Page 1

Hart Scientific

9934 LogW are

User’s Guide

Rev. 592201

Page 2

Fluke Corporation, Hart Scientific Division (Hart) warrants this product to be free

from defects in material and workmanship under normal use and service for a pe

riod as stated in our current product catalog from the date of shipment. This war

-

ranty extends only to the original purchaser and shall not apply to any product

which, in Hart’s sole opinion, has been subject to misuse, alteration, abuse or abnor

mal conditions of operation or handling.

Software is warranted to operate in accordance with its programmed instructions on

appropriate Hart products. It is not warranted to be error free.

Hart’s obligation under this warranty is limited to repair or replacement of a product

which is returned to Hart within the warranty period and is determined, upon exam

ination by Hart, to be defective. If Hart determines that the defect or malfunction

has been caused by misuse, alteration, abuse or abnormal conditions or operation or

handling, Hart will repair the product and bill the purchaser for the reasonable cost

of repair.

To exercise this warranty, the purchaser must forward the product after calling or

writing Hart for authorization. Hart assumes NO risk for in-transit damage.

For service or assistance, please contact the manufacturer.

THE FOREGOING WARRANTY IS PURCHASER’S SOLE AND EXCLUSIVE

REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OR

MERCHANTABILITY, OR FITNESS FOR ANY PARTICULAR PURPOSE OR

USE. HART SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSS WHETHER IN CONTRACT, TORT, OR OTHERWISE.

-

-

Rev. 592201

Microsoft, MS-DOS, Windows, Window for Workgroups, and Windows 95, 98,

ME, NT, 2000, and XP are either registered trademarks or trademarks of Microsoft

Corporation.

Fluke Corporation

Hart Scientific Division

799 E. Utah Valley Drive American Fork, UT 84003-9775 USA

Phone: +1.801.763.1600

Telefax: +1.801.763.1010

Email: support@hartscientific.com

www.hartscientific.com

Subject to change without notice. Copyright © 2005 Printed in USA

Page 3

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 What is LogWa re? . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.1 Thermometer readout requirements . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.2 Communications requirements. . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.3 Computer hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.4 Computer software requirements. . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.6 Regional settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7 Running LogWare . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7.1 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.8 LogWa re main display . . . . . . . . . . . . . . . . . . . . . . . . 6

1.9 Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.9.1 File toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.9.2 Datalog toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.9.3 Graph toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.9.4 Tools toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.9.5 Help toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 How to... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Using an I/R dongle with LogWa re . . . . . . . . . . . . . . . . . 11

2.2 Opening a configuration file automatically on start-up . . . . . . . 13

2.3 Starting a real-time log session unattended (delayed start) . . . . . 15

2.4 Stopping a real-time log session automatically . . . . . . . . . . . 16

2.5 Downloading logged data from the memory of a thermometer . . . 17

2.6 Viewing remaining memory for logging data . . . . . . . . . . . . 17

2.7 Changing thermometer and/or INFO-CON/probe settings . . . . . 18

2.8 Saving thermometer and/or INFO-CON/probe settings to a configura

tion file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.9 Synchronizing the thermometer’s clock to the computer . . . . . . 21

2.10 Importing logged data into a spreadsheet . . . . . . . . . . . . . . 22

3 File menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 New . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

i

-

Page 4

3.2 Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Save as. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4 Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4.2 Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.5 Print setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.6 Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.6.1 Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.6.2 Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.7 Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4 Datalog menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 Setup log session . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1.1 Thermometer settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.1.2 Communication settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.1.3 Log settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1.4 Channel settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.1.5 Open and save as . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1.6 Set as default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2 Start log session . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3 Stop log session . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4 Close log session . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.5 Mute all alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.6 Alarm settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.7 Delayed start date/time . . . . . . . . . . . . . . . . . . . . . . . 42

4.8 Real-time log session . . . . . . . . . . . . . . . . . . . . . . . . 44

5 Download menu. . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.1 Download logged data. . . . . . . . . . . . . . . . . . . . . . . . 49

5.2 Log status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.3 Download Process. . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.4 Binary download discrepancies . . . . . . . . . . . . . . . . . . . 56

6 View menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.1 Alarm log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.1.1 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Readings history. . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.1 Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.3 Open previously logged datafile. . . . . . . . . . . . . . . . . . . 63

7 Graph menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

ii

Page 5

7.1 Graph settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.1.1 Titles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1.2 Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.1.3 Fonts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.1.4 Trends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.1.5 Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.1.6 Legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.1.7 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.2 Restore default settings . . . . . . . . . . . . . . . . . . . . . . . 83

7.3 Trace color. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.4 Zoom in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.5 Restore (zoom out) . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.6 Print graph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8 Tools menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.1 Synchronize date/time . . . . . . . . . . . . . . . . . . . . . . . . 87

8.2 Write labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.3 INFO-CON/probe settings . . . . . . . . . . . . . . . . . . . . . 89

8.4 Thermometer settings . . . . . . . . . . . . . . . . . . . . . . . . 93

8.5 Select model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.6 Enter passcode. . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.7 Callendar-Van Dusen coefficients . . . . . . . . . . . . . . . . . 100

8.8 High temperature PRT coefficients . . . . . . . . . . . . . . . . 102

8.9 IPTS-68 coefficients . . . . . . . . . . . . . . . . . . . . . . . . 103

8.10 ITS-90 coefficients . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.11 Thermistor coefficients. . . . . . . . . . . . . . . . . . . . . . . 105

9 Window menu . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10 Help menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

10.1 Technical support . . . . . . . . . . . . . . . . . . . . . . . . . 109

10.2 About. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

11 Configuration and other files . . . . . . . . . . . . . . . . . . 113

11.1 Single channel configuration file . . . . . . . . . . . . . . . . . 113

11.2 Alarms configuration file . . . . . . . . . . . . . . . . . . . . . 113

11.3 Thermometer configuration file . . . . . . . . . . . . . . . . . . 114

11.4 Channel configuration file . . . . . . . . . . . . . . . . . . . . . 114

11.5 Conversion configuration files . . . . . . . . . . . . . . . . . . . 114

11.6 Output files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

iii

Page 6

11.7 Download files . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

11.8 Alarm log file . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

iv

Page 7

Figures and Tables

Figure 1 9934 LogWare main display. . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2 LogWare toolbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3 File toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4 Datalog toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5 Graph toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6 Tools toolbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 7 Help toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 8 Model 2374 Infrared Dongle . . . . . . . . . . . . . . . . . . . . . . . 12

