Page 1

™

E-DWT-H

Electronic Deadweight Tester

Hydraulic deadweight tester performance

with digital measurement convenience

Page 2

E-DWT-H Electronic Deadweight Tester™— leave the deadweight behind

A modern alternative to the traditional deadweight tester

E-DWT-H breaks new ground,

improving the hydraulic pressure

calibration process. E-DWT-H is

an electronic calibrator designed

to replace mechanical, pistoncylinder and weight based

deadweight testers. It’s a lighter

weight, easier-to-use deadweight

tester alternative that is at home in

the lab or instrument shop, as well

as in the field performing in-situ

calibrations and tests.

This complete hydraulic pressure calibration system combines

the convenience and precision of

continuous, real time electronic

pressure measurement with the

simple and direct operation of

high quality operator controlled

pressure generation hardware.

E-DWT-H one year measurement

uncertainty is ± 0.02 %

of reading with ranges up to

30,000 psi. It can be configured to

provide this uncertainty from its

full scale down to 1% of its range.

Built-in pressure generation and

control hardware allow the operator to fill and prime the system

under test and generate and precisely adjust pressure throughout

the range with ease.

Deadweight tester performance with digital measurement convenience

E-DWT-H offers precision, low

measurement uncertainty and the

stability over time of a conventional deadweight tester without

the inconveniences associated

with the piston-cylinders, weights,

hand pumps, and interconnecting

plumbing.

• No weights to load and unload

or regularly send out for

calibration

• No need to know and correct

for local gravity or ambient

temperature

• No piston-cylinder changes;

switch Q-RPT ranges in seconds

• Not sensitive to level or

vibration

• Able to set and read any pressure value exactly, no minimum

increment limited by smallest

available masses

• Operates in any unit of measure

while deadweight tester is typically limited to the pressure unit

stamped on the mass

• Perfect for applications that

require setting a nominal

pressure precisely on the

device under test and measuring it, such as analog gauge

calibration

• On-board, AutoTest calibration

routines and data acquisition

• Interfaceable with a PC or

laptop to allow for automated

data acquisition

• Two year calibration interval

supported at measurement

uncertainty of ± 0.025 % of

reading.

• Easily recalibrated without

crossfloating. Automated calibration of E-DWT-H is possible

using COMPASS

software.

®

for Pressure

Versatility to cover a broad

workload in a variety of

environments

The E-DWT-H is at home in

metrology and calibration labs, on

the production floor or in the field.

It operates with Sebacate calibration fluid, mineral oil, Skydrol

and other liquids.

An optional battery/charger

pack supports up to eight hours of

operation away from line power.

®

AutoTest™ lets E-DWT-H

operators quickly define test

points and adjust all of the

range-dependent settings

with a single function.

The resolution and stability test

used by the RPM4-E-DWT are

set according to the range of the

device under test. The upper limit

setting is also set and provides

range-based warnings and

overpressure protection. While

running AutoTests, the operator is

prompted to set each sequential

test point and test data is stored

2 Fluke Calibration E-DWT-H™ Electronic Deadweight Tester

in the RPM4-E-DWT for recall or

download. Typical test setup is

quick and easy, but more complex tests can also be stored and

reused.

Broad workload coverage

The E-DWT-H has the operational

versatility to calibrate and test a

broad range of pressure measuring instruments including:

• Analog gauges

• Transducers

• Calibrators

• Sensors

• Transmitters

E-DWT-H in lab environment

Page 3

All the features you expect in today’s

Measurement Uncertainty (% of Q-RPT Max Span)

state-of-the-art instruments, including:

Accuracy and performance

• Can be configured to provide

uncertainty of ± 0.02 % of reading from 1 % to 100 % of full

scale range

• Low torque variable volume

allows for pressure generation

up to 200 MPa (30,000 psi) with

minimal physical effort

• Separate fine adjustment

tool for maximum, superfine

controlresolution

• User defined resolution and

ready limits enable user to

optimize performance based

on DUT specifications

• High pressure isolation valve

and pressure relief valve protect

the low pressure reference

transducer from over pressure

when high pressure reference

transducer is active

Ease of use

• AutoRange feature optimizes

measurement and safety

features for the specific range of

the instrument being calibrated

• Simple rezeroing while vented

at atmospheric pressure

• Simple, objective pressure

“ready/not ready” indicator

with user adjustable criteria

to ensure repeatable results

among operators

• Not dependent on local gravity

or ambient temperature

• Sets and reads any pressure

value directly in any unit of

measure, without moving

weights

• Built-in priming system to fill

system with test fluid and purge

unwanted air to assure smooth

operation

• Optional foot switch accessory

allows hands-free data collection when running AutoTests

Portability

• Rechargeable battery pack

option for eight hours of field

operation

• Everything to set, adjust and

read pressure in one compact,

transportable package

• Optional shipping/carrying

case with handles and wheels

allows for easy transport to field

application

• Proven rugged and weatherproof design with room for

accessories.

