Page 1

956A-201-M2 & 897A-2XX

Area Monitoring System

Instruction Manual

Page 2

(Blank page)

Page 3

CONTENTS

Section 1: GENERAL INFORMATION........................................................ 1-1

1.1 Product Specification ................................................................................... 1-1

1.2 Specifications, G-M Detector, Model 897A Series ....................................... 1-3

1.3 Specifications, G-M Detector Check Source, Model 897A Series................ 1-4

1.4 Specifications, Detector Preamplifier (Integral)............................................ 1-4

1.5 Detector Part Number Description ............................................................... 1-5

1.6 Readout Part Number Description ............................................................... 1-6

1.7 Universal Digital Ratemeter, Model 956A-201-M2....................................... 1-7

1.8 Application ................................................................................................... 1-8

1.9 Specifications Model, 956A-201-M2 ............................................................ 1-9

1.10 Auxiliary Equipment ................................................................................... 1-10

1.11 956A-201-M2 Modifications ....................................................................... 1-11

1.12 Recommended Spares .............................................................................. 1-12

1.13 Receiving Inspection.................................................................................. 1-12

1.14 Storage ...................................................................................................... 1-13

Section 2: OPERATION .............................................................................. 2-1

2.1 Installation.................................................................................................... 2-1

2.2 G-M Detector Mounting................................................................................ 2-1

2.3 G-M Detector Setup..................................................................................... 2-1

2.4 UDR Mounting ............................................................................................. 2-2

2.5 Electrical Interface ....................................................................................... 2-3

2.6 Setup ........................................................................................................... 2-6

Section 3: THEORY OF OPERATION ........................................................ 3-1

3.1 Operation ..................................................................................................... 3-1

3.2 Detector Operation, Model 897A-2XX.......................................................... 3-1

3.3 UDR Operation, Model 956A-201-M2.......................................................... 3-2

3.4 Operational Modes ...................................................................................... 3-4

3.5 Alarms.......................................................................................................... 3-7

3.6 Jumper Selectable Configuration Functions .............................................. 3-10

3.7 Power Up Procedure ................................................................................. 3-12

3.8 UDR Function Switch and Parameter Entry............................................... 3-13

3.9 Setpoint Descriptions................................................................................. 3-15

3.10 Setpoint Error Codes ................................................................................. 3-16

3.11 Analog Output............................................................................................ 3-17

3.12 Software Calculations ................................................................................ 3-18

3.13 Functional Description, Model 897A G-M Detector.................................... 3-19

3.14 Functional Description Universal Digital Ratemeter (URD), Model 956A-

201............................................................................................................. 3-21

i

Page 4

Section 4: MAINTENANCE AND CALIBRATION....................................... 4-1

4.1 Maintenance ................................................................................................ 4-1

4.2 Calibration.................................................................................................... 4-1

4.3 Calibration/Electronic Adjustment ................................................................ 4-1

4.4 955A System Field Calibration..................................................................... 4-3

4.5 Detector Calibration ..................................................................................... 4-5

Section 5: TROUBLESHOOTING ............................................................... 5-1

5.1 Troubleshooting ........................................................................................... 5-1

5.2 HV Power Supply Adjustment...................................................................... 5-7

Appendix A: CONNECTOR DESIGNATIONS ................................................A-1

A.1 Connector Designations............................................................................... A-1

Appendix B: APPLICABLE DRAWINGS........................................................B-1

B.1 Applicable Drawings ....................................................................................B-1

Appendix C: BILL OF MATERIALS................................................................C-1

C.1 Bill of Materials ............................................................................................C-1

Appendix D: COAXIAL CABLE TERMINATION INSTRUCTIONS ................ D-1

D.1 Coaxial Cable Termination Instructions ....................................................... D-1

Appendix E: SUPPLEMENTAL DATA (CUSTOMER SPECIFIC).................. E-1

E.1 Supplemental Data (Customer Specific) ...................................................... E-1

ii

Page 5

SECTION 1

GENERAL

INFORMATION

1.1 PRODUCT SPECIFICATION

The Victoreen Model 956A-201-M2 Digital Ratemeter, when operated in conjunction with an 897A-2XX

G-M detector, is a single-channel area radiation monitoring system capable of operating over the ranges

of 0.01 to 10

monitors gamma radiation over a 5-decade range and provides indication when the radiation level

decreases below a fail threshold, exceeds a warn setpoint, exceeds a high setpoint, or exceeds an over

range setpoint. The over range feature provides two significant benefits. First, it prevents the system

from displaying an on-scale, but inaccurate, reading should the detector become saturated. Second, it

lessens the risk of damaging the detector by disabling it during an overrange condition. Relay outputs are

available to activate alarm annunciators. Analog outputs are available for trend display on a strip chart

recorder or computer. In addition, the monitoring system has an integral check source to verify

operational integrity. The system consists of a Model 897A Series Geiger-Mueller (G-M) Tube Detector

with integral preamplifier and the Model 956A-201-M2 Universal Digital Ratemeter (UDR). A more

detailed description of each piece of equipment can be found in the following paragraphs.

3

mR/h, 0.1 to 104 mR/h, or 1 to 105 mR/h, depending on the detector selected. The system

The Model 956A-201-M2 is a modified version of the standard Model 956A-201. The modification

consists of adding the Optional 0-10mV analog output, a “Trip Test” function, and 120 Vac powered,

FAIL and HIGH Alarm outputs (connector P2) to operate a locally mounted alarm.

The 0-10mV analog output is provided by installing the P/N 942-200-95-M1 Dual Analog Output option

circuit board. The 0-10mV output is wired to UDR P6-7/8. The 0-5v output is not used, and is not wired

out to the rear panel.

The “Trip Test” function is provided by replacing the front panel with the P/N 956A-201-20M2 front panel.

The modified front panel adds switch SW5, to actuate the “Trip Test” function. The standard EPROM is

also replaced with P/N 94095605 EPROM. When the “Trip Test” pushbutton is depressed, the alarm

relays will trip, the analog outputs will be driven upscale, the bargraph is driven upscale, the units

backlights are illuminated, the alarm LEDs illuminate, the check source LED illuminates, and the digital

display is forced to display 8.8.8.8.8. Releasing the pushbutton returns all functions except the alarms to

normal. The alarm LEDs and bargraph are returned to normal by pressing the Acknowledge pushbutton.

The 120 Vac powered FAIL and HIGH Alarm outputs (connector P2) are implemented via internal wiring

modifications in the UDR. The FAIL alarm output is obtained by operating the Auxiliary Relay, K1, in

parallel with the normal Fail relay, K3. The HIGH alarm output is obtained from the HIGH alarm relay, K5.

Refer to Modification Sheet 956A-201-M2MS for additional information on the modification.

1-1

Page 6

The Model 956A-201 Series Readout and 897A Series G-M detectors have been successfully subjected

to seismic and environmental qualification testing per IEEE 344-1975 and IEEE-323-1983. In addition,

EMI/RFI testing per the requirements of EPRI TR-102323-R1, MIL-STD-461D, and EN 61000-6-1:2001

has also been successfully performed. Please consult the factory for specific details of the qualification

testing program.

The 956A-201-M2 operation described herein is based on the use of EPROM P/N 94095605, Rev. 1.

Geiger-Mueller Detector, Model 897A-Series

Victoreen 897A-Series G-M detectors use a thin walled Geiger-Mueller tube to detect ionizing radiation.

Each 897A-Series detector has a G-M tube, a check source, and a preamplifier. The check source is a

low-level radioactive source actuated by a + 15 Vdc meter movement. The preamplifier provides the

pulse conditioning and cable driving capability necessary to drive a Victoreen 956A-201 Series digital

ratemeter.

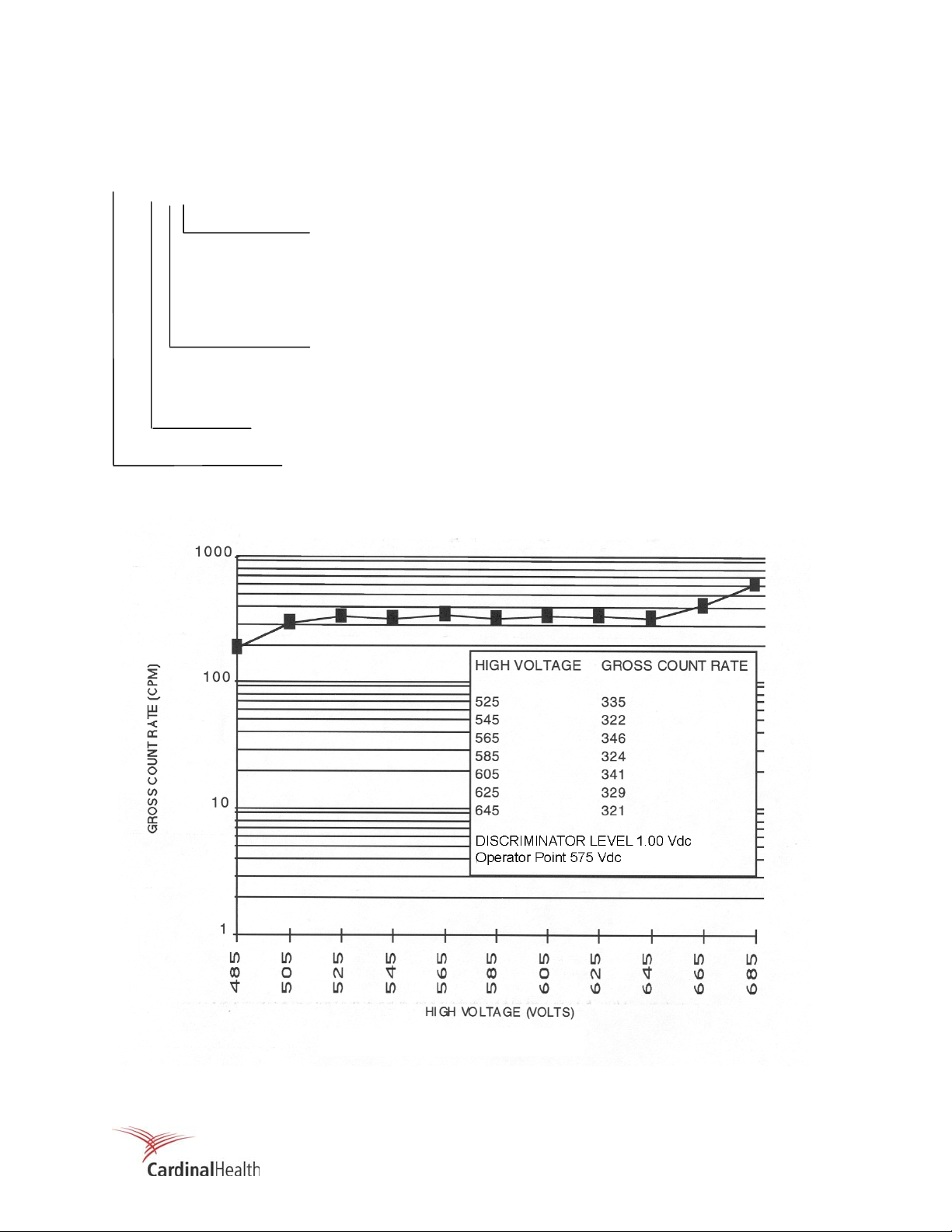

All 897A-Series detectors are functionally identical. They differ only in housing material, tube type, and

range. The 897A Series detectors operate in the voltage range of 500 - 650 Vdc. An example of the

detector plateau, based on different high voltages, is located in Figure 1-1. Refer to the specifications for

all 897A-Series G-M detectors for further information.

NOTE

The 897A Series G-M detectors contain an eight-microcurie 36CI

check source. Nuclear Regulatory Commission regulations

define this source as an exempt quantity.

Application

The Model 897A G-M Detector is designed to operate with the Victoreen Model 956A-201 Universal

Digital Ratemeter (UDR) or with other Victoreen readouts. Each detector measures a five-decade range.

Three measurement ranges are available: low, medium, and high. The low range covers 0.01 to 10

mR/h, the medium covers 0.1 to 10

4

mR/h, and the high covers 1 to 105 mR/h. The Model 897A detector

may also be used with the Victoreen Model 960 Digital Radiation Monitoring System equipment or the

Victoreen Model 856 Analog Readout.

