Page 1

ESA612

Electrical Safety Analyzer

Users Manual

FBC-0031

March 2009, Rev. 2, 3/13

© 2009, 2013 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and workmanship for one year from the date of

original purchase OR two years if at the end of your first year you send the instrument to a Fluke Biomedical service center

for calibration. You will be charged our customary fee for such calibration. During the warranty period, we will repair or at our

option replace, at no charge, a product that proves to be defective, provided you return the product, shipping prepaid, to

Fluke Biomedical. This warranty covers the original purchaser only and is not transferable. The warranty does not apply if the

product has been damaged by accident or misuse or has been serviced or modified by anyone other than an authorized

Fluke Biomedical service facility. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE

EXPRESSED OR IMPLIED. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

This warranty covers only serialized products and their accessory items that bear a distinct serial number tag. Recalibration

of instruments is not covered under the warranty.

This warranty gives you specific legal rights and you may also have other rights that vary in different jurisdictions. Since

some jurisdictions do not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages,

this limitation of liability may not apply to you. If any provision of this warranty is held invalid or unenforceable by a court or

other decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

7/07

Page 3

Notices

All Rights Reserved

Copyright 2008 2013, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system,

or translated into any language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in service

training programs and other technical publications. If you would like other reproductions or distributions, submit a written request to Fluke

Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage is found, stop unpacking

the instrument. Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no special unpacking

instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such as bent or

broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techservices@flukebiomedical.com or call 1-800- 648-7952 or 1-425446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing materials in

their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical condition but does not

operate within specifications, or if there are any other problems not caused by shipping damage, please contact Fluke Biomedical or your local

sales representative.

Page 4

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items bearing a distinct serial number tag) are

eligible for partial refund and/or credit. Nonserialized parts and accessory items (e.g., cables, carrying cases, auxiliary modules, etc.)

are not eligible for return or refund . Only products returned within 90 days from the date of original purchase are eligible for refund/credit. In

order to receive a partial refund/credit of a product purchase price on a serialized product, the product must not have been damaged by the

customer or by the carrier chosen by the customer to return the goods, and the product must be returned complete (meaning with all manuals,

cables, accessories, etc.) and in “as new” and resalable condition. Products not returned within 90 days of purchase, or products which are not

in “as new” and resalable condition, are not eligible for credit return and will be returned to the customer. The Return Procedure (see below)

must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15 %. Products returned in excess

of 30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20 %. Additional charges for damage and/or

missing parts and accessories will be applied to all returns.

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our factory location. When you return an

instrument to Fluke Biomedical, we recommend using United Parcel Service, Federal Express, or Air Parcel Post. We also recommend that

you insure your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost shipments or instruments that are

received in damaged condition due to improper packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for repackaging:

Use a double–walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent material around the instrument.

Page 5

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our Order

Entry Group at 1-800-648-7952 or 1-425-446-6945.

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service or

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-99 FLUKE (1-888-993-5853)

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when it was

shipped from the factory. Calibration measurements are traceable to the National Institute of Standards and Technology (NIST). Devices for

which there are no NIST calibration standards are measured against in-house performance standards using accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or improper

operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Page 6

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes made to the

information in this document will be incorporated in new editions of the publication. No responsibility is assumed by Fluke Biomedical

for the use or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its affiliated dealers.

Manufacturing Location

The ESA612 Electrical Safety Analyzer is manufactured at Fluke Biomedical, 6920 Seaway Blvd., Everett, WA, U.S.A.

Page 7

Table of Contents

Title Page

Introduction .................................................................................................................... 1

Safety Information .......................................................................................................... 3

Intended Use .................................................................................................................. 4

Unpacking the Analyzer ................................................................................................. 5

Instrument Familiarization .............................................................................................. 6

How to Hold the Product ................................................................................................ 10

Connecting to Line Power .............................................................................................. 10

Connecting a DUT to the Analyzer ................................................................................. 11

Turning the Analyzer On ................................................................................................ 11

Accessing the Analyzer’s Functions ............................................................................... 13

Setting Up the Analyzer .................................................................................................. 14

Setting Polarity Switching Delay ................................................................................ 14

Setting the Display Contrast ...................................................................................... 15

Setting up the Beeper ................................................................................................ 15

Viewing Instrument Information ................................................................................. 15

i

Page 8

ESA612

Users Manual

Viewing Memory ....................................................................................................... 16

Setting the GFCI Limit ............................................................................................... 16

Performing Electrical Safety Tests ................................................................................. 16

Setting the Test Standard ......................................................................................... 16

Performing Mains Voltage Testing ............................................................................ 17

Performing a Ground Wire (Protective Earth) Resistance Test ................................. 17

Performing an Insulation Resistance Test ................................................................ 23

Performing a Current Consumption Test .................................................................. 29

Performing Leakage Current Tests ........................................................................... 29

Measuring Earth Leakage Current ....................................................................... 30

Performing a Chassis (Enclosure) Leakage Test ................................................. 33

Performing a Lead-to-Ground (Patient) Leakage Test ......................................... 35

Performing Lead-to-Lead (Patient Auxiliary) Leakage Tests ................................ 37

Performing a Lead Isolation (Mains on Applied Part) Leakage Test ......................... 40

Performing an Alternative Equipment Leakage Test ................................................. 43

Performing an Alternative Applied Part Leakage Test .............................................. 44

Performing a Direct Equipment Leakage Test .......................................................... 46

Performing a Direct Applied Part Leakage Test ........................................................ 49

Performing a Differential Leakage Current Test ........................................................ 52

Using the 1-to-10 Adapter .............................................................................................. 54

Making Point-To-Point Measurements ........................................................................... 58

Measuring Voltage .................................................................................................... 58

Measuring Resistance .............................................................................................. 58

Measuring Current .................................................................................................... 59

Simulating ECG Waveforms .......................................................................................... 59

Using Memory ............................................................................................................... 62

Storing Data into Memory ......................................................................................... 62

Viewing Memory Data ............................................................................................... 63

Deleting Data from Memory ...................................................................................... 64

ii

Page 9

Contents (continued)

Controlling the Analyzer Remotely ................................................................................. 64

Maintenance ................................................................................................................... 65

Testing and Replacing the Fuses ................................................................................... 65

Cleaning the Analyzer .................................................................................................... 67

Replaceable Parts .......................................................................................................... 68

Accessories .................................................................................................................... 70

Specifications ................................................................................................................. 71

Detailed Specifications ................................................................................................... 72

iii

Page 10

ESA612

Users Manual

iv

Page 11

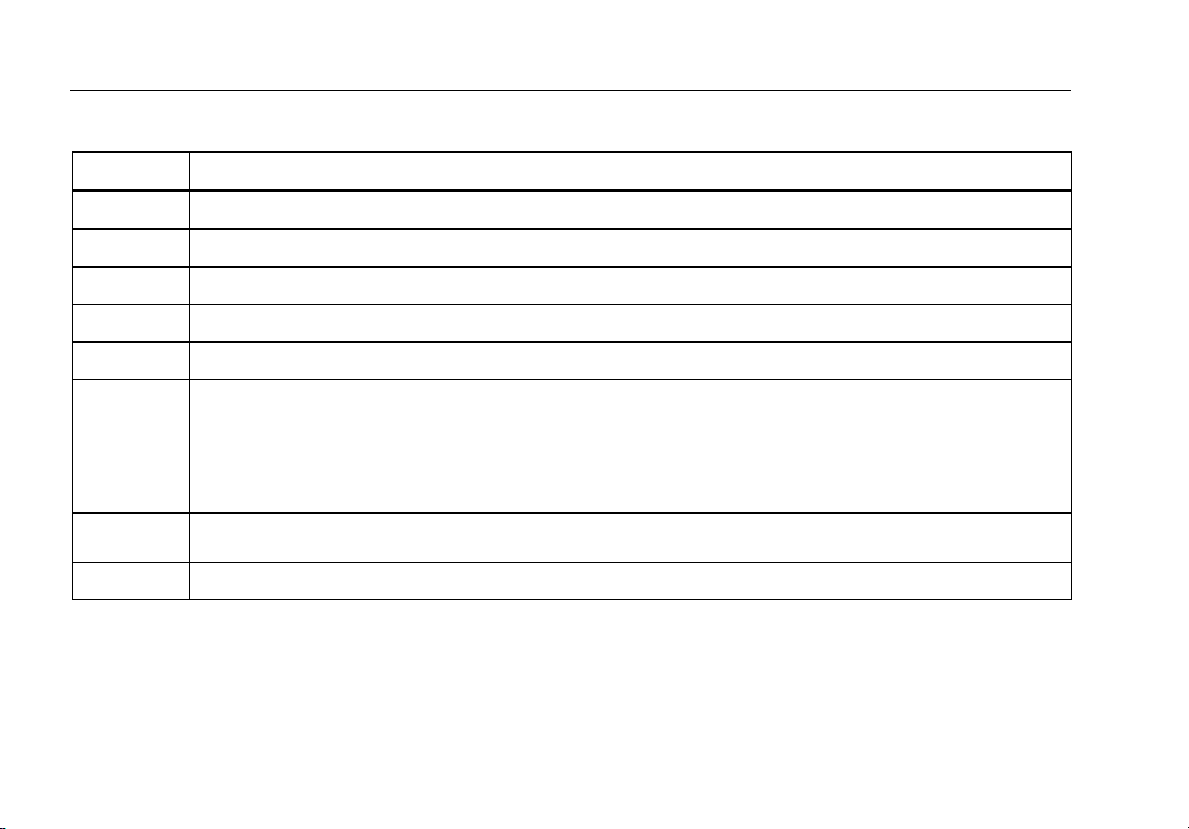

List of Tables

Table Title Page

1. Symbols ................................................................................................................................. 2

2. Top-Panel Controls and Connections .................................................................................... 6

3. Side and Top-Panel Connections .......................................................................................... 9

4. Schematic Abbreviations ....................................................................................................... 21

