Fluid Components Intl ST51A, ST75A, ST75AV Installation, Operation & Maintenance Instruction Manual

Doc. No. 06EN003426 Rev. C

06EN003426 Rev. C ST51A/ST75A/ST75AV Mass Flow Meters

Notice of Proprietary Rights

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Fluid Components

International LLC (FCI).Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company

only (and does not include manufacture or processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

© Copyright 2019 by Fluid Components International LLC. All rights reserved. FCI is a registered trademark of Fluid Co mponen ts Internat iona l LLC. Info rmation subject to change w ithout not ice.

Fluid Components International LLC

ST51A/ST75A/ST75AV Flow Meter s 06EN003426 Rev. C

Table of Contents

Table of Contents ......................................................................................................................................................................................iii

List of Figures ..........................................................................................................................................................................................vii

List of Tables ........................................................................................................................................................................................... viii

1 GENERAL ......................................................................................................................................................................................... 1

Product Description ........................................................................................................................................................................... 1

Theory of Operation .......................................................................................................................................................................... 1

Safety Instructions ............................................................................................................................................................................. 1

Order Verification .............................................................................................................................................................................. 1

Hardware – Model Descriptions ................................................................................................................................................ 2

Optional Accessories ................................................................................................................................................................ 2

Specifications .................................................................................................................................................................................... 3

2 INSTALLATION ................................................................................................................................................................................. 5

Instrument Identification and Outline Dimensions ............................................................................................................................. 5

Pre-Installation .................................................................................................................................................................................. 5

Serial Number ........................................................................................................................................................................... 5

Flow Direction Alignment .......................................................................................................................................................... 5

Recommended Straight Run ..................................................................................................................................................... 7

Installing ST51A Flow Element ......................................................................................................................................................... 7

Compression Fitting Mounting .................................................................................................................................................. 7

Retractable Packing Gland Mounting ........................................................................................................................................ 9

Retraction/Removal Procedure ....................................................................................................................................... 10

Installing ST75A/ST75AV Flow Element ......................................................................................................................................... 11

Pipe Tee Installation ................................................................................................................................................................ 11

Tube Tee Installation ............................................................................................................................................................... 11

NPT Flow Tube Installation ..................................................................................................................................................... 11

Flanged Installation ................................................................................................................................................................. 11

Re-positioning the Display .............................................................................................................................................................. 11

Installing the Remote Flow Meter System ....................................................................................................................................... 12

Remote Cable ......................................................................................................................................................................... 13

Local Enclosure ....................................................................................................................................................................... 14

Remote Enclosure ................................................................................................................................................................... 15

Instrument Wiring ............................................................................................................................................................................ 17

Accessing the Interface Board Connection Terminals ............................................................................................................ 18

ESD Precautions ............................................................................................................................................................. 18

Interface Board Connections ................................................................................................................................................... 19

Power Connections ......................................................................................................................................................... 19

Signal Connections ................................................................................................................................................................. 21

4-20 mA Analog Outputs ................................................................................................................................................. 21

HART Connections .......................................................................................................................................................... 22

Fluid Components International LLC iii

06EN003426 Rev. C ST51A/ST75A/ST75AV Mass Flow Meters

Pulse Output and Alarm (Source/Sink) ........................................................................................................................... 23

Modbus Connections ....................................................................................................................................................... 24

Serial Interface Connector J9 .................................................................................................................................................. 25

3 OPERATION ................................................................................................................................................................................... 27

Overview ......................................................................................................................................................................................... 27

Instrument Configuration and Setup Using the Service Port (RS-232) ........................................................................................... 27

Main Menu .............................................................................................................................................................................. 28

Top Level Menu Commands ................................................................................................................................................... 28

Secondary Commands: CLI .................................................................................................................................................... 28

Start-up and Commissioning ........................................................................................................................................................... 28

Z Menu: Configure Flow Units and 4-20 mA Output Scaling .......................................................................................................... 29

Changing Flow Units, Example ............................................................................................................................................... 30

V Menu: Configure Outputs (4-20 mA and Source/Sink Outputs) ................................................................................................... 30

4-20 mA Configuration ............................................................................................................................................................ 32

Flow/Temperature Assignment ....................................................................................................................................... 32

NAMUR Mode ................................................................................................................................................................. 32

HART Damping Value ..................................................................................................................................................... 32

Source/Sink Output Configuration ........................................................................................................................................... 32

Source/Sink Output Functions ......................................................................................................................................... 32

Source/Sink Output Programming Parameters ............................................................................................................... 32

Serial Interface Command Reference ............................................................................................................................................. 33

Top Level Menu Commands ................................................................................................................................................... 33

CLI Commands ....................................................................................................................................................................... 34

HART Operation .............................................................................................................................................................................. 36

Process Data Operation .......................................................................................................................................................... 36

ST51A/ST75A/ST75AV HART Process Data Organization .................................................................................................... 36

ST51A/ST75A/ST75AV Process Variable Slots .............................................................................................................. 36

Primary Variable Classifications ...................................................................................................................................... 36

Device Description Files .......................................................................................................................................................... 36

EDDL Files ...................................................................................................................................................................... 37

Loading the DD Files to the 475 Field Communicator ............................................................................................................ 37

Service Data Operation ........................................................................................................................................................... 37

HART Command List Reference ..................................................................................................................................................... 40

ST51A/ST75A/ST75AV HART Universal Commands ............................................................................................................. 40

ST51A/ST75A/ST75AV HART Common Practice Commands ............................................................................................... 47

ST51A/ST75A/ST75AV HART Device Specific Commands ................................................................................................... 49

HART Command Bit Assignments .......................................................................................................................................... 52

Command Status Bytes ................................................................................................................................................... 52

Command 48, Additional Device Status Bytes ................................................................................................................ 54

HART Engineering Units Codes .............................................................................................................................................. 55

iv Fluid Components International LLC

ST51A/ST75A/ST75AV Flow Meter s 06EN003426 Rev. C

Modbus Operation ........................................................................................................................................................................... 56

Setting Up the ST51A/ST75A/ST75AV for Modbus Operation ............................................................................................... 56

ST51A/ST75A/ST75AV Modbus Commands .......................................................................................................................... 57

ST51A/ST75A/ST75AV Process Data Registers .................................................................................................................... 57

Totalizer Register Description ................................................................................................................................................. 58

ST51A/ST75A/ST75AV Modbus Service Registers ................................................................................................................ 59

Examples of Totalizer Service Register Access using ModScan32 ........................................................................................ 59

Checking the Totalizer Value .......................................................................................................................................... 59

Resetting the Totalizer Value .......................................................................................................................................... 61

Starting/Stopping the Totalizer Count ............................................................................................................................. 61

Checking K Factor Values ............................................................................................................................................... 62

Changing/Setting K Factor Values .................................................................................................................................. 62

Modbus Engineering Units Codes Table ................................................................................................................................. 64

Modbus Device Status Code Table ......................................................................................................................................... 64

4 MAINTENANCE .............................................................................................................................................................................. 65

Calibration ....................................................................................................................................................................................... 65

Electrical Connections ..................................................................................................................................................................... 65

Remote Enclosure ........................................................................................................................................................................... 65

Electrical Wiring .............................................................................................................................................................................. 65