3

1-2

Page 7

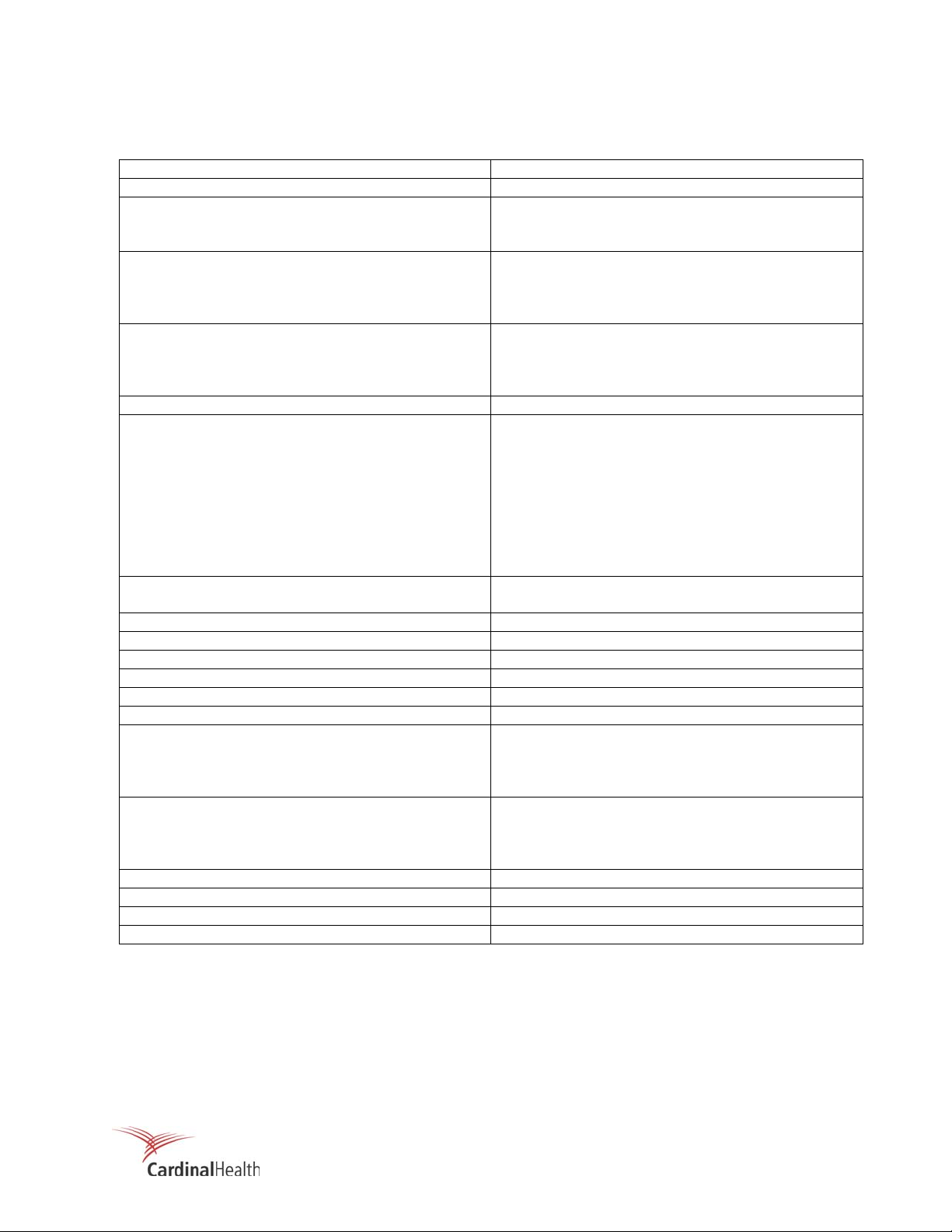

1.2 SPECIFICATIONS, G-M DETECTOR, MODEL 897A SERIES

Dimensions (Approximate 7 1/8 x 3 inches (18.1 x 7.6 cm)

Weight (Approximate) 2.5 lbs.

Housing Material

897A-210, 897A-220, 897A-230

897A-211, 897A-221, 897A-231

Fill Gas:

897A-210, 897A-211

897A-220, 897A-221

897A-230, 897A-231

G-M Tube Wall Thickness:

897A-210, 897A-211

897A-220, 897A-221

897A-230, 897A-231

Mounting Wall mount

Mating Connectors 897A-2x0:

Required Cable P/N 50-100 or substitute with two coaxial

External Pressure Limit 30 psig

Storage Temperature -10° to 122°F (-23° to 50°C)

Operating Temperature -10° to 122°F (-23° to 50°C)

Relative Humidity 0 to 95% non-condensing

Operating Voltage 500 – 650 Vdc (supplied by digital ratemeter)

Plateau Length 100 – 150 Vdc

Plateau Slope:

897A-210, 897A-211

897A-220, 897A-221

897A-230, 897A-231

Dead Time (Approximate)

897A-210, 897A-211

897A-220, 897A-221

897A-230, 897A-231

Detector Element Life Exceeds 1000 hours at full-scale

Energy Dependence of Reading +/- 15% from 80 keV to 1.5 MeV

Detector Accuracy ± 20% of actual dose for Cs-137

Radiation Detected Gamma rays, X-rays

Aluminum, weatherproof

Stainless Steel, weatherproof

Neon/Argon/Halogen

Helium/Neon/Halogen

Helium/Neon/Halogen

40 mg/cm

80 mg/cm

2

2

80 mg/cm2

92-7005-17A, 12 Pin Female

92-7005-12A, Bushing

92-7005-9A, Clamp

897A-2x1 (stainless steel):

92-7005-15A, 12 Pin Female (stainless steel)

92-7005-12A, Bushing

92-7005-13A, Bushing

conductors, two twisted pairs, and overall shield.

0.1%/V

0.2%V

0.3%V

45 microseconds

28 microseconds

20 microseconds

1-3

Page 8

1.3 SPECIFICATIONS, G-M DETECTOR CHECK SOURCE,

MODEL 897A SERIES

Radionuclide

Source Activity: 8 microcuries

Scale Reading (Approximate)

897A-210, 897A-211

897A-220, 897A-221

897A-230, 897A-231

Voltage 12 – 15 Vdc

Encapsulation Brass, high temperature soldered

36

CI

10-150 mR/h, Typical

10-50 mR/h, Typical

10-50 mR/h, Typical

1.4 SPECIFICATION, DETECTOR PREAMPLIFIER

(INTERGRAL)

Input Impedance >100 k-ohms

Output Impedance 50 ohms

Output Pulse Polarity Positive

Output Signal (50 ohm terminated) + 5 Vdc square-wave

Low Voltage* + 15 Vdc (Optional + 10 Vdc is Jumper Selectable)

Power Requirements + 15 Vdc @ 120 mA

Maximum Cable Length 2000 feet

Electronic Exposure Life Approximately 105 rads

Discriminator Level Adjustable from 0 to 1.5 Vdc (nominal value =1.00

Vdc)

Anti-Jam Level Adjustable from 0 to + 3 Vdc

Anti-Jam Oscillator Frequency Approximately 50 kHz

Pre-divide* Jumper Selectable

Analog & Digital Monitor Configuration Divide by 2, Square wave output

Optional Monitor Configuration Raw pulse output

* Preamplifier low voltage and pre-divide are selected with jumpers. Refer to the preamplifier circuit

description for more information. Standard Configuration is +15 Vdc Divide by 2.

1-4

Page 9

1.5 DETECTOR PART NUMBER DESCRIPTION

897A-2 XY

2 = High reliability components for Class 1E service

PRODUCT SERIES

897 = Sr-90 check source (NRC license required) with a

Y = 0, Aluminum Housing

Y = 1, Stainless Steel Housing

X = 1, 0.01 mR/h – 1E3 mR/h

X = 2, 0.10 mR/h – 1E4 mR/h

X = 3, 1.00 mR/h – 1E5 mR/h

120 VAC solenoid actuator. No longer manufactured.

897A = CI-36 check source (exempt quantity) with + 15

VDC meter movement actuator.

1-5

Page 10

1.6 READOUT PART NUMBER DESCRIPTION

956A-20X-MX

2 = High reliability components for Class 1E service

PRODUCT SERIES

956 = 16k x 8 PROM, 8k x 8 RAM; 128 bytes EEPROM; V-Channel front

Blank = Standard Unit

M = Special Options/Modifications

MX = Special Modification (X = Modification Number)

M2 = Add 942-200-95-MI Dual Analog Output Circuit Board, Trip Test

Function, and Externally Powered Fail and High Alarm Relay

Contacts

00 = 120 Vac Check Source Mechanical (Discontinued 9/95)

01 = 15 Vdc Check Source Mechanical (current product configuration)

0X = Future Variations

panel – No longer manufactured

956A = 32k x 8 PROM, 8k x 8 RAM, 256 bytes EEPROM; flat front panel –

revised rear panel pinouts.

Figure 1-1 Detector Plateau (typical)

1-6

Page 11

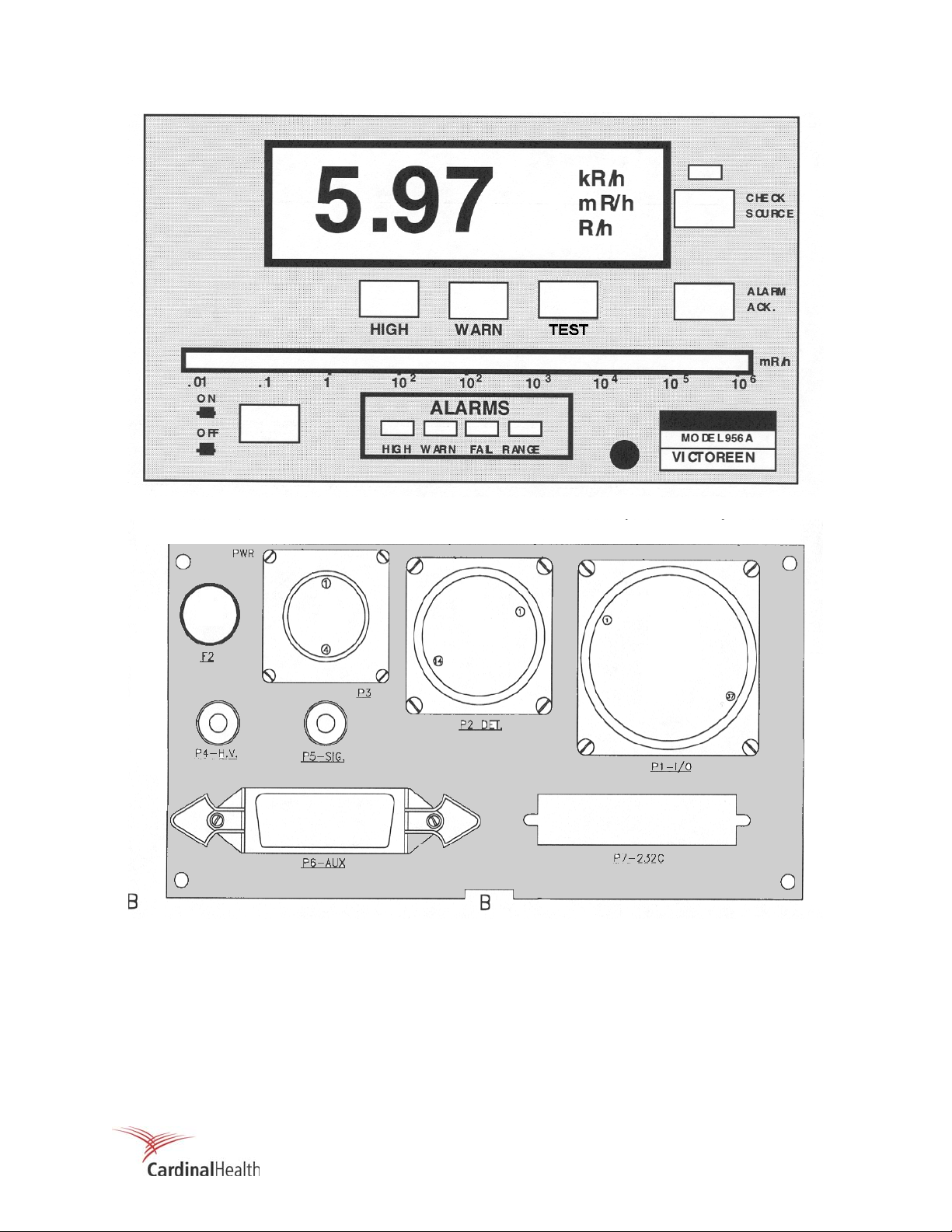

1.7 UNIVERSAL DIGITAL RATEMETER, MODEL 956A-201-M2

The Victoreen Model 956A-201-M2 is a modified version of the Model 956A-201 Universal Digital

Ratemeter (UDR), when connected to a Victoreen Model 897A-2XY Geiger-Mueller (G-M) tube detector,

comprises a monitoring system that operates over a five-decade range. The UDR provides display,

control, and annunciation functions for the monitoring system, and will display readings in the range of

0.01 to 10

Standard features for the instrument consist of a three-digit display of the radiation value, in units of

mR/h, R/h, or kR/h, and a multi-colored bargraph indicator that covers the entire range of the UDR. The

bargraph will change color in the event of an alarm condition (green for normal, amber for warning, and

red for high). Front panel alarm indicators and rear panel relay outputs for alarm annunciation are also

included. Front panel pushbuttons are provided to apply power, display alarm limit setpoints,

acknowledge alarms, and to activate the check source. In addition, the 956A-201-M2 is provided with a

front panel mounted TEST pushbutton, that performs a self-test of the UDR.

