Page 1

Endurance

Innovative High Temperature Infrared Pyrometers

®

Series

Users Manual

PN 59511

Nov 2016, Rev.E1, 11/2016

© 2016 Fluke Process Instruments, All rights reserved. Printed in Germany. Specifications subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

Page 3

The device complies with the requirements of the European Directives.

EC – Directive 2004/108/EC (EMC)

Electromagnetic Compatibility Applies to use in Korea only. Class A Equipment

business environments and is not to be used in homes.

Warranty

The manufacturer warrants this instrument to be free from defects in material and workmanship under

normal use and service for the period of four years from date of purchase. This warranty extends only to

the original purchaser. This warranty shall not apply to fuses, batteries, or any product which has been

subject to misuse, neglect, accident, or abnormal conditions of operation.

In the event of failure of a product covered by this warranty, the manufacturer will repair the instrument

when it is returned by the purchaser, freight prepaid, to an authorized Service Facility within the

applicable warranty period, provided manufacturer’s examination discloses to its satisfaction that the

product was defective. The manufacturer may, at its option, replace the product in lieu of repair. With

regard to any covered product returned within the applicable warranty period, repairs or replacement will

be made without charge and with return freight paid by the manufacturer, unless the failure was caused

by misuse, neglect, accident, or abnormal conditions of operation or storage, in which case repairs will

be billed at a reasonable cost. In such a case, an estimate will be submitted before work is started, if

requested.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY,

FITNESS, OR ADEQUACY FOR ANY PARTICULAR PURPOSE OR USE. THE MANUFACTURER

SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES,

WHETHER IN CONTRACT, TORT, OR OTHERWISE.

Software Warranty

The manufacturer does not warrant that the software described herein will function properly in every

hardware and software environment. This software may not work in combination with modified or

emulated versions of Windows operating environments, memory-resident software, or on computers

with inadequate memory. The manufacturer warrants that the program disk is free from defects in

material and workmanship, assuming normal use, for a period of one year. Except for this warranty, the

manufacturer makes no warranty or representation, either expressed or implied, with respect to this

software or documentation, including its quality, performance, merchantability, or fitness for a particular

purpose. As a result, this software and documentation are licensed “as is,” and the licensee (i.e., the

User) assumes the entire risk as to its quality and performance. The liability of the manufacturer under

this warranty shall be limited to the amount paid by the User. In no event shall the manufacturer be

liable for any costs including but not limited to those incurred as a result of lost profits or revenue, loss of

use of the computer software, loss of data, the cost of substitute software, claims by third parties, or for

other similar costs. The manufacturer’s software and documentation are copyrighted with all rights

reserved. It is illegal to make copies for another person.

Specifications subject to change without notice.

(Industrial Broadcasting & Communication Equipment)

This product meets requirements for industrial (Class A) electromagnetic wave equipment

and the seller or user should take notice of it. This equipment is intended for use in

Page 4

Fluke Process Instruments

Fluke Process Instruments North America

Santa Cruz, CA USA

Tel: +1 800 227 8074 (USA and Canada, only)

+1 831 458 3900

solutions@flukeprocessinstruments.com

Fluke Process Instruments Europe

Berlin, Germany

Tel: +49 30 4 78 00 80

info@flukeprocessinstruments.de

Fluke Process Instruments China

Beijing, China

Tel: +8610 6438 4691

info@flukeprocessinstruments.cn

Worldwide Service

Fluke Process Instruments offers services, including repair and

calibration. For more information, contact your local office or e-mail

support@flukeprocessinstruments.com

www.flukeprocessinstruments.com

© Fluke Process Instruments

Specifications subject to change without notice.

Contacts

Page 5

Table of Contents

Title Page

1. Safety Instructions .................................................................................. 1

2. Product Description ................................................................................ 3

2.1. Theory of Operation for 2-Color Sensors .................................................... 5

2.1.1. Partially Obscured Targets ..................................................................... 5

2.1.2. Targets Smaller Than Field of View ........................................................ 5

2.1.3. Emissivity and 1-color (single wavelength) measurements ..................... 5

2.1.4. Slope (2-color ratio) measurements ....................................................... 6

3. Technical Data ......................................................................................... 7

3.1. General Specifications ................................................................................ 7

3.2. Electrical Specifications .............................................................................. 8

3.3. Measurement Specifications ....................................................................... 9

3.4. Optical Specifications .................................................................................. 10

3.5. Dimensions ................................................................................................. 11

3.6. Scope of Delivery ........................................................................................ 12

4. Environment ............................................................................................. 12

4.1. Ambient Temperature ................................................................................. 12

4.2. Atmospheric Quality .................................................................................... 12

4.3. Electrical Interference ................................................................................. 13

5. Installation................................................................................................ 13

5.1. Mechanical Installation ................................................................................ 13

5.1.1. Distance to Object .................................................................................. 13

5.1.2. Sensor Placement (1-Color Mode) ......................................................... 13

5.1.3. Sensor Placement (2-Color Mode) ......................................................... 14

5.1.4. Viewing Angles ....................................................................................... 15

5.1.5. Aiming and Focusing ................................ .............................................. 16

5.2. Electrical Installation ................................................................................... 17

5.2.1. M16 12-Pin DIN Connector Signal Assignment ...................................... 17

5.2.2. M12 4-Socket LAN/Ethernet Connector.................................................. 18

5.2.3. Accessory Cables and Terminal Block ................................................... 18

5.2.4. Power Supply ......................................................................................... 20

5.2.5. Computer Interfacing via RS485 link ...................................................... 20

5.2.6. Addressing the Endurance® sensor in a RS485 Multidrop Network ....... 21

6. Device Control ......................................................................................... 22

6.1. Control Panel .............................................................................................. 22

6.1.1. The Object / Target Temperature Display (green 7-segment LED type) . 22

6.1.2. The Screen / Menu Display ................................ .................................... 23

6.1.3. The LASER / LED / CAMERA Indicator LED (red) ................................. 23

6.1.4. The Status Indicator LED (green) ........................................................... 23

6.1.5. The 4 Control Panel Pushbuttons ........................................................... 23

6.2. The control panel menu structure and their associated entries ................... 24

6.2.1. The INFORMATION MENU .................................................................... 26

6.2.2. The CONFIGURATION MENU ............................................................... 28

6.2.3. The UNIT SETUP MENU ....................................................................... 30

6.2.4. The INTERFACE MENU ........................................................................ 33

6.2.5. The ANALOG MENU .............................................................................. 35

i

Page 6

7. Signal Processing .................................................................................... 36

7.1. Averaging ................................................................................................... 36

7.2. Peak Hold ................................................................................................... 36

7.2.1. Reset Peak Hold by Peak Hold Time expiration ..................................... 36

7.2.2. Reset Peak Hold by external Trigger signal ............................................ 37

7.2.3. Signal Slope (decay) in case of Peak Hold Reset ................................... 38

7.3. Advanced Peak Hold .................................................................................. 39

7.4. Valley Hold ................................................................................................. 39

7.5. Advanced Valley Hold ................................................................................. 40

7.6. Setpoint ...................................................................................................... 40

7.7. Deadband ................................................................................................... 40

7.8. Outputs ....................................................................................................... 41

7.8.1. Analog Output (current loop) .................................................................. 41

7.8.2. Relay Outputs ........................................................................................ 41

7.8.3. Trigger.................................................................................................... 41

7.9. Factory Defaults .......................................................................................... 42

8. Device Options ........................................................................................ 43

8.1. Adjustable Focus (3 focus options available) .............................................. 43

8.2. Laser Sighting (Sighting Option L) .............................................................. 43

8.3. LED Sighting (Sighting Option D) ................................................................ 44

8.4. Video Sighting (Sighting Option V) .............................................................. 44

8.5. Air/Water Cooled Housing (Cooling Option 1) ............................................. 44

8.5.1. Avoidance of Condensation .................................................................... 45

8.6. PROFINET IO (Communication Option 1) ................................................... 46

8.6.1. Description ............................................................................................. 46

8.6.2. I/O Device Configuration ........................................................................ 47

8.6.3. Parameter Setting .................................................................................. 47

8.6.4. Structure of the input/output data ........................................................... 48

8.6.5. Diagnostics ............................................................................................ 49

8.7. ISO Calibration Certificate, based on DAkkS (German accreditation body) . 50

9. Accessories ............................................................................................. 51

9.1. Electrical Accessories ................................................................................. 51

9.1.1. High Temp. Multi-conductor cable with M16 connector (E-2CCBxx) ....... 52

9.1.2. Low Temp. Multi-conductor cable with M16 connector (E-2CLTCBxx) ... 53

9.1.3. High Temp. Ethernet cable with M12 connector (E-ETHCBxx) ............... 54

9.1.4. Low Temp. Ethernet cable with M12 connector (E-ETHLTCBxx)............ 55

9.1.5. Endurance® Terminal Block Accessory (E-TB) ...................................... 55

9.1.6. Endurance® Terminal Block in a NEMA 4 enclosure (E-TBN4) .............. 56

9.1.7. 24VDC, 1.2A industrial power supply, DIN rail mount (E-SYSPS) .......... 56

9.1.8. 24VDC, 1.1A, 100-240VAC power supply in NEMA 4/IP65 case (E-PS) 57

9.1.9. PoE Injector to provide power over a single Ethernet hub (E-POE) ........ 58

9.1.10. 12-socket DIN Cable connector (E-2CCON) for multi-conductor cable ... 59

9.1.11. Modline5 patch cable kit to use existing Modline5 cables (E-M5PK) ...... 60

9.1.12. USB to RS232/422/485 converter (E-USB485) ...................................... 60

9.2. Mechanical/Optical Accessories for Endurance® sensors only ................... 61

9.2.1. Air purge collar (E-AP) ........................................................................... 62

9.2.2. Pipe adapter to attach sighting tubes (E-PA) .......................................... 62

9.2.3. Mounting nut (E-MN) .............................................................................. 63

9.2.4. Fixed bracket (E-FB) .............................................................................. 63

9.2.5. Adjustable bracket (E-AB) ...................................................................... 63

9.2.6. Swivel bracket (E-SB) ............................................................................ 64

9.2.7. Right angle mirror for targets at right angles to sensor axis (E-RA) ........ 65

9.2.8. Adapter kit to use Endurance® sensors in Modline5 WJA (E-M5WJAK) 65

9.2.9. Endurance® universal adapter accessory (E-UAA) ................................ 66

9.2.10. Adapter kit for Endurance® in WJ-5 water jacket installations (E-AK-7) . 66

ii

Page 7

9.2.11. Mounting flange (E-MF-7) ...................................................................... 66

9.2.12. Flange adapter (E-MFA-7) to allow Endurance® to mount to E-MF-7 ..... 67

9.2.13. Replacement glass end-cap for Endurance® sensors (E-ECAP) ........... 67

9.2.14. Protective front window, including O-Ring (E-PW) .................................. 68

9.2.15. Polarizing filter end cap for use in high temperature applic. (E-PFEC) ... 68

9.3. ThermoJacket and related Accessories ...................................................... 69

9.3.1. Imperial unit ThermoJacket housing for Endurance® sensors (E-TJ1) ... 69

9.3.2. Metric unit ThermoJacket housing for Endurance® sensors (E-TJ1M) ... 71

9.3.3. Mounting Flange for ThermoJacket (E-MF) ............................................ 71

9.3.4. Adjustable mounting base for ThermoJacket (E-MB).............................. 71

9.3.5. Blast Gate Assembly with Quartz Window, HT model (E-GTQ) .............. 72

9.3.6. Adjustable pipe adapter assembly (E-APA) ............................................ 73

9.3.7. Mounting flange for use with sighting tubes (E-MST).............................. 74

9.3.8. 30cm (12") sighting tube, ceramic up to 1500°C/2730°F (E-STC12) ...... 74

9.3.9. 30cm (12") sighting tube, stainless steel up to 800°C/1470°F (E-ST12) . 75

9.3.10. 30cm (12") sighting tube, carbon steel, 45° end cut (E-BEESIGHT) ....... 76

