Page 1

How to calibrate an RTD

or Platinum Resistance

Thermometer (PRT)

Topics Covered

●

Calibration by characterization

ITS-90

Callendar-Van Dusen

Polynomial

●

Tolerance testing

ASTM 1137

IEC 60751

Application Note

Introduction

There are two types of calibrations applicable to PRTs—characterization and tolerance

testing. The type of calibration to perform is determined by the way in which the UUT is

to be used and the accuracy required by the user. Characterization is the type of calibration in which the unit under test (UUT) resistance is determined at several temperature

points and the data are fitted to a mathematical expression. Tolerance testing on the

other hand is a calibration in which the UUT resistance is compared to defined values at

specific temperatures. No data fitting is performed. In the laboratory, we are required to

perform both types of calibration depending upon our customer’s needs.

Calibration Procedures

Characterization

Characterization is the method that is most often used for medium to high accuracy PRT

calibration. With this method, a new resistance vs. temperature relationship is determined anew with each calibration. Generally, with this type of calibration, new calibration coefficients and a calibration table are provided as a product of the calibration.

There are five basic steps to perform as listed below:

1. Place the reference probe and the UUTs in the temperature source in close proximity to one another.

2. Connect the leads to the readout(s) ensuring proper 2-, 3-, or 4-wire connection.

3. Measure the reference probe and determine the temperature.

4. Measure and record the resistance of the UUT(s).

5. Fit the data.

Some readouts simplify the technique by combining or eliminating some of the steps.

In the following discussion, we will consider an application involving PRT characterization by comparison to an SPRT.

Step 1: Probe Placement

All temperature sources have instabilities and gradients. These translate into calibration errors and/or uncertainties. To minimize the effects, the probes should be placed

as close together as practical. In baths the probes to be calibrated should be placed

in a radial pattern with the reference probe in the center (focus) of the circle. This

ensures an equal distance from the reference probe to each of the UUTs. In dry-well

temperature sources, the reference probe and probes to be calibrated should all be

placed the same distance from the center for best results, but the reference may be

placed in the center if needed.

Also, the sensing elements should be on the same horizontal plane. Even though

sensing elements are different lengths, having the bottoms of the probes at the same

level is sufficient. Sufficient immersion must be achieved so that stem losses do not

occur. Generally, sufficient immersion is achieved when the probes are immersed

to a depth equal to 20 times the probe diameter plus the length of the sensing element. For example, consider a 3/16 inch diameter probe with a 1 inch long sensing

element. Using the rule of thumb, 20 x 3/16 in + 1 in = 3 3/4 in + 1 in = 4 3/4 in.

In this example, minimum immersion is achieved at 4 3/4 inches. This rule of thumb

is generally correct with thin wall probe construction and in situations of good heat

transfer. If the probe has thick wall construction and/or poor heat transfer is present

(such as in the case of a dry-well with incorrectly sized holes), more immersion is

required.

F r o m t h e F l u k e D i g i t a l L i b r a r y @ w w w . f l u k e . c o m / l i b r a r y

Page 2

Step 2: Connection to Readout

This step is straightforward. Connections must be

tight and in proper 2-, 3-, or 4-wire configuration. If

using 4-wire configuration, ensure that the current

and voltage connections are correct. See Figure 1.

temperature data is available in real time. Some

modern readouts also display the data in graphical

format, allowing the operator to determine stability at a glance. Both of these features speed up the

process and eliminate possible operator error due to

incorrect table interpolation.

The second method is used when the readout

does not provide for proper temperature calculation.

(Some readouts, particularly DMMs, have some of

the more popular temperature conversions built in.

These typically do not allow use of unique calibration coefficients and cannot be used for accurate

temperature calibration.) In this case, the resistance

is measured and the temperature is determined

from either a calibration table or from a computer or

calculator program.

Since the temperature must be calculated after

the resistance is measured, the process is slower

and does not provide immediate, real time temperature data. See Tables 1 and 2 below.

Table 1. Interpolation from an RTD calibration table

(resistance vs. temperature).

t( °C) R(t) (W) dR/dt(t) W/°C

400 249.8820 0.3514

401 250.2335 0.3513

402 250.5848 0.3512

403 250.9360 0.3511

450 267.3108 0.3456

451 267.6564 0.3455

452 268.0019 0.3454

453 268.3472 0.3452

Figure 1. Thermometer readout connection schematics

Step 3: Measurement of Reference Probe

and Temperature Determination

There are two ways to measure the reference probe

and determine the temperature. Both techniques

have the same potential accuracy. That is, if done

correctly, neither technique is inherently more

accurate than the other.

