Page 1

®

Victoreen

Current Mode Beta Scintillation Detector,

Model 943-27

February 2007

Manual No. 943-27-31-1, Rev. 3

©2007 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Operator Manual

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: General Information............................................................................................................. 1-1

1.1 General Description ............................................................................................................... 1-1

1.2 Application.............................................................................................................................. 1-1

1.3 Specifications......................................................................................................................... 1-2

1.4 Auxiliary Equipment...............................................................................................................1-3

1.5 Recommend Spare Parts.......................................................................................................1-3

1.6 Receiving Inspection.............................................................................................................. 1-3

1.7 Storage................................................................................................................................... 1-4

Section 2: Theory of Operation............................................................................................................. 2-1

2.1 Functional Description ........................................................................................................... 2-1

2.2 Theory of Operation............................................................................................................... 2-1

Section 3: Operation..............................................................................................................................3-1

3.1 Installation.............................................................................................................................. 3-1

3.2 Set-Up.................................................................................................................................... 3-3

3.3 Operation ............................................................................................................................... 3-4

Section 4: Maintenance, Calibration and Troubleshooting ............................................................... 4-1

4.1 Maintenance........................................................................................................................... 4-1

4.2 Calibration.............................................................................................................................. 4-1

4.3 Troubleshooting ..................................................................................................................... 4-9

Appendix A: Connector Designations .....................................................................................................A-1

A.1 Connector Designations.........................................................................................................A-1

Appendix B: Applicable Drawings............................................................................................................B-1

B.1 Applicable Drawings...............................................................................................................B-1

Appendix C: Bill of Materials.....................................................................................................................C-1

C.1 Bill of Materials.......................................................................................................................C-1

Appendix D: Cable Termination Instructions..........................................................................................D-1

D.1 Cable Termination Instructions..............................................................................................D-1

Appendix E: Modification Sheets/Engineering Instructions .................................................................E-1

E.1 Modification Sheets/Engineering Instructions........................................................................E-1

Page 4

(Blank Page)

Page 5

General Information

General Description

1

Section 1

General Information

1.1 General Description

The Victoreen® Model 943-27 Current Mode Beta Scintillation detector is a radiation detection device that

detects beta radiation. The detector is housed in a 1.5-inch diameter stainless steel tube. The detector is

identified as the Model 943-27 and is manufactured as a P/N 943-27-31 detector assembly. Both

identification numbers are used interchangeably throughout this manual. The detector is designed for

accident range operation.

The detector operates at a potential of approximately (-) 500 VDC and provides a nominal DC output

current of 1 x 10

The detector consists of a 0.002-inch thick Titanium end window, a calcium fluoride scintillation crystal

optically coupled to a quartz light pipe and a photomultiplier tube.

The detector is designed to operate with a Model 943-227-15 Series Digital preamplifier and a Model 960

Digital Process Radiation monitoring system or a Model 942A-200C Series Digital Ratemeter. The Model

943-227-15 Digital Preamplifier is a self-contained electrometer housed in a NEMA 4 enclosure. The

preamplifier processes the DC input signal, digitizes the signal, and then transmits the digitized radiation

value to the readout device via a RC232C compatible serial data communication. For additional

information on the preamplifier and readout device, refer to the applicable product or system level

instruction manual.

Interconnection between the detector and preamplifier is accomplished using two (2) six (6) foot coaxial

cables. One cable supplies the detector high voltage and the other cable provides the signal output

For additional information on the detector preamplifier or readout device, refer to the instruction manual

for the Model 943-227-15 Preamplifier, the Model 942A-200C UDR, or the applicable Model 960 System

manual.

-12

amperes at 1 x 10-3 to 1 x 10-5 uCi/cc. The maximum current output is 1 x 10-4 amperes.

1.2 Application

The Model 943-27-31 Detector is used with the Victoreen 942A-200C or Model 960 Digital Process

Radiation monitor and the Model 943-227-15 Series Digital preamplifier. The Model 942A-200C or 960

system readouts provide the +15 VDC preamplifier electronics power, (-) 500 VDC detector power and

the RS232C serial communications support. The digital preamplifier converts the detector output into a

digital signal for processing by the digital readout. Table 1-1 is a list of available configurations and

compatible 9XX series equipment. Please contact Fluke Biomedical Radiation Management Services for

additional information.

Table 1-1 943-27 Variations and Compatible Equipm ent

Detector Preamplifier

Variations

943-27-31 Beta

Detector,

Current Mode

Operation

943-227-15 Digital

Preamplifier

943-227-15VL Digital

Preamplifier

Application Readout

Transmission

Distances

Less than 50 feet

Transmission

Distances up to 1

mile

942A-200C Digital Ratemeter

or Model 960 Digital Process

Control System

942A-200C Digital Ratemeter

or Model 960 Digital Process

Control System

1-1

Page 6

943-27 Beta Scintillation Detector

Operator Manual

1.3 Specifications

General specifications for the Model 943-27 Detector are listed below. The 943-27 series products are

designed for nuclear applications, and any repairs to it by personnel not qualified to ANSI 45.2.6 1978,

Skill Level II may void the nuclear rating.

If a problem develops, the preamplifier may either be returned to the factory for service, or repaired by a

qualified technician.

