Page 1

5700A/5720A Series II

®

Multi-Function Calibrator

Getting Started

PN 1668111

March 2002

© 2002 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of thei r r espective c omp ani es.

Page 2

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship

under normal use and service. The warranty period is one year and begins on the date

of shipment. Parts, product repairs and services are warranted for 90 days. This

warranty extends only to the original buyer or end-user customer of a Fluke authorized

reseller, and does not apply to fuses, disposable batteries or to any product which, in

Fluke’s opinion, has been misused, altered, neglected or damaged by accident or

abnormal conditions of operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days and that it has

been properly recorded on non-defective media. Fluke does not warrant that software

will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to

end-user customers only but have no authority to extend a greater or different warranty

on behalf of Fluke. Warranty support is available if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke

reserves the right to invoice Buyer for importation costs of repair/replacement parts

when product purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price,

free of charge repair, or replacement of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send

the product, with a description of the difficulty, postage and insurance prepaid (FOB

Destination), to the nearest Fluke authorized service center. Fluke assumes no risk for

damage in transit. Following warranty repair, the product will be returned to Buyer,

transportation prepaid (FOB Destination). If Fluke determines that the failure was

caused by misuse, alteration, accident or abnormal condition of operation or handling,

Fluke will provide an estimate of repair costs and obtain authorization before

commencing the work. Following repair, the product will be returned to the Buyer

transportation prepaid and the Buyer will be billed for the repair and return transportation

charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMI TED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES O R LOSSES, INCLUDING

LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR BASED

ON CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty,

or exclusion or limitation of incidental or consequential damages, the limitations and

exclusions of this warranty may not apply to every buyer. If any provision of this

Warranty is held invalid or unenforceable by a court of competent jurisdiction, such

holding will not affect the validity or enforceability of any other provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

5/94

Page 3

Claims

Immediately upon arrival, purchaser shall check the packing container against the enclosed

packing list and shall, within thirty (30) days of arrival, give Fluke notice of shortages or any

nonconformity with the terms of the order. If purchaser fails to five notice, the delivery shall be

deemed to conform with the terms of the order.

The purchaser assumes all risk of loss or damage to instruments upon delivery by Fluke to the

carrier. If an instrument is damaged in transit, PURCHASER MUST FILE ALL CLAIMS FOR

DAMAGE WITH THE CARRIER to obtain compensation. Upon request by purcha ser, Fluke will

submit an estimate of the cost to repair shipment damage.

Fluke will be happy to answer all questions to enhance the use of this instrument. Please address

your requests or correspondence to: Fluke Corporation, P.O. Box 9090, Everett, WA 98206-9090.

Declaration of the Manufacturer or Importer

We hereby certify that the Fluke Models 5700A Series II and 5720A Series II are in compliance

with Postal Regulation Vfg. 1046 and is RFI suppressed. The marketing and sale of the

equipment was reported to the German Postal Service. The right to retest this equipment to verify

compliance with the regulation was given to the German Postal Service.

Bescheinigung des Herstellers/Importeurs

Hiermit wird bescheinigt, daβ Fluke Models 5700A Series II und 5720A Series II in

Übereinstimung mit den Bestimmungen der Amtsblattverfügung Vfg. 1046 funk-entstört ist, Der

Deutschen Bundespost wurde das Inverkehrbringen dieses Gerätes angezeigt und die

Berechtigung zur Überpr üf ung der Seir e auf Einh alt un g der Be st imm ung en eingeräumt.

Fluke Corporation

Interference Information

This equipment generates and use s radio frequ en cy energy and if not installed and used in strict

accordance with the manufacturer’s instructions, may cause interference to radio and television

reception. It has been type tested and found to comply with the limits for a Class B computing

device in accordance with the specifications in Subpart J of Part 15 of FCC Rules, which are

designed to provide reasona bl e protec tio n agai ns t su ch inter f eren ce in a res id ent ial in st al lati on.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one

of more of the following measures:

Reorient the receiving antenna

•

• Relocate the equipment with respect to the receiver

• Move the equipment away from the receiver

• Plug the equipment into a different outlet so that the computer and receiver are on dif ferent

branch circuits

If necessary, the user should consult the dealer or an experienced radio/television technician for

additional suggestions. The user may find the following booklet prepared by the Federal

Communications Commission helpful: How to Identify and Resolve Radio-TV Interference

Problems. This booklet is available from the U.S. Government Printing Office, Washington, D.C.

20402. Stock No. 004-000-00345- 4.

Page 4

Page 5

OPERATOR SAFETY

SUMMARY

WARNING

HIGH VOLTAGE

is used in the operation of this equipment

LETHAL VOLTAGE

may be present on the terminals, observe all safety precautions!

To avoid electrical shock hazard, the operator should not electrically contact

the output hi or sense hi binding posts. During operation, lethal voltages of

up to 1100V ac or dc may be present on these terminals.

Whenever the nature of the operation permits, keep one hand away from

equipment to reduce the hazard of current flowing thought vital organs of

the body.

Terms in this Manual

This instrument has been designed and tested in accordance with the safety standards

listed in the Gen eral Specific ations. Thi s manual contains informat ion and warnings which

have to be followed by the user to ensure safe operat ion and to retain the instrument in

safe condition.

WARNING statements ident if y condit ions or pra ctice s that could result in per sonal injur y or

loss of life.

CAUTION statements identify conditions or practices that could result in damage to the

equipment or other property.

Page 6

Symbols Marked on Equipment

DANGER — High Voltage

Protective ground (earth) terminal

Attention — refer to the manual. This symbol indicates that information about

the usage of a feature is contained in the manua

l.

Power Source

The 5700A Series II and 5720A Series II are intended to operate from a power source that

will not apply more than 264V ac rms between the supply conductors or between either

supply conductor and ground. A protective ground connection by way of the grounding

conductor in the power cord is essential for safe operation.

Use the Proper Fuse

To avoid fire hazard, use only the fuse specified on the line voltage selection switch label,

and which is identical in type voltage rating, and current rating.

Grounding the 5700A Series II or 5720A Series II

The 5700A Series II and 5720A Series II are Safety Class I (grounded enclosure)

instruments as defined in IEC 348. The enclosure is grounded through the grounding

conductor of the power cord. To avoid electrical shock, plug the power cord into a

properly wired earth grounded receptacle before connecting anything to any of the 5700A

Series II or 5720A Series II terminals. A protective ground connection by way of the

grounding conductor in the power cord is essential for safe operation.

Use the Proper Power Cord

Use only the power cord and connector appropriate for proper operation of a 5700A Series

II or 5720A Series II in your country.

Use only a power cord that is in good condition.

For detailed information on power cords, refer to Figure 24.

Refer cord and connector changes to qualified service personnel.

Do Not Operate in Explosive Atmospheres

To avoid explosion, do not operate the 5700A Series II or 5720A Series II in an

atmosphere of explosive gas.

Do Not Remove Cover

To avoid personal injury, do not remove the cover from the 5700A Series II or 5720A

Series II. Do not operate the 5700A Series II or 5720A Series II without the cover properly

installed. There are no user-serviceable parts inside the 5700A Series II or the 5720A

Series II, so there is no need for the operator to ever remove the cover.

Page 7

FIRST AID FOR ELECTRIC SHOCK

Free the Victim From the Live Conductor

Shut off high voltage at once and ground the circuit. If high voltage cannot be turned off

quickly, ground the circuit.

Get Help!

Call loudly for help. Call an emergency number. Request medical assistance.

Never Accept Ordinary and General Tests for Death

Symptoms of electric shock may include unconsciousness, failure to breathe, absence of

pulse, pallor, and stiffness, and well as severe burns.

Treat the Victim

If the victim is not breathing, begin CPR or mouth-to-mouth resuscitation if you are

certified.

Page 8

Page 9

Table of Contents

Title Page

Introduction.......................................................................................................... 1

Instruction Manuals.............................................................................................. 2

Wideband AC Voltage Module (Option 5700A-03)............................................ 3

Auxiliary Amplifier.............................................................................................. 3

5725A Amplifier.............................................................................................. 3

Support Equipment and Services.......................................................................... 4

732B Direct Voltage Reference Standard........................................................ 4

732B-200 Direct Volt Maintenance Program (U.S.A. Only)........................... 4

742A Series Resistance Standards................................................................... 4

Wideband AC Module (Option 5700A-03) Calibration Support..................... 5

Service Centers................................................................................................. 5

The Components of the 5700A/5720A Series II Calibrator................................. 6

Calibrating the 5700A/5720A Series II Calibrator............................................... 6

The Calibration Process................................................................................... 7

Establishing Traceability.................................................................................. 8

Calibration Reports.......................................................................................... 8

Calibration Check................................................................................................. 9

Developing a Performance History ...................................................................... 9

Range Calibration................................................................................................. 9

DC Zeros Calibration ........................................................................................... 9

Specifications ....................................................................................................... 10

Specification Confidence Levels...................................................................... 10

Using Absolute and Relative Uncertainty Specifications................................ 10

Using Secondary Performance Specifications ................................................. 10

DC Voltage Specifications................................................................................... 11

AC Voltage Specifications................................................................................... 14

Resistance Specifications..................................................................................... 20

DC Current Specifications.................................................................................... 24

AC Current Specifications.................................................................................... 27

Wideband AC Voltage (Option 5700-03) Specifications..................................... 32

General Specifications.......................................................................................... 33

Auxiliary Amplifier Specifications ...................................................................... 34

Unpacking and Inspection.................................................................................... 35

Service Information.............................................................................................. 35

Contacting Fluke .................................................................................................. 36

Placement and Rack Mounting............................................................................. 36

i

Page 10

5700A/5720A Series II

Getting Started

Cooling Considerations........................................................................................ 36