Flow Element Connections ............................................................................................................................................................. 65

Flow Element Assembly .................................................................................................................................................................. 65

5 TROUBLESHOOTING .................................................................................................................................................................... 67

Application Verification .................................................................................................................................................................... 67

Equipment Needed ......................................................................................................................................................................... 67

Check Serial Numbers .................................................................................................................................................................... 67

Check the Instrument Installation .................................................................................................................................................... 67

Check for Moisture .......................................................................................................................................................................... 67

Check Application Design Requirements ........................................................................................................................................ 67

Verify Standard Versus Actual Process Conditions ........................................................................................................................ 67

Verifying Calibration Parameters (Diagnostics) .............................................................................................................................. 68

Hardware Verification ...................................................................................................................................................................... 69

Fuse Check ............................................................................................................................................................................. 69

Sensor Check .......................................................................................................................................................................... 69

Transmitter Circuit Calibration Check (Delta R Verification) ........................................................................................................... 70

References .............................................................................................................................................................................. 70

Equipment ............................................................................................................................................................................... 70

Procedure ................................................................................................................................................................................ 70

Fluid Components International LLC v

06EN003426 Rev. C ST51A/ST75A/ST75AV Mass Flow Meters

APPENDIX A DRAWINGS .................................................................................................................................................................. 73

APPENDIX B GLOSSARY .................................................................................................................................................................. 91

Abbreviations .................................................................................................................................................................................. 91

Definitions ....................................................................................................................................................................................... 91

APPENDIX C APPROVAL INFORMATION ........................................................................................................................................ 93

EU Information ........................................................................................................................................................................ 93

Specific Conditions of Use per FM16ATEX0008X .................................................................................................................. 94

IEC Information ....................................................................................................................................................................... 95

APPENDIX D CUSTOMER SERVIC E .............................................................................................................................................. 101

Customer Service/Technical Support .................................................................................................................................... 101

Warranty Repairs or Returns ................................................................................................................................................ 101

Non-Warranty Repairs or Returns ......................................................................................................................................... 101

Extended Warranty ............................................................................................................................................................... 101

Return to Stock Equipment ................................................................................................................................................... 101

Field Service Procedures ...................................................................................................................................................... 102

Field Service Rates ............................................................................................................................................................... 102

vi Fluid Components International LLC

ST51A/ST75A/ST75AV Flow Meter s 06EN003426 Rev. C

List of Figures

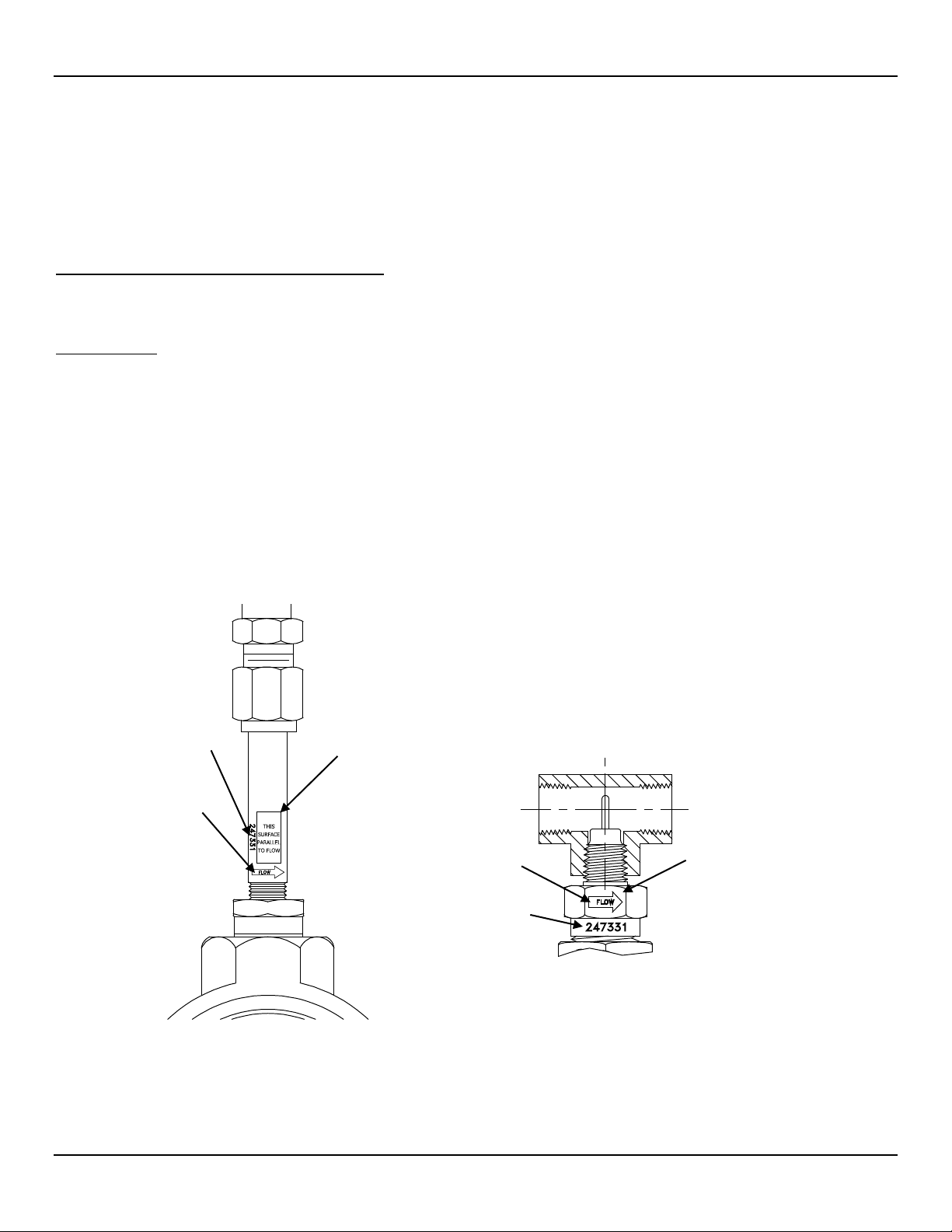

Figure 1 – Probe Serial Number, Reference Flat and Flow Direction Mark .............................................................................................. 5

Figure 2 – Serial Number Location on Interface Board (AC Version Shown) with Blind Cover Removed ................................................ 6

Figure 3 – ST51A Flow Arrow Alignment .................................................................................................................................................. 6

Figure 4 – Recommended Straight Run (ST75A Shown) ......................................................................................................................... 7

Figure 5 – Flow Element Installation, Compression Fitting ST51A ........................................................................................................... 8

Figure 6 – Flow Element Installation, Retractable Packing Gland ST51A ................................................................................................ 9

Figure 7 – Retractable Packing Gland Locking Collar Detail .................................................................................................................. 10

Figure 8 – Display Re-positioning ........................................................................................................................................................... 12

Figure 9 – Typical Remote Flow Meter System (ST51A with ½" NPT Cable Port Shown) ..................................................................... 12

Figure 10 – Remote Cable, Interconnecting ........................................................................................................................................... 13

Figure 11 – Remote Cable Installation, Local Enclosure ........................................................................................................................ 14

