Page 1

Document number:

72.120.601

Document title:

FGM 160 Operating Instructions

Additional Information (when applicable):

E

Removed from User Manual, updated:

modules

Issued for Fluenta release; moved to User

Manual

Rev.

index

Review

by QA

n/a

Scope: ISO 9001:2015 §8.6 Release of products and services

2018.09.17 Updated Abbreviations and removed O&SC AK NB MR MM MB

D 2014.01.20 Proofread and updated JB AP CT MB MW

C 2013.01.30

B 2009.06.02 Updated information AAJ RT N/A N/A AAJ

A 2007.11.30

Issue date Reason for issue Author Review Review

Replacement for:

Fluenta source doc.

(for translations):

changes in text formatting; modifying

graphics in Appendix II and Electronic

n/a

MKJ KH - MW MW

MS RT - N/A AAJ

Approved

Total pages:

27

Page 2

FGM 160 Operating Instructions

72.120.601

Page 2 of 27

TABLE OF CONTENTS

1. Purpose ........................................................................................................................................... 3

2. Abbreviations/Definitions ............................................................................................................. 3

2.1 Abbreviations ......................................................................................................................... 3

2.2 Definitions .............................................................................................................................. 3

3. General Information ....................................................................................................................... 3

3.1 Hardware Description ............................................................................................................ 3

3.1.1 Electrical Connections .............................................................................................. 4

3.1.2 Power Supply ............................................................................................................ 4

3.1.3 Input Signals ............................................................................................................. 4

3.1.3.1 Ultrasonic Transducers ............................................................................. 4

3.1.3.2 Pressure and Temperature Transmitters .................................................. 5

3.1.4 Output Signals .......................................................................................................... 5

3.1.4.1 Modbus Communication (RS-485) ............................................................ 5

3.1.4.2 Foundation Fieldbus Output ...................................................................... 5

3.1.4.3 Current Loop Outputs ................................................................................ 5

3.1.4.4 HART Output ............................................................................................. 5

3.1.4.5 Pulse/Frequency Output ............................................................................ 5

3.1.5 Electronic Modules in FGM 160................................................................................ 6

3.1.5.1 Digital Signal Processing (DSP) Module ................................................... 6

3.1.5.2 Analog Front End (AFE) Module ............................................................... 6

3.1.5.3 Pressure & Temperature (P&T) Module .................................................... 6

3.1.5.4 Input/Output (I/O) Module .......................................................................... 6

3.1.5.5 Intrinsic Safety Barrier (IS Barrier) Module ............................................... 6

3.1.5.6 Surge Protection Module ........................................................................... 6

3.1.5.7 Local Display Module ................................................................................ 6

3.1.6 Non-Resettable Counter Function ............................................................................ 7

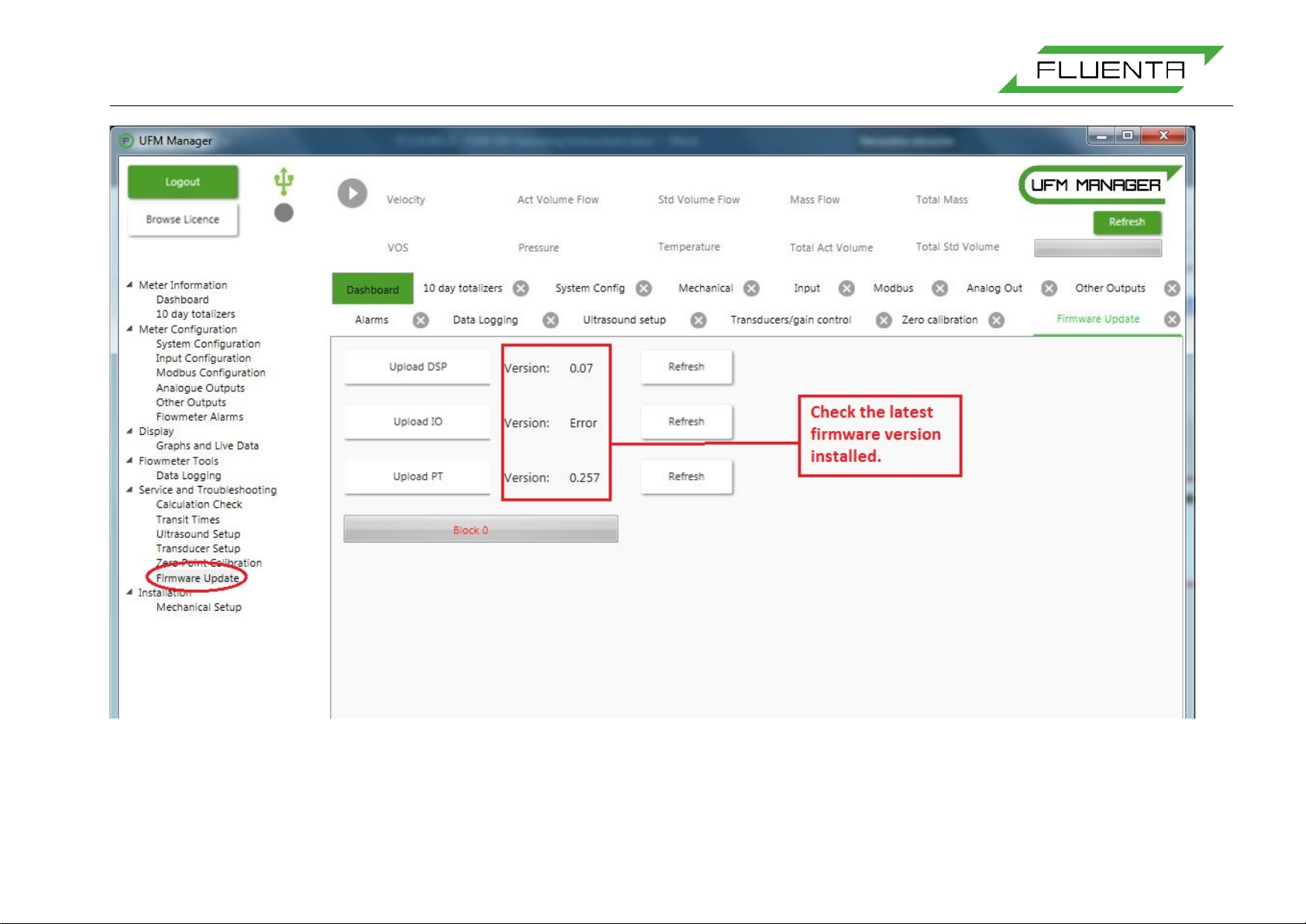

3.2 Firmware Description ............................................................................................................. 7

3.2.1 DSP Module .............................................................................................................. 7

3.2.2 P&T Module .............................................................................................................. 8

3.2.3 I/O Module ................................................................................................................ 8

