Page 1

HVAC pressure

applications with

the Fluke 922

For contractors troubleshooting pressure,

a lot depends on system peculiarities. Are

the installation instructions with the equipment? Is the start-up performance report

with them? Is the TAB (test and balance)

report available? Do you understand the

Application Note

control system? More often than not, it

seems, you can only answer yes to the

last question. You rely on your experience,

knowledge, and tools to check the fundamentals. And for that much, at least, Fluke

can help.

Pressure measurement

Pressure is measured in several different scales. Pounds

per square inch (psi), inches of

water column (in. wc), inches

of mercury column (in. hg), and

millionths of a meter of mercury

column (microns) are the most

typical in HVAC work.

Bourdon gauges are the traditional choice for higher pressure

readings in psi. Finer precision

measurements use mercury column scales. And for the most

precise measurements—and most

low pressure measurements in

HVAC—inches water column is

the standard.

The following chart compares

these common pressure scales

and their precision.

Using the Fluke 922 low pressure differential meter in a duct traverse.

F r o m t h e F l u k e D i g i t a l L i b r a r y @ w w w . f l u k e . c o m / l i b r a r y

Atmospheric Pressure 1 psi 1” hg 1” wc

14.696 psia 1 psi 0.019 psi 0.0361 psi

29.921 “ hg 2.036” hg 1” hg 0.0736” hg

406.8” wc 27.68” wc 13.595” wc 1” wc

Of the many different low

pressure measuring instruments

used over the years, electronic

manometers/micromanometers

(very low pressure gauges)

now offer durability, precision,

accuracy, and the significant

time saving convenience of fully

automatic calculations as well as

minimum-maximum-average and

memory functions.

Page 2

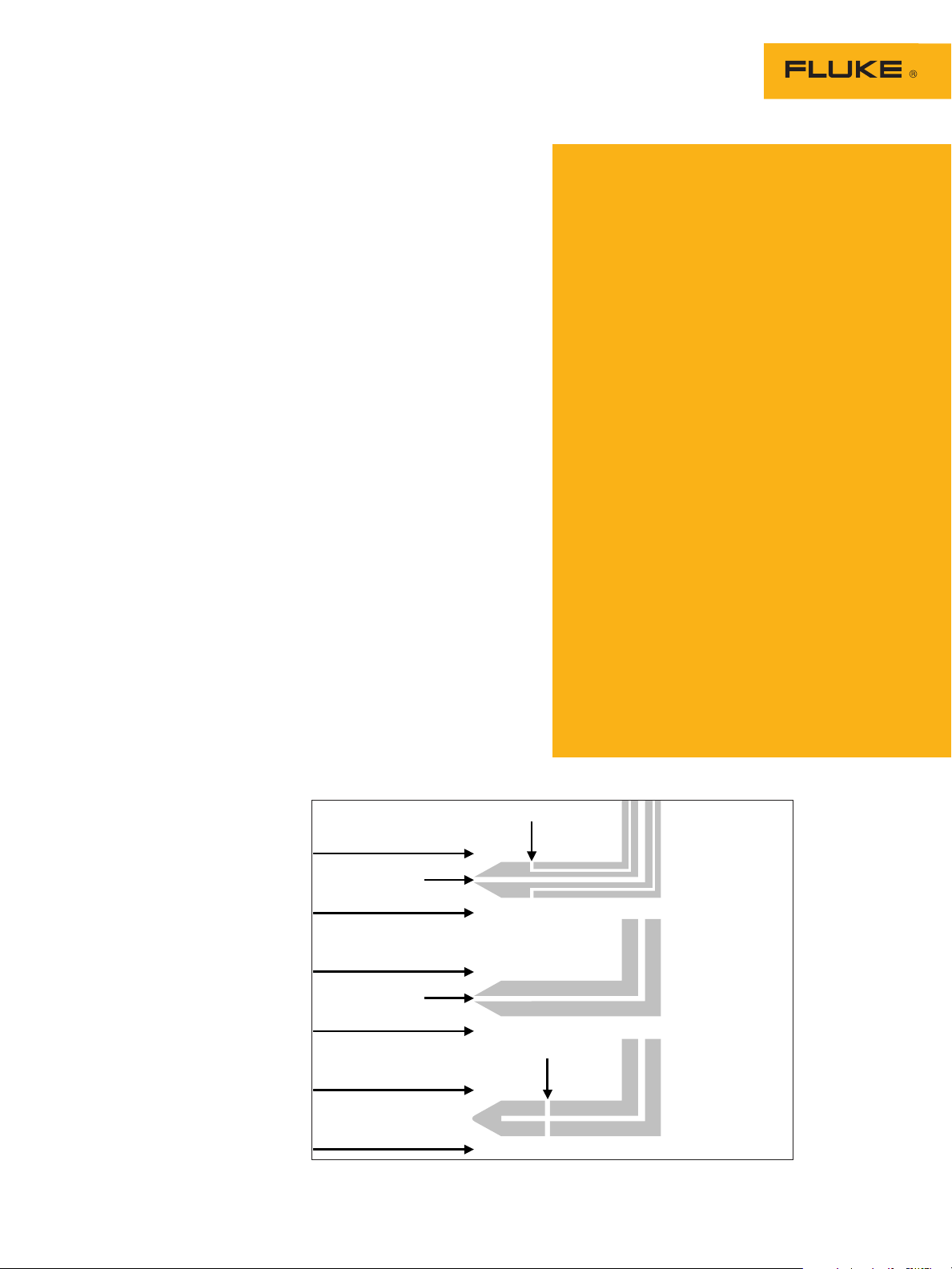

How pressure sensing

Total Pressure

Airflow

Airflow

Pitot-Static Tube

Pitot Tube

Static Pressure

Static Pressure

Total Pressure

Airflow

Airflow

Airflow

Airflow

Static Tip

works

The Fluke 922 is a low pressure differential meter used in

traditional manometer or micromanometer applications. It has

a range of +/-16” wc, resolution

of 0.001” wc, and over-pressure protection of 10 psi at each

high and low pressure port.

With a single tube connected to

its high or low port, the meter

will display positive or negative

pressure relative to the ambient pressure at the meter’s open

port. For a pressure differential

at two remote points, use tubing

to connect the higher pressure

sensing point to the “+” port and

the lower pressure sensing point

to the “-” port.

The meter uses a variety of

sensing probes and fittings to

access the type and location of

pressure measurement points.

These can be as simple as a

straight metal tube for checking draft, a “Tee” for tapping

into pressure sensing tubing

connected to a pressure switch,

a Pitot tube for sensing total

pressure, a Pitot-Static tube for

sensing both total and/or static

pressure, or a static pressure tip.

Pressure applications

Draft pressures: Draft pressures

are negative relative to ambient

pressures at the burner. Measuring and controlling draft is a critical step in combustion tests and

influences net thermal efficiency

of the appliance. Draft is created

by vertical vents or powered

sidewall vent systems connected

to fossil fuel equipment. Like too

much air, excessive draft through

a heat exchanger increases the

velocity of the combustion products containing heat, thereby

reducing the contact time in the

heat exchanger. Follow guidelines from the manufacturer or

standards authority.

Over-fire draft: Power burners typically have specifications

related to over-fire draft, which

relates to the velocity of combustion products through the

heat exchanger. This over-fire

draft typically is slightly negative (-0.01” wc to -0.02” wc)

but, depending on burner type

and application, may be slightly

positive (0.01” wc to 0.02” wc).

Follow guidelines from the manufacturer or standards authority.

Draft inducer pressure:

Category I fan-assisted gas appliances utilize a combustion air

inducer to create draft through

the appliance and deliver the

combustion products to a negative pressure vent. A pressure

switch is normally connected

to the inlet side of the inducer

to ensure a minimum draft has

been established before allowing

an ignition sequence to begin

or continue. For testing, a “Tee”

taps into the pressure sensing

tubing, to monitor the draft

created by the inducer. This is an

important value to benchmark at

appliance installation. While the

pressure switch ratings list cut-in

and cut-out (or differential)

pressures, without a benchmark

you can’t evaluate changes

within the appliance or vent over

time. Follow guidelines from the

manufacturer.

Pressure effects and

measurements

Pressure is an integral part of HVAC

equipment design, system design, function, application, control and diagnostics.

Pressure determines

• cleanliness of airside devices (pressure

drop across filters, evaporators, etc.)

• boiler steam temperature

• the saturation temperature of a fluid

(boiling temperature of a liquid, the condensing temperature of a vapor)

• the direction of fluid flow (fluids flow

from higher to lower pressures)

• fluid volume flow rate (pressure drop

across an orifice)

• whether or not a control or safety switch

will make or break (high/low pressure

switches, draft proving switches)

• the availability of a fluid to perform work

(oxygen/nitrogen tank pressures, gas

supply pressures, duct static pressures)

Pressure also

• senses zone device positions, modu

lates VFD drives, bypass dampers and

valves

• affects solubility of air in water

• contributes to flue gas velocity

(stack draft)

-

2 Fluke Corporation HVAC pressure applications with the Fluke 922

Options for sensing probes and fittings when accessing pressure measurement points.

Page 3

Combustion air blower pres-

sure differential: Category IV

direct vent gas appliances typically use a combustion air blower

to ensure airflow through the

vent system and appliance before

ignition. In most cases, a pressure differential switch monitors

pressure differential across an

orifice. Greater pressure differential indicates more airflow, lower

differential indicates less airflow.

In this case, two tees are needed

to tap into both the high and

low pressure sensing tubes connected to the pressure differential switch. This is an important

value to benchmark during appliance installation. Pressure differential depends on the length of

connected vent and the application. If this value is benchmarked

when installed, degradation

to differential created by heat

exchanger, condensate or vent

problems is more likely to be

detected before a failure occurs.

If not benchmarked, there’s no

way to evaluate degradation.

Follow guidelines from the

manufacturer.

Fan effects on combustion

pressures: When checking stack

draft, over-fire draft or combustion air inducer/blower pressure

differential, an abrupt change

in pressure when the blower

starts may indicate a compromise

between the flue passages and

the air passages. Fan pressure

can easily be 15 times or more

greater than flue passage pressure (-0.03” wc draft vs 0.5”

ESP), so abruptly changing draft

pressures commonly indicate

heat exchanger leaks. Gradual

changes in draft pressures most

likely mean combustion air supply problems or vent problems,

especially when accompanied

by rising CO and CO2, and falling O2 levels in the combustion

products. This can be caused

by insufficient make-up air or

return leaks, especially in spaces

that are considered confined

(less than 50 cu ft per 1,000

Btu input) or tight construction.

Use the Fluke 922 to compare

equipment room pressure to

outside pressure before and dur-

the equipment room can often

compensate for this engineering

design deficiency.

VAV (Variable Air Volume)

control: Pressure sensors are

often used to control VFD (variable frequency drive motor) RPM.

For instance, a supply duct pressure sensor can modulate the

RPM of a VFD, based on pressure

changes caused by a combination of open and closed zone

dampers. Exhaust VFD blowers

may modulate RPM based on

pressure differential between the

occupied space and outdoors. In

each of these cases, the VFD varies RPM to maintain a relatively

consistent pressure or pressure

differential. The Fluke 922 can

be used to monitor or check the

calibration of these sensors.

CAVB (Constant Air Volume

with Bypass) damper control:

Equipment with a constant RPM

blower may need to simulate

VAV in the supply duct, when

zoning is used. The control is

similar to a true VAV system. A

pressure sensor monitors supply

and modulates a bypass damper.

The damper relieves pressure

from the supply to the return,

maintaining a consistent supply

static pressure. The Fluke 922

can monitor or check the calibration of these sensors.

Pressure differential defrost

control: Some enthalpy wheels

use a differential pressure sensor to determine if a defrost cycle

is needed during cold weather.

A pressure differential increase

(indicating a frost build up) will

cycle the outdoor air intake

blower off , so it can use the

indoor air to defrost the wheel.

The Fluke 922 can be used to

monitor pressure differential,

check the calibration of the sensor, or test defrost operation.

Some air-to-air heat pumps use

a pressure switch to monitor

pressure drop across the outdoor

coil to determine if frost build-up

warrants a defrost cycle. In that

circumstance, the Fluke 922 can

be used to monitor defrost pressure differential, since restricted

airflow may indicate a frosted

coil.

ing equipment operation. Simply

adding a small supply register in

3 Fluke Corporation HVAC pressure applications with the Fluke 922

Airside devices: Pressure

drop across airside devices is

published by manufacturers and

is necessary for design considerations, including selecting

equipment for satisfactory blower

performance and for duct design

considerations. Once installed,

these same performance tables

are useful in estimating airflow

and determining end of life for

filters. Evaporators, for instance,

will have pressure drops with

associated cfm’s for a clean dry

coil and for a clean wet coil.

High performance filters will

have pressure drops with associated cfm’s for a clean filter, and

pressure drops with associated

cfm’s for that same filter when it

has reached the end of its life.

The Fluke 922 can be used

with a choice of pressure sensing devices to check pressure

drop across an airside device.

If the approach to and from the

device is straight, a Pitot tube

can be placed on each side of

the device and the difference in

total pressure readings will result

in pressure drop. The tube connected to the upstream side Pitot

tube is connected to the 922

“+” port, the tube connected to

the downstream side Pitot tube

is connected to the “-” port, the

pressure reading displayed will

be the device pressure drop. If

the approach is not straight to

the device, then use the static

sensing side of the two PitotStatic tubes, or use two static

pickups connected to the meter

in the same manner.

Confirming pressure drop across the air filter bank.

Page 4

TSP and ESP: Total Static

Pressure (TSP) and External Static

Pressure (ESP) are used in conjunction with the manufacturer’s

blower performance tables to

ensure that the blower performance is sufficient to overcome

airside device pressure drops

and the pressure drop associated

with duct friction and fittings

losses. Manufacturer’s blower

performance tables will specify

whether the tables are based

on TSP or ESP. Once installed,

the TSP or ESP is measured to

select the appropriate fan RPM

that will deliver the desired cfm.

It’s important to remember that

manufacturer’s blower curves

are developed by AMCA test

procedures that do not exhibit

any system effect. Due to equipment installation space and

configuration limitations, blower

performance is rarely the same

as system performance (“as-built”

rarely performs exactly “asdesigned”). Initial blower set up

is by TSP or ESP. Duct traverses

that measure actual airflow are

required for final blower set up.

TSP is normally provided for

commercial and industrial unitary

equipment. TSP includes internal

and external dynamic pressure

losses the equipment fan must

overcome. A static pickup is used

on the inlet side of the fan to

measure static pressure and the

connecting tube is connected to

the “-” port on the Fluke 922.

A static pickup is placed on the

discharge side of the blower and

the connecting tube is connected

to the “+” port on the Fluke 922.

The displayed pressure is the

TSP.

ESP is normally provided for

residential unitary equipment.

ESP is provided for equipment

that does not have optional

components that can be added

within the cabinet or when drilling holes to take TSP may violate

equipment agency certifications.

The blower tables are based on

dynamic pressure losses external

to the equipment, measured at

the return opening and at the

supply opening of the unitary

equipment. Check the blower

table instructions to determine

whether or not the filter should

be in place when measuring ESP.

Place a static pickup in the return

duct at the equipment return

opening. Connect this tube to the

“-” port of the Fluke 922. Place

a static pickup in the supply

duct at the equipment discharge

opening before any external

devices such as an external

evaporator, if so equipped. Connect this tube to the “+” port on

the Fluke 922. The displayed

reading will be the ESP.

FSP (Psf) is Fan Static Pressure

and is used to independently

rate a fan’s ability to overcome

all system dynamic pressure

losses. A Pitot tube is used on the

inlet side of the fan to measure

total pressure and the connecting

tube is connected to the “-” port

on the Fluke 922. A static pickup

is placed on the discharge side

of the blower and the connecting

tube is connected to the “+” port

on the Fluke 922. The displayed

pressure is the FSP.

Conclusion

Pressure is an often-misunderstood aspect of HVAC diagnostics. Everyone has refrigerant

pressure gauges, but to understand why “the pressures are

wrong,” you need to think about

fluid flow and heat transfer

too, instead of just adding gas

to force the pressures up. And,

while everyone probably has a

pressure gauge, it’s not always

the right kind for accurately

reading low pressure systems.

Now, with electronic meters like

the Fluke 922, you not only get

an accurate read, you can check

the actual pressure differential

instead of replacing pressure differential switches by default.

Using the Min/Max/Avg feature

The MIN-MAX feature on

the Fluke 922, in addition

to capturing minimum and

maximum readings, will

record and average readings when a fluctuating

pressure, velocity, or airflow

is encountered.

Once you’ve captured

pressure, velocity, and/or

airflow readings and stored

them in memory, they can

be recalled per selected

mode for review and

deleted individually, or as a

group.

4 Fluke Corporation HVAC pressure applications with the Fluke 922

Applications for

Min/Max/Avg include

checking:

• static pressure variations

as zone dampers open

and close

• CAVB bypass sizing and

damper operation

The average function is

most useful when air turbulence causes minor fluctuations in readings. The

average feature smoothes

out the slight variations,

making pressure evaluations more accurate.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2006-2007 Fluke Corporation. All rights reserved.

Specifications subject to change without notice.

Printed in U.S.A. 3/2007 2817879 A-EN-N Rev B

®

Loading...

Loading...