Automation

• RS-232 interface allows for

real time automated data

collection and customized

report generation using Fluke

Calibration’s COMPASS for

Pressure Calibration software

Free upgrades

• Flash memory for simple and

free embedded software

upgrades from

www.flukecal.com

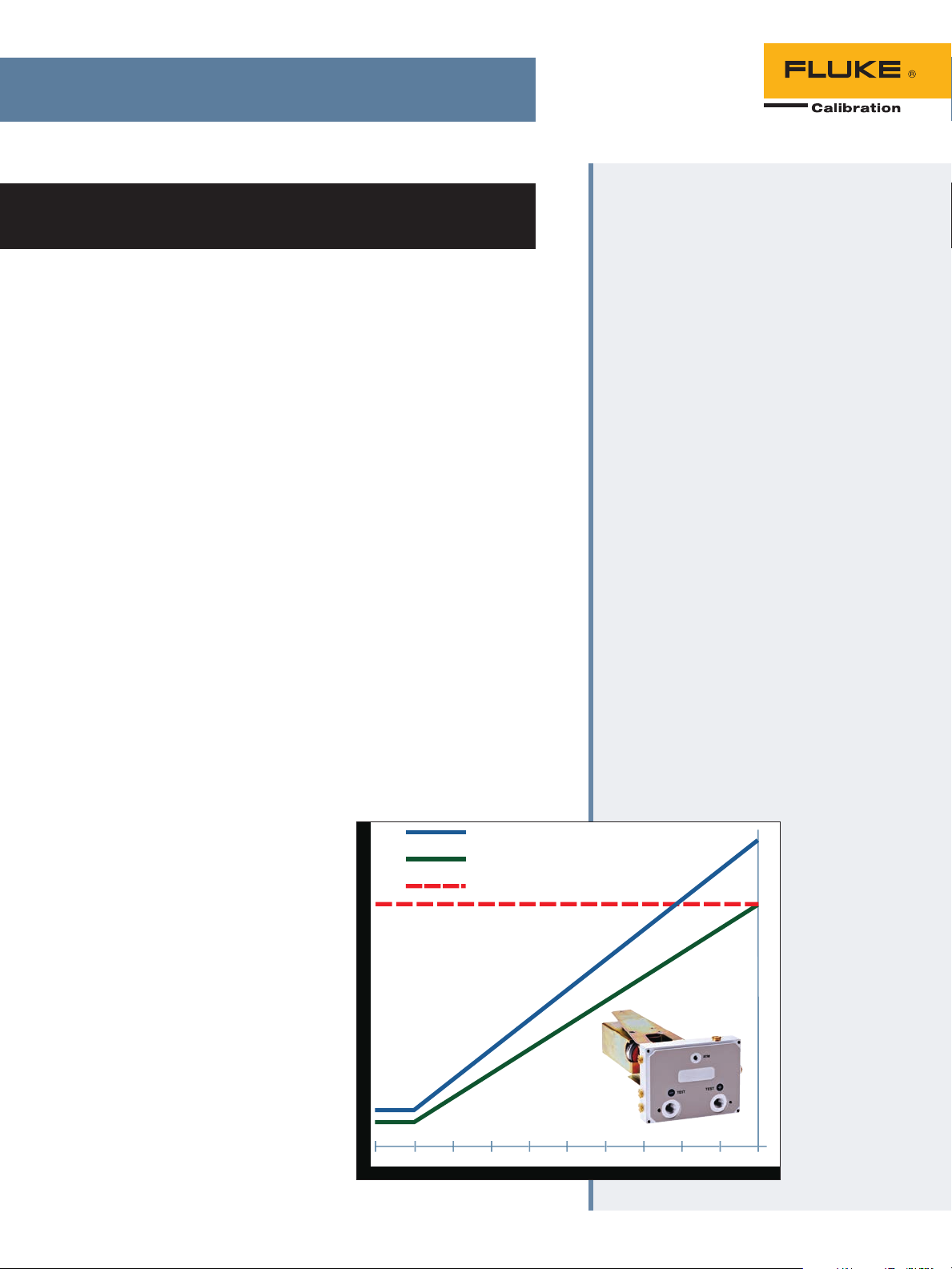

Q-RPT 2 Years : ±(0.025% of reading,

or 0.0025% of Q-RPT span, whichever is greater)