9.3.11. Extraction Tool to remove Endurance® from Thermojacket (E-TJET) .... 76

9.4. Flow Regulator Accessories ........................................................................ 77

9.4.1. Water flow regulator for water cooling (E-WR) ........................................ 77

9.4.2. Air purging flow regulator assembly with air filter (E-AR) ........................ 78

9.4.3. Cooling air flow regulator, high capacity (E-CAFR) ................................. 79

10. Programming Guide ................................................................................ 80

10.1. Remote versus Manual Considerations....................................................... 80

10.2. Command Structure .................................................................................... 80

10.3. Transfer Modes ........................................................................................... 81

10.3.1. Poll Mode ............................................................................................... 81

10.3.2. Burst Mode ............................................................................................. 81

10.4. Command List ............................................................................................. 82

10.5. Command Examples ................................................................................... 85

11. Maintenance ............................................................................................. 85

11.1. Troubleshooting Minor Problems ................................................................ 86

11.2. Fail-Safe Operation ..................................................................................... 86

11.2.1. Fail-Safe Error Codes (displayed or transmitted via electrical interface) . 86

11.2.2. Analog Output current values in dependence of Fail-Safe Error Codes .. 87

11.3. Cleaning the Lens ....................................................................................... 88

11.4. Changing the Window ................................................................................. 89

12. Addendum ................................................................................................ 90

12.1. Determination of Slope (for 2 – color operation) .......................................... 90

12.2. Percentage of allowed signal reduction ....................................................... 90

12.3. Determination of Emissivity (for 1-color operation) ...................................... 91

12.4. Typical Emissivity Values ............................................................................ 91

iii

Page 8

iv

Page 9

List of Tables

Title Page

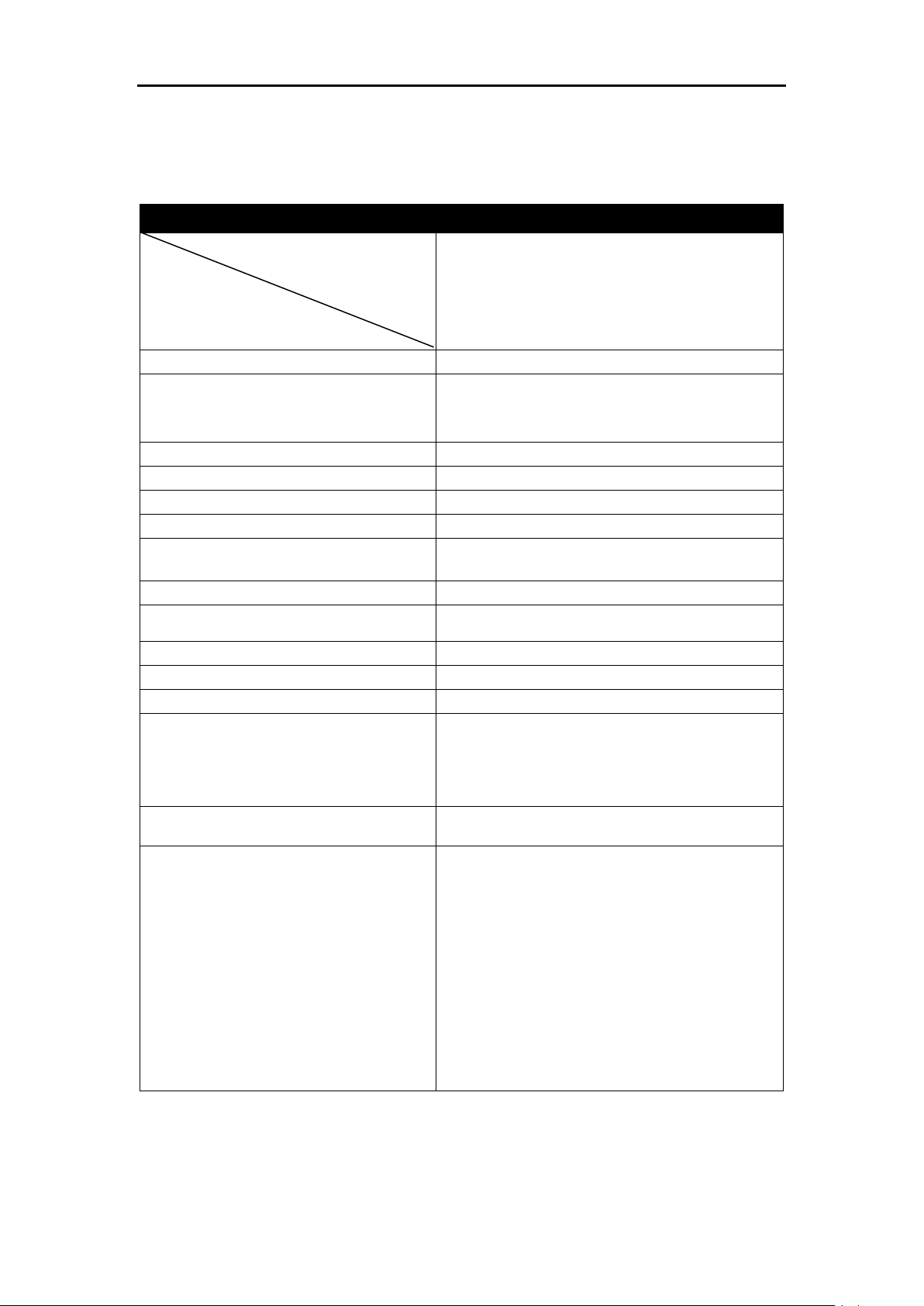

Table 1: General Symbols ......................................................................................... 2

Table 2: Factory Defaults ........................................................................................ 42

Table 3: Minimum device temperatures [°C/°F] ....................................................... 46

Table 4: Electrical Accessories ................................................................................ 51

Table 5: Accessories for Endurance® sensors only ................................................ 61

Table 6: ThermoJacket and related Accessories ..................................................... 69

Table 7: Approximate required coolant flow versus outside ambient temperature ... 70

Table 8: Flow Regulators for use with cooling/purging options ................................ 77

Table 9: Command List ........................................................................................... 82

Table 10: Assignment of Error-Codes ..................................................................... 84

Table 11: Command Examples ............................................................................... 85

Table 12: Troubleshooting ....................................................................................... 86

Table 13: Fail-safe Error Codes .............................................................................. 87

Table 14: Current Output Values in accordance to an Error .................................... 87

Table 15: Typical Emissivity Values (Metals) ........................................................... 92

Table 16: Typical Emissivity Values (Non-Metals) ................................................... 92

v

Page 10

vi

Page 11

List of Figures

Title Page

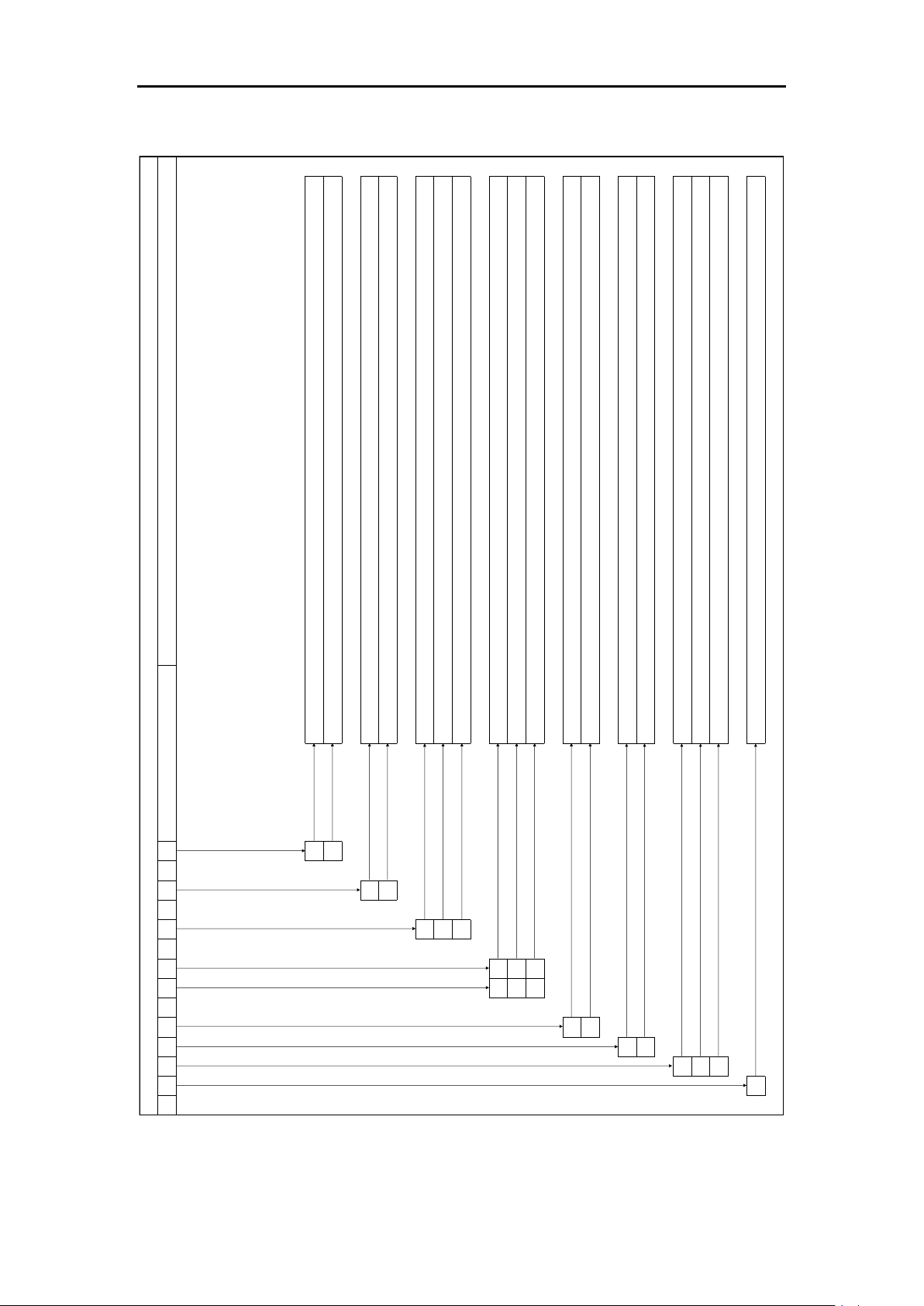

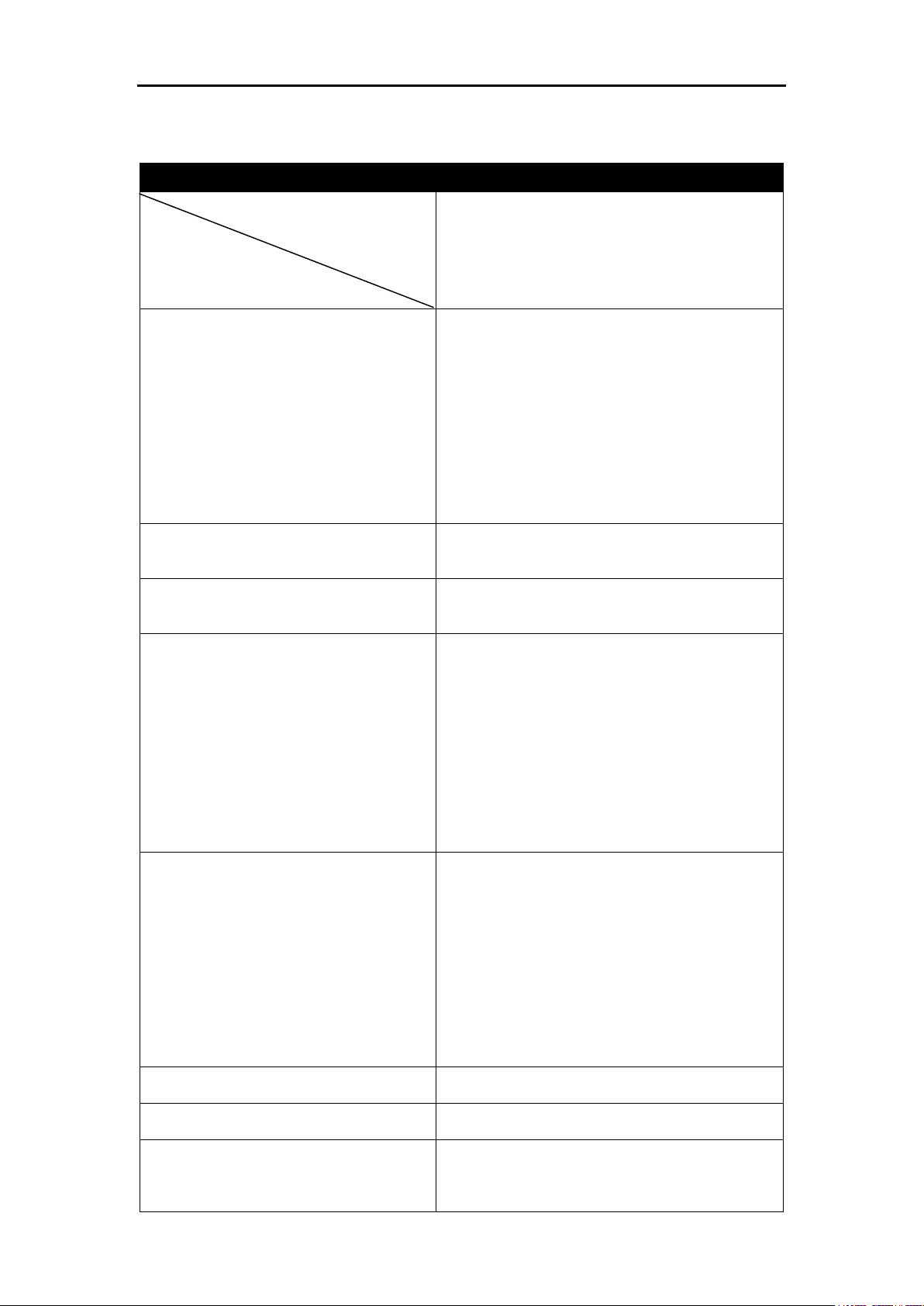

Figure 1: Endurance® Model Identification Matrix ..................................................... 4

