Page 1

99 Washington Street

Melrose, MA 02176

800.517.8431

TestEquipmentDepot.com

®

1745

Power Quality Logger

PN 2560366

April 2006 Rev.1, 7/06

© 2006 Fluke Corporation, All rights reserved.

All product names are trademarks of their respective companies.

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship

under normal use and service. The warranty period is two years and begins on the date of

shipment. Parts, product repairs, and services are warranted for 90 days. This warranty

extends only to the original buyer or end-user customer of a Fluke authorized reseller,

and does not apply to fuses, disposable batteries, or to any product which, in Fluke's

opinion, has been misused, altered, neglected, contaminated, or damaged by accident or

abnormal conditions of operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days and that it has

been properly recorded on non-defective media. Fluke does not warrant that software will

be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to enduser customers only but have no authority to extend a greater or different warranty on

behalf of Fluke. Warranty support is available only if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when

product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price,

free of charge repair, or replacement of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain

return authorization information, then send the product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that failure

was caused by neglect, misuse, contamination, alteration, accident, or abnormal condition

of operation or handling, including overvoltage failures caused by use outside the product’s specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair costs and obtain authorization before commencing the work.

Following repair, the product will be returned to the Buyer transportation prepaid and the

Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF

DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty,

or exclusion or limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is

held invalid or unenforceable by a court or other decision-maker of competent jurisdiction,

such holding will not affect the validity or enforceability of any other provision.

11/99

Page 3

Table of Contents

Title Page

Introduction .......................................................................................... 1

Information and PC Software CD..................................................... 1

Logger Power Supply ....................................................................... 2

Logging Functions ............................................................................ 2

Symbols ............................................................................................ 4

Safety Instructions ................................................................................ 4

Qualified Personnel........................................................................... 6

Standard Equipment and Optional Accessories ................................ 6

Features............................................................................................. 8

Power Network Configurations ........................................................ 11

Working with Logged Data............................................................... 11

Using the 1745 Power Quality Logger.................................................. 12

About Logging Jobs.......................................................................... 12

Preparing the Logger for Use............................................................ 13

Test Leads - Markings .................................................................. 15

Connecting Current Probes ........................................................... 15

Logging with Voltage Converters................................................. 15

Connecting the Logger...................................................................... 16

Connections in 3-Phase 4-Wire (Wye) Systems ........................... 19

Connections in 3-Phase 3-Wire (Delta) Systems .......................... 20

Connections for Single-Phase Logging......................................... 21

Connections for Medium Voltage Networks................................. 22

Logging............................................................................................. 24

Completing the Logging Job......................................................... 24

Evaluating the Logged Data.............................................................. 25

Methods of Logging.......................................................................... 25

Voltage Ranges................................................................................. 26

Signal Sampling............................................................................ 27

Resolution Accuracy......................................................................... 27

Voltage Variations ............................................................................ 27

Averaging Period .............................................................................. 28

Min/Max Values ........................................................................... 29

Voltage Interruptions .................................................................... 30

Voltage Dips and Swells............................................................... 31

Voltage Harmonics ........................................................................... 31

i

Page 4

1745

Users Manual

Current Harmonics ........................................................................... 32

Power ............................................................................................... 37

Measurement Theory............................................................................ 38

Maintenance ......................................................................................... 42

Lithium Battery ................................................................................ 42

Disposal............................................................................................ 42

Technical Specifications....................................................................... 43

Logging Parameters – Overview ...................................................... 43

General Specifications...................................................................... 48

Logging Function Parameters........................................................... 50

PQ Log PC Application Software ........................................................ 52

Index

Mains Signaling............................................................................ 32

THD V – In Function A................................................................ 33

Calculation of THD in Measuring Function P.............................. 34

Flicker .......................................................................................... 35

Unbalance..................................................................................... 36

Frequency..................................................................................... 36

Current Logging ........................................................................... 36

Logging Function A ..................................................................... 36

Crest Factor (CF).......................................................................... 36

Maximum Number of Intervals for Logging Funtion P................ 44

General Information ..................................................................... 44

Environmental Specifications....................................................... 45

EMC ............................................................................................. 45

Power Supply ............................................................................... 45

Measurement ................................................................................ 46

Input Voltage................................................................................ 46

Current Input with Flexi Set......................................................... 47

Current Input for Clamp ............................................................... 47

RMS Logging Slow Voltage Variations....................................... 48

Current Logging Values ............................................................... 48

Events Dips, Swells, Interruptions................................................ 48

Flicker .......................................................................................... 48

Power P, S, |P| .............................................................................. 49

Harmonics (Logging Function A Only)........................................ 49

Statistics ....................................................................................... 49

Logging Values ............................................................................ 50

Applications ................................................................................. 51

Live Reading (Online Test).......................................................... 53

ASCII Export................................................................................ 54

Timeplot Diagram ........................................................................ 55

UNIPEDE DISDIP Table............................................................. 56

Cumulative Frequency – Harmonics ............................................ 56

ii

Page 5

List of Tables

Table Title Page

1. Symbols.............................................................................................. 4

2. Standard Equipment........................................................................... 7

3. Optional Accessories.......................................................................... 7

4. 1745 Power Quality Logger - Controls and Indicators....................... 9

5. Test Leads - Markings........................................................................ 15

6. Measuring Ranges.............................................................................. 26

7. Logging Parameters - Overview......................................................... 43

iii

Page 6

1745

Users Manual

iv

Page 7

List of Figures

Figure Title Page

1. 1745 Power Quality Logger ............................................................... 3

2. 1745 Power Quality Logger - Front View.......................................... 8

3. Supplying Operating Power to the Logger......................................... 14

4. Logging in a 3-Phase 4-Wire System................................................. 19

5. Logging in a 3-Phase 3-Wire (Delta) System..................................... 20

6. Single-Phase Logging ........................................................................ 21

7. Measuring 3 Phase Voltages in a 3-Wire (Delta)

System with Three Voltage Converters.............................................. 22

8. Two-Element Delta Connections ....................................................... 23

9. Basic Logger Setup Parameters.......................................................... 26

10. Measuring Voltage Variations............................................................ 28

11. Logging Min and Max Values............................................................ 29

12. Voltage Interruption........................................................................... 30

13. Voltage Dips and Swells .................................................................... 31

14. Measuring Flicker Values .................................................................. 35

15. Live Reading (Online Test)................................................................ 53

16. ASCII Export ..................................................................................... 54

17. Timeplot Diagram .............................................................................. 55

18. UNIPEDE DISDIP Table................................................................... 56

19. Cumulative Frequency - For Voltage and Current Harmonics ........... 56

v

Page 8

1745

Users Manual

vi

Page 9

1745

Power Quality Logger

Introduction

The Fluke 1745 Power Quality Logger, see Figure 1, is a sophisticated, easyto-use, electrical power-recording device for the electrician or power-quality

specialist.

Note

This manual also refers to the 1745 Power Quality Logger simply as

“the Logger”.

The Logger conatins an automatically charged 8-hour UPS (uninterruptable

power supply) battery for long-term voltage interruption ride-through, and an

LCD status display to provide confidence in setup before you leave the Logger

in place to collect data.

You can power the logger in parallel with the test leads or through an outlet.

Adapter cords for both methods of power in the Logger are included as

standard equipment.

You’ll prepare the Logger for use with the included PQ Log software. You can

then connect the Logger to an electrical power-distribution network to log a

variety of power parameters, recorded as sequential averaged values over an

averaging period you can define. The Logger can measure up to three voltages

and four currents simultaneously.

Information and PC Software CD

The CD included with the Logger contains the PQ Log application software for

Windows, along with users manuals in multiple languages.

The PQ Log software prepares the Logger for use, and downloads data from

the Logger to a connected PC.You can then view the logged data in graphical

and tabular form, export it to a spreadsheet, or create reports for printing. For

details and instructions, see the PQ Log Users Manual on the CD.

1

Page 10

1745

Users Manual

Logger Power Supply

The Logger does not include a power switch, but turns on automatically

whenever its power supply leads are connected to a voltage in its allowed

range. You can plug the Logger’s power supply leads into a standard wall

outlet (using the included adapter cord), or you can connect them directly to

the power network under test (in parallel with the test leads) if there is no

convenient wall outlet (only if the voltage at the test leads is below 660V

RMS.)

Logging Functions

The Logger monitors power quality and locates disturbances in low and

medium voltage distribution networks. It measures up to 3 voltages and

4 currents. Logged values are saved in your choice of sequential averaging

periods. You graphically or numerically evaluated measured values with PQ

Log.