Figure 12 – Local Enclosure Remote Cable Wiring ................................................................................................................................ 14

Figure 13 – Remote Cable/Bracket Installation, Remote Enclosure ....................................................................................................... 16

Figure 14 – Remote Enclosure Interface Board Connector J4 Detail (AC Version Shown).................................................................... 16

Figure 15 – ST51A/ST75A/ST75AV Wiring Access ................................................................................................................................ 17

Figure 16 – Recommended Wire Routing/Internal Ground Screw .......................................................................................................... 18

Figure 17 – Power and Signal Wiring Terminals ..................................................................................................................................... 19

Figure 18 – Input Power Fuse Locations ................................................................................................................................................ 20

Figure 19 – Single Connection and Multidrop HART Setups .................................................................................................................. 22

Figure 20 – Sink Output .......................................................................................................................................................................... 23

Figure 21 – Source Output ...................................................................................................................................................................... 23

Figure 22 – Modbus Wiring ..................................................................................................................................................................... 24

Figure 23 – Serial Cable Adapter 025859-01 Plugged Into Flow Meter J9 Header ................................................................................ 25

Figure 24 – Block Diagram: Flow Meter Serial Port Connections, FC88 and Computer ........................................................................ 26

Figure 25 – Z Menu Command Structure: Units and Scaling Setup ....................................................................................................... 29

Figure 26 – V Menu Command Structure: Output Configuration Setup .................................................................................................. 31

Figure 27 – Field Communicator Easy Upgrade Utility, Import DD ......................................................................................................... 37

Figure 28 – Reference and Active Sensor Resistance Check (AC Version Shown) .............................................................................. 69

Figure 29 – Transmitter Circuit Calibration Diagram ............................................................................................................................... 71

Figure 30 – Basic Instrument Assembly: ST51A, ST75A and ST75AV .................................................................................................. 74

Fluid Components International LLC vii

06EN003426 Rev. C ST51A/ST75A/ST75AV Mass Flow Meters

List of Tables

Table 1 – Optional Accessories ................................................................................................................................................................ 2

Table 2 – Compression Fitting Material .................................................................................................................................................... 8

Table 3 – Power and Signal Wiring Summary ........................................................................................................................................ 21

Table 4 – Serial Port J9 Pinout ............................................................................................................................................................... 25

Table 5 – Serial (COM) Port Configuration ............................................................................................................................................. 27

Table 6 – Typical Serial Interface Top Level Commands for Flow Meter Configuration ......................................................................... 29

Table 7 – Flow Unit Example .................................................................................................................................................................. 30

Table 8 – Top Level Menu Commands ................................................................................................................................................... 33

Table 9 – List of CLI Commands ............................................................................................................................................................ 34

Table 10 – ST51A/ST75A/ST75AV HART Process Variables ................................................................................................................ 36

Table 11 – ST51A/ST75A/ST75AV HART Device Registration Information ........................................................................................... 37

Table 12 – HART Universal Commands ................................................................................................................................................. 40

Table 13 – HART Common Practice Commands ................................................................................................................................... 47

Table 14 – HART Device Specific Commands ....................................................................................................................................... 49

Table 15 – Command Status Bytes, Bit Assignments ............................................................................................................................ 53

Table 16 – Command-Specific Response Codes ................................................................................................................................... 53

Table 17 – Command 48, Additional Device Status Bytes Bit Assignments ........................................................................................... 54

Table 18 – HART Engineering Units Codes ........................................................................................................................................... 55

Table 19 – ST51A/ST75A/ST75AV Modbus Function Codes ................................................................................................................. 57

Table 20 – ST51A/ST75A/ST75AV Modbus Process Data .................................................................................................................... 58

Table 21 –Modbus Service Data ............................................................................................................................................................. 59

Table 22 – Modbus Engineering Units Codes ........................................................................................................................................ 64

Table 23 – Device Status Code Bit Assignments, Register #4025 ......................................................................................................... 64

Table 24 – Diagnostic Test Sequence .................................................................................................................................................... 68

Table 25 – Appendix A, List of Drawings ................................................................................................................................................ 73

viii Fluid Components International LLC

ST51A/ST75A/ST75AV Mass Flow Meters GENERAL

Warning:

Explosion Hazard. Do not disconnect equipment when flammable or combustible atmosphere is present.

1 GENERAL

Product Description

The ST51A and ST75A/ST75AV Series are thermal dispersion, industrial process grade air/gas flow meters. They are suitable for all air

and gas flow measurement applications. The ST51A is an insertion type flow meter for line sizes ranging from 2″ to 24″ [51 to 610 mm].

The ST75A is an in-line type flow meter for line sizes ranging from ¼″ to 2″ [6 mm to 51 mm]. Both ST51A and ST75A/ST75AV flow meters

provide direct mass flow measuring and measures flow rate, totalized flow and temperature.

The measurements are made available to the user through dual 4-20 mA analog output channels, a separate source and sink channel (pulse

output for totalizer or level output for alarm) and HART. The optional alphanumeric LCD display provides real-time process variable values, flow

range and process description information. There are no moving parts to clean or maintain. These flow meters are offered in a wide selection of

process connections to fit with any process piping and versions are available for temperature service from -0 °F [-18 °C] to 350 °F [177 °C].

ST51A and ST75A/ST75AV’s electronics/transmitter can be integrally mounted with the flow sensor or remote mounted up to 100′ [30 m]

from the sensor element. All ST51A and ST75A/ST75AV flow meters are precision calibrated in FCI’s world-class, NIST traceable

calibration facility on one of our flow stands matched to the customer’s gas application and actual installation conditions.

Theory of Operation

The instrument is functionally based on the thermal dispersion operating principal. A low powered heater produces a temperature

differential (ΔT) between two Resistance Temperature Detectors (RTDs) by heating one of the RTDs above process temperature. As the

process mass flow rate increases, the temperature differential (ΔT) between the RTDs decreases. The ΔT between the RTDs is

proportional to the process mass flow. The flow transmitter converts the RTD’s ΔT signal into a scaled flow output signal. The signal from

the unheated RTD is used to provide the process temperature value.

Safety Instructions

● Field wiring shall be in accordance with NEC (ANSI-NFPA 70) for Division 2 hazardous locations and CEC (CSA C22.1) for division 2

locations as applicable.

● The instrument must be installed, commissioned and maintained by qualified personnel trained in process automation and control

instrumentation. The installation personnel must ensure the instrument has been wired correctly according to the applicable wiring diagram.

● All location specific installation and wiring requirements (i.e., local electrical codes) must be met and maintained. Install an input

power circuit breaker or power disconnect switch and fuse near the flow meter to interrupt power during installation and maintenance.

A switch or circuit breaker is required if installation is in a hazardous area.

● The flow meter contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions when handling the circuit

board assemblies.

● Hazardous Areas: The instrument is designed for use in hazardous areas. The approved area classification is identified on the

nameplate along with the temperature and pressure limitations. See Agency Approvals, page 3 and APPENDIX C, page 93 for a

complete listing of the instrument’s safety/hazardous areas approvals.

Order Verification

● Verify the received hardware matches the purchased hardware and application requirements. Verify the model number and part

number on the instrument I.D. tag matches the purchased model number part number.