Q-RPT 1 Year: ±(0.02% of reading, or 0.002% of

Q-RPT span, whichever is greater)

0.02% FS Device

Measured Pressure (% of Q-RPT Span)

Reference pressure monitor and

Q-RPT quartz reference pressure

transducers

The E-DWT-H’s electronic reference pressure

monitor is a dedicated version of the Fluke

Calibration RPM4, designated RPM4-E-DWT.

RPM4-E-DWT can be configured with one

or two high precision quartz reference pressure transducers (Q-RPTs) with ranges from

7 MPa (1000 psi) to 200 MPa (30,000 psi).

E-DWT-H’s outstanding pressure measurement specifications are made possible by

Fluke Calibration’s exclusive quartz reference

pressure transducer (Q-RPT) modules.

Q-RPTs measure pressure by measuring the change in the natural oscillating

frequency of a quartz crystal with pressure

induced stress. To be qualified for use in

a Q-RPT module, each transducer is individually evaluated and characterized using

automated primary pressure standards. Only

transducers exhibiting superior levels of linearity, repeatability and stability are selected.

A proprietary compensation model, derived

from 20+ years experience with thousands

of quartz pressure transducers, is applied to

optimize the metrological characteristics.

Q-RPT module advantages

In addition to outstanding metrological

characteristics, Q-RPT modules offer the

advantages of:

• Negligible warm-up time

• Quartz element isolated from test medium

• Minimal sensitivity to orientation

Q-RPT

measurement

uncertainty

% of reading

uncertainty gives

tremendous

rangeability.

30 40 60 70 80 90 1002010 50

E-DWT-H™ Electronic Deadweight Tester Fluke Calibration 3

Page 4

E-DWT-H combines reliable, digital

reference pressure measurement with

high quality, easy-to-use pressure

generation and control hardware.

Provides low torque, pressure

generation and adjustment

Warning light and audible alarm

when Lo Q-RPT isolation valve is

not in correct position

E-DWT-H—high pressure hydraulic calibration made simple

Isolates reservoir when

generating pressure

Indicator lights with audible alert

to instruct user of correct position

of Lo Q-RPT isolation valve

RPM4 reference pressure monitor front panel display

A clean, simple front panel with a large display screen makes the

E-DWT-H easy to learn and straightforward to use

1

6

4 Fluke Calibration E-DWT-H™ Electronic Deadweight Tester

4 Fluke Calibration E-DWT-H™ Electronic Deadweight Tester

2 3 4 5

1. Pressure “Ready” (green) “Not Ready”

(red) based on real time measurement of

pressure stability

2. Value of measured pressure

3. Pressure unit of measure

4. Measurement mode

5. Active Q-RPT module (Hi or Lo)

6. The Function/Data keys allow commonly

used functions, such as unit of measure

change, to be accessed directly by a single

7

keystroke when pressed

7. Launch pre-recorded or quick set up

automated calibration sequences

Page 5

Test port for single device under test or connection

to test system/manifold (2nd test port on rear)

Fill, purge and prime the test system

Calibration uid reservoir

RPM4-E-DWT reference pressure

monitor with user interface

In E-DWT-Hs with dual Q-RPTs, half turn, spring

loaded valve isolates the low pressure Q-RPT

when the high pressure Q-RPT is in use

Shuts off test ports to rell variable

volume if needed and provides superne pressure adjustment

E-DWT-H with single Q-RPT

E-DWT-H™ Electronic Deadweight Tester Fluke Calibration 5

E-DWT-H™ Electronic Deadweight Tester Fluke Calibration 5

Page 6

Automation and support—integration made easy

E-DWT-H in the field

E-DWT-H has been designed for ease of

use in the field performing in-situ calibrations and tests. The optional rugged,

wheeled case allows quick setup and

makes transport easy and worry free.

With the battery pack option, eight hours

of field application is possible. No need

to drain fluid or disassemble hardware

for transport. Simply remove from case

connect to test item.

Automate data collection and manage calibration assets with

COMPASS for Pressure software

E-DWT-H can run stand-alone tests and collect test data. Test data can

be downloaded over the RPM4-E-DWT’s RS-232 interface.