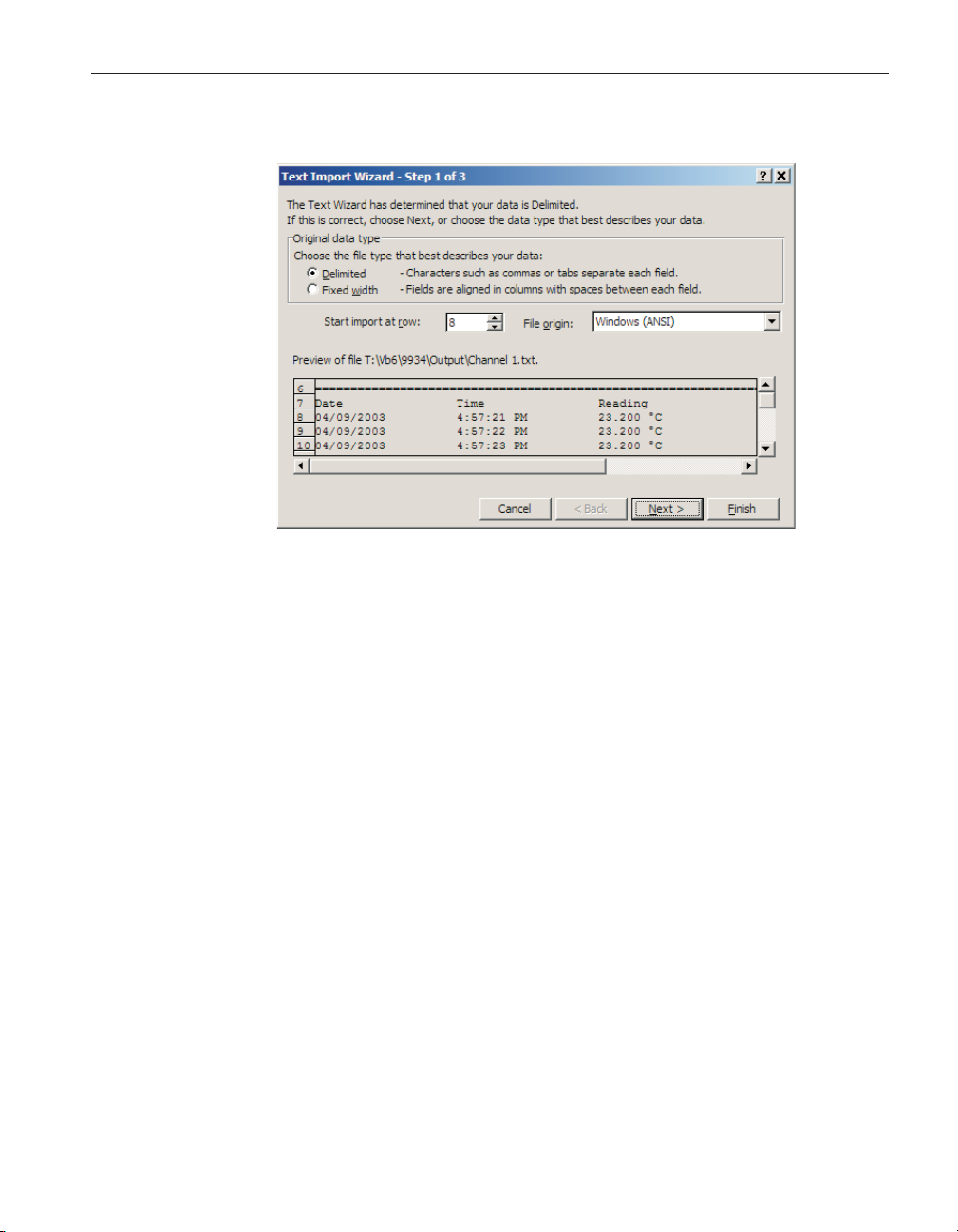

Figure 9 Text Import Wizard – Step 1 of 3 dialog . . . . . . . . . . . . . . . . . 23

Figure 10 Output file displayed in spreadsheet . . . . . . . . . . . . . . . . . . . 24

Figure 11 Text Import Wizard – Step 2 of 3 dialog . . . . . . . . . . . . . . . . . 24

Figure 12 Chart of output file . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 13 File menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 14 Default Settings dialog . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 15 File|Defaults General tab. . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 16 File|Defaults Folders tab . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 17 Datalog menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 18 Log Session settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 19 Log Session Start Time . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 20 Alarm Settings dialog . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 21 Delayed Start Date/Time dialog . . . . . . . . . . . . . . . . . . . . . 43

Figure 22 Real-Time Log Session window . . . . . . . . . . . . . . . . . . . . . 44

Figure 23 Download menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 24 1522 Download dialog . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 25 1522 Log Status dialog. . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 26 Downloaded Files dialog. . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 27 View menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 28 Alarms.log Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 29 Alarms dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 30 Output file dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 31 Statistics dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 32 Log File dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 33 Graph menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 34 Graph Settings dialog . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 35 Graph Settings - Titles tab . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 36 Graph Settings - Axis tab . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 37 Graph Settings - Fonts tab . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 38 Graph Settings - Trends tab . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 39 Graph Settings - Background tab . . . . . . . . . . . . . . . . . . . . 78

Figure 40 Graph Settings - Legend tab . . . . . . . . . . . . . . . . . . . . . . . 80

v

Page 8

Figure 41 Graph Settings - System Tab. . . . . . . . . . . . . . . . . . . . . . . 81

Figure 42 Trace Color dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 43 Zoom In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 44 Tools menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 45 Data Labels dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 46 Channel Settings dialog . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 47 Calendar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 48 Thermometer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 49 Select Model dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 50 Enter Passcode dialog. . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 51 Callendar-Van Dusen Coefficients dialog . . . . . . . . . . . . . . . 101

Figure 52 High Temp. PRT Coefficients dialog . . . . . . . . . . . . . . . . . . 102

Figure 53 IPTS-68 Coefficients Dialog . . . . . . . . . . . . . . . . . . . . . . 103

Figure 54 ITS-90 Coefficients dialog . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 55 Thermistor Coefficients dialog . . . . . . . . . . . . . . . . . . . . . 106

Figure 56 Window menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 57 Help menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 58 About LogWare dialog . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 1 Conversion types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 59 Example output file . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 60 Example alarm log file . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 61 Example download file . . . . . . . . . . . . . . . . . . . . . . . . . 117

vi

Page 9

1 Introduction

1 Introduction

What is LogWare?

1.1 What is Log

Hart’s 9934 LogWare is a real-time data logging, storage and analysis software

program designed specifically for use with Hart Scientific digital thermometers.

LogWare automates the logging of data from a single channel or input.

LogWare is designed to work with the following Hart Scientific digital

thermometers:

1502 Thermometer Readout (2 styles)

•

1502A Thermometer Readout

•

1503 Thermometer Readout

•

1504 Thermometer Readout

•

1521 Handheld Thermometer Readout

•

• 1522 LLL Handheld Thermometer Readout and Datalogger

Ware

?

1.2 License Agreement

For information and details regarding the software End User License Agreement (EULA), refer to the online help file’s License Agreement topic

1.3 Features

LogWare provides an easy-to-use Windows® interface to log, store and analyze

data from Hart Scientific digital thermometers. LogWa re also provides a

method to download readings that are stored in the memory of thermometers

that support this feature, such as the model 1522 LLL Handheld Datalogger.

After being logged or downloaded, the readings are written to a file that can be

opened by LogWare , spreadsheet or other analysis software.

LogWare ’s data logging features include:

•

Quick and easy configuration

•

Ability to save and open setup configuration files

•

Selectable sample interval from 1 second to 24 hours

•

Selectable delayed start time/date for off-hours logging

•

Selectable end log options (allows a log session to stop automatically af

ter a specified time or a specified number of readings)

•

Logs readings to ASCII text files that can then be opened, graphed and

printed

•

Graphs readings as they are being logged

•

Maintains statistical data for logged readings

-

1

Page 10

9934 LogWare

User’s Guide

Ability to set High and Low alarms

•

Can play .WAV file or launch any other software package when an alarm

•

trips (such as Pager software)

Many user-customizable graph settings including alarm, statistical and

•

trend lines

LogWare ’s data analysis features include:

Can open both real-time log files and downloaded files

•

Spreadsheet-style grid to view all readings

•

Graph that displays up to 32,767 readings at a time

•

Graph zooming capability

•

Statistical lines and calculations

•

Printing graph and readings

•

Can have multiple windows open simultaneously

•

LogWare also provides utilities which allow access to the following thermometer features (as applicable):

• Download logged data

• View log status

• Change log labels

• Synchronize date/time with computer

• Change thermometer-specific parameters (filter, resolution, units, calibra-

tion dates and constants, etc.)

• Change INFO-CON or probe-specific parameters (conversion type and

coefficients, calibration dates, excitation current, etc.)

Version 1.3

A list of new features and enhancements in this software follows:

•

Branding/Logo change – The logos and graphics displayed in LogWa re

have been updated.

Also, various features have been added to the software to aid in troubleshooting

issues related to downloading logged data

1.4 Requirements

LogWare supports the Hart Scientific digital thermometer models as listed be

low. The communication and computer requirements are also listed.

1.4.1 Thermometer readout requirements

LogWare is designed to work with the following Hart Scientific digital ther

mometer readouts:

2

-

-

Page 11

1502 Thermometer Readout (2 styles)

•

1502A Thermometer Readout

•

1503 Thermometer Readout

•

1504 Thermometer Readout

•

1521 Handheld Thermometer Readout

•

1522 Handheld Thermometer Readout and Datalogger

•

1.4.2 Communications requirements

The instrument being used with LogWare must be connected to a COM

(RS-232 serial) port on a computer using a “null modem” cable. (A “null mo

dem” cable is a cable that effectively replaces two modems. Refer to the ther

mometer’s User Guide for more information on the cable or contact hart

Scientific Customer Service to purchase a “null modem” cable.) The baud rate

can be set from 300 baud to 9600 baud depending on the instrument. However,

the instrument and computer baud rates must match.

1.4.3 Computer hardware requirements

The following minimum computer configuration is required to use LogWare .

• IBM Compatible 486 PC or better with 8MB RAM (Pentium® class pro-

cessor with 16MB RAM or more recommended)

• VGA monitor or better

• CD-ROM drive for installation

• 1 – RS-232 (COM) port)

•

Minimum of about 8MB of disk space (for installation) - The program re

quires additional disk space to store the data as it is acquired.

1 Introduction

Requirements

-

-

-

1.4.4 Computer software requirements

Note: To use LogWare, Windows® login accounts must be granted full ac

cess to the folder to which the software is installed and all subfolders. If

the folder has read-only access, errors will occur when LogWare attempts

to access its configuration files.