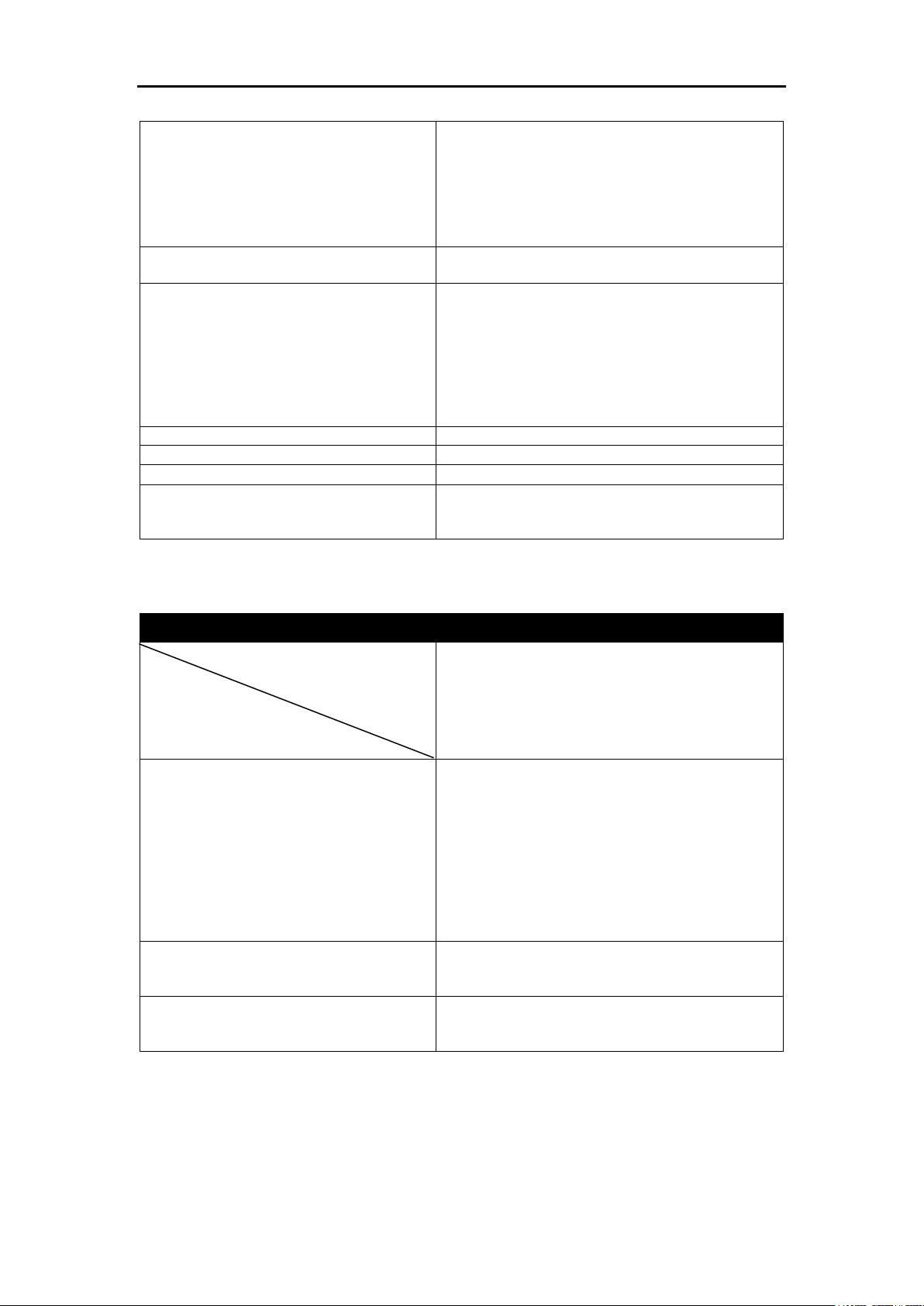

Figure 2: Spot Size Chart ........................................................................................ 11

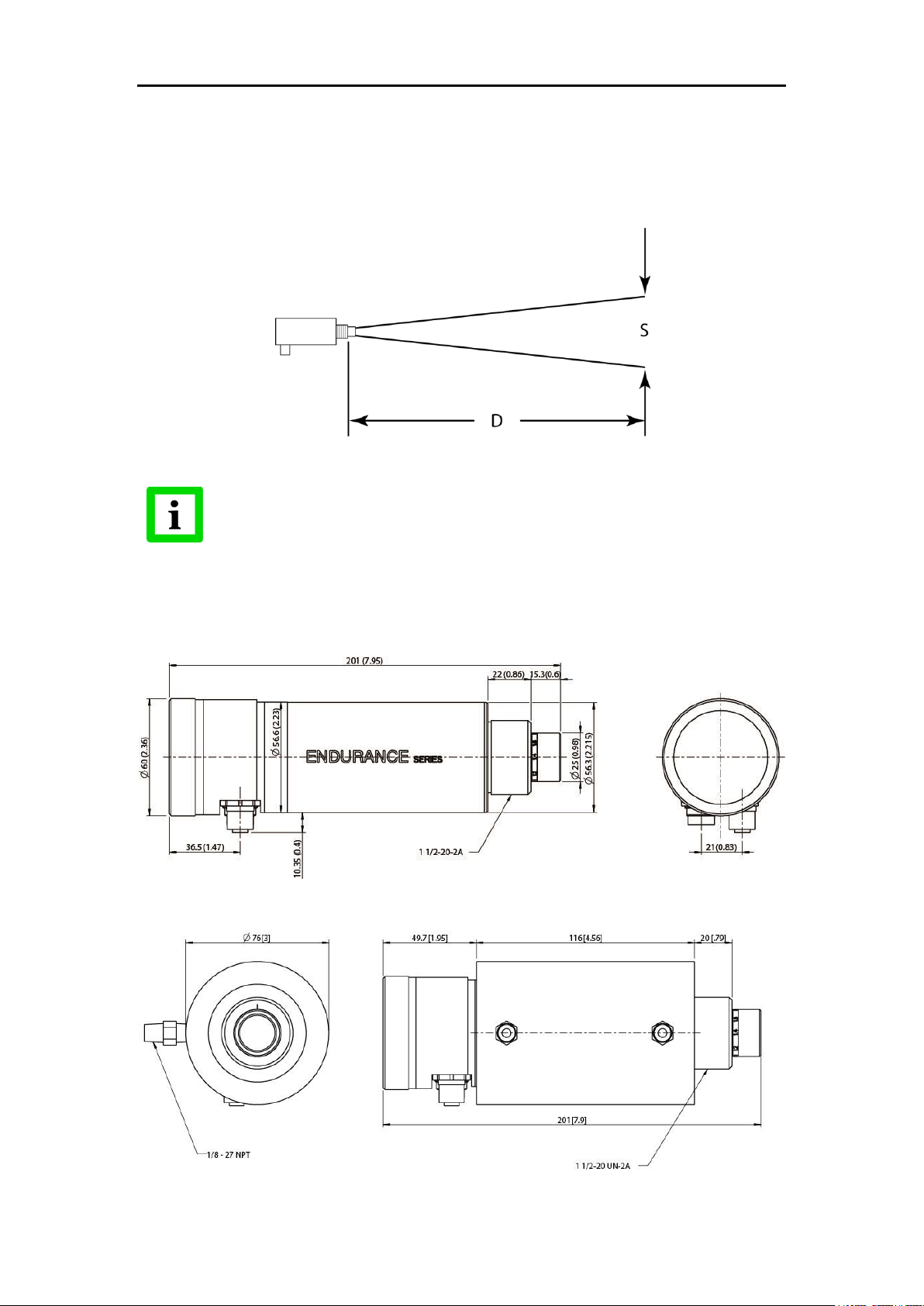

Figure 3: Dimensions of Endurance® Sensor .......................................................... 11

Figure 4: Dimensions of Endurance® Sensor in Air/Water-Cooled Housing Option . 11

Figure 5: Proper Sensor Placement in 1-Color Mode .............................................. 13

Figure 6: Sensor Placement in 2-Color Mode .......................................................... 14

Figure 7: Acceptable Sensor Viewing Angles .......................................................... 15

Figure 8: Sensor Eyepiece and Reticle.................................................................... 16

Figure 9: M16 12-Pin connector (left) and the corresponding cable socket (right) ... 17

Figure 10: M16 DIN Connector signal assignment .................................................. 17

Figure 11: M12 Socket (left) and the corresponding cable plug (right) ..................... 18

Figure 12: Ethernet Cable with M12 Plug and RJ45 Connector ............................... 18

Figure 13: M16 12-Conductor shielded cable with colored wire/signal assignments 19

Figure 14: M12 4-Conductor shielded cable with RJ45 on counter side................... 19

Figure 15: Endurance® series labeled terminal block .............................................. 20

Figure 16: USB/RS485 Converter ........................................................................... 21

Figure 17: Control Panel ......................................................................................... 22

Figure 18: Upper Object/Target Temperature Display ............................................. 22

Figure 19: Lower Screen / Menu Display ................................................................. 23

Figure 20: Upper LASER / LED /CAMERA Activation LED (red) ............................. 23

Figure 21: Lower Status Indicator LED (green) ........................................................ 23

Figure 22: Overview about the menu structure with five (5) sub-menus .................. 25

Figure 23: The INFORMATION MENU with sensor type related variations ............. 26

Figure 24: The CONFIGURATION MENU with sensor type related variations......... 28

Figure 25: The UNIT SETUP MENU with sensor type related variations ................. 30

Figure 26: The static (fixed) INTERFACE MENU .................................................... 33

Figure 27: The static (fixed) ANALOG MENU .......................................................... 35

Figure 28: Averaging ............................................................................................... 36

Figure 29: Peak Hold reset by Peak Hold Time expiration ....................................... 37

Figure 30: Peak Hold reset by external Trigger signal ............................................. 37

Figure 31: Perpendicular Signal Drop (default mode) .............................................. 38

Figure 32: Linear Signal Drop (decay mode) ........................................................... 38

Figure 33: Average Time Dependent Signal Drop (averaging mode) ....................... 39

Figure 34: Advanced Peak Hold .............................................................................. 39

Figure 35: Valley Hold ............................................................................................. 40

Figure 36: Deadband Example ................................................................................ 41

Figure 37: LASER Spot Size Indication ................................................................... 43

Figure 38: LED Spot Size Indication ........................................................................ 44

Figure 39: Endurance® Head with Air/Water-Cooled Housing Option ..................... 45

Figure 40: High Temp. Multi-Conductor Cable with M16 Connector (E-2CCBxx) .... 53

Figure 41: Low Temp. Multi-Conductor Cable with M16 Connector (E-2CLTCBxx) . 54

Figure 42: High Temp. Ethernet Cable with M12, RJ45 Connector (E-ETHCBxx) ... 55

Figure 43: Low Temp. Ethernet Cable with M12, RJ45 Connector (E-ETHLTCBxx) 55

Figure 44: Endurance® Terminal Block (E-TB) with wire color assignment ............. 56

Figure 45: Endurance® Terminal Block in a NEMA 4 Enclosure (E-TBN4) .............. 56

Figure 46: 24VDC, 1.2A Industrial Power Supply (E-SYSPS) .................................. 57

Figure 47: 24VDC, 1.1A, 100-240VAC power supply in NEMA 4/IP65 case (E-PS) 58

Figure 48: PoE Injector to provides power over a single Ethernet hub (E-POE) ...... 59

Figure 49: 12-socket DIN Cable connector (E-2CCON) for multi-conductor cable ... 59

Figure 50: Modline5 patch cable kit to use existing Modline5 cables (E-M5PK) ....... 60

Figure 51: USB to RS232/422/485 converter (E-USB485)....................................... 60

Figure 52: Extraction view of Endurance® sensor with mechanical accessories ..... 61

vii

Page 12

Figure 53: Air purge collar (E-AP) ............................................................................ 62

Figure 54: Pipe adapter to attach sighting tubes (E-PA) .......................................... 62

Figure 55: Mounting nut (E-MN) .............................................................................. 63

Figure 56: Drawing and Photo of Fixed Bracket (E-FB) ........................................... 63

Figure 57: Adjustable bracket (E-AB) ...................................................................... 64

Figure 58: Swivel bracket (E-SB)............................................................................. 64

Figure 59: Right angle mirror for targets at right angles to sensor axis (E-RA) ........ 65

Figure 60: Adapter kit to use Endurance® sensors in Modline5 WJA (E-M5WJAK) 65

Figure 61: Endurance® universal adapter accessory (E-UAA) ................................ 66

Figure 62: Adapter kit for Endurance® in WJ-5 water jacket installations (E-AK-7) . 66

Figure 63: Mounting flange (E-MF-7) ....................................................................... 67

Figure 64: Flange adapter to allow Endurance® to mount to MF-7 (E-MFA-7) ........ 67

Figure 65: Replacement glass end-cap for Endurance® sensors (E-ECAP) ............ 67

Figure 66: Protective front window, including O-Ring (E-PW) .................................. 68

Figure 67: Polarizing filter end cap for use in high temperature applic. (E-PFEC) .... 68

Figure 68: Dimensions for the ThermoJacket .......................................................... 70

Figure 69: Mounting Flange for ThermoJacket (E-MF) ............................................ 71

Figure 70: Adjustable Mounting Base for ThermoJacket (E-MB) ............................. 71

Figure 71: Explosion view of the Adjustable Mounting Base (E-MB) ........................ 72

Figure 72: Dimensions of the Blast Gate Assembly ................................................. 73

Figure 73: Mounting the Blast Gate Assembly ......................................................... 73

Figure 74: Adjustable Pipe Adapter (E-APA) ........................................................... 74

Figure 75: Mounting Flange for Sighting Tube (E-MST) .......................................... 74

Figure 76: Ceramic Sighting Tube (E-STC12) ......................................................... 75

Figure 77: Stainlless Steel Sighting Tube (E-ST12) ................................................. 75

Figure 78: Carbon Steel Sighting Tube with 45° end cut (E-BEESIGHT) ................. 76

Figure 79: Drawing and picture of the extraction tool (E-TJET) ............................... 76

Figure 80: Extraction tool (E-TJET) attached to Endurance® M16 Connector ......... 77

Figure 81: Water Flow Regulator (E-WR) ................................................................ 78

Figure 82: Air Purging Flow Regulator with air filter (E-AR) ..................................... 78

Figure 83: Dimensions of Cooling Air Flow Regulator (E-CAFR-7 ........................... 79

Figure 84: Model L Percentage of Allowed Signal Reduction .................................. 90

Figure 85: Model H Percentage of Allowed Signal Reduction .................................. 91

viii

Page 13

Innovative High Temperature Infrared Pyrometers

Disposal of old instruments should be handled according to professional and

environmental regulations as electronic waste.

Helpful information regarding the optimal use of the instrument.

Warnings concerning operation to avoid instrument damage and personal injury.

The instrument can be equipped with a Class 2 laser. Class 2 lasers shine only

within the visible spectrum at an intensity of 1 mW. Looking directly into the laser

beam can produce a slight, temporary blinding effect, but does not result in physical

injury or damage to the eyes, even when the beam is magnified by optical aids. At

any rate, closing the eye lids is encouraged when eye contact is made with the laser

beam. Pay attention to possible reflections of the laser beam. The laser functions

only to locate and mark surface measurement targets. Do not aim the laser at

people or animals.

Use in 115/230 V~ electrical systems can result in electrical hazards and personal

injury, if not properly protected. All instrument parts supplied by electricity must be

covered to prevent physical contact and other hazards at all times.

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

1. Safety Instructions

This document contains important information, which should be kept at all times with the

instrument during its operational life. Other users of this instrument should be given these

instructions with the instrument. Eventual updates to this information must be added to the

original document. The instrument can only be operated by trained personnel in accordance

with these instructions and local safety regulations.