Accessing the Fuse............................................................................................... 37

Selecting Line Voltage......................................................................................... 38

Connecting to Line Power.................................................................................... 40

Connecting a 5725A Amplifier............................................................................ 40

Selecting Output Binding Posts............................................................................ 40

Front Panel Features............................................................................................. 41

Display Screen Saver....................................................................................... 41

Rear Panel Features.............................................................................................. 50

Softkey Menu Tree............................................................................................... 52

ii

Page 11

List of Tables

Table Title Page

1. Auxiliary Amplifier Data.......................................................................................... 3

2. 5720A Series II DC Voltage Specifications: 99 % and 95 % Confidence Levels.... 11

3. 5700A Series II DC Voltage Specifications: 99 % and 95 % Confidence Levels.... 12

4. DC Voltage Secondary Performance Specifications and Operating Characteristics 13

5. 5720A Series II AC Voltage Specifications: 99 % Confidence Level...................... 14

6. 5720A Series II AC Voltage Specifications: 95 % Confidence Level...................... 15

7. 5700A Series II AC Voltage Specifications: 99 % Confidence Level...................... 16

8. 5700A Series II AC Voltage Specifications: 95 % Confidence Level...................... 17

9. AC Voltage Secondary Performance Specifications and Operating Characteristics 18

10. 5720A Series II Resistance Specifications: 99 % and 95 % Confidence Levels...... 20

11. 5700A Series II Resistance Specifications: 99 % and 95 % Confidence Levels...... 21

12. Resistance Secondary Performance Specifications and Operating Characteristics.. 22

13. Current Derating Factors........................................................................................... 23

14. 5720A Series II DC Current Specifications: 99 % and 95 % Confidence Levels .... 24

15. 5700A Series II DC Current Specifications: 99 % and 95 % Confidence Levels .... 25

16. DC Current Secondary Performance Specifications and Operating Characteristics. 26

17. 5720A Series II AC Current Specifications: 99 % Confidence Level...................... 27

18. 5720A Series II AC Current Specifications: 95 % Confidence Level...................... 28

19. 5700A Series II AC Current Specifications: 99 % Confidence Level...................... 29

20. 5700A Series II AC Current Specifications: 95 % Confidence Level...................... 30

21. AC Current Secondary Performance Specifications and Operating Characteristics. 31

22. Wideband AC Voltage (Option 5700-03) Specifications......................................... 32

23. Standard Equipment.................................................................................................. 35

24. Line Power Cord Types Available from Fluke......................................................... 38

25. Front Panel Features................................................................................................. 42

26. Rear Panel Features .................................................................................................. 50

iii

Page 12

5700A/5720A Series II

Getting Started

iv

Page 13

List of Figures

Figure Title Page

1. Time and Costs: Calibrator Calibration.................................................................... 7

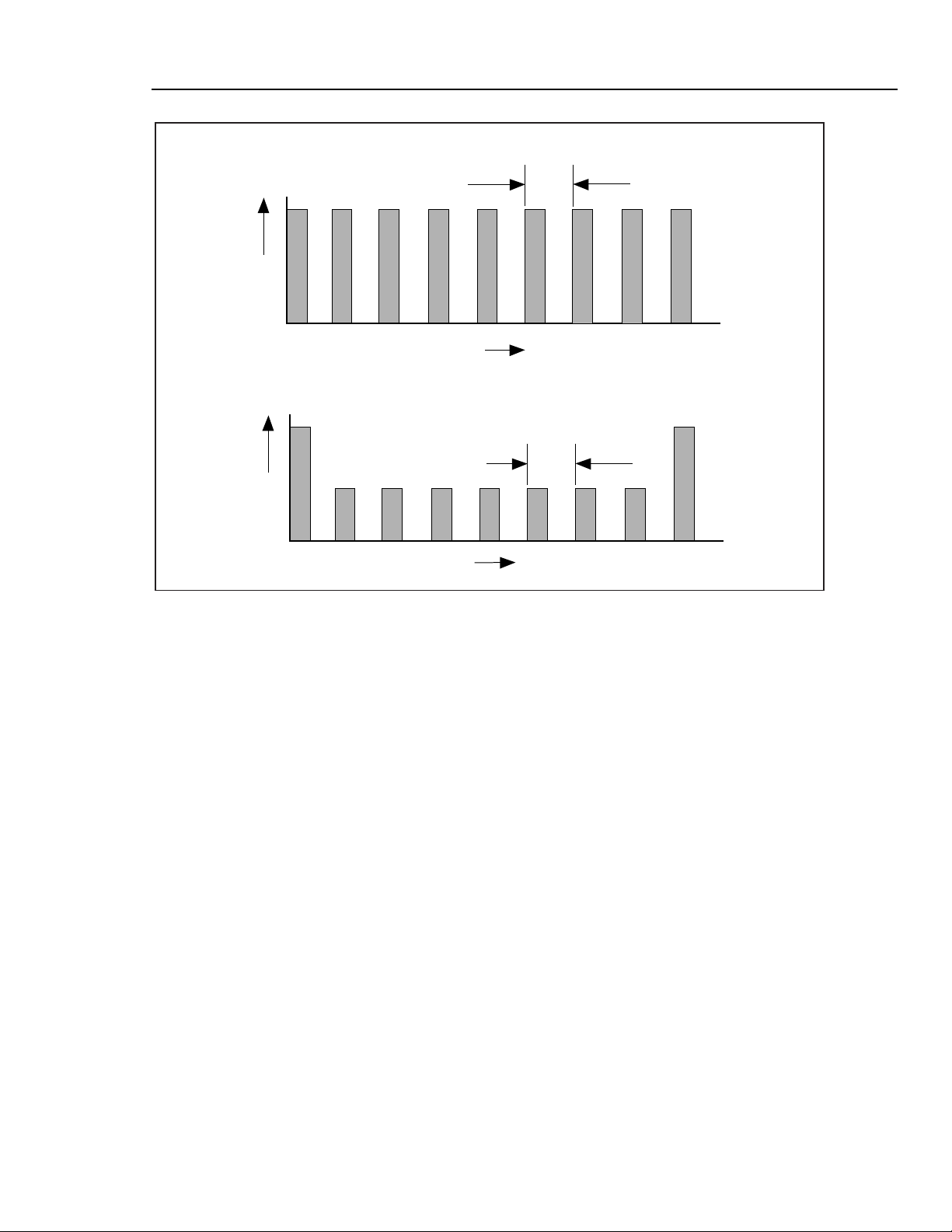

2. Volt-Hertz Capability................................................................................................ 19

3. Accessing the Fuse.................................................................................................... 37

4. Line Power Cord Types Available from Fluke......................................................... 38

5. Line Power Label and Switch Location.................................................................... 39

6. Front Panel Features................................................................................................. 43

7. Rear Panel Features .................................................................................................. 51

8. Softkey Menu Tree................................................................................................... 53

v

Page 14

5700A/5720A Series II

Getting Started

vi

Page 15

Introduction

The Fluke Model 5700A/5720A Series II Calibrators are precise instruments that

calibrate a wide variety of electrical measuring instruments. These calibrators maintain

high accuracy over a wide ambient temperature range, allowing them to test instruments

in any environment, eliminating the restrictions to calibrate only in a temperaturecontrolled standards laboratory . With a 5700A/5720A Ser ies II, you can calibra te

precision multimeters that measure ac or dc voltage, ac or dc current, and resistance. The

5720A Series II operates in a similar manner to the 5700A Series II, the difference is that

the 5720A Series II has a considerably higher specified accuracy. Option 5700A-03

Wideband AC Voltage, which is available for both the 5700A Series II and the 5720A

Series II, extends this workload to include rf voltmeters.

The calibrator is a fully-programmable precision source of the following:

• DC voltage to 1100 V

• AC voltage to 1100 V, with output available from 10 Hz to 1.2 MHz

• AC and DC current to 2.2 A, with output available from 10 Hz to 10 kHz

• Resistance in values of 1x10

Getting Started

n

and 1.9x10n from 1 Ω to 100 MΩ, plus a short

• Optional wideband ac voltage from 300 µV to 3.5 V into 50 Ω (-57 dBm to

+24 dBm), 10 Hz to 30 MHz

Features of the calibrator include the following:

• Internal environmentally-controlled references allowing the calibrator to maintain

full performance over a wide ambient temperature range

• Automatic meter error calculation obta ined th rough usin g a simple output adjust

knob; the display shows linearity, offset, and scale errors

• Keys that multiply and divide the output value by 10 to simplify work on meters with

calibration points at decade multiples of a fraction of full-scale

• Programmable entry limits used for restricting the levels that can be keyed into the

calibrator, preventing access to levels that may be harmful to equipment or personnel

• A s key that provides the capability of displaying the instrument’s specification at

the selected operating point, calibration interval, and specification confidence level

1

Page 16

5700A/5720A Series II

Getting Started

• An auxiliary current binding post that allows you to calibrate meters with separate

• Real-time clock and calendar for date stamping reports

• Offset and scaling modes that simplify linearity testing of multimeters

• Variable phase reference signal output and phase-lock input

• Interface for the Fluke 5725A Amplifier

• Standard IEEE-488 (GPIB) interface, complying with ANSI/IEEE Standards

• Selectable normal remote mode or emulation of the Fluke 5100B and 5200A Series

• EIA Standard RS-232C serial data interface for printing, displaying, or transferring

• Extensive internal self-testing and diagnostics of analog and digital functions

• A traceable calibration procedure for all modes and ranges that requires only 10 V,

• Fast, simple, automated calibration check providing added confidence between

current inputs without moving cables

488.1-1987 and 488.2-1987

calibrators in functions and response to system controller software

internally-stored calibration constants, and for remote control of the calibrator

1 Ω, and 10 kΩ external standards, with only occasional independent verification

calibration recalls, and data that can be used to document and characterize the

calibrator’s performance between calibration recalls

Instruction Manuals

The 5700A/5720A Series II Calibrators ship with a complete manual set that contains

information for the operator and service or maintenance technicians. The set includes:

• 5700A/5720A Series II Getting Started Manual (PN 1668111)

• 5700A/5720A Series II Operator Reference Guide (PN 601648)

• 5700A/5720A Series II Remote Programming Reference Guide (PN 601655)

• 5700A/5720A Series II Operator Manual (provided on CD-ROM, PN 1668127, or

a printed copy is available for purchase through the Fluke Service Department

under PN 601622)

• 5700A/5720A Series II Service Manual (provided on CD-ROM, PN 1668127, or a

printed copy is available for purchase through the Fluke Service Department under

PN 105798)

Order additional copies of these instruction manuals separately using the part numbers

provided. For ordering instructions, refer to the Fluke Catalog or contact a Fluke sales

representative.