The RPM4-E-DWT’s RS-232 interface can also be used to run the

E-DWT-H with COMPASS for Pressure software or user developed

software.

COMPASS for Pressure software is universal pressure calibration

software for the laboratory, which can be used to run simple or complex

tests with multiple instruments. The user can create his/her own calibration report, and data can be exported to Fluke MET/CAL Calibration

Management Software.

6 Fluke Calibration E-DWT-H™ Electronic Deadweight Tester

If you need support, we’re here to help

Fluke Calibration’s testing, repair and calibration services are dedicated to filling your needs quickly and at a fair cost while maintaining

the unmatched level of quality that is our trademark. Our pressure

calibration laboratories are accredited by the American Association for

Laboratory Accreditation (A2LA) for conformance to ISO Guide 17025.

We maintain global calibration and repair facilities to help you keep

your hardware in top working order.

Page 7

Specications

General

Power requirements To RPM4-E-DWT: 12 V dc 1.2 A

Operating temperature 10 °C to 40 °C (50 °F to 104 °F)

Storage temperature -20 °C to 70 °C (-4 °F to 158 °F)

Relative operating humidity 0 % to 70 %

Relative storage humidity 0 % to 100 %

Weight 1 Q-RPT: 12 kg (26 lb) approximate

Dimensions E-DWT-H footprint (W x D): 41.4 cm x 37.1 cm (16.3 in x 14.6 in)

Pressure ranges (Dependent on Q-RPT(s)

included in RPM4-E-DWT.)

Operating medium Delivered filled with oil (di-ethyl-hexyl sebacate) or dry. Standard E-DWT-H compatible with Sebacate, silicon oils,

Reservoir capacity 300 cc (18 in

Variable volume displacement Standard: 3 cc (0.18 in

Filling and priming pump displacement 3.7 cc (0.23 in

TEST pressure connection DH500 female. Note: DH500 is a gland and collar type fitting for 6 mm (1/4 in) coned and left hand threaded tubes

Pressure limits Maximum working pressure: Range of RPM4-E-DWT monitor’s Hi Q-RPT

Communication ports RS-232 (COM1, COM2)

To ac to dc power supply: 100 V ac to 240 V ac, 50/60 Hz

2 Q-RPT: 14 kg (30 lb) approximate

E-DWT-H height: 26.9 cm (10.6 in), 33.6 cm (13.2 in) to max variable volume handle height)

200 MPa (30,000 psi) maximum with standard variable volume

100 MPa (15,000 psi) maximum with high volume (-HV) variable volume

propylene glycol, fully fluorinated liquids, partially fluorinated liquids, isopropyl alcohol, and distilled water. Option for

Skydrol or mineral oil preparation.

3

)

3

), 200 MPa (30,000 psi) maximum

3

High: 7 cc (0.43 in

), 100 MPa (15,000 psi) maximum

3

)

equivalent to AE F250C, HIP HF4, 9/16-18 UNF, etc..

200 MPa (30,000 psi) with standard variable volume

100 MPa (15,000 psi) with high volume variable volume

Maximum priming pump pressure: 700 kPa (100 psi)

Maximum working pressure with Lo Q-RPT selected: Range of RPM4-E-DWT monitor’s Lo Q-RPT

Pressure measurement

Warm up time 15 minute temperature stabilization recommended from cold power up

Normal operating

10 °C to 40 °C (50 °F to 104 °F)

temperature range

Resolution Default: 0.01 % of active range. User adjustable to 1 ppm of Q-RPT maximum or 10 ppm of active AutoRange, whichever is larger

Precision

Predicted stability

1

2

Measurement uncertainty

200 MPa (30,000 psi) ranges: ± 0.018 % of reading or 0.0036 % of Q-RPT span, whichever is greater

All other ranges: ± 0.018 % of reading or 0.0018 % of Q-RPT span, whichever is greater

One year: ± 0.0075 % of reading

Two year: ± 0.015 % of reading

3

One year: 200 MPa (30,000 psi) ranges: ± 0.02 % of reading or 0.004 % of Q-RPT span, whichever is greater

All other ranges: ± 0.02 % of reading or 0.002 % of Q-RPT span, whichever is greater

Two year: 200 MPa (30,000 psi) ranges: ± 0.025 % of reading or 0.005 % of Q-RPT span, whichever is greater

All other ranges: ± 0.025 % of reading or 0.0025 % of Q-RPT span, whichever is greater

1.