LogWare requires one of the following operating systems

•

Windows® 95/98

•

Windows® NT with SP4/2000/XP

Note: LogWare has only been tested on Windows® NT with Service Pack

4 installed.

-

3

Page 12

9934 LogWare

User’s Guide

1.5 Installation

Note: Before installing LogWare, be sure to read the License Agreement

and Warranty.

A backup should always be made of your hard disk drive and registry before in

stalling any software, and all running applications should be closed.

Note: To successfully install LogWare, you must be logged into Windows

as an Administrator.

Installing LogWare

1. Insert the LogWa re CD-ROM into your CD-ROM drive. The Setup pro

gram should run automatically.

2. Follow the on-screen instructions to install LogWare .

3. When prompted, enter the product serial number. The serial number is

provided on a sticker typically located on the CD pouch on the inside

back cover of the LogWare User’s Guide.

4. After all files have been installed, a program group is created with icons

for the software, the Help file, the README.TXT file, and an icon to

uninstall the software. The installation process is complete.

5. The README.TXT file can be displayed by checking the appropriate

check box before the setup program finishes. Read this file for important

information that was not available when the User Guide was printed.

Uninstalling LogWare

To uninstall the software, use the Windows® Add/Remove Programs icon in

the Control Panel. Follow the instructions given. The program files that were

installed to your system are removed. Any files that were created or saved by

users will not be removed from the system. These files, along with the folders

that these files are in, must be manually deleted using Windows® Explorer to

remove them from your system.

-

-

1.6 Regional settings

LogWare recognizes and uses the regional settings such as the date, time and

number formats as set in the Windows® Control Panel’s Regional Settings or

Regional Options icon.

1.7 Running Log

The following sections describe how to get LogWare up and running quickly.

4

Ware

Page 13

1.7.1 Getting started

The following information is intended to provide a brief overview on how to

get LogWare up and running quickly. For more detailed information, please re

fer to the following sections:

Section 1.8, LogWa re Main Display

•

Section 4, Datalog Menu

•

To use this software:

1. Click the Start button, then locate and click the icon created by the setup

process.

2. The software will start with the Log Session Settings dialog displayed on

top of the main display (see Section 4.1). If the Log Session Settings dia

log is not displayed when the software starts, select the Setup option

from the Datalog menu.

Note: In order to make the Log Session Settings dialog appear when the

software starts, check the “Show Log Session Settings dialog on start-up”

check box on the General tab of the Defaults dialog.

To start a log session, fill in the information on the Log Session Settings dialog.

The following information must be entered before a log session can start:

1 Introduction

Running LogWare

-

-

• Select the Model of the thermometer to use. Enter the Serial Number and

select the Readings Scale from the available choices.

• Select the COM port to which the thermometer is connected and choose

the baud rate.

•

Power up the thermometer and make sure it is connected to the specified

COM port. Click the Test Communication button to make sure LogWa re

can communicate with the thermometer.

•

Choose the log interval (time between readings)

•

Choose the appropriate end log option and set the other end log settings

as required.

•

To set a delayed start date/time, click the Delayed Start button and choose

the appropriate date and time for the log session to begin. Otherwise, the

log session will begin when the Start button is clicked.

•

Select the trace color, enter the output filename and set the statistics op

-

tions as desired.

•

To configure alarms, click the Alarm Settings button and set the appropri

ate alarm settings as desired.

These settings can be saved to a configuration file by clicking the Save As but

ton. If this configuration should be opened every time the software runs, click

the Set as Default button.

-

-

5

Page 14

9934 LogWare

User’s Guide

After entering this information, click the Start button to start the log session.

1.8 Log

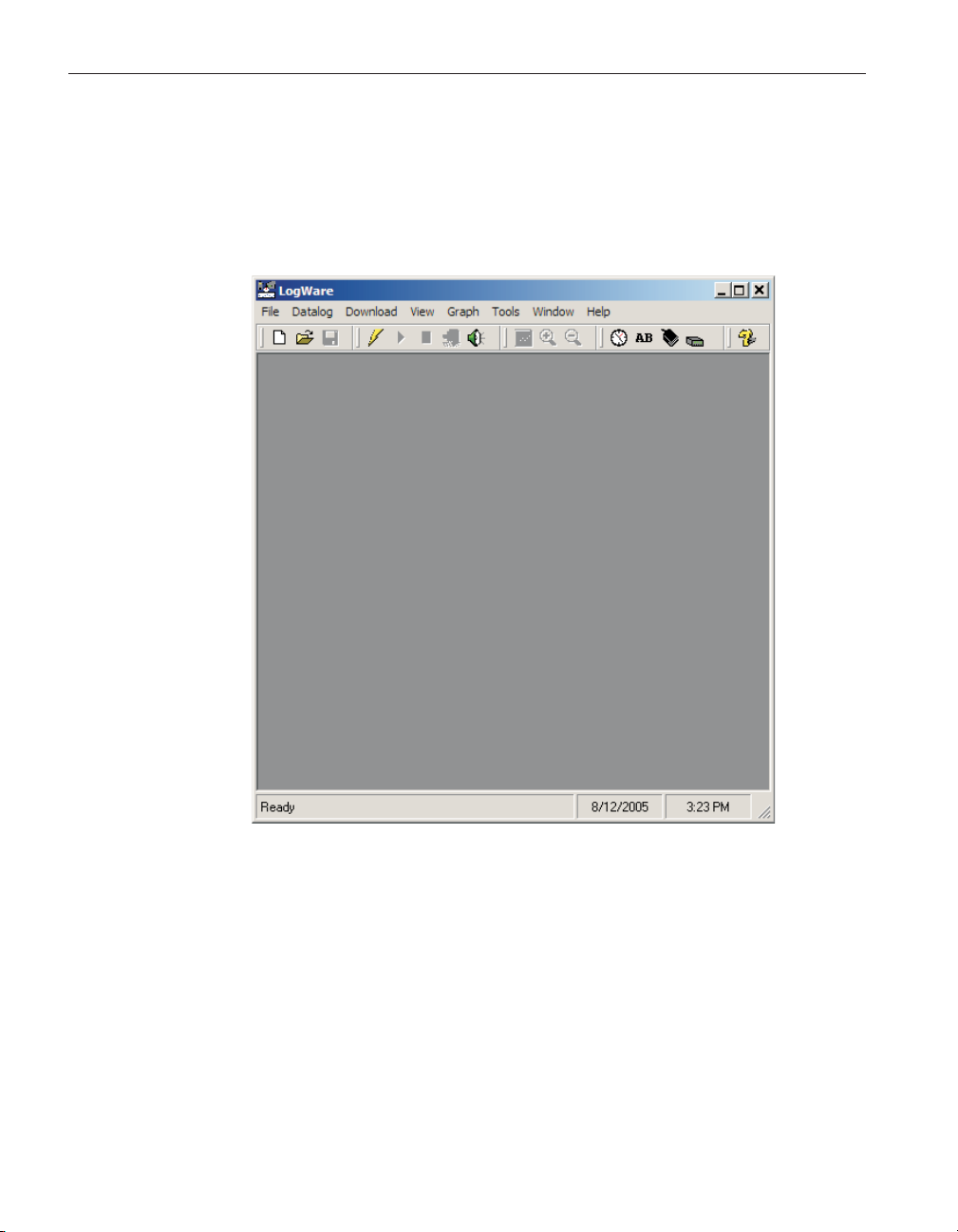

The main display (Figure 1) consists of the menu bar, toolbar, a workspace area

and a status bar.

Ware

main display

Figure 1 9934 LogWare main display

The menu bar allows access to the various features of the software. A general

description of the options in each menu is given below:

•

File – Open and save configuration files, change default settings, printing

options, exit the software

•

Datalog – Setup, Start, Stop and Close real-time log sessions

•

Download – Download logged readings from a thermometer and view log

status

•

View – View alarm log and reading history during real-time log session

and open previously logged data files

6

Page 15

1 Introduction

Toolbar

Graph – Change graph settings, zoom in and out, and print the current

•

graph

Tools – Synchronize thermometer date/time, configure various thermome

•

ter and INFO-CON/probe settings

Window – Rearrange and switch between open windows

•

Help – Display help topics and About dialog

•

The toolbar allows quick access to the most common menu functions. The

toolbar is divided into sections that correspond to related functions. Toolbar

sections may be rearranged as desired by clicking on the vertical bar on the left

side of the section and dragging it to the desired location.

The status bar indicates the function that the software is currently performing

as well as the current system date and time.