● Review the calibration requirements as specified on the Engineering Data Sheet in the documentation package. Verify the flow,

temperature and pressure limits meet the application requirements.

Fluid Components International LLC 1

GENERAL ST51A/ST75A/ST75AV Mass Flow Meters

Part Number

Description

FC88

014108-03

Hardware – Model Descriptions

ST51A – Single point insertion element with flow and temperature process output

ST75A – In-line element with flow and temperature process output

ST75AV – Vortab In-line element with flow and temperature process output

Optional Accessories

Table 1 – Optional Accessories

Portable Hand-held Communicator

PC Interface Communications Kit, for RS-232 serial port connection

2 Fluid Components International LLC

ST51A/ST75A/ST75AV Mass Flow Meters GENERAL

NPT Line

Size

Min SCFM

0.04

0.13

0.22

0.35

0.85

1.40

Min [NCMH]

[0.07]

[0.22]

[0.38]

[0.59]

[1.44]

[2.38]

Max SCFM

17.34

50.64

88.88

139.95

539.31

559.27

Max [NCMH]

[29.47]

[86.04]

[151.00]

[237.78]

[576.48]

[950.20]

Tubing Line Size

¼"

½"

1"

Min SCFM

0.01

0.05

0.25

Min [NCMH]

[0.01]

[0.09]

[0.42]

Max SCFM

3.02

21.15

99.08

Max NCMH

[5.14]

[35.94]

[168.33]

Specifications

Instrument

■ Media Compatibility

ST51A: Air, compressed air, nitrogen, biogas, digester gas,

methane, natural gas

ST75A/ST75AV: Air, compressed air, nitrogen, oxygen, argon,

CO2, other inert gases, natural gas and other gases as identified

in the Order Information Sheet (OIS)

■ Pipe/Line Size Compatibility

ST51A: 2″ to 24″ [51 mm to 610 mm]

ST75A/ST75AV: ¼″ to 2″ [6 mm to 51 mm]

■ ST51A Flow Range

0.3 SFPS to 400 SFPS [0.08 MPS to 122 MPS]

■ ST75A/ST75AV Flow Range*

¼" ½" ¾" 1" 1 ½" 2"

Directive 2014/30/EU Electromagnetic Compatibility EMC

Directive 2014/35/EU Low Voltage

Directive 2011/65/EU RoHS 2

FM, FMc

Explosion-proof: Class I, Div. 1, Groups B, C, D

Dust-ignitionproof: Class I I/II I, Div. 1, G roups E, F, G; Type 4X; IP66

Nonincendive: Class I, Div. 2, Groups A, B, C, D

SIL 1 compliant; Safe Failure Fraction (SFF) 78.5% to 81.1%

CRN No.: 0F0303

Contact FCI for other approvals and conditions of use.

■ Warranty

2 years

Flow Element

■ Type

Thermal dispersion

■ Material of Construction

ST51A: 316L stainless steel body with Hastelloy-C22 thermowells; 316

stainless steel compression fitting with Teflon or stainless steel ferrule.

ST75A/ST75AV: All -welded 316 stainless steel probe element with

Hastelloy-C22 thermowells; 316 stainless steel NPT, flange and

tube fittings.

* Range subject to gas type and conditions

■ Accuracy

ST51A/ST75A: Standard: ±2% reading ±0.5% full scale

Optional: ±1% reading ±0.5% full scale

ST75AV: ±1% reading ±0.5% full scale

■ Repeatability

±0.5% of reading

■ Temperature Compensation

Standard: 40 to 100 °F [4 to 38 °C]

Optional: 0 to 250 °F [-18 to 121 °C]

■ Turndown Ratio

3:1 to 100:1

■ Agency Approvals

CE Mark

Directive 2014/34/EU ATEX

IECEx Scheme

ATEX/IECEx: II 2 G Ex db IIC T6...T1 Gb

II 2 D Ex tb IIIC T85°C...T300°C Db; IP66/IP67

Ta = -40°C to +65°C

FM, FMc: Class I, Div 1, Groups B, C, D

Class I, Div 2, Groups A, B, C, D

Class II/III Div 1, Groups E, F, G

Type 4X, IP66

■ Process Connection

ST51A: ½″ Male NPT or ¾″ Male NPT compression fitting with

stainless steel or Teflon ferrule

Insertion Length:

1″ to 6″ [25 mm to 152 mm]

1″ to 12″ [25 mm to 305 mm]

1″ to 18″ [25 mm to 457 mm]

ST75A: T-fitting [Female NPT]: ¼″, ½″, ¾″, 1″, 1-½″ or 2″

Tubing: ¼″, ½″, 1″

ST75AV: Female NPT, Male NPT

Flange: ¼″, ½″, ¾″, 1″, 1-½″ or 2″

■ Maximum Operating Pressure

ST51A stainless steel ferrule: 500 PSIG [34 bar(g)]

Teflon ferrule: 150 PSIG [10 bar(g)]

ST75A: T-fitting [Female NPT]: 240 PSIG [16.5 bar(g)]

Tube: 600 PSIG [41 bar(g)]

ST75AV: 600 PSIG [41 bar(g)]

■ Flow Element Temp Range

ST51A

stainless s

teel ferrule: 0 °F to 350 °F [-18 °C to 177 °C]

ST75A: 0 °F to 250 °F [-18 °C to 121 °C]

Teflon ferrule: 0 °F to 200 °F [-18 °C to 93 °C]

Fluid Components International LLC 3

GENERAL ST51A/ST75A/ST75AV Mass Flow Meters

Part No.

Type

Amp

Code

Ampere

Rating

Max. Voltage

Rating

Littelfuse Series

454: 045401.5

Slo-Blo

01.5

1.50 A

125 V

Flow Transmitter

■ Enclosure

Rating: NEMA 4X [IP67]

Material: Standard – Aluminum, polyester powder-coated

Optional – 316 stainless steel

Cable/Wiring port: Dual ½" female NPT or M20x1.5

■ Operating Temperature

0 °F to 140 °F [-18 °C to 60 °C]

■ Maximum Relative Humidity

100%

■ Maximum Altitude

12,000 feet (3,658 meters)

■ Input Power

DC: 18 VDC to 36 VDC

AC: 90 VAC to 264 VAC (4.5 Watts max.; CE Mark voltage 100

VAC to 240 VAC)

Instrument (Element + Sensor): 4.5 Watts

Sensor only: 0.30 Watts

■ Analog Output Signals

Two 4-20 mA outputs configured for flow rate or temperature.

Typical load: 250 Ω; Max load: 500 Ω. Both outputs have fault

indication per NAMUR NE43 guidelines, user selectable for high

(> 21.0 mA) or low (< 3.6 mA).

■ Installation and Mounting

ST51A – Integral with sensor element or remote mountable with

interconnecting cable length of: 10′ [3 m), 25′ [7,6 m], 50′ [15 m],

100' [30 m] or custom length.

ST75A/ST75AV – In-line “T”, NPT or tube. Available in remote

mountable configuration with interconnecting cable length of: 10′

[3 m], 25′ [7,6 m], 50′ [15 m], 100' [30 m] or custom length.

■ Source/Sink Outputs

One source output and one sink output provides totalized flow

(pulse signal) or alarm setpoint (level signal). Pulse width at 50%

duty cycle. 1-500 Hz pulse output for total flow.