Analog outputs of 0 - 10 Vdc (1) and 4 - 20 mA (2) are provided for recording and computer monitoring.

The outputs may also be used to drive a remote meter or a local (i.e. near the detector) indicator.

In addition, the 956A-201-M2 is provided with the P/N 942-100-95-M1 dual analog output option circuit

board that provides a 0-10 mV dc analog output.

The 956A-201-M2 also included an internal wiring modification that applies 120 Vac to the Fail and Alarm

relay contacts. The auxiliary relay, K1, is hard wired to operate in parallel with the Fail relay to supply AC

power to a local alarm. AC power is supplied from rear panel connector P1 to detector connector P2.

Refer to Modification Sheet 956A-201-M2MS for additional information on the modification.

5

mR/h. Refer to Figure 1-2 for view of the 956A-201-M2 front panel.

All electronics required to interface with the VICTOREEN 897A Series G-M detector are included within

the 956A-201 UDR. The electronics consist of a high voltage power supply, low voltage DC power supply

and the hardware/software required for UDR operation. The system also includes an overrange indicator

to preclude the possibility of on-scale readings when the radiation field is beyond the range of the

detector.

The following paragraphs describe the available options. A separate manual for each option board is

available with more detailed information. Listed below are the option boards currently available.

1. 942-200-75: ANALOG INPUT OPTION BOARD - (Generally not used for normal operation with the

956A-201 UDR, however, it is used if the UDR is part of a simulator) Contains four (4) separate

channels for analog inputs. A 0 to 10 Vdc input or 4 to 20 mA input can be selected independently for

each channel using the jumpers and switches provided on the board. Possible inputs to the board

include: temperature, pressure, flow, or simulated radiation.

2. 942-200-80: COMMUNICATIONS LOOP OPTION BOARD - Designed to enable a EIA RS232C

standard communications link between VICTOREEN's ratemeter and a user computer system or CRT

terminal, with baud rates ranging from 50 to 19200 baud. An asynchronous communication interface

adapter is utilized to format the data and control the interface.

The VICTOREEN Communication Loop Option Board also provides an isolated multi-drop, serial

communications port for interface with a supervisory computer system. The serial data is in a

modified RS-232 format, and utilizes Victoreen's proprietary VICO loop protocol. For maximum

external noise protection, a six-conductor communications cable is used.

1-7

Page 12

3. 942-200-95: ANALOG OUTPUT BOARD - Designed to provide a user selectable single output

voltage of: 0 - 10 Vdc, 0 - 5 Vdc, 0 - 1 Vdc, 0 - 500 mVdc, 0 - 100 mVdc, 0 - 50 mVdc, or 0 - 10

mVdc.

4. 942-200-95M1: DUAL ANALOG OUTPUT BOARD - Designed to provide two user selectable output

voltages. Output #1 is either 0 - 5 Vdc, or 0 - 10 Vdc, while output #2 is either 0 - 10 mVdc, 0 - 50

mVdc, 0 - 100 mVdc, 0 - 500 mVdc, or 0 - 1 Vdc included in the 956A-201-M2.

5. S157033A2 Line Filter/Surge Suppressor Assembly Designed to provide EMI/RFI protection for two

956A Series digital ratemeters and 897A Series G-M detectors. The assembly consists of two (2)

separate and independent line conditioning circuits that provide filtered AC power to each 956A

Series ratemeter. The S157033A2 is designed to mount in the center section of the 948B-1A-5 dual

module rack chassis, to provide EMI/RFI protection for two (2) 956A Series ratemeters. The major

active components of the S157033A2 are two (2), 960SS-200 Surge suppressor circuit boards, two

(2), 92-9015-A Line Filters, and two (2) 14-235 ferrite cubes. The S157033A2 also contains AC line

and neutral fuses to protect the internal circuitry from over current conditions.

To meet the requirements of EPRI TR-102323-R1, for radiated fields above 80MHz, the low

discriminator in the detector preamplifier must be set to 1.0 volts. This setting has been incorporated

into the factory calibration of all 897A Series G-M detectors.

1.8 APPLICATION

The Model 956A-201-M2 UDR is used with all Victoreen 897A Series G-M Detectors. The detector

specific setpoints for the 956A-201-M2 UDR are configured by the user for the range of the particular

detector supplied. The detector/preamp, when connected to a UDR, will function as a single channel

digital area monitoring system. For additional information on various applications, please contact

Cardinal Health, Radiation Management Services Applications Engineering Group.

1-8

Page 13

1.9 SPECIFICATIONS MODEL, 956A-201-M2

General specifications for the 956A-201-M2 UDR are listed below. The 956A-201-M2 is designed for

nuclear applications, and any repairs to it by personnel not qualified may void the nuclear rating. If a

problem develops, the UDR can either be returned to the factory for service or repaired by a qualified

technician.

Main Display

Bargraph Display

(Dynamic Range)

Alarm Indicators

Display Selection (Momentary Pushbuttons)

Check Source

Alarm Ack.

Power ON/OFF

Relay Outputs

(Fail-safe operation)

High Voltage Output

Detector Check Source Power

Analog Outputs

Remote Alarm Ack Input

Seven segment – three digits with backlighted

radiation units display, floating decimal point and

exponential setpoint entry

Three segments per decade, .01 to 10

segments) (green for norm, amber for warn, and red

for high)

HIGH Alarm (Red LED) – Flashing until acknowledged

WARN Alarm (Amber LED) – Flashing until

acknowledged

FAIL Alarm (Red LED) – Does not flash, automatically

resets

RANGE Alarm (Red LED), overrange/underrange –

Does not flash, automatically resets

HIGH, High Alarm Setpoint

WARN, Warn Alarm Setpoint

TEST, Initiates Trip Test Function (956A-201-M2)

Activates radioactive Check source and associated

green LED indicator. Momentary, non-latching

pushbutton operation

Alarm acknowledgment causes alarm indicators to go

to a steady on state after acknowledgment. Relays

will reset when radiation level drops below setpoint.

Internal jumper causes alarms to be reset

automatically when radiation level drops below

setpoint (no operator input required).

Alternate action pushbutton for AC power.

HIGH Alarm – DPDT rated 5 A @ 120 Vac (one set

120 Vac powered for use with optional local alarm)

WARN Alarm – DPDT rated 5 A @ 120 Vac

FAIL Alarm – DPDT rated 5 A @ 120 Vac

AUX (Fail) – DPDT rated 5 A @ 120 Vac (956A-201-

M2)

DC rating for all relays is 5 A @ 29 Vdc

NOTE: 120 Vac has been internally wired to the

Alarm, and AUX relay contacts, connector P2. Refer

to Loop Diagram S174014C-102.

300 Vdc – 1800 Vdc @ 0.4 mA

+15 Vdc @ 20 mA

4 to 20 mA (2) (500 Ω load each, max.) and 0 to 10

Vdc (1 KΩ load min.), logarithmic. May be scaled for

any one decade (minimum) or to the full range of the

detector (maximum).

0 to 10 mV (1 KΩ load min) is available from the 942200-95-M1 Analog Output Option Board (956A-201M2).

Optically isolated DC input

6

mR/h (24

1-9

Page 14

Detector Input

UDR Electronic Accuracy

Dimensions (H x W x D)

Weight

Power

Operating Temperature

Relative Humidity

Compatible Detector

Heat Loading

Digital Pulse, Up to 2000 feet from UDR, 50 ohm input

impedance

± 1 digit (± 1% of the displayed value, exclusive of the

detector energy response

3.5 in. x 5.6 in. x 13.5 in. (8.9 cm x 14.2 cm x 34.3 cm)

Approximately 3.7 lb. (1.67 kg)

120 Vac ± 10%, 50/60 Hz, 28 watts (240 Vac optional)

32°F to 122°F (0°C to + 50°C)

0 to 99% non-condensing

897A Series, G-M (Geiger Mueller tube)

Approximately 96 BTU/hr

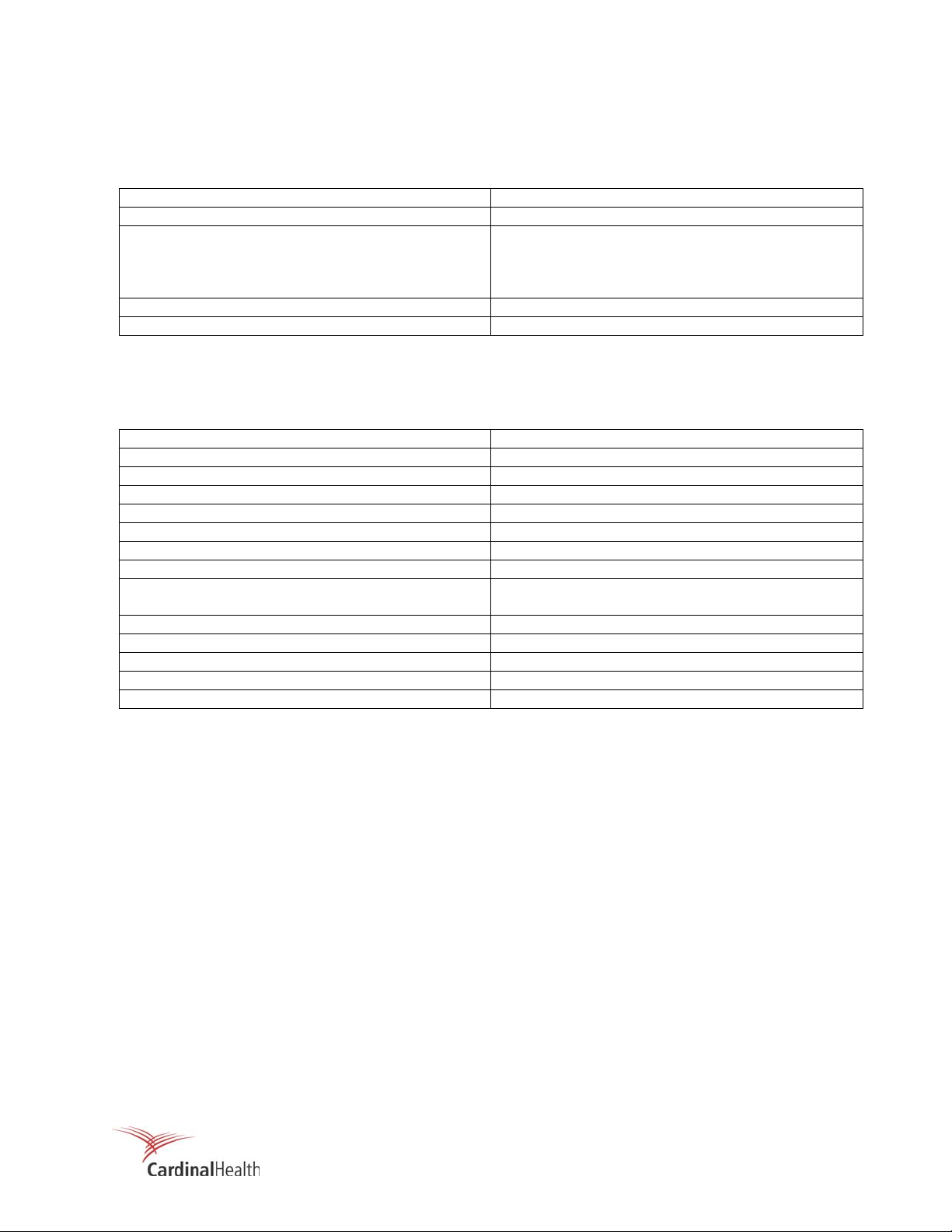

1.10 AUXILIARY EQUIPMENT

Auxiliary Equipment

Model Description

Model 848-8 Field Calibrator (100 mCi)

Model 848-8A Field Calibrator (10 mCi)

Model 848-8B Field Calibrator (20 mCi)

Model 848-8-105 897A Adapter (all types)

Model 848-8-400 897A Stainless Steel Detector Adapter, 897A-

2x1

Model 942TS UDR Test Set

Model 958A-40 Local Alarm, without meter

Model 958A-10, -20, -30 Local Alarm, with meter

Model 948-1 Rack Chassis, 3 Channel

Model 948A-2 Blank Panel

Model 948-3 Table Top Enclosure

Model 948-10 Panel Adapter

Model 50-100 Interconnecting Cable

Model S157033A2 Line Filter/Surge Suppressor

Model 948B-1A-5 Dual Channel Rack Chassis

1-10

Page 15

Figure 1-2. Front Panel, Model 956A-201-M2 Universal Digital Ratemeter (not to scale)