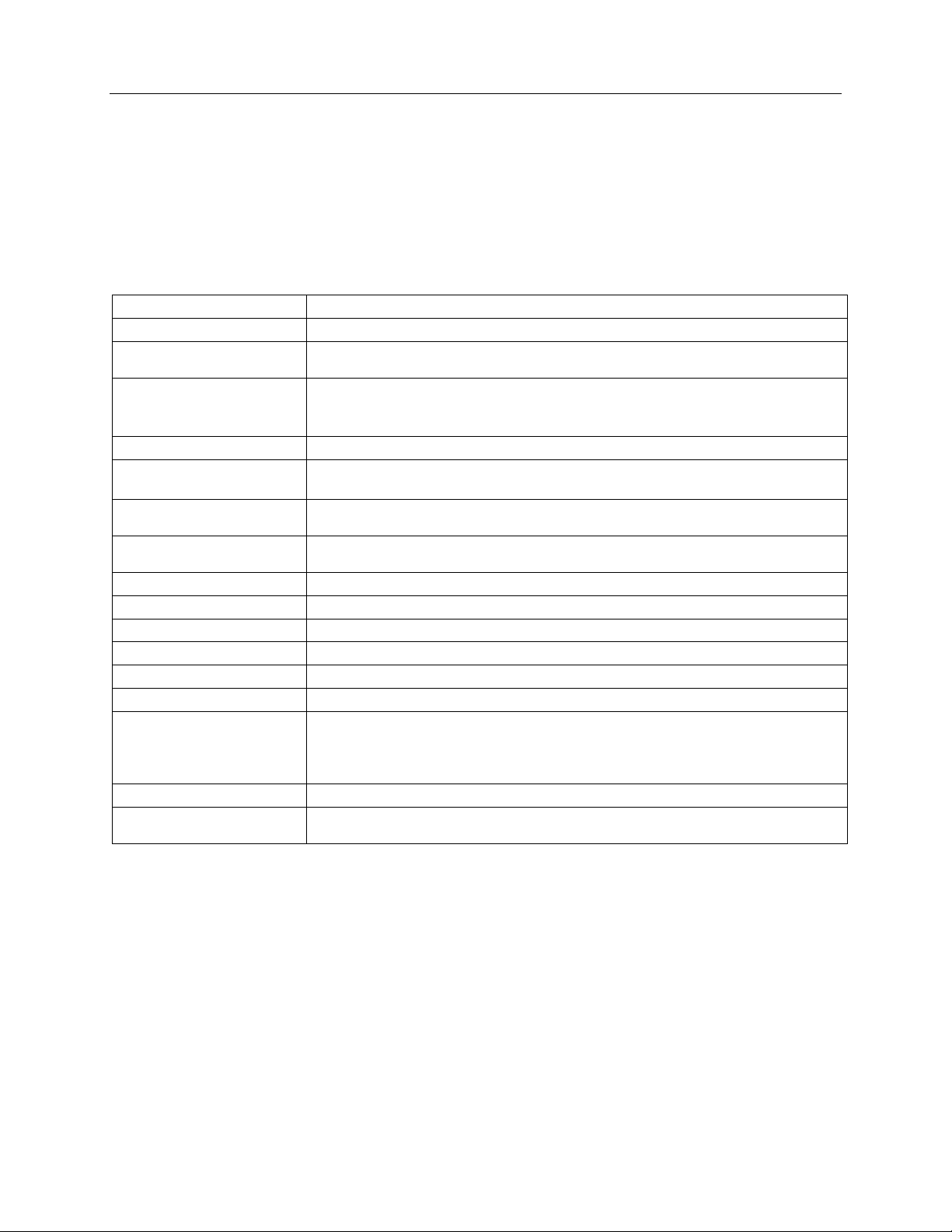

Table 1-2. General Specifications for the 943-27 Detector

Feature: Specification:

Radiation Detected

End Window

Scintillation Crystal

Detector Housing

Detector Constant

Detector Range

Energy Dependence

and Efficiency

Power Requirements

Operating Temperature

Relative Humidity

Operating Pressure

Dimensions

Weight

Preamplifier Interface

Modification

Information

Beta rays

Titanium, 1.125 in dia. x 0.0002 in thick, designed to maximize beta

transmission and minimize noble gas adsorption

Calcium Fluoride, CaF

(Eu)

2

1.125 in dia. X 0.005 in thick interfaced to 1.125 in dia. x 0.125 in thick

quartz light pipe

Stainless Steel

1.0 x 10

sampling geometry

1.0 x 10

-3

uCi/cc/picoampere, typical, based on calibration method and

-12

to 1.0 x 10-4 amperes (approximately 1.0 x 10-3 to 1.0 x 105

uCi/cc, based on calibration method and sampling geometry

Dependent on sampling geometry; Refer to Appendix C for applicable

isotopic calibration reports

(-) 500 VDC @ 400 uAmperes

0° F to 122 °F (-16 °C to 50 °C)

0 – 95 %, non-condensing

12 psig max

1.5 in dia. x 9.0 in long (3.8 cm x 22.9 cm)

3 lbs (1.4 kg)

High Voltage: Six (6) foot coaxial cable with pre-terminated SHV connector

and “Seal Grip”;

Signal: Six (6) foot coaxial cable with pre-terminated BNC connector and

“Seal Grip”;

None

1-2

Page 7

General Information

Inspection & Storage

1.4 Auxiliary Equipment

Model

None See Table 1-1 for compatible equipment

Description

1.5 Recommended Spare Parts

Table 1-9 Recommended Spare Parts List for the Model 943-27 Detector

Part Number Description Used On

There are no replaceable parts in the 943-27 detector

1

1.6 Receiving Inspection

Upon receipt of the unit:

1. Inspect the carton(s) and contents for damage. If damage is evident, file a claim with the carrier and

notify the Fluke Biomedical Radiation Management Services Customer Service Department.