Acceptable Operation

This instrument is intended only for the measurement of temperature. The instrument is

appropriate for continuous use. The instrument operates reliably in demanding conditions, such

as in high environmental temperatures, as long as the documented technical specifications for

all instrument components are adhered to. Compliance with the operating instructions is

necessary to ensure the expected results.

Unacceptable Operation

The instrument should not be used for medical diagnosis.

Replacement Parts and Accessories

Use only original parts and accessories approved by the manufacturer. The use of other

products can compromise the operation safety and functionality of the instrument.

Instrument Disposal

Operating Instructions

The following symbols are used to highlight essential safety information in the operation

instructions:

Pay particular attention to the following safety instructions.

1

Page 14

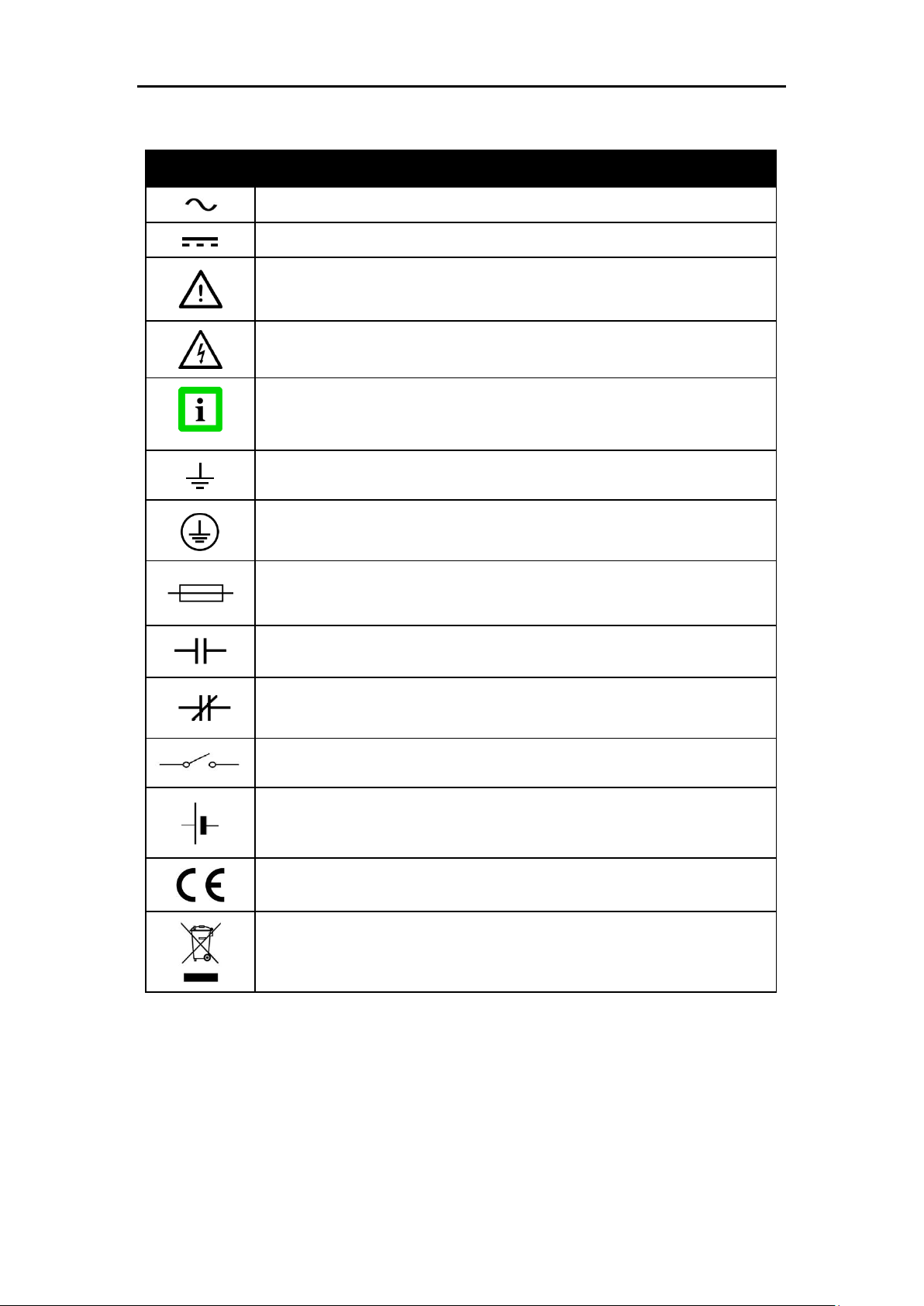

Endurance® Series

Symbol

Definition

AC (Alternating Current)

DC (Direct Current)

Risk of danger. Important information. See manual.

Hazardous voltage. Risk of electrical shock.

Helpful information regarding the optimal use of the instrument.

Earth ground

Protective ground

Fuse

Normally-open (NO) relay

Normally-closed (NC) relay

Switch or relay contact

DC power supply

Conforms to European Union directive.

Disposal of old instruments should be handled according to professional and

environmental regulations as electronic waste.

Users Manual

Table 1: General Symbols

2

Page 15

Innovative High Temperature Infrared Pyrometers

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

2. Product Description

The Endurance® Series of instruments consist of 1-Color (monochrome) and 2-Color (ratio)

infrared noncontact temperature measurement systems with variable focus, through-the-lens

sighting, and parallax-free optics. They are energy transducers designed to measure accurately

and repeatedly the amount of heat energy emitted from an object, and then convert that energy

into a measurable electrical signal. Temperature measurements can be taken using either of

the following modes:

1-Color mode (monochrome) – for standard temperature measurements. The 1-color

mode is best for measuring the temperature of targets in areas where no sighting

obstructions, either solid or gaseous, exist. The 1-color mode is also best where the

target completely fills the measurement spot.

2-Color mode – temperatures are determined from the ratio of two separate and

overlapping infrared bands. The 2-color mode is best for measuring the temperature of

targets that are partially obscured (either intermittently or permanently) by other objects,

openings, screens, or viewing windows that reduce energy, and by dirt, smoke, or steam

in the atmosphere. The 2-color mode can also be used on targets that do not completely

fill the measurement spot, provided the background is much cooler than the target.

Each model operates as an integrated temperature measurement subsystem consisting of

optical elements, spectral filters, detector, digital electronics and an IP65 (NEMA-4) rated

housing. Each is built to operate on a 100 percent duty cycle in industrial environments. Various

output types are offered for easy integration into industrial monitoring and control environments.

The following Endurance® series model variants are available, including the several sighting,

cooling and communication options.

1-Color (monochrome) models: E1ML, E1MH, E2ML, E2MH, E3ML, E3MH

2-Color (ratio) models: E1RL, E1RH, E2RL

Please see detailed information under chapter 3 (Technical Data).

3

Page 16

Endurance® Series

X

0 1

---

X

0 1

---

Y

L D V

---

X

0 1 2

Y

F F F

---

Y

L H

Y

M R

X

1 2 3

E

E

Endurance®-Series Model Variants Identification By Defined Numbering Tree

X = Number

Y

= Capital

None

Harsh environment option - Air purge and integrated water cooling

Communication Interface

Cooling Option

Sighting Option

Focus Identifier (0, 1, 2)

Focus Distance (F)

Profinet network communications interface with installed M12 fieldbus connector

Ethernet network communications interface with installed M12 fieldbus connector, built-in HTTP-Server (ASCII, MJPEG-Video 720p, Web)

Temperature Range (L, H)

Pyrometer Type (M = monochrome, R = ratio)

Infrared sensor wavelength (1, 2, 3 ~ 1µm, 1.6µm, 2.4µm)

Unique Endurance® Identifier

→→→

LED target pointing through the lens and visible through the lens

Laser target pointing through the lens and visible through the lens

Fixed defined "E" for Endurance® series devices

Infrared sensor wavelength = 2.4µm

Infrared sensor wavelength = 1.6µm

Infrared sensor wavelength = 1µm

R = Ratio (2-color) pyrometer type

M = Monochrome (single color) pyrometer type

High Temperature Range

Low Temperature Range

600mm - ∞ (2 4” - ∞) Manual Variable Foc us

300 - 600mm (12 - 24”) Manual Variable Focus

190 - 300mm (7.5 - 12”) Manual Variable Focus

Video Camera, visible through the lens

Users Manual

4

Figure 1: Endurance® Model Identification Matrix

Page 17

Innovative High Temperature Infrared Pyrometers

1-color sensors see polluted atmosphere and dirty windows and lenses as

a reduction in energy and give much lower than actual temperature

readings!

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

2.1. Theory of Operation for 2-Color Sensors

Two-color ratio technology makes possible accurate and repeatable temperature

measurements that are free from dependence on absolute radiated energy values. In use, a 2color sensor determines temperature from the ratio of the radiated energies in two separate

wavelength bands (colors).

The benefits of 2-color sensors are that accurate measurements can be made under the

following conditions:

When the field of view to the target is partially blocked or obscured.

When the target is smaller than the sensor’s field of view.

When the target emissivity is low or changing by the same factor in both wavelength

bands.

Another benefit is that 2-color sensors measure closer to the highest temperature within the

measured spot (spatial peak picking) instead of an average temperature. A 2-color sensor can

be mounted farther away, even if the target does not fill the resulting spot size. The convenience

is that you are not forced to install the sensor at some specific distance based upon target size

and the sensor’s optical resolution.

2.1.1. Partially Obscured Targets

The radiated energy from a target is, in most cases, equally reduced when objects or

atmospheric materials block some portion of the optical field of view. It follows that the ratio of

the energies is unaffected, and thus the measured temperatures remain accurate. A 2-color

sensor is better than a 1-color sensor in the following conditions:

Sighting paths are partially blocked (either intermittently or permanently).

Dirt, smoke, or steam is in the atmosphere between the sensor and target.

Measurements are made through items or areas that reduce emitted energy, such as

grills, screens, small openings, or channels.

Measurements are made through a viewing window that has unpredictable and

changing infrared transmission due to accumulating dirt and/or moisture on the window

surface.

The sensor itself is subject to dirt and/or moisture accumulating on the lens surface.

2.1.2. Targets Smaller Than Field of View

When a target is not large enough to fill the field of view, or if the target is moving within the

field of view, radiated energies are equally reduced, but the ratio of the energies is unaffected

and measured temperatures remain accurate. This remains true as long as the background

temperature is much lower than the target’s. The following examples show where 2-color

sensors can be used when targets are smaller than the field of view:

Measuring wire or rod — often too narrow for field of view or moving or vibrating

unpredictably. It is much easier to obtain accurate results because sighting is less

critical with two-color sensors.

Measuring molten glass streams — often narrow and difficult to sight consistently with

single-wavelength sensors.

2.1.3. Emissivity and 1-color (single wavelength) measurements

Emissivity is a calculated ratio of infrared energy emitted by an object to the energy emitted by

a blackbody at the same temperature (a perfect radiator has an emissivity of 1.00). The

5

Page 18

Endurance® Series

The slope is the important parameter for measurements in 2-color mode!

The emissivity affects only measurements in 1-color mode.

Users Manual

emissivity is preset at 1.00. For information on determining an unknown emissivity, and for

sample emissivities, refer to the appendix of this manual.

When target emissivity is uncertain or changing, a 2-color sensor can be more accurate than a

1-color instrument as long as the emissivity changes by the same factor in both wavelength

bands. Accurate measurement results are dependent on the application and the type of

material being measured. The emissivity of all real objects changes with wavelength and

temperature, at varying degrees, depending on the material. To determine how to use 2-color

sensors with your application when uncertain or changing emissivities are a factor, please

contact our sales representative or technical support department.

2.1.4. Slope (2-color ratio) measurements

The slope is the quotient of the emissivities based on the narrow and the wide spectral range

(first and second wavelength). The slope is preset at the factory at 1.000.

For information on determining an unknown slope, and for sample slopes, refer to the appendix

of this manual.

6

Page 19

Innovative High Temperature Infrared Pyrometers

General Specifications

Device Model

Parameter

E1ML, E1MH,

E2ML, E2MH,

E3ML, E3MH,

E1RL, E1RH,

E2RL

Environmental Rating for housing

IP65 (IEC529) / NEMA 4

Ambient Temp. without cooling

All models, except E2RL

E2RL

0 - 65°C (32 - 149°F)

0 - 60°C (32 - 140°F)

Ambient Temp. with air cooling

0 - 120°C (32 - 248°F)

Ambient Temp. with water cooling

0 - 175°C (32 - 347°F)

Ambient Temp. with ThermoJacket

0 - 315°C (32 - 600°F)

Storage Temperature

-20 to 70°C (-4 to 158°F)

Relative Humidity

10 to 95%, non-condensing

at 22°C to 43°C (72°F - 110°F)

EMC

EN 61326-1:2006

Safety

EN 60825-1:2008-05

FDA laser safety compliant

Mechanical Shock

IEC 68-2-27 (5 G, 11 msec duration, 3 axes)

Vibration

IEC 68-2-6 (2 G, 10 to 150 Hz, 3 axes)

Warm up Period

15 minutes

Weight

Endurance® sensor

Air / Water cooled housing

Mounting nut

Fixed mounting bracket

1220g (2.69 lbs)

1760g (3.88 lbs)

62g (0.14 lbs)

264g (0.58 lbs)

Sensor Head Housing Material

Stainless Steel

Mat.-No.: 1.4305, Mat.-Name.: X8CrNiS18-9

Control Panel (User Interface)

Upper Display: Green 7-segment, 4 digits LED

type for displaying the measured object

temperature and error codes.

Lower Display: Green/Red background

illuminated graphics display type. Resolution is

32 * 136 pixels to display 2 text lines of about

16 characters per line. It is the main

screen/menu display, which shows all

information and configuration topics.

LED #1: (red/green) Sensor alarm status and

LED #2: Laser/LED/Video on/off.

4 individual control pushbuttons, to walk through

the menu structure and to enter setup values.

