Page 1

Certifications

P Conforms to European Standard EN61010-1, EN61326.

Limited Warranty

Each Fluke product is warranted to be free from defects in material and

workmanship under normal use and service. The warranty period is one year

and begins on the date of shipment. Parts, product repairs and services are

warranted for 90 days. This warranty extends only to the original buyer or end

user customer of a Fluke authorized reseller, and does not apply to fuses,

disposable batteries or to any product which, in Fluke’s opinion, has been

misused, altered, neglected or damaged by accident or abnormal conditions of

operation or handling. Fluke warrants that software will operate substantially in

accordance with its functional specifications for 90 days and that it has been

properly recorded on nondefective media. Fluke does not warrant that software

will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused

products to enduser customers only but have no authority to extend a greater or

different warranty on behalf of Fluke. Warranty support is available if product is

purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for

importation costs of repair/replacement parts when product purchased in one

country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase

price, free of charge repair, or replacement of a defective product which is

returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center

or send the product, with a description of the difficulty, postage and insurance

prepaid (FOB Destination), to the nearest Fluke authorized service center. Fluke

assumes no risk for damage in transit. Following warranty repair, the product

will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that the failure was caused by misuse, alteration, accident or

abnormal condition of operation or handling, Fluke will provide an estimate of

repair costs and obtain authorization before commencing the work.

Following repair, the product will be returned to the Buyer transportation prepaid

and the Buyer will be billed for the repair and return transportation charges (FOB

Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IM PLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENT AL OR CONSEQUENTIAL

DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING

FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT,

RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied

warranty, or exclusion or limitation of incidental or consequential damages, the

limitations and exclusions of this warranty may not apply to every buyer. If any

provision of this Warranty is held invalid or unenforceable by a court of

competent jurisdiction, such holding will not affect the validity or enforceability of

any other provision.

In Case of Difficulty

For service or calibration, call your nearest authorized Fluke

Service Center.

For application or operation assistance or information on

Fluke products, call:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke’s Web site at www.fluke.com

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 B.D. Eindhoven

USA The Netherlands

700P29, 700P30, 700P31

Pressure Modules

Instruction Sheet

Introduction

Fluke Models 700P29, 700P30, and 700P31 Pressure

Modules allow you to measure high pressure with the Fluke

700 Series Documenting Process Calibrators. Read this

sheet before you use the pressure module. This sheet

contains specifications and information about how to avoid

personal injury and damage to the pressure module. This

instruction sheet assumes that you know how to use the 700

Series Documenting Process Calibrator. (Refer to the

Manual

if necessary.)

Note

If you are using a Fluke Model 701 or 702 calibrator,

it must have software V1.3 or later to achieve the

specifications in this sheet. See Specifications

note 1.

The pressure module measures pressure using an internal

microprocessor. It receives operating power from and sends

digital information to the 700 Series calibrator.

Box Contents

Pressure module, strap, and instruction sheet.

Caution

Only use with Group 2 Fluids

compatible with Hastelloy C276.

W WARNING

To avoid injury due to the release of high

pressure fluid, use only adapters and fittings

rated to withstand the appropriate pressure.

Ensure that all adapters and fittings are securely

connected.

W WARNING

To avoid a violent release of pressure in a

pressurized system, shut off the isolation valve

and slowly bleed off the pressure before you

attach or remove the pressure module from the

pressure line.

Users

PN 602083 (English)