Fluke Biomedical

Radiation Management Service

6045 Cochran Road

Cleveland, Ohio 44139

Phone: 440.248.9300

Fax: 440.542.3682

2. Remove the contents from the packing material.

3. Verify that all items listed on the packing list have been received and are in good condition.

NOTE

Management Service Customer Service Department If any of the

listed items are missing or damaged, notify the Fluke Biomedical

Radiation

1-3

Page 8

943-27 Beta Scintillation Detector

Operator Manual

1.7 Storage

Storage of Fluke Biomedical instruments must comply with Level B storage requirements as outlined in

ANSI N45.2.2 (1972) Section 6.1.2(.2). The storage area shall comply with ANSI N45.2.2 (1972) Section

6.2 Storage Area, Paragraphs 6.2.1 through 6.2.5. Housekeeping shall conform to ANSI N45.2.3 (1972).

Level B components shall be stored within a fire resistant, tear resistant, weather tight enclosure, in a

well-ventilated building or equivalent.

Storage of Fluke Biomedical instruments must comply with the following:

1. Inspection and examination of items in storage must be in accordance with ANSI N45.2.2 (1972)

Section 6.4.1.

2. Requirements for proper storage must be documented and written procedures or instructions must

be established.

3. In the event of fire, post-fire evaluation must be in accordance with ANSI N45.2.2 (1972), Section

6.4.3.

4. Removal of items from storage must be in accordance with ANSI N45.2.2 (1972), Sections 6.5 and

6.6.

1-4

Page 9

Theory of Operation

Functional Description

2

Section 2

Theory of Operation

2.1 Functional Description

The detector is comprised of a thin calcium fluoride scintillation disc located behind an ultra-thin (0.0002

in) Titanium end window. The end window permits the penetration of Beta rays as low as 80 Kev. The

calcium fluoride disc is optically coupled to the active cathode of a one-inch diameter photomultiplier tube

(PMT). A schematic representation of the detector is shown on drawing 943-27-32, located in Appendix

A. As shown in the schematic, the cathode of the PMT is tied to a negative high voltage through a ten

(10) megohm current limiting resistor, R1. The PMT dynodes are biased by the divider string formed by

resistors R2 through R13. The output signal is taken directly from the PMT anode, which is held at a

virtual ground potential by the input of the associated integrating electrometer.

2.2 Theory of Operation

Beta particles that have enough energy to penetrate the end window and impinge upon the disc will

produce light pulses, proportional to the energy deposited in the disc. The disc is thin so that gamma rays

will not have a high incidence of interaction with the disc. This yields a high rejection of gamma rays while

still possessing good sensitivity to beta particles.

A photomultiplier tube, optically coupled to the scintillation disc, detects visible light emitted from the disc

and converts this light to electrical energy that is proportional to the energy deposited by the beta particle.

The electrical charge is sent to an electrometer in an external preamplifier that converts the charge into a

digital value for display and processing.

2-1

Page 10

(Blank Page)

Page 11

Operation

Installation

3

Section 3

Operation

3.1 Installation

Installation consists of mounting the detector in its associated sampling geometry and making the

required electrical connections. Refer to the applicable sampling geometry in struction manual for

detector installation instructions.

CAUTION

Remove all power prior to installing the Detector.

Detector Mounting

The detector is designed to be installed within a sampling geometry. The detector is normally part of the

process pressure boundary, and is normally installed using to mounting flanges and 2 quad-lobed seal orings. The basic mounting procedure is provided below. Refer to the specific sampling geometry

installation procedure for further information.

The following materials are normally needed to remove or install the Model 943-27 detector:

O-Ring Lubricant, Dow Corning #55, or equivalent

1ea, 3/16 Hex head bit or T-handle tool

1ea, P/N 943-27-47, Detector Mounting Flange

1ea, P/N 46-103, Quad lobed seal (Detector mounting flange to Adapter flange)

6ea, P/N 5-610, 10-32 x 0.62 Socket head cap screws (varies with application)

6ea, P/N 5-795, #10 split washes, Stn Stl (varies with application)

1ea, P/N 943-27-48, Adaptor Flange

1ea, P/N 46-104, Quad lobed seal (Adapter flange to sampler body)

6ea, P/N 5-1080, 10-32 x 0.88 Socket head cap screws (varies with application)

6ea, P/N 5-795, #10 split washes, Stn Stl (varies with application)

6ea, P/N 5-795, #10 flat washers, Stn Stl (varies with application)

CAUTION

Due to the potential for high activity radioactive

gasses in or around the vicinity of the detector,

protective Clothing should be worn while installing

or removing the detector

Detector Installation

Detector installation includes installing the adaptor flange and quad-lobed seal o-ring, installing the

detector mounting flange, detector flange quad-lobed seal o-ring, inserting the detector into the detector

mounting tube and securing the detector mounting flange. The high voltage power supply for the detector,

if operational, must be turned off by turning the controlling Digital Ratemeter or 960 System power OFF.