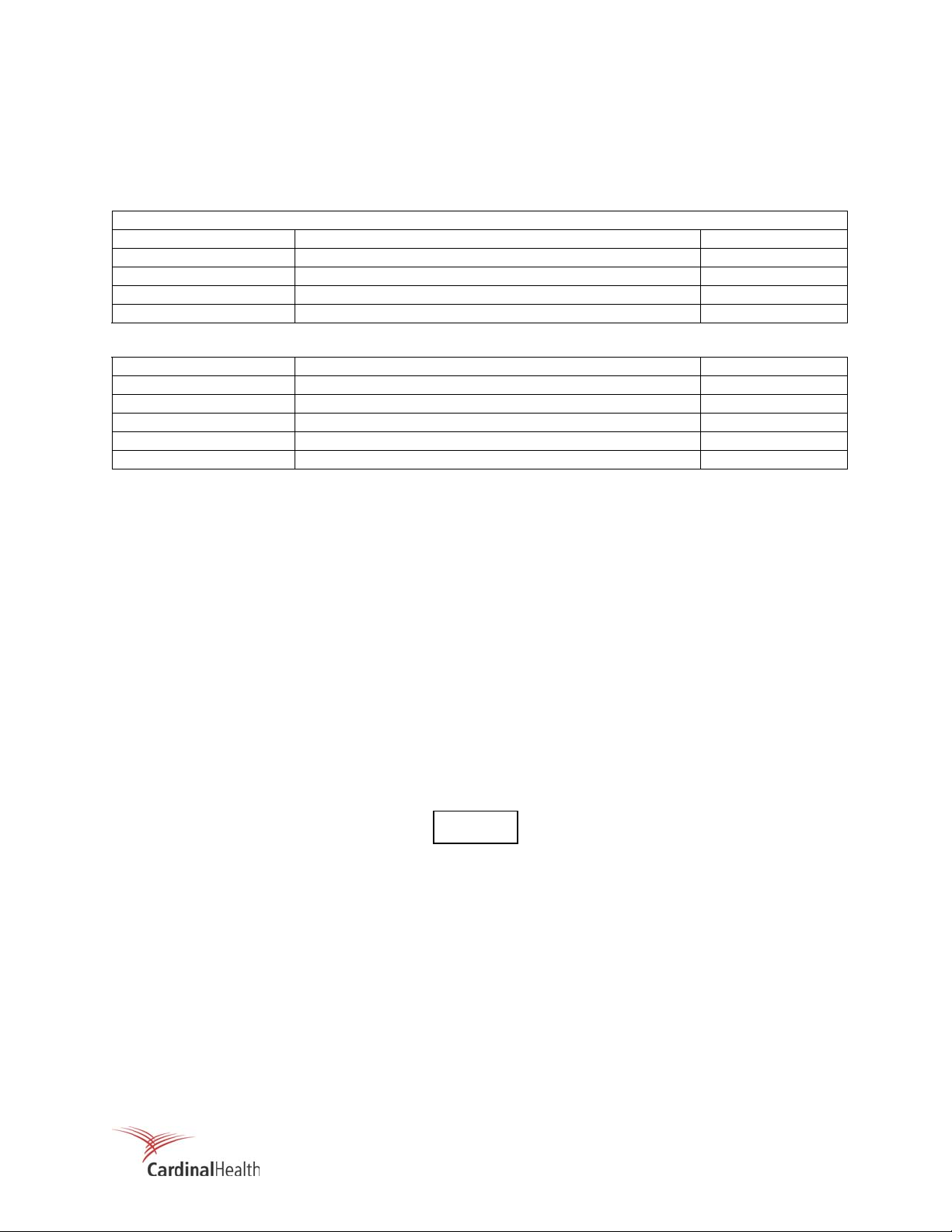

Figure 1-3. Rear Panel, Model 956A-201-M2, Universal Digital Ratemeter (not to scale)

1.11 956A-201-M2 MODIFICATIONS

Refer to Modification Sheet 956A-201-M2 for a complete description of the modification performed on this

unit.

1-11

Page 16

1.12 RECOMMENDED SPARES

Table 1-2 lists the recommended spare parts for the 955A Radiation Monitoring System.

Table 1-2. Recommended Spare Parts List

897A Detector

Part Number Description Used On

46-77 “O”-Ring, Detector Housing 897A-2X0

857-211-15 Gasket, Detector Housing 897A-2X1

857-211-19 Mounting Strap 897A-2X1

857-211-18 Detector Mounting Bracket 897A-2X1

956A-201 UDR

Part Number Description Used On

92-7027-1A Fuse F2, 2 Amp, main AC power All

19-62 Fuse F1, 50 mA, anti-jam circuit All

92-9042-A Jumper Block (10 required) All

942-200-50 Power Supply All

82-73-1 Relay All

1.13 RECEIVING INSPECTION

Upon receipt of the unit:

1. Inspect the carton(s) and contents for damage. If damage is evident, file a claim with the carrier and

notify the Cardinal Health, Radiation Management Services Customer Service Department.

Cardinal Health, Radiation Management Services

6045 Cochran Rd.

Cleveland, Ohio 44139

Phone: 440.248.9300, Fax: 440.542.3682

2. Remove the contents from the packing material.

3. Verify that all items listed on the packing list have been received and are in good condition.

If any of the listed items are missing or damaged, notify the

Cardinal Health, Radiation Management Services Customer

Service Department.

NOTE

1-12

Page 17

1.14 STORAGE

Instruments storage must comply with Level B storage requirements as outlined in ANSI N45.2.2 (1972)

Section 6.1.2(.2). The storage area shall comply with ANSI N45.2.2 (1972) Section 6.2 Storage Area,

Paragraphs 6.2.1 through 6.2.5. Housekeeping shall conform to ANSI N45.2.3 (1972).

Level B components shall be stored within a fire resistant, tear resistant, weather tight enclosure, in a

well-ventilated building or equivalent.

Instruments storage must comply with the following:

1. Inspection and examination of items in storage must be in accordance with ANSI N45.2.2 (1972)

Section 6.4.1.

2. Requirements for proper storage must be documented and written procedures or instructions must be

established.

3. In the event of fire, post-fire evaluation must be in accordance with ANSI N45.2.2 (1972), Section

6.4.3.

4. Removal of items from storage must be in accordance with ANSI N45.2.2 (1972), Sections 6.5 and

1-13

Page 18

(Blank page)

Page 19

Section 2

OPERATION

2.1 INSTALLATION

Installation consists of selecting suitable mounting sites for the detector and ratemeter, mounting the

equipment, making the required electrical connections, and entering the desired setpoints. Installation

drawings are provided in Appendix B of this manual.

Remove all power prior to installing the UDR or detector.

CAUTION

2.2 G-M DETECTOR MOUNTING

The 897A Series G-M detectors can be mounted to any suitable structure e.g. a wall or post, using the

mounting bracket (P/N 843-6-26) included with the detector. The maximum distance between the

detector and ratemeter is 2000 feet (610 meters). The detector should be mounted above normal head

height with the detector connector facing away from the area being monitored. For additional information

refer to the applicable engineering drawings, provided in Appendix B, for detector mounting dimensions.

To protect the monitor from EMI/RFI transients, the detector must be earth grounded through its wallmounting bracket.

2.3 G-M DETECTOR SETUP

The low voltage power supply input for the preamplifier is jumper selectable. This allows the use of either

a +10 Vdc or +15 Vdc supply for detector power. If the detector is used with a 956A-201 Series UDR, the

standard +15 Vdc position is used. If the detector is used in an analog radiation monitoring system, the

+10 Vdc position is used. Jumper configurations are listed in Table 2-1.

Table 2-1 Input Voltage Jumper Position

Jumper Position Input Voltage

J3 AB + 15 Vdc (factory set), digital readout

J3 BC + 10 Vdc, analog readout

The G-M tube output pulse is conditioned with a divide by 2 pulse shaping circuit to transmit a square

wave from the detector. The conditioning also permits use of the detector with analog readouts, using a

diode pump counting circuit. For use with fast rise time scalers, a jumper is provided to output the

detector pulse directly. Jumper configurations are listed in Table 2-2.

2-1

Page 20

Table 2-2 Divide Options Jumper Position

Jumper Position Divide Option

J1, J2 AB 2, square wave output (factory set)

J1, J2 BC 1, direct coupled

2.4 UDR MOUNTING

The UDR is a self-contained unit that can be mounted in four different ways.

When installing the UDR in enclosed panels or cabinets, ensure

that the maximum operating temperature (122° F) is not exceeded.

The total heat load should be calculated to determine whether

cooling by natural convection or forced ventilation (i.e. fans) is

required. The heat load for a single UDR is approximately 96

BTU/hr.

CAUTION

Where more than four units are to be mounted in a cabinet, it is

recommended that the center position in each chassis be left blank

to facilitate the flow of cooling air through the cabinet.

For seismic applications, the rear of the chassis must be

supported, or the sides of the chassis must be fastened

together. For further information, contact Cardinal Health,

Radiation Management Services.

To protect the monitor from EMI/RMI transients, the Rack

Chassis must be connected to an earth ground.

1. The first mounting utilizes a 19-inch rack chassis adapter, Victoreen Model 948-1. This configuration

requires 3.5 inches of rack height and can be used to mount up to three UDRs side by side. A blank

filler panel, Victoreen Model 948A-2, is available to cover unused mounting positions. Refer to

drawing GEL-948-1 for mounting dimensions.

Where EMI/RFI compliance is required, the Model 948B-1A-5 Dual Channel rack chassis is

available. The Model 948B-1A-5 is designed to accept two Model 956A UDR’s, mounted in the left

and right side positions. The center position is used to mount a Model S157033A2 Line Filter/Surge

Suppressor Assembly. AC power for each channel is routed to the surge suppressor, which then

feeds the AC power to the 956A UDR’s. Refer to GEL-948B-1A for mounting dimensions.

NOTE

NOTE

NOTE

2. The second mounting consists of a single channel tabletop enclosure, Victoreen Model 948-3.

Dimensions for the enclosure are 4.5 inches high by 6.8 inches wide by 14.9 inches deep. Refer to

drawing 948-3-5 for mounting dimensions.

3. The third mounting consists of a panel mount enclosure, Victoreen Model 948-9. Cutout dimensions

for this enclosure are 3.75 inches high by 6.45 inches wide; the outside dimensions for the enclosure

are 4.0 inches high by 6.7 inches wide by 13.7 inches deep. Refer to drawing 948-9-5 for mounting

dimensions.

2-2

Page 21

4. The fourth mounting utilizes the Victoreen Model 948-10 Rack Chassis Adapter to mount a 956A

UDR into an existing Victoreen analog ratemeter rack chassis such as those used for the Victoreen

842 series analog ratemeter. Refer to drawing GEL-948-10 for mounting dimensions.

The UDR is simply inserted into the selected mounting enclosure and secured using the front panel pawl

fastener.

2.5 ELECTRICAL INTERFACE

Ensure all power is off prior to connecting the field wiring

Electrical interconnections at the detector are made via the mating "MS" style connector supplied with the

detector and loop drawing S174014A-102.

Electrical interconnections to the UDR are implemented with the mating connector kit, P/N 942A-100- 4

(supplied with the readout) by using the connector input/output assignments provided in Tables 2-3

through 2-10, and loop drawing S174014A-102, provided in Appendix B. Termination instructions for

coaxial connections can be found in Appendix D. A service loop of a minimum of 12 to 16 inches should

be provided to permit partial withdrawal of the UDR for setpoint adjustment and troubleshooting.

Connector pins should be soldered to the cable using 60/40-tin/lead resin core solder and a soldering iron

of 50 watts or less.

To protect the monitor from EMI/RFI transients, the mounting chassis must be earth grounded.