5. Test Names Based on Selected Standard ............................................................................. 29

6. Replaceable Parts ................................................................................................................. 68

7. Accessories ........................................................................................................................... 70

v

Page 12

ESA612

Users Manual

vi

Page 13

List of Figures

Figure Title Page

1. Front-Panel Controls and Connections ................................................................................. 6

2. Side and Top-Panel Connections .......................................................................................... 8

3. Product Handle ...................................................................................................................... 10

4. Analyzer Ready for Operation ............................................................................................... 11

5. DUT Connections to the Analyzer ......................................................................................... 12

6. Leakage Current Menu .......................................................................................................... 13

7. Setup Menu ........................................................................................................................... 14

8. Mains Voltage Test Menu ...................................................................................................... 17

9. DUT Ground Resistance Measurement................................................................................. 18

10. Ground Wire (Protective Earth) Resistance Measurement Connections ............................... 20

11. Ground Wire (Protective Earth) Resistance Measurement Schematic .................................. 22

12. Insulation Resistance Measurement ..................................................................................... 23

13. Mains to Protective-Earth Insulation Resistance Test Schematic .......................................... 24

14. Applied Parts to Protective-Earth Insulation Test Schematic ................................................. 25

15. Mains to Applied Parts Insulation Test Schematic ................................................................. 26

vii

Page 14

ESA612

Users Manual

16. Mains to Non-Earth Accessible Conductive Points Schematic ............................................. 27

17. Applied Parts to Non-Earth Conductive Points Schematic .................................................... 28

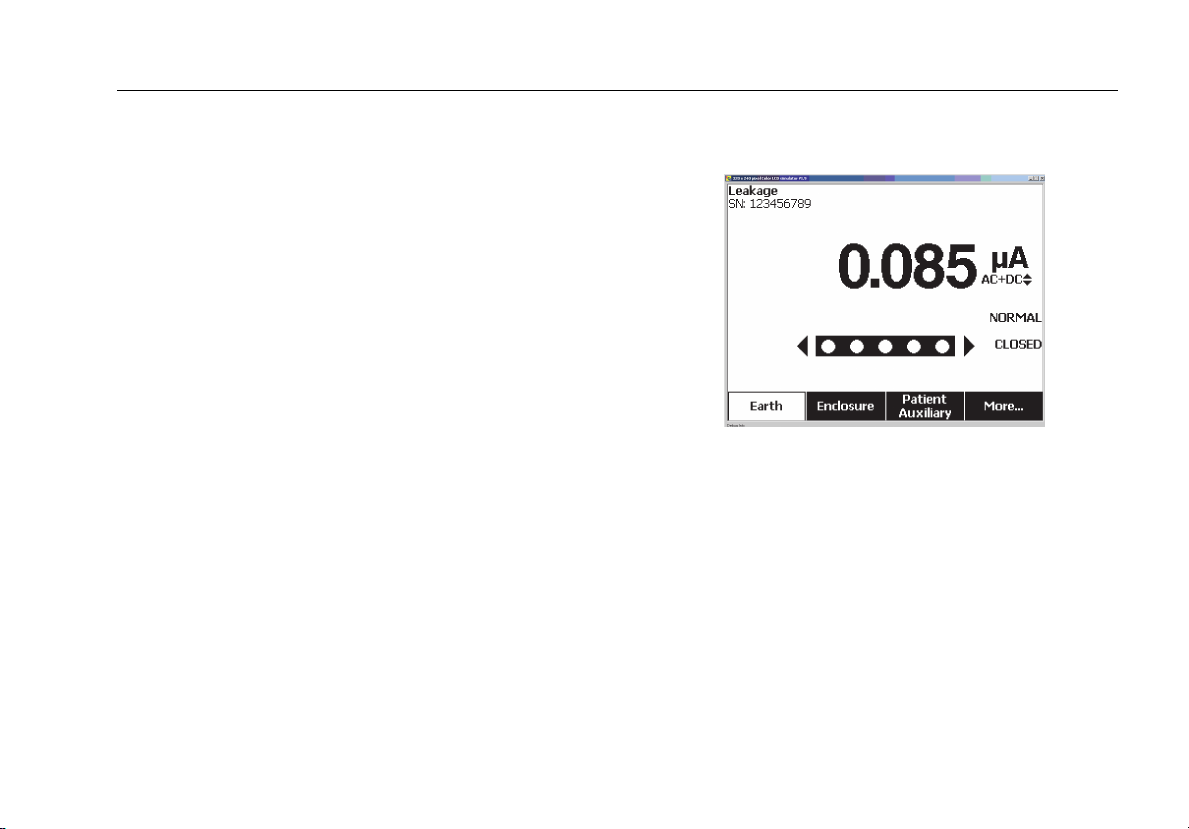

18. Leakage Current Main Menu ................................................................................................ 30

19. Earth Leakage Current Test Schematic ................................................................................ 32

20. Enclosure Leakage Current Test Schematic ......................................................................... 34

21. Lead-to-Ground (Patient) Leakage Current Test Schematic ................................................. 36

22. Applied Parts Connection Posts Display ............................................................................... 37

23. Lead-to-Lead (Patient Auxiliary) Leakage Current Test Schematic ...................................... 39

24. Lead Isolation (Mains On Applied Parts) Leakage Test Schematic ...................................... 42

25. Alternative Equipment Leakage Current Test Schematic ...................................................... 45

26. Alternative Applied Part Leakage Test Schematic ................................................................ 48

27. Direct Equipment Leakage Test Schematic .......................................................................... 50

28. Direct Applied Parts Leakage Current Test Schematic ......................................................... 51

29. Differential Leakage Current Test Schematic ....................................................................... 53

30. 1-to-10 Adapter Connections ................................................................................................ 55

31. ECG Lead Connection with 1-to-10 Adapter ......................................................................... 57

32. Point-To-Point Function Menu .............................................................................................. 58

33. ECG Waveform Simulation Menu ......................................................................................... 59

34. ECG Monitor Connections .................................................................................................... 61

35. Test Record ID Entry Screen ................................................................................................ 63

36. Fuse Access ......................................................................................................................... 66

viii

Page 15

Electrical Safety Analyzer

Introduction

The Fluke Biomedical ESA612 Electrical Safety Analyzer

(hereafter the Analyzer) is a full-featured, compact,

portable analyzer, designed to verify the electrical safety

of medical devices. The Analyzer tests to domestic

(ANSI/AAMI ES1, NFPA 99) and international (IEC62353,

AN/NZS 3551, and parts of IEC 60601-1) electrical-safety

standards. The integrated ANSI/AAMI ES1 and

IEC60601-1 patient loads are easily selectable.

The Analyzer performs the following tests:

• Line (Mains) voltage

• Ground Wire (or Protective Earth) Resistance

• Equipment current

• Insulation resistance

• Ground (Earth) leakage

• Chassis (Enclosure) leakage

• Lead to Ground (Patient) and Lead to Lead (Patient

Auxiliary) leakage

• Lead isolation (Mains on applied parts leakage)

• Differential leakage

• Direct equipment leakage

• Direct applied part leakage

• Alternative equipment leakage

• Alternative applied part patient leakage

• Point to point leakage, voltage, and resistance

• ECG simulation and performance waveforms

1

Page 16

ESA612

Users Manual

Table 1. Symbols

Symbol Description

Important information; refer to manual.

Hazardous voltage

Conforms to relevant Canadian and US standards

Conforms to relevant Australian EMC requirements

Conforms to European Union directives

This product complies with the WEEE Directive (2002/96/EC) marking requirements. The affixed label

indicates that you must not discard this electrical/electronic product in domestic household waste. Product

CAT II

2

Category: With reference to the equipment types in the WEEE Directive Annex I, this product is classed as

category 9 "Monitoring and Control Instrumentation" product. Do not dispose of this product as unsorted

municipal waste. Go to Fluke’s website for recycling information.

IEC Measurement Category II – CAT II equipment designed to protect against transients from energyconsuming equipment supplied from fixed installations.

Accessible Functional Earth Terminal

Page 17

Electrical Safety Analyzer

Safety Information

Safety Information

In this manual, a Warning identifies hazardous conditions

and actions that could cause bodily harm or death. A

Caution identifies conditions and actions that could

damage the Analyzer, the equipment under test, or cause

permanent loss of data.

Warning

To avoid possible electrical shock or

personal injury, follow these guidelines:

• Use this Analyzer only in the manner

specified by the manufacturer or the

protection provided may be impaired.

• Read the Users Manual before operating

the Analyzer.

• Do not connect the Analyzer to a patient or

equipment connected to a patient. The

Analyzer is intended for equipment

evaluation only and should never be used

in diagnostics, treatment or in any other

capacity where the Analyzer would come

in contact with a patient.

• Do not use the product in wet or damp

locations, around explosive gases or dust.

• Inspect the Analyzer before using it. Do

not use the Analyzer if abnormal

conditions of any sort are noted (such as a

faulty display, broken case, etc.)

• Inspect the test leads for damaged

insulation or exposed metal. Check test

lead continuity. Replace damaged leads

before using the Analyzer.

• When testing, always be sure to keep your

fingers behind the safety barriers on the

test leads.

• Never open the Analyzer's c ase.

Dangerous voltages are present. There are

no user replaceable parts in the Analyzer.

• Have the Analyzer serviced on l y by

qualified personnel.

3

Page 18

ESA612

Users Manual

• The Analyzer must be properly earthed.

Only use a supply socket that has a

protective earth contact. If there is any

doubt as to the effectiveness of the supply

socket earth, do not connect the Analyzer.

Do not use a two-conductor adapter or

extension cord; this will break the

protective ground connection.

• Do not use the 15-20 A adapter to power

devices rated in excess of 15 A. Doing so

may overload the installation.

• Use extreme caution when working with

voltages above 30 V.

• Use the proper terminals, functions and

ranges for the test being performed.