3-1

Page 12

943-27 Beta Scintillation Detector

Operator Manual

Adapter Flange Installation: Lubricate the P/N 46-104 Quad lobed seat, the larger of the 2 seals, with Oring lubricant, Dow Corning #55, or equivalent. Insert the seal into the groove on the P/N 943-27-48

adaptor flange, the larger of the 2 flanges, with 2 sets of mounting holes. Place the adaptor flange over

the mating mounting surface. The quad lobed seal must be located between the adaptor flange and the

mating stationery mounting surface. Secure the adaptor flange to the mounting surface using the

hardware provided with the sampling geometry. Tighten the nuts securely (50 inch-lbs).

Detector Installation: Locate the P/N 943-27-47 detector-mounting flange, the smaller of the 2 flanges,

with 1 set of mounting holes. From the bottom of the detector, the end with the titanium window, slide the

detector flange over the body of the detector, up to the cables at the opposite end of the detector. The

groove cut into the flange must face the bottom of the detector. Lubricate the P/N 46-103 Quad lobed

seat, the smaller of the 2 seals, with O-ring lubricant, Dow Corning #55, or equivalent. Slide the quad

lobed seal over the body of the detector, up to the detector flange. Insert the seal into the groove on the

P/N 943-27-47 detector flange. The quad lobed seal must face the bottom, or sensitive end of the

detector to permit sealing to the adaptor flange.

Install the Model 943-27 detector, with detector flange and quad lobed seal, into the hole in the adaptor

flange and into the detector housing. Insert the detector into the detector housing until the sensitive end

of the detector rests on the support ring on the bottom of the detector tube. Use care to not damage the

thin, beta sensitive end window on the detector.

Detector Flange Installation: Slide the detector mounting flange and quad lobed seal down the body of

the detector until it stops on the detector adaptor flange. Install the 6, 10-32 x 0.62 inch long, stainless

steel, Socket head cap screws and lock washers into the holes provided in the detector flange. Line up

the holes in the detector flange with the threaded holes in the adaptor flange. Screw the cap screws into

the threaded mounting holes in the adaptor flange. Tighten the nuts securely (50 inch-lbs ).

This completes the detector installation. The sampling geometry may now be pressure tested. The

maximum pressure for the system is 12 psig.

Detector Removal:

CAUTION

Due to the potential for high activity radioactive gasses in or

around the vicinity of the detector, protective Clothing should

be worn while installing or removing the detector.

WARNING

The sampling geometry is an accident range noble gas monitor,

and radioactive gasses may be present within the sampling

volume. The local plant Health Physicist should be consulted

prior to removing the Detector or opening the Grab sample valve.

Detector removal is the opposite of the typical detector installation described above. If the detector has

not been replaced for over 18 months, the 46-103 Quad lobed seal should be inspected for wear or

damage. If the seal is worn, it should be replaced at this time. When replacing the seal, the new seal

should be lubricated with O-ring lubricant, Dow Corning #55, or equivalent. If the detector adaptor flange

has not been replaced for over 6 years, the 46-104 Quad lobed adaptor flange seal should be inspected

for wear or damage. If the seal is worn, it should be replaced at this time. When replacing the seal, the

new seal should be lubricated with O-ring lubricant, Dow Corning #55, or equivalent

3-2

Page 13

Operation

Installation

3

CAUTION

Remove all power prior to connecting field wiring.

Electrical Interface

Electrical connections from the detector include a high voltage and a signal coaxial cable, with preterminated connectors. The connectors are designed for termination within the associated preamplifier.

The detector high voltage and signal cables enter the preamplifier through “Seal Grip” type penetrations

on the enclosure body. The “Seal Grips” contain a rubber gland that is intended to grip the coaxial cables

to prevent moisture entry into the enclosure. The “Seal Grips” are an integral part of the detector cables.

The “Seal Grip” enclosure nut is removed from the fitting. The insulating washer stays with the fitting.

The detector signal and high voltage cables, with connectors and “Seal Grip” fitting nuts are then inserted

into the holes preamplifier enclosure. The “Seal Grip: end fittings are then re-installed securely against

the wall of the enclosure.

The detector Signal (BNC) and High Voltage (SHV) cables are then terminated on the bulkhead

connectors located on the enclosure inner panel.

NOTE

The electrometer circuitry in the preamplifier is highly sensitive to

moisture and physical damage. Use extreme care when the preamplifier

case is opened as the high impedance electrometer circuitry is easily

damaged. Do not leave the preamplifier enclosure in the open position

for any extended period of time.

3.2 Set-up

Once the detector is installed and electrically connected to the preamplifier, the detector must be

calibrated. This includes exposing the detector to a series of standard radioactive sources and adjusting

the high voltage supplied by the readout device to obtain the same output current (adjusted for

radioactive decay) that was obtained during the factory calibration. This data is provided on the

Calibration Data sheet provided with the detector. To place the system in operation, the following steps

should be performed:

NOTE

Ensure you have read and fully understand

Section 1, 2 and 3 prior to continuing.

1. Adjust the High Voltage. Refer to the applicable preamplifier and readout/controller device manual

prior to powering up the controller and adjusting the high voltage.

3-3

Page 14

943-27 Beta Scintillation Detector

Operator Manual

3.3 Operation

Once the detector/preamplifier/readout devices have been installed and the high voltage has been

adjusted, operation of the Model 943-27 Current Mode Beta Scintillation Detector is automatic.