• Source: 22 ±2 VDC, 25 mA

• Sink: External (user) power source and load not to exceed 40

VDC and 150 mA

■ Communication Port

• RS-232C, standard

• Modbus, standard

• HART, standard

1

■ Digital Display

Two-line x 16 character LCD; displays measured value and

engineering units. Top line assigned to flow rate, second line user

assignable to temperature reading, flow totalizer or alternating. Display

can be rotated in 90° increments for optimum viewing orientation.

1

Display “delete” option (Blind, no display window) also available.

■ Input Power Fuse

Refer to Power Fuse Replacement on page 20 for fuse

replacement instructions.

4 Fluid Components International LLC

ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Warning:

The ambient temperature range and applicable temperature class of the ST51A and ST75A/ST75AV Series flow

C01157-1-1

SERIAL NUMBER

ORIENTATION

ST51 EXTENSION PIPE

ST75/ST75V HEX

FLOW DIRECTION

MARK

FLOW DIRECTION

MARK

SERIAL NUMBER

ORIENTATION

2 INSTALLATION

meters are based on the maximum process temperature for the particular application as follows; T6 for -40 °C ≤ Ta ≤

+55 °C; T3 for -40 °C ≤ Ta ≤ +65 °C.

Instrument Identification and Outline Dimensions

Appendix A provides outline dimensions and mounting bracket dimensions for all integral and remote mounted electronic configurations.

Verify all dimensions meet the application requirements before beginning installation.

Pre-Installation

Serial Number

The ST51A, ST75A and ST75AV (Vortab) flow meters can be specified with integral or remote electronics. The flow element has a serial

number etched into the side of the extension pipe (ST51A) or HEX (ST75A/ST75AV) as shown in Figure 1 below. The tag on the enclosure

includes serial number and model number. A serial number is written on the transmitter’s PWB silkscreen (both AC and DC input) as

shown in Figure 2. The flow sensor and transmitter circuit are calibrated as a matched set. Always pair these components together unless

an exception is made by an FCI technician.

Flow Direction Alignment

All sensor elements have a flow arrow indicator marked on the element assembly at the reference flat, which indicates the flow direction for

which the flow element has been calibrated. Install the instrument with the flow arrow facing in the same direction as flow in the pipe

stream as shown in Figure 3 and Figure 4. The ST75A/ST75AV flow element has been calibrated directly in the pipe tee or tube tee for

orientation and insertion depth, as shown on Figure 4. See APPENDIX A, page 73 for orientation details.

REFERENCE FLAT

Figure 1 – Probe Serial Number, Reference Flat and Flow Direction Mark

Fluid Components International LLC 5

REFERENCE HEX FLAT

INSTALLATION ST51A/ST75A/ST75AV Mass Flow Meters

C01158-1-2

90°

C01159-1-1

SERIAL NUMBER

FLOW DIRECTION MARK

POINTS TO FLOW DIRECTION

REFERENCE/O RIE NT ATI ON FLAT

THERMOWELLS PERPENDICULAR

BLOCK

Figure 2 – Serial Number Location on Interface Board (AC Version Shown) with Blind Cover Removed

6 Fluid Components International LLC

TO FLOW DIRECTION

Figure 3 – ST51A Flow Arrow Alignment

PARALLEL TO FLOW DIRECTION

ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Caution:

Elements are shipped in a protective sleeve. After removing the sleeve, keep the element from sliding through the

C00568-3-1

* AT LEAST 20 DIAMETERS

10 DIAMETERS

DIAMETER

* OPTIMUM CONDITION

FLOW

Recommended Straight Run

For optimal flow meter performance FCI recommends a minimum of 20 pipe diameters upstream straight run and 10 pipe diameters of

downstream straight run. See Figure 4 below. Where straight run is limited, FCI offers Vortab flow conditioners for use in applications that

have significant straight run limitations. FCI uses the AVAL application modeling software to predict meter performance in each installation.

AVAL outputs are available to review prior to order placement and will indicate performance expectations both with and without flow

conditioning.

Installing ST51A Flow Element

Compression Fitting Mounting

The ST51A is available with both Teflon compression fitting ferrules and metal ferrules. While the Teflon ferrule can be readjusted, it has a

lower process pressure rating and over-tightening may cause it to become stuck or damage the extension pipe. The metal ferrule version

can only be tightened down once and becomes permanently positioned. The ferrule type is indicated in the instrument part number

displayed on the instrument tag. This can be cross-referenced with the Ordering Information Sheet (OIS).

All flow meters have been calibrated with the flow element located at the centerline of the pipe and flow stream as shown in Figure 5.

Couplings and threadolets come in various dimensions. Proper installation requires that the element be measured with consideration to

process connection dimensions and pipe centerline. Install the element in the line with the compression fitting lightly tightened around the

extension, then slowly move the pipe extension forward until the element is at centerline as shown.

compression fitting and contacting the opposing wall with any force. Hitting the pipe wall may damage the element

and upset the calibration (critical in top mount installations).

See APPENDIX A for instrument outline dimensional details.

AFTER LAST FLO W DISTURBANCE

BEFORE NEXT

FLOW DISTURB ANCE

Figure 4 – Recommended Straight Run (ST75A Shown)

Fluid Components International LLC 7

INSTALLATION ST51A/ST75A/ST75AV Mass Flow Meters

Ferrule

Torque

Teflon

65 in - lbs

316 SST

65 ft - lbs

Note:

XXXX

FLUID COMPONENTS

INTERN A TIONAL LLC

y

C00584-1-3

MOUNTING ORIEN TATION OF FLATS

TO BE PARALLEL TO FLOW

2X 1/2" NPT,

OPTIONAL M20 x 1.5

ADJUSTABLE COMPRES SION FITTING,

OPTIONA L TEFLON OR METAL FERRULE

ENCLOSURE MEETS EXPLOSION PROOF

WATER AND DUST TIGHT APPROVALS

OPTIONAL DUAL LINE DIGITAL DISPLAY,

90° INCREMENTAL ROTATION

1/2 OR 3/4 INCH NPT

PROCESS CONNECTION

FLOWARROW

LASER ETCHED INSERTION SCALE

SERIAL NUMBER

REDUCER

BUSHING

PROTEC TIVE SHROUD

OVER PROBE TIPS

0.56

[014]

4.00

[102]

U LENGTH

VARIABLE

4.5

[114]

3.28

[83]

3.56

[90]

L

C

Figure 5 – Flow Element Installation, Compression Fitting ST51A

The flow element is properly mounted when the tip of the flow element is located 0.50 inches (13 mm) past the pipe centerline. The scale

etched on the side of the insertion pipe indicates the length to the tip of the flow element. Follow the steps below to install the ST51A flow

element.

1. Calculate the insertion depth using the equation below.

I = Insertion depth

I.D. = Pipe inside diameter

T = Pipe wall thickness

C = Pipe mounting coupling and compression fitting (installed length)

..

= 0.50" +

I = __________

2. Mark the insertion pipe at the calculated insertion depth.

3. Apply proper thread sealant to the tapered pipe thread on the compression fitting and secure into pipe mounting coupling.