August 1996 Rev.3, 10/02

1995-2002 Fluke Corporation. All rights reserved. Printed in USA

Page 2

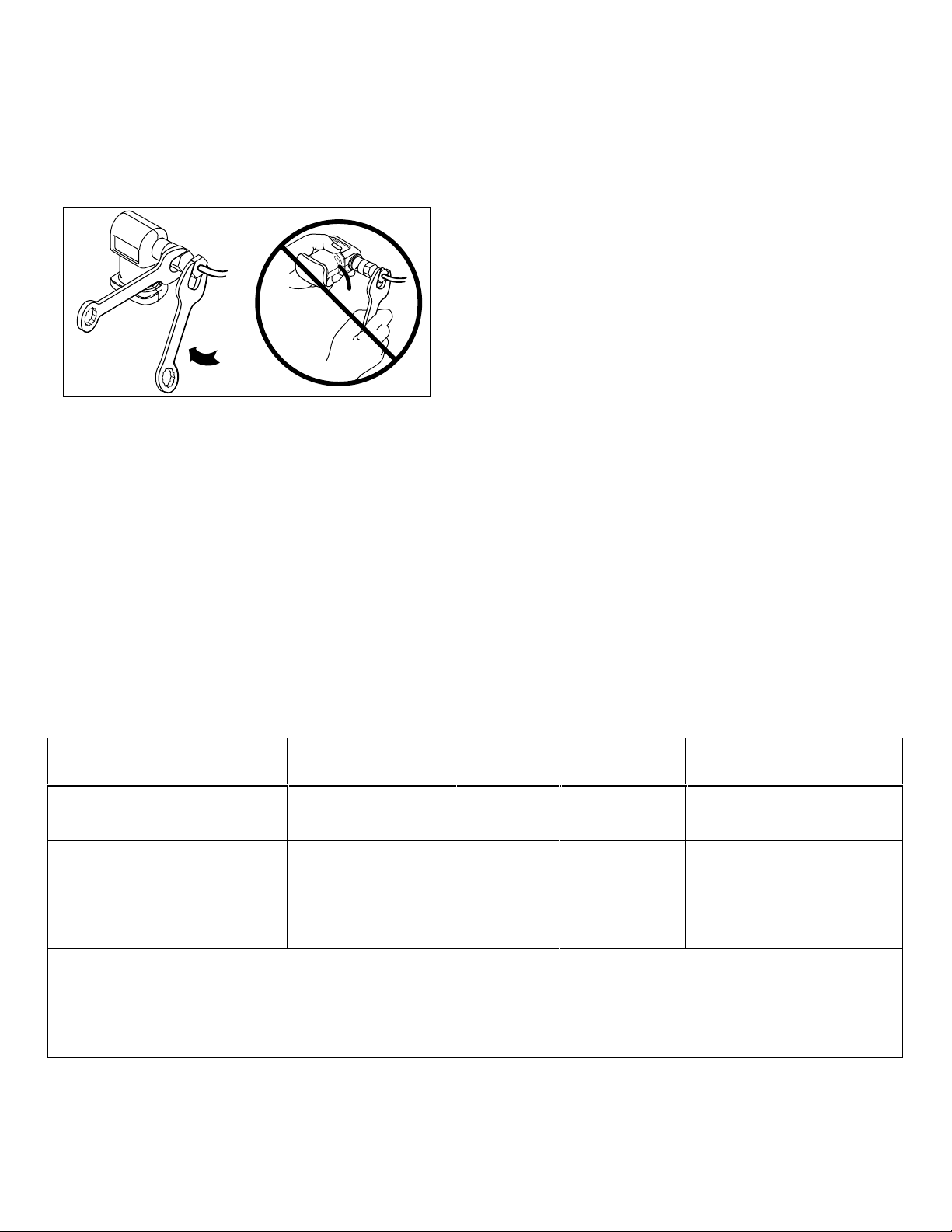

Avoiding Mechanical Damage

To avoid damaging the pressure module, never apply more

than 10 ft.-lb. of torque between the pressure module fitting

and the body of the module. Always apply appropriate torque

between the pressure module fitting and connecting fittings

or adapters. Figure 1 shows the correct and incorrect ways

to use a wrench when applying torque to the pressure

module fitting.

Pressure Calibration Kit

The Fluke 700PCK Pressure Calibration Kit makes it possible

to calibrate pressure modules at ambient temperature with a

precision pressure calibrator or dead weight tester. The

accuracy of the dead weight tester or pressure calibrator

must be significantly better than the pressure module

specification. A 386 or better PC and Windows® 3.1 or later

are required. The kit is an optional accessory available from

your distributor or Fluke.

RANGE

100 kPa

1 bar

Figure 1.

Avoiding Overpressure Damage

Applying pressure in excess of the BURST PRESSURE

specified on the pressure module can destroy the pressure

module. Burst pressure is 2X full scale for the 700P29 and

700P30, and 1.5X full scale for the 700P31.

Avoiding Corrosion Damage

To avoid damaging the pressure module from corrosion, use

it only with a medium that is compatible with Hastelloy C276.

Recommended Measurement Technique

For best results, it is recommended that the module be

pressurized to full scale and then vented to zero pressure

(atmosphere) prior to zeroing and making measurements

with the 700 Series calibrator.

Table 1. Specifications

Model

4

Range

2

Reference Uncertainty

(23 ° ± 3 °C)

Performance Test

If you need to check that the pressure module meets its

accuracy specification, use a dead weight tester or suitable

pressure calibrator. The accuracy of the dead weight tester or

pressure calibrator should be significantly better than the

pressure module specification. Proceed as follows to verify

that a pressure module is operating within specification:

1. Read the pressure value with no externally applied

pressure to make sure the 0% of scale is correct. When

reading the pressure with a 700 Series calibrator, press

the CLEAR (ZERO) key to remove any zero offset.

Note

The pressure zero function is available on Fluke 701

and 702 calibrators with V1.3 or later software.

Contact a Fluke Service Center to upgrade your

V1.0, V1.1, or V1.2 calibrator.

2. Connect the pressure module to a dead weight tester.

3. Set the dead weight tester to 20% of the pressure

module’s full scale value.

4. Make sure the reading agrees with the dead weight

tester value within the specification in Table 1.

5. Set the dead weight tester to 40, 60, 80, and 100% of

full scale and compare the respective readings.

6. If temperature sensitivity is of concern, repeat steps 1

through 5 at various controlled temperatures.

1

(% of full span)

Stability

(1 Year)

Temp

(0 ° to 50 °C)

Total Uncertainty

3

700P29 0 to 3000 psi

0 to 20680 kPa

0 to 207 bar

700P30 0 to 5000 psi

0 to 34500 kPa

0 to 345 bar

700P31 0 to 10000 psi

0 to 69000 kPa

0 to 690 bar

1. Use of pressure zero funct i on i s required to achieve these spec i fications. Contact a Fl uke Service Center to upgrade your Fluke 701 or 702 V1.0,

V1.1, or V1.2 Calibrator.

2. Available pressure units (psi, kPa, bar, inHg, mm Hg, inH

3. Accuracy specifications apply for 1 y ear f or 0 to 100% of full span from 0 to 50 °C. Typical uncertainty i s 1% of full span from -10 °C to 0 °C.

4. Maximum non-destructi ve pressure: 2X maximum rated pressure for P29 and P30, 1.5X f or P31.

5. Specifications reflect a confidence interval of 95%.

0.050% 0.010% 0.020% 0.080%

0.050% 0.010% 0.020% 0.080%

0.050% 0.010% 0.020% 0.080%

0, ftH20, kg/cm2, mmH20) are determined by the calibrator bei ng us ed.

2

Loading...

Loading...