2

Page 17

Wideband AC Voltage Module (Option 5700A-03)

Wideband AC Voltage Module (Opt ion 5700A-03)

The Wideband AC Voltage Module (Option 5700A-03) can be installed in both the

5700A and 5720A Series II Calibrators. The module is a high-accuracy, low-noise,

extremely flat ac voltage source for calibrating rf voltmeters, with a frequency range of

10 Hz to 30 MHz. Output is in seven ranges from 300 µV (-57 dBm) to 3.5 V

(+24 dBm) through a Type-N coaxial connector into a 50 Ω load. The output level is

selected in volts or dBm through either the front panel controls or under remote control.

The wideband module also functions with the calibrator’s output adjust controls that let

display the error of a wideband meter in either percentage of output or in decibels.

Included with the wideband module is a Type-N output cable and a 50 Ω terminator.

The wideband module is calibrated to the end of its standard-equipment output cable.

Auxiliary Amplifier

The Fluke Model 5725A Amplifier is available to extend the high voltage performance

and current range of the calibrator:

Interface connectors on the calibrator’s rear panel accept cables to directly operate a

5725A. Three amplifiers can be connected to the calibrator at the same time, but only

one output can be active at a time. Once you have connected the amplifiers and

configured the calibrator in a setup menu, amplifier operation is controlled by the

calibrator.

Getting Started

Operating instructions for the 5725A are provided in Chapter 4 of the Operators

Manual. The General Specifications include specifications for operating the calibrator

with the 5725A. For other amplifier specifications, refer to their instruction manuals.

Table summarizes the extended capabilities offered by the 5725A. Brief descriptions

of the extended capabilities follow.

Table 1. Auxiliary Amplifier Data

Model Mode Range

5725A Amplifier AC V 20 to 1100 V rms up to 70 mA, 40 Hz to 30 kHz

(50 mA < 5 kHz)

220 to 750 V rms up to 70 mA, 30 kHz to 100 kHz

DC Amps 0 to ±11 A

DC Amps 1 to 11 A rms, 40 Hz to 10 kHz

5725A Amplifier

The Fluke 5725A Amplifier is an external unit operating under calibrator control to

extend ac voltage drive capabilities and both ac and dc current output range. The

amplifier adds the following capabilities to the calibrator’s 1100 V AC range with no

compromise in accuracy:

• Frequency limits at higher voltage increase to 100 kHz at 750 V, 30 kHz at 1100 V.

• Load limit increases to 70 mA for frequencies above 5 kHz.

• Capacitive drive increases to 1000 pF, subject to the maximum output current.

Extended-performance voltage is available at the calibrator’s front or rear binding

posts, eliminating the need to change cables during a procedure.

3

Page 18

5700A/5720A Series II

Getting Started

A separate set of binding posts on the front panel of the 5725A supplies extended-range

ac and dc current outputs. Since most meters have a separate input terminal for the high

current ranges, this eliminates the need to change cables during a procedure. The

5725A can also be configured to source all current (both standard calibrator-generated

current and its own current) through the 5725A binding posts.

Support Equipment and Ser vices

Fluke supports your calibration needs with precision, high-quality equipment and a

wide range of services. Depending on your needs, location, and capabilities, you may

decide to support your 5700A/5720A Series II Calibrator independently or use Fluke

services for part, or all, of your support needs. The following paragraphs describe the

support equipment and services offered by Fluke for the calibrator. For specifications

and ordering instructions for this support equi pm ent and othe r Fluke ins tru men ts, re fer

to the Fluke catalog, or contact a representative at a Fluke Sales and Service Center.

732B Direct Voltage Reference Standard

The Fluke 732B is a rugged, easily transported solid state direct voltage reference

standard with a highly predictable 10 V output. This predictability allows the Fluke

Standards Laboratory, as well as many Fluke customers, to completely eliminate

fragile, saturated standard cells. Laboratories still maintain standard cells using the

732A and 732B as a transportable voltage standard, eliminating the need to transport

their standard cells. The 732B can be short-circuited, even for extended periods of time,

without damage or loss of stability. It maintains full specified stability over a

temperature span of 18 to 28 °C.

The calibrator uses a 10 V reference standard such as the Fluke 732B in its semi-

automated calibration procedure to establish external voltage traceability. Chapter 7 of

the Operators Manual describes this procedure.

732B-200 Direct Volt Maintenance Program (U.S.A. Only)

The Fluke 732B-200 Direct Volt Maintenance Program provides your laboratory with

NIST-traceable 10 V calibration uncertainty as low as 0.6 parts per million.

The program maintains the 732B that you keep in your laboratory. To accomplish this,

the following occurs:

1. Fluke sends you a calibrated Fluke-owned 732B standard, together with all-

necessary connecting cables and instructions for comparison with your 10 V

reference standard.

2. You take a series of readings over a five-day period, and return the results to the

Fluke Standards Laboratory.

3. The Fluke Standards Laboratory assigns a value to your 10 V standard relative to

the NIST legal volt and sends you a report of calibration.

742A Series Resistance Standards

The calibrator uses 1 Ω and 10 kΩ resistor standards such as the 742A Series in its

semi-automated calibration procedure to establish external traceability of resistance and

current. Chapter 7 of the Operators Manual describes this procedure.

The 742A Resistance Standards, which are constructed of arrays of Fluke wirewound

precision resistors, are ideally sui ted as suppo rt sta ndard s for the cal ib rat or. Stab il ity of

the resistance transfer standards and their temperature coefficients make them ideal for

easy transport to and operation in the calibrator's working environment.

4

Page 19

Wideband AC Module (Option 5700A-03) Calibration Support

The Wideband AC Module (Option 5700A-03) requires two kinds of calibration: gain

and flatness. Gain constants are checked and recalibrated as a part of the normal

calibrator semi-automated calibration process.

Since frequency flatness is determined by such stable parameters as circuit geometry

and dielectric constants, flatness of the Wideband AC module has excellent long-term

stability. This stability gives the Wideband AC Module a two-year calibration cycle for

flatness calibration. Flatness calibration is required only infrequently, and can be done

when the calibrator is returned to a standards laboratory for periodic verification. The

5700A/5720A Series II Service Manual contains the wideband flatness calibration

procedure. Chapter 7 of the Operators Manual contains the wideband gain calibration

procedure.

Service Centers

A worldwide network of Fluke service centers supports Fluke instruments and assists

customers in many ways. Most service centers have standards and calibration

laboratories certified by local national standards organizations. The following is a

partial list of the services provided by most service centers:

• Repair and certified traceable calibration of all Fluke products.

Getting Started

Support Equipment and Services

• Certified traceable calibration of many non-Fluke standards and calibrators.

• Worldwide exchange of calibrator internal modules. Delivery inside the U.S.A. is

typically within 48 hours.

• Service agreements with the flexibility to suit your needs. These can be a simple

warranty extension or an agreement that includes on-site support. Calibration

service agreements are also available in many areas.

• Training programs and seminars, including laboratory metrology, system

applications, and product maintenance.

• Application help and consulting, including system design, hardware selection,

custom software, site evaluation and installation.

• Replacement parts inventory, including recommended spare parts and module kits.

Visit www.fluke.com for locations and phone numbers of authorized Fluke service

centers.

5

Page 20

5700A/5720A Series II

Getting Started

The Components of the 570 0A/5720A Series II Calibr ator

The calibrator is configured internally as an automated calibration system, with process

controls and consistent procedures. Internal microprocessors control all functions and

monitor performance, using a switching matrix to route signals between modules.

Complete automatic internal diagnostics, both analog and digital, confirm operational

integrity.

Reference amplifiers maintain dc accuracy and stability. Of all technologies available,

reference amplifiers have the lowest noise and best stability. Reference amplifiers in

the calibrator go through special selection processes including long-term aging to

ensure high reliability and performance well within specifications.

The calibrator achieves its exceptional ac voltage accuracy by using a patented Fluke

rms sensor to make real-time AC/DC comparison measurements. The Fluke rms sensor

is similar in principle to the traditional thermal voltage converter, but has a shorter time

constant, virtually no reversal error, higher signal-to-noise ratio, and better frequency

response. In the calibrator, one Fluke rms sensor serves as an AC/DC transfer standard

to develop gain and flatness correction constants during calibration. The second Fluke

rms sensor continuously monitors and corrects output voltage during operation.

A patented 26-bit digital-to-analog converter (dac) provides the calibrator with the

ability to precisely vary its output. This is a pulse-width-modulated dac with linearity

typically better than 0.2 ppm of full scale. As with the other internal functions, the

linearity of the dac is automatically checked during calibration and analog diagnostics.