The Logger has two types of logging functions: logging function A

(Advanced) and logging function P (Power). Function A is the full set of

parameters, and function P provides logging capability optimized for load

studies and basic power logging. Function P contains every parameter in

Function A except voltage and current harmonics and interharmonics.

Logging function P allows longer logging periods because it does not save

harmonics values.

2

Page 11

Power Quality Logger

Introduction

Logging function parameters:

• RMS Voltage of each phase (average, min, max)

• RMS Current of each phase and neutral (average, min, max)

• Voltage events (dips, swells, interruptions)

• Power (kW, kVA, kVAR, Power PF, Power tangent)

• Energy, total energy

• Flicker (Pst, Plt)

• Voltage THD

• Current THD

• Current CF

• Voltage harmonics to the 50

th

(not in P function)

• Voltage interharmonics (not in P function)

• Mains signalling voltage

• Unbalance

• Frequency

1745

POWER QUALITY LOGGER

LOGGING STATUS

SUPPLY INPUT

L

1

A

L

B

2

L

C

3

660V MAX

88-660V

100-350V

45

-65Hz

5VA

VOLTAGE INPUT

830

V 480V

60

0V

CAT

-

L

/

L

30

0V

CA

T

CURRENT INPUT

10 V

MAX

-

L

N

RMS

MAX

/

RS232

START / STOP

T

egc001.eps

Figure 1. 1745 Power Quality Logger

3

Page 12

1745

Users Manual

Symbols

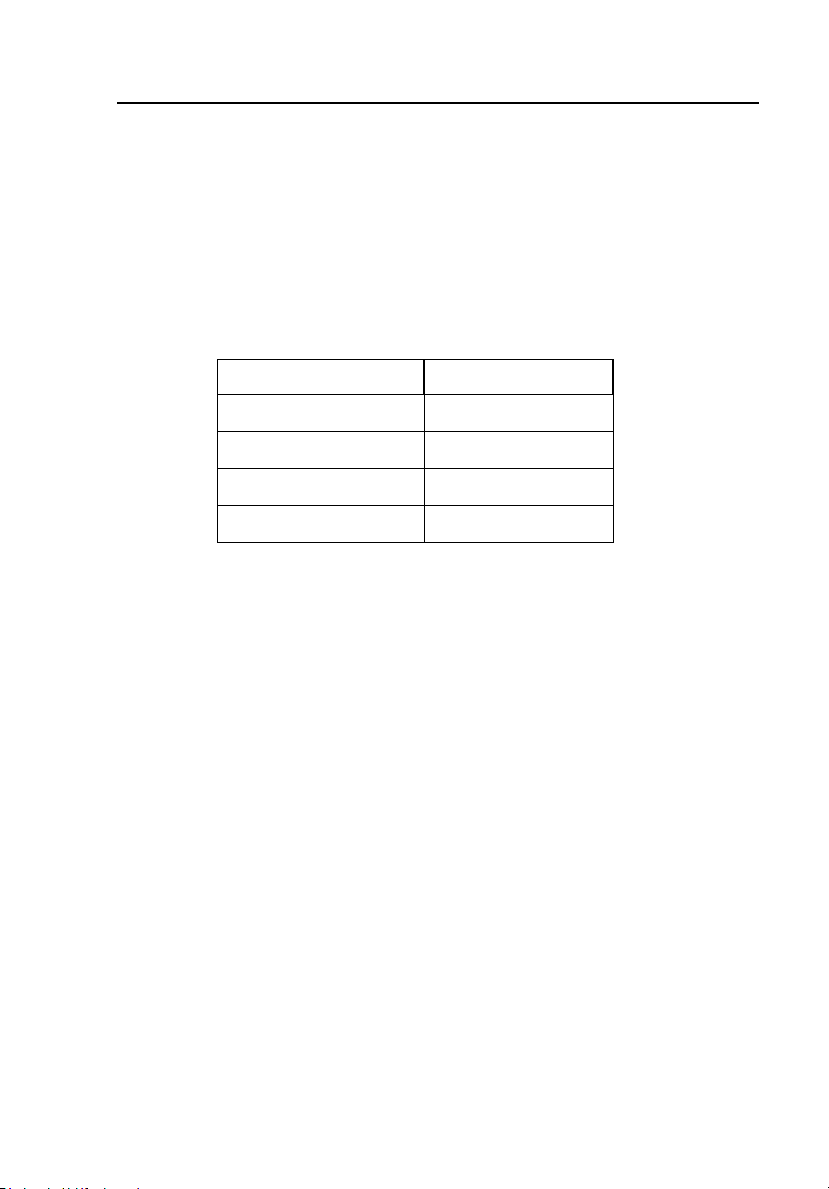

Table 1 lists the symbols used on the instrument and in this manual.

Table 1. Symbols

Symbol Description

W

X

J

T

F

P

)

~

;

Important information. See the manual.

Hazardous voltage.

Earth ground.

Double insulation.

Direct Current (DC).

Conforms to European Union requirements

Canadian Standards Association is the certified body used

for testing compliance to safety standards.

Do not dispose of this product as unsorted municipal waste.

Contact Fluke or a qualified recycler for disposal.

Conforms to relevant Australian Standards.

Safety Instructions

Please read this section carefully. It will make you familiar with the most

important safety instructions for using the Logger.

Warnings identify conditions and actions that pose safety hazards to the

user and Cautions identify conditions and actions that can damage the

Logger.

4

Page 13

Power Quality Logger

Safety Instructions

W X Warnings

• To avoid electrical shock, do not connect any part of

the Logger to systems that have higher voltages to

ground (earth) than are marked on the Logger.

• Areas between the power company meter and the

source of the distribution system are characterized as

CAT IV areas. To avoid electrical shock or equipment

damage, never connect the Logger to power in CAT IV

areas if the voltage-to-earth ground is greater than

300 V.

• To avoid damaging the Logger, never connect its

voltage measuring inputs to phase-to-phase voltages

higher than 830 V.

• To avoid damaging the Logger, never connect the

power supply leads to voltages higher than 660 V-RMS

AC.

• The Logger is to be used and handled only by qualified

personnel (see page 8).

• Maintenance work on the Logger must be done only by

qualified service personnel.

• Use only the current probes specified in this manual. If

you use flexible current probes, wear suitable

protective gloves or work on de-energized conductors.

• Do not expose the Logger to moisture or humidity.

• To prevent electrical shock, always connect power

supply and voltage test leads to the Logger before

connecting to the load.

• All accessories must be approved for 600 V CAT III or

higher.

• Use the Logger only with its original standard

equipment or with approved optional accessories, as

listed in Table 2 and Table 3 in this manual.

5

Page 14

1745

Users Manual

• Connect clip-on current transformers and/or Flexi Set

to insulated live conductors only.

• If measuring sensors are to be connected to non-

insulated live conductors, additional personal

protective measures must be taken as required by local

government agencies.

WCaution

To avoid damage, use the 1745 Power Quality Logger, only

with the following nominal voltages:

• Single/3 phase, 4-wire (Wye) systems (P-N): 69 V to

480 V

• 3-phase-3-wire(Delta) systems (P-P): 120 V to 830 V

WX Warning

To avoid electrical shock, or damaging the Logger’s

internal protective circuitry weatherproof seal, do not open

the Logger.

Qualified Personnel

The following qualifications are required for using the Logger safely:

• Trained and authorized to switch on/off, ground (earth), and mark

power distribution circuits and devices in accordance with electrical

engineering safety standards.

• Trained or instructed in safety engineering standards for maintaining

and using appropriate safety equipment.

• Trained in first aid.

Standard Equipment and Optional Accessories

Table 2 lists the standard equipment for the 1745 Power Quality Logger and

Table 3 lists optional accessories.

6

Page 15

Power Quality Logger

Safety Instructions

Table 2. Standard Equipment

Equipment Model/Part

Number

Power Quality Logger 1745

International IEC Power Plug Adapter Set 2441372

RS232 Cable, Red, Null-Modem 2540511

Shielded 4-Phase Flexi Set (15 A/150 A/1500 A/3000 A) FS17XX

Dolphin Clip, Black (4x) 2540726

Color Coding Wire Clips WC17XX

Soft Case 2715509

English Users Manual 2560366

CD with Users Manual (English, German, French, Spanish,

Portuguese, Simplified Chinese, Italian), and PQ Log

software (same languages as the manual)

Power cord adapter for parallel connection to test leads 2651702

Power cord 2715492

USB Adapter 2539565

Table 3. Optional Accessories

Description Accessory

3-Phase Flexi Set MBX 3FLEX

3-Phase 1 A/10 A micro CT EPO405A

C425 Hardcase 2654865

Permlink Software for Modem E631820090

3-Phase Voltage Leads 2645854

2583507

Inspect the contents of the shipping box for completeness and damage. Report

any damage, to the shipper.