Operation of the 943-27 Detector is controlled by the Model 943-227-17 Digital Preamplifier and the

Model 942A-200C Digital Ratemeter or Model 960 Digital Process Radiation monitoring system. Once

the power to the controlling device is turned on, detector operation begins. No operator interaction is

required.

An operational check source is normally provided with the sampling geometry. The check source is

actuated from the controlling device and is used to verify operation of the detector by producing an

upscale reading on the controlling device.

Normal Operation

If the measured radiation field is within the range of the detector during power-up, the uCi/cc value will be

displayed on the controller. The digital display will update once per second.

Alarms

The radiation alarms are initiated by the applicable controller. Refer to the applicable controller manual.

3-4

Page 15

Maintenance, Calibration and Troubleshooting

Maintenance

4

Section 4

Maintenance, Calibration and Troubleshooting

4.1 Maintenance

The 943-27-15 Detector is designed to operate for extended periods of time with no scheduled

maintenance required. Operation may be verified by periodically actuating the check source (provided

with the detector and sampling assembly) and observing the response of the unit. If the response varies

by more than 50% of the normal value, further troubleshooting may be required. If a problem develops,

troubleshoot the unit per Section 4.3 and the drawings in Appendix B.

Periodically, approximately every 18 months, it is suggested that the detector be re-calibrated.

4.2 Calibration

Electronic Adjustments

There are no user adjustments available on the 943-27 Detector. The detector high voltage is determined

during calibration and is provided by the associated readout/controller.

Point source Calibration

WARNING

The calibration procedures require the use of high activity

beta emitting button sources. These sources are intended

solely to provide a beta radiation field. They should be

used only by persons who have been trained in the

appropriate safety procedures to be followed in the

presence of beta radiation and the proper interpretation of

the data. Notify the plant Health Physicist prior to the use

of these sources.

SPECIAL NOTE

Due to the activity of these sources, possession of these

sources requires a USNRC Byproduct Material License or

Agreement State License, as defined in Title 10 of the

Code of Federal Regulations.

4-1

Page 16

943-27 Beta Scintillation Detector

Operator Manual

Source and Source Holder Description

WARNING

USE PRECAUTIONS FOR HANDLING

RADIOACTIVE MATERIAL SOURCES

WARNING

HANDLE WITH CAUTION

WARNING

”HIGH BETA RADIATION FIELDS”

Handle the sources with caution.

Direct the open end of the source holder away from personnel.

DO NOT Look at the Open Source.

Wear safety glasses.

DO NOT touch the source window.

DO NOT remove the large end of the holder. It contains the source.