3.3 Device Integrity ...................................................................................................................... 8

3.3.1 Self-Checking ........................................................................................................... 8

3.3.2 Watchdog Timer ....................................................................................................... 8

3.3.3 Flash Memory ........................................................................................................... 8

3.4 Configuration and Operating Software .................................................................................. 9

4. Operating Procedure ................................................................................................................... 10

4.1 Introduction .......................................................................................................................... 10

4.2 Power-Up Sequence ........................................................................................................... 10

4.3 Field Computer Configuration.............................................................................................. 10

4.4 Local Display Functions ....................................................................................................... 11

4.5 Error Check and Troubleshooting ....................................................................................... 12

4.5.1 Error Check with Local Display ............................................................................... 12

4.5.2 Error Check with UFM Manager ............................................................................. 13

5. References .................................................................................................................................... 13

6. Appendix I – System Configuration File .................................................................................... 14

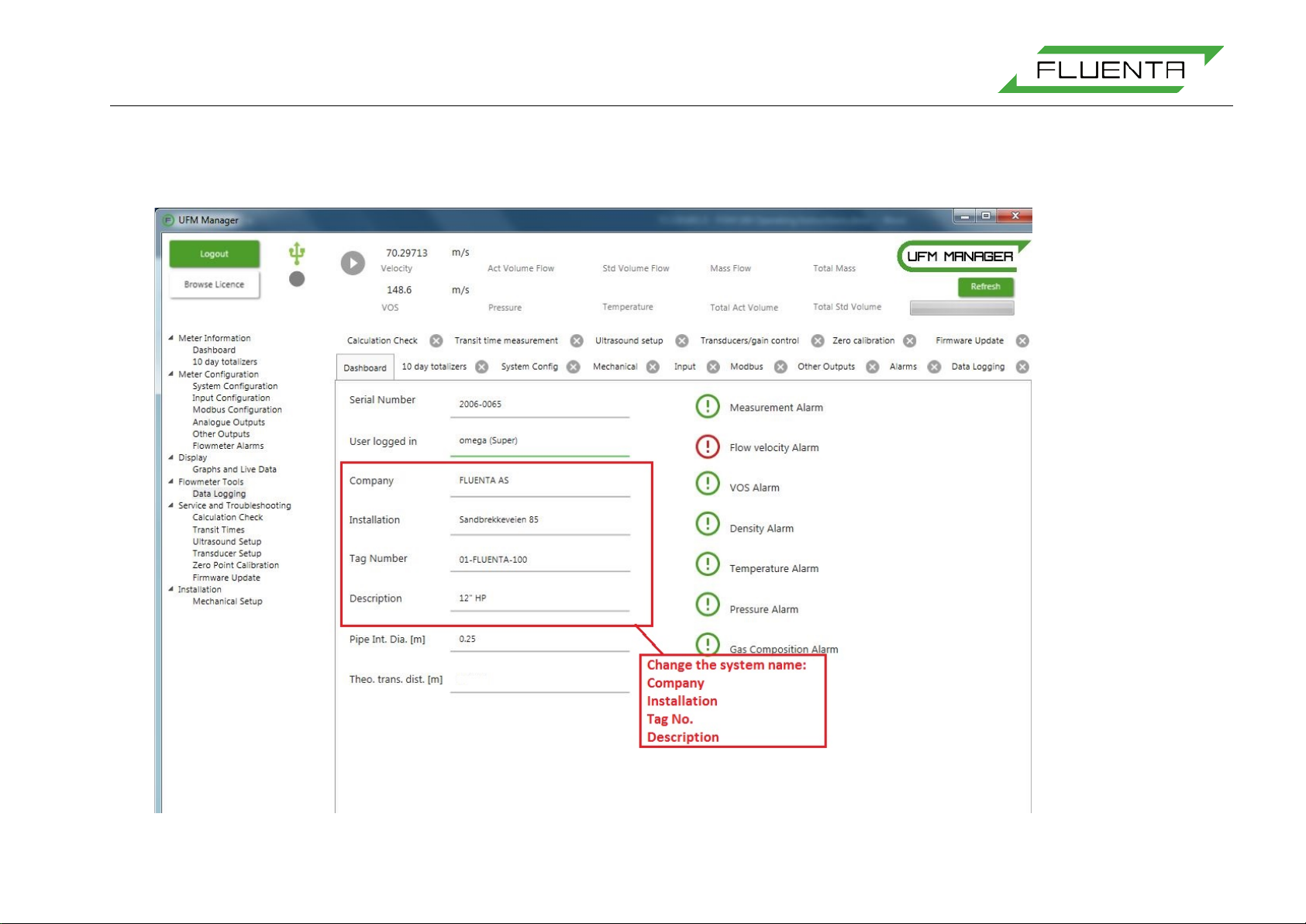

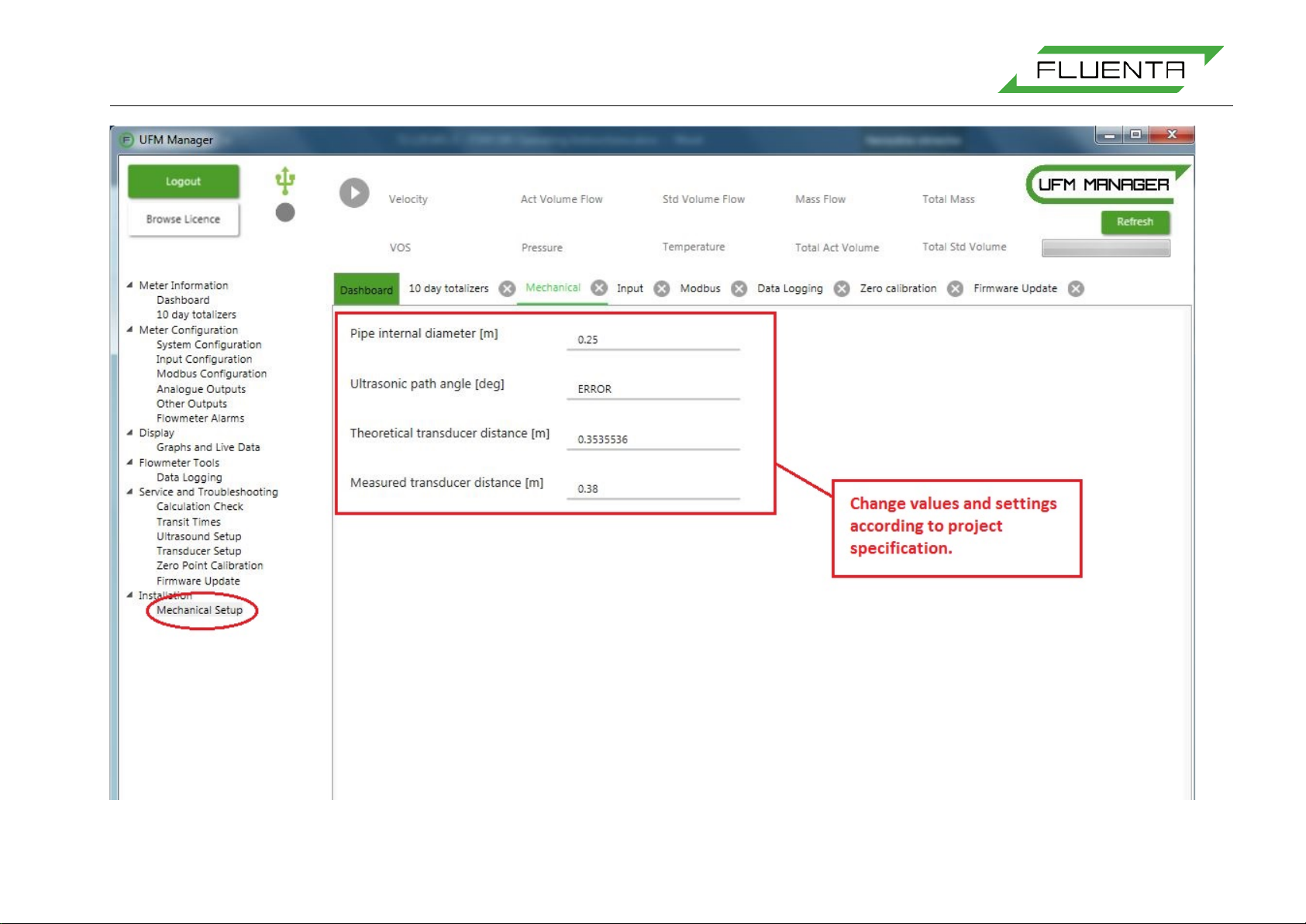

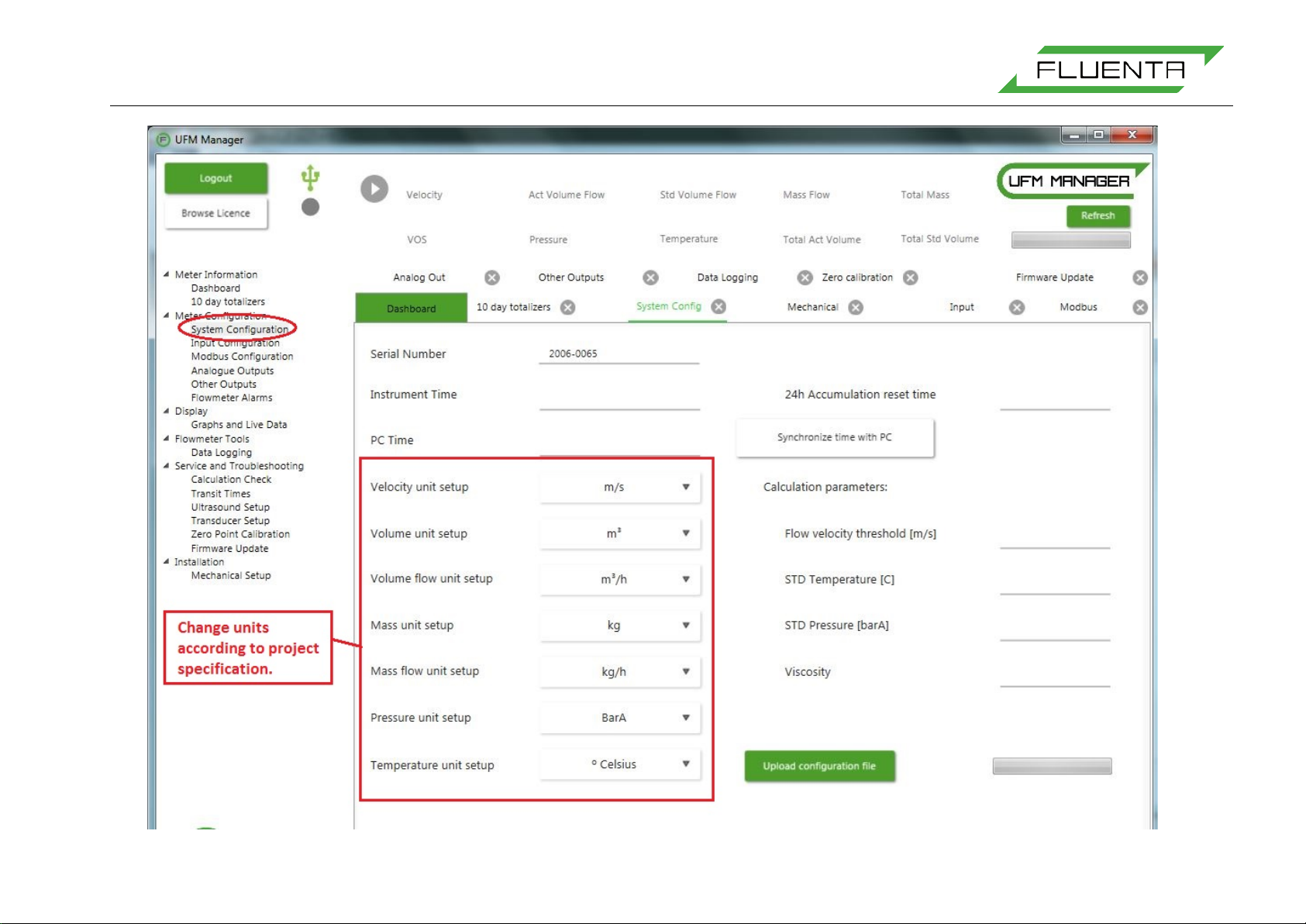

7. Appendix II – Inserting settings from Clie n t parameter list .................................................... 18

Page 3

FGM 160 Operating Instructions

72.120.601

Page 3 of 27

1. PURPOSE

This document describes the Fluenta Flare Gas Meter, FGM 160 hardware and software, and

the device integrity.

2. ABBREVIATIONS/DEFINITIONS

2.1 Abbreviations

TFS Transducer Full Size

FGM Flare Gas Meter

2.2 Definitions

Module PC-board with a local controller and a processor

TFS Series T ransducers based on the TFS. See document 72.050.001 f or details on this

range

3. GENERAL INFORMATION

3.1 Hardware Description

The FGM 160 Field Computer, illustrated in Figure 1, is designed as a distributed system. The

FGM 160 consists of five or six modules, the Digital Signal Processing (DSP) module, the

Analog Front End (AFE) module, the Pressure & Temperature (P&T) module, Input/Output

(I/O) module, Intrinsic Safe Barrier (IS Barrier) module, Surge Protection module and the Local

Display. A distributed system gives several advantages. This design will be more flexible with

respect to future expansions and modifications, as the total processing load for the system can

be divided in several modules. Thus, the danger of overloading a single CPU unit is reduced.

