Page 1

Off-Line Sampler

Model 940-513,

11cc Volume

Installation and Operation Manual

April, 2006, P/N 940-513-1, Rev. 2

©2006 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Page 3

Model 940-513

Operators Manual

Table of Contents

Section 1: General Information................................................................................... 1-1

1.1 Product Description................................................................................................................ 1-1

1.2 Specifications ......................................................................................................................... 1-1

1.3 Features and Benefits............................................................................................................ 1-3

1.4 Safety Precautions and Terms............................................................................................... 1-3

1.5 Product Handling and Storage............................................................................................... 1-4

1.6 Accessories............................................................................................................................ 1-4

1.7 Customer Service/Technical Assistance................................................................................ 1-5

1.8 Manual Addenda.................................................................................................................... 1-5

Section 2: Theory of Operation................................................................................ 2-1

2.1 Functional Description............................................................................................................ 2-1

Section 3: Operation.................................................................................................... 3-1

3.1 Installation ............................................................................................................................. 3-1

3.2 Operator Interface Functions ................................................................................................. 3-2

3.3 Accessories............................................................................................................................ 3-2

3.4 Preoperational Checks........................................................................................................... 3-2

Section 4: Maintenance and Calibration .................................................................... 4-1

4.1 Maintenance........................................................................................................................... 4-1

4.2 Calibration .............................................................................................................................. 4-1

Section 5: Troubleshooting ........................................................................................ 5-1

5.1 Troubleshooting ..................................................................................................................... 5-1

5.2 Start-up Test .......................................................................................................................... 5-1

5.3 Periodic Manual Test ............................................................................................................. 5-1

5.4 Recommended Spare Parts................................................................................................... 5-1

5.5 Return Authorization .............................................................................................................. 5-2

Appendix A: Applicable Drawings..................................................................................A-1

A.1 Applicable Drawings...............................................................................................................A-1

Appendix B: Bill of Materials .......................................................................................... B-1

B.1 Bill of Materials.......................................................................................................................B-1

Appendix C: Cable Termination Instructions ................................................................C-1

C.1 Cable Termination Instructions ....................................................................C-1

Appendix D: Supplemental Data (Customer Specific)..................................................D-1

D.1 Supplemental Data (Customer Specific)...................................................... D-1