The first and best method is used with sophisticated readouts designed for temperature work.

The resistance is measured and the temperature

calculated from calibration coefficients which were

entered into the readout previously. Once these

calibration coefficients have been entered, the temperature calculations are accomplished internally

and the readout displays in temperature units. The

1. Measure the reference

probe resistance

2. Locate where it falls on

the table

3. Subtract lower table value

from measured value

4. Divide by dR/dT(t) (slope

of curve)

5. Add fractional

temperature to table value

249.9071 W

between 249.8820 W and

250.2335 W

249.9071 W – 249.8820 W =

0.0251 W

0.0251 / 0.3514 = 0.0714 °C

0.0714 ’C + 400 =

400.0714 °C

Tech Tip

Manual calculation is more

prone to human error and

is more time consuming than using a readout

designed for temperature

work.

2 Fluke Corporation, Hart Scientific Division How to calibrate an RTD or Platinum Resistance Thermometer (PRT)

Page 3

Table 2. Interpolation from an RTD calibration

(resistance ratio (W) table).

t( °C) W(t) dt/dW(t)

300 2.1429223 275.2199

301 2.1465557 275.3075

302 2.1501880 275.3951

303 2.1538192 275.4827

350 2.3231801 279.6655

351 2.3267558 279.7559

352 2.3303304 279.8464

353 2.3339037 279.9369

1. Measure reference probe

resistance

2. Calculate W (Rt/R

= 25.54964)

3. Locate where it falls on

the table

4. Subtract lower table value

from measured value

5. Multiply by dt/dW(t)

(inverse slope of curve)

6. 6) Add fractional

temperature to table value

) (R

tpw

54.75258 W

54.75258 W / 25.54964 W =

tpw

2.1429883

between 2.1429223 and

2.1465557

2.1429883 – 2.1429223 =

0.000066

0.000066 • 275.2199 =

0.0182 °C

0.01821 °C + 300 °C =

300.0182 °C

Number of readouts - will the reference probe

•

and UUTs be measured with the same readout or

different readouts?

Type of readout - a readout designed for temper-

•

ature calibration often has features which allow

flexibility in the measurement scheme.

UUT characteristics - self-heating time, source

•

current requirements, stability, and overall quality influence the measurement process.

It is not possible for us to anticipate all of the

variables and discuss the optimum solutions here.

However, in the following examples, we will consider some typical calibration scenarios and suggested measurement schemes.