-

1.9 Toolbar

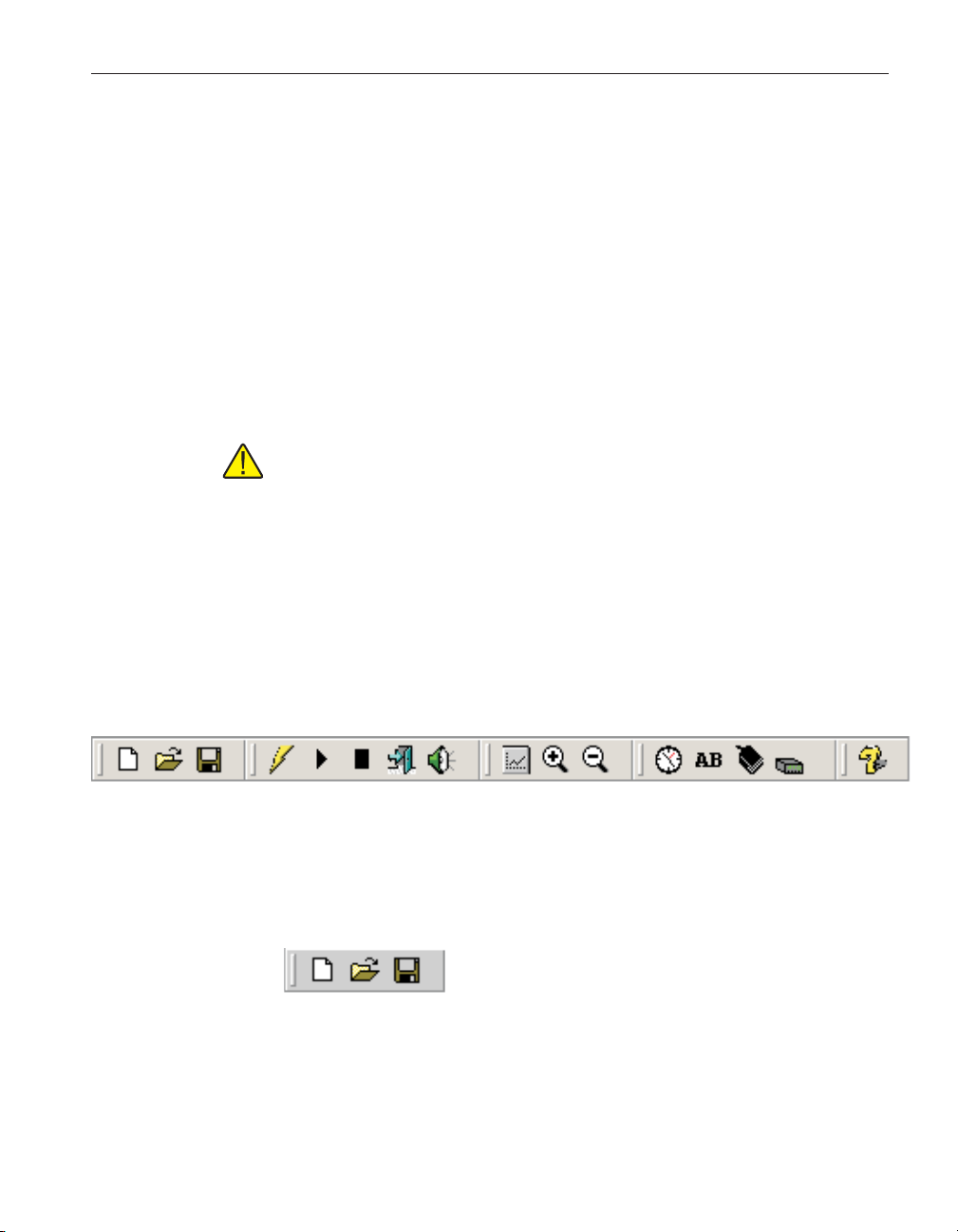

Figure 2 LogWare toolbar

1.9.1 File toolbar

Note: The date and time displayed are based on the computer’s clock set

tings and can be modified through the Windows® Control Panel. The date

and time formats used can be changed by selecting the Regional Settings

icon in the Control Panel.

The toolbar (Figure 2) provides quick access to many of the most common

functions of the software. The toolbar is divided into sections that correspond

to related menu options. Toolbar sections may be rearranged as desired by

clicking on the vertical bar on the left side of the section and dragging it to the

desired location.

The following toolbars are available:

Figure 3 File toolbar

New – Create a new real-time log session configuration

Open – Open a real-time log session configuration file

Save As – Save the current real-time log session settings to a configuration file

7

Page 16

9934 LogWare

User’s Guide

1.9.2 Datalog toolbar

1.9.3 Graph toolbar

Figure 4 Datalog toolbar

Setup – Setup a real-time log session

Start – Start a real-time log session

Stop – Stop a real-time log session

Close – Close a real-time log session

Mute all alarms – Mute/Unmute all real-time log session alarms

Figure 5 Graph toolbar

Graph settings – Change graph settings, add trend lines, alarm lines, titles,

captions, etc.

Zoom in – Zoom in to view a section of the graph

Restore (zoom out) – Zoom out to view entire graph

1.9.4 Tools toolbar

Figure 6 Tools toolbar

Synchronize date/time – Synchronize thermometer’s date/time with computer

Write labels – Change the labels associated with datalogging

INFO-CON/probe settings – Change settings associated with the INFO-CON

connector or probe

Thermometer settings – Change settings associated with the thermometer

8

Page 17

1.9.5 Help toolbar

Figure 7 Help toolbar

Help – Open the help file

1 Introduction

Toolbar

9

Page 18

2 How to...

Using an I/R dongle with LogWare

2 How to...

This section contains some “How to…” step-by-step instructions and other in

formation on how to use LogWa re to perform certain tasks. The following top

ics are included:

Using an I/R dongle with LogWa re (see Section 2.1).

•

Opening a configuration file automatically on start-up (see Section 2.2).

•

Starting a real-time log session unattended (Delayed Start) (see Section

•

2.3).

Stopping a real-time log session automatically (see Section 2.4).

•

Downloading logged data from the memory of a thermometer (see Sec

•

tion 2.5).

Viewing remaining memory for logging data (see Section 2.6).

•

Changing thermometer and/or INFO-CON/probe settings (see Section

•

2.7).

• Saving thermometer and/or INFO-CON/probe settings to a configuration

file (see Section 2.8).

• Synchronizing the thermometer’s clock to the computer (see Section 2.9).

• Importing logged data into a spreadsheet (see Section 2.10).