Page 4

Model 940-513

Operators Manual

This Page is Intentionally Left Blank

Page 5

Model 940-513

Operators Manual

Section 1

General Information

1.1 Product Description

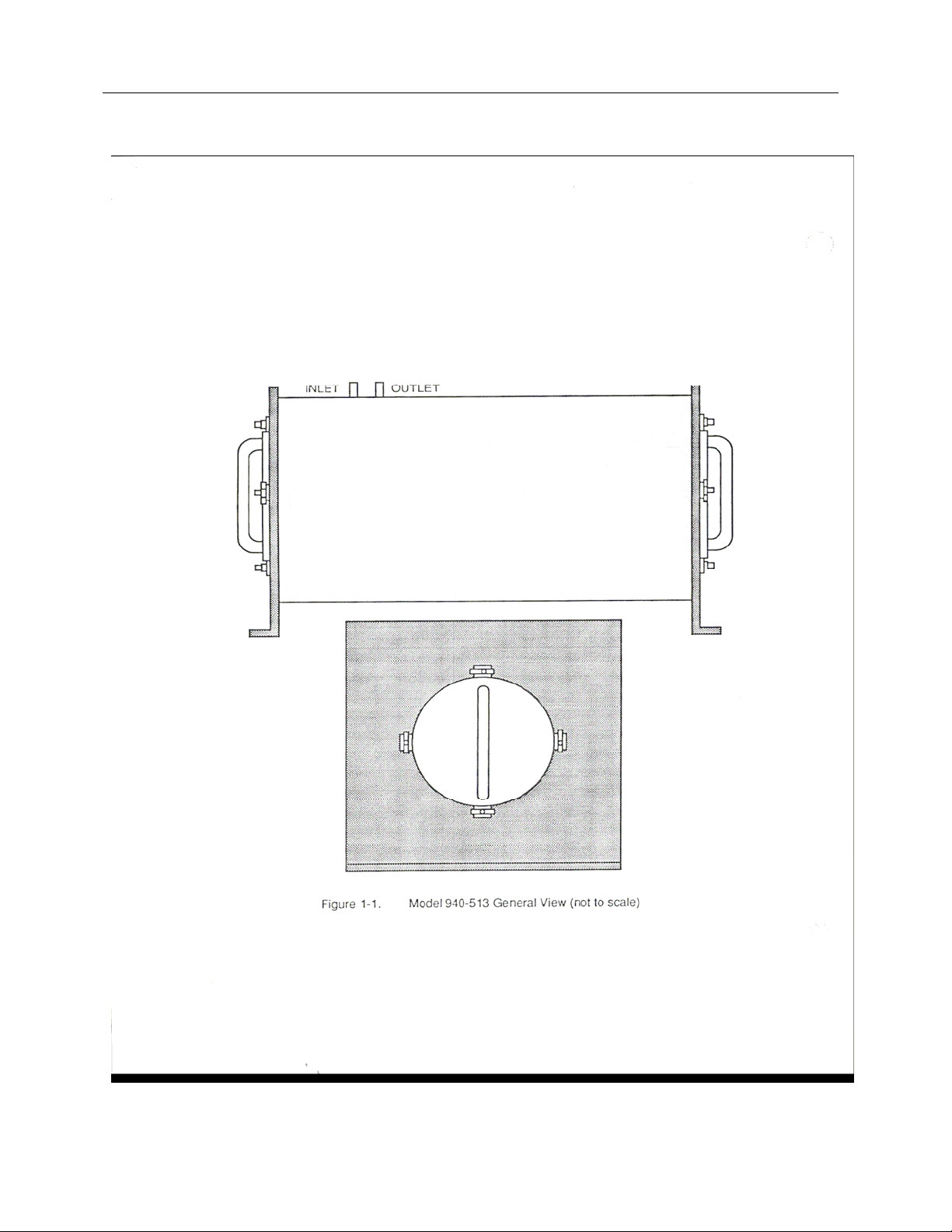

This manual outlines the procedures required for installation, operation and maintenance of the Model

940-515 Off-Line Sampler. The Model 940-513 is an off-line, single channel sampler suitable for

monitoring accident range radioactive gases. The sampler is only used with the Model 943-27-31

Current Mode Beta Scintillation Detector and radioactive check source part number 841A-123-50. The

Model 943-27-31 detector and 841A-123-50 check source are described in separate manuals. Refer to

Figure 1-1 for a general view of the sampler and Appendix A for assembly and dimensional drawings.

The sampler consists of a weldment, a detector end cap and a Gas chamber end cap. The sampler

weldment provides three (3) inches of 4 pi lead shielding around a sensitive volume and provides

inlet/outlet connections to the ample volume. Tube stubs with a ¼ inch OD are provided for connecting

the sample volume to other sampling system components (e.g. a vacuum pump, inlet filters, isolation

valves, etc.).

The detector end cap provides a means to remove and install the detector and to shield the rear of the

detector from ambient background radiation.

The Gas chamber cap provides access to the sample volume for cleaning and shields the sample volume

from ambient background radiation. The Gas chamber cap also houses the solenoid assembly used to

position a radioactive check source in view of the beta sensitive scintillation detector. The radioactive

check source available is a 100 microCurie Strontium 90 source capsule.

The Gas chamber plug is attached to the Gas chamber cap. The Gas chamber plug provides a pressure

tight seal (10 psig) for the sample volume and provided access to the sample volume for cleaning or

decontamination.

1.2 Specifications:

The following technical specifications apply to the Model 940-513 Sampler:

Dimensions ( H x W x L):

Weight: Approximately 500 lbs (227 kg)

Shielding: 4 pi, 3 in Lead

Inlet Diameter: ¼ inch O.D. Stn Stl tubing

Outlet Diameter: ¼ inch O.D. Stn Stl tubing

Effective Chamber Volume: Approximately 11cc

Pressure Limit: 10 psig

High Voltage Cable: Detector High Voltage cable exits the detector cap

Signal Voltage Cable: Detector Signal Voltage cable exits the detector cap

Check Source: A 100 microCurie, Sr-90 source and rotary solenoid are

11.5 x 11.5 x 21 inches

(29.2 x 29.2 x 53.3 cm)

assembly for termination at the detector preamplifier

assembly for termination at the detector preamplifier

located in the Gas chamber cap. Entry for the solenoid

control wiring is provided via a ½ in NPT threaded port

in the gas chamber cap.