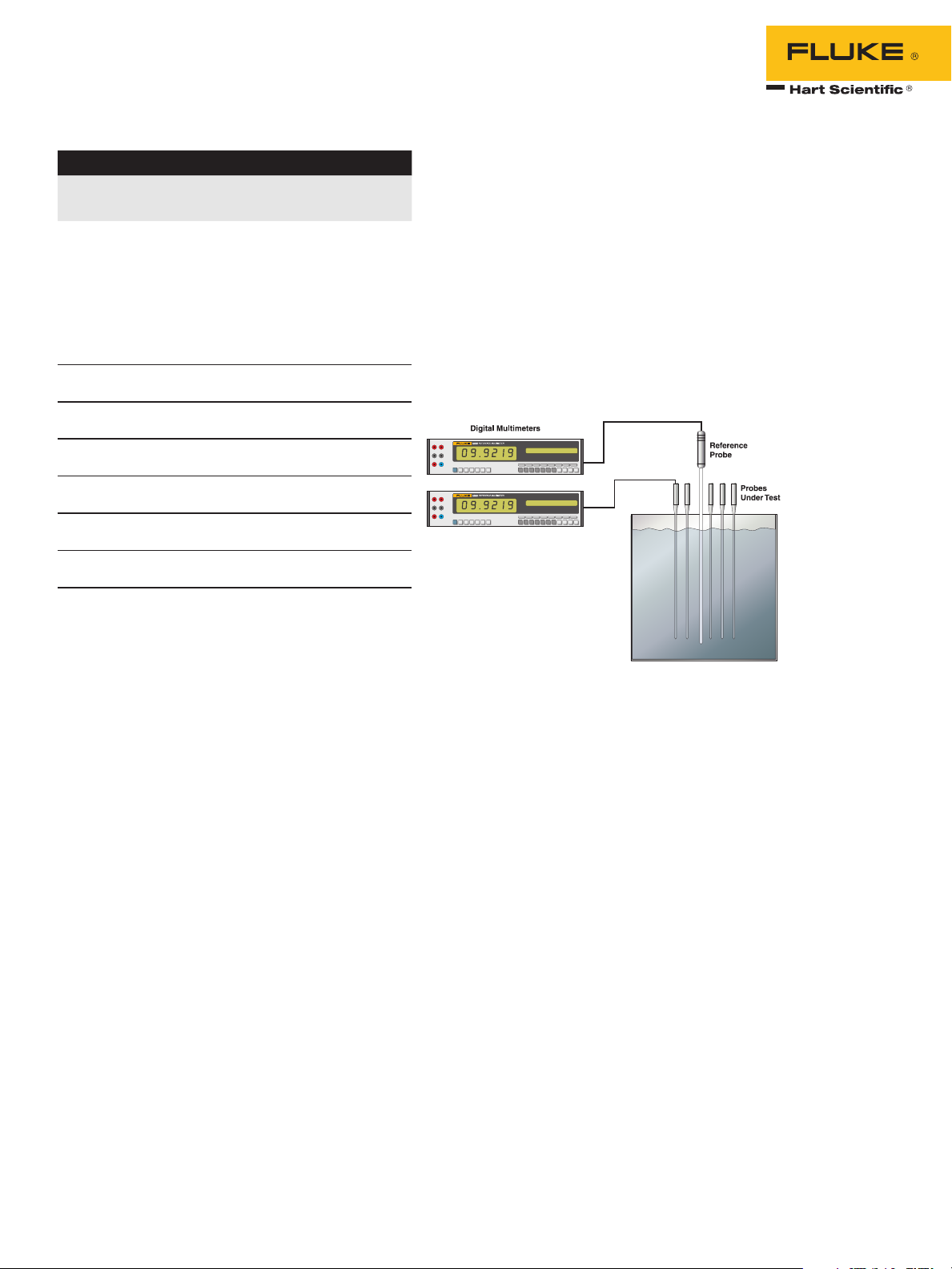

Example 1: 2 DMM readouts, 1 reference

probe and 5 UUTs

Step 4: Measurement of Units Under Test

(UUTs)

Since the UUTs are resistance thermometers similar to the reference probe, they are measured in

a similar manner. If several UUTs are undergoing

calibration, ensure that when they are connected

or switched in, sufficient time is allowed for selfheating to occur before the data is recorded. Also,

ensure that the readout is set to the correct range

to provide the proper source current and to prevent

range changes between the measurements at different temperatures. Typically, the measurements

are conducted starting at the highest temperature

of calibration and working down. Additionally, it

increases the precision of the calibration to use

a mean (average) value calculated from multiple

measurements at the same temperature. Often, the

readout is designed with statistical features to facilitate this practice. It is also a good practice to close

the process with an additional measurement of the

reference probe. The sequence in which the probes

(reference and UUT) are measured is referred to as a

measurement scheme. There are many variables to

consider when designing a measurement scheme.

Some points to consider are:

Accuracy - the higher the accuracy desired, the

•

more all of the following must be considered.

Temperature source stability - the more stable

•

the source, the more time exists to conduct

the measurements before temperature changes

cause unwanted error.

Number of UUTs - the higher the number, the

•

longer it takes to cycle through all UUTs.

The reference probe is connected to one readout

and the first UUT is connected to the second readout. This places the probes to be measured under

current at all times, thus, eliminating self-heating

errors caused by changing current conditions. The

UUTs will be connected and measured individually.

The scheme is as follows:

REF(1)-UUT (1) - REF(2)-UUT (2) - REF(3)-UUT (3) -

REF(4)-UUT (4) - REF(5)-UUT (5)

This provides 5 readings each of the reference

and the UUT. Take the average of the readings and

use it for the data fit. If the reference probe readings are in resistance, the temperature will have to

be computed. After completion, repeat the process

for the additional UUTs.

Fluke Corporation, Hart Scientific Division How to calibrate an RTD or Platinum Resistance Thermometer (PRT) 3

Page 4

Example 2: 1 DMM readouts, 1 reference

probe and 5 UUTs

This example is similar to the first except that the

reference probe and UUT must be measured by the

same readout. The same scheme can be followed

but more time must be allowed between readings to

allow for self-heating. Since more time is involved,

it might be beneficial to reduce the number of readings from five to three unless the heat source is

extremely stable. Each probe will be connected and

measured individually

The scheme is as follows:

wait-REF(1)-wait-UUT (1) - wait-REF(2)-wait-

UUT(2) - wait-REF(1)-wait-UUT(3)-done

This provides 3 readings each of the reference

and the UUT. Take the average of the readings and

use it for the data fit. Again, the reference probe

readings are in resistance so the temperature will

have to be computed. After completion, repeat the

process for the additional UUTs.

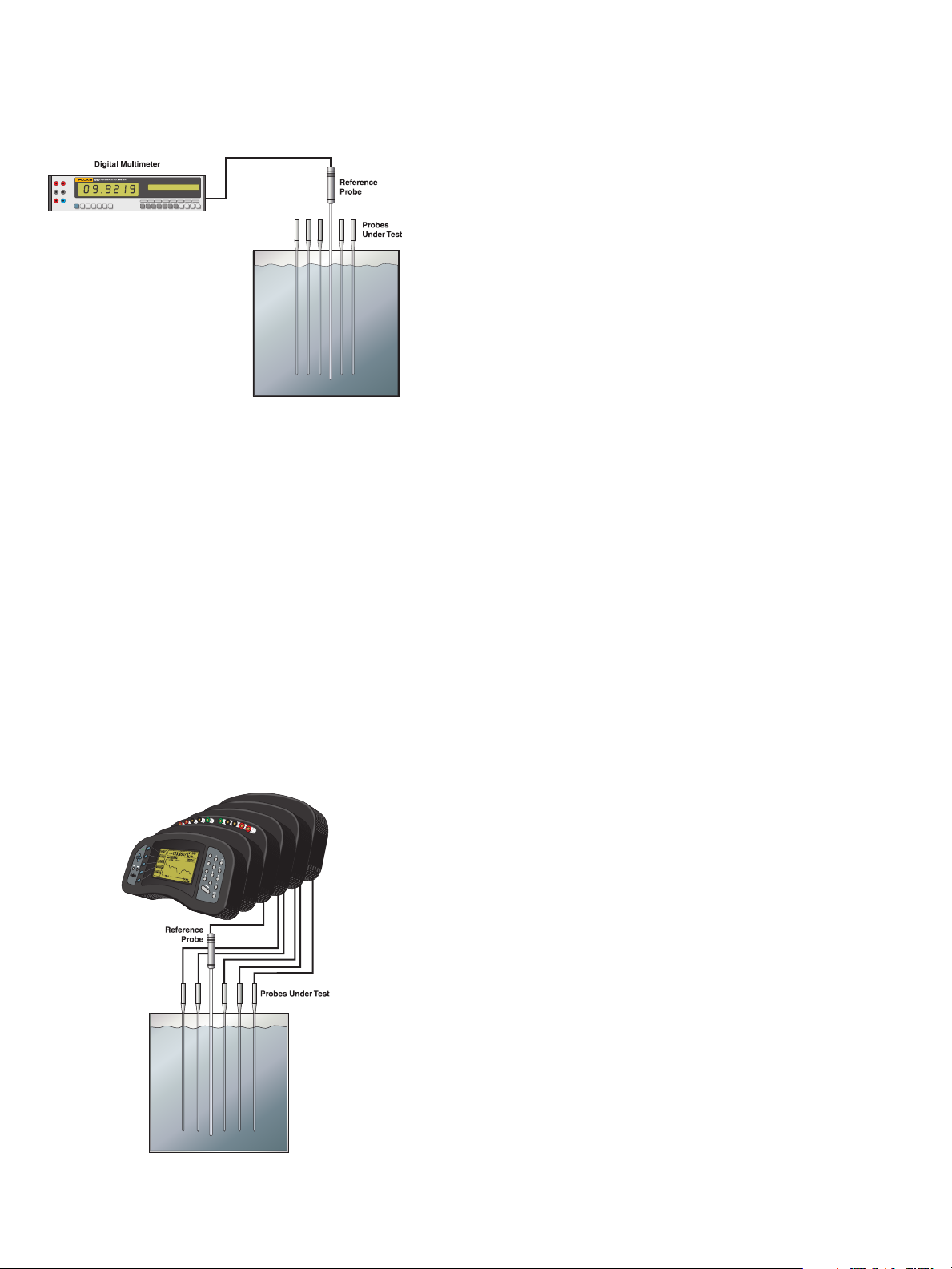

Example 3: 1 multi-channel thermometer

readout, 1 reference probe and 5 UUTs

In this example, all of the probes are connected

directly to the thermometer readout, a Hart Scien-

tific 1560 Black Stack. The readout controls the

measurement and scans through all probes performing statistics in real time. Current may or may not

be supplied at all times depending on the type of

thermometer readout. If current is supplied at all

times, there will be no self-heating errors. If current

is not supplied at all times, ensure that the switching is done rapidly enough to reduce self-heating

errors to a negligible level.

The scheme is as follows

REF - UUT 1 - UUT 2 - UUT 3 - UUT 4 - UUT 5 -

repeat 10 or more times

This provides many readings each of the reference and all of the UUTs. The average can be calculated and displayed directly by the readout. Also,

the reference probe readings are in temperature

so no further computation is required - the data is

ready to fit.

Step 5: Thermometer calibration

curve fitting

Data fitting is simple in concept but can be complicated in practice. Essentially it is a process of solving a set of simultaneous equations which contain

the calibration data to arrive at a set of coefficients

unique to the PRT and calibration. There are several

commercial software programs available specifically

written to accomplish this task. Some are limited

in function and do no more than solve the basic

temperature functions. Others are more flexible and

allow options regarding the number and location

of calibration points and provide analysis regarding

the precision of the resultant fit. The latter type of

program is preferred. For metrologists who wish to

tackle the algorithms themselves, a good mathematics application software like Mathcad or Mathematica or even a spreadsheet like Excel is extremely

helpful. Hart Scientific offers two programs:

TableWare for calculating calibration coefficients

and MET/TEMP II for automating calibration tasks

and calculating calibration coefficients. Of course,

programs can be written in any of the modern computer languages (with double precision or better

floating point capability) to perform the calculations

with equal accuracy.

There are several equations which are used for

PRT characterization. Among the most common

are the International Temperature Scale of 1990

(ITS-90) series, the Callendar-Van Dusen, and

third through fifth order polynomials. Obviously,

with more than one model available to describe

the behavior of a physical system, we must choose

which one is best for our situation. The following

discussion covers the features and purpose of each

of these models and describes the form of the equations. The steps necessary to actually fit the data

will be discussed in the section on mathematics

later in this manual.

ITS-90: The ITS-90 series of functions were

developed through a concerted effort from the

international metrology community’s leading temperature experts. These functions are intended to

describe how the behavior of the SPRT relates, with

a very high degree of precision, to the fixed points

4 Fluke Corporation, Hart Scientific Division How to calibrate an RTD or Platinum Resistance Thermometer (PRT)

Page 5

on which the scale is based. It does this extremely

well SPRTs and with high quality PRTs. The ITS90 uses a reference function - deviation function

structure that has many advantages over traditional

polynomials and is the preferred model for high

accuracy applications. In the equations below, capital T refers to ITS-90 temperatures expressed in

Kelvin units.

Equation 1. ITS-90 resistance ratio

R T

( )

W T

( )

90

90

=

R

TPW

Where: W(T90) = resistance ratio at temperature T

R(T90) = measured resistance at temperature T

RTPW = measured resistance at the triple

point of water

Equation 2. Deviation from ITS-90 reference function.

∆W T W T W T

( ) ( ) ( )

= −

90 90 90

r

Where: ∆W(T90) = deviation of calculated W from

reference function at temperature T

W(T90) = calculated resistance ratio at temperature T (from equation (1))

Wr(T90) = reference function value at temperature T

Equation 3. Reference function for the range

13.8033 K to 273.16 K (–259.3467 °C to 0.01 °C):

i

.

1 5

+

12

ln W T A A

( ( ))

= +

r i

90 0

∑∑

i

=

1

T

ln

90

.

273 16

.

1 5

Where: Wr(T90) = reference function value at tem-

perature T

Ai = reference function coefficients from

definition

Equation 4. Deviation function for the subrange

83.8058 K to 273.16 K (–189.3442 °C to 0.01 °C):

∆W T a W T b W T W T

4 90 4 90 4 90 90

1 1( ) ( ( ) ) ( ( ) ) ln( ( ))= ⋅ − + ⋅ − ⋅

Where: ∆W(T90) = calculated deviation value at

temperature T (from equation (2))

W(T90) = calculated resistance ratio at

temperature T (from equation (1))

a4, b4 = resulting calibration coefficients

Where: Wr(T90) = reference function value at tem-

perature T

Ci = reference function coefficients from

definition

Equation 6. Deviation function for the subrange

273.15 K to 692.677 K (0.00 °C to 419.527 °C):

∆W T a W T b W T

8 90 8 90 8 90

1 1( ) ( ( ) ( ( ) )= ⋅ − + ⋅ −

2

Where: ∆W(T90) = calculated deviation value at tem-

perature T (from equation (2))

W(T90) = calculated resistance ratio at temperature T (from equation (1))

a8, b8 = resulting calibration coefficients

The designations 4 and 8 in the deviation functions, equations (4) and (6) were inserted by NIST

for identification of specific subranges. The values

for the coefficients Ai and Ci in the reference functions, equations (3) and (5) are given in Table 3.

Table 3. ITS-90 Reference Function Coefficients

Coefficient Value

A

0

A

1

A

2

A

3

A

4

A

5

A

6

A

7

A

8

A

9

A

10

A

11

A

12

C

0

C

1

C

2

C

3

C

4

C

5

C

6

C

7

C

8

C

9

–2.135 347 29

3.183 247 20

–1.801 435 97

0.717 272 04

0.503 440 27

–0.618 993 95

–0.053 323 22

0.280 213 62

0.107 152 24

–0.293 028 65

0.044 598 72

0.118 686 32

–0.052 481 34

2.781 572 54

1.646 509 16

–0.137 143 90

–0.006 497 67

–0.002 344 44

0.005 118 68

0.001 879 82

–0.002 044 72

–0.000 461 22

0.000 457 24

Equation 5. Reference function for the range

273.15 K to 1234.93 K (0.00 °C to 961.78 °C):

i

.

Fluke Corporation, Hart Scientific Division How to calibrate an RTD or Platinum Resistance Thermometer (PRT) 5

9

W T C C

( )

= +

r i

90 0

∑

i

=

1

T

90

754 15

−

K

481

Page 6

Callendar-Van Dusen: The Callendar-Van

Dusen (CVD) equation has a long history. It was the

main equation for SPRT and PRT interpolation for

many years. It formed the basis for the temperature

scales of 1927, 1948, and 1968. This equation is

far simpler than the ITS-90 equations but has serious limitations in the precision of fit. As a result, it

is not suitable for high accuracy applications but

is perfectly suited to modest accuracy applications.

Partly due to its history and simplicity, but mostly

due to its continued suitability, it continues to be

the preferred model for industrial platinum resistance thermometers today. In the equations below,

lower case t refers to ITS-90 temperature in Celsius

units.

Equation 7. Callendar-Van Dusen resistance ratio

R t

( )

( )

=

R

0

W t

Where: W(t) = resistance ratio at temperature t

R(t) = measured resistance at temperature t

R0 = measured resistance 0 °C

And...

Equation 8. Callendar-Van Dusen equation

W t At Bt Ct t( ) ( )= + + + ⋅ −1 100

2 3

Where: W(t) = resistance ratio at temperature t (ref-

erence 0 °C)

A,B,C = calibration coefficients (C is = 0

for temperatures above 0 °C)

NOTE: All temperatures are expressed in °C and

the resistance ratio (W) is referenced to

0 °C rather than the triple point of water

(0.010 °C) as with the ITS-90.

Polynomials: Polynomials are frequently used

to model physical phenomena from all fields of science. They have limited use with PRTs because of

the high order required to achieve a suitable fit.

(Recall that the reference functions for the ITS-90

are 9th and 12th order polynomials for the ranges

above 0 °C and below 0 °C.) Additionally, the previous models use resistance ratio as the variable to fit.

Most polynomials in use fit the resistance directly.

Since resistance is not as stable as the resistance

ratio, these models have serious limitations. That

having been said, polynomials can be very useful

over limited ranges and in applications where accuracy requirements are very modest.

Equation 9. Typical RTD polynomial equation

t a bR cR dR eR= + + + +

2 3 4

Tolerance Testing Method

PRT calibrations involving tolerance testing are

reserved for low accuracy applications. With this

type of calibration the UUT resistance is compared

to defined values at specific temperatures. The

values are defined by one of the common models

such as the ASTM 1137 or IEC 60751 curve. PRTs

calibrated in this way are generally used in industrial style applications where the readout is unable

to accept unique coefficients but is pre-programmed

with a common PRT curve. The probe must be

tested to ascertain its compliance to the curve of

interest. There are accuracy classes defined that

probes are intended to fit.

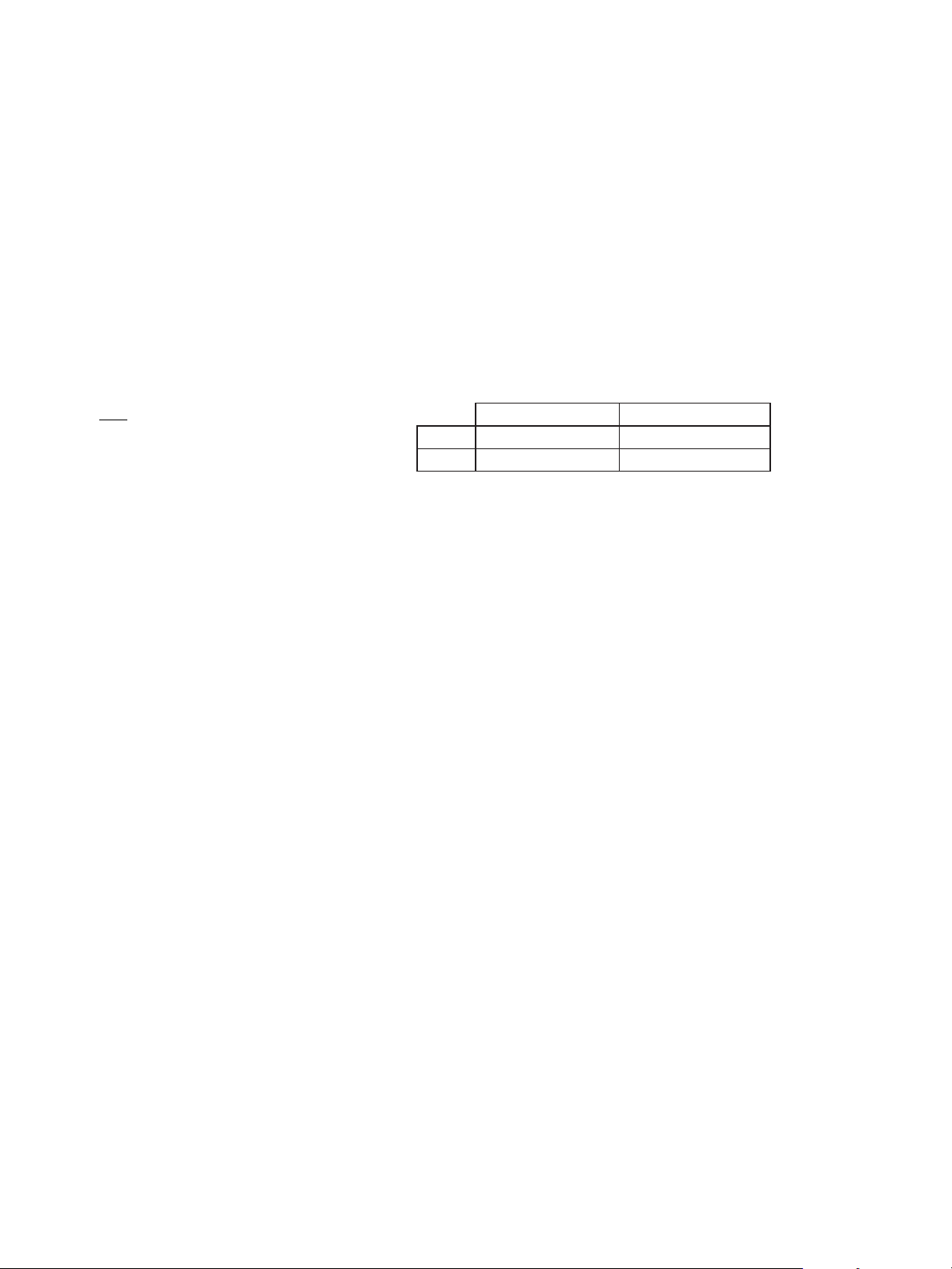

The two common accuracy classes are class A

and class B::

IEC 60751 ASTM 1137

Class A

Class B

± [0.15 + (0.002 · t)] °C ± [0.13 + (0.0017 · t)] °C

± [0.30 + (0.005 · t)] °C ± [0.25 + (0.0042 · t)] °C

These include errors arising from deviations in

R0 and from errors in slope. Frequently, we will see

probes rated at a fraction of Class A. For example,

0.1 ASTM Class A. Fractional accuracy is achievable

in sensors alone, but are very difficult to achieve in

probes. The calculations are straightforward. See

below:

Example 4: Calculate the accuracy of a 0.1

ASTM Class A probe at 100 °C

1. = (0.13 + (0.0017 · t)) · 0.1

2. = (0.13 + (0.0017 · 100)) · 0.1

3. = (0.13 + 0.17) · 0.1 = 0.03

PRTs that conform to a standard specification

such as ASTM 1137 or IEC 60751 are expected to

be within tolerances of defined resistance values

for any given temperature. The resistance values

are defined by a form of the Callendar-Van Dusen

(CVD) equation and specified values for coefficients

A,B and C (see table 4). These values may be determined using a published table or calculated by solving the equations.

Measurements for tolerance testing are carried

out in the same manner as measurements for characterization. ITS-90 temperature is determined by

the reference thermometer. The resistance of the

UUT is then compared to the defined resistance values, and pass or fail status is determined based on

the specified tolerances (i.e. Class A or Class B).

Where: t = temperature

R = resistance

a,b,c,d,e = calibration coefficients

6 Fluke Corporation, Hart Scientific Division How to calibrate an RTD or Platinum Resistance Thermometer (PRT)

Page 7

Table 4. Equations for ASTM 1137 and IEC 60751

− ° ≤ < °200 0 C Ct

0 650 ° ≤ ≤ °C Ct

Range Callendar-Van Dusen Equation

R R At Bt C t t

= + + + −

1 100[ ( ) ]

t

0

R R At Bt

= + +

1[ ]

t

0

ASTM 1137 and IEC 60751 coefficient values

A = 3.9083 X 10–3

B = –5.775 X 10–7

C = –4.183 X 10–12

2 3

2

Example 5: Calculate the tolerance of a 0.1

ASTM Class A probe at 100 °C

Measure the reference probe

temperature

Measure the indicated

UUT temperature using

ASTM 1137 equation and

coefficients

Calculate the error 0.05 °C

Calculate the tolerance at

100.00 °C

Determine tolerance status Fail (0.05 °C > 0.03 °C)

100.00 °C

100.05 °C (Given)

0.03 °C (See example 4)

To be certain of the tolerance status of a calibrated instrument it is necessary to have calibration uncertainties that are significantly better than

the tolerance of the instrument being calibrated.

Typically a ratio of 4:1 or four times better than

the tolerance of the instrument being calibrated is

required. When this is not the case the risk may be

unacceptably high that out of tolerance instruments

will be falsely accepted or that in tolerance instruments will be falsely rejected. As the magnitude of

the detected error approaches the tolerance of the

calibrated instrument, the risk of incorrectly assigning a tolerance status increases. Guard bands may

be helpful in these circumstances. For example if

a guard band is 80% of the tolerance then instruments found within 80% of their tolerance will

pass, instruments outside of the tolerance will fail

and instruments that are in between will be indeterminate. The better the calibration uncertainties

the tighter the guard band can be.

Conclusion

Platinum Resistance Thermometer calibration procedures are similar whether the method selected

is characterization or tolerance testing. For best

accuracy with modern equipment choose characterization. For equipment that does not allow characterization, tolerance testing may be your only choice

and this is a common situation in industry today.

When conducting tolerance testing it is important to

use equipment and procedures with sufficient accuracy to determine the tolerance status confidently.

Fluke Corporation, Hart Scientific Division How to calibrate an RTD or Platinum Resistance Thermometer (PRT) 7

Page 8

8 Fluke Corporation, Hart Scientific Division How to calibrate an RTD or Platinum Resistance Thermometer (PRT)

Fluke. Keeping your world

up and running.

Fluke Corporation

Hart Scientific Division

799 E Utah Valley Drive

American Fork, UT 84003

Tel: 801.763.1600

Fax: 801.763.1010

E-Mail: info@hartscientific.com

www.hartscientific.com

Fluke Eurpoe B. V.,

Hart Scientific Division

PO Box 1186, 5602 BD Eindhoven

The Netherlands

Tel: +31 (0)40 2675 403

Fax: +31 (0)40 2675 404

E-mail: Hart.Logistics@Fluke.NL

All other countries:

Tel: +1 801.763.1600

Fax: +1 801.763.1010

©2009 Fluke Corporation. All rights reserved.

Specifications subject to change without notice.

6/2009 3498460 A-EN-Rev A

®

Loading...

Loading...