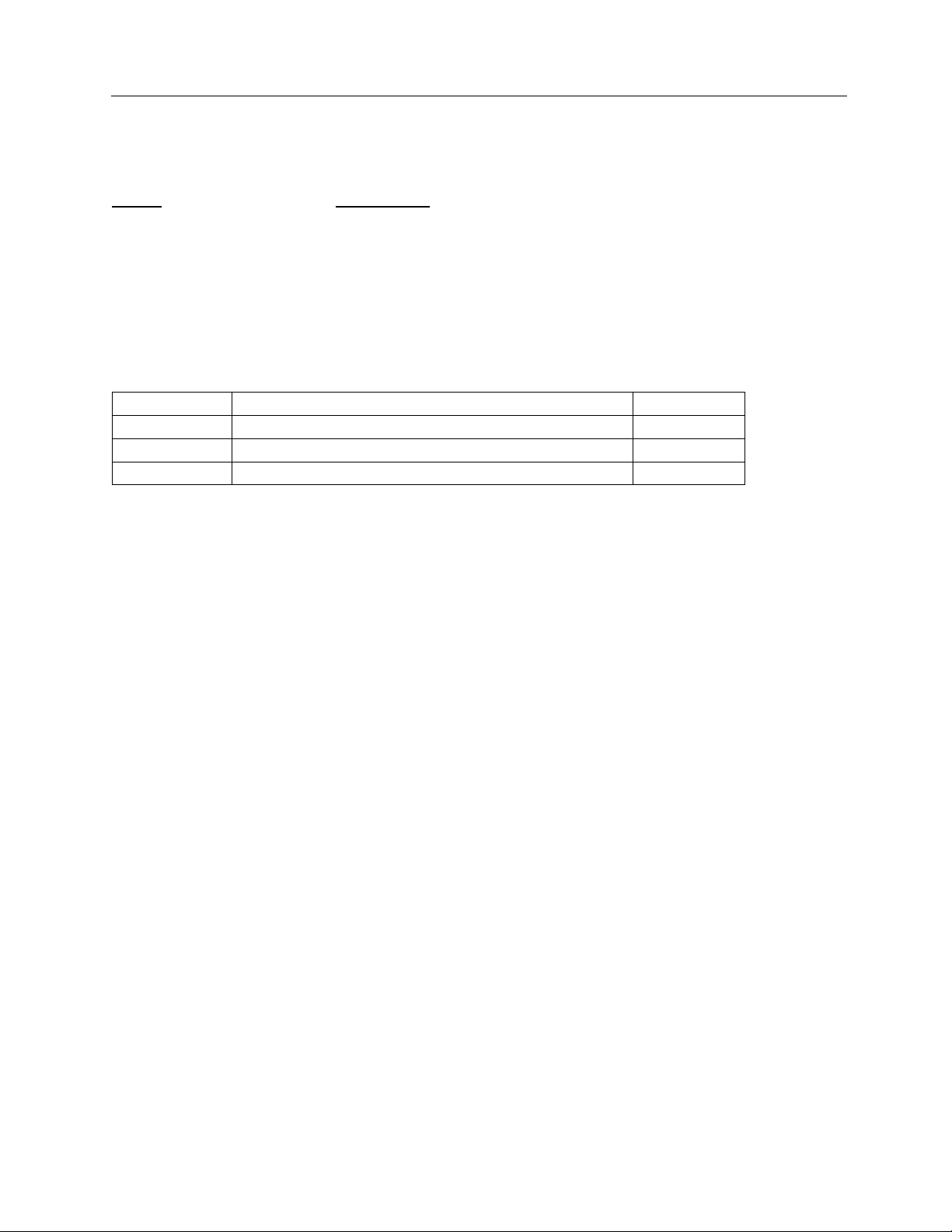

Table 4-1. Current Mode Beta Detector Calibration Source Set

Part Number: Isotope: Activity, microCuries

844-130-1-12

844-130-1-13

844-130-1-14

Refer to figure 4-1 for a pictorial view of the source holder assembly. The source holder

consists of the following components:

Shielding: The source is housed in an Aluminum cylinder, 2.5-inch diameter x 4.5inch length. The source is sealed in one end of the cylinder. Refer to drawing844131-1-TAB, included in Appendix A.

90

Sr

137

Cs

36

Cl

CAUTION

200

200

200

4-2

The activity of the sources are a nominal 200

microCuries. The cesium source holder has no lead

shielding and readings on the surface of the holder are

approximately 25 mR/hr (0.25 mGy/hr). Consult the

local Health Physicist for precautions that must be

followed when handling the sources.

Page 17

Maintenance, Calibration and Troubleshooting

Calibration

Source: The activity is deposited on a 40 mm diameter Whatman #1 qualitative filter paper that is

bonded to a 0.51 mm thick stainless steel disc. The disc is sealed with a 2-mil Kapton window and

sealed into an aluminum mount. The overall dimensions on the source disc are 3.2 mm in height

and 47 mm in diameter

.

Calibration: To calibrate the detector, the small end cap on the source holder is removed,

exposing the internal radioactive source.

WARNING

”HIGH BETA RADIATION FIELDS”

Handle the sources with caution.

Direct the open end of the source holder away from personnel.

DO NOT Look at the Open Source.

Wear safety glasses.

DO NOT touch the source window.

Follow the following precautions when handling the source holder:

1. Remember that high Beta radiation fields exist when the end cap is

removed

2. Direct the open end of the source holder away from people.

3. Do not look directly into the end of the open source holder.

4. Wear safety glasses when using the source.

5. Do Not Touch the source window. The thin window is easily

punctured, directly exposing the source material.

6. The U.S. Nuclear Regulatory Commission requires a leak test of the

source every six (6) months.

7. The large end cap of the holder contains the radioactive source

capsule. DO NOT REMOVE.

4

4-3

Page 18

943-27 Beta Scintillation Detector

Operator Manual

Figure 4-1 Source Holder Assembly and Operation

4-4

Page 19

Maintenance, Calibration and Troubleshooting

Calibration

4

Source Wipe Test

Due to the amount of activity in each source, the Current Mode Beta source set requires a USNRC or

Agreement State Byproduct Material license. To guard against leaks of radioactive material, or possible

contamination, the regulatory agency generally requires a wipe test be performed at an interval not to

exceed six (6) months for each source.

WARNING

The wipe test of the source is made with the end cap

removed. Any part of the body in front of the open

source may be exposed to high radiation fields. Do

not test quickly to minimize exposure. Direct the open

end away from personnel and wear safety glasses.

The activity is covered with a 2 mil Kapton window and

is sealed into the aluminum mount. DO NOT TOUCH

the source window with anything, including the wipes.

Wipe Test Procedure:

1. Procure a long handled Q-tip type cotton swab and moisten it with alcohol.

2. Remove the small end cap. Direct the open end away from any personnel.

WARNING

Do not swab the source window. It is a 2-mil Kapton window

that may easily be broken.

3. Holding the swab, quickly swab the internal surface of the cylinder.

4. Replace the small end cap. Return the holder to storage.

5. Measure the swab using a detector capable of detecting 0.005 microCuries or

less and record the data.

6. If more than 0.005 microCuries of activity is detected, notify the cognizant plant

Radiation Safety Officer or Health Physicist.

4-5

Page 20

943-27 Beta Scintillation Detector

Operator Manual

Source Holder Data Sheet:

The following summarizes the data provided with the source holders:

CURRENT MODE BETA SOURCE SET

P/N 844-130-1-12

P/N 844-130-1-13

P/N 844-130-1-14

USE PRECAUTIONS FOR HANDLING SOURCES

RADIOACTIVE MATERIAL

90

137

36

Sr

Cs

Cl

WARNING: HANDLE WITH CAUTION

HIGH BETA RADIATION FIELDS EXIST WHEN END CAP IS REMOVED

DIRECT THE OPEN SOURCE AWAY FROM PEOPLE

WEAR SAFETY GLASSES WHEN USING THE SOURCES

DO NOT TOUCH THE SOURCE WINDOW – THE THIN WINDOW WILL

PUNCTURE EASILY

U. S. NUCLEAR REGULATORY COMMISSION REQUIRES SIX MONTH LEAK TESTING

NOTICE: THE LARGE END CAP CONTAINS THE RADIOACTIVE SOURCE

CAPSULE

DO NOT REMOVE

PART

NUMBER

844-130-1-12 XXXX XXXX

SERIAL

NUMBER,

FLUKE

SERIAL

NUMBER,

MANUFACTURER

RADIOACTIVE

MATERIAL

90

Sr

ACTIVITY,

microcuries

200 XX/XX/XX

DATE OF

MEASUREMENT

844-130-1-13 XXXX XXXX

844-130-1-14 XXXX XXXX

137

36

Cs

Cl

200 XX/XX/XX

200 XX/XX/XX

Detector Calibration Procedure

The following procedure is recommended to assure an accurate calibration of the Model 943-27 Current

Mode Beta scintillation detector.

Equipment Required:

1. Detector to be calibrated

2. Electronics to be used with the detector

3. Calibration sources P/N 844-130-1-12, 844-1-130-1-13 and 844-1 30-1-14.

4. Data Sheet: The data sheets are used to delineate the minimum recording requirements. The

baseline calibration data is supplied at the time of installation. Record all identification

information on the data sheet prior to doing any measurements. The expected calibration

values must be corrected for decay prior to doing the calibration. Refer to the calibration

procedures in Appendix B for sample data sheets.

4-6

Page 21

Maintenance, Calibration and Troubleshooting

Calibration

Detector Leakage:

1. With the detector connected to the readout device, apply power and allow a 15-minute warmup.

2. Record the readout with no radiation sources present. The maximum background current is

approximately 4.0 x 10

3. Expose the window of the detector directly to light. Read detector leakage. There should be

little difference between this and the previous reading. If there is a significant increase in

readings, the detector window has a light leak and must be repaired before p roceeding.

Calibration Source Measurements, General:

1. Remove the detector from the sampling geometry and note the background radiation reading.

In a normal background environment, the background should be less than 4.0 x 10

If the background is greater than this, the detector should be replaced. Record the ambient

background radiation value.

-11

amps.

-11

WARNING

The following procedure exposes the operator to beta

radiation. Safety glasses must be worn and the amount

of “line of sight” exposure time must be minimized.

2. Remove the source holder end cap. This is the smaller of the two end caps.

3. Insert the detector into the P/N 844-211-1-13,

4. With the source in place, allow approximately two minutes for the reading to stabilize. Record

the reading displayed on the readout device. The reading should yield a net value , within +/2%, of the decay corrected, background subtracted target value provided on the original

calibration data sheet. If the reading is not within +/- 2%, the high voltage may be increased or

decreased as necessary. Once +/-2% agreement is reached, NO FURTHER ADJUSTMENTS

of the high voltage are permitted.

5. Remove the detector from the source holder and re-install the end cap.

6. Re-run the background measurement. The background should remain less than 4.0 x 10

amperes

7. Repeat steps 2 through 5 using the remaining two sources. The reading should yield a net

value, within +/- 6%, of the decay corrected, background subtracted target value provided on

the original calibration data sheet.

Calibration Source Measurements, using Model 960 Digital Radiation Monitoring System:

1. Select the Display Option on the 960 front panel keypad that converts the display units to

raw output from the detector (in amperes).

2. Remove the detector from the sampler.

3. Decay to the present day the “net current” value printed on the calibration data sheet,

under the heading of customer sources, for the Cesium-137 source.

137

Cs reference source.

WARNING

4

amperes.

-11

The following procedure exposes the operator to beta

radiation. Safety glasses must be worn and the amount

of “line of sight” exposure time must be minimized.

4. Remove the cap marked “Removing this cap will expose user to beta radiation”.

5. Place the Cesium-137 source assembly on the ground with the open side up.

6. Insert the detector into the source assembly.

4-7

Page 22

943-27 Beta Scintillation Detector

Operator Manual

7. Wait a minimum of 1 minute, and then observe the 960 display. Compare the value

displayed to the calculated value in step 3 above. The observed value must be within +/2% of the calculated value.

8. If the value is within the required tolerance, proceed to step 10.

9. If the value is not within the required tolerance, adjust the scaler high voltage (96SF, R8)

until the observed value falls within the required tolerance. If the observed value is too

low, increase the high voltage. If the observed value is too high, decrease the high

voltage.

DO NOT adjust the high voltage after this point

10. Remove the detector from the source holder and lay it on the ground. Replace the end

cap on the source holder.

11. Wait 5 minutes, and then observe the 960 display. The displayed value is the

background current for this detector. The value must be less than 4.0 x 10

greater than 4.0 x 10

replacement.

12. Decay to the present day the “net current” value printed on the calibration data sheet,

under the heading of customer sources, for the Strontium-90 source.

13. Remove the cap from the Strontium-90 source holder. Place the source holder on the

ground. Insert the detector into the holder.

14. Wait a minimum of 1 minute, and then observe the 960 display. Compare the value

displayed to the calculated value in step 12 above. The observed value must be within

+/-6% of the calculated value.

15. Remove the detector from the source holder and lay it on the ground. Replace the end

cap on the source holder.

16. Decay to the present day the “net current” value printed on the calibration data sheet,

under the heading of customer sources, for the Chlorine-36 source.

17. Remove the cap from the Chlorine-36 source holder. Place the source holder on the

ground. Insert the detector into the holder.