• Do not touch metal parts of the device

under test (DUT) during analysis. The DUT

should be considered an electrical shock

hazard when connected to the Analyzer as

some tests involve high voltages, high

currents, and/or the removal of DUT earth

bond.

Intended Use

The Product is an electronic signal source and

measurement device for verifying the electrical safety of

medical devices. The Product also provides ECG

simulation and performance waveforms to verify patient

monitors are performing within their operating

specifications.

The Product provides the following function categories:

• ECG Functions

• ECG-Performance Testing

4

Page 19

Electrical Safety Analyzer

Unpacking the Analyzer

The intended user is a trained biomedical equipment

technician who performs periodic preventative

maintenance checks on patient monitors in service. Users

can be associated with hospitals, clinics, original

equipment manufacturers and independent service

companies that repair and service medical equipment.

The end user is an individual, trained in medical

instrumentation technology.

This Product is intended to be used in the laboratory

environment, outside of the patient care area, and is not

intended for use on patients, or to test devices while

connected to patients. This Product is not intended to be

used to calibrate medical equipment. It is intended for

over-the-counter use.

Unpacking the Analyzer

Carefully unpack all items from the box and check that

you have the following items:

• ESA612

• Getting Started Manual

• Users Manual CD

• Carrying case

• Power cord

• 15 – 20 A Adapter (USA only)

• ESA USA Accessory Kit (USA, Australia, and Israel

only)

• ESA EUR Accessory Kit

• Ansur demo CD

• Null Post Adapter

• 5-to-5 Banana to ECG Adapter (BJ2ECG)

• Transfer cable

5

Page 20

ESA612

Users Manual

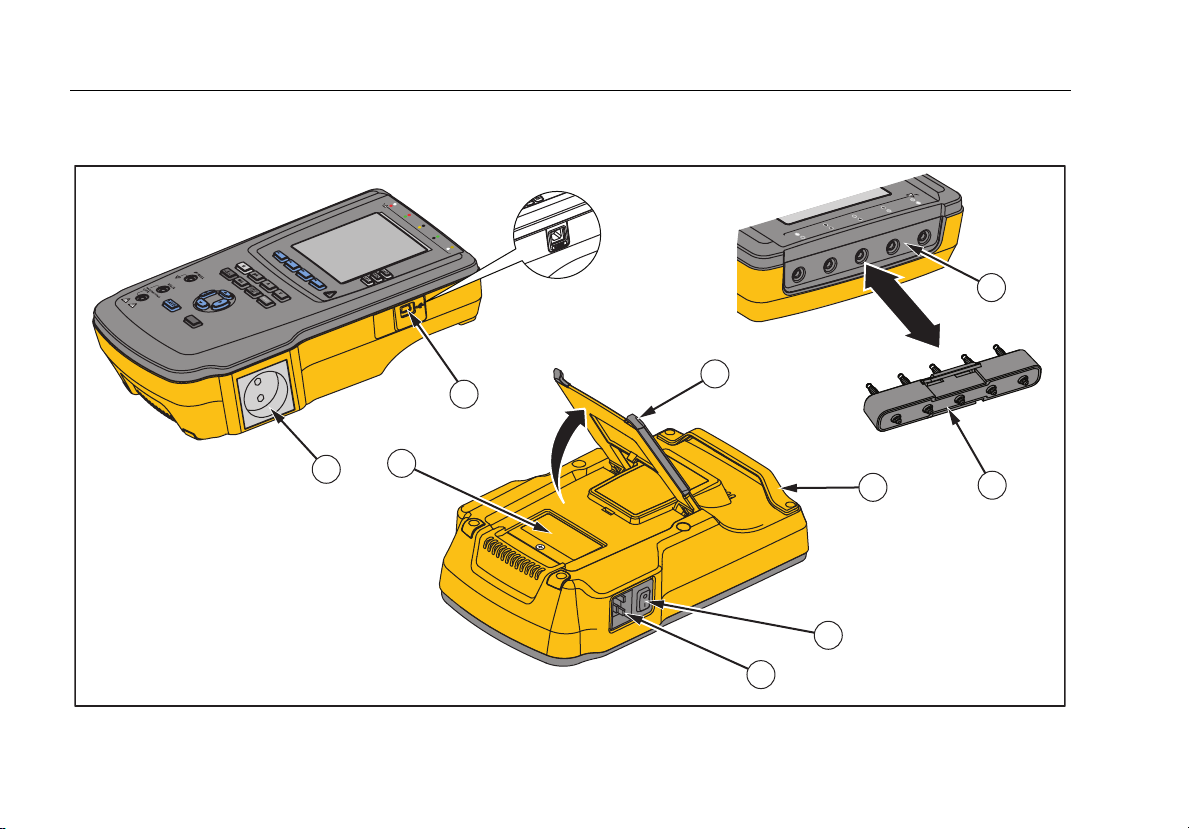

Instrument Familiarization

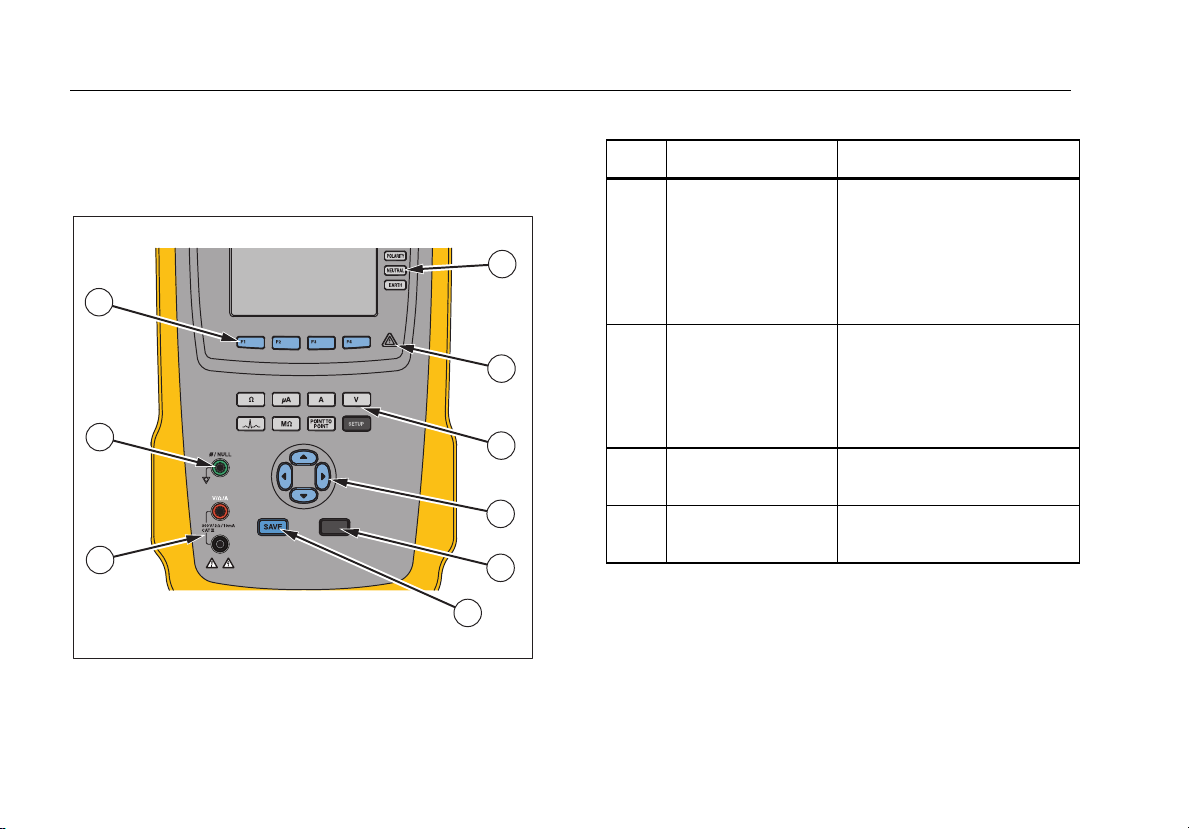

Figure 1 and Table 2 describes the front-panel controls

and connections of the Analyzer.

1

9

2

8

TEST

7

Figure 1. Front-Panel Controls and Connections

3

4

5

6

fis116.eps

Table 2. Top-Panel Controls and Connections

Item Name Description

Controls the configuration of

Equipment Outlet

Configuration

1

Buttons

the equipment outlet. Opens

and closes the neutral and

ground connection and

reverses the polarity of the

neutral and hot connection.

Indicates when high voltage

High Voltage

2

Indicator

is applied to the

ECG/Applied Parts posts or

L1 and L2 of the Test

Receptacle.

Test Function

3

Buttons

Navigation Buttons

4

Selects the various Analyzer

test functions.

Cursor control buttons for

navigating menus and lists.

6

Page 21

Electrical Safety Analyzer

Instrument Familiarization

Item Name Description

Test Button

5

Save Button

6

Input Jacks

7

Nulling Jack

8

Function Softkeys

9

Initiates selected tests.

Saves the measurement or

ECG waveform to memory.

Test lead connectors.

Connection for zeroing test

lead resistance.

Keys F1 through F4 are used

to select from a number of

selections that appear in the

LCD display above each

function softkey.

7

Page 22

ESA612

Users Manual

Figure 2 and Table 3 describe the side and top-panel connections of the Analyzer.

RA

RFLNC1

LL LA RL

V1

R

RA

FLN

LL LA RL

C1

V1

TEST

1

3

*Old versions have a B style connector for USB port.