Calibrating the 5700A/5720A Series II Calibrator

The traditional practice of returning a calibrator to a standards laboratory at regular

intervals for a full calibration is time consuming, expensive, and disruptive to the task

to which the calibrator is being applied. Moreover, it leaves gaps in confidence. You

must rely on manufacturer’s specifications to determine if a calibrator will perform

acceptably in an operating environment outs ide the lab. A lso, you mus t assu me that

drift is predictable enough so that performance is within limits between recalls.

The 5700A/5720A Series II Calibrator makes use of Fluke design breakthroughs in the

use of internal check standards and measurement systems. As a result, it can be

completely calibrated in place to full specifications using a small number of

convenient, portable, environmentally tolerant standards available from Fluke. As you

will see below, this procedure is traceable to military standard requirements.

When manufactured, each calibrator is calibrated and thoroughly verified with process

metrology and calibration standards traceable to the U.S. National Bureau of Standards.

A certificate of calibration is included.

A calibration verification procedure described in the 5700A/5720A Series II Service

Manual is recommended every two years or as required by your established policies.

This procedure involves no adjustments. It simply ensures internal processes are in

control, and establishes parallel exte rna l tra ceab il it y paths for in ter nal fun ct ions such as

ac transfers that are never adjusted or corrected.

Figure illustrates the time and money that can be saved by using the 5700A/5720A

Series II calibration support plan recommended by Fluke. Depending on your policies,

you may initially decide to perform calibration verification more often. The calibrator

makes this unnecessary and offers you a practical way to collect data unavailable with a

traditional calibrator design about performance between calibrations.

6

Page 21

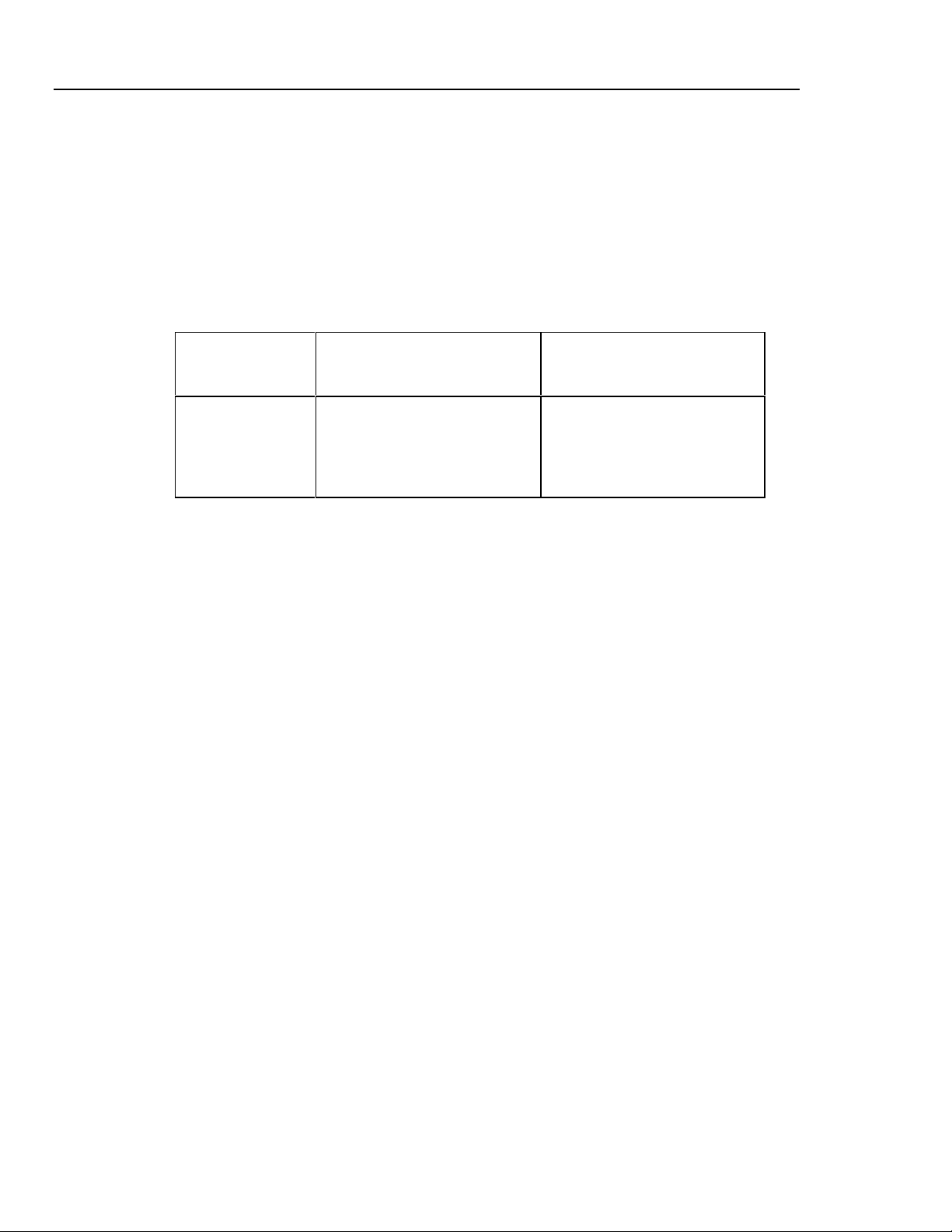

TRADITIONAL CALIBRATOR CALIBRATION

CALIBRATION CYCLE

COST $

CALIBRATION CYCLE

Getting Started

Calibrating the 5700A/5720A Series II Calibrator

TIME

5700A/5720A SERIES II CALIBRATION

COST $

Figure 1. Time and Costs: Calibrator Calibration

The Calibration Process

Calibration requires only three external standards: 10 V, 1 Ω, and 10 kΩ.

Environmentally-controlled internal check standards provide the primary reference

points. A stored table of calibration constants defines additional reference points for

controlling the output. Traceable calibration and adjustment to the specified level of

performance is accomplished in a semi-automated process that revises this table.

When you finish calibration, but before you save the new constants, the calibrator

presents you with the proposed adjustments as +/- ppm of range and percentage change

in specification for each range and function. You can print a list of changes through the

serial (RS-232C) port, or send them to a computer through either the seria l port or the

IEEE-488 port. Also on completion of calibration, the calibrator displays the largest

proposed change.

Calibration can be completed as far as deriving and printing the proposed adjustments

without changing the setting of the rear panel CALIBRATION switch; however, the

switch must be set to ENABLE to store the changes in nonvolatile memory and make

them effective. The switch is recessed to allow the metrologist to cover it with a

calibration sticker to guarantee calibrator integrity.

TIME

alh1.eps

7

Page 22

5700A/5720A Series II

Getting Started

Establishing Traceability

Traceability to national standards is established as follows:

• Except for the internal AC/DC transfer standard, the internal check standards are

• The internal AC/DC transfer standard is never adjusted, so its traceability is not

• Infrequent independent verification is also performed on stable parameters, such as

Calibration Reports

The calibrator stores two sets of calibration constants: the set currently in use and the

old set from the previous calibration. This gives the calibrator the ability at any time to

produce a calibration report of the differences between the present settings and the

settings that were in effect before the last calibration. The report shows changes for

each range and function in +/- ppm of range and in percentage of specification limit.

You can print the report or send it to a host computer through either the RS-232-C or

IEEE-488 interface.

directly calibrated by traceable external standards every time the 5700A/5720A

Series II is calibrated.

disturbed by calibration. Infrequent verification is done in the traditional way, by

comparing selected ac voltage outputs with an external dc voltage standard through

an external ac/dc transfer standard. Fluke recommends this is done every two years

or as determined by the policy of your organization.

frequency flatness, determined more by circuit geometry and dielectric constants

than time.

If you request a calibration report after doing calibration but before saving the new

constants, the report shows proposed changes to the calibration constants relative to the

previously stored settings.

8

Page 23

Calibration Check

Checking the calibration takes about an hour, and provides you with a means of

documenting the calibrator’s performance of a between calibrations. Calibration

checking is similar to calibration, exce pt int ern al check st anda rds are used as primar y

references (no external standards are needed), and changes cannot be stored. The

process produces a report similar to normal ca lib rat ion, showi ng drift rel at ive to

internal check standards. Because cal check does not change stored calibration

constants, there is no need to enable the rear panel CALIBRATION switch. Therefore,

an external computer can do the procedure unattended.

Developing a Performance History

A Fluke specification is a set of performance limits that all products must meet. To

maintain consistent quality, Fluke calibrators are specified with enough margin to

include temperature, line, and load extremes, plus additional margin for production.

This means that a typical 5700A/5720A Series II calibrator in a typical environment

operates inside 50 % of specification limits. For some exacting applications, it can be

helpful to know just how accurately a particular calibrator operates. The proper way to

do this is to accumulate a performance history by calibrating regularly and recording

results on a control chart.

Getting Started

Calibration Check

Calibrating regularly and recording the results on a control chart is tedious and requires

a large array of equipment. The calibrator’s calibration check feature is an alternative

with some distinct advantages:

• Calibrated check standards are already programmed into the unit. You do not have

to use external standards.

• The process is consistent and automatic: it does not require an operator’s

assistance.

Each calibration check produces a new set of data points for accumulating a historical

record. When this process is externally automated, significant history can be

accumulated much faster than with a manual calibration.

Range Calibration

After calibration, you can make further fine adjustments to each range. Range

adjustments are optional; they are not necessary to meet total uncertainty specifications.

However, they do allow you to align your calibrator closer to your standards.

Before you do range calibration, you must first use the calibrator’s semi-automated

calibration procedure. This is to calibrate the ranges that will not be adjusted. It also

performs an initial adjustment for each range, and supplies flatness corrections for ac

functions.