Table 2-3. Rear Panel Connections

Connector Function

P1 Relay/Output, Remote Alarm Acknowledge

P2 Detector Connector

P3 AC Power Input

P4 Detector High Voltage (SHV)

P5 Detector Signal Input (BNC)

P6 Auxiliary outputs 0 – 10 Vdc & 4 – 20 mA DC

P7 RS232C, Optional

WARNING

2-3

Page 22

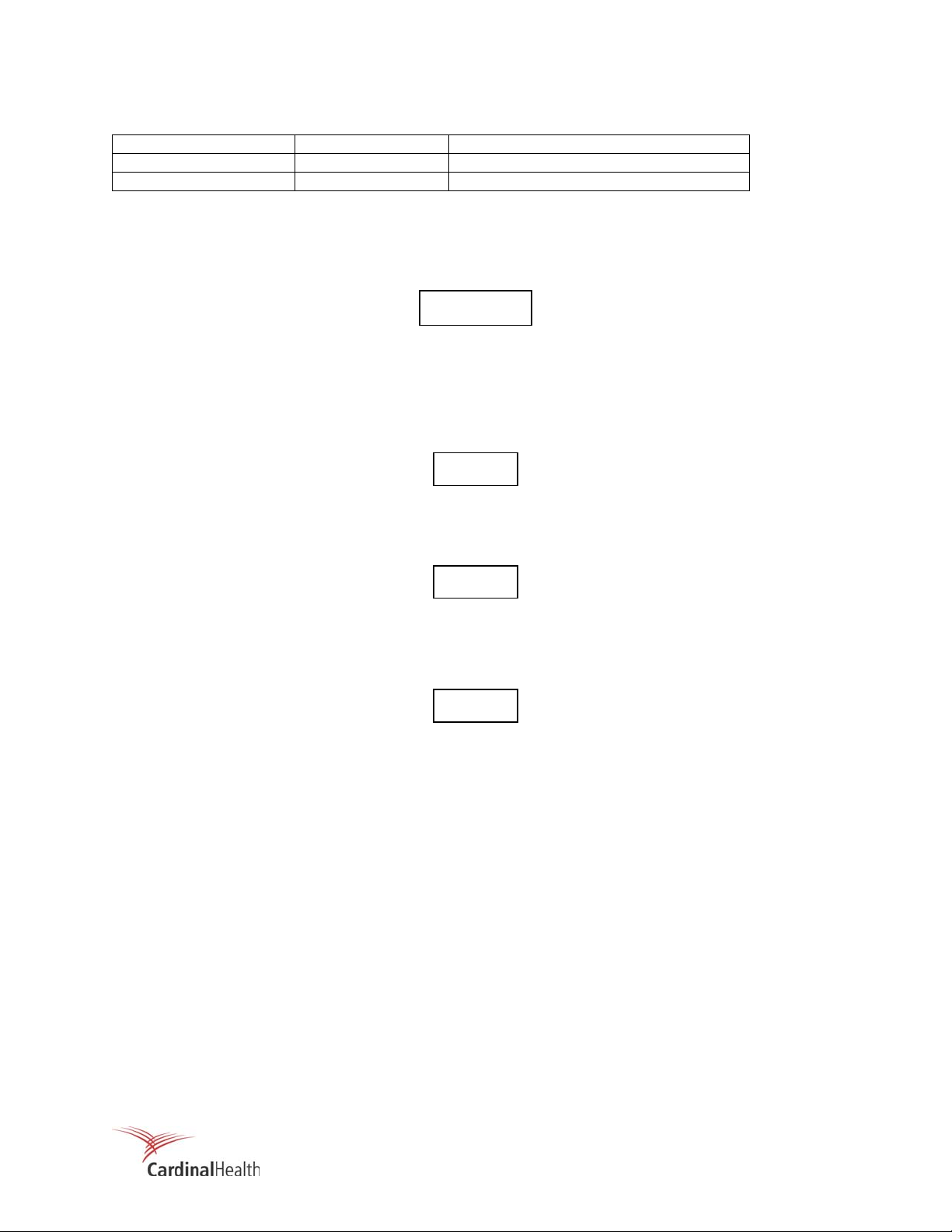

Table 2-4. Connector P1 – Input/Output, 956A-201-M2

Pin Signal Internal Connection

1 120 Vac Line Relay Board K1-A/V2

2 120 Vac Neutral P2-13

3 120 Vac Ground P2-11

4 Spare Relay Board K1-D

5 Spare Relay Board K1-F

6 Spare Relay Board K1-E

7 Fail Relay, Common Relay Board K3-A

8 Fail Relay, n.o. Relay Board K3-B

9 Fail Relay, n.c. Relay Board K3-C

10 Fail Relay, Common Relay Board K3-D

11 Fail Relay, n.o. Relay Board K3-F

12 Fail Relay, n.c. Relay Board K3-E

13 Warn Relay, Common Relay Board K4-A

14 Warn Relay, n.o. Relay Board K4-B

15 Warn Relay, n.c. Relay Board K4-C

16 Warn Relay, Common Relay Board K4-D

17 Warn Relay, n.o. Relay Board K4-F

18 Warn Relay, n.c. Relay Board K4-E

19 Alarm Relay, Common Relay Board K5-A

20 Alarm Relay, n.o. Relay Board K5-B

21 Alarm Relay, n.c. Relay Board K5-C

22 Spare Not Used

23 Spare Not Used

24 Spare Not Used

25 + Remote Acknowledge Main Circuit Board J9-1

26 - Remote Acknowledge Main Circuit Board J9-2

27 - 37 Spare Not Used

n.o. = normally open, n.c. = normally closed, Relays shown in shelf, or de-energized state.

Table 2-5. Connector P2 – Detector Connector, 956A-201-M2

Pin Signal Internal Connection

1 Detector + 15 Vdc Supply Power Supply + 15 Vdc

2 Not Used Power Supply – 15 Vdc

3 Supply Ground Power Supply Ground

4 + 15 V C/S On Relay K2

5 - 15 V C/S Off Relay K2

6 Not Used -

7 Not Used -

8 Not Used -

9 DC Ground Main Circuit Board J5-9

10 0 – 10 Vdc, Remote Meter Main Circuit Board J5-10

11 AC Ground P1-3 AC Ground

12 Fail, N.C (Switched, 120 Vac, Line) Relay Board K1-C (L)

13 120 Vac (Neutral) P1-2, 120 Vac (N)

14 Alarm N.C (Switched, 120 Vac, Line) Relay Board K5-E (L)

0 – 10 Vdc selected for Remote Meter use on P2 (10, 11) not P6 (5, 6).

2-4

Page 23

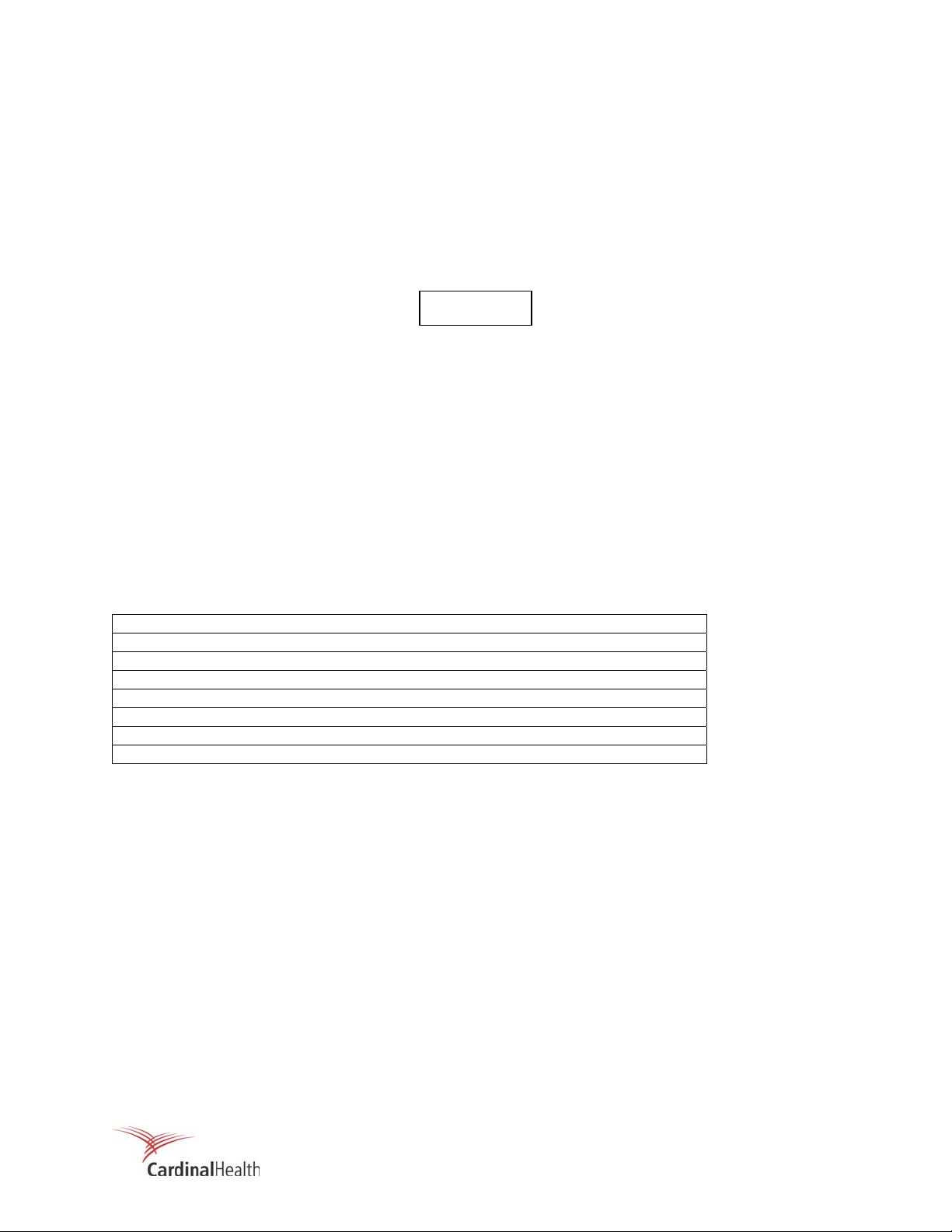

Table 2-6. Connector P3 – Power Input

Pin Signal Internal Connection

1 120 Vac, Line Line fuse (F2)

2 120 Vac, Neutral Power Supply, 120 Vac (n)

3 Safety Ground Chassis

Table 2-7. Connector P4 – Detector High Voltage

Pin Signal Internal Connection

MHV Detector High Voltage Direct

Table 2-8. Connector P5 – Detector Signal Input

Pin Signal Internal Connection

BNC Detector Signal Direct

Table 2-9. Connector P6 – Auxiliary I/O, 956A-201-M2

Pin Signal

1 4 – 20 mA Output #1 (+)

2 4 – 20 mA Ground (-)

3 4 – 20 mA Output #2 (+)

4 4 – 20 mA Ground (-)

5 0 – 10 V* (+)

6 Ground (-)

7 Analog Output Option (+), 0-10 mV

8 Ground (-)

9 through 24 Not used

*0 – 10 Vdc selected for Remote Meter use on P2 (10, 11) and is not available on P6 (5, 6).

Table 2-10. Connector P7 – RS232C Option

Pin Signal

1 Protective Ground

2 Transmit Data

3 Receive Data

4 Request to Send (RTS)

5 Clear to Send (CTS)

6 Data Set Ready (DSR)

7 Signal Ground

8 Receive Line Signal Detect (DCD)

20 Data Terminal Ready

Table 2-11. 897A Detector Connection

Pin Signal

K Protective Ground

H Check Source

J Check Source

E High Voltage

MTG Screw Chassis Ground

C + Voltage In

G Signal Output

2-5

Page 24

2.6 SETUP

Table 2-12 summarizes the jumper selectable configuration options. To place the system in operation,

the following steps should be performed:

Ensure you have read and fully understand Section 3 prior

to continuing.

1. Verify that jumpers and DIP switches, on the UDR and detector, are set for the operational features

desired. Refer to Section 3, Table 3-2. The 897A Detector jumpers are preset at the factory per

Tables 2-1 and 2-2, and should not be changed.

2. Apply power to the unit. The bargraph will illuminate momentarily followed with a momentary

actuation of the digital value display. The unit will then begin to display the ambient radiation at the

detector location.

The default setpoints in the UDR memory are for an 897 A-220

detector (1.00E-1 mR/h to 1.00E4 mR/h); verify the appropriate

setpoints for the actual detector are entered per Section 3

(Parameter Entry).

NOTE

NOTE

Calibration constant and detector deadtime value are obtained

from the factory calibration data sheet for each detector.

3. Detector dependent setpoints such as analog outputs, High/Low scale values, Range, Underrange,

Overrange limit, calibration constant, and detector deadtime may now be verified and if required,

modified using the procedures outlined in Section 3.

4. Channel dependent setpoints such as alarm limits may be verified, and if required, modified using the

procedures outlined in Section 3.

5. Electronic adjustments affecting calibration are factory set and should not be readjusted for initial

operation unless the UDR has been in storage for more than one year. If the Unit has been in

storage for more than one year, the electronic calibration described in Section 4 should be performed.