7

Page 16

1745

Users Manual

Features

This section introduces the Logger’s controls, indicators and other features.

Refer to Figure 2 and Table 4.

7

1745

POWER QUALITY LOGGER

LOGGING S

START / STOP

T

RS232

6

2

3

Figure 2. 1745 Power Quality Logger - Front View

TATUS

SUPPLY INPUT

L

1

A

L

B

2

L

C

3

660V MAX

88-660V

100-350V

45

-65Hz

5VA

8

VOLTAGE INPUT

830

V 480V

60

0V

CAT

-

L

/

L

30

0V

CA

T

1

CURRENT INPUT

10

MAX

V

-

L

N

4

RMS

MAX

/

5

egc002.eps

8

Page 17

Power Quality Logger

Safety Instructions

Table 4. 1745 Power Quality Logger - Controls and Indicators

Item Name Description

Connector for

1

Logger power

supply.

This is where the power cord attaches to the

Logger. The power cord connects in parallel

to any two test leads as long as the voltage

is below 660 V absolute maximum.

Whenever there is any risk that voltage

could be higher, connect the power cord to a

wall outlet using the appropriate

international power plug (supplied).

Power supply voltage range: 88-660 V AC or

100-350 VDC, 50 Hz / 60 Hz, 600 V CAT III.

START/STOP switch The START/STOP button is used to start or

2

LCD status display Shows measured input values to provide

3

end switch-operated logging sessions.

confidence in proper setup and test lead

connections. Every 3 seconds, the display

changes to the next set of readings in the

following sequence:

1. The three voltage levels

2. The main three phase currents

3. Neutral current and real-time clock

4. Active (true) power on each phase

The cycle repeats continuously. Make sure

the readings look reasonable before leaving

the Logger to collect data.

Power supply leads

4

and 3-phase plus

neutral voltage test

leads

Fixed installed voltage input cables for L1 or

A, L2 or B, L3 or C, N.

The highest permissible nominal voltage is

830 V in a 3-wire network with Delta

connection.

In a 4-wire network with Wye connection,

the highest permissible nominal voltage is

480 V.

When using PTs and CTs for measuring

voltage and current in a medium-voltage

network, refer to the IEC 60044 international

standard for guidelines.

9

Page 18

1745

Users Manual

Table 4. 1745 Power Quality Logger - Controls and Indicators (cont)

Item Name Description

Connector for Flexi

5

Set or current

clamps

RS232 interface port The serial RS232 interface is used to

6

Logging Status LED

7

8 Channel LEDs The logging channel LEDs indicate

Flexi sets or current clamps are detected

automatically at power-up. If you change the

current probe type, be sure to remove and

restore power so the Logger will detect the

new current probe.

Nominal ranges for the Flexi Set are 15 A,

150 A, 1500 A, and 3000 A AC. Nominal

input for current clamps is 0.5 V.

communicate with a PC. The Logger is

connected to the PC’s serial port (or a

modem for remote communication) using

the interface cable. Use a USB adapter if

necessary.

Yellow blinking = Logging job not set up yet,

or waiting for start time or START button.

Green blinking = logging is in progress

Steady green = Logging session is finished.

Data are ready to upload to a PC.

whether the applied voltages are within the

nominal range set using the PQ Log

software.

Red = Overload

Green = OK

Yellow = Underload

(There is no detection for the current input)

10

Page 19

Power Quality Logger

Safety Instructions

Power Network Configurations

You can set up the Logger to work with several power network configurations

(listed below). You make these settings using PQ Log software while

connected to the Logger using the interface cable. See the PQ Log Users

Manual for details.

• Delta system

• Delta 2 element system (2 voltage/current transformer)

• Wye (Star) system

• Single phase

• Split single phase

Working with Logged Data

See the PQ Log manual for full details. Logged data can be evaluated using the

PQ Log software to provide the following:

• Amount, date/time, and duration of quick and slow voltage variations

• Half-cycle: 10 ms-extreme values for 50 Hz (8.3 ms at 60 Hz) MIN

and MAX for each measuring interval

• Depth and duration of voltage dips

• Correlation between peak current and voltage dips

• 95 %-flicker values according to EN50160

• Number and duration of interruptions

• Compliance of harmonic levels with defined limits

• Mean and peak values of phase currents

• Value of neutral conductor current

• Current total harmonic distortion (THD) of phase and neutral

conductor currents

• Profile of active, reactive, and apparent power versus time

• Monitoring of power factor (PF) and information about effectiveness

of compensation systems

• Graphical representations of logging data and statistics

11

Page 20

1745

Users Manual

Using the 1745 Power Quality Logger

This section explains how to operate the 1745 Power Quality Logger. You

should also refer to the PQ Log Users Manual to become familiar with the

software you use to prepare the Logger for use and download logged data.

A typical logging session includes four steps:

1. Preparing the Logger for use with the PQ Log software.

2. Installing the Logger at the logging site.

3. Leaving the Logger to collect data for a period.

4. Downloading and evaluating the logged data.

These steps are described in the following pages.

About Logging Jobs

Logging jobs are defined using the PQ Log software, and transferred to the

Logger over the RS-232 cable. Each job contains the following information:

• Logging function P or A

• Measuring period, defined by start and end times

• Time activated, switch or immediate job

• Nominal voltage

• Power type (wye, delta, etc.)

• Averaging period length

• Logging time period

• Interharmonics and signaling voltages

• Limit values for events

• Memory model for events: circular (first-in/first-out, continuous), or

linear (quit logging when logging period is finished)

• Logging of current - neutral wire

• Optional converter ratios for current and voltage if using potential

transformers (PTs) and current transformers (CTs) at a mediumvoltage network site

12

Page 21

Power Quality Logger

Using the 1745 Power Quality Logger

Preparing the Logger for Use

Prepare the 1745 Logger for use with PQ Log software as follows (see

Figure 3):

1. Connect the Logger to line power. Use the power supply cables to

connect to an outlet, or to the test leads phase and neutral for Wye

configurations, or any two-phase leads for delta.

W Caution

If you are powering the Logger in parallel with the test

leads, and the voltage under test at the Logger power

supply connections could be greater than 660 V RMS AC,

plug the power supply leads into an outlet instead.

Otherwise, you could damage the Logger.

2. Connect the RS232 interface cable to the serial port of your PC. Use a

USB adapter if your PC does not have a serial port.

3. Run the PQ Log software as described in the PQ Log Users Manual.

4. Set up the Logging job and transfer the settings to the Logger.

13

Page 22

1745

Users Manual

Power in Parallel

with Test Leads

1745

POWER QUALITY LOGGER

LOGGING S

T

TATUS

Powe r

Supply

Leads

START / STOP

RS232

SUPP

L

Y INPUT

VOLTAGE INPUT

L

1

A

L

B

2

L

C

3

660

V MAX

88-660

V

10

0-350V

830

V 48

600V

4

5

-65

C

AT

Hz

L

5VA

30

0V

CA

T

Voltage

Test Leads

Power from Wall Outlet

1745

P

O

WER QUALITY LOGGER

LOGGING STATUS

START / STOP

T

CURRENT INPUT

-

0V

/

L

10 V

MAX

RMS

-

L

N

MAX

RS232

Power Supply

Leads

SUPP

L

Y INPUT

VOLTAGE INPUT

L

1

A

L

B

2

L

3

C

660

V MAX

88-660

V

10

0-350V

45-65

Hz

5VA

CURRENT INPUT

830

V 48

600V

C

AT

-

0V

L

/

L

10 V

MAX

RMS

-

L

30

N

0V

CA

MAX

T

Voltage

Test Leads

14

Max 660 V

Figure 3. Supplying Operating Power to the Logger

egc031.eps

Page 23

Power Quality Logger

Using the 1745 Power Quality Logger

Test Leads - Markings

The 1745 Logger includes detachable labeled test leads for voltage terminals

L1 or A, L2 or B, L3 or C, and N. Another detachable set of leads provides

operating power to the Logger. The Flexi Set or current clamp sets are

connected by a seven-pin plug to the Logger A connector. Color coding clips

are provided for your convenience.

Table 5 shows the test leads and markings of the Logger.

Table 5. Test Leads - Markings

Test Leads Markings

Phase L1 or A L1 / A

Phase L2 or B L2 / B

Phase L3 or C L3 / C

Neutral wire N N

Connecting Current Probes

Connect current clamps and Flexi Set probes so that current will flow in the

direction marked by arrows on the probes. Current must flow from the energy

generator to the energy consumer (the load) in order to maintain a positive

active power. Orient the Flexi probe so that the arrow points towards the load.

(The polarization of the test lead for neutral conductor current is not

significant, because the phase angle of the neutral conductor current is not

evaluated.)

Logging with Voltage Converters

The 1745 Logger includes an adjustable convertor ratio that enables it to be

used with voltage convertors (potential transformers, or PTs).

Note

When logging with voltage convertors, make sure the power supply

cables are not connected in parallel to the voltage test leads, or the

Logger’s power consumption can reduce accuracy.

The convertor ratio is defined using the PQ Log software.

15

Page 24

1745

Users Manual

Connecting the Logger

W X Warnings

• To avoid electrical shock, do not connect any part of

the Logger to systems that have higher voltages to

ground (earth) than are marked on the Logger.

• Areas between the power company meter and the

source of the distribution system are characterized as

CAT IV areas. To avoid electrical shock or equipment

damage, never connect the Logger to power in CAT IV

areas if the voltage-to-earth ground is greater than

300 V.

• To avoid damaging the Logger, never connect its

voltage measuring inputs to phase-to-phase voltages

higher than 830 V.

• To avoid damaging the Logger, never connect the

power supply leads to voltages higher than 660 V RMS

AC.

• The Logger is to be used and handled only by qualified

personnel (see page 6).

• Maintenance work on the Logger must be done only by

qualified service personnel.

• Use only the current probes specified in this manual. If

you use flexible current probes, wear suitable

protective gloves or work on de-energized conductors.

• Do not expose the Logger to moisture or humidity.

• To prevent electrical shock, always connect power

supply and voltage test leads to the Logger before

connecting to the load.

• All accessories must be approved for 600 V CAT III or

higher.

16

Page 25

Power Quality Logger

Using the 1745 Power Quality Logger

• Use the Logger only with its original standard

equipment or with approved optional accessories as

listed in Table 2 and Table 3 in this manual.

• Connect clip-on current transformers and/or Flexi Set

to insulated live conductors only.

• If measuring sensors are to be connected to non-

insulated live conductiors, additional personal

protective measures must be taken as required by local

government agencies.

WCaution

To avoid damage, use the 1745 Power Quality Logger only

with the following nominal voltages:

Single/3-phase 4-wire (Wye) systems (P-N): 69 V to 480 V

3-phase-3-wire (Delta) systems (P-P): 120 V to 830 V

WX Warning

To avoid electrical shock, or damaging the Logger’s

internal protective circuitry or weatherproof seal, do not

open the Logger.

17

Page 26

1745

Users Manual

Connect the Logger as follows.

Note

∆- (delta) or Υ- (wye) measurements.

The 1745 Logger is prepared for logging in Delta, Delta 2 Element,

Wye (Star), single and split phase. Please note the different types of

connection and configuration in the PQ Log software.

1. Connect all required measuring leads.

2. If you want to supply the Logger from an outlet use the supplied

power cord and plug adapter. The power supply leads can also be

connected in parallel to the voltage test leads, but the voltage is

limited to 660 V RMS AC.

3. Connect the current clamp set or Flexi Set to the Logger.

4. Connect the current sensor to the conductor under test.

5. Connect the dolphin clips to the test leads. For 3-phase, 4-wire

systems, connect the N-test lead first, and then the other phases.

18

Page 27

Power Quality Logger

Using the 1745 Power Quality Logger

Connections in 3-Phase 4-Wire (Wye) Systems

Figure 4 shows the connections for logging 3-phase 4-wire (Wye) systems:

1745

POWER QUALITY LOGGER

LOGGING S

TATUS

SUPP

LY INPUT

VOLTAGE INPUT

L

1

A

L

2

B

L

C

3

660

V MAX

88

660V

100-

350V

4

5

-65Hz

5VA

CURRENT INPUT

830

V 48

600VCAT

0

L

/

V

L

10 V

MAX

RMS

-

L

30

N

0

V

CA

T

MAX

/

Power Supply

START / STOP

T

RS232

L1 L2

L3

N

Figure 4. Logging in a 3-Phase 4-Wire (Wye) System

egc003.eps

19

Page 28

1745

Users Manual

Connections in 3-Phase 3-Wire (Delta) Systems

Figure 5 shows the connections for logging 3-phase 3-wire (Delta) systems.

The test lead “N” can be left open or connected to ground potential.

1745

POWER QUALITY LOGGER

LOGGING STATUS

START / STOP

T

RS232

Power Supply

SUPPLY INPUT

L

L

L

VOLTAGE INPUT

1

A

B

2

C

3

660V MAX

88

660

V

10

0-

350

V

45

-65Hz

5VA

CURRENT INPUT

830

V 48

600VCAT

-

0

L

/

V

L

10 V

MAX

RMS

L

30

N

0

V

CA

MAX

T

/

L1 L2

L3

N

egc004.eps

Figure 5. Logging in a 3-Phase 3-Wire (Delta) System

20

Page 29

Power Quality Logger

Using the 1745 Power Quality Logger

Connections for Single-Phase Logging

Figure 6 shows the connections for logging single-phase logging systems:

1745

POWER QUALITY LOGGER

LOGGING S

START / STOP

T

RS232

Power Supply

TATUS

SUPP

LY INPUT

VOLTAGE INPUT

L

1

A

L

2

B

L

C

3

660

V MAX

88

660V

100-

350V

4

5

-65Hz

5VA

CURRENT INPUT

830

V 48

600VCAT

0

L

/

V

L

10 V

MAX

RMS

-

L

30

N

0

V

CA

T

MAX

/

L1

N

L3

L2

Figure 6. Single-Phase Logging

egc005.eps

21

Page 30

1745

Users Manual

Connections for Medium Voltage Networks

In a 3-phase 3-wire (Delta) system with three separate voltage converters and

three current transformers, the Logger can measure phase-phase (P-P, Delta) or

phase - N (P-N, Wye). See Figure 7.

1745

POWER QUALITY LOGGER

LOGGING S

TATUS

SUPP

LY INPUT

L

L

L

VOLTAGE INPUT

1

A

B

2

C

3

660

V MAX

88

660V

100-

350V

45

-65Hz

5VA

CURRENT IN

PUT

830

V 48

600VCAT

0

L

/

V

L

10 V

MAX

RMS

L

30

N

0

V

CA

MAX

T

/

L1

Power Supply

L1

L2

START / STOP

T

RS232

L2

L3

L1

L2

L3

N

L3

Figure 7. Measuring 3 Phase Voltages in a 3-Wire (Delta) System with

Three Voltage Converters

22

egc006.eps

Page 31

Power Quality Logger

Using the 1745 Power Quality Logger

Figure 9 shows the connections for two-element Delta (Aron or Blondel)

metering connections.

1745

POWER QUALITY LOGGER

LOGGING S

START / STOP

T

RS232

TATUS

SUPP

LY IN

PUT

VOLTAGE INPUT

L

1

A

L

B

2

L

3

C

660

V MAX

88

660V

100-

350V

4

5

-65Hz

5VA

CURRENT INPUT

830

V 48

600VCAT

0

L

/

V

L

10 V

MAX

RMS

-

L

30

N

0

V

CA

T

MAX

/

Power Supply

L1

L2

L3

L3

L2, N

L1

egc009.eps

Figure 8. Two-Element Delta Connections

23

Page 32

1745

Users Manual

Logging

When the Logger is connected and ready, you can perform three types of

logging:

Switch-activated job: The status LED is blinking. Press the

START/STOP button once. As soon as the job is active, the LED is

on continuously. If needed, the job can be cancelled after running for

at least one minute, and restarted later.

Time-activated job: The Logger starts logging as soon as the pre-

programmed start time is reached and stops at the defined end time.

Immediate job: The Logger starts logging as soon as power is on.

Note the following about logging jobs:

1. The connection can be verified with the LCD (voltage, current,

power). If all three LEDs are lit continuously, the voltage connections

and signal levels are within nominal range. For details, see Table 4 in

the Features section.

2. The Logging job status is indicated by the status LED. For details, see

Table 4 in the Features section.

Completing the Logging Job

1. Terminate the job as follows:

• For switch activated jobs: At the end of the logging period,

stop the logging job by pressing the START/STOP button.

• For time activated and immediate jobs: Stop the job in PQ

Log with the icon, or with menu Logger/Stop logging

Note

Make sure the logging job is stopped with the START/STOP button

(switch activated jobs) or PQ Log (time activated jobs) before the

terst leads or power supply leads are removed. Otherwise, the Logger

will record a voltage interruption.

Only switch-activated jobs can be aborted. Time activated jobs are

terminated only when the programmed measuring time has elapsed.

24

Page 33

Power Quality Logger

Using the 1745 Power Quality Logger

2. Remove the test leads of the three phases. Be sure to remove the

measuring cable of the neutral wire last.

3. Remove the current probes.

Evaluating the Logged Data

You’ll use PQ Log to evaluate the logged data. Data can be read out during

logging as well as at the end.

1. Connect the Logger to line power.

2. Connect the RS232 interface cable to your PC’s serial port, then to the

Logger.

3. Start the PQ Log software.

4. Use PQ Log to transfer the data from the Logger to the PC.

5. Once the data is transferred, remove the RS232 interface cable and

operating power from the Logger.

6. Evaluate the data using PQ Log.

For details, refer to the PQ Log manual.

Methods of Logging

The following section describes methods of logging using the 1745 Logger.

25

Page 34

1745

Users Manual

Voltage Ranges

The software calculates the correct measuring range depending on the nominal

voltage (20 % overflow with C

Table 6 shows the measuring ranges of the Logger and Figure 9 shows the

selection for input ranges during job processing.

Connection Nominal Voltages (Wye/Delta) Max. Input Voltage

Wye/Delta 69 V / 120 V 115 V / 200 V 230 V / 400 V 480 V / 830 V

= 1.4).

F

Table 6. Measuring Ranges

Phase/Neutral

3-phase 4 wire

Phase/Phase

3-phase 3 wire

69 V ~, +20 % 115 V ~, +20 % 230 V ~, +20 % 480 V ~, +20 %

120 V ~, +20 % 200 V ~, +20 % 400 V ~, +20 % 830 V ~, +20 %

egb015.bmp

Figure 9. Basic Logger Setup Parameters

26

Page 35

Power Quality Logger

Using the 1745 Power Quality Logger

Signal Sampling

Input signals (up to three voltages and four currents) are filtered with an antialiasing filter and digitized with a 16-bit A/D converter. The sampling rate is

10.24 kHz. All parameters are calculated from this data.

Resolution Accuracy

Resolution and accuracy depend on the logging parameter. For details see

“Technical Specifications”.

Voltage Variations

The interval value of the voltage is defined as the mean value of the RMS

values over the interval length defined in PQ Log.

27

Page 36

1745

Users Manual

Averaging Period

Averaging period can be set in PQ Log to the following:

• 1, 3, 5, 10, or 30 seconds

• 1, 5, 10, 15, or 60 minutes

Figure 10 shows the measuring voltage variations of the Logger.

1 Interval

V

N

28

Measuring period

Figure 10. Measuring Voltage Variations

Time

egb016.eps

Page 37

Power Quality Logger

Using the 1745 Power Quality Logger

Min/Max Values

Logging detects the highest and lowest voltage RMS values and the highest

current RMS value during the test interval, using a minimum resolution of

10 ms.

The response time can be set in PQ Log to the following:

0.5, or 1 line power period

200 ms

1, 3, or 5 seconds.

Figure 11 shows the logging min and max values of the Logger.

U

Max. Value

Min. Value

t

Measuring Interval

egb017.eps

Figure 11. Logging Min and Max Values

29

Page 38

1745

Users Manual

Voltage Interruptions

The Logger records two types of interruptions:

• All measured RMS values of input voltages that are < 1 % of the

nominal voltage. This threshold can be adjusted in PQ Log.

• Interruptions > 1 half-cycle

The start time and duration of each interruption are registered. See Figure 12.

110% Vn

100% Vn

90% Vn

1%

Vn

30

Duration

Figure 12. Voltage Interruption

Time

egb018.eps

Page 39

Power Quality Logger

Using the 1745 Power Quality Logger

Voltage Dips and Swells

If the voltage passes the upper limit (VN + 10 %) or lower limit (VN - 10 %),

the event is registered as a voltage swell or dip respectively (thresholds are

adjustable in PQ Log).

The duration, time and extreme value of the dip or swell is also recorded. See

Figure 13.

Height

110% Vn

100% Vn

90% Vn

Depth

Duration

Figure 13. Voltage Dips and Swells

Duration

Time

egb019.eps

Voltage Harmonics

Voltage harmonics are defined as voltage components that have a frequency

that is an integer multiple of the fundamental frequency. Logging function A

records each individual voltage harmonic, up to the 50

averaged over the interval length defined in PQ Log.

31

th

. These values are

Page 40

1745

Users Manual

Current Harmonics

Current harmonics are defined as current components that have a frequency

that is an integer multiple of the fundamental frequency of the line power

current. Logging function A records ech individual harmonic of the phase

currents and the neutral current, up to the 50

th

order, and presents the

harmonics as absolute values. The values are averaged over the interval length

defined in PQ Log.

Mains Signaling

Voltage components that have frequencies hat are not integer multiples of the

fundamental frequency of the line power voltage are called Mains Signaling

voltages or ripple-control voltages (“interharmonics”). The Logger can be

programmed to record up to five interharmonics with a resolution of 5 Hz. This

function can also be used to monitor ripple-control signals by entering the

signal frequency of the local utility.

The Logger measures the three second RMS value of each interharmonic and

establishes statistics for EN50160 (European standard) evaluation. These

statistics are available after a minimum recording time of 24 hours, or after

regular termination of the measuring job and can be exported from PQ Log and

evaluated later.

Additionally, the Logger provides a long term recording of the interharmonics.

You can select from the following special measurement methods in the PQ

Log software:

• 200 ms maximum value (recommended for estimating ripple-control

signal levels)

• 200 ms minimum value

• 3 seconds maximum value

• Average value over interval

In PQ Log, the frequency can be entered with a resolution of 0.5 Hz, but for

evaluation, the values are corrected to a bandwidth of 5 Hz. One frequency can

be defined for each band: for example, for a ripple-control signal of 183 Hz,

the values will be corrected to 185 Hz). Interharmonics of voltages and

currents with these frequencies are recorded.

See the PQ Log manual for details.

32

Page 41

Power Quality Logger

Using the 1745 Power Quality Logger

THD V – In Function A

50

2

V

∑

n

2

n

Function A:

V

RMS value of harmonic frequency #n.

n:

V

RMS value of the fundamental frequency.

1:

VTHD

THDV: total contents of harmonics of the line power voltage as a percentage

of the fundamental.

This algorithm is according to EN 61000-4-7.

THD of currents:

THDI

=

Function A:

I

RMS value of harmonic frequency #n.

n:

I

RMS value of the fundamental frequency.

1:

THDI: total contents of harmonics of the current as a percentage of the

fundamental.

=

=

V

1

50

2

I

∑

n

2

n

=

I

1

and

()

=

50

∑

=

IATHDI

22n

n

33

Page 42

1745

Users Manual

Calculation of THD in Measuring Function P

THD – Measuring Function P

Function P does not measure harmonic values.

2

2

VV

−

Voltages:

V

RMS:

V

1

Currents:

I

RMS:

I

1:

THDV

RMS value of the total signal

: RMS value of the fundamental

THDI

RMS value of the total signal

RMS value of the fundamental

RMS

=

RMS

=

1

V

1

2

−

I

1

2

II

1

Note

THDI for currents < 5 % of IE (measuring range) can have

additional uncertainties, or can be suppressed.

Harmonics up to 50th order are taken into account.

34

Page 43

Power Quality Logger

Using the 1745 Power Quality Logger

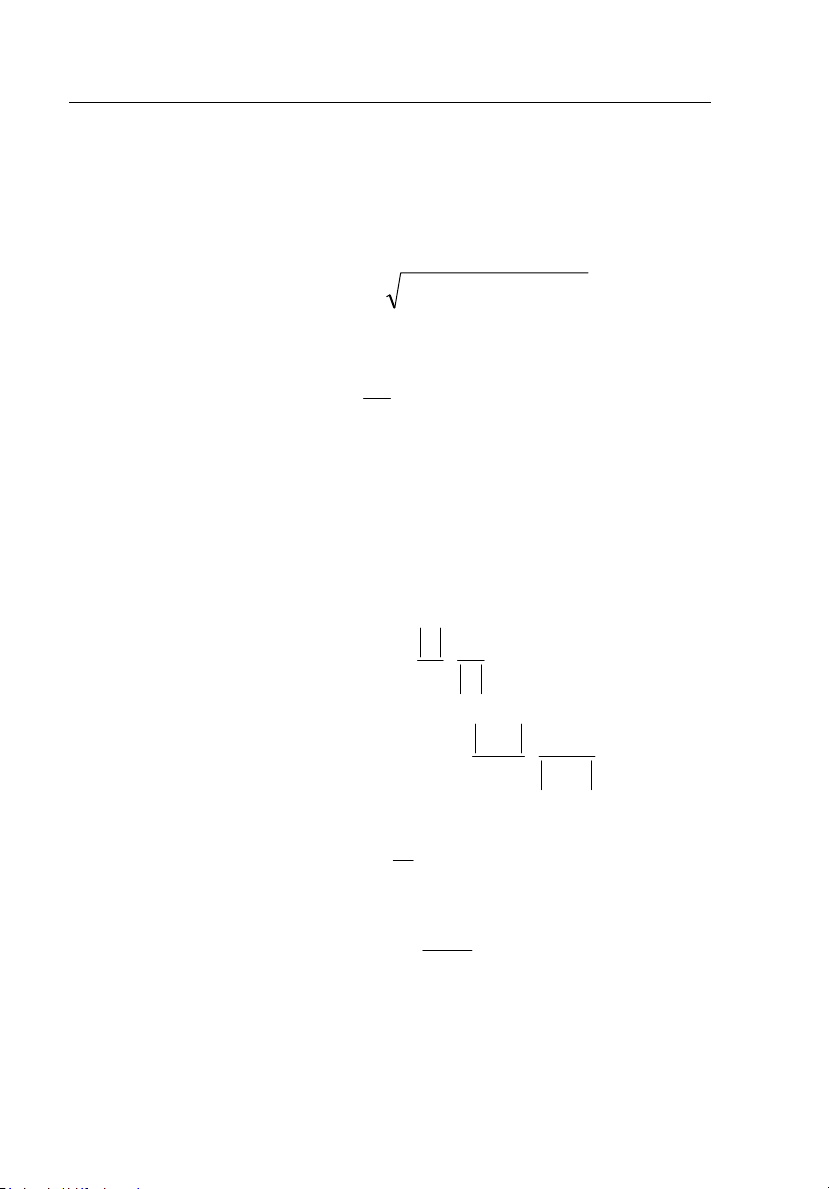

Flicker

Flicker is the visual impression of unsteadiness in a light source whose

luminance or spectral distribution changes over time. Flicker, see Figure 14, is

logged in accordance with the IEC 61000-4-15 standard. The short-term (st)

flicker P

to calculate the long-term (lt) flicker P

is logged over a default standard interval of 10 minutes, and is used

st

by taking the sliding average of 12

lt

short term values. The interval value can be changed as needed in PQ Log.

Formula for Plt Function

3

12

Pst

3

Plt

∑

==i

1

12

Flicker [%]

Inter val le ng th => 1 Pst

12 x interval le ngth => 1 flicker value Pl t

Figure 14. Measuring Flicker Values

Time

egb020.eps

35

Page 44

1745

Users Manual

Unbalance

The ratio of negative-to-positive-sequence harmonics is calculated with the

angles and magnitudes of the phase voltages taken into account. These values

are averaged over the interval length defined in PQ Log.

Frequency

The line power frequency is measured and averaged over 10 seconds and the

resulting values are divided into 42 classes for establishing statistics. Values

are also averaged over the interval length defined in PQ Log.

Current Logging

The maximum values of the currents (L1 or A, L2 or B, L3 or C and N) are

measured, and the interval value of the current is calculated using the mean

value over the RMS values of the interval defined in PQ Log.

Logging Function A

If a 3-phase current sensor is connected, the neutral current is calculated on a

sample basis from the phase currents. If a 3-phase+N sensor is detected, you

can select between logging and calculating the neutral current in PQ Log.

Ipeak

The peak values of the current (samples, not RMS values) are averaged in the

PQ Log software over the predefined measuring interval.

Note

Short peak values do not contribute much to the average value and so I

be higher than I

peak

.

max

can

Crest Factor (CF)

The crest factor (CF) of the currents (L1 or A, L2 or B, L3 or C, and N) is the

ratio of current peak value divided by current RMS value, and is averaged over

the interval length defined in PQ Log. For sinusoidal signals, CF = 1.41, and

for square waves, CF =1.00

36

Page 45

Power Quality Logger

Using the 1745 Power Quality Logger

Power

The power values (L1 or A, L2 or B, L3 or C and N) are averaged over the

interval length, and the maximum value of each is recorded.

The response time can be set to 1 second or 1 minute, and is independent of the

response time for voltage and current.

In logging function P, the active power, apparent power, and reactive power of

the phases and total power of all three phases is calculated.

Logging function A also calculates the distorting power D of the phases and

.

D

total

37

Page 46

1745

ϕ

Users Manual

Measurement Theory

The following are the equations used by the Logger and PQ Log to produce the

results you see in PQ Log. Measurement Function A logs current and voltage

harmonics, while Measurement Function P does not:

N

TRMS value of voltage

and current. Basic values

on 200 ms per phase

RMS value of voltage and

current per logging

interval per phase

1

=

V

N

I

1

N

N: Number of samples in 200 ms intervals (2048)

1

=

V

M

I

RMS

1

M

.

∑

⋅=

i

=

N

∑

i

.

⋅=

1

=

1

M

∑

=

j

M

∑

j

2

V

ibas

2

I

ibas

2

V

basjRMS

1

2

I

bas

j

=

1

M: Number of samples in 200 ms intervals per

logging interval

Active power calculated

from FFT from samples of

voltage and current. Basic

value on 200 ms per phase

Fundamental

V

In: RMS value of current harmonics of order n

n Order of the harmonics

φn : Phase angle between current and voltage

harmonics of order n

P

n

IVP

cos..=

nnnn

: RMS value of voltage harmonics of order n

n

: Harmonics of the active power of order n

50

=

PP

∑

nbas

=

1n

38

Page 47

Power Quality Logger

Measurement Theory

1 PPh

=

1

Active power of logging

interval per phase

bas

P

M

P

to 200 ms value

bas j

M: Number of 200 ms intervals per logging

intervals

M

1

⋅=

P

∑

bas

j

j

=

1

Total active power on all

three phases

Absolute value of the

active power per interval

per phase

Sum of the absolute

values of the active

power on all three phases

Apparent power based on

RMS values of voltage

and current. Basic values

on 200 ms per phase

Apparent power per

logging interval per phase

3

=

PP

∑

ktotal

=

1k

Pk: Active power of the phase

k: Phase (k = 1, 2, 3)

M

1

⋅=

M

∑

j

∑

1

M

IVS .=

=

1

P

basbetr

j

j

=

1

M

∑

j

=

1

basbasbas

S

bas

j

P

M

P

betr

total

1

S

⋅=

M

++=

PPP

basbasbas

321

S

: 200 ms value

bas j

M: Number of 200 ms intervals per logging

intervals

39

Page 48

1745

Users Manual

Total apparent power on

three phases

Distortion power. Basic

value on 200 ms per

phase

Distortion power per

interval per phase

Total distortion power on

three phases

Distortion power per

phase

3

=

SS

∑

ktotal

=

1K

k: Phase (k = 1, 2, 3)

222

QPSD −−=

basbasbasbas

M

1

⋅=

D

M

D

: 200 ms value

bas j

M: Number of 200 ms intervals per logging interval

=

PF ⋅==

D

∑

bas

j

=

3

∑

=

1k

λ

j

1

DD

P

S

ktotal

Q

Q

Total distortion power on

three phases

Tangent φ per phase

Total tangent φ on three

phases

Active power of the

fundamental per phase

Basic value for 200 ms

40

PF ⋅==

ϕ

tan

=

ϕ

tan

total

1 PPh

bas

λ

P

totaltotal

S

total

total

Q

Q

total

total

Q

P

Q

total

=

P

total

=

1

Page 49

Power Quality Logger

Measurement Theory

M

M

1

⋅=

Ph

1

∑

j

basbas

=

1

j

Active power of the

fundamental per phase

per interval

Ph

1

Total active power of the

fundamental for three

phases

Apparent power of the

fundamental per phase.

Basic value for 200 ms.