1-1

Page 6

Model 940-513

Operators Manual

1-2

Page 7

Model 940-513

Operators Manual

1-3

Page 8

Model 940-513

Operators Manual

1.3 Features and Benefits

The Model 940-513 Series Sampler, provides the following features:

• Measurement of accident range noble gasses

• Integral Sr-90 Check Source

• Quad-lobed O-ring sealed detector

• O-ring sealed sample chamber

The design of the Model 1060AM-NM3-XX Controller provides the following User benefits:

• 4 pi shielded sample volume

• 3 inches of lead shielding

• Removable end caps for cleaning

• Rotary Check Source mechanism to minimize background contribution

1.4 Safety Precautions and Terms

The Model 940-513 sampler includes a rotary solenoid inside of the Gas Chamber cap, and voltages up

to 125 VDC may be present when the solenoid is actuated. Turn OFF the AC power on the associated

Local Control unit prior to removing the Gas Chamber Cap.

Model 940-513 sampler also includes a 100 microCurie Sr-90 radioactive source located within the Gas

Chamber Cap. The local plant Health Physist should be consulted prior to removing the Gas Chamber

cap.

The Model 940-513 is an accident noble gas monitor, and radioactive gasses may be present within the

sample volume. The local plant Health Physist should be consulted prior to removing the Gas Chamber

cap or Detector End cap to access the sample volume.

CAUTION

CAUTION

1-4

Page 9

Model 940-513

Operators Manual

1.5 Product Handling and Storage

1.5.1 Receiving Inspection:

Upon receipt of the unit:

Inspect the carton(s) and contents for damage. If damage is evident, file a claim with the carrier and

notify the FLUKE Biomedical Radiation Management Services Customer Service Department.

FLUKE Biomedical

Radiation Management Services

6045 Cochran Rd.

Cleveland, Ohio 44139

Phone: 440.248.9300, Fax: 440.542.3682

Remove the contents from the packing material.

Verify that all items listed on the packing list have been received and are in good condition.

NOTE

If any of the listed items are missing or damaged, notify the

FLUKE Biomedical, Radiation Management Services Customer

Service Department.

1.5.2 Storage:

Instruments storage must comply with Level B storage requirements as outlined in ANSI N45.2.2 (1972)

Section 6.1.2(.2). The storage area shall comply with ANSI N45.2.2 (1972) Section 6.2 Storage Area,

Paragraphs 6.2.1 through 6.2.5. Housekeeping shall conform to ANSI N45.2.3 (1972).

Level B components shall be stored within a fire resistant, tear resistant, weather tight enclosure, in a

well-ventilated building or equivalent.

Instruments storage must comply with the following:

Inspection and examination of items in storage must be in accordance with ANSI N45.2.2 (1972) Section

6.4.1.

Requirements for proper storage must be documented and written procedures or instructions must be

established.

In the event of fire, post-fire evaluation must be in accordance with ANSI N45.2.2 (1972), Section 6.4.3.

Removal of items from storage must be in accordance with ANSI N45.2.2 (1972), Sections 6.5 and 6.6.

1.6 Accessories

Optional accessories available for the Model 940-513 include the following:

Detector: Model 943-27-31 Current Mode Beta Scintillation Detector

Recommended Spare Parts are identified in Section 5.4. Replacement parts are identified in the Product

Bill of Materials provided in Appendix B.

1-5

Page 10

Model 940-513

Operators Manual

1.7 Customer Service/Technical Assistance

For Technical Assistance with this product, contact FLUKE Biomedical Radiation Management Services

Customer Service Department. At the following address:

FLUKE Biomedical

Radiation Management Services

6045 Cochran Rd.

Cleveland, Ohio 44139

Phone: 440.248.9300

Fax: 440.542.3682

1.8 Manual Addenda

Manual Addenda sheets are provided separately with the equipment at the time of shipment.