NOTE

2-6

Page 25

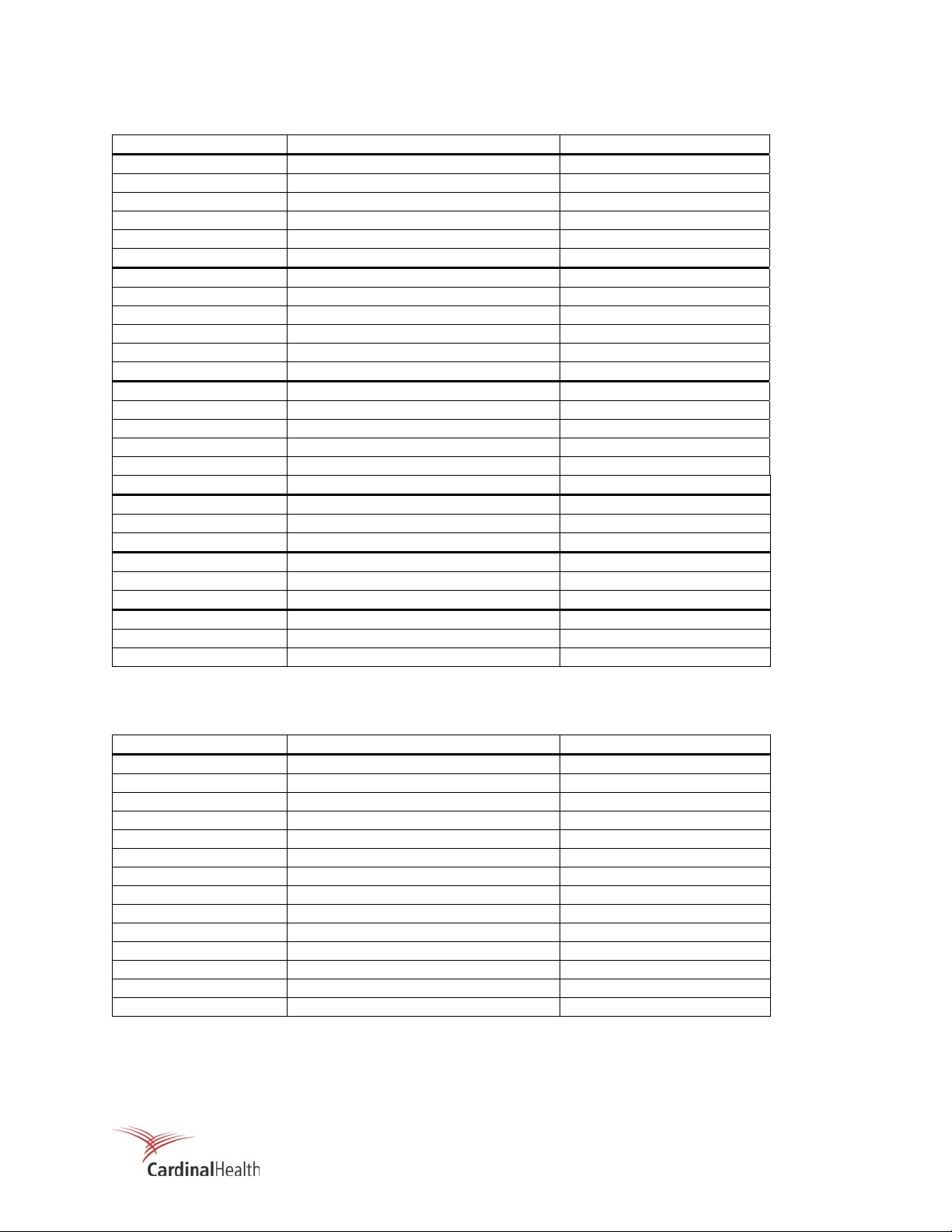

Table 2-12. Model 956A-201-M2 Option Jumpers

Jumper Function Position Operation

JP1 Microprocessor Reset Out

In

JP2 PROM Type 1-2

2-3

JP3-1/JP3-2 Statistical Accuracy (Note: This

accuracy refers only to the

statistical interpretation of

detector counts, and not

Out/Out

Out/In

In/Out

In/In

Normal Operation (factory) Momentary

connect to reset microprocessor without

cycling AC power

Not Applicable

PROM 27128

PROM 27256 (factory)

2% Accuracy – Not Implemented

5% Accuracy – Not Implemented

10% Accuracy – Not Implemented

Fixed one second display update (factory

detector accuracy)

JP3-3 Alarm Acknowledge In

Out

JP3-4 Fail Alarm In

Out

JP3-5 Check Source Alarm In

Out

JP4 Shield Polarity Selection 1-2

2-3

Manual Acknowledge (factory)

Automatic

Enable No Counts Fail Alarm (factory)

Inhibit No Counts Fail Alarm

Alarm Inhibited (factory)

Alarm Enabled

Negative Input Pulse (Other Detectors)

Positive Input Pulse (G-M Detectors)

(factory)

JP5 Shield Polarity Selection 1-2

2-3

JP-6 Anti-Jam Fuse Selection 1-2

2-3

JP7 Detector Type for Anti-Jam

Circuit Timing

1-2

2-3

Out

Shield for Negative Pulse

Shield for Positive Pulse (G-M) (factory)

Enable for Normal Operation (factory)

Anti-Jam Circuit fuse bypassed (testing)

Scintillation

G-M Tube (factory)

Anti-Jam Circuit Disabled (for testing only)

2-7

Page 26

(Blank page)

Page 27

Section 3

THEORY OF

OPERATION

3.1 OPERATION

This section describes the operation and set up of a Digital Area Monitoring System. The system consists

of a Model 956A-201-M2 UDR and a Model 897A Series G-M Detector. The detector preamplifier

provides the electronics interface between the detector and the UDR. The preamplifier provides input

pulse discrimination, pre-divide capability, anti-jam circuitry, pulse amplification and output drive

capabilities. The output of the preamplifier is transmitted to the UDR. The 956A-201-M2 UDR uses this

information to generate the dose rate display, error codes, alarms, and analog outputs.

Operation of the 956A-201-M2 UDR consists of operator functions and configuration functions. All

operator functions are performed using the front panel shown in Figure 1-2. Configuration functions are

performed using internal switches and/or jumpers, which are accessible with partial removal of the UDR

from the mounting enclosure. Calibration involving trim pots is described in Section 4.

For applications where EMI/RFI compliance is required, the S157033A2 Line Filter/Surge Suppressor

Assembly, designed to provide EMI/RFI protection for the 956A Series digital ratemeter and 897A Series

G-M detectors, is available. The assembly consists of two (2) separate and independent line conditioning

circuits that provide filtered AC power to each 956A Series ratemeter. The S157033A2 is designed to

mount in the center section of the 948B-1A-5 dual module rack chassis, to provide EMI/RFI protection for

two (2) 956A Series ratemeters.

3.2 DETECTOR OPERATION, MODEL 897A-2XX

The Digital Area Monitor uses a Model 897A-2XX G-M tube as a gamma radiation detector. The tube is

filled with a mixture of gases, one of which acts as a quenching agent, while the others tend to support

ionization. Electrically, it consists of a positive electrode (anode), which is maintained at a steady potential

of 500/650 Vdc and a negative electrode (cathode) that is near ground potential.

When a gamma photon penetrates the shield encasing the G-M tube, an ionizing event occurs. An ion

pair is produced, triggering an avalanche of ion pairs. The current pulses produced (one pulse per ionizing

event) are independent of the energy of the initiating particle. Multiple discharge, caused by the release of

electrons from the cathode due to excess energy, is eliminated after a short time (called dead time,

typically 20-45 microseconds) by a quenching gas within the tube. The resulting pulses are conditioned

and transmitted to the preamplifier.

The integral detector preamplifier provides input pulse discrimination and amplifies pulses received from

the G-M tube to 5 Vdc amplitude. The current drive output of the preamplifier will drive a signal up to 2000

feet through a 50-ohm transmission line, without signal degradation.

3-1

Page 28

Should a very high intensity radioactive source be detected, the G-M tube may become saturated (i.e.

pulses are separated by a period less than the dead time of the tube). This would have the effect of

holding the preamplifier output at a relatively constant output voltage, resulting in count loss at the readout.

Anti-Jam circuitry in the preamplifier produces a full-scale output square wave signal, providing a full-scale

indication at the readout.

G-M Detector Response Time

The response time of the system to a step change in radiation value is 60 seconds, due to the operation of

the pulse counting algorithms. The detector radiation value displayed is the result of a rolling average of

the latest 60, one-second values, and is updated once per second. An alarm will be initiated within one

second after the current one-minute average exceeds the alarm setpoint.

Check Source

A manual check source may be initiated from the UDR by the operator to check detector operation. The

Check Source push-button is a momentary contact switch, and is active as long as the pushbutton is

depressed. Upon initiation and removal of the check source request, the internal counting registers are

cleared and the display value will be based on the number of new values received. After 60 seconds, the

display value will reflect the average of the past 60 values. During check source activation, analog outputs

are muted (forced to zero). The High and Warn alarms are normally inhibited during check source

operation, but may be enabled by removing Jumper JP3-5, on the UDR main printed circuit board (see

Table 2-12). The counters are cleared upon exiting Check Source mode, resulting in a display of 0.00.

After one minute, the current radiation value will be displayed.

3.3 UDR OPERATION, MODEL 956A-201-M2

Operation of the 956A-201-M2 UDR consists of operator functions and configuration functions. All

operator functions are performed using the front panel. Configuration functions are performed using

internal switches and/or jumpers that are accessible via partial removal of the UDR from the mounting

enclosure.

Normal Operation

If the measured radiation field is within the range of the detector during power-up, the mR/h value will be

displayed as a three digit number: N.NN, where N = 0 to 9. A backlit insert will display engineering units in

mR/h, R/h, or kR/h. The bargraph will display the value on the fixed mR/h scale and any indicator lights

that are on should be green, providing the operator with a visual indication of normal operation. The

analog outputs will track the displayed value, and the alarm outputs will be active. The Warn, High, and

Fail relays operate in the Fail Safe Mode.

WARN/HIGH Alarms

If the measured radiation field increases above the WARN alarm limit, the WARN alarm indicator will turn

on flashing (amber color), the bargraph will change color to amber, and the warn alarm relay will deactivate. If the measured radiation field increases above the HIGH alarm limit, the HIGH alarm indicator

will turn on flashing (red color), the bargraph will change color to red, and the high alarm relay will deactivate.

Non-fail-safe relay operation for the HIGH and WARN alarms is

available as a firmware option at time of purchase.

NOTE

3-2

Page 29

The UDR can be configured to automatically reset the alarm relays and alarm indicators, or it can hold the

alarm relays de-energized and flash the alarm indicators until the alarm acknowledge (ALARM ACK)

pushbutton is pressed. If the ALARM ACK pushbutton is pressed while the alarm condition still exists, the

indicators will go to a steady state, and the relays will remain de-energized until the alarm condition returns

to normal. Upon resumption of normal operation, the relays will energize and alarm indicators will

extinguish. The bargraph color will always indicate the current status; green for normal, amber for warn,

and red for a high alarm.

Front panel pushbuttons labeled HIGH and WARN can be used to display the respective alarm set points.

To drive a local alarm, a 120 Vac is internally wired from alarm output connector P1 to the alarm relay

contact on P2-13 and 14. Refer to Modification Sheet 956A-201-M2MS and Loop Drawing S174014C-

102.

Range Alarm

If the measured radiation field is below the underrange setpoint (minimum range of the detector used), the

front panel display will indicate 0.00 mR/h, the bargraph will indicate the actual radiation value, and the

RANGE alarm indicator will illuminate in red. The minimum range is adjustable by the underrange

setpoint, and is defaulted to 1.00E-1 mR/h. When the measured radiation field increases into the range of

the detector, the RANGE alarm indicator will extinguish and normal operation will begin.

There are three ranges for the ratemeter, one for each detector range (low, medium, & high). The specific

range for each detector is established by operator-entered setpoints (refer to "Setpoint Entry" for actual

entry procedures). The detector range for each specific detector is shown below.

Detector

897A-210/211 0.01 to 10E3 mR/h 1.00E-2 1.00E3

897A-220/221 0.1 to 10E4 mR/h 1.00E-1 1.00E4

897A-230/231 1 to 10E5 mR/h 1.00E0 1.00E5

If the measured radiation field goes above the overrange setpoint, the RANGE alarm indicator will

illuminate and the front panel display will indicate EEEEE, the bargraph will illuminate in red, and the

analog output will be set to full scale. The maximum range of the detector used is determined by the

overrange setpoint. When the measured radiation field returns within the maximum operating range of the

detector and the condition is acknowledged, the RANGE alarm indicator will extinguish and normal

operation will resume.

In addition to the display of EEEEE when in Overrange, the

In the event the detector output exceeds the electronic anti-jam circuit trip level, the anti-jam fuse will open

and the Fail relay will change state to indicate a monitor not in service condition. Replacement of the antijam fuse (F1) will be required in order to return the rate meter to normal operation.

Detector Range

Underrange Setpoint Overrange Setpoint

NOTE

mR/h engineering units will be displayed if the HIGH or WARN

front panel set point display pushbuttons have been accessed.