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

3. Technical Data

3.1. General Specifications

7

Page 20

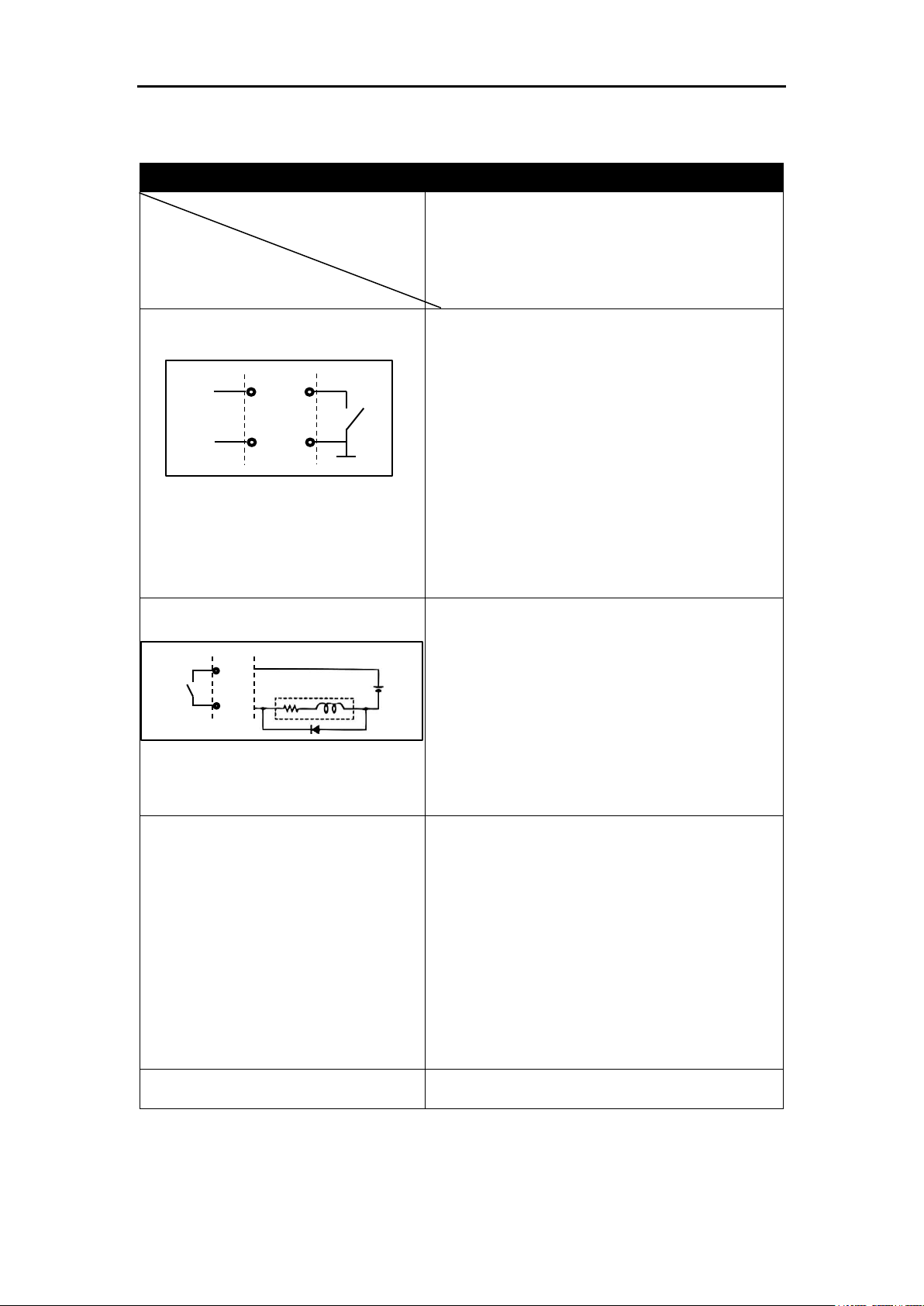

Endurance® Series

Electrical Specifications

Device Model

Parameter

E1ML, E1MH,

E2ML, E2MH,

E3ML, E3MH,

E1RL, E1RH,

E2RL

Inputs (digital, analog)

External Trigger/Hold (digital)

Current loop / mA input (analog)

Galvanically isolated inputs

1.) Trigger input (digital active low)

- Average / Peak / Valley hold reset

to restart signal processing

- LED/Laser on/off

2.) Analog mA input (0/4-20mA)

- Current measurement via command

- Set emissivity (single or 2-color mode)

- Set slope (2-color devices only)

- Set background temperature for

background compensation

Outputs (digital, analog)

Alarm Output Relay (digital)

Current loop / mA output (analog)

Galvanically isolated outputs

1.) Potential-free contact of a solid state relay,

maximum load: 48 V, 300 mA

Contact behavior is settable via user interface

- NO = Normally Open

- NC = Normally Close

- PO = Permanently Open

- PC = Permanently Close

2.) Analog mA output (0 - 20 mA, 4 - 20 mA)

- active output, 16 bit resolution

- max. current loop impedance: 500 Ω

Digital Communications

RS485 (A/B mode)

LAN/Ethernet (comm. Option 0)

Profinet IO (comm. Option 1)

Galvanically isolated communication interfaces

1.) Network compatible up to 32 sensors

(2-wire half duplex, multidrop line capability)

Data format: 8 bit, no parity, 1 stop bit

Data rate (Bit/s): 1200, 2400, 9600, 19200,

38400 (def.), 57600, 115200

2.) 4-Wire 100 Mbit (100Base-TX / IEEE 802.3u)

with “Power over Ethernet” capability to

power the Endurance® device via the

interface. Please refer for the correct wiring to

the PoE standard IEEE 802.3af, mode A,

10/100 Mbit mixed DC & data.

- ASCII, HTTP, MJPEG-Video, Webserver

Power Supply

20 to 48 VDC allowed, max. 12W

Power over Ethernet (IEEE 802.3af)

Endurance®

External process device

≤ 48 V

Relay

GND

Endurance®

Ext. trigger

in process

Trigger

Ground

Users Manual

3.2. Electrical Specifications

8

Page 21

Innovative High Temperature Infrared Pyrometers

Measurement Specifications

Device Model

Parameter

E1ML, E1MH,

E2ML, E2MH,

E3ML, E3MH,

E1RL, E1RH,

E2RL

Temperature Range for model

E1ML:

E1MH:

E2ML:

E2MH:

E3ML:

E3MH:

E1RL (1C-mode):

E1RL (2C-mode):

E1RH (1C / 2C-mode):

E2RL (1C / 2C-mode):

400 - 1740°C (752 - 3164°F) D:S = 160:1

540 - 3000°C (1004 - 5432°F) D:S = 300:1

250 - 1100°C (482 - 2012°F) D:S = 160:1

450 - 2250°C 842 - 4082°F) D:S = 300:1

50 - 1000°C (122 - 1832°F) D:S = 100:1

150 - 1800°C (302 - 3272°F) D:S = 300:1

550 - 1800°C (1022 - 3272°F) D:S = 100:1

600 - 1800°C (1112 - 3272°F) D:S = 100:1

1000 - 3200°C (1832 - 5792°F) D:S = 150:1

Indication from 3000 to 3200°C (5432 to 5792°F

250 - 1200°C (482 - 2192°F) D:S = 75:1

Lens Options

F0: 190 - 300mm (7.5 - 12")

F1: 300 - 600mm (12 - 24")

F2: 600mm - ∞ (24" - ∞)

Sighting Options

Visual/Laser

Visual/Camera

Visual/LED

Accuracy

E1ML ( > 450°C / 842°F):

E1ML ( < 450°C / 842°F):

E1MH ( > 650°C / 1202°F):

E1MH ( < 650°C / 1202°F):

E2ML:

E2MH:

E3ML ( > 100°C / 212°F):

E3MH ( < 100°C / 212°F):

E1RL (with no attenuation):

E1RH (with no attenuation):

E2RL (with no attenuation):

± (0.3% read + 1°C)

± (2% read + 2°C)

± (0.3% read + 1°C)

± (2% read + 2°C)

± (0.3% read + 2°C)

± (0.3% read + 1°C)

± (0.3% read + 1°C)

± (1% read + 2°C)

± (0.5% Tmess +2°C)

± (0.5% Tmess +2°C)

± (0.5% Tmess +2°C)

Repeatability

E1ML ( > 450°C / 842°F):

E1ML ( < 450°C / 842°F):

E1MH ( > 650°C / 1202°F):

E1MH ( < 650°C / 1202°F):

E2ML:

E2MH:

E3ML ( > 100°C / 212°F):

E3MH ( < 100°C / 212°F):

E1RL (Tmeas in °C, no attenuation):

E1RH(Tmeas in °C, no attenuation):

E2RL (Tmeas in °C, no attenuation):

± (0.1% read + 1°C)

± (1% read + 1°C)

± (0.1%read + 1°C)

± (1% read + 1°C)

± (0.1% read + 1°C)

± (0.1% read + 1°C)

± (0.1% read + 1°C)

± (1% read + 1°C)

±(0.3% Tmeas +1°C)

±(0.3% Tmeas +1°C)

±(0.3% Tmeas +1°C)

Temperature Resolution

For display and RS485 interface

±0.1°C (±2°F)

Temperature Coefficient

0.03% full scale change per 1°C change in

ambient temperature

Response Time to reach 95%

of final temperature reading

E1ML:

E1MH:

2 ms

2 ms

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

3.3. Measurement Specifications

9

Page 22

Endurance® Series

E2ML:

E2MH:

E3ML:

E3MH:

E1RL:

E1RH:

E2RL:

2 ms

2 ms

20 ms

20 ms

10 ms

10 ms

20 ms

Selectable Analog Current output

0-20mA or 4-20mA (galvanic isolated)

16bit resolution, max. impedance: 500Ω

Emissivity Coefficient (1-Color mode)

E1ML, E1MH, E2ML, E2MH,

E3ML, E3MH, E1RL, E1RH,

E2RL:

Slope Coefficient (2-Color mode)

E1ML, E1MH, E2ML, E2MH,

E3ML, E3MH

E1RL, E1RH, E2RL:

Digitally adjustable in increments of 0.001

0.100 to 1.100

0.100 to 1.100

0.100 to 1.100

Digitally adjustable in increments of 0.001

N/A

N/A

0.850 to 1.150

Signal Processing

Peak hold or Averaging

Peak Hold Range

0.1 to 299.9 s (300 s = )

Averaging Range

0.1 to 299.9 s (300 s = )

Noise Equivalent Temperature (NET)

1°C peak to peak, target emissivity of 1.00,

unobscured target, 3°C peak to peak for all

specified attenuation conditions

Optical Specifications

Device Model

Parameter

E1ML, E1MH,

E2ML, E2MH,

E3ML, E3MH,

E1RL, E1RH,

E2RL

Optical Resolution D:S

E1ML:

E1MH:

E2ML:

E2MH:

E3ML:

E3MH:

E1RL (1C / 2C-mode):

E1RH (1C / 2C-mode):

E2RL (1C / 2C-mode):

(assumes 95% energy at the focus point)

D:S = 160:1

D:S = 300:1

D:S = 160:1

D:S = 300:1

D:S = 100:1

D:S = 300:1

D:S = 100:1

D:S = 150:1

D:S = 75:1

Lens Options

F0: 190 - 300mm (7.5 - 12")

F1: 300 - 600mm (12 - 24")

F2: 600mm - ∞ (24" - ∞)

Sighting Options

Visual/Laser

Visual/Camera

Visual/LED

Users Manual

3.4. Optical Specifications

Because the sensor has variable focus, through-the-lens sighting, and parallax-free optics, it

can be mounted almost anywhere.

Adjustable focus distance range varies by model:

F0 (Narrow Focus) models can be focused from 190 to 300mm (7.5 - 12")

F1 (Close Focus) models can be focused from 300 to 600 mm (12 - 24”)

F2 (Standard Focus) models can be focused from 600 to infinity (24” - infinity)

10

Page 23

Innovative High Temperature Infrared Pyrometers

The spot size calculated using this method is valid only at the focus distance.

Spot sizes out of focus distances will vary from the rule.

D = Distance

S = Spot

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

For 1-color temperature measurements make sure the target completely fills the measurement

spot. The target spot size for a properly focused target with the given distance to the target can

be determined by using the following formula under Figure 2.

Divide the distance (D, in Figure 2) by the D:S specification to get the target spot size.

Figure 2: Spot Size Chart

3.5. Dimensions

The following illustrations shows the dimensions of an Endurance® sensor, see Figure 3. An

Endurance® sensor installed in the air/water-cooled housing option, see Figure 4.

Figure 3: Dimensions of Endurance® Sensor

Figure 4: Dimensions of Endurance® Sensor in Air/Water-Cooled Housing Option

11

Page 24

Endurance® Series

Specific accessories, which have to be ordered separately!

The following items are not part of the standard delivery

Low temperature 12-conductor cable with connector (E-2CLTCBx)

High temperature 12-conductor cable with connector (E-2CCBx)

Low temperature 4-conductor LAN/Ethernet cable (E-ETHLTCBx)

High temperature 4-conductor LAN/Ethernet cable (E-ETHCBx)

Endurance® series specific terminal block (E-TB)

PoE (Power over Ethernet) injector to act as a single Ethernet hub

and power the Endurance® device via the LAN/Ethernet cable

Users Manual

3.6. Scope of Delivery

The Endurance® standard device delivery includes the following:

Endurance®-Series Infrared Thermometer

Endurance®-Series mounting nut (E-MN)

Fixed mounting bracket (E-FB

End cap for display (E-ECAP)

Mini-DVD with Endurance® SW, Operating Instructions and Quickstart guide

Printed Quickstart guide

4. Environment

Sensor location and configuration depends on the application. Before deciding on a location,

you need to be aware of the ambient temperature at the location, the atmospheric quality at the

location (especially for 1-color temperature measurements), and the possible electromagnetic

interference at the location. If you plan to use air purging, you need to have an air connection

available. Also, wiring and conduit runs must be considered, including computer wiring and

connections, if used. The following subsections cover topics to consider before you install the

sensor.