4. Insert the flow element to the insertion depth mark making sure the orientation flat is aligned parallel to the flow direction. Hand tighten

the compression nut. Compression fitting manufacturer recommends 1-1/4 turns past hand tight.

5. Tighten the compression nut to the torque specified for the corresponding ferrule material as shown in Table 2 below.

+ +

Table 2 – Compression Fitting Material

8 Fluid Components International LLC

The metal ferrule configuration can only be tightened one time. Once tightened, the insertion length is no longer

adjustable.

ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Caution:

For applications where the process media is pressurized to greater than 232 psig [16 bar(g)] make sure to first

C01444-1-1

C

L

LOCKING COLLAR

PACKING NUT

MARK

INSERTION

DEPTH

OPTIONAL BALL VALVE:

CUSTOMER-SUPPLIED OR

PURCHASED FROM FCI

Retractable Packing Gland Mounting

A retractable packing gland, with ½" MNPT or ¾" MNPT threads and graphite or Teflon packing, is a process connection option. FCI single

point flow meters are calibrated at the centerline of the process pipe. The flow element is properly mounted when the tip of the flow

element is located .50 inches (13 mm) past the pipe centerline. Follow the below steps to install/retract instruments with the retractable

packing gland option.

1. The scale etched on the side of the insertion probe indicates the length to the tip of the flow element. Calculate the Insertion depth

using the equation and Figure 6 below.

I = Insertion depth

I.D. = Pipe inside diameter

T = Pipe wall thickness

C = Pipe mounting coupling and compression fitting (installed length)

..

= 0.50" +

I = __________

+ +

Figure 6 – Flow Element Installation, Retractable Packing Gland ST51A

2. Mark the insertion pipe at the calculated insertion depth.

3. Ball Valve Applications Only: If a ball valve is required, install the ball valve to the process mounting coupling. Close the ball valve

to prevent the process media from leaking out when installing the packing gland with the process line pressurized.

4. Apply the proper thread sealant compatible with the process media to the male threads of the packing gland. Fully retract the insertion

probe into the cavity of the packing gland and install the packing gland into the process mounting coupling or ball valve. If a ball valve

is not used, make sure to first depressurize the process line before installing.

5. Tighten the packing nut until the internal packing is tight enough to prevent excess process leakage, but also allow the insertion probe

to be inserted into place. For ball valve applications, open the ball valve after the packing nut has been tightened.

depressurize the process line before making the insertion.

6. Align the orientation flat and flow arrow parallel to the flow direction and proceed to insert the flow element into the process media

pipe up to the insertion depth mark.

7. Tighten the packing nut another ½ to 1 turn tight (approximately 20 ft-lbs) until the packing has created a full seal.

8. Ensure the locking collar is properly secured to the back of the packing gland. Torque the two No. 8-32 socket head cap screws on

the locking collar to 20 in-lbs using a 9/64" hex key.

Fluid Components International LLC 9

INSTALLATION ST51A/ST75A/ST75AV Mass Flow Meters

Caution:

For applications where the process media is pressurized to greater than 232 psig [16 bar(g)] make sure to first

PACKING NUT

LOOSEN THIS SCREW

LOCKING COLLAR

C01445-1-1

Retraction/Removal Procedure

1. Loosen the socket head cap screw on the side of the locking collar. See Figure 7 below.

depressurize the process line before retracting the flow element. At 232 psig [16 bar(g)], the effective force on the

insertion probe is 45.5 lbs (20.6 kg), which is the limit at which the flow element can be safely guided by hand. When

using hands to restrain the retraction, be prepared for a rapid pressure impulse of the flow element. Make sure that

there are no objects directly behind the flow element as the insertion probe may retract very quickly.

Figure 7 – Retractable Packing Gland Locking Collar Detail

2. Slowly loosen the packing nut until the insertion probe begins to retract. Use hands as needed to help control the retraction. If the

probe does not begin to retract itself, gently shake and pull the insertion probe until the flow element has been fully retracted into the

packing gland.

3. For ball valve applications, close the ball valve immediately after retraction to seal off the process. After closing the ball valve it is then

safe to remove the flow element from the back end of the ball valve. If a ball valve is not being used, make sure to first

depressurize the process line before removing the flow element.

10 Fluid Components International LLC

ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Caution:

The element is shipped already installed in the tee oriented for inline installation. Do not remove the sensing element

Caution:

The instrument contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions when

Warning:

To avoid damage to board components use fingers only to remove the board. Do not pry the board off using a

Installing ST75A/ST75AV Flow Element

from the tee during installation as performance can be affected.

The ST75A/ST75AV is available in pipe tee configurations with NPT threads and tubing tees with a compression fitting to clamp down on

concentric smooth surface tubing. The pipe tee versions are standard 150# class rated tees suitable for service up to 150 PSIG at the

process temperature maximum of 250 °F (121 °C). The compression fitting material offered in the tube type configuration is rated for 250

PSIG service. See APPENDIX A for instrument outline dimensional details.

Pipe Tee Installation

With pipe extensions cut to length and sealing materials used on the threads, install flow element section by slowly rotating the

configuration until secure. Complete by installing the opposing end pipe section using care to secure the element assembly either in a top

mount or side mount position.

Tube Tee Installation

Clean all mating surfaces of the tee fitting, ferrules and the flow tube. Insert the flow tubing into the tee fitting. Make sure the tubing rests

firmly in the fitting counter bore seat. Tighten the nut on both ends of the tee by hand. Hold the fitting body steady with a backup wrench

and tighten the fitting nuts 1-1/4 turns from hand-tight baseline.

The ST75AV is available with flow tube configurations offering male and female NPT threads, ANSI flanges and DIN flanges. The flow tube

assemblies are rated for service up to 240 PSIG at the process temperature maximum of 250 °F (121 °C).

NPT Flow Tube Installation

With pipe extensions properly cut to length and sealing materials used on the threads, install flow element section by slowly rotating the

configuration until firmly secure on the pipe section. Complete by installing opposing end pipe section, using care to firmly secure the

element assembly either in a top mount or side mount position.

Flanged Installation

Clean all mating surfaces. Install appropriate sealing gasket between mating flanges. Tighten flange mating hardware to meet system

sealing requirements.

Re-positioning the Display

The LCD digital display can be rotated in 90° increments to improve its readability if necessary for the application. Referring to Figure 8

below, follow these steps to re-position the display.

1. Use .050″ hex key to loosen set screw locking window lid and then unscrew window lid from enclosure body.

2. Lift and remove blue bezel.

3. Unplug transmitter/display board from power supply board by pulling display board straight up. Carefully set board aside.

4. Removing transmitter/display board exposes power supply board in enclosure body. Remove two securing 6-32 x ¼″ Phillips pan

head screws and star washers from power supply board.

5. Turn power supply board in 90° steps in either direction until desired orientation is achieved.

6. Secure power supply board to enclosure body using hardware removed in step 4. Use alternate pair of mounting holes in power

supply board if required for new display orientation.

7. With transmitter/display board aligned over power supply board (connectors mate only one way) press down to fully engage

connectors on both boards.

8. Reinstall bezel over transmitter/display board by engaging bezel guide posts into corresponding holes in display board.