Figure 2. Side and Top-Panel Connections

8

Old Version*

7

4

2

9

8

5

6

fis110.eps

Page 23

Electrical Safety Analyzer

Instrument Familiarization

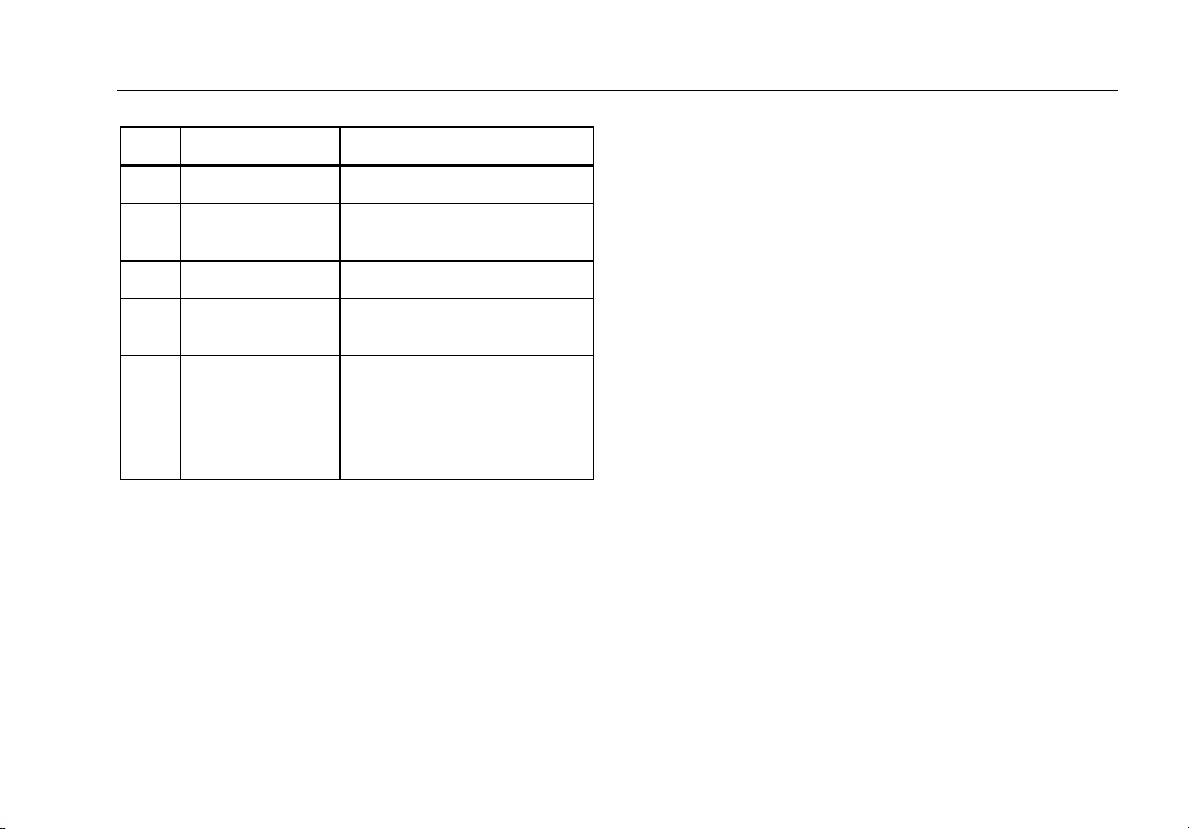

Table 3. Side and Top-Panel Connections

Item Name Description

1 Equipment Outlet

USB Device Port

2

(Mini B-style connector)1

3 Fuse Access Door Covers the equipment outlet fuses.

4 Tilt Stand Support for holding the Analyzer in a tilted position.

5 AC Power Switch Turns ac power on and off.

6 Power Input Connector

7 ECG/Applied Parts Jacks

8 Banana Jack to ECG Adapter Adapter for connecting ECG snap leads to the Analyzer.

9 Carry Handle

1 Older versions of the Analyzer have a B-style USB port connector.

Equipment outlet, specific to the version of the Analyzer, which provides a DUT

connection.

Digital connection for controlling the Analyzer from a PC or instrument

controller.

A grounded male three-prong (IEC 60320 C19) connector that accepts the

line-power cord.

Connection posts for Device Under Test (DUT) applied parts, such as ECG

leads. Used to test for leakage current through leads and to supply ECG

signals and performance waveforms to a DUT.

Handle to transport Analyzer. Note: There is no handle on old versions of the

analyzer.

9

Page 24

ESA612

Users Manual

How to Hold the Product

When you move the Analyzer, use the handle in the

bottom case to hold it. See Figure 3.

Note

There is no handle on old versions of the

Analyzer.

Figure 3. Product Handle

fis122.eps

Connecting to Line Power

Warning

To avoid shock hazard and for proper

Analyzer operation, connect the factory

supplied three-conductor line power cord to

a properly grounded power outlet. Do not

use a two-conductor adapter or extension

cord; this will break the protective ground

connection.

Connect the Analyzer to a properly grounded three-prong

outlet. The Analyzer will not properly test a DUT when the

ground lead is open.

The Analyzer is intended for use with single-phase,

grounded power. It is not intended for dual, split-phase or

three-phase power configurations. But it can be used with

any power system that supplies the correct voltages for

single-phase and is grounded, or is an isolated power

system.

10

Page 25

Electrical Safety Analyzer

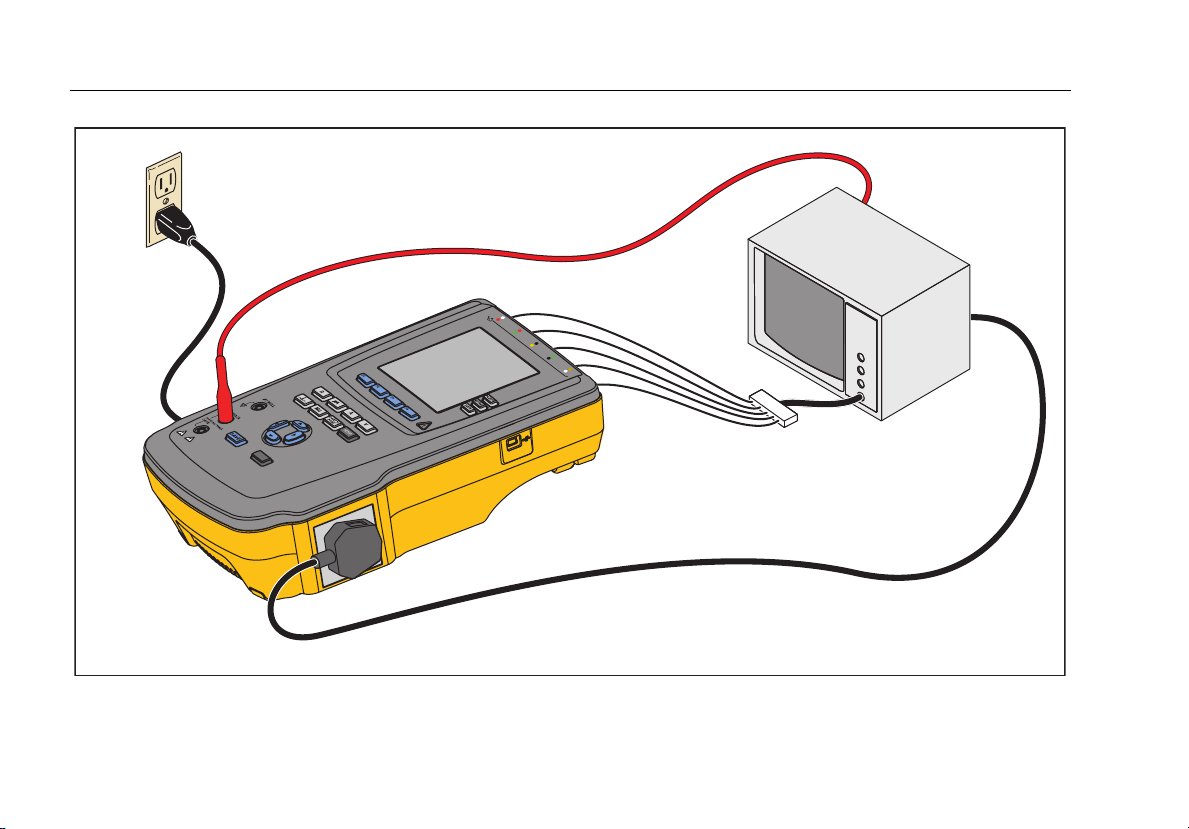

Connecting a DUT to the Analyzer

Connecting a DUT to the Analyzer

A Device Under Test (DUT) can be connected in a

number of different ways depending on the device and

the number of connections needed for a full electrical

safety test. Figure 5 shows a DUT connected to the test

receptacle, applied parts posts, and a separate

connection to the DUT’s enclosure or protective earth

ground.

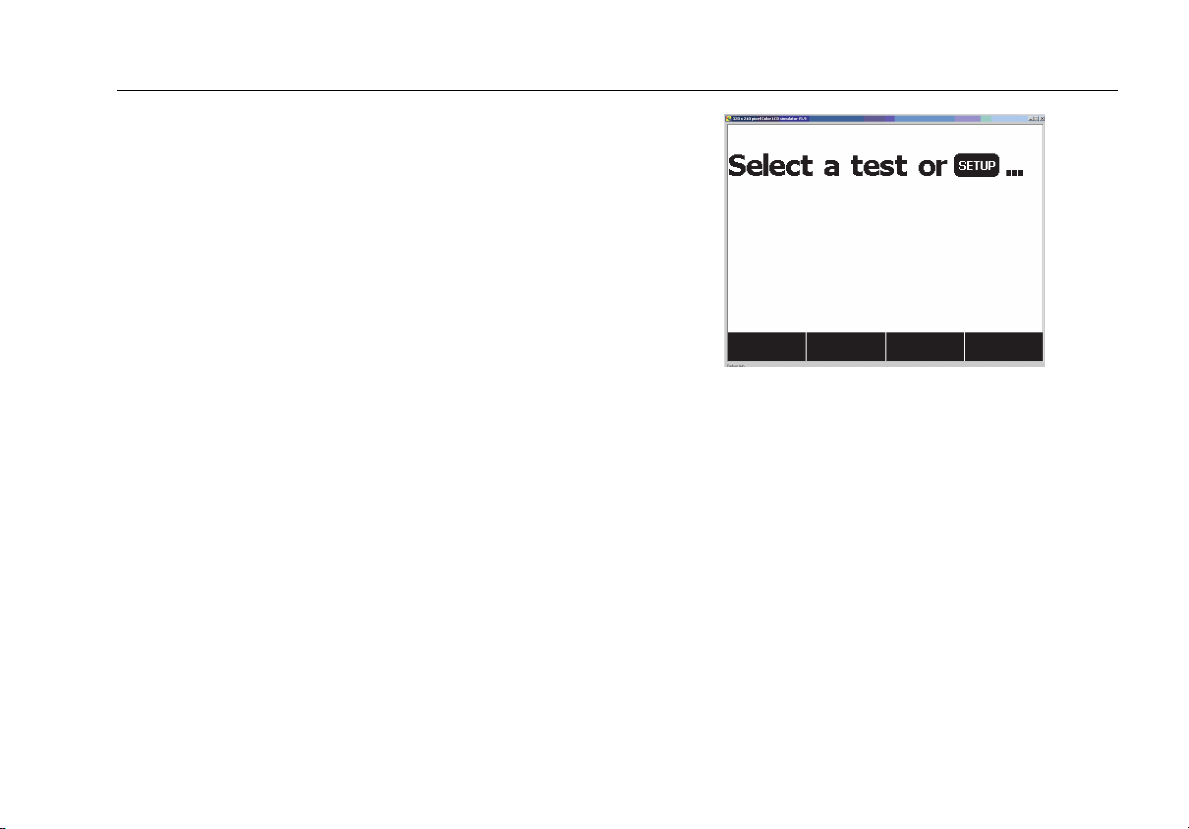

Turning the Analyzer On

Note

To ensure the high voltage indicator is working,

look for it to illuminate during the power-up self

test.

Press the power switch on the left-side panel so the “I”

side of the ac power switch is depressed. The Analyzer

will perform a series of self tests and then display the

message shown in Figure 4 when the self test has

completed successfully.

Figure 4. Analyzer Ready for Operation

fis101.jpg

11

Page 26

ESA612

Users Manual

Connect ESA612

to grounded

mains socket.

To protective earth or

any exposed conductive

surface on the enclosure

RA

R

LL

F

LA

L

RL

N

V1

C1

TEST

Connect the DUT ac power cord to the

equipment outlet on the Analyzer

12

Figure 5. DUT Connections to the Analyzer

fis113.eps

Page 27

Electrical Safety Analyzer

Accessing the Analyzer’s Functions

During the self-test, the Analyzer checks its ac mains

input for proper polarity, ground integrity and voltage

level. The high voltage indicator illuminates briefly during

the self test. If the polarity is reversed, the Analyzer

indicates this condition and allows the polarity to be

reversed internally. If the ground is open, the Analyzer

displays this fault. If the mains voltage is too high or too

low, the Analyzer displays this fault and does not continue

until the supply voltage is corrected and the Analyzer

power cycled off and then on again.

Accessing the Analyzer’s Functions

For each test and setup function, the Analyzer uses a

series of menus to access various Analyzer test and

setup variables. As shown in Figure 6, the Analyzer

indicates various leakage current tests along the bottom

of the display. An Exit selection is also indicated as a way

of backing out of the leakage current tests. Pressing a

softkey (F1 through F4) under a specific test will cause

the analyzer to setup for or perform the selected test.

In addition to the function softkeys, the Analyzer test

functions may require using the navigation buttons to

select parameters as well. In the example above, the

leakage selection has next to it. This icon indicates the

selection is controlled by pressing or . In this

example, the leakage current measurement is switched

between AC+DC, AC only, or DC only. The applied parts

indicator has on the left end and on the right end.

These icons indicate the use of and to select an

applied part.

fis102.jpg

Figure 6. Leakage Current Menu

The three buttons along the right side of the display

() control the wiring of the Analyzer’s

test receptacle for some electrical tests. The present state

of these three buttons is displayed along the right edge of

the display whenever these controls are active.

13

Page 28

ESA612

Users Manual

Figure 6 shows polarity is settable between normal,

reversed, and off. Neutral is also settable to closed or

open. Earth condition is not displayed, which indicates it

can not be changed. However, earth is internally opened

during this test.

Setting Up the Analyzer

There are a number of Analyzer parameters that are

adjusted through a setup function as well as the ability to

save a record by ID and date. To access the first Setup

menu shown in Figure 7, press .

fis114.bmp

Figure 7. Setup Menu

Note

See the Using Memory section later in this

manual for a description of how to enter a test

record ID.

The setup parameters have been grouped into six

categories: Instrument, Display, Sound, Instrument Info,

Calibration, and Diagnostics.

Setting Polarity Switching Delay

When switching the polarity of the Analyzer’s test

receptacle, a delay can be set to control the actual switch

time. To set the polarity delay:

1. From the setup menu, press the softkey labeled

More to reveal additional menu selections.

2. Press the softkey labeled Instrument to reveal the

instrument setup selections.

3. Press the softkey labeled Polarity Delay to open the

scroll box above the softkey label.

4. Press or to adjust the delay from 1 to 5

seconds in 1 second steps.

14

Page 29

Electrical Safety Analyzer

Setting Up the Analyzer

5. Press the softkey labeled Done to exit the switching

polarity delay setup function.

Setting the Display Contrast

There are two methods for setting the display contrast.

From the Select a Test…. menu or through the setup

menu.

Whenever the Analyzer displays its start-up menu (Select

a test…), pressing or will increase or decrease the

display’s contrast respectively. Press the softkey labeled

Done to exit contrast setup.

Another way to adjust the contrast is through the

Analyzer’s setup menu.

1. From the setup menu, press the softkey labeled

More twice to set F1 to the display contrast function.

2. Press the softkey labeled Display Contrast.

3. Press or to increase or decrease the display’s

contrast respectively.

4. Press the softkey labeled Done to exit contrast

setup.

Setting up the Beeper

To enable or disable the beeper:

1. From the setup menu, press the softkey labeled

More twice to set F2 to the beeper on/off function.

2. Press the softkey labeled Beeper to switch the

beeper on and off.

3. Press the softkey labeled Done to go back to the

setup menu.

Viewing Instrument Information

To view information about the Analyzer:

1. From the setup menu, press the softkey labeled

More twice to set F3 to the instrument information

function.

2. Press the softkey labeled Instrument Information.

3. After viewing the displayed information, press the

softkey labeled Done to exit the information screen.

15

Page 30

ESA612

Users Manual

Viewing Memory

Refer to the Using Memory section later in the manual to

learn about viewing memory and how to store data in the

Analyzer.

Setting the GFCI Limit

To set the GFCI current limit:

1. From the setup menu, press the softkey labeled

More to reveal additional menu selections.

2. Press the softkey labeled Instrument to reveal the

instrument setup selections.

3. Press the softkey labeled GFCI Limit to open the

scroll box above the softkey label.

4. Press or to adjust the current limit from 5 to

25 mA.

5. Press the softkey labeled Done to exit the GFCI Limit

setup function.

Performing Electrical Safety Tests

The Analyzer is designed to perform a number of different

electrical and performance tests on biomedical

equipment. The following sections describe the various

tests and how to perform them using the Analyzer.

Setting the Test Standard

The Analyzer is designed to perform electrical safety

testing based on a number of different safety standards:

AAMI ES1/NFPA99, IEC62353, IEC60601-1, and

AN/NZS 3551. AAMI is the Analyzer’s default standard.

To select another standard:

1. Press .

2. From the setup menu, press the softkey labeled

More to reveal additional menu selections.

3. Press the softkey labeled Instrument to reveal the

instrument setup selections.

4. Press the softkey labeled Standard to open the

scroll box above the softkey label.

5. Press or to scroll through the standard

selections.

16

Page 31

Electrical Safety Analyzer

Performing Electrical Safety Tests

6. When the desired standard is displayed, press the

softkey labeled Done.

Some electrical tests may not be applicable for a specific

standard. In these cases, the Analyzer’s menu will not

display the excluded test as a selection.

Performing Mains Voltage Testing

The Mains Voltage test measures the voltage on the

mains input through three separate measurements. To

access the Mains Voltage test, press . The Mains

Voltage test menu is shown in Figure 8.

fis104.jpg

Figure 8. Mains Voltage Test Menu

Press each function softkey to perform each of the three

measurements: Live to neutral, neutral to earth, and live

to earth.

Note

Power to the test receptacle is off during the

Mains Voltage test.

Performing a Ground Wire (Protective Earth) Resistance Test

The Ground Wire (Protective-Earth) Resistance test

measures the impedance between the Analyzer’s test

receptacle’s PE terminal and the exposed conductive

parts of the DUT that are connected to the DUT’s

Protective Earth.

Prior to conducting any leakage tests with the Analyzer, it

is best to test the integrity of the ground connection

between the Analyzer’s test receptacle ground and the

DUT’s Protective earth ground or enclosure with this test.

To access the Ground Wire (Protective Earth) ∅/Null

Resistance Test menu press .

Note

The DUT is powered off for this test.

17

Page 32

ESA612

Users Manual

To perform a ground wire resistance test:

1. Ensure the power cord from the DUT is plugged into

the Analyzer’s test receptacle.

2. Press to reveal the resistance function menu.

3. Connect one end of a test lead to the V/Ω/A jack as

shown in Figure 10.

4. If using an accessories probe, connect it to the other

end of the test lead and place the probe tip into the

∅/Null jack. If using an alligator clip accessory,

connect it to the other end of the test lead, place the

null post adapter in the ∅/Null jack, and clamp the

alligator clip to the null post adapter.

5. Connect the other end of the test lead to ∅/Null jack.

6. Press the softkey labeled Zero Leads. The Analyzer

zeroes out the measurement to cancel the test lead

resistance.

7. Connect the test lead coming from the ∅/Null jack to

the DUT enclosure or protective earth connection.

8. The measured resistance is displayed as shown in

Figure 9 after the DUT connection(s) is/are made.

fis105.jpg

Figure 9. DUT Ground Resistance Measurement

Warning

To avoid electric shock, remove the null post

adapter from the ∅/Null jack after a test lead

zero is performed. The ∅/Null jack becomes

potentially hazardous during some of the test

conditions.

18

Page 33

Electrical Safety Analyzer

Performing Electrical Safety Tests

A low resistance reading is required to confirm a good

ground connection through the power cord. Refer to the

appropriate electrical safety standard for the specific limit

value to be followed.

Figure 10 shows the electrical connections between the

Analyzer and the DUT. Table 4 lists the abbreviations

used in the schematics and their descriptions.

19

Page 34

ESA612

Users Manual

To protective earth or any exposed

conductive surface on the enclosure

RA

RF

LL

LA

L

RL

NC1

V1

TEST

Connect the DUT ac power cord to the

equipment outlet on the Analyzer

Figure 10. Ground Wire (Protective Earth) Resistance Measurement Connections

fis112.eps

20

Page 35

Electrical Safety Analyzer

Performing Electrical Safety Tests

Table 4. Schematic Abbreviations

Abbreviation Meaning

MD Measuring Device (ESA612 Analyzer)

FE Functional Earth

PE Protective Earth

Mains Mains Voltage Supply

L1 Live Conductor

L2 Neutral Conductor

DUT Device Under Test

DUT_L1 Device Under Test Live conductor

DUT_L2 Device Under Test neutral conductor

DUT_PE Device Under Test protective earth

REV POL Reversed mains supply polarity

LEAD GND Lead to ground, used in Patient leakage test

MAP Mains on Applied Part

MAP REV Reverse mains on applied part source voltage

PE Open Open protective earth

Test Voltage

21

Page 36

ESA612

Users Manual

DUT_L1

DUT_L2

DUT_PE

MD

DEVICE UNDER TEST

APPLIED

PART

FE

CONDUCTIVE PART

TEST LEAD

Figure 11. Ground Wire (Protective Earth) Resistance Measurement Schematic

faw26.eps

22

Page 37

Electrical Safety Analyzer

Performing Electrical Safety Tests

Performing an Insulation Resistance Test

The five insulation resistance tests take measurements on

mains (L1 & L2) to Protective earth, applied parts to

Protective earth, mains to applied parts, mains to nonearthed accessible conductive points, and applied parts to

non-earthed accessible conductive points.

To access the Insulation Resistance Test menu,

press .

All Insulation Resistance Tests can be performed using

500 or 250 volts dc. To change the test voltage from the

Insulation Resistance Test menu, press the softkey

labeled More. Pressing the softkey labeled Change

Voltage will cause the test voltage to toggle between 250

and 500 volts dc.

Note

Exiting and re-entering the Insulation Resistance

Test menu causes the test voltage to return to its

default value of 500 volts dc.

As shown in Figure 12, three of the five tests are shown

over function soft keys F1 through F3. To access the other

two tests or test voltage selection, press the softkey

labeled More. The softkey labeled Back will move the

menu back up to the top-level insulation resistance test

menu.

Figure 12. Insulation Resistance Measurement

After selecting one of the tests by pressing the appropriate

softkey, press to apply the selected voltage to the

DUT and take the resistance measurement.

Figures 13 through 17 shows the electrical connections

between the Analyzer and DUT for the five insulation

resistance tests.

Note

The DUT is powered off for this test.

fis106.jpg

23

Page 38

ESA612

Users Manual

DEVICE UNDER TEST

APPLIED

PART

FE

CONDUCTIVE PART

MD

DUT_L1

DUT_L2

DUT_PE

Figure 13. Mains to Protective-Earth Insulation Resistance Test Schematic

faw17.eps

24

Page 39

Electrical Safety Analyzer

Performing Electrical Safety Tests

DUT_L1

DUT_L2

DUT_PE

MD

DEVICE UNDER TEST

APPLIED

PART

FE

CONDUCTIVE PART

Figure 14. Applied Parts to Protective-Earth Insulation Test Schematic

faw18.eps

25

Page 40

ESA612

Users Manual

MD

DUT_L1

DUT_L2

DUT_PE

DEVICE UNDER TEST

APPLIED

PART

FE

CONDUCTIVE PART

Figure 15. Mains to Applied Parts Insulation Test Schematic

faw19.eps

26

Page 41

Electrical Safety Analyzer

Performing Electrical Safety Tests

DUT_L1

DUT_L2

MD

DUT_PE

DEVICE UNDER TEST

APPLIED

PART

FE

CONDUCTIVE PART

TEST

LEAD

Figure 16. Mains to Non-Earth Accessible Conductive Points Schematic

faw20.eps

27

Page 42

ESA612

Users Manual

DUT_L1

DUT_L2

DUT_PE

DEVICE UNDER TEST

APPLIED

PART

CONDUCTIVE PART

TEST

LEAD

MD

FE

faw21.eps

Figure 17. Applied Parts to Non-Earth Conductive Points Schematic

28

Page 43

Electrical Safety Analyzer

Performing Electrical Safety Tests

Performing a Current Consumption Test

To measure the current consumed by the DUT, press

. The Analyzer displays the current flowing through

the mains connections of the test receptacle.

Performing Leakage Current Tests

The Analyzer measures leakage current for a number of

different DUT configurations. In addition to the leakage

found on the enclosure and the earth connection, the

Analyzer can measure leakage on each connected applied

part and combinations of connected applied parts.

Table 5. Test Names Based on Selected Standard

IEC60601 AAMI/NFPA 99

Protective Earth Resistance Ground Wire Resistance

Earth Leakage Current Ground Wire Leakage Current

Touch or Enclosure Leakage Current Chassis Leakage Current

Patient Leakage Current Lead to Ground Leakage Current

Patient Auxiliary Leakage Current Lead to Lead Leakage Current

Mains on Applied Part (MAP) Leakage Current Isolation Leakage Current

Which leakage tests are available depends on which

standard is selected. See the Selecting the Test Standard

section earlier in this manual to change the standard the

Analyzer is using.

Table 5 lists six leakage current tests that have different

names based on which standard is selected.

Press to access the leakage current main menu

shown in Figure 18.

29

Page 44

ESA612

Users Manual

fis117.jpg

Figure 18. Leakage Current Main Menu

Note

The display shown in Figure 18 is the main

leakage current menu when AAMI is the selected

standard.

All leakage currents, with the exception of Lead Isolation

(Mains on Applied parts), are displayed in one of three

ways: AC+DC, AC Only, or DC only. The initial result is

displayed in the appropriate parameter based on the

standard selected. To change the displayed parameter,

press or . The present measurement method is

displayed to the right of the current measurement while

leakage current tests are conducted.

Measuring Earth Leakage Current

Note

The Ground Wire (Earth) Leakage test is

available for AAMI, 60601, and not IEC 62353.

To measure the current flowing in the DUT’s protective

earth circuit, press the softkey labeled Ground Wire

(pending the standard) from the leakage current main

menu. Figure 19 shows the electrical connections between

the Analyzer and the DUT during a Ground Wire Leakage

Current Test.

Within the Ground Wire Leakage Current test there are a

few combination measurements that can be performed.

Pressing switches the polarity of the mains voltage

applied to the Analyzer’s test receptacle between Normal,

Off, Reverse, and Off. Pressing opens and closes

the neutral connection to the Analyzer’s test receptacle.

There is no need to open up the test receptacle earth

(ground), since this is done internally during the

measurement.

30

Page 45

Electrical Safety Analyzer

Performing Electrical Safety Tests

The following outlet conditions apply when performing this

test:

• Normal Polarity

• Normal Polarity, Open Neutral

• Reversed Polarity

• Reversed Polarity, Open Neutral

IEC60601-1 specifies that the applied parts should be

connected for this measurement. Enable this

measurement by pressing or which grounds and

ungrounds all applied parts connection posts.

31

Page 46

ESA612

Users Manual

L1

MAINS

L2

MAINS

ON

PE

L2

MD

APPLIED PART

DUT_L1

DUT_L2

REV

POL

DUT_PE

DEVICE UNDER TEST

APPLIED

PART

CONDUCTIVE PART

Figure 19. Earth Leakage Current Test Schematic

Note

Ground wire leakage is the same schematic without the Applied Parts switch.

FE

faw27.eps

32

Page 47

Electrical Safety Analyzer

Performing Electrical Safety Tests

Performing a Chassis (Enclosure) Lea kage Test

Note

The Chassis (Enclosure) Leakage test is only

available for the IEC60601 or ANSI/AAMI ES1

1993 standard selections.

The Chassis (Enclosure) Leakage Test measures the

current flowing between the DUT’s enclosure and

protective earth. Figure 20 shows the electrical

connections between the Analyzer and the DUT.

To perform a Chassis (Enclosure) Leakage Test:

1. Connect a lead between the Analyzer’s V/Ω/A jack

and the DUT’s enclosure.

2. Press the softkey labeled Chassis from the Leakage

Current Test menu.

3. The Analyzer displays the measured current.

The Chassis Leakage test can be performed with a

number of fault conditions on the test receptacle. Press

to switch the test receptacle between Normal, Off,

Reverse, and Off. Press to open and close the

neutral connection to the receptacle. Press to open

and close the receptacle’s earth connection.

The following outlet conditions apply when performing this

test:

• Normal Polarity

• Normal Polarity, Open Earth

• Normal Polarity, Open Neutral

• Reversed Polarity

• Reversed Polarity, Open Earth

• Reversed Polarity, Open Neutral

IEC60601-1 specifies that the applied parts should be

connected for this measurement. Enable this

measurement by pressing or which grounds and

ungrounds all applied parts connection posts.