DC Zeros Calibration

To ensure the validity of the specifications, a dc zeros calibration must be performed at

least every 30 days. If more than 30 days elapse without a dc zeros calibration a

warning message appears. This procedure does not require any external equipment or

connections and takes approximately 2.5 minutes to complete.

9

Page 24

5700A/5720A Series II

Getting Started

Specifications

The 5700A/5720A Series II Calibrators are verified and calibrated at the factory prior

to shipment to ensure they meet the accuracy stand ards required for all certified

calibration laboratories. By calibrating to the specifications in this manual, you can

maintain the high performance level throughout the life of your calibrator.

Specifications are valid after a warm-up period of twice the time the calibrator has been

turned off, up to a maximum of 30 minutes. For example, if the calibrator has been

turned off for five minutes, the warm-up period is ten minutes.

Specification Confidence Levels

You calibrator’s performance level is ensured by regular calibration to the primary

performance specifications, which are provided at both the 99 % and 95 % confidence

levels. The 95 % confidence level will provide an accuracy that will often surpass the

accuracy requirements for meeting Tag 4 standards, or a coverage factor of 2.

Calibration at the 99 % confidence level is also available for those applications that

require a confidence factor for the specifications that is higher than 95 %. For

information on selecting the confidence level, refer to Chapter 4 of the Operators

Manual.

The specification tables in this manual provide specifications at both the 95 % and 99

% confidence levels for the 5700A/5720A Series II Calibrators. Included with these

tables are operating specifications for using the calibrator with the Wideband AC

Module (Option 5700A-03) and the 5725A Amplifier.

Using Absolute and Relative Uncertainty Specifications

To evaluate the 5700A/5720A Series II coverage of your calibration workload, use the

Absolute Uncertainty specifications. Absolute uncertainty includes stability,

temperature coefficient, linearity, line and load regulation, and the traceability to

external standards. You do not need to add anything to absolute uncertainty to

determine the ratios between the calibrator’s uncertainties and the uncertainties of your

calibration workload.

Relative uncertainty specifications are provided for enhanced accuracy applications.

These specifications apply when range constants are adjusted (see “Range

Calibration”). To calculate absolute uncertainty, you must combine the uncertainties of

your external standards and techniques with relative uncertainty.

Using Secondary Performance Specifications

Secondary performance specifications and operating characteristics are included in

uncertainty specifications. They are provided for special calibration requirements such

as stability or linearity testing.

10

Page 25

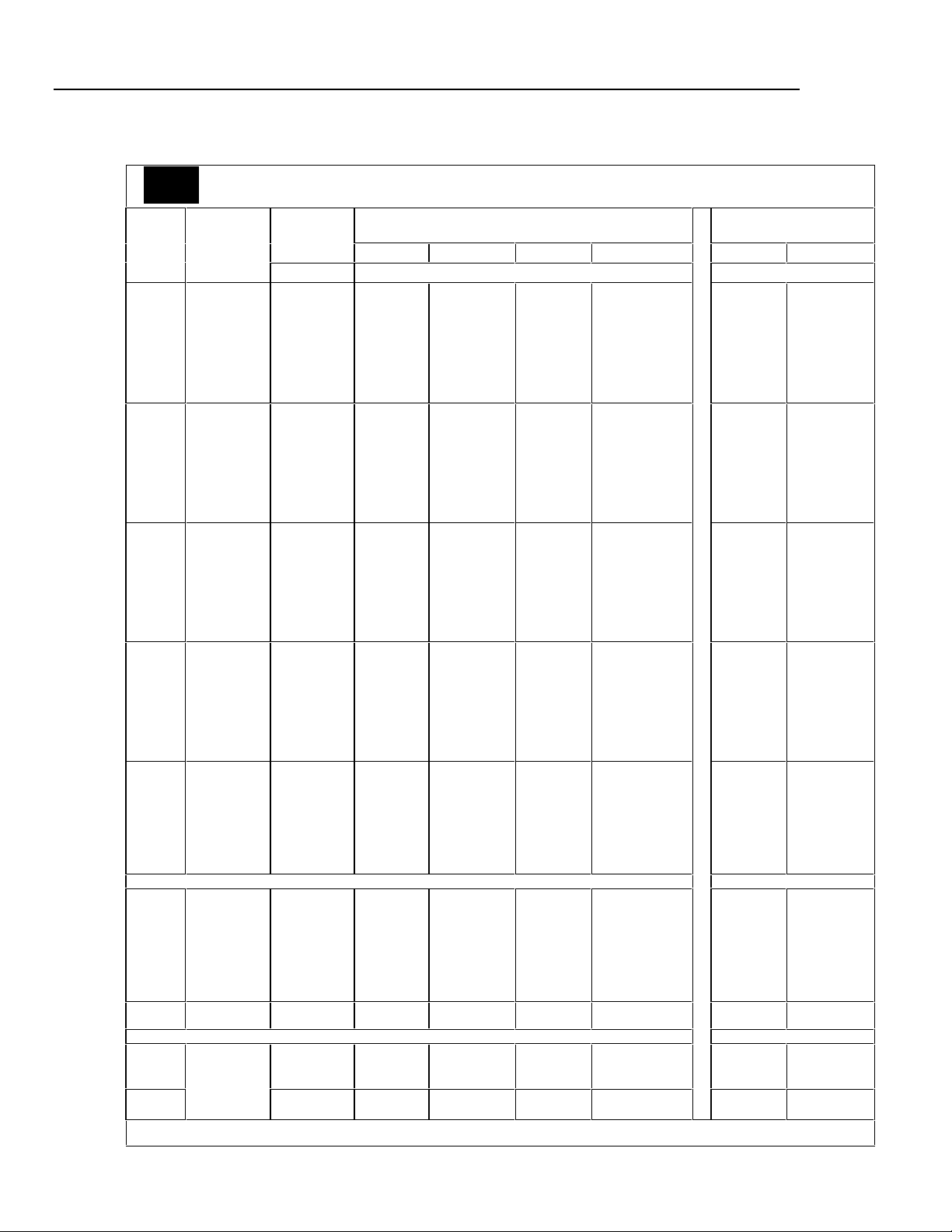

DC Voltage Specificat ions

Table 2. 5720A Series II DC Voltage Specifications: 99 % and 95 % Confidence Levels

5720A

99%

99 % Confidence Level

Getting Started

DC Voltage Specifications

Absolute Uncertainty

± 5 °C from calibration temperature

Range Resolution

220 mV 10 nV 0 5 + 0.5 7 + 0.5 0 8 + 0.5 0 9 + 0.5 0 2 + 0.4 2.5 + 0.4

2.2 V 100 nV 3.5 + 0.8 4 + 0.8 4.5 + 0.8 0 6 + 0.8 0 2 + 0.8 2.5 + 0.8

11 V 1 µV 2.5 + 3 3 + 3 3.5 + 3 0 4 + 3 0 1 + 3 1.5 + 3

22 V 1 µV 2.5 + 5 3 + 5 3.5 + 5 0 4 + 5 0 1 + 5 1.5 + 5

220 V 10 µV 3.5 + 50 4 + 50 0 5 + 50 6 + 50 2 + 50 2.5 + 50

1100 V 100 µV 0 5 + 500 6 + 500 0 7 + 500 8 + 500 2.5 + 400 3 + 400

For fields strengths >1 V/m but ≤3 V/m,

add 0.01% of range.

24 Hours 90 Days 180 Days 1 Year 24 Hours 90 Days

± (ppm output + µV) ± (ppm output + µV)

Relative Uncertainty

± 1 °C

5720A

95%

95% Confidence Level

Range Resolution

Absolute Uncertainty

± 5 °C from calibration temperature

For fields strengths >1 V/m but ≤3 V/m,

add 0.01 % of range.

24 Hours 90 Days 180 Days 1 Year 24 Hours 90 Days

± (ppm output + µV) ± (ppm output + µV)

Relative Uncertainty

± 1 °C

220 mV 10 nV 4 + 0.4 0 6 + 0.4 6.5 + 0.4 7.5 + 0.4 1.6 + 0.4 02 + 0.4

2.2 V 100 nV 3 + 0.7 3.5 + 0.7 0 4 + 0.7 05 + 0.7 1.6 + 0.7 02 + 0.7

11 V 1 µV 2 + 2.5 2.5 + 2.5 03 + 2.5 3.5 + 2.5 0.8 + 2.5 1.2 + 2.5

22 V 1 µV 2 + 4 2.5 + 4 03 + 4 3.5 + 4 0.8 + 4 1.2 + 4

220 V 10 µV 3 + 40 3.5 + 40 04 + 40 0 5 + 40 1.6 + 40 02 + 40

1100 V 100 µV 4 + 400 4.5 + 400 06 + 400 6.5 + 400 02 + 400 2. 4 + 400

11

Page 26

5700A/5720A Series II

Getting Started

Table 3. 5700A Series II DC Voltage Specifications: 99 % and 95 % Confidence Levels

5700A

99%

99 % Confidence Level

Absolute Uncertainty

± 5 °C from calibration temperature

Range Resolution

220 mV 10 nV 6.5 + .75 7 + .75 08 + .75 09 + .8 2.5 + .5 4 + .5

2.2 V 100 nV 3.5 + 1.2 6 + 1. 2 07 + 1.2 08 + 1.2 2.5 + 1.2 4 + 1.2

11 V 1 µV 3.5 + 3 5 + 4 07 + 4 08 + 4 1.5 + 3 3.5 + 4

22 V 1 µV 3.5 + 6 5 + 8 07 + 8 08 + 8 1.5 + 6 3.5 + 8

220 V 10 µV 5 + 100 6 + 100 08 + 100 09 + 100 2.5 + 100 4 + 100

1100 V 100 µV 7 + 600 8 + 600 10 + 600 11 + 600 3 + 600 4.5 + 600

For fields strengths >1 V/m but ≤3 V/m,

add 0.01 % of range.