IF desired, the mR/h units display may be cleared by either

pressing the ENTER push button, or cycling the UDR power

OFF/ON. The mR/h unit’s display, however, does not affect the

operation of the Overrange function.

FAIL Alarm

Detector failure, detector overrange, or microprocessor failure are some of the conditions which can

produce a FAIL alarm and in some cases an error display. The Fail condition is true whenever any

equipment failure is detected and false when no equipment failures are detected.

3-3

Page 30

When a Fail condition occurs, other than power failure, the red FAIL alarm indicator illuminates and the

Fail relay coil de-energizes. On the 956A-201-M2, auxiliary relay K1 is hard wired to operate in parallel

with the Fail relay, to drive a local indicator. Internally, 120 Vac is hard wired from alarm output connector

P1 to the Fail relay contacts on P2-12, and 13. Refer to Modification Sheet 956A-201-M2MS and Loop

Drawing S174014C-102.

To return the channel to normal operation after a FAIL alarm, the condition that caused the alarm must be

located and corrected. Upon correction of the failure condition, the FAIL alarm will automatically close.

Check Source

The check source pushbutton and electronics are provided to verify detector operation. To operate the

check source, press the CHECK SOURCE pushbutton and hold it down. The Check Source LED will

illuminate, and the radiation value will increase. Releasing the check source pushbutton will allow normal

UDR operation. An internal configuration jumper (JP3-5) allows alarms to be activated or deactivated in

the check source mode. The analog outputs are forced to their low scale value during a check source

operation.

Trip Test, 956A-201-M2

A Trip Test Function has been added to the operating firmware of the 956A-201-M2. The purpose of the

function is to verify operation of the output relay, status indicators, display, and analog outputs.

Refer to the Operational Mode section for a complete description of Operation.

Firmware Version

This system requires a PROM for UDR operation. For the part number and the latest revision of the

PROM, see the Factory Test Data Sheet. Operation as described in this manual pertains to the PROM

defined in Section 1.1.

3.4 OPERATIONAL MODES

Normal Operation, Mode

The UDR is in normal operation when the UDR function switch is in any position except 8, and the Check

Source button is OFF. During normal operation, the display shows the dose rate data received from the

preamplifier in mR/h, R/h, or kR/h. The bargraph will also show the dose rate. The color of the illuminated

segments is green when the dose rate is below the WARN setpoint, amber when the dose rate is above

the WARN setpoint and below the HIGH setpoint, and red when the dose rate is above the HIGH setpoint.

The analog outputs are active and all alarms are enabled.

Data Entry Mode

Data Entry Mode is selected by pressing the ENTER pushbutton while the rotary FUNCTION switch is in a

valid setpoint position (see Setpoint Description). The selected setpoint is displayed in exponential

format (e.g. 1.00E2) with the left most digit flashing. Setpoints are entered in exponential format (e.g.

X.XXEN), where X is the mantissa and N is the exponent. The X value may be any integer value between

0 and 9. A positive exponent is entered by selecting the "E" symbol, and a negative exponent is entered

by selecting the "-" symbol. The N value may be any integer value between 0 and 9. If the FUNCTION

switch is not in a setpoint position, pressing the ENTER button has no effect. Refer to Table 3-3 for

FUNCTION switch positions.

In the Data Entry Mode, the bargraph and analog outputs remain active.

3-4

Page 31

Alarm Inhibit Mode

Alarms are inhibited in situations where an alarm trip would be meaningless because the UDR is not in a

normal measurement mode (i.e., when the UDR is in the Check Source Mode). New alarm trips cannot

occur and old alarms cannot be reset. When the inhibit period is over, alarm trips and resets are enabled

again. Alarm inhibit conditions are discussed in the following paragraphs.

3-5

Page 32

Check Source Mode

The check source pushbutton and electronics are provided to verify detector operation. To operate the

check source, press the CHECK SOURCE pushbutton and hold it down. The check source relay will

energize, the check source indicator will illuminate (green), and the check source mechanism will expose

the check source (sealed capsule of

detector printed circuit board. The counters will be cleared and radiation values displayed on the front

panel will reflect the average of the new values received. Releasing the check source pushbutton will

return the source capsule to its shielded position, clear the radiation value stored in the UDR counter and

extinguish the check source indicator, allowing normal UDR operation to resume. After approximately 60

seconds, the displayed value will indicate the average of the previous 60 one-second values stored. An

internal configuration jumper (JP3-5) allows alarms to be activated or muted if alarm limits are exceeded

by the check source radiation value.

The bargraph operates normally during Check Source operation.

The bargraph and alarms are inhibited from changing state for five (5) seconds upon entry and exit of the

Check Source function.

The front panel Alarm and Warn status indicators are disabled during Check Source operation.

The analog outputs are set to zero (i.e. 4 mA or 0V) during Check Source operation.

36

CI) to the G-M tube by positioning the source over an access on the

Calibration (scaler) Mode Operation

Calibrate mode for the UDR is entered by turning the rotary setpoint switch to position 8 and pressing the

ENTER button.

The current calibration time setpoint is displayed in seconds, with the first digit flashing to indicate the edit

mode. The bargraph will turn off, the analog output will remain fixed at their value just prior to entering

Calibrate, the Fail LED will illuminate, the radiation unit backlights will turn off, the HIGH, WARN and

Range LED’s will turn off, and the Fail Safe High, WARN and Fail relays will de-energize. The calibration

setpoint may be edited, but will reset to 60 seconds whenever the unit is turned off or the functional switch

is moved from position 8.

Once the desired calibration time is set, momentarily pressing the ENTER button again will start the

calibration. The display will go to zero and the unit’s backlight will begin to flash. The UDR will count for

the entered calibration time, displaying the current summation of counts each second. When the

calibration is completed, the final summation of counts for the calibration time is displayed and the unit’s

backlights will be steady on.

Another calibration can then be executed by pressing the ENTER key, and the system will again display

the calibration time for editing. Pressing the Enter button again will start the Calibrate timer. A calibration

in process can be stopped by pressing the ENTER key or by moving the rotary switch to a position other

than position 8. The calibration mode is exited by moving the rotary function switch out of position 8. The

UDR will reset, the Fail Safe High, Warn, and Fail relays will energize, and the UDR will continue normal

operation.

When the calibrate mode is initiated (i.e. rotary setpoint switch at

position 8 and the Enter button is pressed), the Alarm, Warn, and

Fail relays change state to indicate the monitor is in a nonoperational state.

NOTE

3-6

Page 33

The calibration mode can also be entered with the UDR in the check source mode of operation. Move the

rotary switch to position 8 and press the check source button. While holding down the check source

button, press the ENTER button. This will turn the Check Source LED on, actuate the check source relay,

and lock the Check Source function on. The Check Source button may now be released and the Check

Source will remain on. Pressing the enter button again will start the calibration. The check source light

will remain on, indicating that the check source relay is energized. The check source condition will clear

when the calibrate mode is exited.

In Calibrate mode, the analog outputs are frozen at their last value, prior to entering the Calibrate mode.

In Calibrate mode, any High and Warn alarms are cleared, the Fail LED is turned on, and the Fail Safe

Alarm, Warn and Fail relays change state, to indicate the unit is not monitoring radiation.

In Calibrate mode, the bargraph display is blanked.

Trip Test Mode, 956A-201-M2

The Trip Test Mode is provided to verify operation of the output relays, status indicators, display and

analog outputs. The Trip Test Mode is entered by pressing and holding in the front panel TEST

pushbutton. The Trip Test Mode is exited by releasing the TEST pushbutton, and then pressing and

releasing the ACKNOWLEDGE pushbutton.

Pressing the TEST pushbutton will cause the Alarm, Warn and Fail

relays to change state and indicate an alarm condition. Prior to

activating the Test Mode ensure the appropriate plant personnel

are notified.

NOTE

A detailed description of the operation is as follows:

TRIP TEST pushbutton depressed to initiate Trip Test Mode

• Front panel display shows 8.8.8.8.8

• KR/h, mR/h and R/h Backlights are illuminated

• Bargraph is fully illuminated, in amber

• HIGH Alarm relay changes state (de-energize)

• WARN Alarm relay changes state (de-energize)

• Aux Relay changes state (de-energize)

• Fail relay changes state (de-energize)

• High, Warn, Fail. Range, and Check Source LEDs are illuminated

• Analog Outputs are at Full Scale

TEST pushbutton Released

• Front panel display shows current value and continues to count

• mR/h backlight is illuminated

• Bargraph will display the actual count rate in Red

3-7

Page 34

If the count rate is below the range limit of the paragraph, the

bargraph will be blanked. When an input signal is present, the

bargraph will illuminate in red as a result to the unacknowledged

alarm condition resulting from actuating the Test Function.

• HIGH Alarm relay changes state (energize)

• WARN Alarm relay changes state (energize)

• Aux Relay changes state (energize)

• Fail relay changes state (energize)

• High and Warn LEDs are illuminated, flashing

The Trip Test Function takes precedence over the automatic alarm

reset option, and the ACK pushbutton, in the next step, must be

pressed to clear the alarm LED’s and bargraph.

• Fail, Range, and Check Source LEDs are turned off and return to normal

• Analog Outputs return to normal

Press and release the ACK pushbutton

NOTE

NOTE

• No Change, display shows current value

• No Change, mR/h backlight is illuminated

• Bargraph will return to normal, displaying actual count rate

• No Change, HIGH Alarm relay

• No Change, WARN Alarm relay

• No Change, Aux Relay

• No Change, Fail relay

• High and Warn LEDs are off, and return to normal operation

• No Change, Fail, Range, and Check Source LEDs return to normal

• No Change, Analog Outputs return to normal

3.5 ALARMS

The alarm functions provided by the UDR include HIGH, WARN, FAIL, and RANGE. The HIGH, WARN,

and FAIL alarms drive relay contact outputs. Some operating modes of the UDR disable alarms. The user

is cautioned to read and fully understand section 3.

Alarm Logic Types

Alarm logic defines whether the alarm is reset manually or automatically and whether alarm relay coils are

energized or de-energized in normal operation.

Standard alarm reset logic for the UDR is manual reset for the HIGH and WARN alarms, and auto reset for

the RANGE and FAIL alarm. Fail-safe operation is also standard.

3-8

Page 35

Auto reset for the HIGH and WARN alarms may be selected by jumper JP3-3.

Manual Reset

When an alarm trips, the relay coil goes to its abnormal position. The indicator flashes until the alarm is

acknowledged by pressing the ALARM ACK button on the UDR. The indicator then remains steady on

until the alarm condition becomes false. At that time, the alarm resets by turning the indicator off and

returning the contact to its normal position.

Auto Reset

When an alarm trips, the contact goes to its abnormal position. The indicator goes steady on. When the

alarm condition becomes false, the alarm automatically resets, returns the relay coil to normal position,

and turns the indicator off.

Auto reset may be selected for the HIGH and WARN alarms by removing jumper JP3-3 from the UDR

main board.

Standard relay operation for the UDR is fail-safe. When the unit is powered, the relay coil energizes. If

power is lost to the relay coil, or an alarm condition occurs, the relay de-energizes, giving a trip indication.

This logic provides fail-safe operation for the alarm function.

Non-Fail-safe relay operation for the HIGH and WARN alarms is available as an option.

High Alarm

The HIGH alarm condition is “true” when the display dose rate is greater than or equal to the HIGH alarm

setpoint and “false” for all other conditions.

The standard logic for the HIGH alarm is fail-safe, manual reset.

When the HIGH alarm is tripped, the red HIGH alarm indicator begins flashing, the bargraph goes to red,

and the HIGH alarm relay coil de-energizes. When the alarm is acknowledged, the HIGH alarm indicator

goes steady on.

The HIGH alarm relay will change state (i.e. energize) after the Acknowledge push button is pressed and

the radiation value drops below the setpoint.

The HIGH alarm is normally inhibited in Check Source mode. By removing jumper PJ3-5, the HIGH and

WARN alarms may be enabled in check Source mode.

The firmware will not accept a High setpoint that is lower than the Warn set point. On the 956A-201-M2,

Error Code E0004 will be displayed.

On the 956A-201-M2, 120 Vac is wired to high alarm relay

contacts P2-13 and 14.

NOTE

WARN Alarm

The WARN alarm condition is “true” when the display dose rate is greater than or equal to the WARN

alarm setpoint and “false” for all other conditions.

The standard logic for the WARN alarm is fail-safe, manual reset.

When the WARN alarm is tripped, the amber WARN alarm indicator begins flashing, the bargraph goes to

amber, the WARN alarm relay coil de-energizes. When the alarm is acknowledged, the WARN alarm

indicator goes steady on. With the alarm acknowledged, the relay will change state when the radiation

value drops below the setpoint.

3-9

Page 36

The WARN alarm is normally inhibited in Check Source mode. By removing jumper JP3-5, the HIGH and

WARN alarms may be enabled in Check Source mode.