Figure 1: FGM 160 Field Computer.

Page 4

FGM 160 Operating Instructions

72.120.601

Page 4 of 27

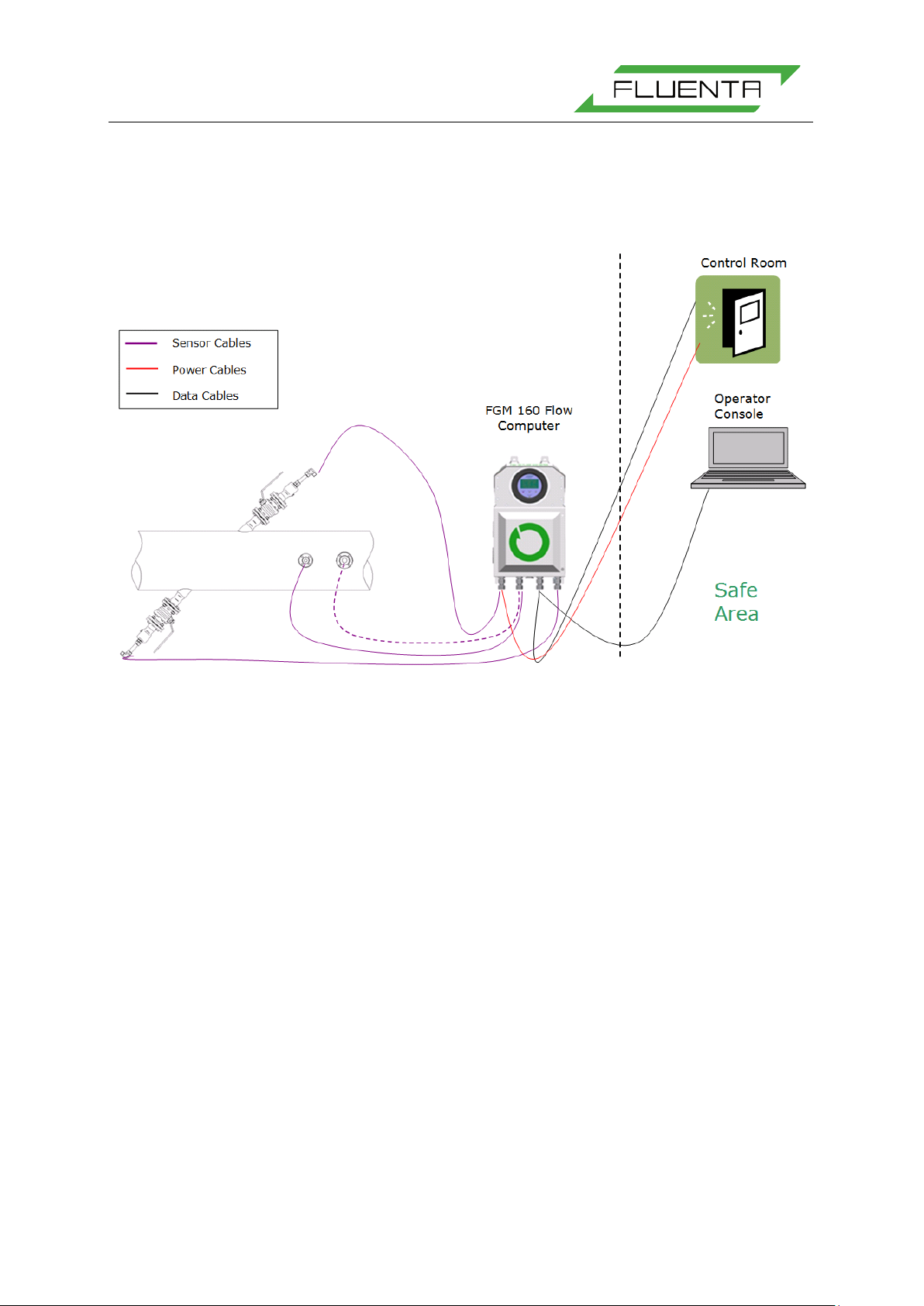

The FGM 160 is certified for operation in Hazardous Area.

For detailed information regarding Hazardous Area installation and operation, please refer to

Fluenta Doc. no. 62.120.006 (Hazardous Area Installation Guidelines [1]) and 75.120.215

(FGM 160 Hazardous Area Certificates [2]).

Figure 2: FGM 160 Hook-Up, with the Field Computer, U l tr asonic T ransducers, Pressure and Temp er atur e

Transmitters, and connections to Safe Area equipment.

3.1.1 Electrical Connections

For detailed information regarding all electrical connections, please refer to Installation & HookUp Instructions [3].

3.1.2 Power Supply

The FGM 160 requires 24 VDC power supply (nominal). If 24 VDC is not available, an optional

110-230 VAC/24 VDC converter can be supplied by Fluenta.

For detailed equipment information and equipment ratings, please refer to Hazardous Area

Installation Guidelines [1].

3.1.3 Input Signals

3.1.3.1 Ultrasonic Transducers

FGM 160 ultrasonic transducers are connected to the FGM 160 Field Computer by means of

prefabricated signal cables included.

Page 5

FGM 160 Operating Instructions

72.120.601

Page 5 of 27

3.1.3.2 Pressure and Temperature Transmitters

The FGM 160 can be configured to accept analog 4-20 mA transmitters or HART compatible

transmitters. The pressure and temperature transmitters may be omitted if the system is

configured to get the pressure and temperature data from the DCS system (Modbus

communication link).

3.1.4 Output Signals

3.1.4.1 Modbus Communication (RS-485)

The FGM 160 has two separate Modbus communication ports.

One is dedicated for communication with a DCS system. The second is a service port for

configuration and monitoring of the FGM 160 system.

In the FGM 160 Foundation Fieldbus configuration, DCS Output is disabled.

3.1.4.2 Foundation Fieldbus Output

A maximum of four (4) parameters can be predefined according to customer requirements.

The list of parameters available for the customer can be found in Fluenta AS doc. No.

72.120.305 (all parameters available by using Modbus Serial Interface are accessible using

Foundation Fieldbus output).

3.1.4.3 Current Loop Outputs

Up to six (6) current loop outputs are availabl e for output of selectable parameter values, w here

three (3) analog outputs are configured as the default. The 4-20 mA current loop output

channels can be configured as active or passive outputs.

4-20 mA Outputs are replaced by FF Outputs in FGM 160 Foundation Fieldbus Configuration.

3.1.4.4 HART Output

One of the current loop outputs can be also configured for HART output communication. Refer

to HART Output Interface Specification [5] for details.

3.1.4.5 Pulse/Frequency Output

The FGM 160 can be also configured to provide a pulse or frequency output si gnal. The pulse

output will represent an incrementation of the totalizer (of e.g. volume or mass), whereas the

frequency output will represent a process parameter (e.g. volume flow rate, mass flow rate

etc.)