33

Page 48

ESA612

Users Manual

L1

MAINS

L2

MAINS

ON

PE

L2

EARTH

MD

APPLIED PART

DUT_L1

DUT_L2

DUT_PE

DEVICE UNDER TEST

APPLIED

PART

CONDUCTIVE PART

TEST LEAD

Figure 20. Enclosure Leakage Current Test Schematic

Note

Chassis leakage is the same schematic without the Applied Parts switch.

FE

faw28.eps

34

Page 49

Electrical Safety Analyzer

Performing Electrical Safety Tests

Performing a Lead-to-Ground (Patient) Leakage Test

Note

The Lead-to-Ground (Patient) Leakage Current

Test is not available for IEC 62353 standard

selections.

The Lead-to-Ground (Patient) Leakage Current test

measures the current flowing between a selected applied

part, selected group of applied parts, or ALL applied parts,

and the Mains PE. Figure 21 shows the electrical

connections between the Analyzer and the DUT.

To perform a Lead-to Ground (Patient) leakage test:

1. Press .

2. Press the soft key labeled More.

3. Select one of the applied part groupings by pressing

or .

Note

Refer to the testing standard when deciding the

type of the applied parts and how they should be

grouped for testing.

4. Press the soft key labeled Select.

5. Press or to advance through each applied part

grouping, or the individual applied parts, to ground.

These are selected and measured.

The Lead-to-Ground Leakage test can be performed with

a number of fault conditions on the test receptacle. Press

to switch the test receptacle between Normal, Off,

Reverse, and Off. Press to open and close the

neutral connection to the receptacle. Press to open

and close the receptacle’s earth connection.

The following outlet conditions apply when performing this

test:

• Normal Polarity

• Normal Polarity, Open Neutral

• Normal Polarity, Open Earth

• Reversed Polarity

• Reversed Polarity, Open Neutral

• Reversed Polarity, Open Earth

Note

If there are more than five applied parts to

connect to the Analyzer, see Using the 1-to-10

Adapter later in this manual.

35

Page 50

ESA612

Users Manual

L1

MAINS

L2

MAINS

ON

DEVICE UNDER TEST

APPLIED

PART

CONDUCTIVE PART

SELECT

RELAY*

PE

LEAD GND

SELECT RELAY

(REMOTE ONLY)

LEAD

PE

L2

EARTH

DUT_L1

DUT_L2

REV

POL

DUT_PE

MD

Figure 21. Lead-to-Ground (Patient) Leakage Current Test Schematic

FE

*Leads not selected are open.

gtv29.eps

36

Page 51

Electrical Safety Analyzer

Performing Electrical Safety Tests

Performing Lead-to-Lead (Patient Auxiliary) Leakage Tests

Note

The Lead-to-Lead (Patient Auxiliary) leakage test

is available when the IEC60601 or ANSI/AAMI

ES1-1993 standard is selected.

To measure the leakage current through each applied part

or lead and selected combination of lead connections (all

other or between two), press the softkey labeled Lead to

Lead from the Leakage Test main menu shown in

Figure 18. Figure 23 shows the electrical connections

between the Analyzer and the DUT during a Lead-to-Lead

(Patient Auxiliary) Leakage Current Test.

The Lead-to-Lead (Patient Auxiliary) Leakage test adds a

diagram of the applied parts connection posts to the

display, as shown in Figure 22. In the figure, the applied

parts post RA/R is shown above the other posts. This

indicates that the leakage measurement is being made

from RA/R to all others. To move to the next applied part

post, press . The first post will appear inline with the

other posts while the LL/F post appears above all others.

This indicates the second leakage measurement is being

made from LL/F to all others. Continue pressing or to

move from one connection post to another and noting the

measured current in the display.

After each post is isolated individually, the Lead-to-Lead

(Patient Auxiliary) Leakage test measures current of three

different combinations of posts tied together: RA/R and

LL/F, RA/R and LA/L, or LL/F and LA/L.

fis107.eps

Figure 22. Applied Parts Connection Posts Display

Within the Lead-to-Lead (Patient Auxiliary) Leakage test, a

number of fault measurements can be made. Pressing

switches the polarity of the mains voltage applied

to the Analyzer’s test receptacle between Normal, Off,

Reverse, and Off. Pressing opens and closes the

neutral connection to the Analyzer’s test receptacle.

Pressing opens and closes the earth or ground

connection to the Analyzer’s test receptacle.

37

Page 52

ESA612

Users Manual

Note

If there are more than five applied parts to

connect to the Analyzer, see Using the 1-to-10

Adapter later in this manual.

38

Page 53

Electrical Safety Analyzer

Performing Electrical Safety Tests

L1

MAINS

L2

MAINS

ON

PE

L2

EARTH

DUT_L1

DUT_L2

REV

POL

DUT_PE

DEVICE UNDER TEST

CONDUCTIVE PART

MD

PE

APPLIED

PART

+

LEAD

SELECT

RELAY*

- LEAD

SELECT

RELAY*

LEAD GND

SELECT RELAY*

(REMOTE ONLY)

FE

Figure 23. Lead-to-Lead (Patient Auxiliary) Leakage Current Test Schematic

*Leads not selected are open.

gtv30.eps

39

Page 54

ESA612

Users Manual

The following outlet conditions apply when performing this

test:

• Normal Polarity

• Normal Polarity, Open Neutral

• Normal Polarity, Open Earth

• Reversed Polarity, Open Neutral

• Reversed Polarity, Open Earth

Performing a Lead Isolation (Mains on Applied Part) Leakage Test

Note

The Lead Isolation (Mains on Applied Part)

leakage test is available when the IEC60601 &

ANSI/AAMI standard is selected.

The Lead Isolation (Mains On Applied Parts) Leakage

Current test measures the current that flows in response

to an isolated AC voltage applied between a selected

applied part, group of applied parts, or ALL applied parts,

and Earth (and any conductive part connected to the RED

terminal). Figure 24 shows the electrical connections

between the Analyzer and the DUT during a Mains on

Applied Part Leakage Current Test.

Note

With 60601 standard selected, the MAP test

voltage is available in both Normal and Reverse

(180 degrees out of phase with mains).

To perform a Lead Isolation (Mains on Applied Part) test:

1. Press .

2. Press the soft key labeled More.

3. Select the desired applied part groupings using

and .

Note

Refer to the testing standard when deciding the

type of the applied parts and how they should be

grouped for testing.

4. Press the soft key labeled Select.

5. Press the soft key labeled Lead Isolation.

6. Press or to select the desired applied part

connection.

7. Press to apply the voltage and read the leakage

current in the display.

Pressing and scrolls through the applied part

connections or groupings. Press for each

connection configuration to thoroughly test the DUT.

40

Page 55

Electrical Safety Analyzer

Performing Electrical Safety Tests

The following outlet conditions apply when performing this

test:

• Normal Polarity

• Reverse Polarity

Note

If there are more than five applied parts to

connect to the Analyzer, see Using the 1-to-10

Adapter later in this manual.

41

Page 56

ESA612

Users Manual

L1

MAINS

L2

MAINS

On

PE

MAP (ISOLATION)

TRANSFORMER

Figure 24. Lead Isolation (Mains On Applied Parts) Leakage Test Schematic

REV

POL

MAP

REV

DUT_L1

DUT_L2

DUT_PE

DEVICE UNDER TEST

CONDUCTIVE PART

TEST

LEAD

MD

APPLIED

PART

LEAD

SELECT

RELAY*

FE

*Leads not selected are open.

gtv31.eps

42

Page 57

Electrical Safety Analyzer

Performing Electrical Safety Tests

Performing an Alternative Equipment Leakage Test

Note

The alternative equipment leakage test is

available when the EN62353 standard is

selected.

During the Alternative Equipment Leakage test, the

voltage source is applied between short-circuited

equipment outlet mains live, neutral, and equipment outlet

earth, the exposed conductive surface on the housing, and

all applied parts short-circuited together. Equipment is

separated from mains during the test. The current which

flows over the insulation of the DUT is measured.

This test is not applicable for equipment with internal

electrical power source. The switches in mains part shall

be closed during measurement.

To perform an alternative equipment leakage test:

1. Press .

2. Press the softkey labeled Alternative Equipment.

3. Press to apply the voltage and read the current

in the display.

Figure 25 shows the electrical connections between the

Analyzer and the DUT during an Alternative Equipment

Leakage Test.

The following outlet conditions apply when performing this

test:

• Closed Earth

• Open Earth

Note

If there are more than five applied parts to

connect to the Analyzer, see Using the 1-to-10

Adapter later in this manual.

43

Page 58

ESA612

Users Manual

Performing an Alternative Applied Part Leakage Test

Note

The Alternative applied part leakage test is

available when the EN62353 standard is

selected.

During the Alternative Applied Part Leakage test, the test

voltage is applied between short-circuited applied parts of

a single function and the short-circuited equipment outlet

mains live, neutral, equipment outlet earth, and exposed

conductive surface on the housing. This test should only

be done for equipment with F-Type applied parts. For

equipment with multiple applied parts, test each group of

applied parts of a single function in turn with all others

floating during the test

to the Analyzer’s applied parts jacks and the lead selection

will float those not selected.

. All applied parts can be connected

44

Page 59

Electrical Safety Analyzer

Performing Electrical Safety Tests

DUT_L1

DUT_L2

DUT_PE

MD

DEVICE UNDER TEST

APPLIED

PART

FE

CONDUCTIVE PART

TEST

LEAD

Figure 25. Alternative Equipment Leakage Current Test Schematic

faw22.eps

45

Page 60

ESA612

Users Manual

To perform an alternative applied part leakage test:

1. Press .

2. Press the soft key labeled More.

3. Select the desired applied part groupings using

and .

4. Press the soft key labeled Select.

5. Press the soft key labeled Alternative A.P..

6. Press to apply the test voltage and read the

current in the display.

7. Press or to advance to the next applied part

group(s) of a single function if applicable. Pressing

to read leakage current for each group.

Figure 26 shows the electrical connections between the

Analyzer and the DUT during an Alternative Applied Part

Leakage current test.

Note

If there are more than five applied parts to

connect to the Analyzer, see Using the 1-to-10

Adapter later in this manual.

Performing a Direct Equipment Leakage Test

Note

The Direct Equipment Leakage test is available

when the EN62353 standard is selected.

The Direct Equipment Leakage Current test measures the

leakage current between all applied parts and the exposed

conductive surface on the housing, to mains earth.

To perform a direct equipment test:

1. Press .

The direct equipment test is the default test and should

already be selected.

2. Press to apply the voltage and read the leakage

current in the display

Figure 27 shows the electrical connections between the

Analyzer and the DUT during a Direct Equipment Leakage

Current Test.

46

Page 61

Electrical Safety Analyzer

Performing Electrical Safety Tests

The following outlet conditions apply when performing this

test:

• Normal Polarity, Closed Earth

• Normal Polarity, Open Earth

• Reversed Polarity, Closed Earth

• Reversed Polarity, Open Earth

Note

If there are more than five applied parts to

connect to the Analyzer, see Using the 1-to-10

Adapter later in this manual.

47

Page 62

ESA612

Users Manual

DUT_L1

DUT_L2

DUT_PE

DEVICE UNDER TEST

APPLIED

PART

CONDUCTIVE PART

TEST

LEAD

LEAD

SELECT

RELAY*

*Leads not selected

are open.

FE

MD

gtv23.eps

Figure 26. Alternative Applied Part Leakage Test Schematic

48

Page 63

Electrical Safety Analyzer

Performing Electrical Safety Tests

Performing a Direct Applied Part Leakage Test

Note

The Direct Applied Part Leakage test is available

when the EN62353 standard is selected.

The Direct Applied Part Leakage Current test measures

the leakage current between all applied parts of a single

function and the exposed conductive surface on the

housing, to mains earth. For equipment with multiple

applied parts, each group of a single function should be

tested each in turn with all other floating during the test.

This test should only be done for equipment with F-Type

applied parts.

For Type B applied part, see direct equipment leakage

schematic in Figure 27.

To perform a direct applied part leakage test:

1. Press .

2. Press the soft key labeled More.

3. Select the desired applied part groupings using

and .

4. Press the soft key labeled Select. The Direct A.P. test

should already be selected.

5. Press or to select the applied part test

configuration.

6. Press to apply the test voltage and read the

current in the display.

7. Press or to advance to the next group of applied

parts, if applicable.

Figure 28 shows the electrical connections between the

Analyzer and the DUT during a Direct Applied Part

Leakage Current Test.

The following outlet conditions apply when performing this

test:

• Normal Polarity

• Reversed Polarity

Note

If there are more than five applied parts to

connect to the Analyzer, see Using the 1-to-10

Adapter later in this manual.

49

Page 64

ESA612

Users Manual

DEVICE UNDER TEST

APPLIED

PART

CONDUCTIVE PART

TEST

LEAD

FE

faw24.eps

L1

MAINS

L2

MAINS

ON

PE

L2

MD

REV

POL

PE

DUT_L1

DUT_L2

DUT_PE

Figure 27. Direct Equipment Leakage Test Schematic

50

Page 65

Electrical Safety Analyzer

Performing Electrical Safety Tests

L1

MAINS

L2

MAINS

ON

PE

DEVICE UNDER TEST

APPLIED

PART

CONDUCTIVE PART

L2

DUT_L1

DUT_L2

REV

POL

DUT_PE

Figure 28. Direct Applied Parts Leakage Current Test Schematic

LEAD

SELECT

RELAY*

*Leads not selected

are open.

FE

MD

gtv25.eps

51

Page 66

ESA612

Users Manual

Performing a Differential Leakage Current Test

Note

The Differential Leakage Current test is available

when the EN62353 standard is selected.

The differential leakage current test measures the

magnitudes of the differential current flowing in the

Equipment Outlet live and neutral, with power applied to

the equipment outlet. All applied parts should be

connected during this test, if equipment has applicable

applied parts.

To perform a differential leakage current test:

1. Press .

2. Press the soft key labeled Differential.

Figure 29 shows the electrical connections between the

Analyzer and the DUT during a Differential Leakage

Current test.

The following outlet conditions apply when performing this

test:

• Normal Polarity, Closed Earth

• Normal Polarity, Open Earth

• Reversed Polarity, Closed Earth

• Reversed Polarity, Open Earth

Note

If there are more than five applied parts to

connect to the Analyzer, see Using the 1-to-10

Adapter later in this manual.

52

Page 67

Electrical Safety Analyzer

Performing Electrical Safety Tests

L1

MAINS

L2

MAINS

ON

PE

DEVICE UNDER TEST

APPLIED

PART

CONDUCTIVE PART

TEST

LEAD

REV

POL

EARTH

DUT_L1

MD

DUT_L2

DUT_PE

Figure 29. Differential Leakage Current Test Schematic

FE

gtv32.eps

53

Page 68

ESA612

Users Manual

Using the 1-to-10 Adapter

The 1-to-10 Adapter, an optional accessory, is designed to

increase the number of lead or applied parts connections

to the Analyzer from five to 14. The adapter itself ties up to

ten leads together into a single lead that is plugged into

one of the input jacks of the Analyzer. The four remaining

Analyzer input jacks can also be used in conjunction with

the Adapter.

Figure 30 shows one application of the Adapter. The

Defibrillator/Monitor in the example has ten ECG leads,

two pacer leads, and two defibrillator paddles which need

to be tested together, and in groups if single function, for

current leakage per IEC62353. The example shows the

ECG leads to be snap type connectors and two BJ2ECG

adapters are shown plugged into the Adapter. If the ECG

leads did not have snap connectors, then the Universal

Snap to Banana Adapter can be used to make the

connections to the Adapter.

The common lead from the Adapter is plugged into the RA

st

jack (1

leads with alligator clips, connect the two defibrillator

paddles into the LL and LA Analyzer jacks and the two

pacer leads into the RL and V1 jacks. Using the selection

that ties all five Analyzer jacks together will test all

fourteen leads for leakage current. Using the selection of

applied part group of 1, 2, and 2 allows for testing of

groups of applied parts of single function.

jack) of the Analyzer. Using four sheathed test

54

Page 69

Electrical Safety Analyzer

Using the 1-to-10 Adapter

Defibrillator/Pacer

Use leads shorted

for electrical safety

testing only. Do not

short leads for ECG

simulation.

Caution: To prevent damage to the Product,

ESA612

do not apply more than 30 V dc to

DEFIB

OFF

PACER

the AP (ECG).

Check unkown connections using a

DMM before connecting to ESA612.

1-to-10 and

Alligator Clips

BJ2ECG

snap adapters

fis120.eps

Figure 30. 1-to-10 Adapter Connections

55

Page 70

ESA612

Users Manual

When performing an applied parts test using the

AAMI/NFPA-99 standard, the normal connections of RA,

LL, LA, and RL are made to their associated Analyzer

input jacks. Four adapters from the Universal Snap to

Banana Adapter set will be required for the first four

connections. The remaining chest leads are connected to

the Adapter and the common lead from the Adapter is

plugged into the V1 jack (5

Figure 31. This configuration allows for isolation of the RA,

LL, LA, and RL leads from each other and the remaining

chest leads, which are shorted together, while performing

leakage tests.

th

jack) of the Analyzer. See

56

Page 71

Electrical Safety Analyzer

Using the 1-to-10 Adapter

ECG Monitor

Use leads shorted

for electrical safety

testing only. Do not

short leads for ECG

simulation.

1-to-10 and

BJ2ECG

snap adapters

Figure 31. ECG Lead Connection with 1-to-10 Adapter

ESA612

fis121.eps

57

Page 72

ESA612

Users Manual

Making Point-To-Point Measurements

The Analyzer can make voltage, resistance, and low

current measurements through its Point-to-Point function.

To access the Point-to-Point function menu shown in

Figure 32, press . Softkeys F1 through F3 are used

to select the measurement function.

fis108.jpg

Figure 32. Point-To-Point Function Menu

Measuring Voltage

To make a voltage measurement:

1. Press the softkey labeled Voltage from the

Point-To-Point menu.

2. Insert test leads in the RED (V/Ω/A ) and BLACK

jacks.

3. Place the probe tips across the unknown voltage and

read the measurement in the Analyzer’s display.

The Analyzer will measure up to 300 volts ac.

Measuring Resistance

To make a resistance measurement:

1. Press the softkey labeled Resistance from the

Point-To-Point menu.

2. Insert test leads in the RED (V/Ω/A ) and BLACK

jacks.

3. Null lead resistance by shorting the leads together

and pressing the softkey labeled Zero Leads.

4. Place the probes across the unknown resistance and

read the measurement in the Analyzer’s display.

The Analyzer will measure resistances up to 2.0 Ω.

58

Page 73

Electrical Safety Analyzer

Simulating ECG Waveforms

Measuring Current

The Analyzer can make dc only, ac only, and ac+dc

current measurements up to 10 mA. To make a current

measurement:

1. Press the softkey labeled Leakage from the

Point-To-Point menu.

2. Using or select between ac only, dc only, or

ac+dc measurement mode.

3. Insert test leads in the RED (V/Ω/A ) and BLACK

jacks.

4. Place the leads on the two points the unknown

current may flow and read the measurement in the

Analyzer’s display.

Simulating ECG Waveforms

The Analyzer is capable of generating various waveforms

on the applied parts connection posts. These signals are

used to test the performance characteristics of ECG

monitors and ECG strip printers. See Figure 34 for proper

connections between the Analyzer and an ECG monitor.

For monitors using the snap style connectors, insert the

BJ2ECG adapter into the connectors at the top of the

Analyzer and connect the monitor leads to the snap

connectors on the adapter.

Note

If the ECG monitor/interpreter has banana posts

instead of snaps, use the optional universal snap

to banana adapter to connect to the Analyzer.

To access the ECG Simulation Waveform menu shown in