4.1. Ambient Temperature

The sensing head is designed to operate in ambient temperatures between 0°C (32°F) and

60/65°C (140/149°F). The internal ambient temperature can vary from 10°C (50°F) to 72°C

(162°F). Internal temperatures outside this range will cause a failsafe error. In ambient

conditions above 60/65°C (140/149°F), an optional air/water cooled housing is available to

extend the operating range to 120°C (250°F) with air-cooling, or 175°C (350°F) with water

cooling. When using the water-cooled housing, it is strongly recommended to also use the air

purge collar to avoid condensation on the lens. In ambient conditions up to 315°C (600°F), the

ThermoJacket accessory should be used.

When using air or water-cooling with air purging, make sure air and water supplies are installed

before proceeding with the sensor installation.

Water and air temperatures for cooling should be 15-30°C (60-86°F) for best performance.

Chilled water or air below 10°C (50°F) is not recommended. For air purging or air cooling, clean

(filtered) or “instrument” air is recommended.

4.2. Atmospheric Quality

Smoke, fumes, dust, and other contaminants in the air, as well as a dirty lens are generally not

a problem when using the 2-color mode (as long as the attenuation is equal in both spectral

bands). However, if the lens gets too dirty, it cannot detect enough infrared energy to measure

accurately, and the instrument will indicate a failure. It is good practice to always keep the lens

clean. The Air Purge Collar helps keep contaminants from building up on the lens.

If you use air purging, make sure an air supply with the correct air pressure is installed before

proceeding with the sensor installation.

12

Page 25

Innovative High Temperature Infrared Pyrometers

When installing the sensor, check for any high-intensity discharge lamps or

heaters that may be in the field of view (either background or reflected on a

shiny target)! Reflected heat sources can cause a sensor to give erroneous

readings.

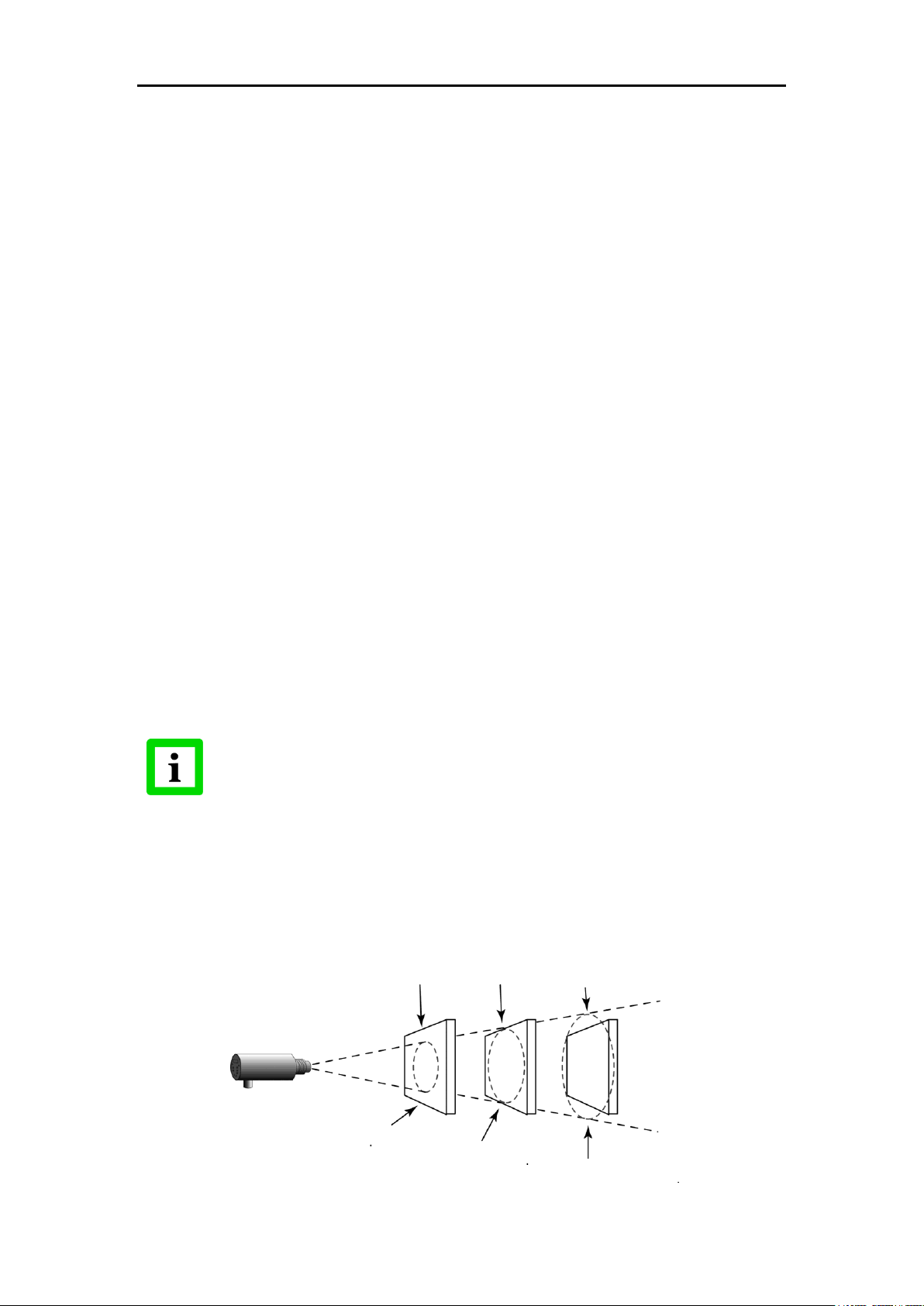

Target greater than spot

Target equal to spot

best

good

incorrect

Target smaller than spot

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

4.3. Electrical Interference

To minimize electrical or electromagnetic interference or “noise” be aware of the following:

Mount the electronics enclosure as far away as possible from potential sources of

electrical interference such as motorized equipment producing large step load

changes.

Use shielded wire for all input and output connections.

Make sure the shield wire from the electronics to terminal block cable is earth grounded.

For additional protection, use conduit for the external connections. Solid conduit is

better than flexible conduit in high noise environments.

Do not run AC power for other equipment in the same conduit.

5. Installation

5.1. Mechanical Installation

After all preparations are complete, you can install the sensor.

How you fix the sensor depends on the type of surface and the type of bracket you are using.

As noted before, all sensors, whether standard or with the air/water-cooled housing option,

come with a fixed bracket (E-FB) and a mounting nut (E-MN). You are able to fix the sensor by

a bracket of your own design, or by one of the available supplier furnished mounting

accessories, see section 9 Accessories, page 51. If you are installing the sensor in a

ThermoJacket accessory, you should use the appropriate mounting device. In such case,

please refer to the ThermoJacket manual for further details. There is no specific focusing tool

accessory for the Endurance® sensor available. The Endurance® sensor needs to be manually

focused before the installation inside a ThermoJacket or before attaching an air purge collar.

5.1.1. Distance to Object

Endurance® sensor placement may vary to suit the application. The following sections

demonstrate the sensor placement under various conditions, where 1- or 2-color temperature

measurements deliver reasonable readings.

5.1.2. Sensor Placement (1-Color Mode)

Sensor placement for 1-color temperature measurements is more critical than for 2-color

measurements. The sensor must have an unobstructed view to the target. Any obstruction on

the lens, the front window, or in the atmosphere influences the temperature reading accuracy.

The sensor distance to the target can be anywhere beyond the minimum requirements, as long

as the target completely fills the field of view.

Figure 5: Proper Sensor Placement in 1-Color Mode

13

Page 26

Endurance® Series

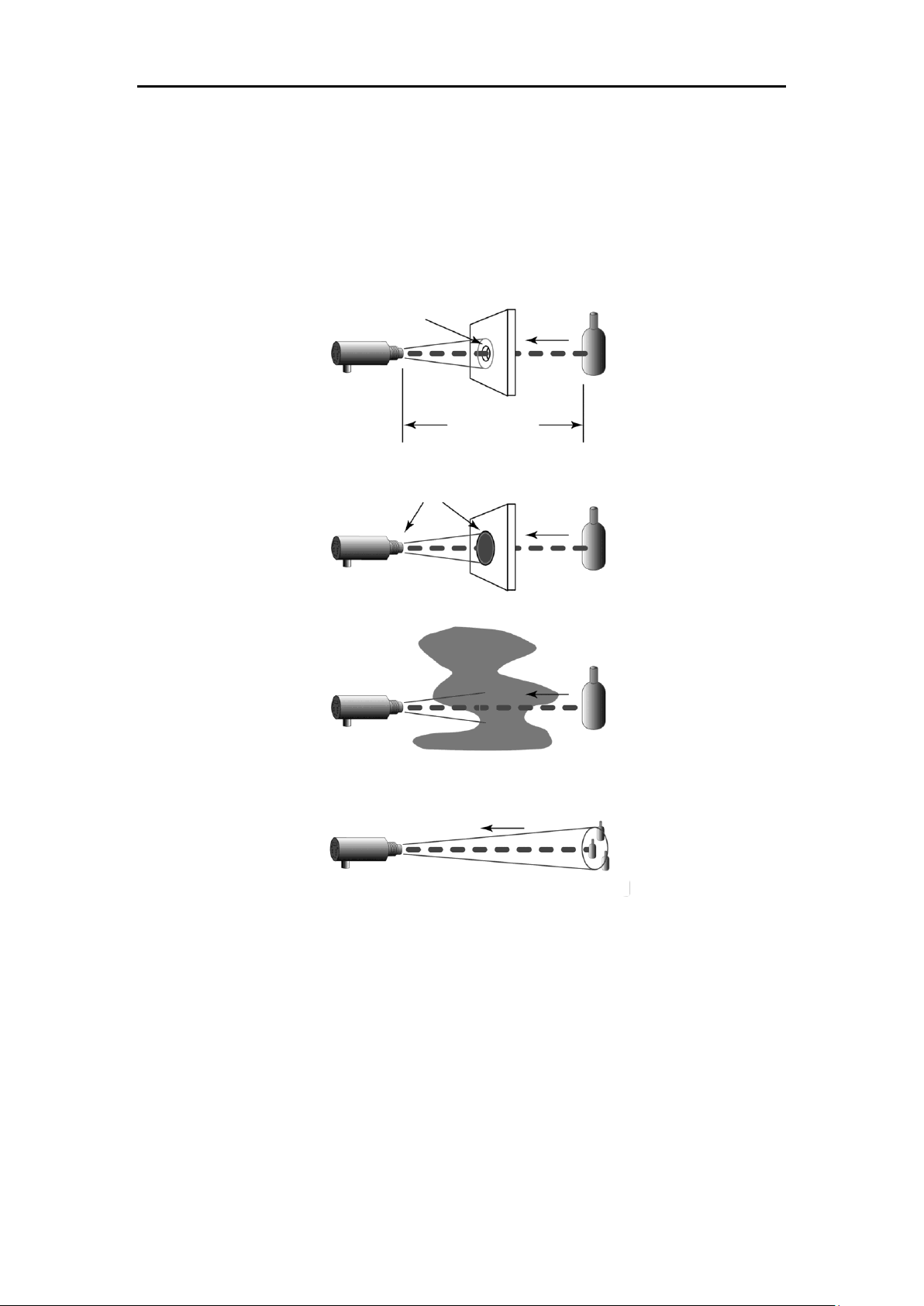

Emitted

energy

Sighting hole smaller than

the sensor’s field of view

Target smaller than field of view

and / or moves or vibrates in and

out of field of view (e.g. wire)

Smoke, steam, dust, gas in atmosphere

Dirty lens or dirty sighting window

Emitted

energy

Emitted

energy

Emitted

energy

Users Manual

5.1.3. Sensor Placement (2-Color Mode)

The following figure demonstrates the sensor placement under various conditions, where valid

2-color temperature measurements are possible. Note, however, that if the sensor signal is

reduced more than 95% (including emissivity and obscuration of the target), the sensor

accuracy also degrades.