Page 6

FGM 160 Operating Instructions

72.120.601

Page 6 of 27

3.1.5 Electronic Modules in FGM 160

3.1.5.1 Digital Signal Processing (DSP) Module

The Digital Signal Processing module is the processing module in the system. The DSP

Module generates the ultrasound measurement signals and controls the measurement

sequences. It collects data from the other module registers and performs flow calculations

based on this data. All calculated parameters are stored in defined registers. All of these

registers are available for UFM Manager software through the Modbus service port at the I/O

Module. A selection of these registers is also available for the DCS system (through the DCS

port at the I/O Module).

3.1.5.2 Analog Front End (AFE) Module

The Analog Front End Module is the interface between the DSP Module and the ultrasonic

transducers via the IS-Barrier unit. At the AFE Module, measurement signals are multiplexed

and switched between upstream and downstream direction.

3.1.5.3 Pressure & Temperature (P&T) Module

The Pressure & Temperature Module collects pressure and temperature information from

external sensors via 4-20 mA current loop or HART Interface. All pressure and temperature

data are stored in predefined registers available for the DSP Module. Accordingly, th e DSP

unit can retrieve P&T parameters in a minimum amount of time.

3.1.5.4 Input/Output (I/O) Module

The Input/Output Module is the interface between the FGM 160 in hazardous areas and

equipment in safe areas. At the I/O Module, 24 VDC (nom.) supply voltage is converted to the

required operational voltages for the other modules. Furthermore, all signals and

communications to and from the DCS system and UFM Manager are handled by this unit.

3.1.5.5 Intrinsic Safety Barrier (IS Barrier) Module

The Intrinsic Safety Barrier Module ensures the intrinsic safety for operation of the ultrasonic

sensors mounted in hazardous area. In addition, the IS-Barrier Module includes safety barriers

for the P&T transmitters. Therefore, the P&T transmitters with “Ex i” certification can be

interfaced directly to the FGM 160. For specifications regarding the P&T transmitter barriers,

please refer to Hazardous Area Installation Guidelines [1].

3.1.5.6 Surge Protection Module

The Surge protection Module protects the power input and the signal output lines from

externally generated spikes, surges and overvoltage.

3.1.5.7 Local Display Module

The Local Display (LD) Module is the front unit, visible through the Ex-d safety glass. At the

LD, a set of predefined metering process parameters can be viewed. In addition, four LEDs

give the status of Power, Alarms, Measurement and Communication.

Page 7

FGM 160 Operating Instructions

72.120.601

Page 7 of 27

3.1.6 Non-Resettable Counter Function

The non-resettable counter function will record and keep the totalized volume and mass. The

totalized values are accessible through the DCS Modbus interface or through UFM Manager.

Figure 3 Electronic modules

3.2 Firmware Description

In the following sections a general description of the firmware for the different modules is

outlined.

3.2.1 DSP Module

• The DSP Module initializes the system at start-up. Tasks are set to initial states and

the system is ready for operation.

• The signals transmitted by the ultrasound transducers are generated by the DSP

Module. The sequencing is controlled by this module, and, depending on the velocity

of the medium in the pipe, either both Chirp and CW signals or just Chirp signals are

used for the flow measurements. One ultrasonic transit time measurement is always

succeeded by an ultrasonic transit time measurement in the opposite direction.

• Data sampling and signal processing are carried out after a specified number of

sequences. Then, the DSP module calculates the difference in transit time

measurements and calculates the parameters available in the FGM system.

• Flow velocity and volume flow rate calculations run continuously, calculating new

values based on data from the P&T module and transit time measurements from the

ultrasonic transducers.

Page 8

FGM 160 Operating Instructions

72.120.601

Page 8 of 27

• Gas density and mass flow calculations are calculated based on calculated velocity of

sound and measured pressure and temperature.

• Volume and mass totalising calculations are continuously updated based on volumetric

and mass flow rate calculations.

• All system configuration parameters are stored in the Flash memory (non-volatile

memory) at the DSP Module.

• The DSP Module carries out self-checking and evaluation of input and calculated

parameters.

3.2.2 P&T Module

• The P&T Module continuously collects pressure and temperature values from the

external pressure and temperature transmitters mounted downstream of the FGM 160.

These readings are used in calculations performed by the DSP module.

• In addition to the external temperature reading, the P&T also reads the internal

temperature value. This value is used to monitor the internal temperature in the Ex-d

enclosure.

3.2.3 I/O Module

• The I/O Module handles all signals and communication with systems in Safe Area.

• Data requests and commands from UFM Manager are processed by the I /O Modul e. A

predefined number of accessible parameters are available from the FGM. Accessible

parameters depend on whether 4-20 mA, HART or Modbus is utilized.

• Software downloads to the DSP-, P&T - and I/O Module are carried out by the I/Omodule.

• All data requests from DCS system are handled by the I/O Module; either through

Modbus or HART interfaces.

3.3 Device Integrity

3.3.1 Self-Checking

The FGM 160 performs a self-checking sequence, where it checks that inputs from the

transducers and Temperature and Pressure transmitters are within a valid range, and that

other functions are operating as intended.

3.3.2 Watchdog Timer

The Watchdog Timer is initialized at start-up, and cannot be disabled, ensuring that in the

unlikely situation of system hang-up occurring, the Watchdog Timer will reset the system

forcing a complete reboot and start-up.

3.3.3 Flash Memory

System configuration is stored in Flash Memory (non-volatile memory). In case of a power

break, all system configurations are reloaded from the Flash memory

Page 9

FGM 160 Operating Instructions

72.120.601

Page 9 of 27

3.4 Configuration and Operating Software

Through the FGM 160 Ultrsonic Flare Meter Manager (UFM Manager), the operator can

monitor process data, configure the meter and specify process data to be saved to a data log

file for later analysis. UFM Manager further enables the operator to operate the meter remotely,

by using e.g. a RS 485/TCP/IP converter and remote control software.

It should be noted, UFM Manager is required to replace the default settings with actual

applicable settings provided by customer. Fluenta service engineers and partners will always

set up the FGM 160 according to the latest submitted parameters from the Client when

installing and commissioning the FGM 160. Fluenta service engineers and partners always

have the UFM Manager with them.

Page 10

FGM 160 Operating Instructions

72.120.601

Page 10 of 27

4. OPERATING PROCEDURE

4.1 Introduction

This section provides information about how to op erate the FGM 160 field computer. The FGM

160 is a field mounted stand-alone ultrasonic gas flow measurement system, and does not

require any safe area communication device in order to operate. However, in order to

continuously monitor data and the meter performance, it is recommended to use the UFM

Manager software package. This program will provide hands-on process and status data

continuously with possible remote access to the FGM 160 system from any remote system

with the appropriate remote control software installed.

