Page 1

DTX-CLT CertiFiber

January 2010, Rev. 1 5/10

©2010 Fluke Corporation. All rights reserved.

All product names are trademarks of their respective companies.

®

Optical Loss Test Set

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke Networks product is warranted to be free from defects in material and workmanship under normal use and service. The

warranty period for the mainframe is one year and begins on the date of purchase. Parts, accessories, product repairs and services are

warranted for 90 days, unless otherwise stated. Ni-Cad, Ni-MH and Li-Ion batteries, cables or other peripherals are all considered parts

or accessories. The warranty extends only to the original buyer or end user customer of a Fluke Networks authorized reseller, and does

not apply to any product which, in Fluke Networks’ opinion, has been misused, abused, altered, neglected, contaminated, or damaged

by accident or abnormal conditions of operation or handling. Fluke Networks warrants that software will operate substantially in

accordance with its functional specifications for 90 days and that it has been properly recorded on non-defective media. Fluke Networks

does not warrant that software will be error free or operate without interruption.

Fluke Networks authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no

authority to extend a greater or different warranty on behalf of Fluke Networks. Warranty support is available only if product is

purchased through a Fluke Networks authorized sales outlet or Buyer has paid the applicable international price. Fluke Networks

reserves the right to invoice Buyer for importation costs of repair/replacement parts when product purchased in one country is

submitted for repair in another country.

Fluke Networks warranty obligation is limited, at Fluke Networks option, to refund of the purchase price, free of charge repair, or

replacement of a defective product which is returned to a Fluke Networks authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke Networks authorized service center to obtain return authorization information,

then send the product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB destination). Fluke

Networks assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation

prepaid (FOB destination). If Fluke Networks determines that failure was caused by neglect, misuse, contamination, alteration, accident

or abnormal condition of operation or handling, or normal wear and tear of mechanical components, Fluke Networks will provide an

estimate of repair costs and obtain authorization before commencing the work. Following repair, the product will be returned to the

Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE

NETWORKS SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING

LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or

consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty

is held invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

4/04

Fluke Networks

PO Box 777

Everett, WA 98206-0777

USA

Page 3

Contents

Title Page

Overview of Features ................................................................................................... 1

Registration .................................................................................................................. 1

Contacting Fluke Networks ......................................................................................... 2

Accessing the Technical Reference Handbook ........................................................... 2

Additional Resources for Cable Testing Information ................................................. 2

Unpacking ..................................................................................................................... 3

DTX-CertiFiber-M Multimode Kit ........................................................................... 3

DTX-CertiFiber-S Singlemode Kit ........................................................................... 3

DTX-CertiFiber-MS Multimode/Singlemode Kit .................................................... 3

Safety Information ....................................................................................................... 4

Physical Features .......................................................................................................... 7

Installing the Connector Adapter .......................................................................... 11

Installing and Removing Fiber Modules ................................................................ 13

Powering the Tester ..................................................................................................... 14

Localizing the Tester .................................................................................................... 14

Essentials for Reliable Fiber Test Results ..................................................................... 16

Cleaning Connectors and Adapters ....................................................................... 16

i

Page 4

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

About Setting the Reference .................................................................................. 17

Selecting Test Reference Cords ............................................................................... 18

Testing Your Test Reference Cords ........................................................................ 18

Using Mandrels for Testing Multimode Fiber ........................................................ 18

Fiber Test Settings ........................................................................................................ 21

About 1 Jumper Connections ...................................................................................... 26

Preparing to Save Tests ................................................................................................ 27

Certifying Fiber Cabling ............................................................................................... 28

Autotest in Smart Remote Mode ........................................................................... 28

Autotest in Loopback Mode ................................................................................... 36

Autotest in Far End Source Mode .......................................................................... 44

Using the Visual Fault Locator ..................................................................................... 52

Monitoring Optical Power ........................................................................................... 55

Cable ID Options .......................................................................................................... 58

Memory Functions ........................................................................................................ 59

Viewing Results ....................................................................................................... 59

Deleting Results ....................................................................................................... 59

Uploading Results to a PC ....................................................................................... 59

Options and Accessories .............................................................................................. 60

About LinkWare and LinkWare Stats Software .......................................................... 60

Maintenance ................................................................................................................. 61

Cleaning ................................................................................................................... 61

Replacing Fiber Test Reference Cords .................................................................... 61

Factory Calibration .................................................................................................. 62

Updating the Tester’s Software .............................................................................. 62

Retraining the Battery Gauge ................................................................................ 64

Using the Smart Remote with an OptiFiber™ Certifying OTDR ................................. 65

Certification, Compliance, and Regulatory Information ........................................... 65

ii

Page 5

CSA Standards ......................................................................................................... 65

Safety ....................................................................................................................... 66

Regulatory Information .......................................................................................... 66

Appendix A: How to Test Your Test Reference Cords ............................................... 67

Appendix B: Test Method Reference Table ................................................................ 75

Appendix C: Modified 1 Jumper Method ................................................................... 77

Index

Contents

iii

Page 6

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

iv

Page 7

List of Figures

Figure Title Page

1. Tester Front Panel Features ................................................................................................. 7

2. Tester Side and Top Panel Features .................................................................................... 8

3. Smart Remote Features........................................................................................................ 9

4. Fiber Module Features .........................................................................................................10

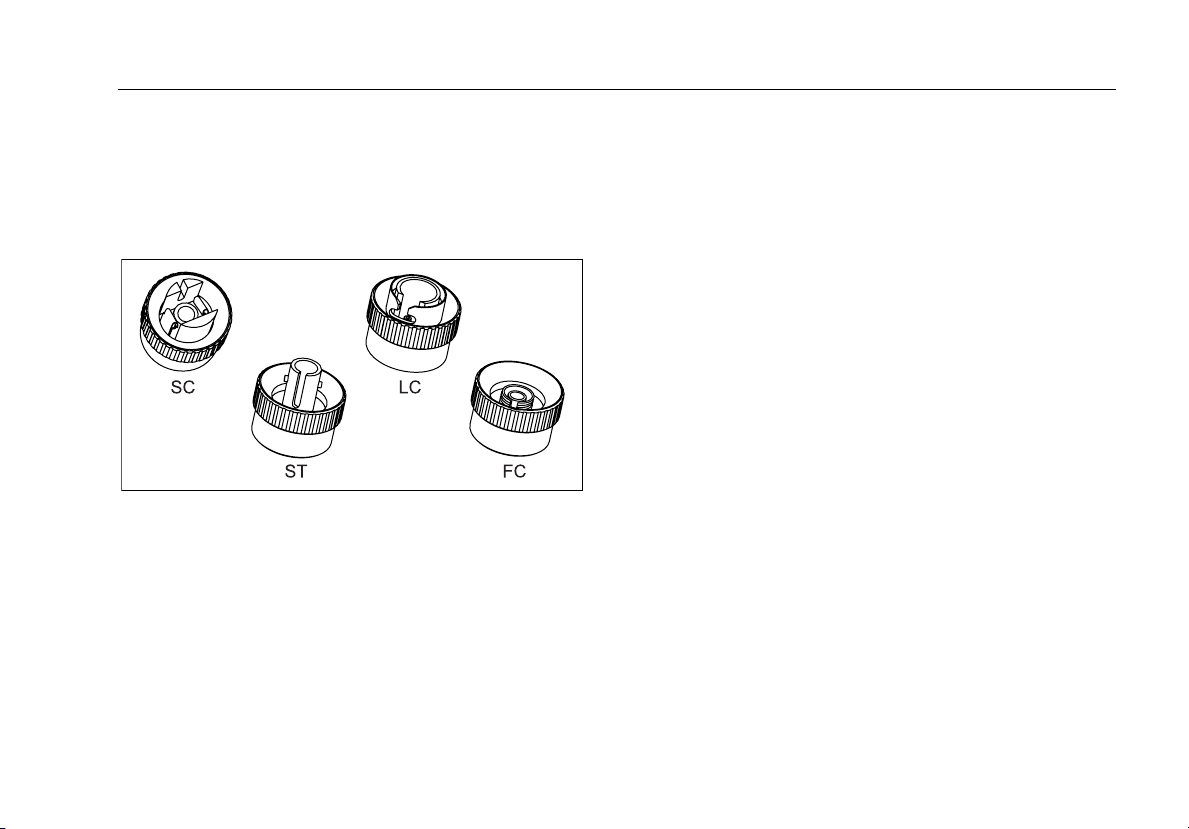

5. SC, ST, LC, and FC Connector Adapters............................................................................... 11

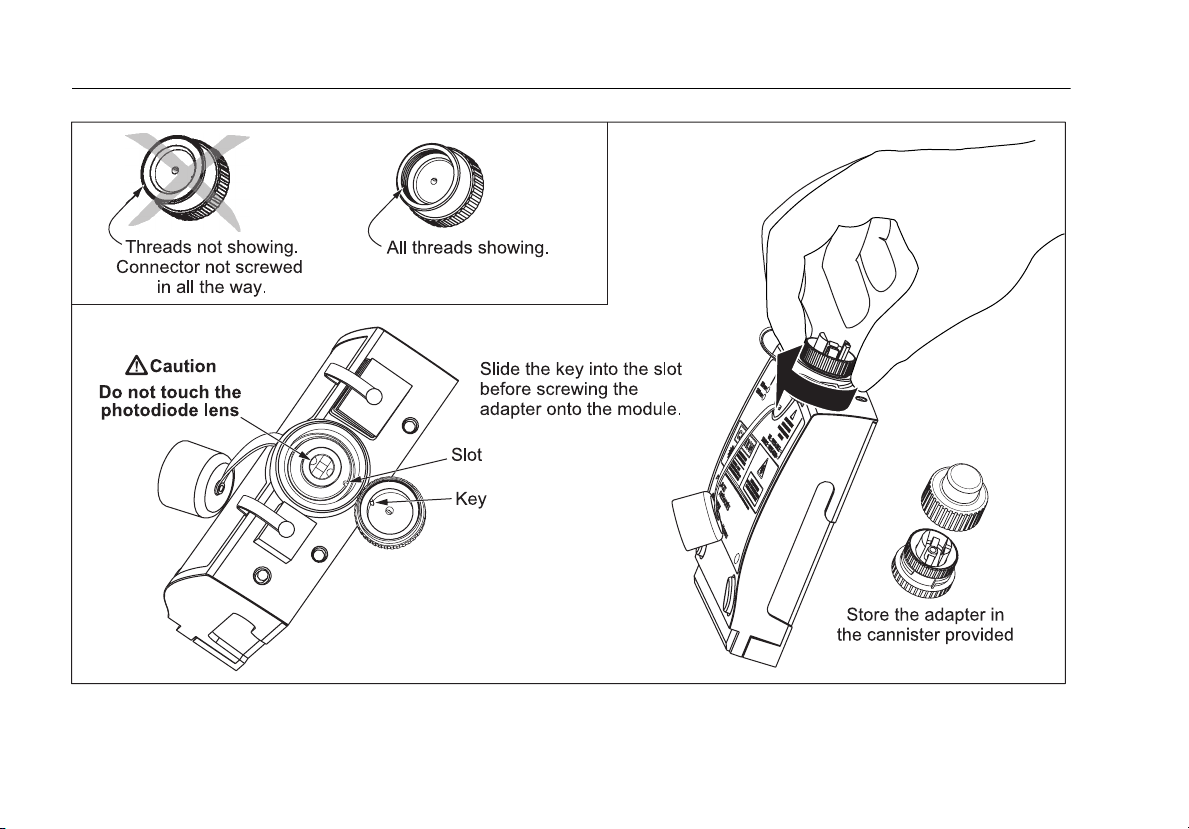

6. Installing the Connector Adapter........................................................................................ 12