24 Hours 90 Days 180 Days 1 Year 24 Hours 90 Days

± (ppm output + µV) ± (ppm output + µV)

Relative Uncertainty

± 1 °C

5700A

95%

95 % Confidence Level

Range Resolution

Absolute Uncertainty

± 5 °C from calibration temperature

For fields strengths >1 V/m but ≤3 V/m,

add 0.01 % of range.

24 Hours 90 Days 180 Days 1 Year 24 Hours 90 Days

± (ppm output + µV) ± (ppm output + µV)

Relative Uncertainty

± 1 °C

12

220 mV 10 nV 5.5 + 0.6 6 + 0.6 7 + 0.6 8 + 0.6 2 + 0.4 3.5 + 0.4

2.2 V 100 nV 3.5 + 1 5 + 1 6 + 1 7 + 1 2 + 1 3.5 + 1

11 V 1 mV 3 + 3.5 4 + 3.5 6 + 3.5 7 + 3.5 1.2 + 3 3 + 3.5

22 V 1 mV 3 + 6.5 4 + 6.5 6 + 6.5 7 + 6.5 1.2 + 6 3 + 7

220 V 10 mV 4 + 80 5 + 80 7 + 80 8 + 80 2 + 80 3.5 + 80

1100 V 100 mV 6 + 500 7 + 500 8 + 500 9 + 500 2.4 + 500 4 + 500

Page 27

DC Voltage Specifications

Table 4. DC Voltage Secondary Performance Specifications and Operating Characteristics

Getting Started

Range Stability [Note 1]

220 mV

2.2 V

11 V

22 V

220 V

1100 V

± 1 °C

24 Hours 40°-50 °C pk-pk RMS

± (ppm output + µV) ± (ppm output + µV)/°C ± (ppm output + µV) µV

0.3 + 0.3

0.3 + 1

0.3 + 2.5

0.4 + 5

0.5 + 40

0.5 + 200

Temperature Coefficient

Adder [Note 2]

10 °-40 °C 0 °-10 °C

00.4 + 0.1

00.3 + 0.1

0.15 + 0.2

00.2 + 0.4

00.3 + 5

00.5 + 10

and

1.5 + 0.5

1.5 + 2

0 1 + 1.5

1.5 + 3

1.5 + 40

0 3 + 200

Linearity

± 1 °C

0 1 + 0.2

0 1 + 0.6

0.3 + 2

0.3 + 4

0 1 + 40

0 1 + 200

Bandwidth

0.1-10 Hz

0.15 + 0.1

0.15 + 0.4

0.15 + 2

0.15 + 4

0.15 + 60

0.15 + 300

Noise

Bandwidth

10 Hz-10 kHz

5

15

50

50

150

500

Notes:

1. Stability specifications are included in the Absolute Uncertainty values in the primary specification

tables.

2. Temperature coefficient is an adder to uncertainty specifications that does

not

apply unless operating

more than ±5 °C from calibration temperature.

Minimum output: 0 V for all ranges, except 100 V for 1100 V range

Maximum load: 50 mA for 2.2 V through 220 V ranges; 20 mA for 1100 V range; 50 Ω output impedance

on 220 mV range; all ranges <1000 pF, >25 Ω

Load regulation: <(0.2 ppm of output + 0.1ppm of range), full load to no load

Line regulation: <0.1 ppm change, ± 10 % of selected nominal line

Settling time: 3 seconds to full accuracy; + 1 second for range or polarity change; + 1 second for 1100 V

range

Overshoot: <5 %

Common mode rejection: 140 dB, DC to 400 Hz

Remote sensing: Available 0 V to ±1100 V, on 2.2 V through 1100 V ranges

13

Page 28

5700A/5720A Series II

0

0

Getting Started

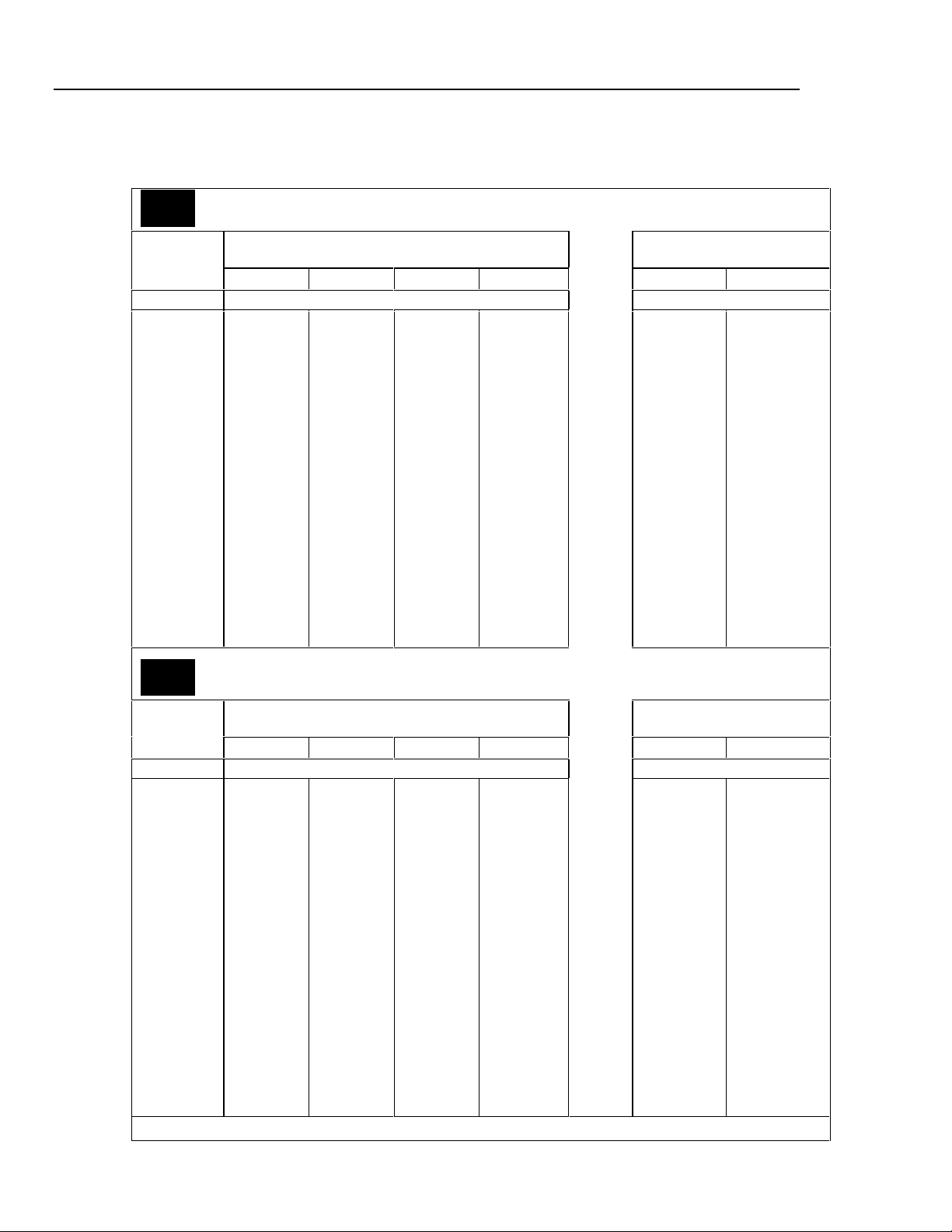

AC Voltage Specificat ions

5720A

99%

99 % Confidence Level

Range Resolution Frequency

2.2 mV 1 nV

22 mV 10 nV

220 mV 100 nV

2.2 V 1 mV

22 V 10 mV

220 V

[Note 2]

1100 V

5725A Amplifier:

1100 V

750 V

Notes: 1. Maximum output 250V from 15- 50 Hz.

2. See Volt-Hertz capability in Figure 1-2.

Table 5. 5720A Series II AC Voltage Specifications: 99 % Confidence Level

Absolute Uncertainty

± 5 °C from calibration temperature

24 Hours 90 Days 180 Days 1 Year 24 Hours 90 Days

Hz ± (ppm output + µV) ± (ppm output + µV)

100 mV

1 mV

[Note 1]