4.2 Power-Up Sequence

The power-up sequence describes the necessary handling of the FGM 160 in order to ensure

correct operation. The power-up sequence is as follows:

1. Connect all power, input and output signals and communication cables according to

the project specification and all relevant procedures and instructions.

2. Make sure that the power cable is connected to a suitable pow er source, ei ther directly

to a 24 VDC supply or through a 110-240 VAC/24 VDC converter.

3. Turn on the power to the FGM 160. There is no power switch on the FGM 160 Field

Computer, so the power must be switched by an external switch or similar, preferably

in safe area.

4. On startup, the FGM 160 will go through a boot and an initialization sequence before

entering the standard operational (measurement) mode.

5. When the FGM 160 has entered the standard operational (measurement) mode, the

meter will, according to the system configuration, carry out t ransit ti me me asurements,

retrieve pressure and temperature data, calculate volumetric and mass flow rates and

either actively output a set of predefined parameters at the analog 4-20mA outputs, or

make a set of process parameters available for DCS HART or Modbus communication.

4.3 Field Computer Configuration

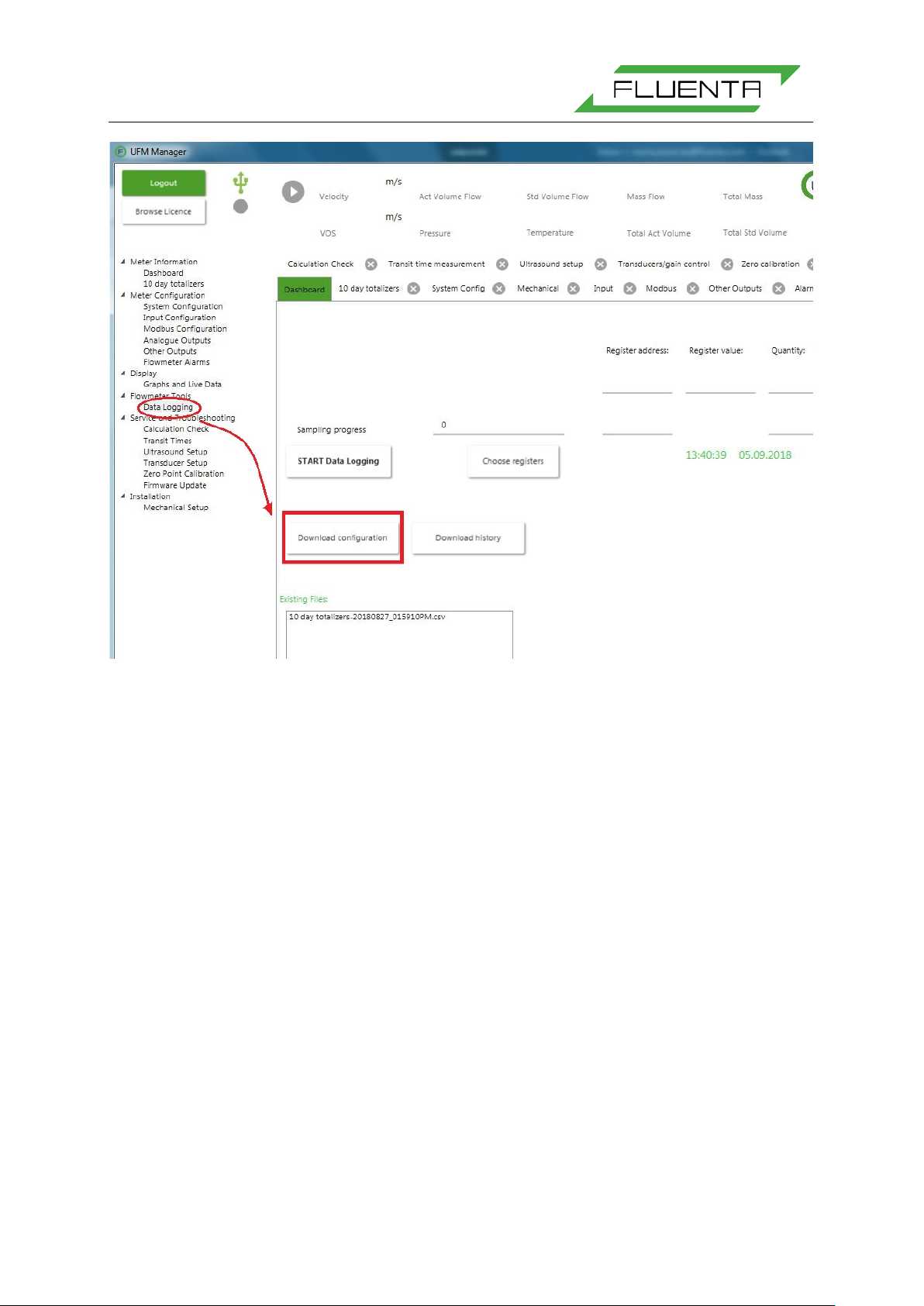

The FGM 160 can be configured by using UFM Manager. During manufacturing, default

configuration is entered into the Field Computer. The system configuration will be modified by

Fluenta service engineers or partners when installing and commissioning the meter. This

configuration can be changed at any time by using The UFM Manager software. All system

configuration parameters are stored in a non-volatile memory, ensuring that no configuration

parameters are lost in case of power loss. Appendix II explains how to insert or modify system

configuration according to a Client parameter list.

Page 11

FGM 160 Operating Instructions

72.120.601

Page 11 of 27

Figure 4: Download of system configuration using the UFM Manager.

The system configuration parameter file can be downloaded from the FGM 160 using the UFM

Manager, ref. Figure 4, by pressing the “Download configuration” button in the “Data Logging”

tab. The system configuration can either be copied to the clipboard and pasted into a

document, or saved directly to a file.

For a full listing of a system configuration file, refer to Appendix I.

Some of the system configuration parameters are also available through the DCS Modbus

registers. However, parameters that should only be accessed by authorized personnel are not

accessible through this communication line. For a full listing of accessible configuration

parameters through the DCS Modbus interface, refer to DCS Modbus Interface Specifications

[4].

4.4 Local Display Functions

The FGM 160 is equipped with a local LCD display mounted at the front, and visible through

the Ex-d safety glass. The display shows predefined process parameters from the FGM 160.

Further, 4 status LEDs are visible at the front for the following status information:

• Power

This LED will have a green light when the system power is ON.

• Status

This LED will light:

GREEN; if no Alarms are active (system status OK).

Page 12

FGM 160 Operating Instructions

72.120.601

Page 12 of 27

• Comm

This LED will light:

GREEN; during Modbus frame reception or sending.

• Meas

This LED will blink GREEN at a regular cycle, indicating that ultrasonicmeasurement cycle

sequence is active.

4.5 Error Check and Troubleshooting

The operator should not perform extensive troubleshooting bey ond the sc ope that is desc ribed

in this section. For repair and module replacement, contact Fluenta AS.

Fluenta AS

Haraldsgate 90

P.O. Box 420

N-5501 Haugesund

NORWAY

Phone: +47 21 02 19 27

E-mail: support@fluenta.com

NOTE!

Before any work can be carried out with the FGM 160 field computer, a hot work permit

must be obtained.

Do not connect or disconnect any signal wires unless the power is turned OFF!

Do not open the Ex-d enclosure containing the field electronics in hazardous area,

without making sure first that the conditions permit such action. Preferably, and as a

general rule; the Ex-d enclosure should only be opened indoors in e.g. a workshop in

safe area.

4.5.1 Error Check with Local Display

As described in Section 4.4, Four (4) LEDs are visible at the front with status information. If

one or more of these LEDs do not have a GREEN light color indicating OK status, the following

status is present and actions should be taken:

• Power

Indication: The LED is not ON (no green light).

Status: System Power is OFF, or LED does not work.

Action: Check that the system Power wires are connected and that 24 VDC is

present at the power input terminals.

• Meas

Indication: The LED is steady OFF or steady GREEN.

Status: The FGM 160 is not in standard operational (measurement) mode.

Page 13

FGM 160 Operating Instructions

72.120.601

Page 13 of 27

Action: Check the Alarm log for any error messages indicating any cause for the

problem. Turn the system Power OFF and ON again. If the situation

remains unchanged, contact Fluenta AS for guidance.

4.5.2 Error Check with UFM Manager

Through the FGM 160 UFM Manager, data can be logged for trend analysis and evaluation.

Figure 5: By pressing the “START Data Logging” butt on at the “Data Logging” tab, a ny or most par ameter s

can be logged to a data file. The data log file name will be generated automatically based on the current

date and time. The registers for the data log can be chosen by pressing the “Choose registers” button.

5. REFERENCES

[1] FGM 160 – Hazardous Area Installation Guidelines

[2] FGM 160 – Hazardous Area Certificates

[3] FGM 160 – Installation & Hook-Up Instructions

[4] FGM 160 – DCS Modbus Interface Specifications

[5] FGM 160 – HART Output Interface Specification

Page 14

FGM 160 Operating Instructions

72.120.601

Page 14 of 27

EXAMPLE

6. APPENDIX I – SYSTEM CONFIGURATION FILE

********************************************************

********************************************************

****************** ***************

****************** Fluenta AS ***************

****************** FGM 160 parameter list ***************

****************** ***************

********************************************************

********************************************************

UFM Manager ver.: 1.040

Field Computer, date and time: 2011-01-17 09:13:25

***************************************

********** System Parameters **********

***************************************

Field Computer Type: FGM 160

Serial number: 2006-0102

Tag number: 1-TAG-1

Company: FLUENTA AS

Installation: Sandbr ekk eveien 85

Description: 10" LP Flare

System Configuration: Single system (ch1)

Local Display: Not installed <- You have to change it manually

SW Version DSP: 0.052 to version number that is installed

SW-app Version I/O: 1.007 using AVR Studio

SW-boot Version I/O: 0.006

SW-app Version P&T: 0.257

SW-boot Version P&T: 0.005

*******************************************

********** Communication Parameters **********

*******************************************

**************** DCS communication **********

------------------------------------------------------------

DCS Modbus Communication: Enabled

Slave address: 224

Type: RTU

Baud rate: 38400

Data bits: 8

Parity: No Par ity

Stop bit: 2

Register Values: 32 bit floating point (IEEE-754)

Register size in request: 32 bits

Register base address: 1000

***************** HART communication **********

---------------------------------------------------------------

Page 15

FGM 160 Operating Instructions

72.120.601

Page 15 of 27

EXAMPLE

HART Output Communication: Enabled

Poll address: 1

Primary Variable: Total Volume @ Ref. Conditions

Secondary Variable: Volume Flowrate @ Ref. Conditions

Tertiary Variable: Temperature

Quaternary Variable: Pressure

**************** Service port *****************

-------------------------------------------------------------

Slave address: 1

Type: RTU

Baud rate: 38400

Data bits: 8

Parity: None

Stop bits: 2

Register Values: 32 bit floating point (IEEE-754)

**********************************************

************ System Configuration ************

**********************************************

Pipe diameter: 0.3800 m

Transducer distance (M): 0.5370 m

Transducer angle: 45.0 deg

******* Units *******

Velocity: m/s

Volume: m3

Volume flow: m3/h (Cubic meter pr. hour)

Mass: kg

Mass flow: kg/h

Pressure: BarA

Temperature: Celsius

Log time for 24h acc. values: 06:00:00

**********************************************

*********** Input Signal Parameters ***********

**********************************************

Pressure input Current Loop (4-20mA)

Temperature input Current Loop (4-20mA)

Current loop ranges

Temperature, 4mA value: 255.15 [Kelvin]

Temperature, 20mA value: 533.15 [Kelvin]

Pressure, 4mA value: 1.013 [BarA]

Pressure, 20mA value: 12.044 [BarA]

Current loop calibration coefficients

Tempe rature, offset: 0.0070

Page 16

FGM 160 Operating Instructions

72.120.601

Page 16 of 27

EXAMPLE

Temperature, scale: 0.9963

Press ure, offset: 0.0220

Pressure, scale: 0.9980

Alarm limits

Temperature, Hi limit: 533.15 [Kelvin]

Temperature, Lo limit: 255.15 [Kelvin]

Pressure, Hi limit: 12.044 [BarA]

Pressure, Lo limit: 1.013 [BarA]

**********************************************

********** Output signal parameters **********

**********************************************

******** Current loops, 4-20mA ********

Current loop 1, Parameter: Volume Flowrate @ Act. Conditions

Current loop 2, Parameter: Molecular Weight

Current loop 3, Parameter: Testvalue Current Loop 3

Current loop 4, Parameter: Testvalue Current Loop 4

Current loop 5, Parameter: Testvalue Current Loop 5

Current loop 6, Parameter: Testvalue Current Loop 6

Current loop ranges

Current loop 1, 4mA value: 0.00

Current loop 1, 20mA value: 2124000.00

Current loop 2, 4mA value: 0.00

Current loop 2, 20mA value: 50.00

Current loop 3, 4mA value: 4.00

Current loop 3, 20mA value: 20.00

Current loop 4, 4mA value: 4.00

Current loop 4, 20mA value: 20.00

Current loop 5, 4mA value: 4.00

Current loop 5, 20mA value: 20.00

Current loop 6, 4mA value: 4.00

Current loop 6, 20mA value: 20.00

Current loop calibration coefficients

Current loop 1, offset: -0.1217

Current loop 1, scale: 0.9980

Current loop 2, offset: -0.1647

Current loop 2, scale: 1.0045

Current loop 3, offset: -0.1633

Current loop 3, scale: 1.0018

Current loop 4, offset: -0.2105

Current loop 4, scale: 1.0025

Current loop 5, offset: -0.0232

Current loop 5, scale: 1.0078

Current loop 6, offset: -0.1358

Current loop 6, scale: 1.0058

**********************************************

******** Measurement/Signal Parameters *******

**********************************************

Page 17

FGM 160 Operating Instructions

72.120.601

Page 17 of 27

EXAMPLE

CW velocity limit up (CW/Chirp -> Ch ir p) : 15 m/s

CW velocity limit down (Chirp -> CW/Chirp): 14 m/s

Chirp Pattern: LinFM

Chirp Limit1 (ArcTan FM -> Lin FM): 25 m/s

Chirp Limit2 ( Lin FM ->ArcTan FM): 50 m/s

Low cutoff velocity: 0.05 m/s

Max. velocity: 100 m/s

Min. velocity: 0 m/s

Max. velocity ju mp: 50 m/s

Max. sound velocity: 500 m/s

Min. sound velocity: 250 m/s

Max. sound velocity jump: 70 m/s

Historical sound vel. weight factor: 40.0

Z Standard: 1.000

Z Operational: 1.000

Ref Temperature (std. conditions): 15.00 ºC

Ref Pressure (std. conditions): 1.01325 BarA

**********************************************

******** Sensor Calibration Parameters *******

**********************************************

Serial No., Upstream Transducer (A): 022U-11

Serial No., Downstream Transducer (B): 022D-11

CW frequency: 68.00 kHz

*** Transducer delays (calibration coefficients) ***

Chirp upstream: 31818.0 nsec

Chirp downstream: 33318.0 nsec

CW upstream: 12557.0 nsec

CW downstream: 12576.0 nsec

Delta CW correction: 0.0 nsec

---------------- END --------------------------

Page 18

FGM 160 Operating Instructions

72.120.601

Page 18 of 27

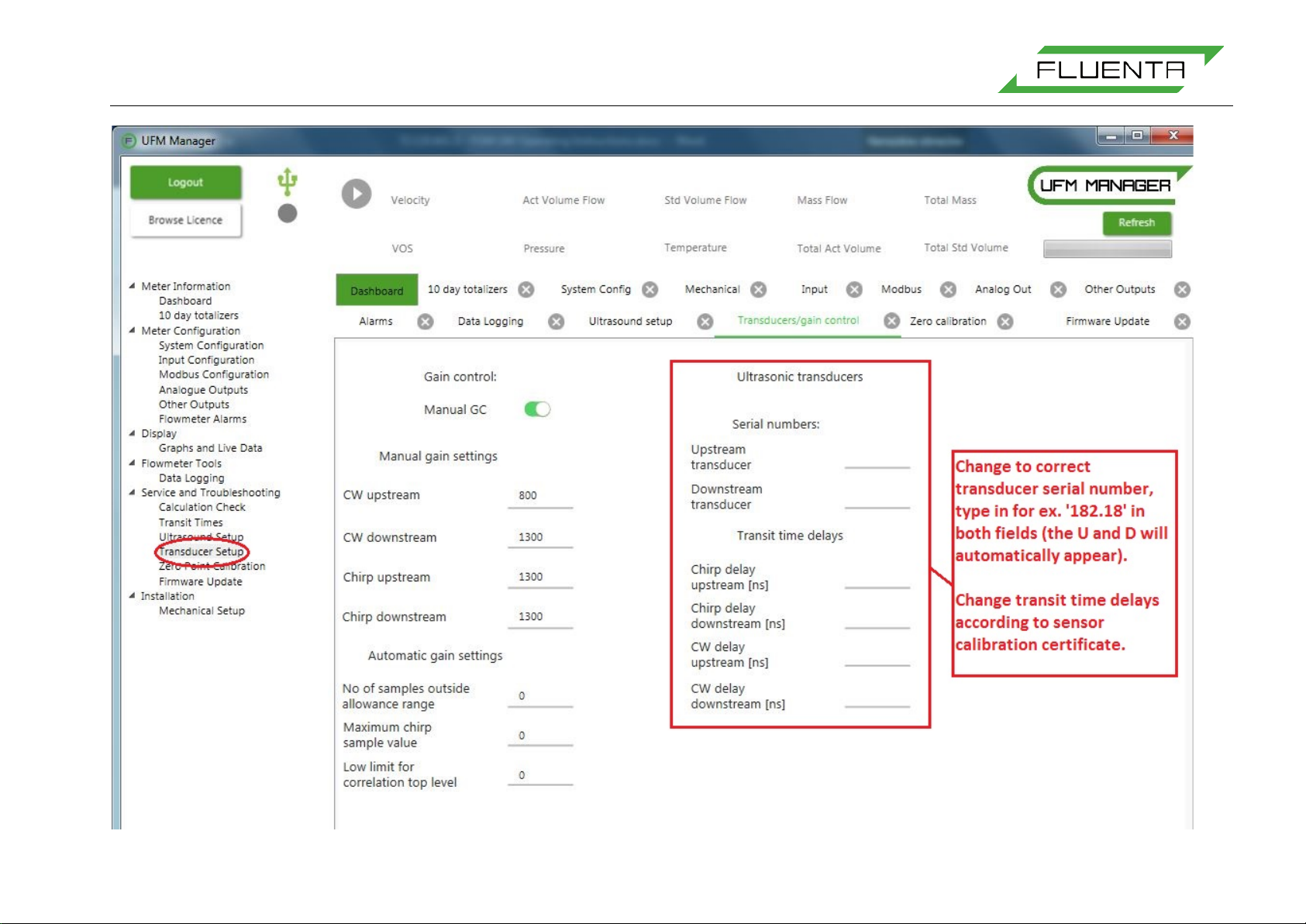

7. APPENDIX II – INSERTING SETTINGS FROM CLIENT PARAMETER LIST

Page 19

FGM 160 Operating Instructions

72.120.601

Page 19 of 27

Page 20

FGM 160 Operating Instructions

72.120.601

Page 20 of 27

Page 21

FGM 160 Operating Instructions

72.120.601

Page 21 of 27

Page 22

FGM 160 Operating Instructions

72.120.601

Page 22 of 27

Page 23

FGM 160 Operating Instructions

72.120.601

Page 23 of 27

Page 24

FGM 160 Operating Instructions

72.120.601

Page 24 of 27

Page 25

FGM 160 Operating Instructions

72.120.601

Page 25 of 27

Page 26

FGM 160 Operating Instructions

72.120.601

Page 26 of 27

Page 27

FGM 160 Operating Instructions

72.120.601

Page 27 of 27

Loading...

Loading...