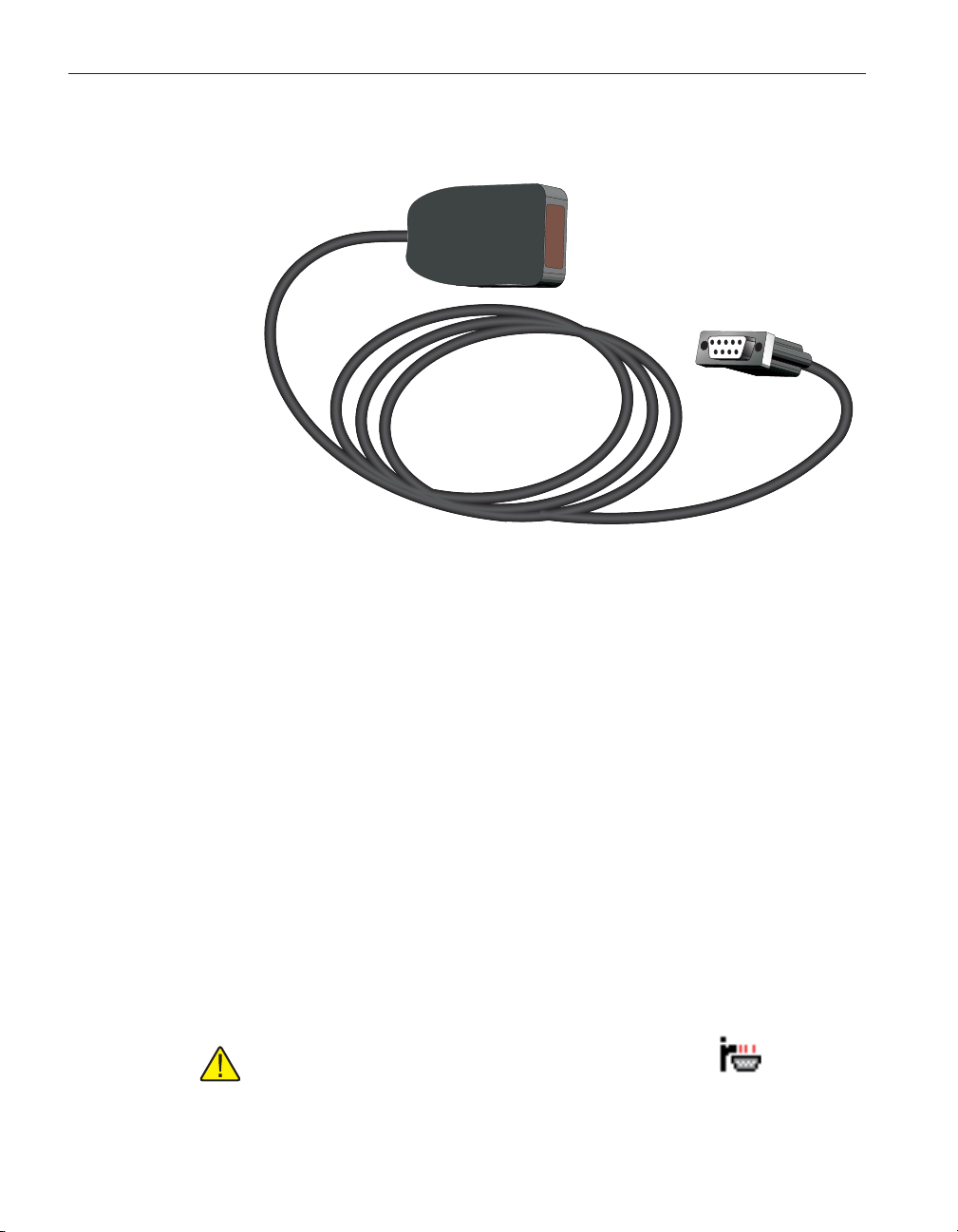

2.1 Using an I/R dongle with Log

Some Hart Scientific thermometer readouts, such as the 1522, have a built-in

I/R port that can be used to communicate with a computer. I/R ports have many

advantages over standard RS-232 ports which include increased data transfer

rate, greater flexibility and ease of use.

Hart thermometer readoutss with an I/R port use a proprietary protocol for

communication. Because of this proprietary protocol, LogWa re is not able to

use I/R ports that are built into a computer. Instead, LogWar e requires the use

of an I/R dongle (Figure 8) which can be connected to a standard RS-232 port.

No special software or drivers are required to use the dongle. All necessary

-

-

-

Ware

11

Page 19

9934 LogWare

User’s Guide

communication protocols and drivers are built into LogWa re . To purchase an

I/R dongle (model 2374), contact technical support.

Figure 8 Model 2374 Infrared Dongle

LogWare provides support for communicating over an I/R port with these thermometers. However, the support is limited to the following features:

• Downloading logged data from memory

• Checking log status

•

Writing labels associated with logged data

LogWar e does not support using the I/R port for real-time log sessions.

To use an I/R dongle with LogWar e, follow these steps.

1. Locate a 9-pin or 25-pin COM (RS-232) port on the computer. Connect

the I/R dongle to the port. If the COM port is a 25-pin port, use a 9-25

pin adapter to connect the dongle.

2. In the Download menu, select either the Download Logged Data option

or the Log Status option. Or, in the Tools menu, select the Write labels

option. The Select Model dialog is displayed (see Section 8.5).

3. Select the thermometer model to use. Then select the COM port to which

the I/R dongle is connected.

Note: In the COM port drop down list, ports with the symbol rep

-

resent built-in I/R ports and cannot be used!!

12

Page 20

Opening a configuration file automatically on start-up

4. Next, check the Use I/R Dongle check box. When this box is checked,

the Baud Rate setting is ignored since the thermometers are fixed at

115,200 baud when using the I/R port.

5. To ensure the computer can communicate with the thermometer using

the I/R port, place the I/R window of the thermometer in close proximity

to the I/R dongle and make sure the path between the two is not ob

structed (see the thermometer’s User Guide for details on the proximity

requirements). Click the Test Communication button. If LogWa re suc

ceeds in communicating with the thermometer a success message is dis

played. Otherwise, a failure message is displayed. In case of failure,

check the following:

The dongle is connected to the selected COM port

•

The thermometer is powered up and operating

•

The dongle is in range of the I/R port on the thermometer

•

The path between the thermometer and dongle is not obstructed

•

Shut the thermometer’s power off, then back on again

•

When communication succeeds, click the OK button to proceed to the appropriate dialog.

2 How to...

-

-

-

2.2 Opening a configuration file automatically on

start-up

LogWare was designed to be flexible with the thermometers that it can use and

the features it supports. However, most users of LogWar e will probably always

use the same thermometer, scale, communication settings, log interval and

channel and alarm settings to do all or most of their logging.

For this reason, LogWar e allows real-time log session settings to be saved to a

configuration file. Opening the configuration file restores the settings eliminat

ing the need to manually enter most of the information for a new log session.

Configuration files save the following information about a real-time log

session:

•

Thermometer model, serial number and readings scale

•

Communications COM port and baud rate

•

Log interval and End Log settings

•

Channel trace color and filename

•

Alarm and statistics settings

The delayed start date and time information is not saved in the configuration

file. For more information on configuration files, please read Configuration

Files.

-

13

Page 21

9934 LogWare

User’s Guide

In addition to allowing configuration files to be saved and opened, LogWa re

also allows one configuration file to be opened automatically every time

LogWare runs. This configuration file can be specified in one of two ways:

From the Defaults dialog (see Section 3.4.1)

•

From the Log Session Settings dialog (see Section 4.1)

•

Opening configuration file automatically using the Defaults dialog:

Select the Defaults option from the File menu (see Section 3.4.1).

•

Select the General tab.

•

Check the Show Log Session Settings dialog on start-up check box.

•

Check the Load default configuration file automatically check box.

•

Click the “…” (Browse) button to select the configuration file to open or

•

type the path and filename in the Default configuration file box.

Click the OK button to save the changes.

•

Note: The real-time log session settings must already be saved to a config-

uration file in order to accomplish these steps.

Opening configuration file automatically using the Log Session Settings

dialog:

14

• Select the Setup option from the Datalog menu (see Section 4.1).

• Fill in all of the information on this dialog.

• Click the Alarm Settings button and fill in the desired alarm settings.

• Click the Set as Default button.

•

A prompt is displayed to save the settings to a configuration file. Enter the

filename for this configuration file (use a descriptive name).

•

A prompt is displayed to confirm setting this configuration as the default

configuration file. Click Yes.

•

Click the Close button to close the dialog.

Test this feature to make sure it works properly by closing LogWa re and run

ning it again. The Log Session Settings dialog should be displayed with all of

the configuration information filled in. If the configuration file is not being

loaded, check the Defaults dialog as explained above.

To disable opening the configuration file on start-up, uncheck the Load default

configuration file automatically check box on the Defaults dialog.

Page 22

Starting a real-time log session unattended (delayed start)

2.3 Starting a real-time log session unattended

(delayed start)

2 How to...

The main purpose of LogWare is to log data in real-time. Many times, the tech

nician is present when a log session starts. However, sometimes it is necessary

or desirable to start a real-time log session at off-hours when the technician is

out.

LogWare has a feature called the Delayed Start which allows a real-time log

session to start at a predefined date and time. By default, a real-time log session

starts immediately when the Start button on the Log Session Settings dialog is

clickedorwhentheStartoptionintheDatalogmenuisselected.

Setting the delayed start date and time for a real-time log session:

Select the Setup option from the Datalog menu to display the Log Session

•

Settings dialog (see Section 4.1).

Fill in the Thermometer settings and Communication settings informa

•

tion.

• Set the Log interval and choose the appropriate End Log settings.

• Click the Delayed Start button to display the Delayed Start Date/Time di-

alog.

• Choose the date and time that the real-time log session should start. The

start date and time are with respect to the computer’s clock settings. Make

sure the computer’s clock is accurate. Click the OK button to accept the

selected date and time.

Note: To cause the real-time log session to start immediately when click-

ing the Start button after having set a delayed start date and time, click the

Reset button.

-

-

•

Fill in the Channels information to complete the setup process.

•

Click the Start button on the Log Session Settings dialog.

•

LogWa re displays a message indicating the date and time the real-time log

session will start.

•

To cancel the delayed start, click the Cancel button at any time.

After a real-time log session ends, the delayed start time is reset so that the next

real-time log session will start immediately when the Start button on the Log

Session Settings dialog is clicked or when the Start option in the Datalog menu

is selected. To set a new delayed start time for the next real-time log session,

follow the steps above.

15

Page 23

9934 LogWare

User’s Guide

2.4 Stopping a real-time log session automatically

Note: Every effort has been made to make the real-time log session take

its first reading at the selected date and time. However, due to the large

variation in the speed at which different computers operate, the first read

ing may be one or more seconds later than the selected time (commonly

known as “latency”). To compensate for this, try a few tests to determine

the approximate latency in the computer being used and then adjust the

start time accordingly by reducing the start time by the difference between

the selected start time and the actual time of the first reading.