14

Figure 6: Sensor Placement in 2-Color Mode

Page 27

Innovative High Temperature Infrared Pyrometers

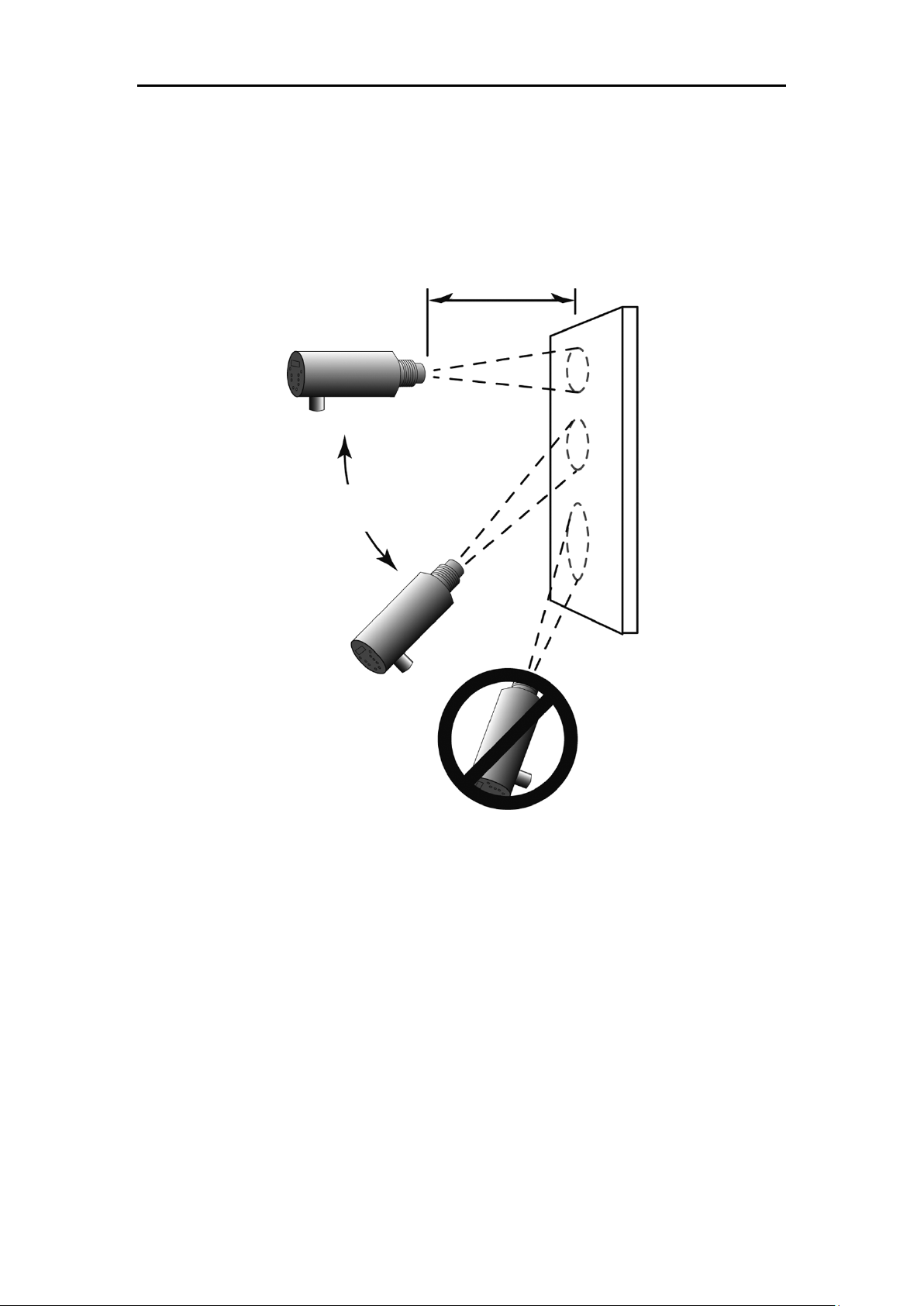

Minimum Distance

SF: 600 mm (24 in)

CF: 300 mm (12 in)

Best

90° to target

Acceptable

Viewing Angles

Bad

1-Color Mode: greater than 30° to target

2-Color Mode: greater than 45° to target

Good

1-Color Mode: 30° to target

2-Color Mode: 45° to target

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

5.1.4. Viewing Angles

The pitch angle of the Endurance® sensor facing the target may vary up to 30° in the 1-color

measurement mode. A pitch angle variation of up to 45° is allowed in the 2-color mode.

Figure 7: Acceptable Sensor Viewing Angles

15

Page 28

Endurance® Series

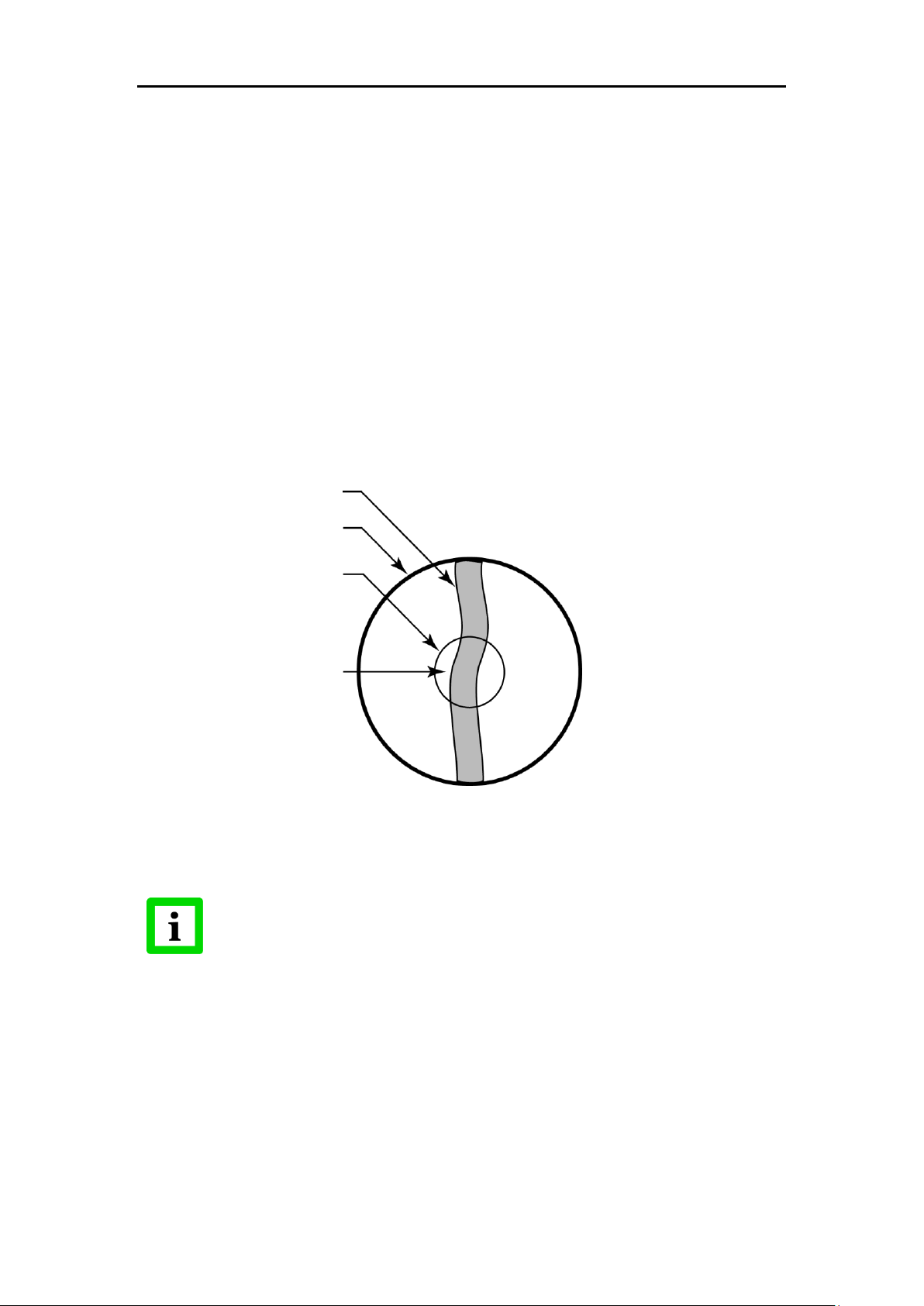

When focusing the sensor, do not depend on the clarity of the image

through the eyepiece to determine the focus. Use the “move the eye”

technique described in step 3 above. If the desired focus distance is known

in advance, this focusing can be conveniently done in the office

environment before installation.

Target

Sighting scope

Reticle

Area to measure

(Inside reticle)

Users Manual

5.1.5. Aiming and Focusing

Once you have the sensor in place, you need to aim and focus it on the target. To aim and

focus the sensor, complete the following:

1. Loosen the nuts or bolts of the mounting base. (This can be either a factory-supplied

accessory or customer-supplied base.)

2. Look through the eyepiece and position the sensor so the target is centered as much as

possible in the middle of the reticle, see Figure 8. (Note that the target appears upside

down.)

3. Turn the lens holder clockwise or counter-clockwise until the target is in focus. You can

tell the lens is focused correctly by moving your eye from side to side while looking

through the eyepiece. The target should not move with respect to the reticle. If it does,

keep adjusting the focus until no apparent motion is observed.

4. Check again to be sure the target is still centered, and secure the mounting base.

Focusing is complete.

Figure 8: Sensor Eyepiece and Reticle

16

Page 29

Innovative High Temperature Infrared Pyrometers

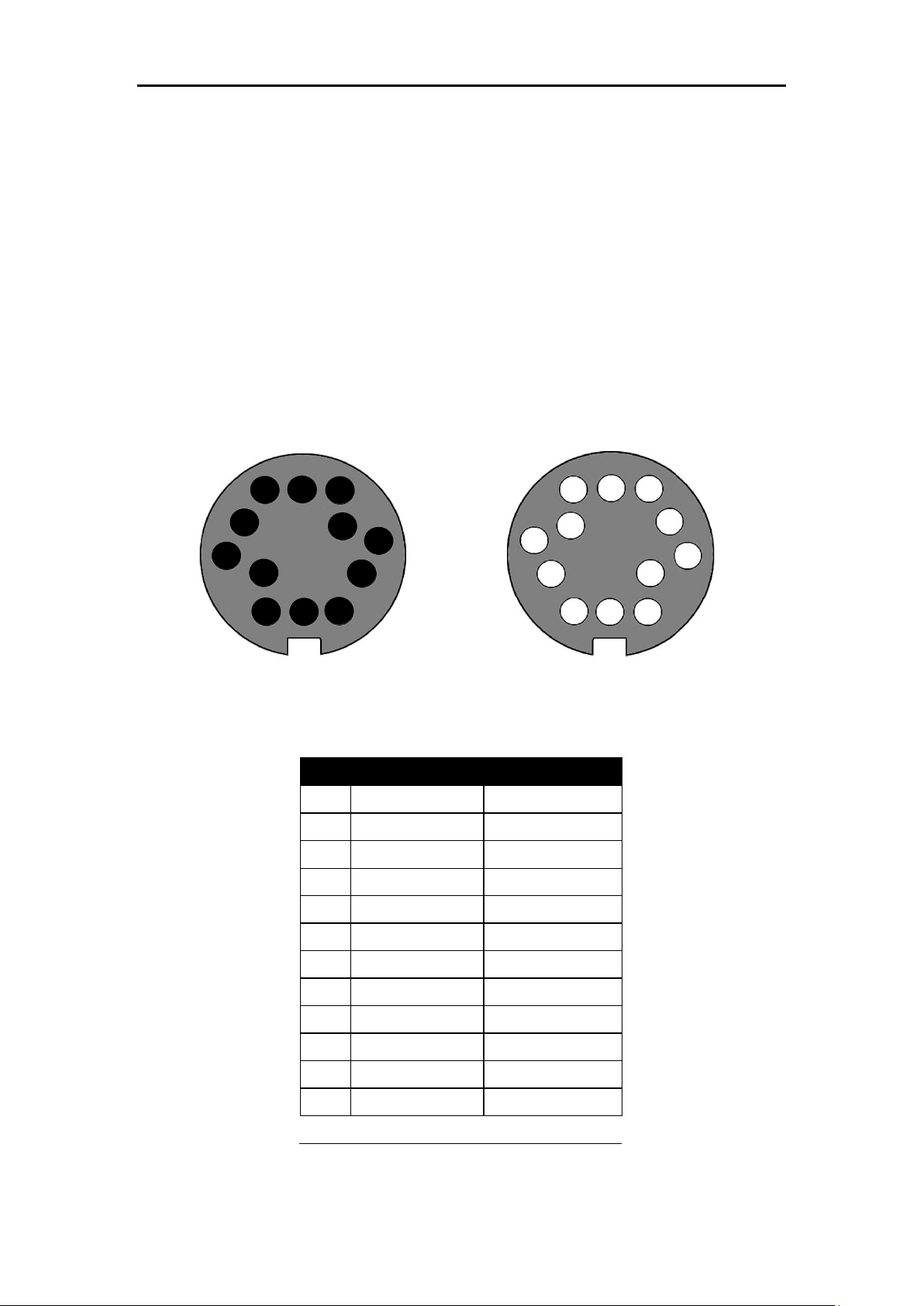

Pin

Color

Description

A

Black*

A B White*

B C Grey*

- mA In

D

Purple*

+ mA In

E

White/Drain

Shield

F

Yellow

Trigger

G

Orange

Relay

H

Blue

Relay

J

Green

+ mA Out

K

Brown

– mA Out

L

Black

Power Ground

M

Red

+ 24 VDC

Note: Twisted Pairs*

F E G A K

B

C

D H J L M A B

C D F E G H J K L

M

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

5.2. Electrical Installation

The Endurance®-Series pyrometers are equipped with two IP67 protected connector sockets.

A M16 (big one) 12-pin DIN connector houses a RS485 interface, trigger input, relay contact,

current input, current output and 24V power supply wires.

A M12 (small one) 4-socket connector houses a 100Mbit/s LAN/Ethernet link with integrated

Power over Ethernet (PoE).

Endurance®-Series pyrometer are able to communicate via both integrated interfaces

(LAN/Ethernet, RS485) simultaneously.

5.2.1. M16 12-Pin DIN Connector Signal Assignment

In case wiring/re-wiring a M16 12-socket DIN connector or a supplied accessory cable

connector, refer to the following illustration and table for the wiring layout.

Figure 9: M16 12-Pin connector (left) and the corresponding cable socket (right)

Figure 10: M16 DIN Connector signal assignment

17

Page 30

Endurance® Series

The sensor head is rated NEMA-4 (IEC 529, IP65).

Endcap must be securely installed to maintain proper sealing.

To prevent possible electrical shock, fire, or personal injury make sure

that the sensor is grounded before use.

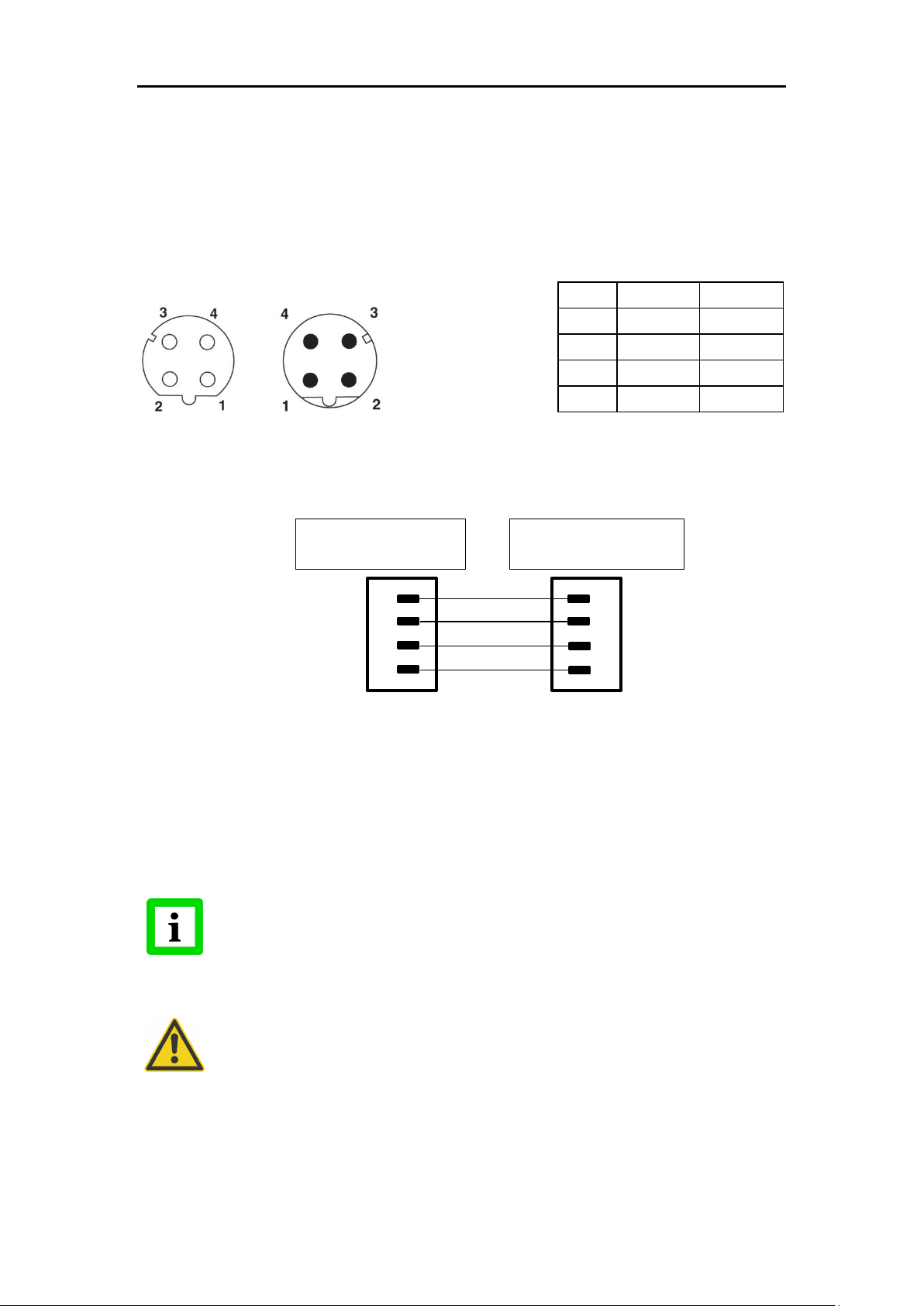

Signal

Pin RJ45

Pin M12-4

TD+ 1 1

TD- 2 3

RD+ 3 2

RD- 6 4

RJ45

PoE Injector/Switch

M12-4

Endurance® Device

Users Manual

5.2.2. M12 4-Socket LAN/Ethernet Connector

The LAN/Ethernet connector on Endurance®-Series side is a M12 4-socket connector type, Dcoded, suited for industrial Ethernet with IP67 protection rate and a screw retention feature. Via

the LAN/Ethernet connector the Endurance®-Series device can also be powered as a PD

(Powered Device) by a PSE (Power Sourcing Equipment) in a PoE (Power over Ethernet)

mode. In such operation mode a PoE injector or a PoE switch is needed. Refer to PoE standard

IEEE 802.3af, mode A, 10/100 Mbit mixed DC & data.

Figure 11: M12 Socket (left) and the corresponding cable plug (right)

Figure 12: Ethernet Cable with M12 Plug and RJ45 Connector

5.2.3. Accessory Cables and Terminal Block

As accessories for the Endurance®-Series devices there are two different communication

cables and a specific terminal block available. Both sensor cables can be ordered in several

cable lengths and two different ambient temperature ratings.

5.2.3.1. M16 12-Conductor shielded cable

The 12-conductor shielded connecting cable is used to wire all the fundamental inputs and

outputs like RS485 interface, trigger input, relay contact, current input, current output and 24V

power supply wires to the Endurance®-Series sensor. The cable is equipped with an IP67 rated

18

Page 31

Innovative High Temperature Infrared Pyrometers

If you cut the cable to shorten it, notice that both sets of twisted-pair wires

have drain wires inside their insulation. These drain wires (and the white wire

that is not part of the twisted pair) must be connected to the terminal labeled

CLEAR or SHIELD.

Longer cables are available from the factory.

Limit power cables to 60 m (200 ft) or less. RS485 cables can be

extended up to 1200 m (4000 ft).

Avoid installing the sensor cable in noisy electrical environments

such as around electrical motors, switch gear, or induction heaters.

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

M16 12-socket DIN connector at one end and colored wires with cable end sleeves at the

counter side.

See below the colored wire to signal assignments, which are identical to the specific terminal

block labeling. For more cable details see section 9.1.

Figure 13: M16 12-Conductor shielded cable with colored wire/signal assignments

5.2.3.2. M12 4-Conductor shielded cable

The 4-conductor shielded connecting cable is used to link the Endurance®-Series device to a

LAN/Ethernet device. A standardized cable, equipped with a M12 4-pin connector type, Dcoded, suited for industrial Ethernet with IP67 protection rate and a screw retention feature on

one side and a RJ45 connector type on the counter side is used. Via the 4-conductor cable the

Endurance®-Series device can also be powered as a PD (Powered Device) by a PSE (Power

Sourcing Equipment) in a PoE (Power over Ethernet) mode. Refer to PoE standard IEEE

802.3af, mode A, 10/100 Mbit mixed DC & data.

Figure 14: M12 4-Conductor shielded cable with RJ45 on counter side

19

Page 32

Endurance® Series

Isolated power is required, and the appropriate manufacturer supplied

power supply accessory provides this. Beware of use of other power

supplies, which may not provide the necessary isolation and could cause

instrument malfunction or damage!

Users Manual

5.2.3.3. Endurance® specific terminal block

An Endurance® specific terminal block is available to attach the 12-wire color-coded sensor

cable via the terminal block to the process world.

Figure 15: Endurance® series labeled terminal block

5.2.4. Power Supply

Connections from a nominal 24VDC (500 mA or higher) power supply attach to the appropriate

terminals on the electronic enclosure’s terminal strip.

5.2.5. Computer Interfacing via RS485 link

The distance between the sensor and a computer can be up to 1200 m (4000 ft.) via RS485

interface. This allows ample distance from the harsh environment where the sensing system is

mounted to a control room or pulpit where the computer is located. The USB/RS485 Interface

Converter allows you to connect your Endurance® sensor to computers by using an USB

interface.

With auto configuration, the converter is able to automatically configure RS485 signals without

external switch setting. The converter is equipped with 3000 VDC of isolation and internal

surge-protection to protect the host computer and the converter against high voltage spikes, as

well as ground potential difference. When the converter is connected the computer gets one

virtual COM port.

Technical Data

Power supply 5 VDC direct from USB port

Speed max. 256 kBit/s

RS485 4 wire (full duplex) and 2 wire (half duplex)

Terminal screwed accepts 0.05 to 3 mm² (AWG 13 to AWG 30)

USB connector type B (supplied with type A to type B cable)

20

Page 33

Innovative High Temperature Infrared Pyrometers

Just the 2-wire (half duplex) mode is supported by the Endurance® devices

in serial RS485 communication!

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

Ambient Temperature 0 to 60°C (32 to 140°F), 10-90% relative humidity,

non-condensing

Storage Temperature -20 to 70°C (-4 to 158°F), 10-90% relative humidity,

non-condensing

Dimensions (L x W x H) 151 x 75 x 26 mm (5.9 x 2.9 x 1 in)

Just the 2-wire (half duplex) communication is supported on the Endurance® sensor side. The

disadvantage is that the data transfer is just alternating possible in one direction at a time. The

maximum communication baud rate between the Endurance® device and the USB/RS485

converter is 115.200 kBaud. A Baud rate of 38.4 kBaud is the default (preset) value in the

Endurance® series device during factory setup.

Figure 16: USB/RS485 Converter

Multiple Endurance® sensors in a RS485 Multidrop Network Wiring

For an installation of two or more Endurance® sensors in a RS485 network (2-wire, half duplex),

each Endurance® sensor needs it’s specific RS485 network address (1 - 32), preset via the

Endurance® control panel (user interface) or alternatively via a standard terminal program

(operating system dependent). Once all the units are addressed, wire up the units in the 2-wire

multidrop manner, whereas all A-signals, as well all B-signals have to be connected to common

lines. The common A-signals have to be routed to the TX+ and the common B-signals to TXterminal at the selected USB/RS485 converter.

5.2.6. Addressing the Endurance® sensor in a RS485 Multidrop Network

If you are installing two or more sensors in a multi-drop configuration, please be aware of the

following:

Each sensor must have a unique address greater zero (1 - 32).

Each sensor must be set to the same baud rate (default is 38.4 kBaud).

Once all the units are addressed, wire up the units in the 2-wire multidrop manner,

keeping all A & B to be common.

Now you can run the supplied Endurance® software, an own written communication

software or an individual terminal program to access the Endurance® sensor for issuing

commands and receive the responses.

21

Page 34

Endurance® Series

Users Manual

6. Device Control

Once you have your sensor(s) positioned and connected properly, the system is ready for

continuous operation. Nonstop operation of the Endurance® device is achieved either by back

panel operation or through software control via the RS485, the LAN/Ethernet or PROFINET IO

communication interface. The Endurance® software, a MS-Windows based setup and

configuration program is supplied with your sensor. You can also create custom programs using

the communication protocols listed in section 10, Programming Guide.

6.1. Control Panel

The Endurance® sensor is equipped with a control panel, which is the manually operated user

interface and consists of two display types, one alarm and one status LED and several

setting/controlling buttons, as shown in

Figure 17. The panel is primarily for setting up the instrument prior to nonstop operation. A

screwable end cap with a sealed glass window protects the user interface during nonstop

operation. You are able to configure sensor settings via the control panel or remotely via a

computer or a programmable logic controller.

The sensor has a remote locking feature to protect the unit from accidental interaction over the

control panel. This lockout mode denies access to the submenu functions of the control panel.

Via the RS485, the LAN/Ethernet, the PROFINET IO communication interface or a specific key

command over the control panel, the Endurance® device can be unlocked.

Figure 17: Control Panel

6.1.1. The Object / Target Temperature Display (green 7-segment LED type)

Figure 18: Upper Object/Target Temperature Display

22

Page 35

Innovative High Temperature Infrared Pyrometers

INTERNAL TEMP.

23.5 °C

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.

The Object/Target Temperature Display fulfills two tasks to inform the operator:

In normal operation after warm up phase, it displays the current measured object

temperature, including any signal processing like “Averaging Hold”, “Peak Hold” or

“Valley Hold”. The displayed temperature depends on the preset measurement unit

(°C or °F), done in the “CONFIGURATION MENU” and described hereafter.

In abnormal operation, during warm up phase or in failure case, discovered through

the failsafe-circuit, it displays an error code (e.g. ECHH, ECUU, EUUU, EAAA…).

Please see section 11.2 Fail-Safe Operation on page 86.

6.1.2. The Screen / Menu Display

Figure 19: Lower Screen / Menu Display

The Screen/Menu Display is the central user interface display, which shows all selected

menus, their submenus and parameters. In dependence of the selected main menu item, it

displays the first submenu item as default. The menu, sub-menu and entry selection will be

done by specific buttons, described herein afterwards.

6.1.3. The LASER / LED / CAMERA Indicator LED (red)

Figure 20: Upper LASER / LED /CAMERA Activation LED (red)

Indicates the activation (switched-on state) of the integrated LASER, LED or CAMERA.

6.1.4. The Status Indicator LED (green)

Figure 21: Lower Status Indicator LED (green)

Shows a steady green after warm up period to indicate an error free function of the Endurance®

device.

6.1.5. The 4 Control Panel Pushbuttons

6.1.5.1. The Browser Button

The Browser Button serves as a selector for one of the five submenus. A

specific submenu selection can be done in the following ways:

Pressing the Browser Button several times in series to toggle between the

5 submenus

Holding the Browser Button pressed, toggles between the 5 submenus

about every 2 sec

Stop to press the Browser Button, if you’ve reached the preferred submenu, displayed on the

Screen/Menu display. The first menu entry of the selected submenu will be displayed as default.

23

Page 36

Endurance® Series

ENT

Users Manual

6.1.5.2. The ENTER Button

The Enter Button confirms the selection of a submenu or a specific submenu

entry. After walking through the listed submenu entries by using the Navigate

Buttons, the selection done by the Enter Button initiates a blinking of the

modifiable entry, displayed in the 2nd row of the Screen/Menu display. To store

updated entries a final press of the Enter Button is needed. With the Enter

Button you also walk through multiple section entries, like network IPaddresses (4 subfields with a value range of 0-255).

6.1.5.3. The Navigate Up Button

The Navigate Up Button enables you to walk through the list of integrated

entries per submenu, increases marked numerical values or toggles the

specific entry.

6.1.5.4. The Navigate Down Button

The Navigate Down Button enables you to walk through the list of integrated

entries per submenu, decreases marked numerical values or toggles the

specific entry.

6.2. The control panel menu structure and their associated entries

There are five (5) submenus available via the control panel:

INFORMATION MENU (delivers condensed Endurance® device information)

CONFIGURATION MENU (display and alteration of configuration settings)

UNIT SETUP MENU (display and alteration of device setups)

INTERFACE MENU (display and alteration of integrated interface setups)

ANALOG MENU (display and alteration of integrated current loop Analog-I/O)

24

Page 37

Innovative High Temperature Infrared Pyrometers

Error! Use the Home tab to apply Überschrift 1 to the text that you want to appear here.