1-6

Page 11

Theory of Operation

Functional Description

2

Section 2

Theory of Operation

2.1 Functional Description

The Model 940-513 is an off-line, single channel sampler suitable for monitoring accident range

radioactive gases. The sampler is only used with the Model 943-27-31 Current Mode Beta Scintillation

Detector and radioactive check source part number 841A-123-50. The Model 943-27-31 detector and

841A-123-50 check source are described in separate manuals. Refer to Figure 1-1 for a general view of

the sampler and Appendix A for assembly and dimensional drawings.

Once the detector is inserted into the sampler and calibrated, operation is automatic. Refer to the

Instruction Manual for the Model 943-27-31 Detector for calibration information.

2-1

Page 12

Theory of Operation

Functional Description

2

This Page is Intentionally Left Blank

2-2

Page 13

Operation

Installation and Set-up

Section 3

Installation and Set-up

3.1 Installation

The following materials are needed to remove or install the Model 943-27-31 detector into the Model 940-513 Sampler:

1, 943-27-31 detector to be installed

3

Detector mounting hardware:

1, P/N 943-27-47, Detector Mounting Flange

1, P/N 46-103, Quad lobed seal (Detector mounting flange to Adapter flange) O-Ring Lubricant, Dow Corning #55, or equivalent 6, P/N 5-1026, 10-32x0.5 Socket head cap screws, Stn Stl 1, P/N 943-27-48, Adaptor Flange

1. P/N 46-104, Quad lobed seal (Adapter flange to sampler body) 6, P/N 5-994, 10-24x0.75 Socket head cap screws, Stn Stl 6, P/N 5-795, #10 split washes, Stn Stl 1, 5/32 Hex head bit or T-handle tool

1, Dial Caliper with depth gage, 6 inch 1, Marking pen or pencil

3.1.1 Mounting

Due to the potential for high activity radioactive

gasses in or around the vicinity of the detector,

protective Clothing should be worn while installing or

removing the detector,

Proper installation of the Model 943-27-31 Detector requires inserting the detector into the sample volume

until it stops against the Gas Chamber plug, inside the sampler. Once the detector has been fully

inserted, the detector is then withdrawn a distance of 0.25 inches. This will replicate the installation

method used during the sampler’s primary isotopic calibration, and the efficiency documented in the

primary isotopic calibration report 958.350. The following procedure is recommended to obtain the

required 0.25 inch detector withdrawal distance.

WARNING

3.1.1.1 Turn OFF the high voltage power supply for the detector by turning the controlling Local Control Unit power OFF.

3.1.1.2 Remove the two (2) Thumb Screws and flat washers retaining the P/N 841A-123-16 Detector Plug and remove the plug. Retain the parts removed for future re-installation.

3.1.1.3 Loosen the six (6), 10-32 x 0.5 in detector flange mounting screws that provide a pressure retaining seal between the detector and the detector mounting flange.

3-1

Page 14

Operation

Installation and Set-up

NOTE:

The potential exists for radioactive gas to be present

within the sample volume. It is recommended that

this procedure be reviewed by the local plant Health

Physist

3.1.1.4 Gently push the detector forward, until the detector end cap stops against the internal

Gas Chamber Cap. The Gas Chamber Cap, P/N 940-513-11, is located on the opposite

end of the sampler, inside of the sampler and attached to the P/N 841A-123-5 Filter Plug

and Solenoid assembly, and defines the outer edge of the sample volume.

3.1.1.5 Tighten the six (6) detector flange mounting screws that were loosened in above.

3.1.1.6 Loosen and remove the six (6), 10-24 x 0.75 in socket head cap screws that retain the adapter flange to the sampler body. Carefully remove the detector and mounting flange assembly.

3.1.1.7 With the detector and mounting flanges removed, draw a line on the detector body,

adjacent to the detector mounting flange, on the side of the detector mounting flange

facing the connector end of the detector. This will indicate the position of the detector

when fully inserted.

3.1.1.8 Loosen the six (6), 10-32 x 0.5 in detector flange mounting screws, the screws that retain the detector to the detector mounting flange.

3

3.1.1.9 If the detector has not been replaced for over 18 months, the detector mounting flange

should be removed, and the 46-103 Quad lobed seal should be inspected for wear or

damage. If the seal is worn, it should be replaced at this time. When replacing the seal,

the new seal should be lubricated with O-ring lubricant, Dow Corning #55, or equivalent,

and the detector mounting flange loosely re-installed

3.1.1.10 With the detector mounting flange mounting screws loosened, slide the detector

mounting flange forward, toward the sensitive end of the detector, until the distance

between the mark applied above and the detector mounting flange is 0.25 inches. Retighten the six (6) detector mounting screws to lock the detector and mounting flange

assembly in position (i.e.with the detector withdrawn 0.25 inches from the Gas Chamber

cap, when re-installed, providing a sensitive volume of approximately 11cc’s).

3.1.1.11 Using the caliper, recheck the distance between the line marked on the detector body,

the fully inserted position, and the detector mounting flange. This distance must be 0.25

inches to ensure the efficiency obtained in the primary isotopic calibration will be realized

in operation.

3.1.1.12 If the detector has not been replaced for over 18 months, the 46-104 Quad lobed seal

that seals the adaptor mounting flange to the sampler body should be removed and

inspected for wear or damage. If the seal is worn, it should be replaced at this time.

When replacing the seal, the new seal should be lubricated with pneumatic grease, Dow

Corning #55, or equivalent, and the Quad lobed seal re-installed

3.1.1.13 Carefully re-insert the detector assembly into the sampler body.

3.1.1.14 Install and tighten the six (6), 10-24 x 0.75 in socket head cap screws and split lock washers that retain the detector assembly to the sampler body.

3.1.1.15 Again, using the caliper, measure the distance from the cable end of the detector to the

rear face of the detector mounting flange. Record this distance on the Data Sheet

provided. This dimension may be used in the future to verify the installed detector

position.

3-2

Page 15

Operation

Installation and Set-up

3.1.1.16 Re-install the P/N 841A-123-16 Detector Cap, the two (2) Thumb screws and the two (2) flat washers. This completes the detector withdrawal adjustment and detector installation.

3.1.1.17 To complete the re-installation, the system should be pressure tested prior to returning the unit to service. The maximum system pressure is 10 psig.

3.1.1.18 This will complete the installation

3

3.1.2 Electrical Interface

The electrical interface with the Model 940-513 Sampler includes connecting the associated Model 94327-31 detector High Voltage and Signal coaxial cables to their associated preamplifier junction box and

interconnecting the P/N 841A-123-50 Rotary Check source assembly control wiring to its associated

Local Control Unit. Refer to the system level drawings supplied with the sampler for specific

interconnecting wiring requirements

3.1.3 Setup

Other than the detector installation described above, there are no Setup requirements associated with the

Model 940-513 Sampler. Refer to the associated Local Control Unit for Detector and Check Source

operation.

3.2 Operator Interface Functions

There are no operator interface functions associated with the Model 940-513 Sampler. Refer to the

associated Local Control Unit for Detector and Check Source operation.

3.3 Accessories

Optional accessories available for the Model 940-513 include the following:

Detector: Model 943-27-31 Current Mode Beta Scintillation Detector

3.4 Preoperational Checks

Prior to operating the unit, the sampler should be subjected to a pressure test at a maximum value of 10 psig.

3-3

Page 16

Operation

Installation and Set-up

This Page is Intentionally Left Blank

3

3-4

Page 17

Maintenance and Calibration

Maintenance

4

Section 4

Maintenance and Calibration

4.1 Maintenance

The Model 940-513 Sampler is designed to operate for extended periods of time with no scheduled

maintenance required. However, periodic inspections may be performed to verify system integrity has not

degraded. This would include the integrity of the cable connectors and the tightness of the mounting

hardware. Dust and dirt may be removed by wiping the surface of the sampler with a damp cloth.

If a maintenance question arises, please contact the FLUKE

Biomedical Radiation Management Services Customer Service

Department at (440) 248-9300 for assistance.

NOTE

4.2 Calibration

The Model 940-513 Sampler is designed for use with the Model 943-27-31 Detector. Refer to the Model

943-27-31 Instruction Manual for detector calibration instructions.

4-1

Page 18

Victoreen 940-513

Operators Manual

This Page is Intentionally Left Blank

4-2

Page 19

Troubleshooting

Troubleshooting

5

Section 5

Troubleshooting

5.1 Troubleshooting

The Model 940-513 is designed to maintain a positive pressure of 10 psig. Troubleshooting for the Model

940-513 include locating pressure leaks, if any, and operation of the check source solenoid.

Troubleshooting procedures for the detector may be found in the Model 943-27-31 Detector Instruction

Manual.

Other that a pressure leak or a detector fault, the operation of the check source solenoid is the only other

component that may require troubleshooting. If the detector is operating properly, and there is no check

source response, the check source hold-in module, located in the associated Local Control Unit or local

Junction Box, may have failed, or the rotary solenoid may have failed. Using the applicable system level

wiring diagrams, first verify the applicable supply voltage is available. If the supply voltage is available to

the rotary solenoid, the solenoid may have failed, or a component within the assemble may have

loosened, obstructing its movement. The Gas Chamber plug will then need to be removed to

repair/replace the rotary solenoid mechanism.

A 100 microCurie Sr-90 Source Capsule is mounted to

the rotary solenoid. Contact the local plant Health

Physist prior to opening the check source assembly

and handling the check source.

With the power to the associated Local Control Unit turned OFF, the Gas Chamber Cap may be removed

from the sampler. The Gas Chamber plug may then be removed, exposing the check source solenoid

mechanism. Being careful to not handle the Sr-90 source, movement of the rotary solenoid may be

checked. If the movement operates freely, the solenoid may need to be replaced. Refer to the drawings

in Attachment A for additional information.

5.2 Start-up Test

Prior to start-up, the integrity of the sampler should be verified. The operation of the detector check

source should be performed to verify detector operation.

5.3 Periodic Manual Test

Periodically, the pressure integrity of the sampler should be verified. This should be performed whenever

the detector is removed and re-installed. The operation of the detector check source should be

performed periodically, to verify detector operation.

5.4 Recommended Spare Parts

5-1

Page 20

Victoreen 940-513

Operators Manual

User serviceable parts in the Model 940-513 are limited to the detector o-rings and the check source

solenoid listed below:

P/N: Description:

46-14 O-ring, Gas Chamber Cap

46-103 O-ring, Quad lobed Seal, Detector Mounting Flange to detector

46-104 O-ring, Quad lobed Seal, Adaptor Disc to Sampler Weldment

S96240091 Rotary Solenoid

Replacement parts FLUKE Biomedical, Radiation Management Services.

5.5 Return Authorization

In the event it becomes necessary to return the unit for repair, contact the FLUKE Biomedical Radiation

Management Services Customer Service Department to obtain a Return Authorization number. The

return Authorization will assist us in tracking the receipt, repair and return of the device. To assist with the

repair process, the following information will be requested by our Customer Service Department:

• Model Number

• Serial Number

• Approximate Shipping Date

• Statement of the malfunction

Our Customer Service Department may be contacted at the following address:

FLUKE Biomedical

Radiation Management Services

6045 Cochran Rd.

Cleveland, Ohio 44139

Phone: 440.248.9300,

Fax: 440.542.3682

5-2

Page 21

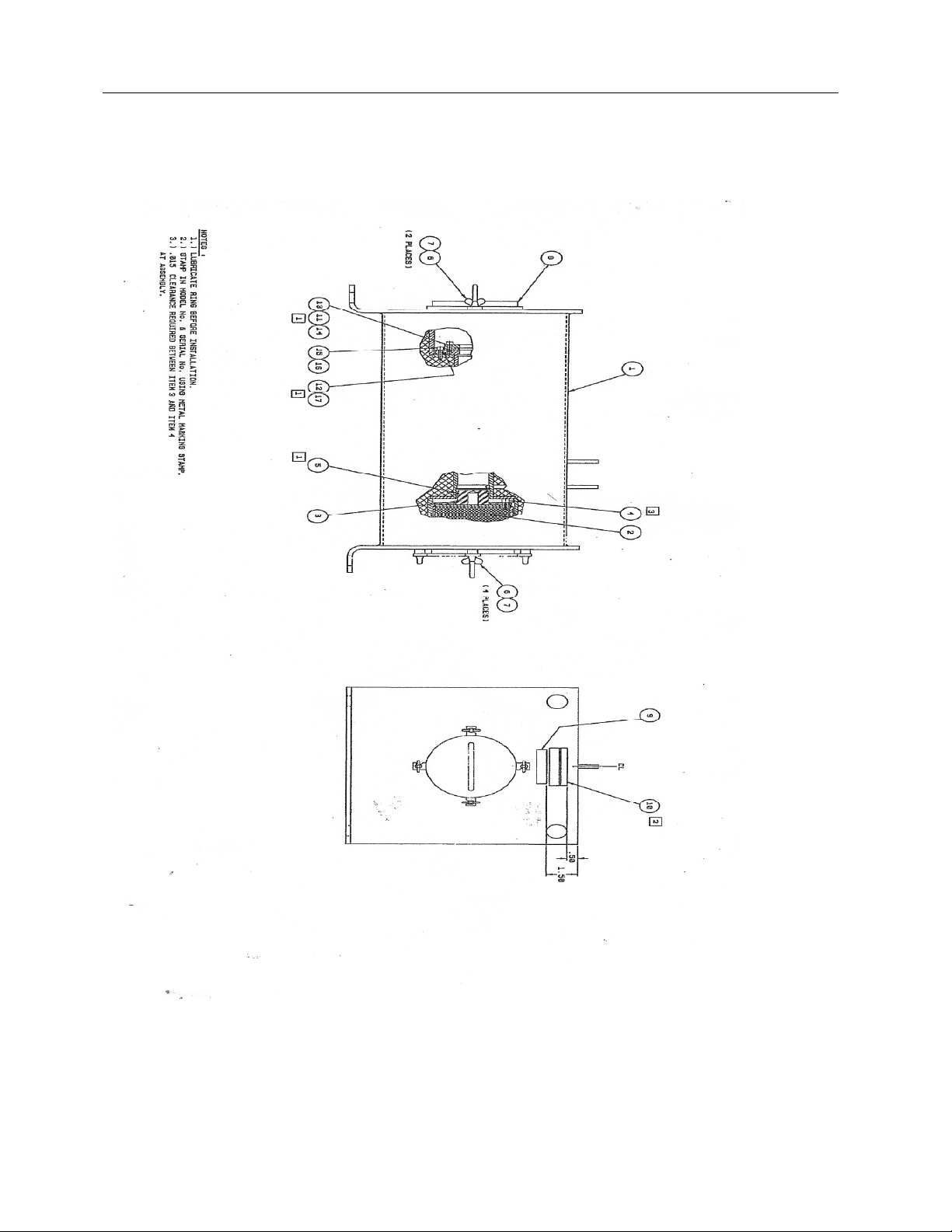

Applicable Drawings

A1 Applicable Drawings

Drawing No. Description

940-513-GEL General Arrangement/Installation Drawing

940-513-5 Main Assembly

841A-123-50 Check Source Plug Assembly

Appendix

Applicable Drawings

Appendix A

A

A-1

Page 22

Victoreen 940-513

Operators Manual

This Page is Intentionally Left Blank

A-2

Page 23

B1 Bill of Materials

Part Number Description

940-513-5 Main Assembly

841A-123-50 Check Source Plug Assembly

Appendix

Bill of Materials

B

Appendix B

Bill of Materials

B-1

Page 24

Victoreen 940-513

Operators Manual

This Page is Intentionally Left Blank

B-2

Page 25

Appendix

Supplemental Data (Customer Specific)

C

Appendix C

Supplemental Data (Customer Specific)

C1 Supplemental Data (Customer Specific)

Appendix E contains all technical information pertaining to a specific 1060AM-NM3-XX part number or

modification. The 940-513 is designed for use with the Model 943-27-31 Detector. Refer to the document

listed below for further information on the operation of the Model 943-27-31 Detector with the 940-513

Accident Range Sampler.

Document Number Description

943-27-31 Users Manual

(For Reference Only, Not Provided)

These manuals are not included in this document. To obtain a

copy of this manual, please contact the Fluke Biomedical,

Radiation Management Services Customer Service Department

at 440.248.9300 for assistance.

NOTE

C-1

Page 26

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

C-2

Loading...

Loading...