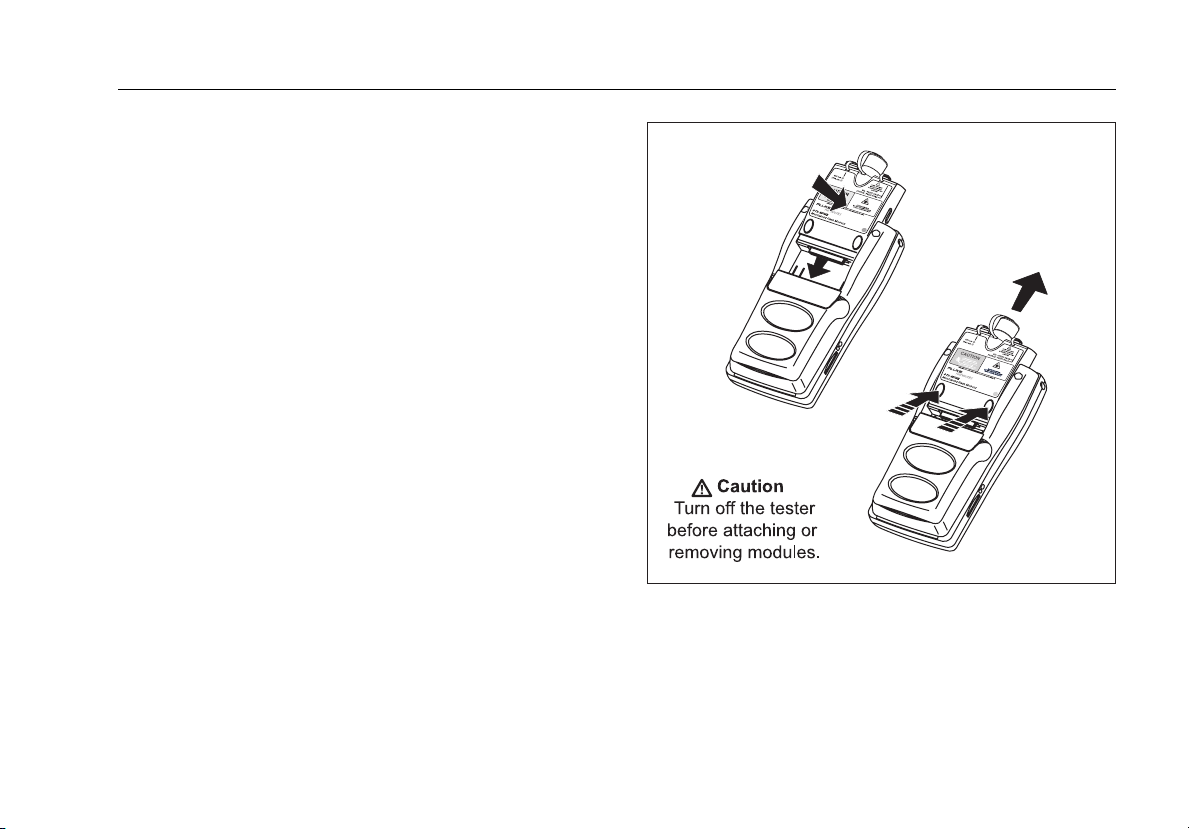

7. Installing and Removing Fiber Modules ............................................................................. 13

8. Removing the Battery Pack.................................................................................................. 15

9. Smart Remote Battery Status Shown After Power-Up....................................................... 15

10. Wrapping a Test Reference Cord Around a Mandrel ........................................................ 20

11. Example of How to Determine the Number of Adapters Setting..................................... 23

12. Equipment for Testing in Smart Remote Mode (1 Jumper Method) ................................ 29

13. Setting the Reference in Smart Remote Mode (1 Jumper Method) ................................. 31

14. Testing the Test Reference Cords in Smart Remote Mode ................................................ 33

15. Testing a Fiber Link in Smart Remote Mode (1 Jumper Method) ..................................... 35

16. Equipment for Testing in Loopback Mode (1 Jumper Method)........................................ 37

17. Setting the Reference in Loopback Mode (1 Jumper Method)......................................... 39

v

Page 8

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

18. Testing the Test Reference Cords in Loopback Mode........................................................ 41

19. Testing a Fiber in Loopback Mode (1 Jumper Method)..................................................... 43

20. Equipment for Testing in Far End Source Mode (1 Jumper Method) .............................. 44

21. Far End Source Mode Reference Connections (1 Jumper Method)................................... 47

22. Testing the Test Reference Cords in Far End Source Mode ............................................... 49

23. Testing a Link in Far End Source Mode (1 Jumper Method).............................................. 51

24. Equipment for Using the Visual Fault Locator.................................................................... 52

25. Using the Visual Fault Locator............................................................................................. 54

26. Equipment for Monitoring Optical Power.......................................................................... 55

27. Connections for Monitoring Optical Power........................................................................ 57

28. Updating the Software with a PC ....................................................................................... 63

29. Updating the Software with an Updated Tester................................................................ 64

A-1. Equipment for Testing Test Reference Cords ..................................................................... 68

A-2. Examples of Fiber Endfaces ................................................................................................. 70

A-3. Reference Connections ........................................................................................................ 71

A-4. Connections for Testing a Test Reference Cord.................................................................. 73

C-1. Modified 1 Jumper Method: Smart Remote Mode Reference Connections..................... 78

C-2. Modified 1 Jumper Method: Smart Remote Mode Test Connections............................... 79

vi

Page 9

DTX-CLT CertiFiber® Optical Loss Test Set

Overview of Features

The DTX-CLT CertiFiber Optical Loss Test Set (OLTS) is a

rugged, hand-held instrument used to test and certify

fiber optic cabling installations. The tester offers the

following functions and features:

•

Measures optical power loss and length on dual-fiber

cabling. The DTX-MFM2 module tests multimode

cabling at 850 nm and 1300 nm. The DTX-SFM2

module tests singlemode cabling at 1310 nm and

1550 nm. The DTX-GFM2 module features a VCSEL for

testing multimode cabling at 850 nm and 1310 nm

when a VCSEL source is required.

•

Each module transmits both wavelengths (850 nm and

1300 nm, 850 nm and 1310 nm, or 1310 nm and

1550 nm).

•

Interchangeable connector adapters allow reference

and test connections that meet ISO standards for most

SFF (small form factor) fiber connectors.

•

Provides pass/fail results based on industry-standard

limits.

•

Visual fault locator helps you locate breaks, bad

splices, bends, and check fiber continuity and polarity.

•

FindFiber™ function helps you identify and verify fiber

connections.

Registration

Registering your product with Fluke Networks gives you

access to valuable information on product updates,

troubleshooting tips, and other support services. To

register, fill out the online registration form on the Fluke

Networks website at www.flukenetworks.com/registration.

1

Page 10

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Contacting Fluke Networks

Note

If you contact Fluke Networks about your tester,

have the tester's software and hardware version

numbers available if possible.

www.flukenetworks.com

support@flukenetworks.com

+1-425-446-4519

•

Australia: 61 (2) 8850-3333 or 61 (3) 9329 0244

•

Beijing: 86 (10) 6512-3435

•

Brazil: 11 3759 7600

•

Canada: 1-800-363-5853

•

Europe: +31-(0) 40 2675 600

•

Hong Kong: 852 2721-3228

•

Japan: 03-6714-3117

•

Korea: 82 2 539-6311

•

Singapore: 65-6799-5566

•

Taiwan: (886) 2-227-83199

•

USA: 1-800-283-5853

Visit our website for a complete list of phone numbers.

Accessing the Technical Reference Handbook

The DTX Series CableAnalyzer Technical Reference

Handbook provides additional information on the tester

and the fiber modules. The handbook is available on the

CD included with your DTX-CLT CertiFiber and on the DTX

CableAnalyzer product page on the Fluke Networks

website.

Additional Resources for Cable Testing Information

The Fluke Networks Knowledge Base provides answers to

common questions about Fluke Networks products, along

with articles on cable testing techniques and technology.

To access the Knowledge Base, log on to

www.flukenetworks.com, then click Support >

Knowledge Base at the top of the page.

2

Page 11

Unpacking

Unpacking

The DTX-CLT CertiFiber tester comes with the accessories

listed below. If something is damaged or missing, contact

the place of purchase immediately.

DTX-CertiFiber-M Multimode Kit

•

DTX-CLT CertiFiber with lithium-ion battery pack

•

DTX-CLT CertiFiber SmartRemote with lithium-ion

battery pack

•

Two DTX-MFM2 Fiber Modules for testing at 850 nm

and 1300 nm

•

Two 50/125 µm multimode test reference cords,

2 m, SC/SC

•

Two red mandrels for 50 /125 µm fiber with 3 mm

jackets

•

DTX-CLT CertiFiber Getting Started Guide

•

DTX-CLT CertiFiber Product Manuals CD

•

LinkWare Software CD

DTX-CertiFiber-S Singlemode Kit

•

DTX-CLT CertiFiber with lithium-ion battery pack

•

DTX-CLT CertiFiber SmartRemote with lithium-ion

battery pack

•

Two DTX-SFM2 Fiber Modules for testing at

1310 nm and 1550 nm.

•

Two 9/125 µm singlemode test reference cords, 2 m,

SC/SC

•

DTX-CLT CertiFiber Getting Started Guide

•

DTX-CLT CertiFiber Product Manuals CD

•

LinkWare Software CD

DTX-CertiFiber-MS Multimode/Singlemode Kit

•

DTX-CLT CertiFiber with lithium-ion battery pack

•

DTX-CLT CertiFiber SmartRemote with lithium-ion

battery pack

•

Two DTX-MFM2 Fiber Modules for testing at 850 nm

and 1300 nm

•

Two 50/125 µm multimode test reference cords,

2 m, SC/SC

•

Two red mandrels for 50 /125 µm fiber with 3 mm

jackets

-continued-

3

Page 12

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

•

Two DTX-SFM2 Fiber Modules for testing at

1310 nm and 1550 nm.

•

Two 9/125 µm singlemode test reference cords, 2 m,

SC/SC

•

DTX-CLT CertiFiber Getting Started Guide

•

DTX-CLT CertiFiber Product Manuals CD

•

LinkWare Software CD

Safety Information

Table 1 shows the international electrical symbols used on

the tester or in this manual.

Table 1. International Electrical Symbols

X

Warning: Risk of fire, electric shock, or

personal injury.

Note

The test reference cords and connector adapter

types provided are suitable for testing SCterminated links. Other test reference cords and

adapter types are required for other connector

types or 62.5 /125 µm fiber. Many are available as

accessories from Fluke Networks.

4

W

j

*

~

Warning or Caution: Risk of damage or

destruction to equipment or software. See

explanations in the manuals.

Do not connect this equipment to public

communications networks, such as telephone

systems.

Warning: Class 1 laser (OUTPUT port). Risk of

eye damage from hazardous radiation.

Class 2 laser (VFL port). Do not stare into

beam.

Do not put products containing circuit boards

into the garbage. Dispose of circuit boards in

accordance with local regulations.

Page 13

Safety Information

WWarningX

To avoid possible fire, electric shock, or personal

injury:

•

Do not open the case; no user-serviceable parts

are inside.

•

Do not modify the tester.

•

Use only ac adapters approved by Fluke Networks

for use with the DTX tester to charge the battery

or power the tester.

•

When servicing the tester, use only specified

replacement parts.

•

Do not use the tester if it is damaged. Inspect the

tester before use.

•

If this equipment is used in a manner not specified

by the manufacturer, the protection provided by

the equipment may be impaired.

•

Do not use the tester if it operates abnormally.

Protection may be impaired.

WWarning: Class 1 and Class 2

Laser Products

To avoid possible eye damage caused by

hazardous radiation:

•

Never look directly into optical connectors. Some

sources produce invisible radiation that can

permanently damage your eyes.

•

Keep the fiber module’s OUTPUT port covered

with a dust cap or keep a test reference cord

attached. The OUTPUT port may be active even

when a test is not in progress. Covering the port

reduces the risk of accidental exposure to

hazardous radiation.

•

Never start a test or activate the OUTPUT port or

VFL port without first connecting a fiber to the

port you will use.

*

5

Page 14

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

•

Never look directly into the visual fault locator

output. Momentary exposure to the locator’s

output will not damage your eyes; however,

direct, long-term exposure is potentially

hazardous.

•

Do not use magnification to view the optical

outputs without proper filtering.

•

Use of controls, adjustments, or procedures not

stated herein might result in hazardous radiation

exposure.

WCaution

To avoid disrupting network operation, to

avoid damaging the tester or cables under test,

to avoid data loss, and to ensure maximum

accuracy of test results:

•

Never connect the tester to an active network.

Doing so may disrupt network operation.

•

Always keep fiber modules installed in the

testers.

•

Turn off the tester before attaching or removing

modules.

•

When using the fiber modules, use proper

cleaning procedures to clean all fiber connectors

before every use. Neglecting this step or using

improper procedures can cause unreliable test

results and may permanently damage the

connectors. See page 16.

•

Use only high-quality test reference cords that

comply with ISO/IEC 14763-3. Test the cords at

regular intervals. See Appendix A.

•

Cover all connectors with dust caps when not in

use.

•

Store the connector adapters for the fiber module

in the canisters provided.

•

Do not touch the photodiode lens (see Figure 6).

•

Do not overtighten the adapter or use tools to

tighten the adapter.

•

Use a Fluke Networks FiberInspector Video

Microscope to periodically inspect the fiber

module’s OUTPUT connector for scratches and

other damage.

6

Page 15

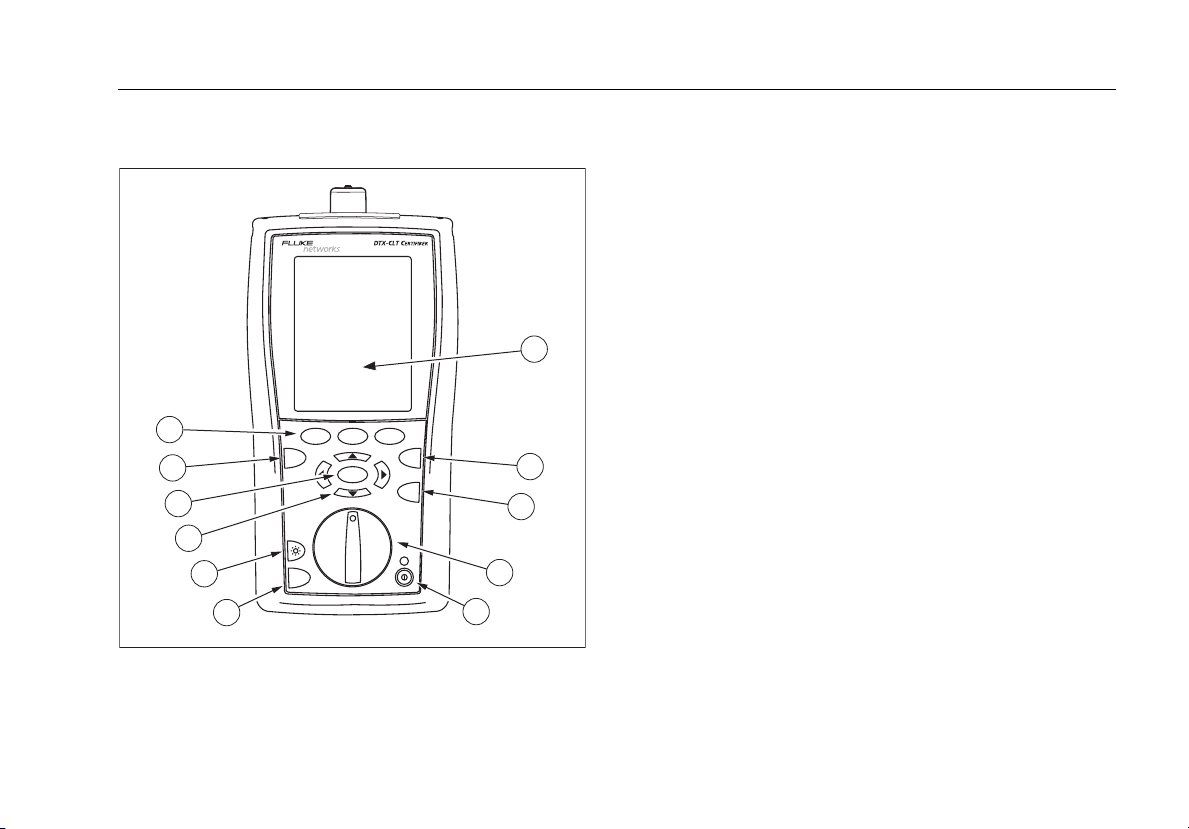

Physical Features

11

10

9

8

7

6

Figure 1. Tester Front Panel Features

F1 F2 F3

EXIT

MONITOR

TALK

Physical Features

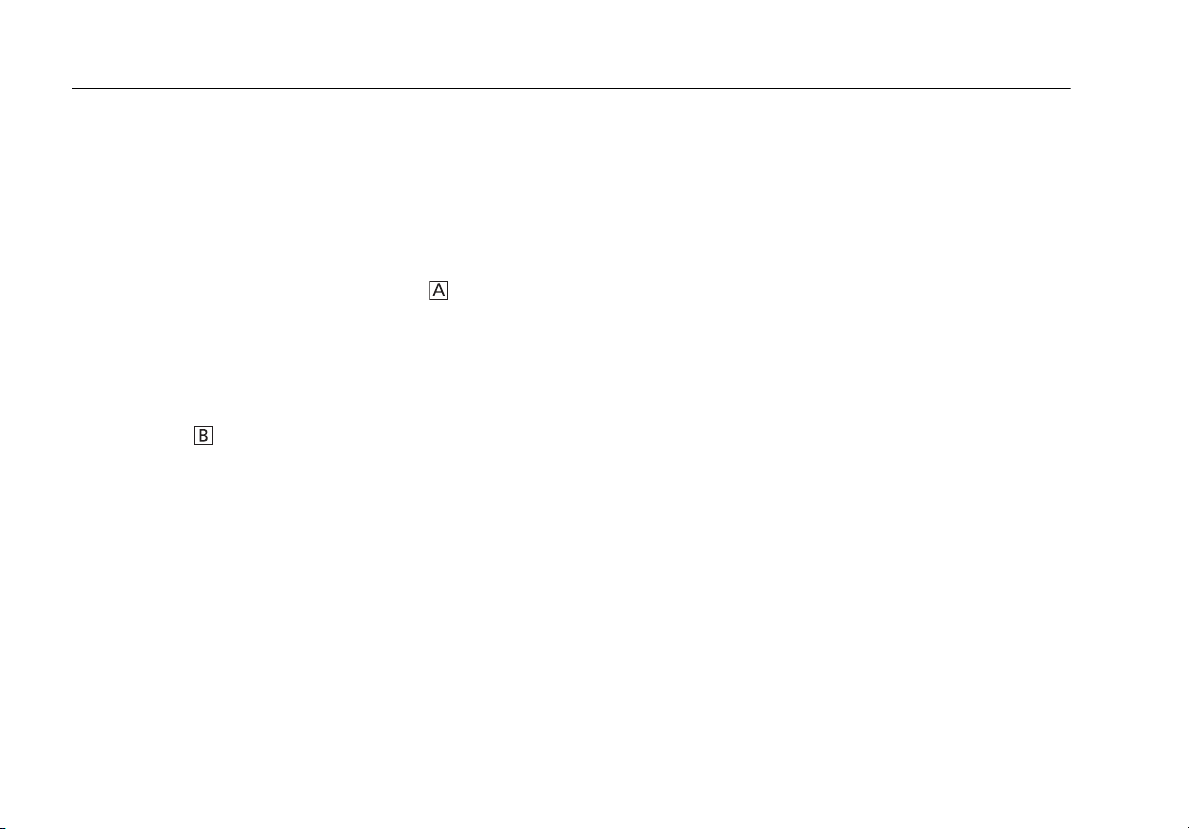

A

LCD display with backlight and adjustable brightness.

B

P: Starts the currently selected test.

C

N: Saves Autotest results in memory.

D

Rotary switch selects the tester’s modes.

E

M: On/off key.

F

O: Press to use the headset to talk to the person at

the other end of the link.

G

1

G: Press to switch the backlight between bright and

dim settings. Hold for 1 second to adjust the display

contrast.

H

BCAD: Arrow keys for navigating

ENTER

SINGLE

TEST

TEST

SAVE

AUTO

TEST

SETUP

SPECIAL

FUNCTIONS

2

3

4

5

gfd03f.eps

through screens and incrementing or decrementing

alphanumeric values.

I

H: Enter key selects the highlighted item from a

menu.

J

I: Exits the current screen without saving changes.

K

J K L: The softkeys provide functions

related to the current screen. The functions are shown

on the screen above the keys.

7

Page 16

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

C

D

E

Figure 2. Tester Side and Top Panel Features

B

A

gfd04f.eps

A

Fiber module. See Figure 4.

B

Bail.

C

USB port for uploading test reports to a PC and for

updating the tester’s software.

D

Headset jack for talk mode.

E

Connector for the ac adapter. The LED turns on when

the tester is connected to ac power.

•

Red: Battery is charging.

•

Green: Battery is charged.

•

Flashing red: Charge timeout. The battery failed to

reach full charge within 6 hours. See “Powering the

Tester” on page 14.

8

Page 17

A

B

C

D

E

F

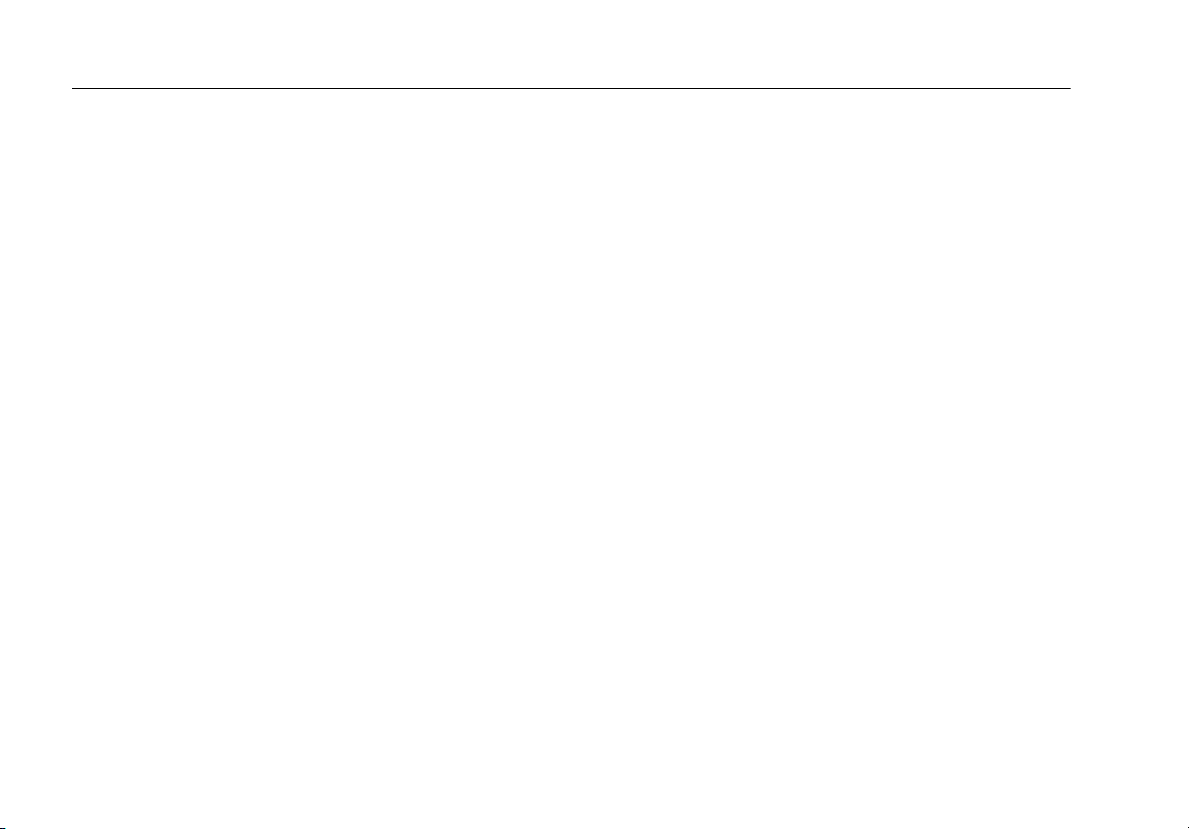

Figure 3. Smart Remote Features

Note

The LEDs also act as a battery gauge. See Figure

9 on page 15.

gfd05f.eps

Physical Features

A

Pass LED lights when a test passes.

B

Test LED lights during cable tests.

C

Fail LED lights when a test fails.

D

Talk LED lights when the smart remote is in talk mode.

Press Oto adjust the volume.

E

The TONE LED is not used for tests on fiber cabling.

F

Low battery LED lights when the battery is low.

G

P: Starts the test currently selected on the main unit.

H

O: Press to use the headset to talk to the person at

the other end of the link. Press again to adjust the

volume. Press and hold to exit talk mode.

I

M: On/off key.

J

USB port for updating the tester’s software with a PC.

K

Headset jack for talk mode.

L

Connector for the ac adapter, as described in Figure 2.

M

Fiber module. See Figure 4.

9

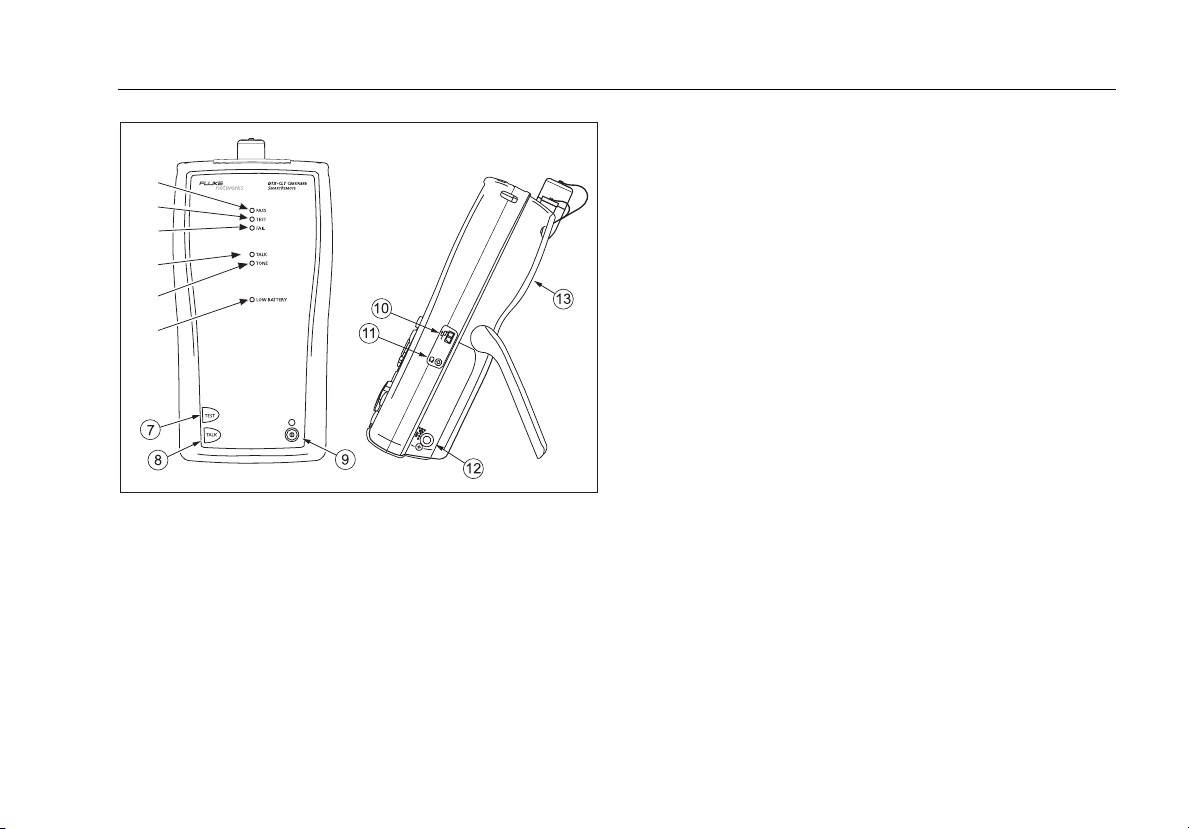

Page 18

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Warning

W

Never look directly into

optical output connectors (B

and D). Some sources produce

invisible radiation that can

permanently damage your

eyes.

*

gfd06f.eps

A

Button for activating the visual fault locator (B) and output port (D). See

“Using the Visual Fault Locator” on page 52 and “Autotest in Far End

Source Mode” on page 44.

B

Universal fiber connector (with dust cap) for the visual fault locator output.

The connector accepts 2.5 mm ferrules. The LED below the connector

indicates the locator’s mode (continuous or blinking).

C

Input connector with dust cap. Receives optical signals for loss, length, and

power measurements. You can change the connector adapter to match the

connectors on the fiber under test. See Figure 6.

D

SC output connector with dust cap. Transmits optical signals for loss and

length measurements.

E

The LED below the connector is red when the output is transmitting the

module’s shorter wavelength, and green for the longer wavelength.

F

Laser safety label (shown at right).

CAUTION

Figure 4. Fiber Module Features

amd128i.eps

10

Page 19

Physical Features

Installing the Connector Adapter

You can change the fiber module's input connector

adapter to connect to SC, ST, LC, and FC fiber connectors

(Figure 5). Additional adapter styles may be available.

Check the Fluke Networks web site for updates.

amd37f.eps

Figure 5. SC, ST, LC, and FC Connector Adapters

WCaution

•

Cover all connectors with dust caps when not in

use.

•

Store the connector adapters for the fiber module

in the canisters provided.

•

Do not touch the photodiode lens (see Figure 6).

•

Do not overtighten the adapter or use tools to

tighten the adapter.

To install a connector adapter, refer to Figure 6 and do the

following:

1

Locate the slot in the fiber module connector and the

key on the adapter ring.

2

Holding the adapter so it does not turn in the nut,

align the adapter's key with the module connector's

slot and slide the adapter onto the connector.

3

Screw the nut onto the module connector.

11

Page 20

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

12

amd99f.eps

Figure 6. Installing the Connector Adapter

Page 21

Installing and Removing Fiber Modules

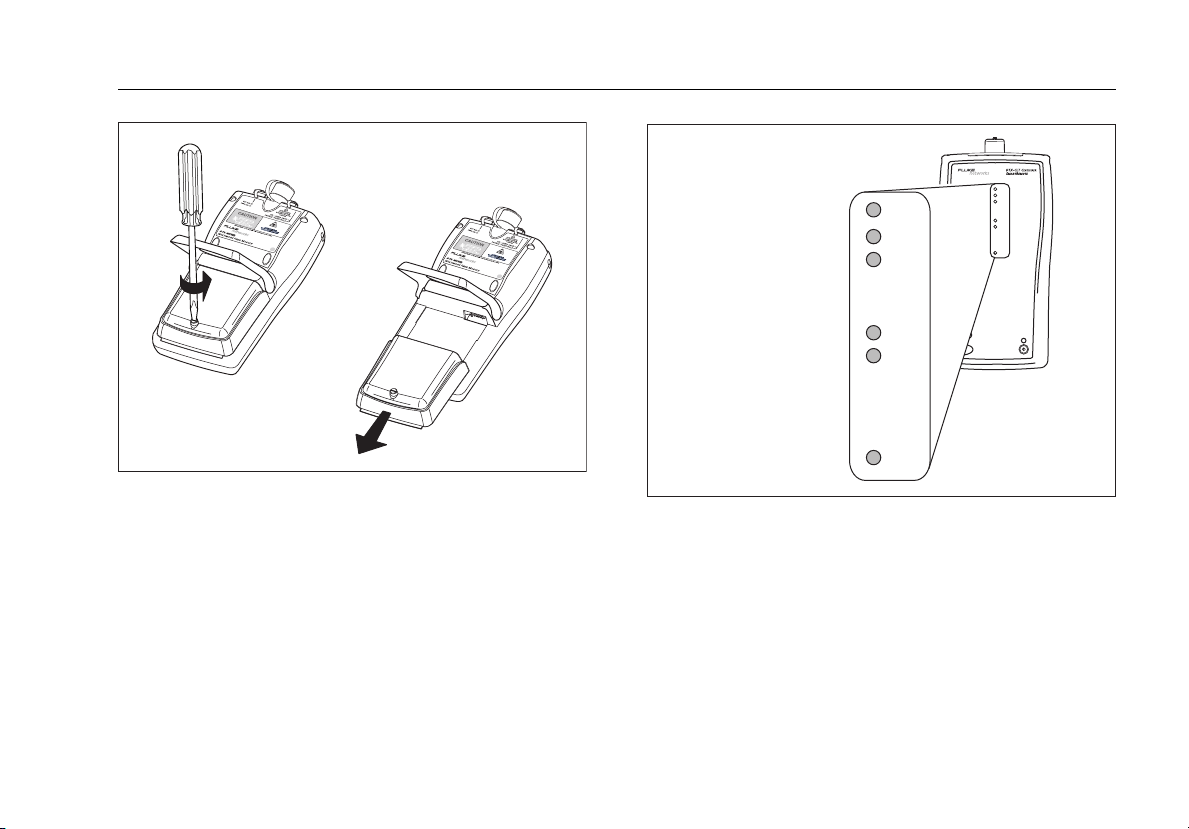

Figure 7 shows how to install and remove the fiber

modules.

WCaution

To prevent damage to the module connectors,

always keep fiber modules installed in the

testers.

Physical Features

gfd34f.eps

Figure 7. Installing and Removing Fiber Modules

13

Page 22

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Powering the Tester

•

You may charge the battery when it is attached or

detached from the tester. Figure 8 shows how to

remove the battery.

•

The battery charges fully in about 4 hours with the

tester off. A fully-charged battery lasts for at least 12

hours of typical use.

Note

The battery will not charge at temperatures outside

of 0 °C to 45 °C (32 °F to 113 °F). The battery

charges at a reduced rate between 40 °C and 45 °C

(104 °F and 113 °F).

•

The battery status icon ( ) near the upper-right

corner of main screens shows the battery’s charge

level. The smart remote’s LEDs show the smart

remote’s battery status at the end of the power-up

cycle, as shown in Figure 9.

•

For additional battery information, connect the main

tester and smart remote through link adapters, turn

the rotary switch to SPECIAL FUNCTIONS; then select

Battery Status. See page 64 for information on

retraining the battery gauge.

•

If the battery does not reach full charge within 6 hours,

the battery LED flashes red. Verify that the battery was

within the temperature range given above during

charging and that the correct ac adapter was used.

Disconnect then reconnect ac power and try charging

the battery again. If the battery does not charge the

second time, retrain the battery gauge. See page 64.

Localizing the Tester

Local settings include Language, Date, Time, Numeric

Format, Length Units, and Power Line Frequency.

1

Turn the rotary switch to SETUP.

2

Use D to highlight Instrument Settings at the

bottom of the list; then press H.

3

Use Cand D to find and highlight Language on

the bottom of tab 2; then press

4

Use D to highlight the desired language; then

press H.

5

Use the arrow keys and H to find and change other

local settings on tabs 2, 3, and 4 under Instrument

Settings.

H.

14

Page 23

84 % - 100 %

67 % - 83 %

51 % - 66 %

Localizing the Tester

PASS

TEST

FAIL

PASS

TEST

FAIL

TALK

TONE

LOW BATTERY

Figure 8. Removing the Battery Pack

gfd07f.eps

34 % - 50 %

18 % - 33 %

0 % - 17 %

TALK

TONE

LOW BA

TEST

TALK

Figure 9. Smart Remote Battery Status

Shown After Power-Up

gfd08f.eps

15

Page 24

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Essentials for Reliable Fiber Test Results

To get reliable fiber test results, you must follow proper

cleaning and referencing procedures and, in some cases,

use mandrels during testing.

Cleaning Connectors and Adapters

Always clean and inspect fiber connectors before making

connections. Use fiber optic solvent and optical-grade

wipes or swabs to clean connectors as follows:

Bulkhead Connectors and the Fiber Module's Output Connector

Note

Use a 2.5 mm foam swab for cleaning the fiber

module's output connector.

1

Touch the tip of a fiber optic solvent pen or swab

soaked in solvent to a lint-free dry wipe or fiber

cleaning card.

2

Touch a new, dry swab to the solvent spot on the wipe

or card.

3

Push the swab into the connector; twist it around 3 to

5 times against the endface, then remove and dispose

of the swab.

4

Dry the connector with a dry swab by twisting it

around in the connector 3 to 5 times.

5

Inspect connectors with a fiber microscope, such as the

Fluke Networks FiberInspector Video Microscope

before making connections.

Fiber Module's Input Connector

1

Remove the connector adapter to expose the

photodiode lens (see Figure 6).

2

Use the method described in steps 1 and 2 above to

dampen a swab with solvent.

3

Twist the damp swab around against the lens 3 to 5

times; then twist a dry swab around against the lens 3

to 5 times.

Connector Adapters and Fiber Adapters

Periodically clean connector adapters and fiber adapters

with a swab and fiber optic solvent. Dry with a dry swab

before use.

16

Page 25

Essentials for Reliable Fiber Test Results

Connector Ends

1

Touch the tip of a fiber optic solvent pen or swab

soaked in solvent to a lint-free dry wipe or fiber

cleaning card.

2

Wipe the connector end-face across the solvent spot,

then back and forth once across the dry area of the

wipe or card.

Note

Some connector styles, such as VF-45, may require

a different cleaning method.

3

Inspect connectors with a fiber microscope, such as the

Fluke Networks FiberInspector Video Microscope

before making connections.

Always cover unused connectors with protective caps. Clean

caps periodically with a swab or wipe and fiber optic

solvent.

About Setting the Reference

The reference serves as the baseline power level for loss

measurements. Regular referencing helps account for

minor variations in source power and connection integrity.

Also, since the reference is the baseline for measurements,

the losses of the test reference cords and adapters used

during referencing are excluded from test results.

Note

Turn on the tester and smart remote and let them

sit for 5 minutes before setting the reference.

Allow additional time if the modules have been

stored above or below ambient temperature.

You should set the reference at these times:

•

At the beginning of each day using the remote end

setup (Figures 13 through 23) you will use that day.

•

Anytime you reconnect a test reference cord to the

module’s output or other source.

•

Anytime the tester warns you that the reference is out

of date.

•

Anytime you see a negative loss measurement. (See

the Technical Reference Handbook for more

information.)

You must set the reference at these times:

•

Anytime you change the fiber module in the tester or

smart remote.

•

Anytime you start using a different smart remote.

•

Anytime you change the Tes t Me tho d in Setup.

•

Twenty-four hours after the reference was previously

set.

17

Page 26

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

WCaution

Do not disconnect the test reference cords from

the testers' output ports after setting the

reference. Doing so may alter the amount of

optical power launched into the fiber and

invalidate the reference.

Reference values should not change by more than a few

tenths of a dB from day to day. Larger changes may

indicate a problem with the test reference cords or

connections.

See the sections on Smart Remote, Loopback, and Far End

Source modes for details on setting the reference for each

mode.

Selecting Test Reference Cords

The DTX Fiber Modules come with high-quality test

reference cords.

To ensure that your measurements are accurate and

repeatable, use test reference cords provided by Fluke

Networks or cords of the same quality. See "Replacing

Fiber Test Reference Cords" on page 61.

Testing Your Test Reference Cords

You must test your test reference cords at regular intervals.

Use the procedure given in Appendix A to test the cords

initially. After that, use the procedure given with the

procedures for certifying cabling to monitor the condition

of the cords.

Using Mandrels for Testing Multimode Fiber

You should use mandrels when testing multimode fiber

with the DTX-MFM2 fiber modules. Mandrels can improve

measurement repeatability and consistency. They also

allow the use of LED light sources to certify 50 µm and

62.5 µm fiber links for current and planned high bit-rate

applications, such as Gigabit Ethernet and 10 Gigabit

Ethernet.

WCaution

Do not use mandrels when testing with the

DTX-GFM2 fiber modules.

18

Page 27

Essentials for Reliable Fiber Test Results

The red mandrels included with the DTX-MFM2 are

compliant with ANSI/TIA-568-C for 50 µm fiber with a

3 mm jacket. Mandrels for 62.5 µm fiber are available from

Fluke Networks. Refer to the appropriate standard for

mandrel requirements if you follow other standards. Table

2 shows a partial list of mandrel requirements for TIA

standards.

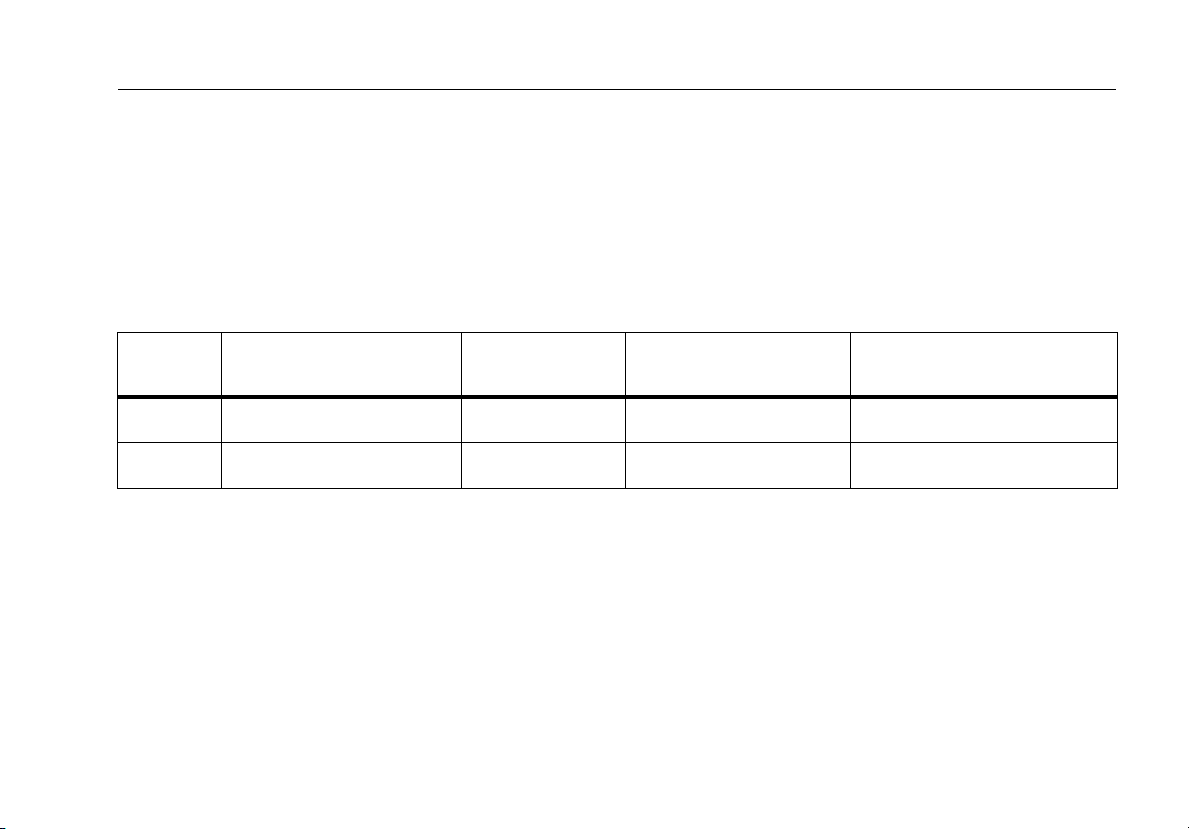

Table 2. ANSI/TIA-568-C Mandrel Requirements

Fiber

core size Standard

50 µm ANSI/TIA-568-C.0 6.4.2.1 5 25 mm (1.0 in) 22 mm (0.9 in)

62.5 µm ANSI/TIA-568-C.0 6.4.2.1 5 20 mm (0.8 in) 17 mm (0.7 in)

Wraps Around

Mandrel

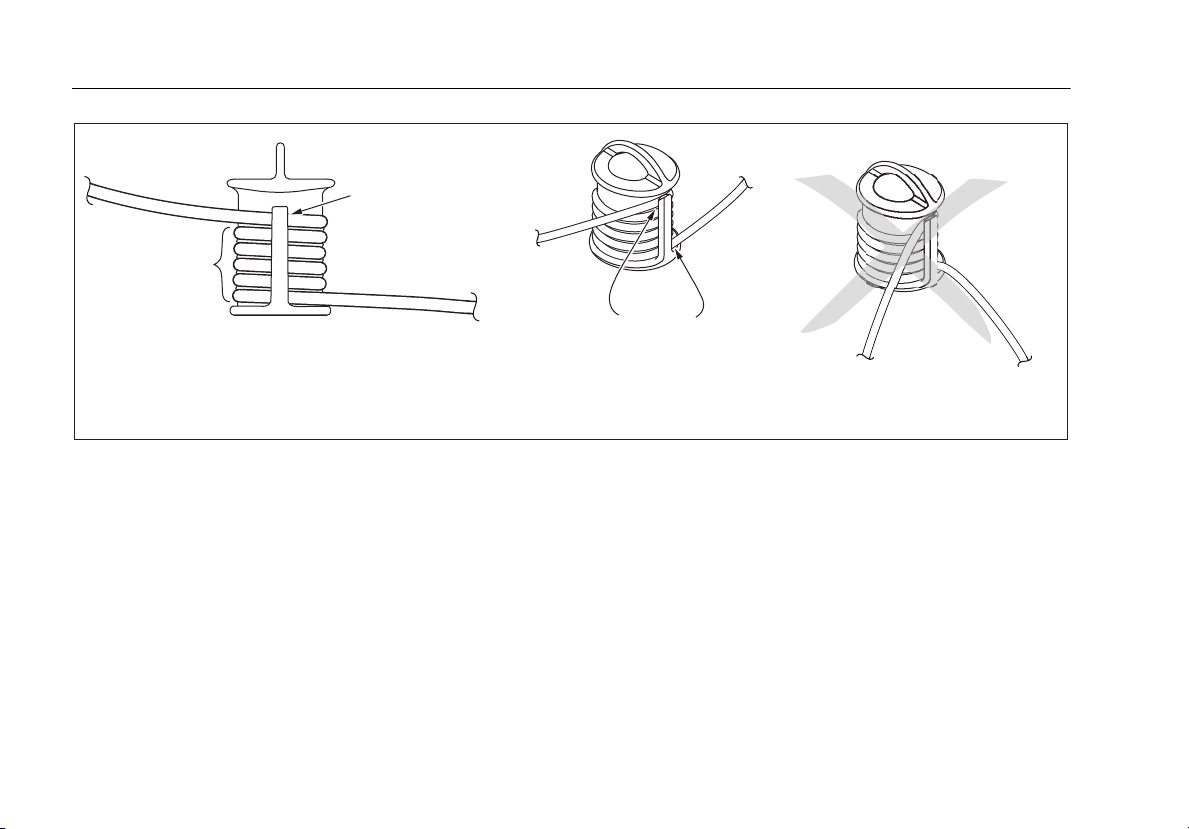

Figure 10 shows how to wrap the fiber around a mandrel.

Place mandrels on the tester’s output fibers, as shown in

Figures 13 through 23.

In the reference and test connection diagrams shown on

the tester, mandrels are indicated by a loop in the fiber.

Mandrel Diameter for

250 µm Buffered Fiber

Mandrel Diameter for 3 mm

(0.12 in) Jacketed Cable

19

Page 28

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Place top wrap

in groove under

retainer

Wrap 5 times

in grooves

Figure 10. Wrapping a Test Reference Cord Around a Mandrel

Right:

no bends

at retainer

Wrong:

bends at

retainer

amd67f.eps

20

Page 29

Fiber Test Settings

Fiber Test Settings

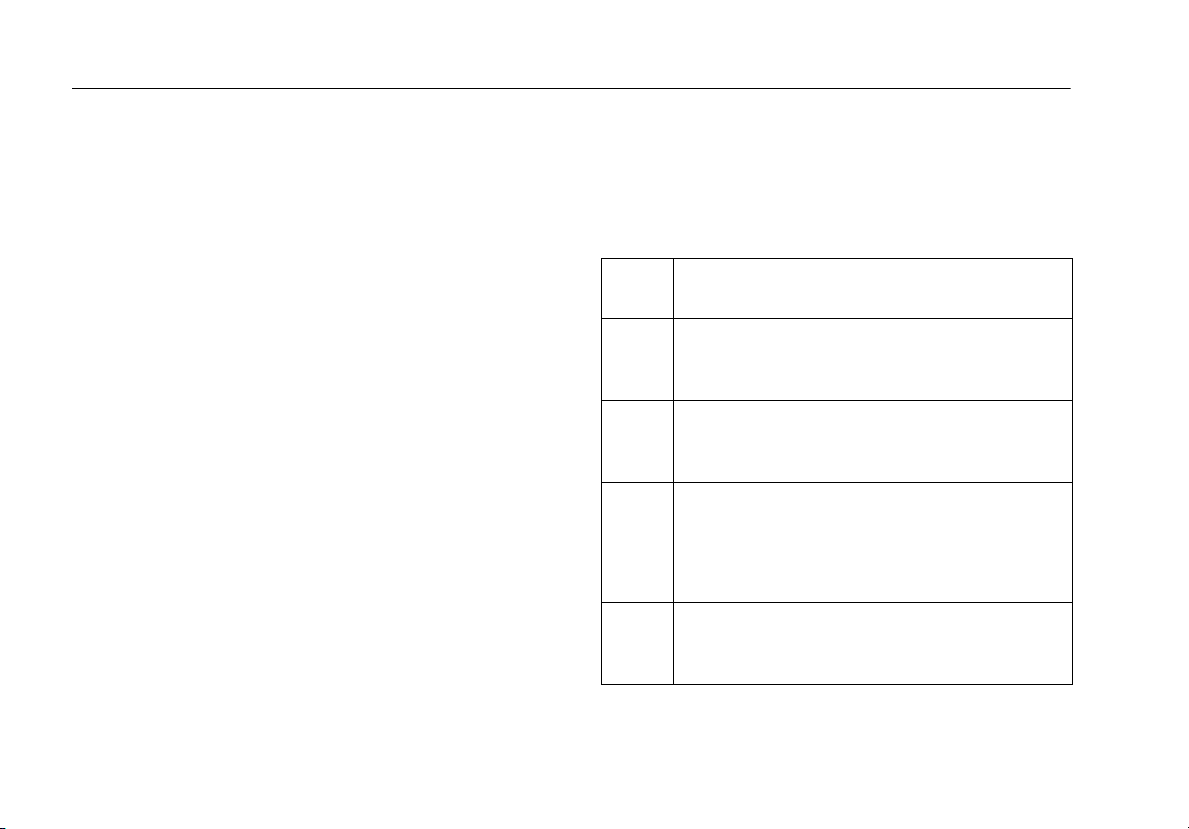

Table 3 describes the test settings that apply to fiber

cabling.

Table 3. Fiber Test Settings

Setting Description

SETUP > Fiber Loss >

Test Li mit

SETUP > Fiber Loss >

Fiber Type

SETUP > Fiber Loss >

Remote End Setup

Select the appropriate test limit for the job. The tester compares the fiber test results to the

selected test limit to produce PAS S or FAIL results. Selecting Custom lets you create a test limit.

See the Technical Reference Handbook for details.

Select a fiber type that is appropriate for the type you will test. Selecting Custom lets you

create a fiber type. See the Technical Reference Handbook for details.

Use Smart Remote mode for testing dual-fiber cabling.

Use Loopback mode for testing test reference cords and cable spools.

Use Far End Source mode with an optical source for testing individual fibers.

To access the fiber test settings turn the rotary switch to

SETUP; then select Fiber Loss. Use

tabs.

The Twisted Pair, Coax, and Network settings do

not apply to the DTX-CLT CertiFiber tester.

BC to see different

Note

-continued-

21

Page 30

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Setting Description

Table 3. Fiber Test Settings (cont.)

SETUP > Fiber Loss >

Bi-Directional

SETUP > Fiber Loss >

Number of Adapters

SETUP > Fiber Loss >

Number of Splices

SETUP > Fiber Loss >

Connector Type

22

When enabled in Smart Remote or Loopback mode, the tester prompts you to swap the test

connections halfway through the test. The tester can then make bi-directional measurements

for each fiber at each wavelength (850 nm/1300 nm, 850 nm/1310 nm, or 1310 nm/1550 nm).

If the selected limit uses a calculated loss limit, enter the number of adapters and splices that

will be added to the fiber path after the reference is set. Figure 11 shows an example of how to

determine the Number of Adapters setting.

Only limits that use maximum values for loss per km, loss per connector, and loss per splice use a

calculated limit for overall loss. For example, limits for fiber backbones use a calculated loss

limit.

Select the type of connector used in the cabling. This setting affects only the diagrams shown

for reference connections. If the cabling's connector type is not listed, use General.

-continued-

Page 31

Fiber Test Settings

Figure 11. Example of How to Determine the Number of Adapters Setting

(singlemode example; mandrels not used)

gfd09f.eps

23

Page 32

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Setting Description

Table 3. Fiber Test Settings (cont.)

SETUP > Fiber Loss >

Test Method

24

Loss results include connections added after referencing. The reference and test connections

determine which connections are included in results. The Te st M eth od refers to the number of

end connections included:

2 Jumper: Loss results include one connection at one end of the link.

1 Jumper: Loss results include connections at both ends of the link. Select this method for

connections shown in this manual. See "About 1 Jumper Connections" on page 26.

3 Jumper: Loss results exclude connections at the ends of the link. Only the fiber loss is

measured.

Different standards have different names for the three test methods. See Appendix B for

details. The Technical Reference Handbook provides additional information on test methods.

This setting does not affect loss results. It is only saved with the results to record which method

you used.

This setting does affect the reference and test connection diagrams shown on the tester's

display. The diagrams show connections for the method selected.

Page 33

Table 3. Fiber Test Settings (cont.)

Setting Description

Fiber Test Settings

SETUP > Fiber Loss >

Index of Ref. Source

(n) > User Defined or

Default

SPECIAL FUNCTIONS

> Set Reference

Patch Lengths

(softkey on the View

Connections screen)

Settings for saving

tests

The tester uses the index of refraction (n) defined in the currently selected fiber type (Default)

or a value you define (User Defined). The default value defined by the selected fiber type

represents the typical value for that fiber type. You may enter a different value if necessary. To

determine the actual value, change the index of refraction until the measured length matches

the known length of a fiber.

Increasing the index of refraction decreases the reported length.

Setting a reference sets the baseline power level for loss measurements. See “About Setting

the Reference” on page 17.

After you set the reference, you can enter the lengths of the test reference cords used. The

lengths are saved with results to meet TIA reporting requirements for fiber test results.

See “Preparing to Save Tests” on page 27.

25

Page 34

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

About 1 Jumper Connections

The reference and test connections shown in this manual

produce 1 Jumper results. 1 Jumper results include the loss

of the fiber plus the loss of the connections at both ends of

the link. To ensure accurate results, the connection to the

fiber module's output port must not be disconnected after

the reference is set. Using connector adapters that match

the connectors in the fiber under test lets you connect to

the fiber without disturbing the output port connection.

WCaution

If you disconnect the test reference cords from

the tester’s or smart remote’s output port after

setting the reference, you must set the

reference again to ensure valid measurements.

If you do not have the correct connector adapters, see

Appendix C, "Modified 1 Jumper Method" for alternative

connections that produce 1 Jumper results.

To test links with different connectors at each end, see the

alternate method described in the Appendix of the DTX

Series CableAnalyzer Technical Reference Handbook or

visit the Fluke Networks Knowledge Base for suggestions.

26

Page 35

Preparing to Save Tests

!

Check the memory space available:

Turn the rotary switch to SPECIAL FUNCTIONS; then

select Memory Status.

!

Select a cable ID source:

You can select IDs from a pre-generated list or create an

ID after each test. Turn the rotary switch to SETUP, select

Instrument Settings, select Cable ID Source; then select a

source. See “Cable ID Options” on page 58 for details.

!

Set up a job folder:

On the Instrument Settings menu select Current Folder.

Select an existing folder or press

create a new folder.

J Create Folder to

Preparing to Save Tests

!

Enter job information:

On the Instrument Settings menu press

tab with the Operator, Site, and Company names. To

enter a new name, select a setting, press

then use the softkeys, BC A D, and H for

editing. Press

!

Enable Auto Save, if desired:

On the Instrument Settings menu press

tab with the Auto Save Results setting. Select Yes to

have the tester automatically save Autotests using the

next ID available from the Cable ID Source.

The Store Plot Data setting does not apply to the

DTX-CertiFiber tester.

N when you are finished.

Note

C to show the

J Create;

C to show the

27

Page 36

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Certifying Fiber Cabling

The Autotest runs the tests required to certify that fiber

cabling meets a particular standard. You run the Autotest

in Smart Remote, Loopback, or Far End Source mode,

depending on whether you are testing duplex cabling,

spools, test reference cords, or single-fiber cabling.

Autotest in Smart Remote Mode

Use Smart Remote mode to test and certify dual-fiber

cabling. In this mode, the tester measures loss, length, and

propagation delay on two fibers at two wavelengths in

one or both directions.

Figure 12 shows the equipment required for testing fiber

in Smart Remote mode.

28

Page 37

A

Tester and smart remote with fiber modules and

connector adapters installed. Match connector adapters

to the connectors in the link.

B

Two ac adapters with line cords (optional)

C

Test reference cords. Match the fiber to be tested. Long

ends must have SC connectors. For the other connectors,

match the connectors in the link.

Figure 12. Equipment for Testing in Smart Remote Mode (1 Jumper Method)

Certifying Fiber Cabling

D

Two singlemode adapters of the appropriate type

E

Two mandrels. Recommended when testing multimode

fiber with DTX-MFM2 modules. See page 18.

F

Fiber cleaning supplies

G

A microscope for inspecting fiber connectors (the FT500

FiberInspector Mini Video Microscope is shown)

gfd10f.eps

29

Page 38

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Smart Remote Mode: Set the Reference

1

Turn on the tester and smart remote and let them sit

for 5 minutes. Allow additional time if the modules

have been stored above or below ambient

temperature.

2

Turn the rotary switch to SETUP, then select Fiber Loss.

Set the following on the Fiber Loss tabs (press C to

see other tabs):

•

Test Li mit : Select the test limit required for the job.

Press J More to see other lists of limits.

•

Fiber Type: Select the fiber type to be tested.

•

Remote End Setup: Set to Smart Remote.

•

Bi-directional: Enable this if you are required to test

the fiber in both directions.

•

Number of Adapters and Number of Splices: Enter

the number of adapters and splices that will be

added to each direction of the fiber path after the

reference is set.

•

Connector Type: Select the connector type used in the

cabling to be tested. Select General if the exact type is

not listed.

•

Test Method: Refers to the number of adapters

represented in the loss results. Select 1 Jumper if you

use the reference and test connections shown in this

manual.

3

Turn the rotary switch to SPECIAL FUNCTIONS, then

select Set Reference.

4

The Set Reference screen shows reference connections

for the test method you selected. Figure 13 shows

connections for the 1 Jumper method. Clean and

inspect the connectors on the testers and test reference

cords, connect the tester and smart remote; then press

P.

See Table 3 on page 21 for details on settings.

30

-continued-

Page 39

Certifying Fiber Cabling

Figure 13. Setting the Reference in Smart Remote Mode (1 Jumper Method)

gfd11f.eps

31

Page 40

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Smart Remote Mode: Make Sure Your Test Reference Cords are Good

WCaution

If you disconnected the test reference cords from

the tester’s or smart remote’s output, you must

set the reference again to ensure valid

measurements.

5

Disconnect the test reference cords from the INPUT

ports on the tester and smart remote.

6

Make the connections shown in Figure 14.

7

Turn the rotary switch to AUTOTEST, then press P.

8

Press H to see the test results. The results for each

fiber (Input Fiber and Output Fiber) must be no more

than these limits:

WCaution

An overall result of PASS does not show that the

test reference cords are good. You must compare

the loss to the limits given here to make sure the

cords are good.

Multimode test reference cord:

850 nm: 0.11 dB or less

1300 nm: 0.10 dB or less

(The limits are different because fiber has more loss at

850 nm than at 1300 nm.)

Singlemode test reference cord:

0.20 dB or less for 1310 nm and 1550 nm

9

If a result is more than the limit shown above, use the

procedure given in Appendix A to test the cords in

the path that failed (Input Fiber or Output Fiber).

When you have good test reference cords, set the

reference and do these steps (5 through 9) again

before you test a fiber link.

10

Save the test results to show that you used good test

reference cords to test the link.

Note

Fluke Networks recommends that you use this

procedure to make sure your test reference cords

are good before you test each fiber link.

32

Page 41

Certifying Fiber Cabling

Figure 14. Testing the Test Reference Cords in Smart Remote Mode

gfd26.eps

33

Page 42

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Smart Remote Mode: Test the Fiber Link

WCaution

If you disconnected the test reference cords from

the tester’s or smart remote’s output, you must

set the reference again to ensure valid

measurements.

11

Clean and inspect the connectors on the cabling to be

tested; then connect to the link. The tester shows test

connections for the test method you selected. Figure 15

shows connections for the 1 Jumper method.

12

Turn the rotary switch to AUTOTEST. Verify that the

media type is set to Fiber Loss. Press

to change it if necessary.

13

Press Pon the tester or smart remote.

14

If Open or Unknown appears, try the following:

•

Verify that all connections are good.

J Change Media

•

Verify that the tester at the other end is on. (The

tester cannot activate a sleeping or powered-down

tester at the far end through the fiber modules.)

•

Try different connections at the patch panel.

•

Try changing the polarity of the connections at one

end.

•

Use the visual fault locator to verify fiber continuity.

15

If bi-directional testing is enabled, the tester prompts

you to switch the fibers halfway through the test.

Switch the fibers at the patch panels or adapters (not

at the tester’s ports) at both ends of the cabling.

16

To save the results, press N, select or create a fiber ID

for the input fiber; then press N. Select or create a

fiber ID for the output fiber; then press

In the results for Smart Remote mode, Input Fiber and

Output Fiber refer to the fibers connected to the main

tester’s input and output ports. For a bi-directional test,

these are the fibers connected to the main tester’s input

and output ports at the end of the test.

N again.

34

Page 43

Certifying Fiber Cabling

Figure 15. Testing a Fiber Link in Smart Remote Mode (1 Jumper Method)

gfd12.eps

35

Page 44

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Loopback Mode

Use Loopback mode to test spools of cable, segments of

uninstalled cable, and test reference cords.

In this mode, the tester measures loss, length, and

propagation delay at two wavelengths in one or both

directions.

Figure 16 shows the equipment required for testing fiber

in Loopback mode.

36

Page 45

A

Tester with fiber module and connector adapter installed

(match connector adapter to the connectors in the link)

B

AC adapter with line cord (optional)

C

Test reference cord. Match the fiber to be tested. Long

end must have SC connector. For the other connectors,

match the connectors in the link.

Figure 16. Equipment for Testing in Loopback Mode (1 Jumper Method)

Certifying Fiber Cabling

D

Two singlemode adapters of the appropriate type

E

Mandrel. Recommended when testing multimode

fiber with a DTX-MFM2 module. See page 18.

F

Fiber cleaning supplies

G

A microscope for inspecting fiber connectors (the

FT500 FiberInspector Mini Video Microscope is shown)

gfd13f.eps

37

Page 46

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Loopback Mode: Set the Reference

1

Turn on the tester and smart remote and let them sit for

5 minutes. Allow additional time if the modules have

been stored above or below ambient temperature.

2

Turn the rotary switch to SETUP, then select Fiber Loss.

Set the following on the Fiber Loss tabs (press C to see

other tabs):

•

Test Li mit : Select the test limit required for the job.

Press J More to see other lists of limits.

•

Fiber Type: Select the fiber type to be tested.

•

Remote End Setup: Set to Loopback.

•

Bi-directional: Enable this if you are required to test

the fiber in both directions.

•

Number of Adapters and Number of Splices: Enter

the number of adapters and splices that will be added

to each direction of the fiber path after the reference

is set.

•

Connector Type: Select the connector type used in

the cabling to be tested. Select General if the exact

type is not listed.

•

Test Method: Refers to the number of adapters

represented in the loss results. Select 1 Jumper if you

use the reference and test connections shown in this

manual.

3

Turn the rotary switch to SPECIAL FUNCTIONS, then

select Set Reference.

4

The Set Reference screen shows connections for the

test method you selected. Figure 17 shows connections

for the 1 Jumper method. Clean and inspect the

connectors on the tester and test reference cord,

connect the tester’s INPUT and OUTPUT ports; then

P.

press

See Table 3 on page 21 for details on settings.

-continued-

38

Page 47

Certifying Fiber Cabling

Figure 17. Setting the Reference in Loopback Mode (1 Jumper Method)

gfd14f.eps

39

Page 48

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Loopback Mode: Make Sure Your Test Reference Cords are Good

WCaution

If you disconnected the test reference cord from

the tester’s output, you must set the reference

again to ensure valid measurements.

5

Disconnect the test reference cord from the INPUT port

on the tester.

6

Make the connections shown in Figure 18.

7

Turn the rotary switch to AUTOTEST, then press P.

8

Press H to see the test result. The result must be no

more than these limits:

WCaution

An overall result of PASS does not show that the

test reference cords are good. You must compare

the loss to the limits given here to make sure the

cords are good.

Multimode test reference cord:

850 nm: 0.11 dB or less

1300 nm: 0.10 dB or less

(The limits are different because fiber has more loss at

850 nm than at 1300 nm.)

Singlemode test reference cord:

0.20 dB or less for 1310 nm and 1550 nm

9

If a result is more than the limit shown above, use the

procedure given in Appendix A to test the cords.

When you have good test reference cords, set the

reference and do these steps (5 through 9) again

before you test a fiber link.

10

Save the test results to show that you used good test

reference cords to test the link.

Note

Fluke Networks recommends that you use this

procedure to make sure your test reference cords

are good before you test each fiber link.

40

Page 49

Certifying Fiber Cabling

Figure 18. Testing the Test Reference Cords in Loopback Mode

gfd27.eps

41

Page 50

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Loopback Mode: Test the Fiber

WCaution

If you disconnected the test reference cord from

the tester’s output port, you must set the

reference again to ensure valid measurements.

11

Clean and inspect the connectors on the cabling to be

tested; then connect to the cabling. The tester shows

connections for the test method you selected. Figure 19

shows connections for the 1 Jumper method.

12

Turn the rotary switch to AUTOTEST. Verify that the

media type is set to Fiber Loss. Press J Change

Media to change it if necessary.

13

Press P.

14

If bi-directional testing is enabled, the tester prompts

you to switch the fibers halfway through the test.

Switch the fibers at the adapters (not at the tester’s

ports).

15

To save the results, press N, select or create a fiber ID;

then press

N again.

42

Page 51

Certifying Fiber Cabling

Figure 19. Testing a Fiber in Loopback Mode (1 Jumper Method)

gfd15f.eps

43

Page 52

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Far End Source Mode

Use Far End Source mode to measure loss at one

wavelength on individual fibers.

A

Tester and smart remote with fiber modules and

connector adapters installed (match connector adapters

to the connectors in the link)

B

Two AC adapters with line cords (optional)

C

Test reference cord. Match the fiber to be tested. SC

connector at one end. Match the link connectors at the

other end.

Figure 20. Equipment for Testing in Far End Source Mode (1 Jumper Method)

Far End Source mode requires a stand-alone optical source.

Figure 20 shows the equipment required for testing fiber

in Far End Source mode.

gfd16f.eps

D

Test reference cord. Match the fiber and connectors in

the link.

E

Singlemode adapter of the appropriate type.

F

Mandrel. Recommended when testing multimode

fiber with a DTX-MFM2 module. See page 18.

G

Fiber cleaning supplies

H

A microscope for inspecting fiber connectors (the

FT500 FiberInspector Mini Video Microscope is shown)

44

Page 53

Autotest in Far End Source Mode: Set the Reference

1

Turn on the tester and smart remote and let them sit for

5 minutes. Allow additional time if the modules have

been stored above or below ambient temperature. For

other sources, warm up according to the manufacturer’s

recommendations.

2

Turn the rotary switch to SETUP, then select Fiber Loss.

Set the following on the Fiber Loss tabs (press

other tabs):

•

Test Li mit : Select the test limit required for the job.

J More to see other lists of limits.

Press

•

Fiber Type: Select the fiber type to be tested.

•

Remote End Setup: Set to Far End Source

C to see

Certifying Fiber Cabling

•

Bi-directional: Does not apply to Far End Source

mode.

•

Number of Adapters and Number of Splices: Does

not apply to Far End Source mode.

•

Connector Type: Select the connector type used in

the cabling to be tested. Select General if the exact

type is not listed.

•

Test Method: Refers to the number of adapters

represented in the loss results. Select 1 Jumper if you

use the reference and test connections shown in this

manual.

See Table 3 on page 21 for details on settings.

-continued-

45

Page 54

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Far End Source Mode: Set the Reference (cont.)

3

Hold down the button on the smart remote’s fiber

module for 3 seconds to turn on the output port at

850 nm (DTX-MFM2/GFM2) or 1310 nm (DTX-SFM2).

Press again to switch to 1300 nm (DTX-MFM2), 1310 nm

(DTX-GFM2), or 1550 nm (DTX-SFM2).

The LED is red for the shorter wavelength and green for

the longer wavelength.

For other sources, verify the output is set to the correct

wavelength and is in continuous-wave mode.

4

Turn the rotary switch to SPECIAL FUNCTIONS, then

select Set Reference.

5

The Set Reference screen shows connections for the

test method you selected. Figure 21 shows connections

for the 1 Jumper method. Clean and inspect the

connectors on the tester, test reference cord, and

source, connect the tester and source; then press

P.

-continued-

46

Page 55

Certifying Fiber Cabling

Figure 21. Far End Source Mode Reference Connections (1 Jumper Method)

gfd17f.eps

47

Page 56

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Far End Source Mode: Make Sure Your Test Reference Cords are Good

WCaution

If you disconnected the test reference cord from

the tester’s output, you must set the reference

again to ensure valid measurements.

6

Disconnect the test reference cord from the INPUT port

on the tester.

7

Make the connections shown in Figure 22.

8

Turn the rotary switch to AUTOTEST, then press P.

9

Press H to see the test result. The result must be no

more than these limits:

WCaution

An overall result of PASS does not show that the

test reference cords are good. You must compare

the loss to the limits given here to make sure the

cords are good.

Multimode test reference cord:

850 nm: 0.11 dB or less

1300 nm: 0.10 dB or less

(The limits are different because fiber has more loss at

850 nm than at 1300 nm.)

Singlemode test reference cord:

0.20 dB or less for 1310 nm and 1550 nm

10

If a result is more than the limit shown above, use the

procedure given in Appendix A to test the cords.

When you have good test reference cords, set the

reference and do these steps (6 through 10) again

before you test a fiber link.

11

Save the test results to show that you used good test

reference cords to test the link.

Note

Fluke Networks recommends that you use this

procedure to make sure your test reference cords

are good before you test each fiber link.

48

Page 57

Certifying Fiber Cabling

Figure 22. Testing the Test Reference Cords in Far End Source Mode

gdf28.eps

49

Page 58

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Autotest in Far End Source Mode: Test the Fiber

WCaution

If you disconnected the test reference cord from

the source’s output port, you must set the

reference again to ensure valid measurements.

12

Clean and inspect the connectors on the cabling to be

tested; then connect the tester and source to the

cabling. The tester shows connections for the test

method you selected. Figure 23 shows connections for

the 1 Jumper method.

13

Turn the rotary switch to AUTOTEST, press P; then

select the wavelength set on the smart remote.

14

To save the results, press N, select or create a fiber ID;

then press

N again.

50

Page 59

Certifying Fiber Cabling

Figure 23. Testing a Link in Far End Source Mode (1 Jumper Method)

gfd18f.eps

51

Page 60

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Using the Visual Fault Locator

The fiber module includes a visual fault locator that helps

you quickly check fiber continuity, trace fibers, and locate

faults along fibers and in connectors.

The visual fault locator port accepts connectors with

2.5 mm ferrules (SC, ST, or FC). To connect to other ferrule

sizes, use a test reference cord with the appropriate

connector at one end and a SC, ST, or FC connector at the

tester end.

Figure 24 shows the equipment needed for using the

visual fault locator.

3

1

52

2

A

Tester or smart remote with fiber module

B

AC adapter with line cord (optional)

C

One test reference cord. Match fiber and connectors

to be tested; SC, ST, or FC at tester end. (optional)

D

Fiber cleaning supplies

Figure 24. Equipment for Using the Visual Fault Locator

4

gfd19f.eps

Page 61

Using the Visual Fault Locator

1

Clean the connectors on the test reference cord, if used,

and the fiber to be tested.

2

Connect the fiber directly to the tester’s VFL port or

connect using the test reference cord.

3

Turn on the visual fault locator by pressing the button

near the VFL connector, as shown in Figure 25. Press

again to switch to flashing mode. Press again to turn

off the locator.

Using the Visual Fault Locator

4

Look for the red light to locate fibers or faults (Figure

25):

•

To check continuity or trace fiber connections, look

for the red light at the end of the fiber. View the VFL’s

light indirectly by holding a white card or paper in

front of the fiber connector emitting the light.

•

To locate faults, move along the fiber from either

end, looking for a red glow coming from the fiber

jacket or a connector housing.

Note

The locator’s light may not be visible through darkcolored fiber jackets.

53

Page 62

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

54

gfd20f.eps

Figure 25. Using the Visual Fault Locator

Page 63

Monitoring Optical Power

The power meter lets you monitor the optical power

produced by a source such as an optical network interface

card or optical test equipment.

The tester offers two versions of the power meter

function:

•

SINGLE TEST mode: Takes one power measurement at

850 nm and 1300 nm (DTX-MFM2), 850 nm and

1310 nm (DTX-GFM2), or 1310 nm and 1550 nm

(DTX-SFM2). You can save the power measurement in

this mode.

•

MONITOR mode: Monitors power continuously at the

input port at 850 nm, 1300 nm, 1310 nm, or 1550 nm.

This measurement cannot be saved.

Figure 26 shows the equipment required for monitoring

power in the MONITOR mode.

Monitoring Optical Power

gfd21f.eps

A

Tester with fiber module

B

Memory card (optional for SINGLE TEST mode)

C

AC adapter with line cord (optional)

D

One test reference cord (match fiber used in

installation, SC at tester end)

E

Fiber cleaning supplies

Figure 26. Equipment for Monitoring Optical Power

55

Page 64

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Monitoring Optical Power

1

Clean the tester’s input port and the test reference cord

and source connectors.

2

Use the test reference cord to connect the source to the

tester’s input port, as shown in Figure 27. Turn on the

source.

3

Turn the rotary switch to MONITOR. If the media type is

not set to Fiber Loss, press

change it.

J Change Media to

4

Select Power Meter. You do not need to select a fiber

type or test limit.

5

Select the correct wavelength; then press P.

To change the wavelength after starting the test, press

L Change λ.

56

Page 65

Monitoring Optical Power

Figure 27. Connections for Monitoring Optical Power

gfd22f.eps

57

Page 66

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Cable ID Options

You can select cable IDs from a pre-generated list or you can

create an ID after each test.

To select a source for cable IDs, turn the rotary switch to

SETUP, select Instrument Settings, select Cable ID Source;

then select a source:

•

Auto Increment: Increments the last character of the ID

each time you press N.

•

List: Lets you use an ID list created in LinkWare

software and downloaded to the tester.

•

Auto Sequence: Lets you use a list of sequential IDs

generated from a template. The horizontal, backbone,

and campus templates follow the ID formats specified

in the ANSI/TIA/EIA-606-A standard. The Free Form

template lets you create your own pattern.

•

None: Lets you create an ID each time you press N.

After you press

using it for saving results.

N, you can also edit an existing ID before

To create a list of sequential IDs, do the following:

1

On the Auto Sequence screen, select a template.

2

On the Auto Sequence screen, select Start ID. Use the

softkeys,

first ID in the sequential list. Press N when you are

finished.

3

Select Stop ID. Use the softkeys, BC A D,

and H to enter the last ID in the sequential list. Press

BC A D, and H to enter the

N when you are finished

4

Press L Sample List to see what the list will look

like.

Used IDs are marked with a “$” in cable ID lists.

58

Page 67

Memory Functions

The DTX-CLT CertiFiber can store a minimum of 3300

Autotest results from single or bi-directional tests on fiber

cabling. The maximum capacity of internal memory

depends on the space taken by the tester’s software.

Memory Functions

•

To delete one result, highlight it, press K Delete,

press L Delete; then press L Yes .

•

To delete all results in the current folder, the current

folder, or all results in the tester (internal memory),

K Delete; then select an option. Press L

press

Delete; then press L Yes .

Viewing Results

To view saved results, do the following:

1

Turn the rotary switch to SPECIAL FUNCTIONS; then

select View/Delete Results.

2

If necessary, press J Change Folder to find the

result you want to view.

3

Highlight the result; then press H.

Deleting Results

To delete results or folders, do the following:

1

Turn the rotary switch to SPECIAL FUNCTIONS, then

select View/Delete Results.

2

If necessary, press J Change Folder to find the

results you want to delete.

3

Do one of the following:

Uploading Results to a PC

To upload results to a PC, do the following:

1

Install the latest version of LinkWare software on your

PC.

2

Turn on the tester.

3

Connect the tester to the PC with the USB cable

provided.

4

Start LinkWare software on the PC.

5

Click Import on the LinkWare toolbar. Select the

tester’s model from the list.

Note

The DTX-CLT CertiFiber shows as “DTX-CLT” on

LinkWare menus.

6

Select the records you want to import; then click OK.

59

Page 68

DTX-CLT CertiFiber Optical Loss Test Set

Users Manual

Options and Accessories

For a complete list of options and accessories visit the Fluke

Networks website at www.flukenetworks.com.

To order options or accessories, contact Fluke Networks as

described on page 2.

About LinkWare and LinkWare Stats Software

The LinkWare™ Cable Test Management software included

with your tester lets you do the following:

•

Upload test records to PC.

•

View test results.

•

Add ANSI/TIA/EIA-606-A administration information to

records.

•

Organize, customize, and print professional-quality

test reports.

•

Update the tester’s software.

•

Create and download data to the DTX, such as Setup

data and cable ID lists.

•

Transfer custom limits between testers.

Details about using LinkWare software are provided in the

LinkWare Getting Started Guide and the online help

available under Help on the LinkWare menu.

Updates to LinkWare software are available on the Fluke

Networks website.

The LinkWare Stats Statistical Report option for LinkWare

software provides statistical analysis of cable test reports

and generates browsable, graphical reports. LinkWare