1 mV

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0015 - 50

0050 - 1 k

0040 - 1 k

001 k - 20 k

020 k - 30 k

030 k - 50 k

050 k - 100k

0250 + 5

0100 + 5

0085 + 5

0220 + 5

0500 + 6

1000 + 12

1400 + 25

2900 + 25

0250 + 5

0100 + 5

0085 + 5

0220 + 5

0500 + 6

1000 + 12

1400 + 25

2900 + 25

0250 + 15

0100 + 8

0085 + 8

0220 + 8

0500 + 20

0850 + 25

1400 + 30

2700 + 60

0250 + 50

0095 + 20

0045 + 10

0080 + 12

0120 + 40

0380 + 100

1000 + 250

1600 + 400

0250 + 500

0095 + 200

0045 + 70

0080 + 120

0110 + 250

0300 + 800

1000 + 250

1500 + 400

0270 + 5

0105 + 5

0090 + 5

0230 + 5

0540 + 6

1200 + 12

1500 + 25

3100 + 25

0270 + 5

0105 + 5

0090 + 5

0230 + 5

0540 + 6

1200 + 12

1500 + 25

3100 + 25

0270 + 15

0105 + 8

0090 + 8

0230 + 8

0540 + 20

0900 + 25

1500 + 30

2900 + 60

0270 + 50

0100 + 20

0047 + 10

0085 + 12

0125 + 40

0420 + 100

1100 + 250

1800 + 600

0270 + 500

0100 + 200

0047 + 70

0085 + 120

0115 + 250

0310 + 800

1100 + 2500

1600 + 4000

0290 + 5

0110 + 5

0095 + 5

0240 + 5

0570 + 6

1250 + 12

1600 + 25

3250 + 25

0290 + 5

0110 + 5

0095 + 5

0240 + 5

0570 + 6

1250 + 12

1600 + 25

3250 + 25

0290 + 15

0110 + 8

0095 + 8

0240 + 8

0570 + 20

1000 + 25

1600 + 30

3100 + 60

0290 + 50

0105 + 20

0050 + 10

0087 + 12

0127 + 40

0460 + 100

1150 + 250

1900 + 400

0290 + 500

0105 + 200

0050 + 70

0087 + 120

0117 + 250

0320 + 800

1150 + 2500

1700 + 4000

00300 + 5

00115 + 5

00100 + 5

00250 + 5

00600 + 6

01300 + 12

01700 + 25

03400 + 25

00300 + 5

00115 + 5

00100 + 5

00250 + 5

00600 + 6

01300 + 12

01700 + 25

03400 + 25

00300 + 15

00115 + 8

00100 + 8

00250 + 8

00600 + 20

01100 + 25

01700 + 30

03300 + 60

00300 + 50

00110 + 20

00052 + 10

00090 + 12

00130 + 40

00500 + 100

01200 + 250

02000 + 400

00300 + 500

00110 + 200

00052 + 70

00090 + 120

00120 + 250

00325 + 800

01200 + 2500

01800 + 4000

± (ppm output + mV) ± (ppm output + mV)

0250 + 5

0095 + 2

0057 + 0.7

0090 + 1.2

0160 + 3

0900 + 20

5000 + 50

8000 + 100

0300 + 20

0070 + 4

0075 + 4

0105 + 6

0230 + 11

0230 + 11

0600 + 45

0270 + 5

0100 + 2

0060 + 0.7

0095 + 1.2

0170 + 3

1000 + 20

5200 + 50

9000 + 100

0320 + 20

0075 + 4

0080 + 4

0125 + 6

0360 + 11

0360 + 11

1300 + 45

0290 + 5

0105 + 2

0062 + 0.7

0097 + 1.2

0175 + 3

1050 + 20

5300 + 50

9500 + 100

0340 + 20

0080 + 4

0085 + 4

0135 + 6

0440 + 11

0440 + 11

1600 + 45

00300 + 5

00110 + 2

00065 + 0.7

00100 + 1.2

00 180 + 3

0 1100 + 20

0 5400 + 50

10,000 + 100

00 360 + 20

00085 + 4

000 90 + 4

00 165 + 6

00 600 + 11

00600 + 11

02300 + 45

Relative Uncertainty

± 1 °C

0250 + 5

0100 + 5

0060 + 5

0085 + 5

0200 + 6

0350 + 12

0800 + 25

2700 + 25

0250 + 5

0100 + 5

0060 + 5

0085 + 5

0200 + 6

0350 + 12

0800 + 25

2700 + 25

0250 + 15

0100 + 8

0060 + 8

0085 + 8

0200 + 20

0350 + 25

0800 + 30

2600 + 60

0250 + 50

0095 + 20

0030 + 10

0070 + 12

0100 + 40

0270 + 100

0900 + 250

1200 + 400

0250 + 500

0095 + 200

0030 + 70

0070 + 120

0100 + 250

0270 + 800

0900 + 2500

1300 + 4000

0250 + 5

0095 + 2

0045 + 0.7

0075 + 1.2

0140 + 3

0600 + 20

4500 + 50

8000 + 100

0300 + 20

0050 + 4

0050 + 4

0085 + 6

0160 + 11

0160 + 11

0380 + 45

0270 + 5

0105 + 5

0065 + 5

0095 + 5

0220 + 6

0400 + 12

1000 + 25

3000 + 25

0270 + 5

0105 + 5

0065 + 5

0095 + 5

0220 + 6

0400 + 12

1000 + 25

3000 + 25

0270 + 15

0105 + 8

0065 + 8

0095 + 8

0220 + 20

0400 + 25

1000 + 30

2800 + 60

0270 + 50

0100 + 20

0040 + 10

0075 + 12

0105 + 40

0290 + 100

1000 + 250

1300 + 400

0270 + 500

0100 + 200

0040 + 70

0075 + 120

0105 + 250

0290 + 800

1000 + 2500

1400 + 4000

0270 + 5

0100 + 2

0050 + 0.7

0080 + 1.2

0150 + 3

0700 + 20

4700 + 50

8500 + 100

0320 + 20

0055 + 4

0055 + 4

0105 + 6

0320 + 11

0320 + 11

1200 + 45

14

Page 29

Table 6. 5720A Series II AC Voltage Specifications: 95 % Confidence Level

0

0

5720A

95%

95 % Confidence Level

Range Resolution Frequency

Hz ± (ppm output + µV) ± (ppm output + µV)

0010 - 20

0020 - 40

0040 - 20 k

2.2 mV 1 nV

22 mV 10 nV

220 mV 100 nV

2.2 V 1 mV

22V 10 mV

220 V

[Note 2]

1100 V

1100 V

750 V

Notes: 1. Maximum output 250V from 15-50 Hz.

100 mV

1 mV

[Note 1]

1 mV

2. See Volt-Hertz capability in Figure 1-2.

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

00010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20k

020k - 50k

050k - 100k

100k - 300k

300k - 500k

500k - 1M

± (ppm output + mV) ± (ppm output + mV)

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0015 - 50

0050 - 1 k

5725A Amplifier:

0040 - 1 k

001 k - 20 k

020 k - 30 k

030 k - 50 k

050 k - 100 k

Getting Started

AC Voltage Specificati on s

Absolute Uncertainty

± 5 °C from calibration temperature

24 Hours 90 Days 180 Days 1 Year 24 Hours 90 Days

0200 + 4

0080 + 4

0070 + 4

0170 + 4

0400 + 5

0300 + 10

1100 + 20

2400 + 20

0200 + 4

0080 + 4

0070 + 4

0170 + 4

0400 + 5

0300 + 10

1100 + 20

2400 + 20

0200 + 12

0080 + 7

0070 + 7

0170 + 7

0400 + 17

0700 + 20

1100 + 25

2400 + 45

0200 + 40

0075 + 15

0037 + 8

0065 + 10

0100 + 30

0300 + 80

0800 + 200

1300 + 300

0200 + 400

0075 + 150

0037 + 50

0065 + 100

0090 + 200

0250 + 600

0800 + 200

1200 + 320

0200 +4

0075 + 1.5

0045 + 0.6

0070 + 1

0120 + 2.5

0700 + 16

4000 + 40

6000 + 80

0240 + 16

0055 + 3.5

0075 + 4

0105 + 6

0230 + 11

0230 + 11

0600 + 45

0220 + 4

0085 + 4

0075 + 4

0180 + 4

0460 + 5

0900 + 10

1200 + 20

2500 + 20

0220 + 4

0085 + 4

0075 + 4

0180 + 4

0460 + 5

0900 + 10

1200 + 20

2500 + 20

0220 + 12

0085 + 7

0075 + 7

0180 + 7

0420 + 17

0750 + 20

1200 +25

2500 + 45

0220 + 40

0080 + 15

0040 + 8

0070 + 10

0105 + 30

0340 + 80

0900 + 200

1500 + 300

0220 + 400

0080 + 150

0040 + 50

0070 + 100

0095 + 200

0260 + 600

0900 + 2000

1300 + 3200

0220 + 4

0080 + 1.5

0047 + 0.6

0075 + 1

0130 + 2.5

0800 + 16

4200 + 40

7000 + 80

0260 + 16

0060 + 3.5

0080 + 4

0125 + 6

0360 + 11

0360 + 11

1300 + 45

0230 + 4

0087 + 4

0077 + 4

0190 + 4

0480 + 5

1000 + 10

1300 + 20

2600 + 20

0230 + 4

0087 + 4

0077 + 4

0190 + 4

0480 + 5

1000 + 10

1300 + 20

2600 + 20

0230 + 12

0087 + 7

0077 + 7

0190 + 7

0440 + 17

0800 + 20

1300 + 25

2600 + 45

0230 + 40

0085 + 15

0042 + 8

0073 + 10

0107 + 30

0380 + 80

0950 + 200

1600 + 300

0230 + 400

0085 + 150

0042 + 50

0073 + 100

0097 + 200

0270 + 600

0900 + 2000

1400 + 3200

0230 + 4

0085 + 1.5

0050 + 0.6

0077 + 1

0140 + 2.5

0850 + 16

4300 + 40

7500 + 80

0280 + 16

0065 + 3.5

0085 + 4

0135 + 6

0440 + 11

0440 + 11

1600 + 45

0240 + 4

0090 + 4

0080 + 4

0200 + 4

0500 + 5

1050 + 10

1400 + 20

2700 + 20

0240 + 4

0090 + 4

0080 + 4

0200 + 4

0500 + 5

1050 + 10

1400 + 20

2700 + 20

0240 + 12

0090 + 7

0080 + 7

0200 + 7

0460 + 17

0900 + 20

1400 + 25

2700 + 45

0240 + 40

0090 + 15

0045 + 8

0075 + 10

0110 + 30

0420 + 80

1000 + 200

1700 + 300

0240 + 400

0090 + 150

0045 + 50

0075 + 100

0100 + 200

0275 + 600

1000 + 2000

1500 + 3200

0240 + 4

0090 + 1.5

0052 + 0.6

0080 + 1

0150 + 2.5

0900 + 16

4400 + 40

8000 + 80

0300 + 16

0070 + 3.5

0090 + 4

0165 + 6

0600 + 11

0600 + 11

2300 + 45

Relative Uncertainty

± 1 °C

0200 + 4

0080 + 4

0050 + 4

0070 + 4

0160 + 5

0280 + 10

0650 + 20

2100 + 20

0200 + 4

0080 + 4

0050 + 4

0070 + 4

0160 + 5

0280 + 10

0650 + 20

2100 + 20

0200 + 12

0080 + 7

0050 + 7

0070 + 7

0160 + 17

0280 + 20

0650 + 25

2100 + 45

0200 + 40

0075 + 15

0025 + 8

0055 + 10

0080 + 30

0230 + 80

0700 + 200

1000 + 300

0200 + 400

0075 + 150

0025 + 50

0055 + 100

0080 + 200

0250 + 600

0700 + 2000

1100 + 3200

0200 + 4

0075 + 1.5

0035 + 0.6

0060 + 1

0110 + 2.5

0500 + 16

3600 + 40

6500 + 80

0240 + 16

0040 + 3.5

0050 + 4

0085 + 6

0160 + 11

0160 + 11

0380 + 45

0220 + 4

0085 + 4

0055 + 4

0080 + 4

0180 + 5

0320 + 10

0800 + 20

2400 + 20

0220 + 4

0085 + 4

0055 + 4

0080 + 4

0180 + 5

0320 + 10

0800 + 20

2400 + 20

0220 + 12

0085 + 7

0055 + 7

0080 + 7

0180 + 17

0320 + 20

0800 + 25

2400 + 45

0220 + 40

0080 + 15

0035 + 8

0060 + 10

0085 + 30

0250 + 80

0800 + 200

1100 + 300

0220 + 400

0080 + 150

0035 + 50

0060 + 100

0085 + 200

0270 + 600

0800 + 2000

1200 + 3200

0220 + 4

0080 + 1.5

0040 + 0.6

0065 + 1

0120 + 2.5

0600 + 16

3800 + 40

7000 + 80

0260 + 16

0045 + 3.5

0055 + 4

0105 + 6

0320 + 11

0320 + 11

1200 + 45

15

Page 30

5700A/5720A Series II

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

13,000 + 220

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Getting Started

Table 7. 5700A Series II AC Voltage Specifications: 99 % Confidence Level

5700A

99%

99 % Confidence Level

Range Resolution Frequency

2.2 mV 1 nV

22 mV 10 nV

220 mV 100 nV

2.2 V 1 mV

22 V 10 mV

220 V

[Note 2]

1100 V 1 mV

100 mV

[Note 1]

5725A Amplifier:

1100 V 1 mV 00040 - 1 k

750 V 0030 k - 50 k

Notes: 1. Maximum output 250V from 15- 50 Hz.

2. See Volt-Hertz capability in Figure 1-2.

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

0010 - 20

0020 - 40

0040 - 20 k

020 k - 50 k

050 k - 100 k

100 k - 300 k

300 k - 500 k

500 k - 1 M

00015 - 50

00050 - 1 k

0001 k - 20 k

0020 k - 30 k

0050 k - 100 k

Absolute Uncertainty

± 5 °C from calibration temperature

Relative Uncertainty

± 1 °C

24 Hours 90 Days 180 Days 1 Year 24 Hours 90 Days

Hz ± (ppm output + µV) ± (ppm output + µV)

0 500 + 5

00200 + 5

0 100 + 5

0 340 + 5

0 800 + 8

01100 + 15

01500 + 30

4000 + 40

0 500 + 6

0 200 + 6

0100 + 6

0340 + 6

0800 + 8

1100 + 15

01500 + 30

04000 + 40

0500 + 16

0 200 + 10

0 095 + 10

0 300 + 10

0 750 + 30

0 940 + 30

1500 + 40

3000 + 100

0 500 + 100

0 150 + 30

00 70 + 7

0 120 + 20

0 230 + 80

0 400 + 150

1000 + 400

2000 + 1000

0 500 + 1000

0 150 + 300

00 70 + 70

0 120 + 200

0 230 + 400

0 500 + 1700

1200 + 5000

2600 + 9000

0 550 + 5

0 220 + 5

0 110 + 5

0 370 + 5

0 900 + 8

01200 + 15

01700 + 30

04400 + 40

0 550 + 6

0 220 + 6

0 110 + 6

0 370 + 6

0 900 + 8

01200 + 15

01700 + 30

04400 + 40

0 550 + 16

0 220 + 10

0 100 + 10

0 330 + 10

0 800 + 30

1000 + 30

01700 + 40

03300 + 100

0 550 + 100

0 170 + 30

00 75 + 7

0 130 + 20

0 250 + 80

0 440 + 150

1100 + 400

2200 + 1000

0 550 + 1000

0 170 + 300

00 75 + 70

0 130 + 200

0 250 + 400

0 550 + 1700

1300 + 5000

2800 + 9000

0 600 + 5

0 230 + 5

0 120 + 5

0 390 + 5

0 950 + 8

1300 + 15

01700 + 30

4700 + 40

00600 + 6

0 230 + 6

0 120 + 6

0 390 + 6

0 950 + 8

1300 + 15

1700 + 30

4700 + 40

0 600 + 16

0 230 + 10

0 110 + 10

0 350 + 10

0 850 + 30

01100 + 30

1700 + 40

3500 + 100

0 600 + 100

0 170 + 30

00 80 + 7

0 140 + 20

0 270 + 80

0 470 + 150

1200 + 400

2300 + 1000

0 600 + 1000

0 170 + 300

00 80 + 70

0 140 + 200

0 270 + 400

0 550 + 1700

1300 + 5000

2900 + 9000

0 600 + 5

0 240 + 5

0 120 + 5

0 410 + 5

0950 + 8

1300 + 15

1800 + 30

4800 + 40

0600 + 6

0 240 + 6

0 120 + 6

0 410 + 6

0 950 + 8

1300 + 15

1800 + 30

4800 + 40

0 600 + 16

00240 + 10

00110 + 10

00360 + 10

0900 + 30

01100 + 30

01800 + 40

03600 + 100

0 600 + 100

0 180 + 30

00 85 + 7

0 140 + 20

0 280 + 80

0 480 + 150

1200 + 400

2400 + 1000

0 600 + 1000

0 180 + 300

00 85 + 70

0 140 + 200

0 280 + 400

0 600 + 1700

1400 + 5000

3000 + 9000

00 500 + 5

00 200 + 5

000 60 + 5

00 100 + 5

00 220 + 8

00 400 + 15

01000 + 30

00 400 + 30

00 500 + 6

00 200 + 6

000 60 + 6

00 100 + 6

00 220 + 8

00 400 + 15

01000 + 30

0 4000 + 30

00 500 + 16

00200 + 10

00060 + 10

00100 + 10

00220 + 30

00400 + 30

01000 + 40

03000 + 100

00 500 + 100

00 150 + 30

000 40 + 7

00 100 + 20

00 200 + 80

00 400 + 150

0 1000 + 400

0 2000 + 1000

00 500 + 1000

00 150 + 300

000 40 + 70

00 100 + 200

00 200 + 400

00500 + 1700

01200 + 5000

02600 + 9000

0 550 + 5

0220 + 5

0 065 + 5

0 110 + 5

0 240 + 8

0 440 + 15

1100 + 30

4400 + 30

0 550 + 6

0 220 + 6

00 65 + 6

0 110 + 6

0 240 + 8

0 440 + 15

1100 + 30

4400 + 30

00550 + 16

00220 + 10

00065 + 10

00110 + 10

00240 + 30

00440 + 30

01100 + 40

03300 + 100

0 550 + 100

0 170 + 30

00 45 + 7

0 110 + 20

0 220 + 80

0 440 + 150

1100 + 400

2200 + 1000

0 550 + 1000

0 170 + 300

00 45 + 70

0 110 + 200

0 220 + 400

0 550 + 1700

1300 + 5000

2800 + 9000

± (ppm output + mV) ± (ppm output + mV)

0 500 + 10

0 150 + 3

00 75 + 1

0 200 + 4

0 500 + 10

1500 + 110

5000 + 110

12,000 + 220

0 400 + 20

00 75 + 4

00 75 + 4

0 105 + 6

0 230 + 11

0 230 + 11

0 600 + 45

0 550 + 10

0 170 + 3

00 80 + 1

0 220 + 4

0 550 + 10

1500 + 110

5200 + 110

12,500 + 220

00420 + 20

00 80 + 4

00 80 + 4

0 125 + 6

0 360 + 11

0 360 + 11

1300 + 45

0600 + 10

0 170 + 3

00 85 + 1

0 240 + 4

0 600 + 10

1600 + 110

5300 + 110

12,500 + 220

00440 + 20

00 85 + 4

00 85 + 4

0 135 + 6

0 440 + 11

0 440 + 11

1600 + 45

0 600 + 10

0 180 + 3

00 90 + 1

0 250 + 4

0 600 + 10

1600 + 110

5400 + 110

00460 + 20

00 90 + 4

00 90 + 4

0 165 + 6

0 600 + 11

0 600 + 11

2300 + 45

00 500 + 10

00 150 + 3

000 45 + 1

00 100 + 1

00 300 + 10

01500 + 110

0 5000 + 110

12,000 + 220

00400 + 20

000 50 + 4

000 50 + 4

000 85 + 6

00 160 + 11

00 160 + 11

00 380 + 45

0 550 + 10

0 170 + 3

00 50 + 1

0 110 + 1

0 330 + 10

1500 + 100

5200 + 110

12,000 + 220

00420 + 20

00 55 + 4

00 55 + 4

0 105 + 6

0 320 + 11

0 320 + 11

1200 + 45

16

Page 31

Table 8. 5700A Series II AC Voltage Specifications: 95 % Confidence Level

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0