The firmware will not accept a Warn setpoint that is higher than the High setpoint. ON the 956A-201-M2

Error Code E0004 will be displayed.

RANGE Alarms

The underrange condition is "true" when the dose rate is below the underrange setpoint and "false" for all

other conditions. The RANGE indicator illuminates, the analog output is set to zero, and the display reads

0.00 mR/h when the underrange condition is true. The bargraph will operate normally. The Alarm, Warn,

and Fail relays are not affected by the underrange alarm.

The underrange condition clears automatically when the detector output returns within the normal range.

There is no relay associated with the UNDERRANGE alarm.

The OVERRANGE is true when the dose rate is greater than or equal to the overrange setpoint or the

Model 897A preamplifier is sending an output pulse greater than the detector preamplifier Anti-Jam circuit

setpoint. The condition is false when neither of the conditions are true.

When the OVERRANGE alarm is active, WARN and HIGH alarms are true, the red RANGE indicator

illuminates, the bargraph illuminates red, the analog output reads full scale, and the display reads EEEEE.

The OVERRANGE alarm setpoint is operator adjustable.

NOTE

In addition to the display of EEEEE when in Overrange, the

mR/h engineering units will be displayed if the HIGH or WARN

front panel set point display pushbuttons have been accessed.

IF desired, the mR/h units display may be cleared by either

pressing the ENTER push button, or cycling the UDR power

OFF/ON. The mR/h unit’s display, however, does not affect the

operation of the Overrange function.

The OVERRANGE alarm must be reset by pressing the acknowledge pushbutton when the overrange

condition is false (i.e. radiation level returns to a value below the overrange setpoint). The OVERRANGE

alarm will not reset automatically, at a later time, after the acknowledge pushbutton is pressed as it does

for the HIGH and WARN alarms. If auto reset is selected for HIGH and WARN alarms, these will reset

automatically, but the overrange display will remain until the acknowledge pushbutton is pressed.

In addition, if the detector output is above the electronic anti-jam circuit threshold of the UDR, the anti-jam

circuit will be activated, opening the anti- jam fuse on the UDR. This causes the Fail LED to turn on, the

Fail relay to change state, and the detector High Voltage power supply to turn off indicating a nonoperational mode. After the anti-jam condition has cleared, to return to normal operation, the 956A UDR

must be powered off, the anti-jam fuse replaced, and the power turned back on.

FAIL Alarms

Several equipment failure conditions are monitored which produce a FAIL alarm and in some cases an

error message. The Fail condition is "true" whenever any equipment failure is detected and "false" when

no equipment failures are detected. When a Fail condition occurs, other than power failure, the red FAIL

alarm indicator illuminates and the Fail relay coil de-energizes.

The FAIL alarm logic is always fail-safe, auto reset.

3-10

Page 37

The following are the FAIL alarms included in the 956A-201-M2 UDR:

1. NO COUNT Failure

2. POWER Failure

3. MPU Failure (hardware)

4. Anti-Jam Trip

No Count Failure

If no pulses are received by the UDR for five minutes, a no count failure is detected. A no count alarm

usually indicates a failure in the detector or UDR detector high voltage supply. The UDR display, however,

may read zero for five minutes or more without a low signal FAIL alarm. This is because the re-amplifier is

reporting a non-zero dose rate that is below the low range value. The No Count failure alarm can be

disabled by removing jumper JP3-4 from the UDR main board.

Power Failure

If power is lost to the UDR, the bargraph, alarm indicators, and the display are blanked (turned off). The

HIGH, WARN, and Fail relay coils de-energize.

MPU Failure

If the Fail timer circuit, which checks the MPU (main processor) function, is allowed to time out (because of

a hardware failure), a failure condition will be indicated.

In the unlikely event of a watchdog timer trip, the display may

“Freeze” or the unit may appear to be operating normally. The

Fail Alarm, however, will remain de-energized until a refresh

signal is provided from the microprocessor to prevent the Fail

Timer from timing out. It is to advise the operator of this condition,

recommended that the Fail Relay contact be wired into the user’s

radiation monitor trouble anunciator.

NOTE

Anti-Jam Trip

Should the detector output exceed the UDR anti-jam circuit threshold, the anti-jam fuse opens the detector

high voltage is shut down the Fail LED will illuminate, and the Fail relay will de-energize.

ON the 956A-201-M2, 120 Vac is wired to Fail relay contacts P212 and 13. Auxiliary relay K1 is internally wired to operate in

parallel with the Fail relay.

NOTE

3.6 JUMPER SELECTABLE CONFIGURATION FUNCTIONS

The UDR contains a series of eleven hardware jumpers and nine user specified setpoints that affect

operation of the unit.

The jumpers are designated as JP1 and JP2, JP3-1 through JP3-5, and JP4 through JP7. Refer to the

main circuit board assembly drawing located in Appendix B of this manual for jumper locations. The

functions affected by JP1 through JP7 are described in the following paragraphs and shown in Table 3-2.

3-11

Page 38

The unit will only read jumper selection on power-up; therefore,

the unit must be turned off when changing jumpers.

NOTE

Microprocessor Reset

Jumper JP1 permits local reset of the microprocessor without cycling AC power.

PROM Type

Jumper JP2 must be installed in position 2-3 for use with the 27256 PROM installed.

Count Time Selection (Statistical Accuracy)

The statistical accuracy jumpers JP3-1 & JP3-2, are not implemented. This statistical accuracy, count

time and consequently, the update time of the display are fixed. The unit is shipped from the factory with

both JP3-1 and JP3-2 installed, resulting in a displayed value that is the sum of 60, one second values,

updated once per second.

Alarm Reset (Acknowledge)

1. JP3-3 OUT - The unit resets alarm indicators and alarm relays after the radiation value falls below the

setpoint without regard to the alarm acknowledge pushbutton.

2. JP3-3 IN - The unit maintains the alarm indicators and alarm relays in the alarm state until the alarm

acknowledge pushbutton has been pressed and the radiation value falls below the setpoint. If the

alarm acknowledge pushbutton is pressed while the radiation value is still above the setpoint, the

flashing indicator will go to a steady state ON condition.

The UDR is normally shipped from the factory with JP3-3 installed.

No Counts FAIL Alarm

JP3-4 IN - The unit will go into a FAIL mode after five minutes with no counts from the detector.

JP3-4 OUT - The unit will not go into a FAIL mode when there are no counts from the detector.

The UDR is normally shipped from the factory with JP3-4 installed.

Inhibit Alarms (Check Source Operation)

1. P3-5 OUT - The alarms will become active during check source operation if alarm limits are exceeded.

2. JP3-5 IN - Alarms are inhibited during check source operation, but if the unit is in an alarm condition

when the check source is activated, it will remain in the alarm condition.

The UDR is normally shipped from the factory with JP3-5 in.

Input Pulse Selection

Jumper JP4 is set to position 2-3 for G-M detector inputs. Position 1-2 is provided for use with other

detectors.

Input Shield Polarity

Jumper JP5 is set to position 2-3 for G-M detector inputs. Position 1-2 is provided for use with other

detectors.

3-12

Page 39

Anti-Jam Selection

Jumper JP6 is normally installed in position 1-2. Position 2-3 bypasses the anti-jam fuse for test purposes.

Detector Type

Jumper JP7 is set to position 2-3 for a G-M detector input. Position 1-2 is provided for use with a

scintillation detector. Removing the Jumper disables the anti-jam circuit for test purposes.

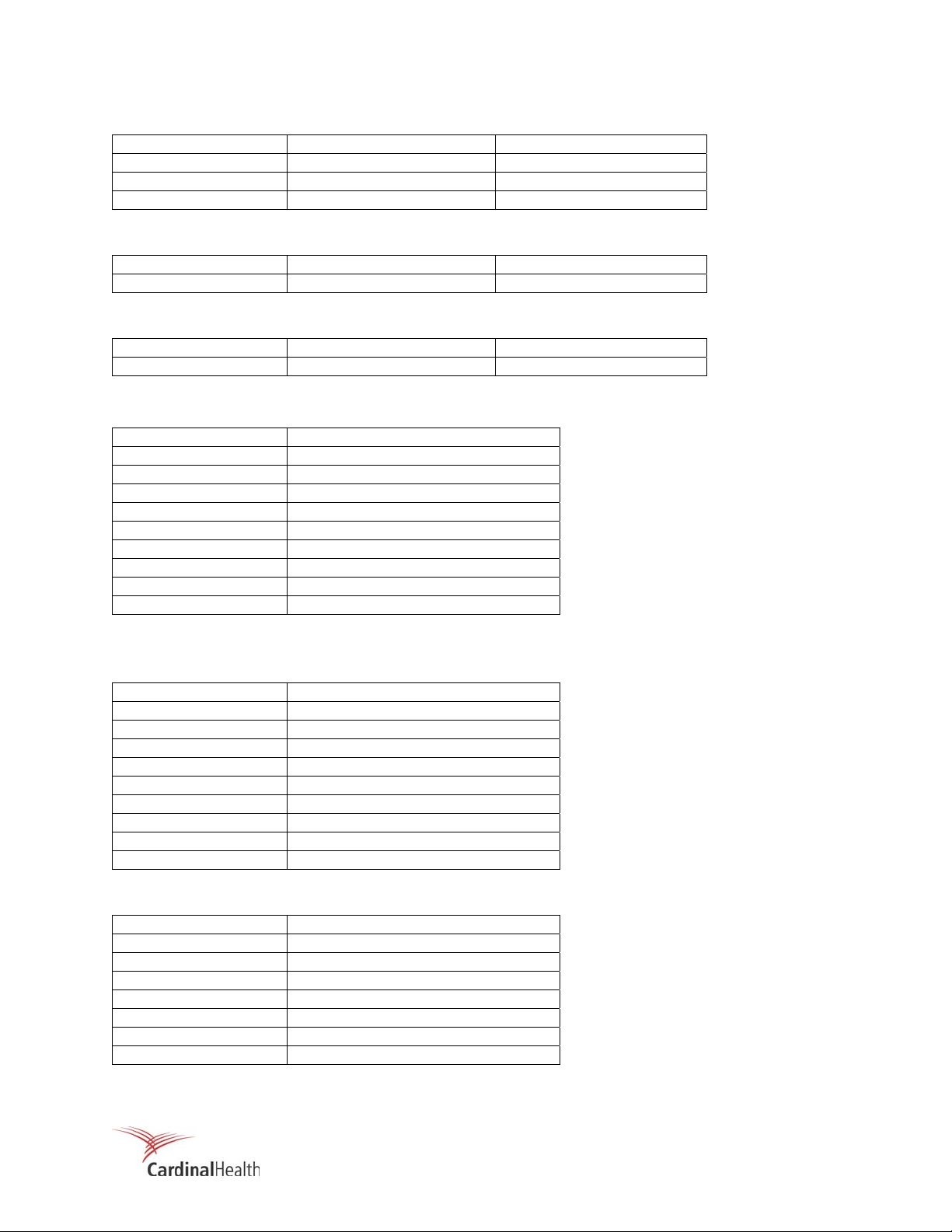

Table 3-2. Model 956A-201-M2 Option Jumpers

Jumper Function Position Operation

JP1 Microprocessor Reset Out

IN

JP2 PROM Type 1-2

2-3

JP3-1/JP3-2 Statistical Accuracy (Note: this

accuracy refers only to the

statistical interpretation of

detector counts, and not

detector accuracy)

JP3-3 Alarm Acknowledge In

JP3-4 Fail Alarm In

JP3-5 Check Source Alarm In

JP4 Input Pulse Selection 1-2

JP5 Shield Polarity Selection 1-2

JP-6 Anti-Jam Fuse Selection 1-2

JP7 Detector Type for Anti-Jam

Circuit Timing

Out/Out

Out/In

In/Out

In/IN

Out

Out

Out

2-3

2-3

2-3

1-2

2-3

Out

Normal Operation (factory) Momentary connect to

reset microprocessor without cycling AC power

Not Applicable

PROM 27128

PROM 27256 (factory)

2% Accuracy – 9604 Target Counts, Not

implemented

5% Accuracy – 1537 Target Counts, Not

implemented

10% Accuracy – 384 Target Counts, Not

implemented

Fixed one second display update of 60 one

second values (factory)

Manual Acknowledge (factory)

Automatic

Enable No Counts Fail Alarm (factory)

Inhibit No Counts Fail Alarm

Alarm Inhibited (factory)

Alarm Enabled

Negative Input Pulse (Other Detectors)

Positive Input Pulse (G-M Detectors) (factory)

Shield for Negative Pulse

Shield for Positive Pulse (G-M) (factory)

Enable for Normal Operation (factory)

Anti-Jam Circuit fuse bypassed (testing)

Scintillation

G-M Tube (factory)