18. Wait a minimum of 1 minute, and then observe the 960 display. Compare the value

displayed to the calculated value in step 16 above. The observed value must be within

+/-6% of the calculated value.

19. Remove the detector from the source holder and lay it on the ground. Replace the end

cap on the source holder.

20. If all 4 values fall within the required tolerances, the detector is calibrated. Record the

values obtained as well as the detector high voltage. The high voltage may be measured

at the 1000:1 test jack on the 960 front panel.

21. If any of the 4 values does not fall within the required tolerances, return the detector for

repair or replacement.

22. Re-install the detector into the sampler.

23. This concludes the field detector calibration procedure.

NOTE

-11

amperes, the det4ector should be returned for repair or

-11

amperes. If

4-8

Page 23

Maintenance, Calibration and Troubleshooting

Troubleshooting

4

4.3 Troubleshooting

WARNING

Extreme care must be used when troubleshooting a

system that has power applied. All standard

troubleshooting precautions apply.

WARNING

Once a problem has been located, remove all power

before continuing with the repair.

CAUTION

Personnel performing the troubleshooting/repair

must be qualified to ANSI 45.2.6, 1978, Skill Level II.

Personnel performing the following procedure must

be familiar with the operation of the monitoring

system and the location of each piece of equipment

used in the system.

If a problem develops, verify that the voltages at connection point inputs and outputs are present and that

all wiring is secure. Refer to Appendix B and C for drawings and parts lists. If a PROM requires

replacement, specify the board revision level when ordering the part.

Troubleshooting / Adjustments

Troubleshooting includes a verification of detector response by actuating the radioactive check source

and verification of the high voltage value. The check source is actuated from the associated

readout/controller. The high voltage may be measured at the connection point in the digital preamplifier

enclosure.

Specialized test equipment and firmware are required to adjust the auto-zero and PGA subsystems in the

electrometer. If the test equipment and firmware is not available, the unit should be returned to Fluke

Biomedical RMS for re-alignment.

4-9

Page 24

(Blank Page)

Page 25

Connector Designations

A.1 CONNECTOR DESIGNATIONS, 943-27

Table A-1 Field Electrical Connections, 943-27

943-27

Connects To

Cable Description

High Voltage, 6 Ft

HV

SIG

Coaxial Cable with

SHV Connector

Signal, 6 Ft Coaxial

Cable with BNC

Connector

943-227-15 or

943-227-15VL

HV

SIG

Appendix A

Connector Designations

Appendix A

A

A-1

Page 26

(Blank page)

Page 27

Appendix

Applicable Drawings

Appendix B

Applicable Drawings

B.1 Applicable Drawings, 943-27

Drawing No. Description

GEL-943-27 Dimensional Drawing

943-27-31 Detector Assembly

943-27-32 Detector Socket Assembly

844-130-1-TAB Source Holder Assembly

B.2 Related Manuals (Not Supplied with this document)

B

SXXXXXX-1 Applicable 960 Series system Manual

942A-200C-M1 Digital Ratemeter

943-227-15-1 Digital Preamplifier Manual

B.3 Related Calibration Reports

(Not supplied with this document)

The available detector calibration procedures and primary isotopic calibration reports

applicable to the detector are listed below. The calibration reports each describe a

different sampling geometry. Copies of these procedures are available from Fluke

Biomedical RMS Customer Service Department at (440) 498-2564.

Reference Procedures:

Document Number: Description:

CAL- BETA2 943-27-31 Beta Scintillation Detector Factory Calibration Procedure,

300cc and other

CAL- BETA3 943-27-31 Beta Scintillation Detector Factory Calibration Procedure,

11cc only

B-1

Page 28

943-27 Beta Scintillation Detector

Operator Manual

Reference Primary Calibration Reports (not included in this manual):

958.316 Primary Isotopic Calibration for 300cc Offline Gas monitor with 943-27

Current Mode Beta Scintillation Detector

958.323 Linearity Test Report, Current Mode Beta Scintillation Detector

958.350 Primary Isotopic Calibration for 11cc Offline Gas monitor with 943-27

Current Mode Beta Scintillation Detector

958.401 Primary Isotopic Calibration an In-line Accident Range Noble Gas

Monitor with 943-27 Current Mode Beta Scintillation Detector

958.405 Primary Isotopic Calibration for Model 940-513, 11cc Offline Sampler

with 943-27 Current Mode Beta Scintillation Detector

958.407 Primary Isotopic Calibration for Model 940-483EH with 943-27 Current

Mode Beta Scintillation Detector

B-2

Page 29

C.1 Bill of Materials, 943-27

Part Number Description

943-27-31 Detector Assembly

943-27-32 Socket Assembly

844-130-1-TAB Source Holder Assembly

Appendix

Bill of Materials

C

Appendix C

Bill of Materials

C-1

Page 30

(Blank page)

C-

2

Page 31

Appendix

Cable Termination Instructions

Appendix D

Cable Termination Instructions

D.1 Cable Termination Instructions

The cables provided with the Model 943-27 Detector are factory pre-terminated.

D

D-1

Page 32

(Blank page)

D-

2

Page 33

Appendix E

Modification Sheets, Engineering Instructions

E.1 Modification Sheets, Engineering Instructions

P/N Description

943-27 None

Appendix

Modifications

E

1

E-

Page 34

(Blank page)

Page 35

(Blank page)

Page 36

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Loading...

Loading...