10:1 or 100:1 probe..........1 mV

Full scale reading...................................................... 999 counts

50 Hz ........................................................................±(3 % + 10 counts) -0.6 %

60 Hz ........................................................................±(3 % + 10 counts) -0.4 %

60 Hz to 20 kHz ........................................................±(4 % + 15 counts)

20 kHz to 1 MHz .......................................................±(6 % + 20 counts)

1 MHz to 25 MHz ...................................................... ±(10 % + 20 counts)

True-rms voltage (V AC+DC)

Maximum voltage with 10:1 or 100:1 probe.............. 1000 V

Maximum resolution with 10:1 or 100:1 probe..........1 mV

Full scale reading...................................................... 1100 counts

DC to 60 Hz ..............................................................±(3 % + 10 counts)

60 Hz to 20 kHz ........................................................±(4 % + 15 counts)

20 kHz to 1 MHz .......................................................±(6 % + 20 counts)

1 MHz to 25 MHz ...................................................... ±(10 % + 20 counts)

PWM Voltage (V Pwm)

Purpose ....................................................................To measure on pulse width modulated signals, like Motor Drive inverter outputs

Principle .................................................................... Readings show the effective voltage based on the average value of samples over a whole number of

periods of the fundamental frequency

Accuracy ................................................................... As V AC+DC for sinewave signals

Peak Voltage (V Peak)

Modes ....................................................................... Max peak, Min peak, or pk-to-pk

Maximum voltage with 10:1 or 100:1 probe.............. 1000 V

29

Page 34

MDA-550/MDA-510

Users Manual

Maximum resolution with 10:1 or 100:1 probe..........10 mV

Accuracy

Max peak, Min peak ..............................................±0.2 division

Pk-to-Pk.................................................................±0.4 division

Full scale reading...................................................... 800 counts

Amperes (AMP) with current clamp

Ranges .....................................................................Same as V AC, VAC+DC or V Peak

Scale Factors............................................................0.1 mv/A, 1 mV/A, 10 mV/A, 20 mV/A, 50mV/A, 100 mV/A, 200 mV/A, 400 mV/A

Accuracy ...................................................................Same as V AC, VAC+DC or V Peak (add current clamp accuracy)

Frequency (Hz)

Range .......................................................................1.000 Hz to 500 MHz

Full scale reading...................................................... 999 counts

Accuracy ...................................................................±(0.5 % + 2 counts)

Voltage Hz ratio (V/Hz)

Purpose ....................................................................To show the measured Vpwm value (see Vpwm) divided by the fundamental frequency on Variable AC

Motor Speed drives

Accuracy ...................................................................% Vrms + % Hz

Voltage Unbalance Drive Input

Purpose ....................................................................To show the highest percentage difference of one of the phase vs. average of the 3 true-rms voltages

Accuracy ...................................................................Indicative percentage based on V AC+DC values

Voltage Unbalance Drive Output and Motor Input

Purpose ....................................................................To show the highest percentage difference of one of the phase vs. average of the 3 pwm voltages

Accuracy ...................................................................Indicative percentage based on V Pwm values

Current Unbalance Drive Input

Purpose ....................................................................To show the highest percentage difference of one of the phase vs. average of the 3 ac current values

Accuracy ...................................................................Indicative percentage based on A AC+DC values

Current Unbalance Drive Output and Motor Input

Purpose ....................................................................To show the highest percentage difference of one of the phase vs. average of the 3 ac current values

Accuracy ...................................................................Indicative percentage based on A ac values

Rise and Fall time

Readings................................................................... Voltage difference (dV), time difference (dt), voltage vs. time difference (dV/dt), overshoot

Accuracy ...................................................................Same as oscilloscope accuracy

30

Page 35

Motor Drive Analyzer

Harmonics and Spectrum

Harmonics ................................................................ DC to 51st

Spectrum ranges ......................................................1 kHz to 9 kHz, 9 kHz to 150 kHz (20 MHz filter on), up to 500 MHz (voltage modulation)

Shaft Voltage

Events / second ........................................................Indicative percentage based on rise and fall time (Impulse discharges) measurements

Report Data Capture

Number of screens ...................................................Typical 50 screens can be saved in Reports (depends on compression ratio)

Transfer to PC ..........................................................Using 2 GB USB stick or mini-USB to USB cable and FlukeView

Probe Settings

Voltage Probe ........................................................... 1:1, 10:1, 100:1, 1000:1, 20:1, 200:1

Current Clamp ..........................................................0.1 mV/A, 1 mV/A, 10 mV/A, 20mV/A, 50mV/A, 100mV/A, 200 mV/A, 400 mV/A

Shaft Voltage Probe.................................................. 1:1, 10:1, 100:1

VPS4xx Probe accuracy when adjusted on the test tool

DC to 20 kHz .........................................................±1 %

20 kHz to 1 MHz.................................................... ±2 %

1 MHz to 25 MHz................................................... ±3 % (for higher frequencies the probe roll off starts affecting the accuracy)

Safety

General ..................................................................... IEC 61010-1: Pollution Degree 2

Measurement

IEC 61010-2-030

BNC Input A, B, (C, D)

From any terminal to

earth ground.................................................... 1000 V CAT III, 600 V CAT IV

Between any terminal .....................................300 V CAT IV

IEC 61010-2-031

Voltage Probe VPS410 10:1

From any terminal to

earth ground.................................................... 1000 V CAT III, 600 V CAT IV

Between any terminal .....................................1000 V CAT III, 600 V CAT IV

Voltage Probe VPS42x 100:1

From any terminal to

earth ground.................................................... 1000 V CAT III 600 V CAT IV

Between probe tip and

reference lead ................................................. 2000 V

Note: Voltage ratings are given as “working voltage”. They should be read as Vac-rms (50-60 Hz) for ac sinewave applications and as Vdc for dc

applications.

®

2 for ScopeMeter

®

Specifications

31

Page 36

MDA-550/MDA-510

Users Manual

Electromagnetic Compatibility (EMC)

International ..............................................................IEC 61326-1: Portable Electromagnetic Environment IEC 61326-2-2

CISPR 11: Group 1, Class A

Group 1: Equipment has intentionally generated and/or uses conductively-coupled radio frequency

energy that is necessary for the internal function of the equipment itself.

Class A: Equipment is suitable for use in all establishments other than domestic and those directly

connected to a low-voltage power supply network that supplies buildings used for domestic purposes.

There may be potential difficulties in ensuring electromagnetic compatibility in other environments due

to conducted and radiated disturbances.

Caution: This equipment is not intended for use in residential environments and may not provide

adequate protection to radio reception in such environments.

Emissions that exceed the levels required by CISPR 11 can occur when the equipment is connected to

a test object.

Korea (KCC) .............................................................Class A Equipment (Industrial Broadcasting & Communication Equipment)