-

The main purpose of LogWare is to log data in real-time. Many times, the tech

nician is present when a log session needs to be stopped. However, sometimes

it is necessary or desirable to stop a real-time log session when the technician is

busy with another task, or at off-hours when the technician is out.

The End Log feature of LogWare provides three methods for stopping a

real-time log session:

• Manually, by the technician

• Automatically, after a specific number of readings

• Automatically, after a specific period of time

The first method, Manually, by the technician, is the default End Log setting.

Stopping the real-time session automatically:

• Select the Setup option from the Datalog menu to display the Log Session

Settings dialog (see Section 4.1).

•

Fill in the Thermometer settings and Communication settings informa

-

tion.

•

Set the Log interval.

•

If needed, select the appropriate delayed start date and time.

•

Using the End Log drop down list, select the method to use to stop the

real-time log session:

By user – Log session stops when the Stop option in the Datalog menu is

selected

-

16

After specified # of readings – Log session stops automatically when number

of readings specified have been logged

After specified time – Log session stops automatically after the specified time

has elapsed

•

Specify the End Log criteria by selecting either the number of readings or

the elapsed time

•

Fill in the Channels information to complete the setup process.

Page 24

thermometer

2.5 Downloading logged data from the memory of a

Downloading logged data from the memory of a

Click the Start button on the Log Session Settings dialog to start the

•

real-time log session.

2 How to...

thermometer

Some thermometers that are supported by LogWare allow readings to be logged

to the memory of the thermometer. LogWa re provides a feature to download the

logged readings from the memory of the thermometer and save them to a text

file (or files) on the computer.

Currently, only the Model 1522 LLL Handheld Datalogger has this capability.

Downloading readings from the memory of a thermometer to a text file (or

files) on the computer:

Select Download Logged Data from the Download menu (see Section

•

5.1).

• The Select Model dialog is displayed (see Section 8.5). Select the ther-

mometer model from which the readings are to be downloaded. Also, select the COM port to which the thermometer is connected and the baud

rate to use. If using the I/R port, check the Use I/R Dongle check box.

Note: The 1522 LLL Handheld Datalogger has an I/R port which can be

used to download readings. Using the I/R port requires an I/R dongle to

be connected to a COM port on the computer. For more information,

please read Section 2.1 Using an I/R dongle with LogWare.

•

Make sure LogWare can communicate with the thermometer by clicking

the Test Communication button.

•

Click the OK button when communication is successful.

•

The Download dialog is displayed. This dialog is specific to the options

and features of the selected thermometer model.

•

Select the appropriate download options and click the Download button to

download the readings.

•

Click the Close button to close the Download dialog when finished.

2.6 Viewing remaining memory for logging data

Some thermometers that are supported by LogWare allow readings to be logged

to the memory of the thermometer. LogWa re provides a feature that indicates

how much of the thermometer’s memory is already used.

Currently, only the Model 1522 LLL Handheld Datalogger has this capability.

Viewing the status of the thermometer’s log(s):

17

Page 25

9934 LogWare

User’s Guide

Select Log Status from the Download menu (see Section 5.2).

•

The Select Model dialog is displayed (see Section 8.5). Select the ther

•

mometer model from which the readings are to be downloaded. Also, se

lect the COM port to which the thermometer is connected and the baud

rate to use. If using the I/R port, check the Use I/R Dongle check box.

Note: The 1522 LLL Handheld Datalogger has an I/R port which can be

used to download readings. Using the I/R port requires an I/R dongle to

be connected to a COM port on the computer. For more information,

please read Section 2.1 Using an I/R dongle with LogWare.

Make sure LogWare can communicate with the thermometer by clicking

•

the Test Communication button.

Click the OK button when communication is successful.

•

The Log Status dialog is displayed indicating how much of the thermome

•

ter’s memory is already used. This dialog is specific to the features of the

selected thermometer model.

• Click the Close button to close the Log Status dialog when finished.

-

-

-

2.7 Changing thermometer and/or INFO-CON/probe

settings

LogWare provides a feature which allows many of the thermometer and

INFO-CON/probe settings to be read in, viewed, modified and written back out

to the thermometer. These settings include:

•

Filter

•

Resolution

•

Thermometer calibration and recalibration dates

•

Thermometer calibration constants

•

Probe serial number

•

Probe wires

•

Probe calibration and recalibration dates

•

Probe conversion type and calibration coefficients

Viewing, modifying and writing the new settings to the thermometer:

•

Select Thermometer Settings from the Tools menu (see Section 8.4).

•

The Select Model dialog is displayed (see Section 8.5). Select the ther

mometer model from which the settings are to be read in. Also, select the

COM port to which the thermometer is connected and the baud rate to

use.

-

18

Page 26

Changing thermometer and/or INFO-CON/probe settings

Make sure LogWare can communicate with the thermometer by clicking

•

the Test Communication button.

Click the OK button when communication is successful.

•

All thermometer and INFO-CON/probe settings are then read in and dis

•

played in the Thermometer Settings dialog.

2 How to...

-

Note: The controls for settings which do not apply to the selected ther

-

mometer are disabled.

Any of the settings can be modified at this time. All passcode protected

•

settings are indicated in RED. These settings can be modified freely but

will not be written back to the thermometer without the correct passcode

being entered when prompted.

To view or modify the INFO-CON/probe settings, select the appropriate

•

channel from the Channels list and click the Channel Settings button to

display the Channel Settings dialog.

• All thermometer and INFO-CON/probe settings can be saved to a configuration file by clicking the Save As button. To read in a configuration file

containing thermometer and INFO-CON/probe settings, click the Open

button. Thermometer configuration files have a .THM extension.

Note: Thermometer configuration files are specific to each thermometer

model. LogWare does not allow a thermometer configuration file for a

1502 to be opened when working with a 1521, etc. Therefore, when saving

thermometer configuration files, include the thermometer model number

in the filename so that the contents of the file are known.

•

To write any changes that have been made back out to the thermometer,

click the OK button. If any of the passcode protected settings were

changed, the Enter Passcode dialog is displayed (see Section 8.6). The

correct passcode MUST be entered in order for the new settings to be

properly written to the thermometer.

Note: LogWare cannot verify that the correct passcode was entered except

on the model 1522 LLL Handheld Datalogger. If an incorrect passcode

was entered, LogWare continues and attempts to write the new settings,

however the thermometer will not accept the new settings.

•

To close the Thermometer Settings dialog without writing the settings

back out to the thermometer, click the Cancel button.

19

Page 27

9934 LogWare

User’s Guide

2.8 Saving thermometer and/or INFO-CON/probe

settings to a configuration file

LogWare provides a feature which allows many of the INFO-CON/probe set

tings to be read in, viewed, modified and written back out to the thermometer.

These settings include:

Probe serial number

•

Probe wires

•

Probe calibration and recalibration dates

•

Probe conversion type and calibration coefficients

•

Viewing, modifying and writing the new settings to the thermometer:

Select INFO-CON/Probe Settings from the Tools menu (see Section 8.3).

•

The Select Model dialog is displayed (see Section 8.5). Select the ther

•

mometer model from which the settings are to be read in. Also, select the

COM port to which the thermometer is connected and the baud rate to

use.

• Make sure LogWare can communicate with the thermometer by clicking

the Test Communication button.

• Click the OK button when communication is successful.

• All INFO-CON/probe settings are then read in and displayed in the Chan-

nel Settings dialog.

Note: The controls for settings which do not apply to the selected ther-

mometer are disabled.

-

-

20

•

Any of the settings can be modified at this time. All passcode protected

settings are indicated in RED. These settings can be modified freely but

will not be written back to the thermometer without the correct passcode

being entered when prompted.

•

All INFO-CON/probe settings can be saved to a channel configuration

file by clicking the Save As button. To read in a channel configuration file

containing INFO-CON/probe settings, click the Open button. Channel

configuration files have a .CHN extension.

Note: Channel configuration files are specific to each thermometer model.

LogWare does not allow a channel configuration file for a 1502 to be

opened when working with a 1521, etc. Therefore, when saving channel

configuration files, include the thermometer model number in the filename

so that the contents of the file are known.

Page 28

Synchronizing the thermometer’s clock to the computer

To write any changes that have been made back out to the thermometer,

•

click the OK button. If any of the passcode protected settings were

changed, the Enter Passcode dialog is displayed (see Section 8.6). The

correct passcode MUST be entered in order for the new settings to be

properly written to the thermometer.

Note: LogWare cannot verify that the correct passcode was entered except

on the model 1522 LLL Handheld Datalogger. If an incorrect passcode

was entered, LogWare continues and attempts to write the new settings,

however the thermometer will not accept the new settings.