Apparent power of the

fundamental per phase

per interval

Power factor of the

fundamental per phase

Total power factor on all

three phases

Active energy per phase

and total

Sign of PF, tan φ, cos φ:

3

⋅=

=

bas

1

Sh

1

⋅=

M

Ph

ϕ

cos

1

=

ϕ

cos

total

1

Active power accumulated on each logging

interval

∑

k

.1 IVSh

M

∑

j

Sh

11

PhPh

ktotal

=

1

11

=

1

1

Sh

total

1

1

bas

j

1

Qh

⋅=

1

Qh

Ph

1

total

ShShSh

111

++

321

Qh

1

total

⋅

Qh

1

total

Sign “+” : Q positive (“inductive”)

Sign “-“ : Q negative (“capacitive”) independent of the sign of active power P

41

Page 50

1745

Users Manual

Maintenance

WCaution

Maintenenca work on the done only by trained and

qualified personnel at a company approved service center

within the warranty period. For locations of Fluke Service

Centers worldwide and contact information, see the Fluke

website.

With the proper use, the Logger does not require special maintenance other

than periodic calibration at a Fluke calibration center.

If the Logger gets dirty, wipe it off carefully with a damp cloth without

cleaning agents.

Lithium Battery

The 1745 Logger contains a vanadium pentoxide lithium rechargeable battery

and a sealed gel-type, lead-acid battery. These batteries are automatically

recharged during normal operation. Neither one is user-servicable.

Disposal

If you discard the Logger, you must recycle it at an appropriate recycling

center as required by local regulations.

42

Page 51

Power Quality Logger

Technical Specifications

Technical Specifications

Logging Parameters – Overview

Table 7 shows an overview of the logging parameters.

Table 7. Logging Parameters - Overview

Measuring Function P A

Voltage: mean, min, max

values

Current: Mean, max-values z z

Neutral current N z z

Voltage events z z

Power: P, |P|, S, D, PF,

tangent

Power total P, |P|, S, D, PF,

tangent

Energy z z

Flicker: Pst, Plt z z

Voltage harmonics z

Current harmonics (L1 or A,

L2 or B, L3 or C, N,

up to 50

Interharmonics, ripple-control

signals

THDV (voltage) z z

th

order)

z z

z z

z z

z

z z

THDI (current) z z

CF (crest factor current) z z

Unbalance z z

Frequency z z

43

Page 52

1745

Users Manual

Maximum Number of Intervals for Logging Funtion P

The maximum recording period can be calculated by multiplying the interval

time defined in PQ Log with the maximum number of intervals in the

following table.

Version P, V+I A, V+I

Averaged periods > 24,000 > 10,000

General Information

Intrinsic uncertainty Valid for reference conditions, and guaranteed for

two years.

Quality system Developed, designed, and manufactured according to

DIN ISO 9001.

Recalibration interval Fluke recommends a recalibration interval of no

more than two years, depending on use.

Reference conditions 23 C ±2 K, 230 V ±10 %

50 Hz ± 0.1 Hz / 60 Hz ± 0.1 Hz

44

Phase sequence: L1 or A, L2 or B, L3 or C

Interval length: 10 minutes, 3-phase Wye

configuration.

Power supply: 88 to 265 V AC

Page 53

Power Quality Logger

Technical Specifications

Environmental Specifications

Working temperature

range

Operating temperature

range

Storage temperature range -20°C to +60°C

Reference temperature

range

Relative humidity 10 to 90 %, no condensation

Housing Robust, compact housing of CYCOLOY

Protection IP50 per EN 60529

Safety EN 61010-1 600 V CAT III, 300 V CAT IV

Type test voltage 5.2 kV AC, 50 Hz / 60 Hz, 5 s

-10°C to +55°C

0°C to +35°C

23°C ± 2 K

pollution degree 2, double insulation

EMC

Emission IEC/EN 61326-1, EN 55022

Immunity IEC/EN 61326-1

Power Supply

Functional range 88 to 660 V RMS AC absolute, 50 Hz / 60 Hz

Safety EN 61010-1 600 V CAT III, 300 V CAT IV,

pollution degree 2, double insulation

Fuse Power supply fuse can be replaced only in service

facility. Supply can be connected in parallel to

measuring inputs (up to 660 V RMS AC).

Power consumption 5 W

Memory capacity 8 MB Flash-EPROM

Intervals > 10000 intervals, > 70 days with 10 min intervals

Events > 13000

45

Page 54

1745

Users Manual

Memory model Linear or circular, user-selectable

Interface RS-232, 9600 to 115.000 Baud, automatic selection,

3-wire communication.

Dimensions 170 mm x 125 mm x 55 mm

Weight

Approx. 0.9 kg

Measurement

A/D converter 16 bit

Sampling frequency 10.24 kHz

Anti-aliasing filter FIR-Filter, fC = 4.9 kHz

Frequency response Uncertainty < 1 % of Vm for 40 Hz to 2500 Hz

Interval length 1, 3, 5, 10, or 30 seconds,

1, 5, 10, 15, or 60 minutes

Averaging time for

min/max values

½ , 1 line power period, 200 ms

1, 3, 5 s

Time base Resolution: 10 ms (at 50 Hz) deviation: 2 s/day at

23°C.

Input Voltage

Input range VI P-N: 69, 115, 230, or 480 V AC

Input range V

Max. overload voltage 1.2 V

Input range selection Automatically set by user-entered nominal voltage

P-P 120, 200, 400, or 830 V AC

I

I

value.

Connections P-P or P-N, 1- or 3-phase

Nominal voltage V

≤ 999 kV (using PTs and ratios)

N

Input resistance Approx. 820 ke per channel. Lx-N Single phase

(L1 or A, L2 or B, L3 or C connected): app. 300 ke

Intrinsic uncertainty 0.1 % of V

Voltage transformer Ratio : < 999 kV / V

I

I

Ratio selection Optional: user-selectable

46

Page 55

Power Quality Logger

Technical Specifications

Current Input with Flexi Set

Input ranges II L1 or A, L2

or B, L3 or C, N:

Measuring range 0.75 A to 3000 A AC

Intrinsic uncertainty < 2 % of I

Position influence Max. ±2 % of m.v. for distance conductor to

Stray field influence <± 2 A for Iext= 500 A AC and distance to

Temperature coeff < 0.005 % / K

Current transformer Ratio : ≤ 999 kA / I

Ratio selection Optional: user-selectable

Connection Power type selectable in PQ Log

15, 150, 1500, or 3000 A AC

I

measuring head >30 mm

measuring head >200 mm

I

Current Input for Clamp

Input signal: 0.5 V AC nominal (for II) 1.4 V peak

Intrinsic uncertainty < 0.3 % of II

Max. overload 10 V AC

Input resistance App. 8.2 ke

Current transformer Ratio : ≤ 999 kA / ≤ II

Ratio selection By job programming

47

Page 56

1745

Users Manual

General Specifications

RMS Logging Slow Voltage Variations

Logging values: Mean value RMS values averaged over interval length

Min, Max values Averaging with selectable averaging time from

half-cycle to 5 s

Max value Max. 10 ms RMS value per interval

Min value: Min. 10 ms RMS value per interval

Current Logging Values

Mean value RMS values averaged over interval length

Max value Highest RMS value per interval

Events Dips, Swells, Interruptions

Limit value Variable

Lower limit: 0 to 95 % V

Upper limit: 105 to 120 % VN

Set in PQ Log

Range 0 to VI + 20 %

Logging value Half-cycle RMS value

Operating uncertainty < 2 % of V

Response time ½ line power period

I

N,

Flicker

Logging value Flicker severity (Plt / Pst) according to

IEC 61000-4-15

Intrinsic uncertainty P

Measuring range Pst 0.4 to 4

48

< 5 % of measured value

st

Page 57

Power Quality Logger

Technical Specifications

Power P, S, |P|

Active power P As per EN 61036, class 2

Distorting power D As per EN 61268, class 2 (A-version only)

Max value Highest value per interval

Min value Smallest value per interval

Phase uncertainty < 0.3 degrees

Conditions Conductor centered within clamp jaws or

Flexi Set.

Harmonics (Logging Function A Only)

Vm, Im, THDV, THDI per IEC/EN 61000-4-7, class B

Voltage harmonics (function A)

intrinsic uncertainty:

Current harmonics (function A)

Intrinsic uncertaintyi

THD V (function A) intrinsic

uncertainty at V

THD V (function P) intrinsic

uncertainty at VN

THD I (functions A, P) intrinsic

uncertainty at II

N

For Vm < 3 % VN: < 0.15 % VN

For Vm ≥ 3 % VN: < 5 % Vm

For Im < 10 % IN: < 0.5 % IN

For Im ≥ 10 % IN: < 5 % Im

For THD V < 3 %: < 0.15 %

For THD V ≥ 3 %: < 5 %

For THD V < 3 %: < 1 %

For THD ≥3 %: < 5 %

For THD I < 3 %: < 2 %

For THD I ≥ 3 %: < 5 %

Statistics

Frequency 42 classes for 10 s mean values

Ripple-control signals.