Combined linearity, hysteresis, and repeatability. Precision does not include stability or calibration reference uncertainty.

2.

Predicted Q-RPT measurement stability limit (k=2) assuming regular use of AutoZero function and short term stability between rezeroing.

3.

Maximum deviation of the Q-RPT indication from the true value of applied pressure including precision, predicted stability with rezeroing, temperature effect from 10 ºC to 40 ºC (50 °F to 104 °F)

and calibration uncertainty (assumes calibration reference uncertainty of ± 0.005 % of reading, k=2), combined and expanded (k=2) following the ISO “Guide to the Expression of Uncertainty in

Measurement.”

E-DWT-H™ Electronic Deadweight Tester Fluke Calibration 7

Page 8

Ordering information

Configuring an E-DWT-H Electronic Deadweight Tester

1. Determine the maximum pressure desired and select the Hi Q-RPT from the

E-DWT-H Q-RPTs chart.

2. If uncertainty better than ± 0.02 % reading is needed below 10 % of the span of

the Hi Q-RPT, add a Lo Q-RPT from the E-DWT-H Q-RPTs chart. Lo Q-RPT cannot

be higher than A40M.

3. If desired, specify the high volume variable volume rather than the standard

volume variable volume (limits maximum pressure to 100 MPa).

4. Standard preparation for unit is filled with Sebacate oil calibration fluid. See

specifications for compatibility with other liquids. If other preparation is needed,

must specify either “Shipped Dry, Std Prep,” “Shipped Dry, Skydrol Ready,” or

“Shipped Dry, Mineral Oil Ready.” The fill kit accessory is recommended for units

that are shipped dry and for refilling in the field.

The configured E-DWT-H instrument designation is: E-DWT-H-HV AhhhM/AlllM

Where:

E-DWT-H: Hydraulically operated electronic deadweight tester (E-DWT)

HV: High volume variable volume if desired (limits max pressure to 100

MPa). Do not include if high volume variable volume is not desired.

AhhhM: Hi Q-RPT designator

AlllM: Lo Q-RPT designator. Do not include if Lo Q-RPT is not desired.

Accessories

E-DWT Liquid Fill Kit To fill E-DWT- delivered dry or to refill.

E-DWT that has drawn in air.

Fluid, Sebacate Sebacate oil, 1 qt.

Case Rugged, wheeled, reusable molded shipping case

Battery Pack/Charger 12 V dc battery with charger

Foot Switch Remote [ENTER] foot switch

Interconnect Kit Connect E-DWT rear test port to test devices

NPT Adaptor Kit Adaptors to 1/8, 1/4, 1/2 NPTF

BSP Adaptor Kit Adaptors to 1/8, 1/4, 3/8, 1/2 BSP

E-DWT-H Quartz Reference Pressure

Transducers (Q-RPTs)

Q-RPT

Designator

A200M-B 200 30,000

1

A140M

1

A100M

1

A70M

A40M 40 6,000

A20M 20 3,000

A14M 14 2,000

A10M 10 1,500

A7M 7 1,000

1.

Available as Hi Q-RPT only. Lo Q-RPT must be A40M or lower.

Battery Pack/Charger. With the optional battery pack/

charger, E-DWT-H can be used remotely for up to eight

hours without the need for line power.

SI Version

Maximum

Range [MPa]

Gauge

140 20,000

100 15,000

70 10,000

US Version

Maximum

Range [psi]

Gauge

The broadest range of calibration solutions

Fluke Calibration provides the broadest range of

calibrators and standards, software, service, support

and training in electrical, temperature, pressure, RF

and flow calibration.

Visit www.flukecal.com for more information

about Fluke Calibration products and services.

8 Fluke Calibration E-DWT-H™ Electronic Deadweight Tester

Fluke Calibration. Precision, performance, confidence.

Fluke Calibration

PO Box 9090,

Everett, WA 98206 U.S.A.

For more information call:

In the U.S.A. (877) 355-3225 or Fax (425) 446-5716

In Europe/M-East/Africa +31 (0) 40 2675 200 or Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or Fax (905) 890-6866

From other countries +1 (425) 446-6110 or Fax +1 (425) 446-5716

Web access: http://www.flukecal.com

©2010-2015 Fluke Calibration. Specifications subject to change without notice.

Printed in U.S.A. 5/2015 3440040c-en

Modification of this document is not permitted without written permission

from Fluke Calibration.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

Web access: http://www.flukecal.eu

™

Loading...

Loading...