To close the Channel Settings dialog without writing the settings back out

•

to the thermometer, click the Cancel button.

2 How to...

2.9 Synchronizing the thermometer’s clock to the

computer

Most of the thermometers supported by LogWare have an internal clock.

LogWare provides a feature to synchronize the thermometer’s clock with the

clock on the computer.

Note: LogWare itself does not use the clock on the thermometer at all. All

dates and times associated with readings logged by LogWare use the current date and time according to the computer’s clock.

Before synchronizing the thermometer’s clock, make sure the computer’s clock

is accurate. Use the Windows® Control Panel to adjust the date and time as

necessary.

Synchronizing the thermometer’s clock with the computer’s clock:

•

Select Synchronize Date/Time from the Tools menu.

•

The Select Model dialog is displayed (see Section 8.5). Select the appro

priate thermometer model. Also, select the COM port to which the ther

mometer is connected and the baud rate to use.

•

Make sure LogWare can communicate with the thermometer by clicking

the Test Communication button.

•

Click the OK button when communication is successful.

Note: If the date and/or time setting on the selected thermometer’s clock

is passcode protected, the Enter Passcode dialog is displayed (see Section

8.6). Enter the passcode and click the OK button to continue. If the

passcode is not known, click the Cancel button to abort setting the ther

mometer’s clock.

-

-

-

21

Page 29

9934 LogWare

User’s Guide

2.10 Importing logged data into a spreadsheet

LogWa re attempts to set the thermometer’s clock to match the clock on

•

the computer.

Note: LogWare cannot verify that the correct passcode was entered except

on the model 1522 LLL Handheld Datalogger. If an incorrect passcode

was entered, LogWare continues and attempts to write the new settings,

however the thermometer will not accept the new settings.

The data logged by LogWare is saved into ASCII text files referred to as output

files. These files can be opened and graphed by LogWar e by selecting the Open

Previously Logged Data File option from the View menu.

However, these files may also be imported into spreadsheet software such as

Microsoft® Excel for graphing or analysis.

Importing an output file into Excel:

Note: This example uses Microsoft® Excel 2002. These steps may not ap-

ply if using a different version of Excel or another spreadsheet software

package.

22

• In Excel, select the Open option from the File menu to display the Open

dialog.

• In the Files of type box at the bottom of the open dialog, select the Text

Files option.

•

Navigate to the folder where the output file is located. Select the output

file to open and click the Open button.

Page 30

Importing logged data into a spreadsheet

The Text Import Wizard – Step 1 of 3 dialog appears, Figure 9.

•

Figure 9 Text Import Wizard – Step 1 of 3 dialog

2 How to...

• Make sure the Original data type option is set to Delimited. If the thermometer and probe information is not needed, set the Start import at row

option to row 8 or the first row containing the logged readings. Set the

File Origin option to Windows (ANSI) and click the Next > button.

23

Page 31

9934 LogWare

User’s Guide

The Text Import Wizard – Step 2 of 3 dialog appears, Figure 11.

•

Figure 11 Text Import Wizard – Step 2 of 3 dialog

• In the Delimiters box, select the Tab and Space options. Make sure the

Treat consecutive delimiters as one check box is checked and click the

Finish button.

• The output file is displayed in the spreadsheet. Resize the columns so the

contents of each cell are visible.

•

Select the Date, Time, and Reading columns by clicking on the gray col

umn headers labeled A, B, C and D as shown in Figure 10.

Figure 10 Output file displayed in spreadsheet

•

From the Insert menu of Excel, select the Chart option.

•

The Chart Wizard – Step 1 of 4 – Chart Type dialog is displayed.

•

In the Chart type list, select Line and click the Finish button.

-

24

Page 32

Importing logged data into a spreadsheet

The graph should be displayed as shown in Figure 12.

•

Figure 12 Chart of output file

2 How to...

• Format and size the graph as desired.

25

Page 33

3 File menu

The File menu (Figure 13) provides options for creating a new configuration,

opening an existing configuration file, saving a configuration file, setting up

program defaults, setting up the printer, printing, and exiting the program.

Figure 13 File menu

3 File menu

New

3.1

3.2

New

The New menu option should be selected when a new configuration needs to be

created. When this option is selected, the user must confirm resetting all exist

ing configuration settings before starting a new configuration. Resetting the

configuration causes all thermometer, communications, log interval, channel,

alarm and statistics settings to be reset. If the user chooses not to reset all exist

ing settings, this process is aborted and no changes are made.

If the user chooses to reset all existing settings, the Log Session Settings dialog

is displayed and a new configuration can be started.

-

Open

The Open menu option allows a previously saved configuration file containing

test, thermometer, channel, alarm, statistics and conversion settings.

Selecting the Open menu option displays the Open Single Channel Configura

tion File dialog. Select the configuration file that contains the settings that

match the instrument from which you wish to collect data. Then click the Open

button to open the configuration file. The Log Session Settings dialog will be

displayed with the current settings.

-

27

-

Page 34

9934 LogWare

User’s Guide

3.3

Save as

Selecting the Save As menu option displays the Save Single Channel Configu

ration File As dialog. Enter a descriptive, unique filename that identifies the

current configuration being saved to the file. You may want to include the ther

mometer model number and serial number. This filename can be up to 256

characters in length.

3.4 Defaults

The Defaults menu option displays the Default Settings dialog (Figure 14) and

allows the user to set default settings by selecting one of two tabs: General or

Folders. The General tab consists of miscellaneous settings for the software.

The Folders tab consists of the locations of the configuration, output, and

download files. The settings and selections entered on these tabs determine the

behavior of the software.

-

-

28

Figure 14 Default Settings dialog

Click the OK button to accept the current settings and close this dialog.

Click the Cancel button to discard any changes you have made.

Click the Help button to display the appropriate help topic for this dialog.

Page 35

3.4.1 General

The General tab (Figure 15) consists of miscellaneous settings for the software.

3 File menu

Defaults

Figure 15 File|Defaults General tab

The settings on this tab are:

Remember window positions and settings

This option is used to make sure that dialogs and windows always appear in the

same location on the screen every time they are displayed. If checked, dialogs

and windows appear in the same position they were in when last closed. Other

wise, dialogs and windows always appear in the same place on the screen, re

-

gardless of their position when last closed.

Show log session settings dialog on start-up

This option is used to specify whether or not the Log Session Settings dialog is

displayed every time the software runs. If checked, the Log Session Settings di

alog is displayed. Otherwise, this dialog is not displayed.

If this option is selected, the Load default configuration file automatically op

tion is enabled. Checking this option allows a configuration file to be specified

in the Default configuration file box below. If a configuration file is specified, it

will be loaded every time the software runs. Use the “…” (Browse) button to

locate the configuration file to load or type the path and filename into the box.

29

-

-

Page 36

9934 LogWare

User’s Guide

3.4.2 Folders

Enable communication debugging

This option is used to enable debugging features in LogWar e. This option

should remain unchecked unless otherwise directed by a customer service rep

resentative. If enabled, LogWar e creates a file that contains information for all

communications that happen between the software and an instrument. This file

can be evaluated by customer service representatives to troubleshoot and deter

mine the source of possible problems.

Click the OK button to accept the current settings and close this dialog. If the

Load default configuration file automatically check box is checked, a valid con

figuration file must be specified. If this file does not exist, a message is dis

-

played and the dialog will not close. Please select an existing configuration file.

Click the Cancel button to discard any changes you have made.

Click the Help button to display the appropriate help topic for this dialog.

The Folders tab (Figure 16) consists of the locations of the configuration, output, and download files.

-

-

-

30

Figure 16 File|Defaults Folders tab

These folders default to specific subfolders of the folder where the software is

installed. The default subfolder names are as follows:

Page 37

3 File menu

Print setup

Default folder for configuration files

This is the default folder, <Drive>:\<AppFolder>\Config, that is selected

when the Open and Save As dialogs are displayed for opening and saving con

figuration files. For more information on configuration files, see Section 11

Configuration Files.

Default folder for output files

This is the default folder, <Drive>:\<AppFolder>\Output, where the output

files from a real-time log session are written. Output files contain the data that

was collected during a real-time log session. For more information on output

files, see Section 11.6 Output Files.

Default folder for downloads

This is the default folder, <Drive>:\<AppFolder>\Download, that is selected

when downloading data from thermometers that support this capability. Down

loaded files contain data that the thermometer stores in memory. For more in

formation on download files, see Section 11.7 Download Files.

To change the default folder for any of these options, either type the path into

the appropriate box or select the “…” (Browse) button to browse for an existing

folder.