Interharmonics 21 classes for 3 s mean values.

Analysis of logging data

Programming and analysis is done by PQ Log software on PC.

49

Page 58

1745

Users Manual

Logging Function Parameters

Logging Values

Voltage L1 or A, L2 or B, L3 or C: phase-phase or phase-neutral:

• Voltage (mean, max, min values)

• Voltage harmonics 1

• THDV (harmonic contents of voltage)

• Interharmonics 5 to 2500 Hz (in steps of 0.5 Hz) (Logging Function A

only)

• Flicker P

st,Plt

• Unbalance

• Signaling voltages

• Frequency

• Voltage events (dips, swells, interruptions)

Current L1 or A, L2 or B, L3 or C, and N:

• Current (mean, max values)

• Harmonics of phase and neutral currents up to 50

Function A only)

st

to 50th order (Logging Function A only)

th

order (Logging

• Crest factor and peak values of the currents

Power:

• Active power P (mean, min, and max values)

• Absolute values active power |P| (mean, min, and max values)

• Distorting power D (mean, min, and max values)

• Apparent power S (mean, min, and max values)

• Power Factor PF, tangent

• Energy per averaging interval

Total power:

• Total power P, |P|, D, S

• 3-wattmeter method

• 2-wattmeter method (Aron circuitry)

• 2 ½ wattmeter method

50

Page 59

Power Quality Logger

Technical Specifications

Applications

Power quality:

• Voltage quality analysis according to EN 50160 over a 1-week period

(time-activated job)

• Examination of measurement quantities per standards

Disturbance analysis:

• Long-term analysis of line power voltage

• Examination of voltage dips, swells, and harmonic problems

(Logging Function A only)

• Flicker measurement

• Examination of ripple control signals (level) (Logging Function A

only)

• Specific search for disturbances through correlation of relevant

logging quantities (e.g. current, voltage, and flicker), time of

occurrence, periodicity

Network Optimization:

• Load logging

• Current logging (with Flexi Set 5 to 3000 A or clamps 1 to 1000 A)

• Capture of current peaks

51

Page 60

1745

Users Manual

PQ Log PC Application Software

PQ Log for PCs is the application for use with the 1745 Power Quality

Logger. The data are also available in ASCII format.

Programs available for setting up the Logger:

• Averaging period length

• Memory model

• Nominal voltage

• Response time for min, max values

• Power type (wye, delta, etc.)

• Thresholds for event detection, interruptions

Setup:

• Internal clock (date/time)

• Assign 1745 Power Quality Logger instrument name

• Parameters for data export

• Software updates

Analysis:

• ASCII data export

• Graphical summary of all EN50160 parameters

• Live reading viewing

52

Page 61

Power Quality Logger

PQ Log PC Application Software

Live Reading (Online Test)

Figure 15 shows a typical display of online test:

Figure 15. Live Reading (Online Test)

egb024.bmp

53

Page 62

1745

Users Manual

ASCII Export

Figure 16 shows a typical display of ASCII export.

Figure 16. ASCII Export

egb025.bmp

For special cases, additional evaluations are available:

• Graphic representation of measured data

• Timeplot diagrams

• Application oriented analysis

• Logging value list

• Table of events (UNIPEDE DISDIP)

• Table summary

• Cumulative frequency, harmonics (Logging Function A only)

• Statistical values

• All exceeding table

• Most critical values

54

Page 63

Power Quality Logger

PQ Log PC Application Software

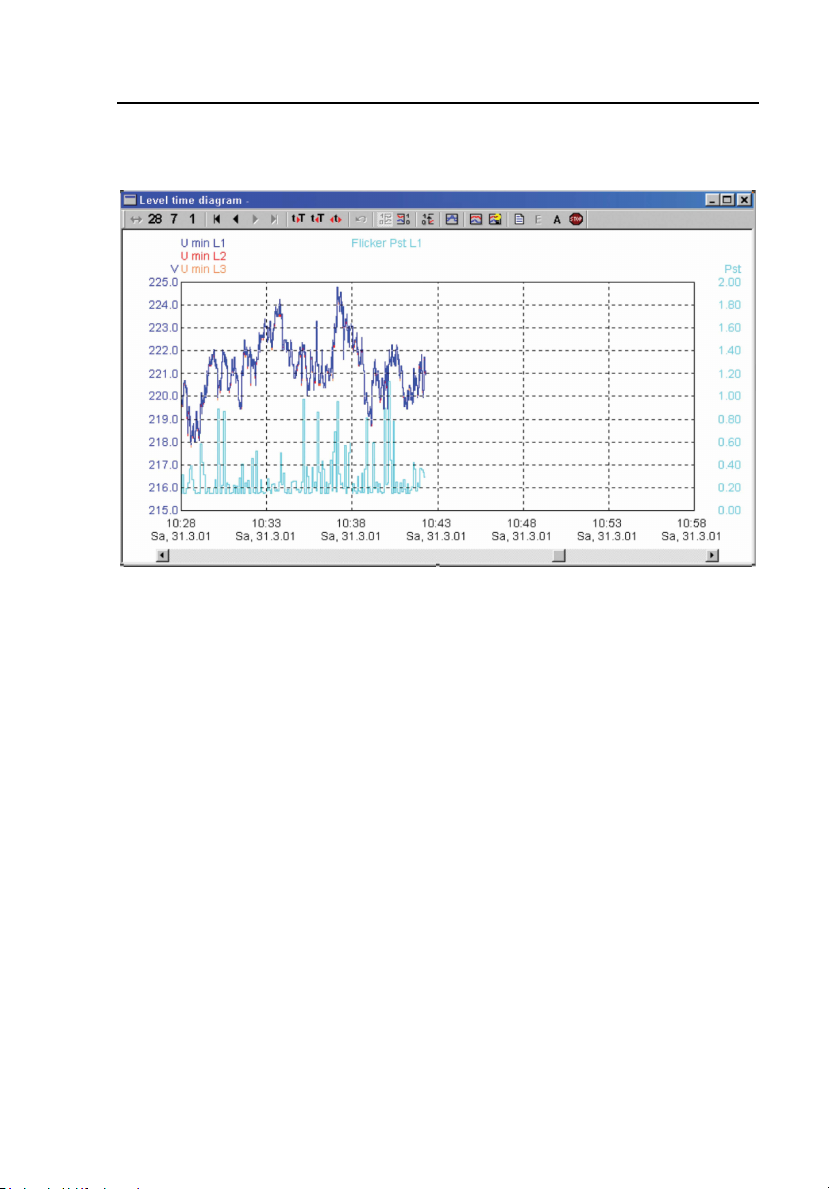

Timeplot Diagram

Figure 17 shows a typical display of Timeplot diagram:

Figure 17. Timeplot Diagram

egb026.bmp

55

Page 64

1745

Users Manual

UNIPEDE DISDIP Table

Figure 18 shows a typical display of UNIPEDE DISDIP table:

Figure 18. UNIPEDE DISDIP Table

Cumulative Frequency – Harmonics

egb027.bmp

Figure 19 shows a typical display of cumulative frequencies for current and

voltage harmonics:

egb028.bmp

Figure 19. Cumulative Frequency - For Voltage and Current Harmonics

56

Page 65

Index

—A—

Anti aliasing filter, 27

Apparent Power, 37

—C—

Completing the Logging, 24

Connecting the clip on probes, 15

Connection modes, 26

Connections for Medium Voltage

Networks, 22

Crest Factor, 36

Current, 36

Current Harmonics, 32

—D—

Disposal, 42

—E—

Evaluation, 25

Extreme values, 29

—F—

Flicker, 35

Frequency, 36

—I—

Installation at the measuring site, 18

Interharmonics, 12

Interval length, 12

Ipeak, 36

—L—

Limit values for events, 12

Lithium Battery, 42

Logging Configurations, 11

Logging input for voltages, 10

Logging segments, 12

—M—

Maximum nominal voltages, 6, 17

Methods of Logging, 25

—N—

Nominal Voltage, 26

—P—

Power factor, 37

Program a logging job, 13

—R—

Reactive Power, 37

—S—

Sampling rate, 27

signaling voltages, 12

Signaling voltages, interharmonics, 32

—T—

THD I, 34

THD V, 33

—U—

Unbalance, 36

User Interface, 1

—V—

Voltage dips/swells, 31

Voltage Harmonics, 31

Voltage interruptions, 30

Voltage variations, 28

57

Page 66

1745

Users Manual

58

Loading...

Loading...