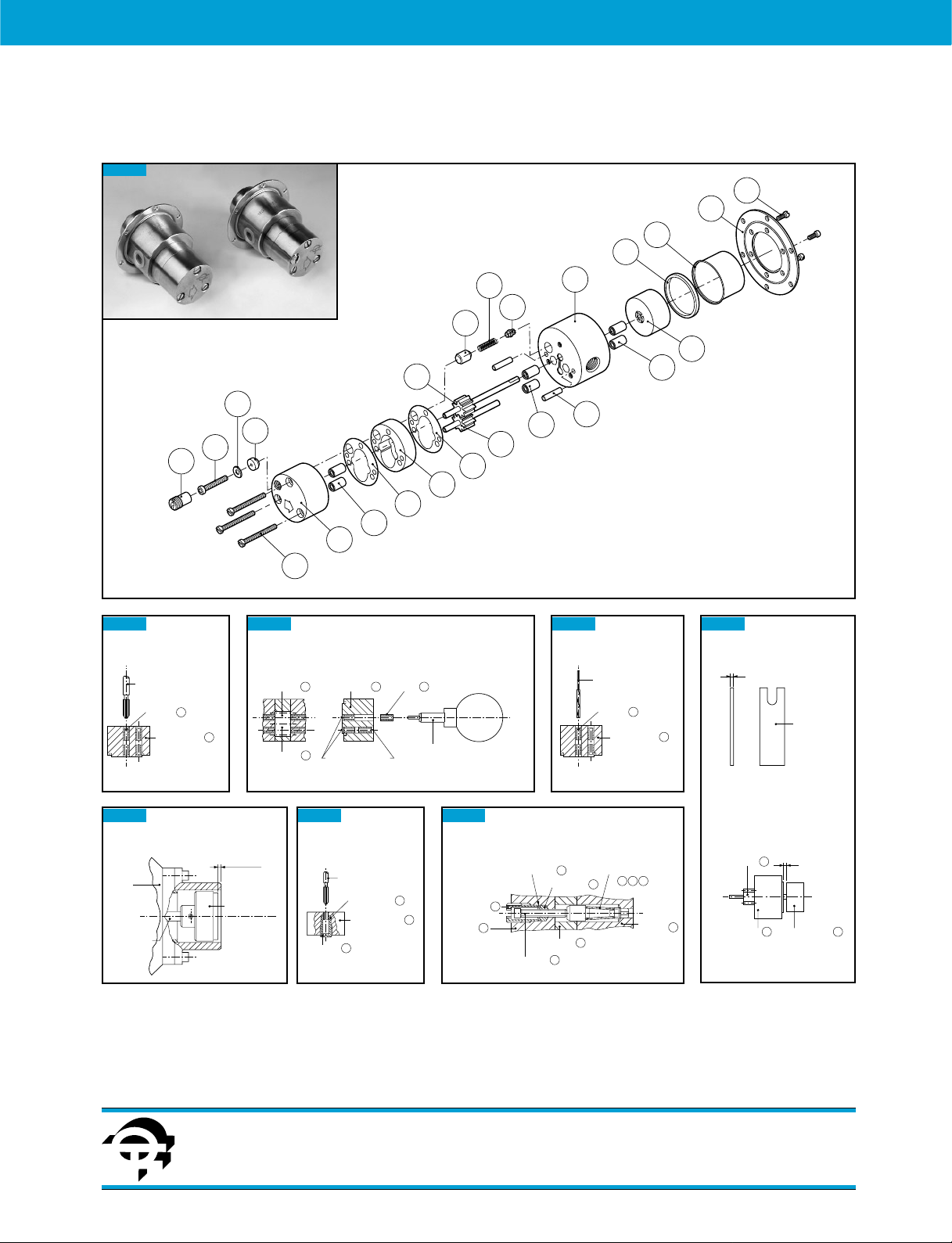

fluid-o-tech MG 200 Series, MG 204, MG 209, MG 213 Refurbishing Instructions

http://www.fluidotech.it

Fluid-o-Tech

Fluid-o-Tech magnet drive gear pumps MG 200 series

spare parts list and refurbishing instructions

Via Morimondo, 23

20143 Milano - Italy

Tel. (39) 02 8917071

Fax (39) 02 89170799

AF204, 8-10-17, Fukasawa,

Setagaya, Tokyo 158-0081 Japan

Tel. (81) (0) 3-3705-5440

Fax (81) (0) 3-5707-7414

161 Atwater St.,

Plantsville CT (USA) 06479

Tel. (1) (860) 276-9270

Fax (1) (860) 620-0193

1

2

3

4

15

Bushings extraction

Bushing extractor tool

P/N 60211

6

Bushing

Rear housing

Figure 1

17

7

21

16

Driving gear

Driven gear

13

14

Bushings installation

8 Rear housing7Bushing

9

Recessed 0.5 mm

19

7

20

18

5

8

12

6

6

9

10

11

10

6

Driven magnet setting

A

Spacer

P/N 60213

6

Bushing tool

P/N 60212

Figure 2

Bushings reaming

Reamer

P/N 60210

6

Bushing

Rear housing

Figure 3

7

Driving magnet setting positioning

Motor

Motor shaft

By-pass seal tapping

0

3-0.1 mm

Driving magnet

By-pass nut

Figure 7

Tap P/N 60214

By-pass seal

Front housing

15

Figure 6

16

By-pass nut

13

Front

13

housing

By-pass

21

By-pass seal

15

Housing

11

Adjusting screw

17

Figure 4

7

Driving gear 8

Rear housing 7

Poppet assemblyBy-pass washer

20

18

19

16

Rear

housing

Figure 5

A

Driven magnet 5

Disassembly Instructions

Provide a clean surface for work area.

Separate the pumphead from the magnet cap.

Remove the 3 screws and disassemble front housing ,

driven gear , central housing and dowel pins .

If the pump is equipped with by-pass, make sure not

to damage the sealing poppet .

Remove the poppet assembly from the adjusting screw

(fig. 5),remove the by-pass nut , the adjusting screw

turning counter-clockwise,the by-pass washer and

the by pass seal from the cap.

Remove the screws which secure the magnet cup

and the mounting plate to the rear housing and

disassemble.

Remove and discard all the bushings from the rear

housing and the front housing with the bushing

extractor tool P/N 60211 (fig.1).

Remove seal and flat seals from the rear housing

and from the front housing and discard them.

If wear on front housing, rear housing or center housing

is excessive, rebuilding the pump my not be advisable.

Re-Assembly Instructions

Clean carefully all parts before re-assembling.

Any foreign body material clinging to magnet must

be removed.

Note

Bushings - Bushings on both sides of gears must be

recessed 0.5 mm from the face of the rear housing

and front housing (fig. 2)

Bushings Installation - Press 6 new bushings into

the rear housing and front housing as shown

in figure 2 using P/N 60212 installation tool.

Once in place, the bushings need to be reamed with

P/N 60210 reamer tool (fig. 3).

Seals - Apply a thin coat of silicone grease on the central

housing surfaces and place the flat seals on each

side of it insert the driving gear into the rear housing

and then insert the shaft of the driving gear in the

driven magnet using the spacer P/N 60213 (fig. 4).

Insert 2 dowel pins in the body.

Slip carefully central housing onto dowel pins against

body face, verifying the proper,alignment of the screw

holes.

Install the driven gear (The side of gear assembly

with longer shaft extension goes into the rear housing).

If pump is equipped with by-pass, install the by-pass

seal , then by-pass nut and tighten to prevent

by-pass seal rotation.

Then tap the by-pass seal with the P/N 60214 tool (fig. 6).

Disassemble the by-pass nut and install by-pass washer

and turn clockwise the adjusting screw before

installing again the by-pass nut tightening.

Align the cap bushing holes with gear shafts, and dowel

pins with cap dowel pin holes and assemble.

Make sure that the poppet assy goes fully into poppet

holes and seat (fig. 5).

Install 3 screws in cap and tighten alternately

as tight as possible.

Turn driven magnet with fingers to check for any

binding during the rotation: the magnet should turn

freely.

Install magnet cup and mounting plate with

3 screws and turn alternately until tight.

Assemble the driving magnet to the motor (see fig. 7)

and the pumphead to the motor.

Service Kit - MG Gear Pump

Stainless steel pumphead

Service kit contents

2 gears - 1 Teflon “O” ring - 2 Teflon flat seals - 6 bearings

Service kit tools

1 reamer P/N 60210

1 extractor P/N 60211

1 bushing tool P/N 60212

1 spacer P/N 60213

1 tap P/N 60214

SPARES & INSTRUCTIONS – 10/01 Ed.

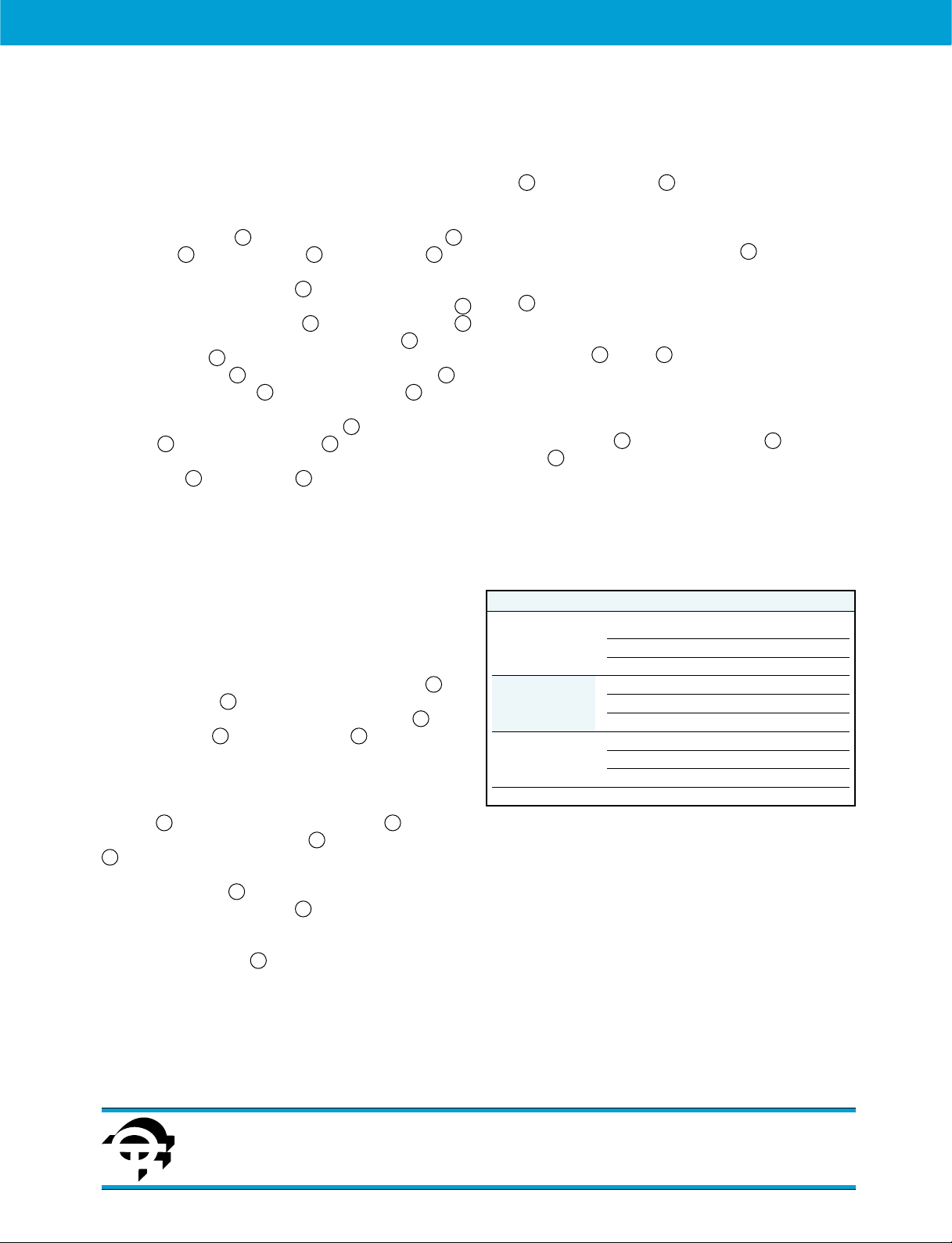

Fluid-o-Tech magnet drive gear pumps MG 200 series

spare parts list and refurbishing instructions

14

9 11

11 10

8

7

12

11

9

20

15

16

1 3

72

6

7

4 10

13

13

6

7 13

7

21

17

17

12

13

16

12

14 13

3

1

2

15

17

Gear material Service Kit P/N

PTFE MGKT3

204 pumphead RYTON

®

MGKR3

PEEK

™

MGKP3

PTFE MGKT4

209 pumphead RYTON

®

MGKR4

PEEK

™

MGKP4

PTFE MGKT5

213 pumphead RYTON

®

MGKR5

PEEK

™

MGKP5

http://www.fluidotech.it

Fluid-o-Tech

Via Morimondo, 23

20143 Milano - Italy

Tel. (39) 02 8917071

Fax (39) 02 89170799

AF204, 8-10-17, Fukasawa,

Setagaya, Tokyo 158-0081 Japan

Tel. (81) (0) 3-3705-5440

Fax (81) (0) 3-5707-7414

161 Atwater St.,

Plantsville CT (USA) 06479

Tel. (1) (860) 276-9270

Fax (1) (860) 620-0193

Loading...

Loading...