-

-

-

Note: If the folder does not already exist, the path must be typed into the

box provided. If the folder does already exist, use the “…” (Browse) button to select it.

Click the OK button to accept the current settings and close this dialog.

Click the Cancel button to discard any changes you have made.

Click the Help button to display the appropriate help topic for this dialog.

3.5 Print setup

Selecting the Print Setup menu option displays the Windows® Print Setup dia

log. Select the settings you wish to change and click the OK button.

Note: The graph is always printed in a Landscape orientation regardless

of the default orientation setting of the printer.

Select the Cancel button to discard any changes you have made.

3.6 Print

The Print menu option is only enabled when acquiring or analyzing data.

-

31

Page 38

9934 LogWare

User’s Guide

3.6.1 Readings

3.6.2 Graph

Use this option to print readings and graphs.

The Print menu option has a submenu which consists of two options – Read

ings and Graph.

When printing the readings or graph, the information is sent to the current

printer. To change the current printer, use the Print Setup menu option.

The Print | Readings menu option is used to print the data located in the current

output file, which consists of the date and time each reading was taken, the

reading and scale, and some alarm information. This file also contains some in

formation about the thermometer and probe that were used to collect the data

and the alarm settings (if applicable).

When logging real-time data, selecting the Print | Readings menu option prints

all of the readings that have been taken up until the time this option is selected.

When viewing previously logged data, all readings are printed.

The Print | Graph menu option is used to print the current graph. This menu option performs the same task as selecting the Print Graph menu option from the

Graph menu.

-

-

32

3.7 Exit

Select the Exit menu option from the File menu to close the software.

If any changes have been made to the configuration, the user is prompted to

save the settings.

Page 39

4 Datalog menu

The Datalog menu (Figure 17) provides options for setting up a real-time log

session, starting, stopping and closing a real-time log session and muting all

alarm events.

Figure 17 Datalog menu

4.1 Setup log session

4 Datalog menu

Setup log session

The Setup menu option displays the Setup Log Session (Figure 18) dialog. This

dialog allows a real-time log session to be configured.

Figure 18 Log Session settings

33

Page 40

9934 LogWare

User’s Guide

4.1.1 Thermometer settings

4.1.2 Communication settings

To start a real-time log session, the software must know what thermometer it is

logging data from. Select the thermometer’s model number from the Model

drop down list.

Enter the serial number of the thermometer in the Serial Number box. The se

rial number and the model number are both written to the header of the output

file to indicate the instrument that was used to log the data.

Select the scale for the readings for this log session using the Readings Scale

drop down list. The Readings Scale drop down list only displays the scales that

are supported by the selected thermometer. To use the scale that the thermome

ter is currently set to, select the <Keep Existing> option.

-

Select the COM port to which the thermometer is connected. This software ex

pects to communicate with the thermometer via an RS-232 serial connection.

Most laptop and desktop computers have at least one 9-pin or 25-pin COM

port. Refer to your computer’s owner’s manual if you are unable to locate or

identify a COM port on your computer.

Note: All Hart Scientific instruments require a “null modem” cable to in-

terface with a computer. Please refer to the thermometer’s User Guide for

more information on this type of cable.

Each COM port is accompanied by a symbol that reflects the current state of

the COM port as follows:

- COM ports with this symbol are available on this computer

and can be selected.

- COM ports with this symbol are virtual COM ports used to

interface with an I/R port. This software does not support using COM

ports with this associated symbol.

- The COM port with this symbol is currently being used by

this software.

-

34

- COM ports with this symbol are in use by another application

and cannot be used by this software at this time.

Select the baud rate that should be used to communicate with the thermometer.

The available choices are determined by the baud rates supported by the se

-

lected thermometer.

Page 41

Note: The thermometer and this software must both be set to the same

baud rate in order to communicate successfully. Please refer to the ther

mometer’s User Guide for more information on setting the baud rate of

the thermometer.

Once the thermometer and communication settings have been selected, click

the Test Communication button to attempt to establish communication with the

thermometer and verify that the proper thermometer model is selected. If the

software succeeds in communicating, a success message is displayed.

If the software is not able to successfully establish communication with the

thermometer or if the software determines that the selected model does not

match the model of the connected thermometer, a failure message is displayed

indicating the reason for the failure. In case of failure, check to make sure that:

The communication cable is connected to the thermometer and the se

•

lected COM port

• The thermometer is powered up and operating

• The correct type of cable (null modem) is being used

• The thermometer is set to operate at the selected baud rate

4.1.3 Log settings

4 Datalog menu

Setup log session

-

-

LogWare supports logging real-time data at intervals from 1 second to 24

hours. Select the desired interval using the Interval – Once every box.

Note: The maximum sample rate for Hart Scientific thermometer readouts

is one reading per second. Although every attempt is made, selecting a one

second sample interval in this software does not guarantee that one read

ing will be taken every second (because of processing overhead and calcu

-

lations that this software must perform between each reading). Typical

tests have shown that, on average, this software can acquire about 9 read

ings every 10 seconds on a Pentium® class computer. Slower computers

may not be able to log data at this rate.

If the real-time log session should automatically stop after a certain number of

readings or after a specific amount of time, select the appropriate options from

the End Log drop down list and specify the number of readings or time in the

After boxes. If the real-time log session should continue until it is explicitly

stopped, select the By User option in the End Log drop down list.

LogWare is capable of starting a real-time log session at a future date and/or

time for unattended operation. The box to the right of the Delayed Start and

Reset buttons indicate when the log is scheduled to start.

To start the real-time log session at a future date and/or time, click the Delayed

Start button. The Delayed Start Date/Time dialog is displayed. The delayed

35

Page 42

9934 LogWare

User’s Guide

4.1.4 Channel settings

start date and time will be displayed in the box to the right of the Delayed Start

and Reset buttons.

Note: Every effort has been made to make the real-time log session take

its first reading at the selected date and time. However, due to the large

variation in the speed at which different computers operate, the first read

ing may be one or more seconds later than the selected time (commonly

known as “latency”). To compensate for this, try a few tests to determine

the approximate latency in the computer being used and then adjust the

start time accordingly by reducing the start time by the difference between

the selected start time and the actual time of the first reading.

To start a real-time log session immediatelywhentheStartbuttonisclickedon

this dialog, click the Reset button. This will ignore any delayed start date/time

and the log session will start when the Start button is clicked. The box to the

right of the Delayed Start and Reset buttons indicates that the log session will

start immediately.

The Channels list displays an item for every channel on the selected thermometer. Currently, LogWa re only supports thermometers with a single channel. To

specify settings for a channel, click on the appropriate item in the Channels list.

Select the color to use for the trace on the graph using the Trace Color drop

down list.

Enter the name of the output file that the logged data for the selected channel

should be saved to in the Filename box. Choose a descriptive filename that

identifies the data contained in the file. LogWar e automatically appends a .TXT

extension on the end of the filename. The name of the output file is also used as

the channel “label”. The channel label is a descriptive identifier assigned to a

channel to give meaning to the readings being logged on that channel, instead

of using only the channel number. By default, the filename is set to Channel

N.txt (where N is the channel number).

Output files are written to the folder specified on the File | Defaults Folders tab.

To change the folder where the output file will be saved for this log session,

click the “…” (Browse) button on the right side of the Filename box. The Win

dows® Save As dialog is displayed. Navigate to the desired folder and click the

OK button.

Check the Overwrite existing file check box if this output file should overwrite

any existing file with the same name in the selected folder. If this box is not

checked, this software will display a prompt if a file with the same name exists

and allow the filename for this output file to be changed. It is recommended

that this check box NOT be checked to prevent accidentally overwriting output

files.

-

36

Page 43

LogWare supports configuring low and high alarms for each channel. Alarms

can be used to indicate readings that are out of a specified tolerance or to trig

ger an event. To configure alarms for the selected channel, click the Alarm Set

tings button. The Alarm Settings dialog is displayed (see Section 4.6).

To display the statistics for the selected channel, check the Show statistics

check box. Statistical data is maintained for each channel regardless of whether

it is being displayed or not. During a real-time log session, each statistical da

tum can be enabled or disabled independent from the others. See Section 4.8,

Real-time Log Session for more details.

4.1.5 Open and save as

4 Datalog menu

Setup log session

-

-

-

Click the Open button to display the Windows® Open dialog to open a previ

ously saved configuration file which contains test settings information. Click

the Save As button to display the Windows® Save As dialog to save the current

settings you have selected to a configuration file.

Note: For more information on configuration files, see Section 11 Config-

uration Files.

4.1.6 Set as default

The current configuration can be set as the default configuration by clicking the

Set as Default button. The default configuration is loaded automatically on