9. Reinstall window lid. Tighten lid one full turn past point where O-ring makes contact with lid, then tighten lid set screw to lock lid (set

screw must not protrude from its threaded hole after tightening).

handling the instrument.

screwdriver or similar tool.

Fluid Components International LLC 11

INSTALLATION ST51A/ST75A/ST75AV Mass Flow Meters

C01314-1-1

U LENG TH

DIMENSION

BEZEL

TRANSMITTER/

DISPLAY BOARD

GUIDE POST

HOLES

POWER SUPPLY BOARD

BEZEL GUIDE PO ST (2 PLACES)

WINDOW LID

2X ½" NPT PORT

LOCAL

(BLIND)

REMOTE

ELECTRONICS

BRACKET

ASSEMBLY

REMOTE CABLE

(NPT CONFIGURATI O N SHOW N)

PROBE

PIPE

(TURN THIS BOARD 90°

INCREMENTS TO POSITION DISPLAY)

Installing the Remote Flow Meter System

Remote transmitter instruments include the following components: local enclosure containing the flow element sensor, remote enclosure

containing the display/electronics and interconnecting remote cable. Both enclosures are explosion-proof ATEX/IECEx rated. A typical

remote flow meter system is shown in Figure 9 below.

ENCLOSURE

Figure 8 – Display Re-positioning

ENCLOSURE,

ASSEMBLY

12 Fluid Components International LLC

Figure 9 – Typical Remote Flow Meter System (ST51A with ½" NPT Cable Port Shown)

ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Remote Cable

The remote cable connects the local enclosure’s flow element sensor to the transmitter electronics in the remote enclosure. The cable is

available in standard lengths (10/25/50/100 ft. [3/7.6/15/30 m]) as well as custom length as specified in the order information sheet (OIS).

The customer is to supply the appropriate NPT or metric cable fittings for the remote cable. The cable end terminated in a 2x4 female

socket plug connects to the 2x4 pin connector on the interface board inside the remote enclosure. The cable end with 6 metal ferrules

connects to Phoenix connector TB1 on the interconnection board inside the local enclosure. Figure 10 below shows the remote cable

assemblies with customer-supplied pieces.

Figure 10 – Remote Cable, Interconnecting

Fluid Components International LLC 13

INSTALLATION ST51A/ST75A/ST75AV Mass Flow Meters

EXT. GROUND SCREW,

HEX WASHER

LOCAL

ENCLOSURE

(BLIND LID

REMOVED)

REMOTE CABLE

C01317-1-1

6-POS. PHOENIX

CONN. TB1

Remote Cable Connnections to TB1

2X 6-32 x ½" PAN HD.

PHILLIPS SCREW/

#6 STAR WASHER

INTER-

CONNECTION

BOARD

TIE-WRAP

GROMMET

TB1 Pin No. Wire Color Label

1 Orange ACT_EXC+

Black ACT_SEN+

Green ACT_EXC-

Red REF_EXC+

Brown REF_SEN+

Yellow REF_EXC-

2

3

4

5

6

Local Enclosure

Install the local enclosure as described in Installing ST51A Flow Element and Installing ST75A/ST75AV Flow Element above. Depending

on the configuration as specified by the order information sheet the ST51A local enclosure is supplied with a ½" or ¾” process connection,

and the ST75A/ST75AV is supplied with a male NPT, female NPT or flanged process connection.

Figure 11 below shows the local enclosure remote cable installation.

14 Fluid Components International LLC

Figure 11 – Remote Cable Installation, Local Enclosure

Figure 12 below shows the remote cable wiring inside the local enclosure. After installing the local enclosure in the pipe follow the steps

below to install the local enclosure cable. Refer to Figure 11 and Figure 12 when following the steps.

Figure 12 – Local Enclosure Remote Cable Wiring

1. Remove local enclosure blind lid covering interconnection board (note orientation of external ground screw in Figure 12). Remove

blind lid as described in Accessing the Interface Board Connection Terminals on page 18.

2. If not already installed, install supplied dome head stopping plug in local enclosure’s other (unused) cable port.

3. Remove interconnection board (remove two ea. 6-32 x ½" pan hd. Phillips screw/#6 star washer).

ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Note:

4. Install remote cable to local enclosure as shown in Figure 11. For NPT port units: Use an appropriate size reducer as applicable to the

cable fitting used and the application. Ensure adequate cable service loop length before tightening the customer-supplied cable fitting.

5. Thread cable end (metal ferrule leads) through interconnection board grommet (from solder side) and un-cinched (open) tie-wrap.

6. Connect the cable leads to Phoenix connector TB1 as shown in Figure 12. After attaching all leads cinch tie-wrap to secure cable to

board (snip off excess tie-wrap length).

7. Reinstall interconnection board to local enclosure mounting bosses.

8. Reinstall local enclosure blind lid as described in Accessing the Interface Board Connection Terminals on page 18.

Remote Enclosure

Install the remote enclosure at the desired location using the supplied mounting bracket. Follow the steps below to install the remote

enclosure cable. Refer to Figure 13 below when following the steps.

1. Install mounting bracket at desired location.

2. Metric thread application only: Assemble cable gland, washer and adaptor (all customer-supplied items).

3. Thread connector end of the remote cable through customer-supplied cable fitting (3/8" NPT or M16 cable gland/washer/adapter) then

make a knot in cable 1.5" (38 mm) from connector tip.

4. Apply Loctite 567 to customer-supplied liquid tight fitting threads or cable gland adapter threads as applicable. Then install customersupplied liquid tight fitting/cable gland-adapter assembly into mounting bracket reducer bushing making sure that connector end of

remote cable exits through reducer bushing.

5. Access remote enclosure interface board as described in Accessing the Interface Board Connection Terminals on page 18.

6. Remove interface board: Remove two ea. 6-32 x ½" pan hd. Phillips screw/#6 star washer, and then unplug board by pulling straight out.

7. Thread remote cable connector end through ¾-14 NPT threaded opening at enclosure bottom.

8. Apply Loctite 567 to mounting bracket reducer bushing threads.

9. Install remote enclosure onto mounting bracket reducer bushing making sure that the fit is tight with the display in the desired

orientation.

10. Place remote cable in notch on curved edge of interface board PWB (with connector on component side of PWB) then reinstall

interface board. See Figure 14 on page 16.

11. Firmly plug cable connector into interface board connector J4 header until cable connector latch clicks. (Connector is keyed to ensure

correct mating.)

Connector J4 is located differently on AC and DC interface boards (i.e., the J4 location/orientation is not the same for

both interface board types).

12. Connect power wiring as described in Interface Board Connections on page 19.

13. Reinstall remote enclosure blind lid as described in Accessing the Interface Board Connection Terminals.

Fluid Components International LLC 15

INSTALLATION ST51A/ST75A/ST75AV Mass Flow Meters

C01319-1-2

REMOTE CABLE,

CONNECTOR END WIRES

CIRCUIT BOARD NOTCH,

2X 6-32 x ½" PAN HEAD

CABLE CONNECTOR,

J4 HEADER

(PLUG CABLE HE RE)

REMOTE ENCLOSURE

INTERFACE BOAR D

ASSEMBLY

Figure 13 – Remote Cable/Bracket Installation, Remote Enclosure

FOR SENSOR WIRE ROUTING

PHILLIPS SCREW/

#6 STAR WASHER

LATCHED

(BLIND LID REMOVED)

16 Fluid Components International LLC

Figure 14 – Remote Enclosure Interface Board Connector J4 Detail (AC Version Shown)

ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Warning:

Only qualified personnel are to wire or test this instrument. The operator assumes all responsibility for safe practices

WIRING PORT, ½″ NPT or M20

(2 PLACES)

EXTERNAL GROUND SCREW

10-32 x ¼″ SLOTTED HEX WASHER

BLIND LID

SET SCREW

BLIND LID

Instrument Wiring

while wiring and troubleshooting.

Install an input power disconnect switch and fuse near the instrument to interrupt power during installation

and maintenance. Always disconnect/shut-off power before wiring.

See Agency Approvals, page 3 and APPENDIX C, page 93 for a complete listing of the instrument’s

safety/hazardous areas approvals.

Refer to Figure 15 and Figure 16 below.

A cable/wiring port on each side of the enclosure body is provided for wiring access. These ports are labeled with its thread size (½″ NPT

or M20) via the instrument tag and a label (engraved for stainless steel case) near each port. Either or both ports can be used for wiring.

Use an appropriate plug on the unused port. For the neatest wire routing use the wiring port closest to J7/J8 for all signal wiring and the

wiring port closest to power connector TB1 for power wiring. Provide a service loop for all connections to make rewiring/repairs easier.

An external and internal ground screw (10-32 x ¼″ slotted hex washer) is provided. Use the external ground screw as needed. For

example, use the external ground screw if the probe connection does not make a reliable ground such as a plastic pipe. For EU

applications use only the internal ground screw.

(Remove to

access wiri ng)

Figure 15 – ST51A/ST75A/ST75AV Wiring Access

Fluid Components International LLC 17

INSTALLATION ST51A/ST75A/ST75AV Mass Flow Meters

Warning:

Turn OFF instrument power source before wiring the instrument.

Caution:

Use caution inserting wires into electronics housing. The metal ends can damage circuit boards.

Caution:

FCI flow meters contain static-sensitive devices. To avoid damage to the instrument observe the ESD precautions

C01162-1-2

INTERNAL GROUND

SLOTTED HEX WASHER

POWER WIRING

SIGNAL WIRING

ENCLOSURE BODY

AC VERSION SHO W N)

(BLIND LID REMOVED,

Figure 16 – Recommended Wire Routing/Internal Ground Screw

Accessing the Interface Board Connection Terminals

SCREW, 10-32 x ¼″

Remote Units: Avoid pulling, or inadvertently tugging, the remote cable when wiring the instrument. The sensor

connector/circuit board can be easily damaged by excess pulling of the remote cable.

To access the instrument’s connection terminals first use a .050″ hex key to loosen the set screw locking the enclosure body blind lid (see

Figure 15, page 17). Then unscrew the blind lid from the enclosure. Carefully pull the power and signal wires through the port to avoid

damaging the electronics.

Connect wiring as shown in the diagram in Figure 17, page 19 and the summary list in Table 3, page 21. Reinstall the blind lid when done

making the connections: Tighten the lid one full turn past the point where the O-ring makes contact with the lid, and then tighten the lid set

screw to lock the lid (set screw must not protrude from its threaded hole after tightening).

ESD Precautions

listed below before opening the instrument for wiring.

● Use a wrist band or heel strap with a 1 MΩ resistor connected to ground.

● Use a static conductive mat on the work table or floor with a 1 MΩ resistor connected to the ground when working on the instrument in

a shop setting.

● Connect the instrument to ground.

● Apply antistatic agents such as Static Free made by Chemtronics to hand tools used on the instrument.

● Keep high static-producing items away from the instrument.

18 Fluid Components International LLC

ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Warning:

The above precautions are minimum requirements. The complete use of ESD precautions can be found in the U.S. Department of Defense

Handbook 263.

Interface Board Connections

Power and signal connections are made at the interface board. Refer to Figure 17 below.

Power Connections

Turn OFF instrument power source before wiring instrument power.

The instrument is offered in DC and AC input power configurations. DC units include DC interface and power supply boards. Similarly, AC

units include AC interface and power supply boards. Interface boards are specifically marked for AC or DC power. Only connect the power

specified on the wiring module as shown in Figure 17. Both AC and DC inputs require a ground wire to be connected. Input power terminal

blocks accept 14-26 AWG wire. Observe power wire routing as described in Instrument Wiring, page 17.

NBOARD POWER ON LED INDICATOR

O

An LED on the interface board lights up green when instrument power is ON. The LED is visible only when the blind lid is removed, which

serves to alert the user that power is active when accessing the instrument’s signal/power wiring.

Figure 17 – Power and Signal Wiring Terminals

Fluid Components International LLC 19

INSTALLATION ST51A/ST75A/ST75AV Mass Flow Meters

C01164-1-2

Ω

FUSE 1.5A SLO-BLO

045401.5

AC-POWER

COMPONENT SID E

DC-POWER

Ω

TEST

POWER FUSE REPLACEMENT

Input power overload protection is provided by a 1.5 A slo-blo surface mount fuse installed in a fuse holder on the interface board. (To

access this board see Accessing the Interface Board Connection Terminals, page 18.) Refer to Figure 18 below.

● AC-powered instruments: Locate the fuse at the center of the interface board on top.

● DC-powered instruments: Locate the fuse at the center of the interface board on the back (solder side). With power OFF remove two

securing 6-32 x ½″ Phillips pan head screws and star washers from the DC-powered interface board. Pull board straight up from mating

sockets to access the fuse at the back.

To check for a blown fuse:

1. Turn instrument power OFF.

2. Access the interface board (see text above).

3. Using an ohmmeter touch metal cap at each end of fuse with the test leads. Any reading other than a short (i.e., open circuit)

indicates a blown fuse. Replace with Littelfuse 454 Series fuse, part no. 045401.5.

LITTELFUSE 454 SERIES

INTERFACE BOAR D

INTERFACE BOAR D

(Remove Interface Board to

access fuse. See manual text.

Figure 18 – Input Power Fuse Locations

TEST

SOLDER SIDE

20 Fluid Components International LLC

ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Connector

Pin No.

Function

Description

1

INT_HART+

Internal HART connection / 4-20 mA Ch. #1 (+)

2

EXT_HART-

External HART connection (-)

INT_HART-

Internal HART connection / 4-20 mA Ch. #1 (-)

EXT_HART+

External HART connection (+)

4

4-20 mA Ch. #2

4-20 mA Ch. #2 – default parameter assignment: Temperature

1

B+

Modbus Data B+ line

2

A-

Modbus Data A- line

3 — Reserved 4 SINK

Sink Output

5

GND

Return for 4-20 mA Ch. #2 and Source/Sink, and Gnd/Common

for Modbus.

6

SOURCE

Source Output

1

AC LINE

AC Line (typical wire color: black or brown)

2

AC NEUTRAL

AC Neutral (typical wire color: white or blue)

3

EARTH GND

Earth Ground (typical wire color: bare, green or green/yellow)

1

DC+

DC Positive (typical wire color: red or white)

2

DC-

DC Negative (typical wire color: black)

3

EARTH GND

Earth Ground (typical wire color: bare, green or green-yellow)

Caution: