Page 1

microLinK

Temperature Compensating Linearizing Pickoff

CANbus Implementation Manual

TM-100823, Rev A

Page 2

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 2

Thank you for selecting a Flow Technology, Inc. product for your flow measurement

application.

Virtually every major commercial, government, and scientific organization is making use of our

products, expertise and extensive technical support. This is a culmination of years of

refinement in our flow meter and calibrator designs, which has resulted in the technological

leadership in the flow measurements field that we enjoy.

We are proud of our quality products, our courteous service and welcome you, as a valued

customer, to our growing family.

Flow Technology Inc.

8930 South Beck Ave

Suite #107

Tempe, AZ 85284

Tel: +1 480 240 3400

Fax: +1 480 240 3401

www.ftimeters.com

SF-100828 Rev A

Page 3

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 3

DATE

REVISION

ECO NUMBER

APPROVAL

11/12/2012

A

22345

J. BLASIUS

The specifications contained in this manual are subject to change

without notice and any user of these specifications should verify from

the manufacturer that the specifications are currently in effect.

Otherwise, the manufacturer assumes no responsibility for the use of

specifications, which have been changed, and are no longer in effect.

TM-100823 REVISIONS

PUBLISHED BY FLOW TECHNOLOGY, INC. – November 2012

SF-100828 Rev A

Page 4

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 4

WARRANTY

Limited Warranty

Seller warrants that goods delivered hereunder will at delivery be free from defects in materials and workmanship

and will conform to seller's operating specifications. Seller makes no other warranties, express or implied, and

specifically makes NO WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Limitation of Liability

Seller's obligation under the warranty shall be limited to replacing or repairing at Seller's option, the defective

goods within twelve (12) months from the date of shipment, or eighteen (18) months from the date of shipment

for destination outside of the United States, provided that Buyer gives Seller proper notice of any defect or failure

and satisfactory proof thereof. Defective goods must be returned to Seller's plant or to a designated Seller's

service center for inspection. Buyer will prepay all freight charges to return any products to Seller's plant, or other

facility designated by Seller. Seller will deliver replacements for defective goods to Buyer freight prepaid. The

warranty on said replacements shall be limited to the unexpired portion of the original warranty. Goods returned

to Seller for which Seller provides replacement under the above warranty shall become the property of the Seller.

The limited warranty does not apply to failures caused by mishandling or misapplication. Seller's warranty

obligations shall not apply to any goods that (a) are normally consumed in operation or (b) have a normal life

inherently shorter than the warranty period stated herein. In the event that goods are altered or repaired by the

Buyer without prior written approval by the Seller, all warranties are void. Equipment and accessories not

manufactured by Seller are warranted only to the extent of and by the original manufacturer's warranty. Repair or

replacement goods furnished pursuant to the above warranty shall remain under warranty only for the unexpired

portion of the original warranty period.

Should Seller fail to manufacture or deliver goods other than standard products appearing in Seller's catalog,

Seller's exclusive liability and Buyer's exclusive remedy shall be release of the Buyer from the obligation to pay

purchase price therefore.

THE FORGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES WHETHER ORAL, WRITTEN, EXPRESSED,

IMPLIED OR STATUTORY. IMPLIED WARRANTIES OF FITNESS AND MERCHANTABILITY SHALL NOT APPLY SELLER'S

WARRANTY OBLIGATIONS AND BUYER'S REMEDIES THEREUNDER (EXCEPT AS TO TITLE) ARE SOLELY AND

EXCLUSIVELY AS STATED HEREIN. IN NO CASE WILL SELLER BE LIABLE FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGE.

The total liability of Seller (including its subcontractors) on any claim whether in contract, tort (including

negligence whether sole or concurrent) or otherwise, arising out of or connected with, or resulting from the

manufacture, sales, delivery, resale, repair, replacement or use of any goods or the furnishing of any service

hereunder shall not exceed the price allocable to the product or service or part thereof which gives rise to the

claim.

SF-100828 Rev A

Page 5

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 5

TABLE OF CONTENTS

1 INTRODUCTION ................................................................................................................... 7

1.1 Scope ............................................................................................................................. 7

1.2 Reference Documentation ............................................................................................ 7

2 INSTALLATION ..................................................................................................................... 8

2.1 Mechanical Installation of the microLinK pickoff to the flow meter ............................ 8

2.2 Electrical Installation ..................................................................................................... 8

3 CANOPEN INFORMATION ................................................................................................. 10

3.1 Device Profile .............................................................................................................. 10

3.2 Service Data Objects (SDO) Communication .............................................................. 10

3.3 Process Data Objects (PDO) Communication ............................................................. 10

3.4 Run Levels ................................................................................................................... 10

3.4.1 Changing run levels ............................................................................................... 12

3.5 Object Dictionary ........................................................................................................ 12

3.5.1 Object 0x1000 – Device Type ................................................................................ 12

3.5.2 Object 0x1001 – Error Register ............................................................................. 12

3.5.3 Object 0x1002 – Manufacturer Status Register ................................................... 13

3.5.4 Object 0x1003 – Pre-Defined Error Field .............................................................. 13

3.5.5 Object 0x1008 – Manufacturer Device Name ...................................................... 14

3.5.6 Object 0x1009 – Manufacturer Hardware Version .............................................. 14

3.5.7 Object 0x100A – Manufacturer Software Version................................................ 15

3.5.8 Object 0x1017 – Producer Heartbeat Time .......................................................... 15

3.5.9 Object 0x1018 – Identity Object ........................................................................... 15

3.5.10 Object 0x1800 – Transmit PDO Communication Parameter 1 ............................. 16

3.5.11 Object 0x1801 – Transmit PDO Communication Parameter 2 ............................. 17

3.5.12 Object 0x1A00 – TPDO Mapping Parameter 1 ..................................................... 18

3.5.13 Object 0x1A01 – TPDO Mapping Parameter 2 ..................................................... 18

3.5.14 Object 0x2010 – Flow Totals ................................................................................. 19

3.5.15 Object 0x2011 – Flow Rates .................................................................................. 20

3.5.16 Object 0x2012 – Raw Frequency .......................................................................... 20

3.5.17 Object 0x2013 – Live Temperature....................................................................... 20

3.5.18 Object 0x2021 – Flow Constants .......................................................................... 21

3.5.19 Object 0x2022 – Frequency Information .............................................................. 21

3.5.20 Object 0x2023 – Customer Information ............................................................... 23

3.5.21 Object 0x2024 – Model Numbers ......................................................................... 24

3.5.22 Object 0x2025 – Serial Numbers .......................................................................... 25

3.5.23 Object 0x2026 – Programming and Calibration Information ............................... 26

3.5.24 Object 0x2030 – Curve Data ................................................................................. 27

3.5.25 Object 0x2040 – Density Data .............................................................................. 27

3.5.26 Object 0x2041 – Viscosity Data ............................................................................ 29

3.5.27 Object 0x2042 – Fluids .......................................................................................... 31

3.5.28 Object 0x2050 – Density ....................................................................................... 32

SF-100828 Rev A

Page 6

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 6

3.5.29 Object 0x2051 – Viscosity ..................................................................................... 32

3.5.30 Object 0x2052 – COE ............................................................................................ 32

3.5.31 Object 0x2053 – Temperature Correction ............................................................ 32

3.5.32 Object 0x2054 – Calibration Temperature ........................................................... 33

3.5.33 Object 0x2055 –Temperature Source ................................................................... 33

3.5.34 Object 0x2057 – Fault Temperature ..................................................................... 34

3.5.35 Object 0x2060 – Units ........................................................................................... 34

3.5.36 Object 0x20FF – Boot Load Entry .......................................................................... 36

3.5.37 Object 0x2106 – Power On Counter ..................................................................... 36

3.5.38 Object 0x2107 – Run Level.................................................................................... 36

3.5.39 Object 0x2108 – CANbus Active COM Parameters ............................................... 37

3.5.40 Object 0x2109 – CANbus Bootup COM Parameters ............................................. 37

APPENDIX A MODEL NUMBER BREAK DOWN ........................................................................... 39

LIST OF FIGURES

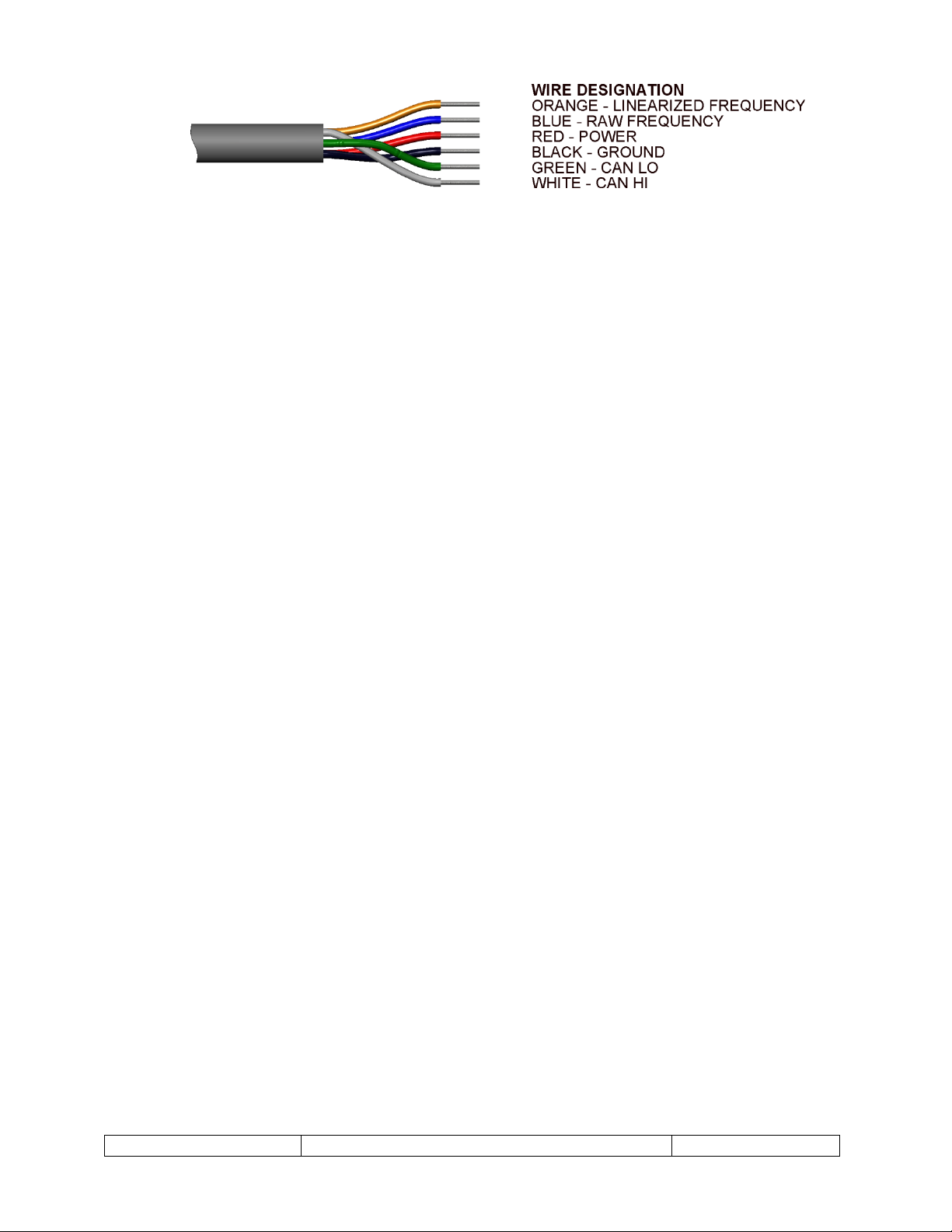

Figure 1 – MS Connector Pinout ..................................................................................................... 8

Figure 2 – Flying Leads Wire Designators ....................................................................................... 9

LIST OF TABLES

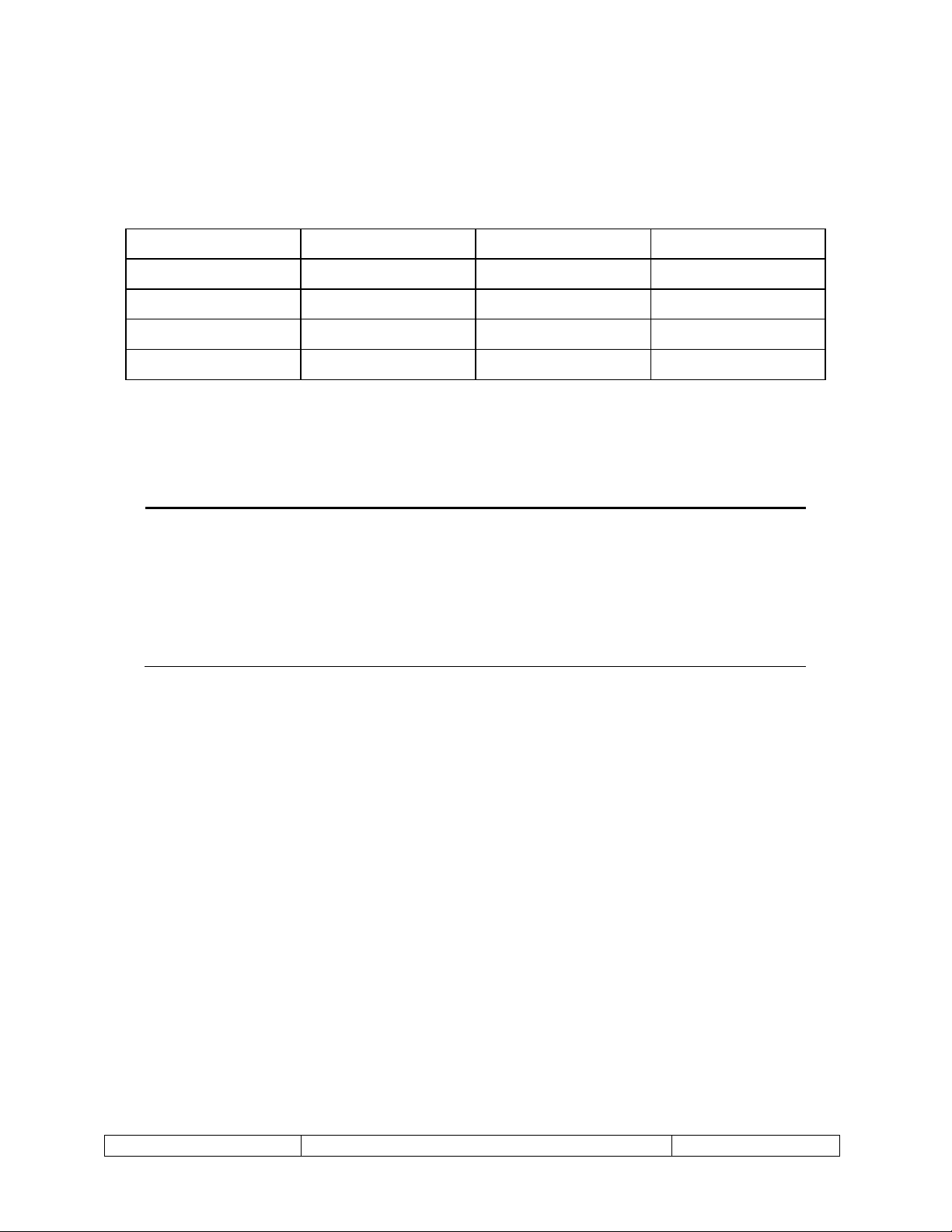

Table 1 - Run Level Write Permissions .......................................................................................... 11

Table 2 - Error Register Bits (from CiA 301) ................................................................................. 13

Table 3 – Product Codes ............................................................................................................... 15

SF-100828 Rev A

Page 7

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 7

1 INTRODUCTION

1.1 Scope

This manual provides information and guidance for personnel responsible for using the

microLinK pickoff in a CANbus environment. For general purpose information regarding the

microLinK product, please consult Flow Technology manual TM-100736

1.2 Reference Documentation

This manual is not intended to be an all-inclusive CAN resource; it provides information

that is unique to the microLinK product. For more detailed information regarding CAN

communications and protocols, please consult the following documents.

CiA 102: CAN Physical Layer for Industrial Applications

CiA 301: CANopen Application layer and communication profile

CiA 303-1: CANopen Recommendation - Cabling and Connector Pin Assignment

CiA 306: CANopen Electronic data sheet specification

Additional Resources:

CAN in Automation (CiA) http://www.can-cia.org/

http://www.canopen.us/

SF-100828 Rev A

Page 8

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 8

2 INSTALLATION

2.1 Mechanical Installation of the microLinK pickoff to the flow meter

The pickoff should bottom in the well of the flow meter housing but only be finger

tightened to approximately 4 lb-in (0.5 N-m) max to prevent distortion of the coil housing.

The pickoff is secured in position by tightening the lock nut to approximately 25 lb-in (2.8

N-m). The pickoff can be removed by loosening the hex lock nut and unscrewing the

pickoff from the housing.

2.2 Electrical Installation

This section provides the professional installer with information for connecting the

microLinK to the user's system.

WARNING:

Verify that the power is off before connecting or servicing!

The connecting cable between the pickoff and the electronic instrumentation should use

22-28 AWG conductors. Shielded and twisted pairs are recommended for CANbus

installations. The cable should not be installed in a conduit or tray containing power lines,

or close to strong electromagnetic sources such as electric lines, electric motors,

transformers, welding machines, or high voltage lines. These sources may induce

transient electrical noise in the coil and cause false readings.

Since the Linearized Frequency and the Raw Frequency outputs both output pulse signals,

these signals can couple or crosstalk between wires. It is recommended that these wires

not be run together for more than 10 feet to avoid problems with crosstalk. Since the

Raw frequency is primarily used for diagnostics, it is recommended that this wire not be

attached to the connector wiring except when diagnostics are needed.

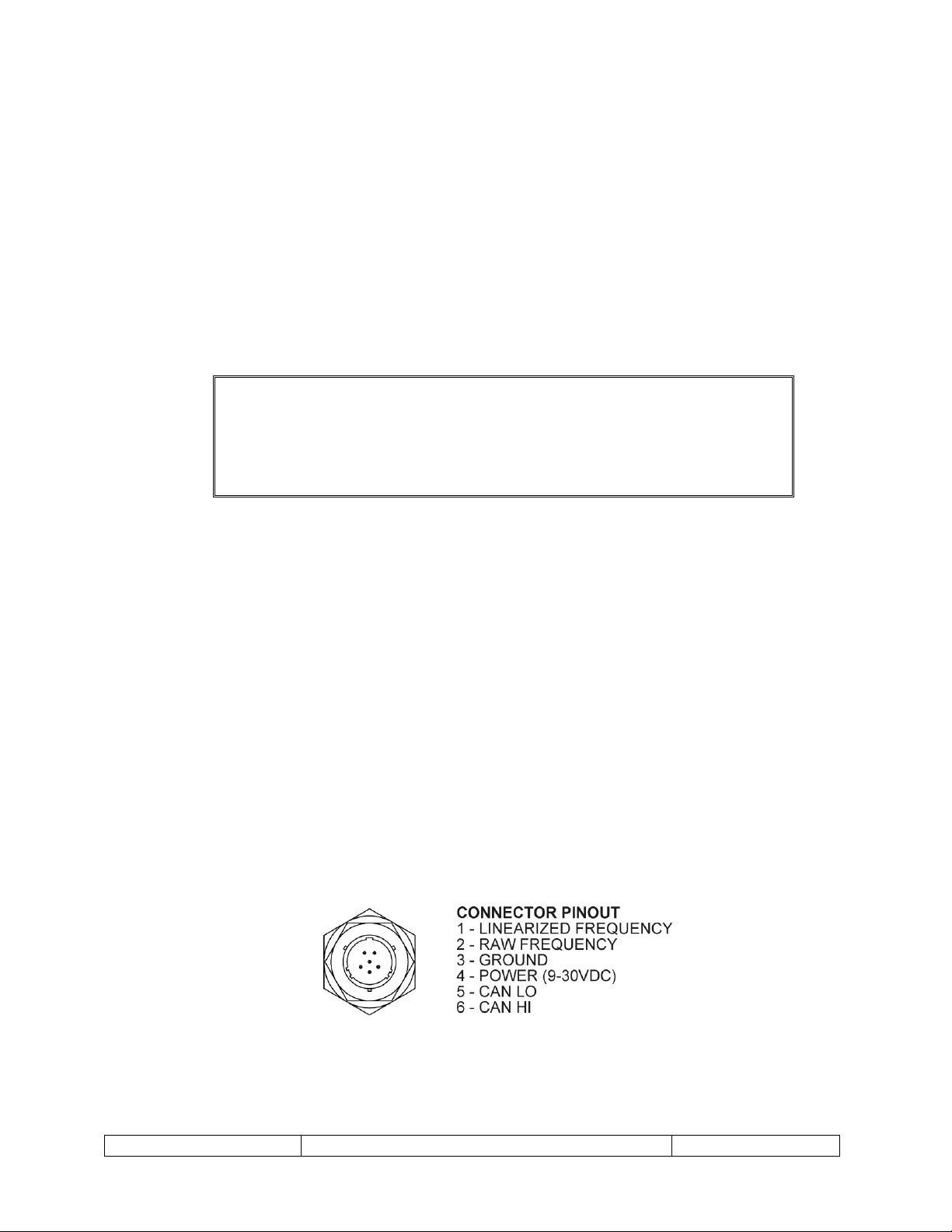

The connector pinout is shown in below Figure 1. The connector on the pickoff is a

commercial equivalent of MS27478Y8E35P. For package options “-5” and “-6” (flying

leads) see Figure 2.

SF-100828 Rev A

Figure 1 – MS Connector Pinout

Page 9

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 9

Figure 2 – Flying Leads Wire Designators

SF-100828 Rev A

Page 10

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 10

3 CANOPEN INFORMATION

3.1 Device Profile

The microLinK product follows the basic device profile specified in CiA 301. Additional

objects unique to the product are discussed in section 3.5. All objects are listed in EDS file

82-100951-xx.eds, where xx is the major revision number listed in object 0x1018sub3. For

example, if the major revision number is 1, then xx will be 01. Be sure that the EDS file

matches the microLinK revision.

3.2 Service Data Objects (SDO) Communication

Communication via Service Data Objects provides access to the objects listed in the

device dictionary. All of the objects listed may be queried and will respond with the data

stored in the object. Some of these objects are read only, some are read/write, and some

will respond as read only until the proper password is written to the Bootloader Object

(0x20FF), then are read/write.

The microLinK pickoff meets the requirements of the CANopen CiA 301 Application layer

and communication profile specification for SDOs. Please refer to this document for more

information on Service Data Objects.

3.3 Process Data Objects (PDO) Communication

Real time data transfer is provided via Process Data Objects. PDOs provide a lower

overhead communication method. The microLinK pickoff provides two PDO

transmissions, each of which contains two operating parameters. The first PDO provides

the volume rate and mass rate data. The second PDO provides raw frequency and

temperature data. The microLinK pickoff only supports timer-driven asynchronous

transmit PDOs.

The microLinK pickoff meets the requirements of the CANopen CiA 301 Application layer

and communication profile specification for PDOs. Please refer to this document for more

information on Process Data Objects.

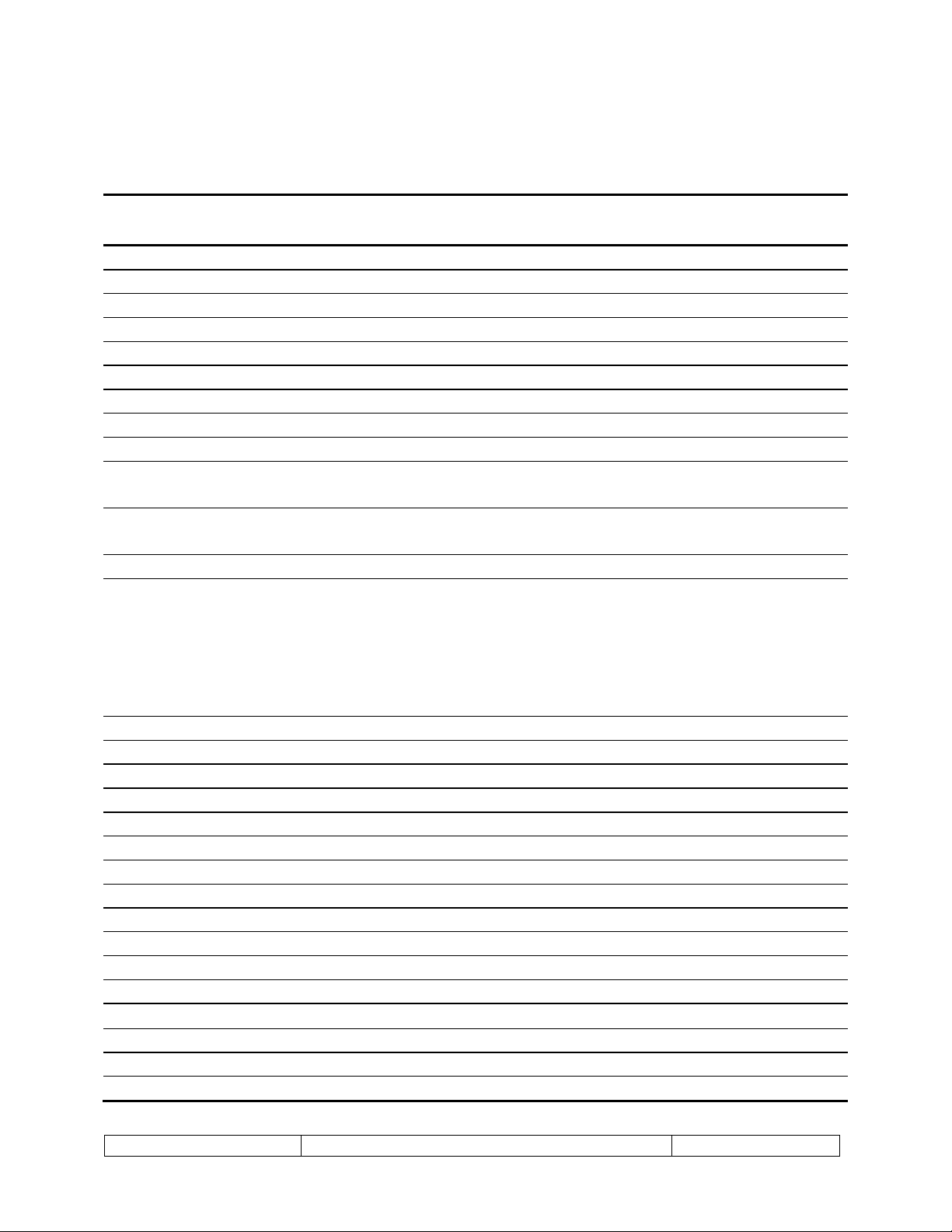

3.4 Run Levels

The microLinK uses three run levels to protect data from accidental modification. SDO

data is readable at any run level, but may only be written if the current run level supports

writing for that object. The run level privileges are incremental, i.e. any object that is

writable at run level 1 is also writable at run level 2.

The run level scheme is intended to prevent accidental modification to SDO data. It is not

intended as a security scheme to prevent malicious changes to the SDO data.

Run level 0 is the default run level. The microLinK is set on power up or reset to this run

level. This run level protects most objects from accidental writing.

Run level 1 is user level. Certain objects that may need to be changed during operation

can be written to at this run level.

SF-100828 Rev A

Page 11

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 11

Description

Index

Run Level

0 1 2

Customer Name

0x2023sub1

X X X

Job Number

0x2023sub2

X X X

PO Number

0x2023sub3

X X X

Meter Model Number

0x2024sub1

X X X

Meter Tag Number

0x2024sub2

X X X

Electronic Model Number

0x2024sub3

X X X

Electronic Tag Number

0x2024sub4

X X X

Bootloader Object

0x20FF

X X X

Producer Heartbeat Time

0x2017

X X

PDO Inhibit Times

0x1800sub3,

0x1801sub3

X X

PDO Event Timers

0x1800sub5,

0x1801sub5

X X

Totalizers

0x2010sub1-4

X X

Frequency Information

Low Frequency Cutoff

Frequency Averaging Factor

Scaling Data

Volumetric or Mass Flow

Averaging Limit

0x2022sub1

0x2022sub4

0x2022sub5-8

0x2022sub9

0x2022subA

X X

Active Fluid

0x2042sub1

X X

Fluid Names

0x2042sub2-4

X X

Temperature Correction

0x2053

X X

External Temperature Control

0x2055

X X

Baud Rate

0x2109sub2

X X

Node ID

0x2109sub1

X X

Timebase

0x2021sub2

X

Meter Overspeed Frequency

0x2022sub2

X

Meter Serial Number

0x2025sub1

X

Electronic Serial Number

0x2025sub2

X

Programming Date

0x2026sub1

X

Technician Name

0x2026sub2

X

Calibration Curve Data (f/ curve)

0x2030

X

Fluid Viscosity Data

0x2041

X

Fluid Density Data

0x2040

X

COE

0x2052

X

Run level 2 is the pickoff configuration level. Objects such as calibration data that will not

be changed during normal operation are only writable at this run level.

Table 1 - Run Level Write Permissions

SF-100828 Rev A

Page 12

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 12

Description

Index

Run Level

0 1 2

Calibration Temperature

0x2054

X

Fault Temperature

0x2057

X

Data Units

0x2060

X

Index

0x1000

Object Name

Device Type

Data Type

UNSIGNED32

Access Type

RO | RO | RO

3.4.1 Changing run levels

The run level is changed by writing a password to object 0x20FF. The run level change is

persistent until another password is written to object 0x20FF or until the pickoff is reset.

Object 0x20FF is used for other functions such as putting the pickoff into bootloader

mode. This object is used for some factory-only functions and writing values other than

the specified passwords may cause erroneous operation of the pickoff.

Run Level 0 password = 0x0FF

Run Level 1 password = 0xC5EF

Run Level 2 password = 0xACC355

3.5 Object Dictionary

This section lists objects available for configuration and operation of the microLinK

pickoff. The read-write status for each object is shown as three choices. These choices are

listed in the following order run level 0 | run level 1 | run level 2. For example the

Producer Heartbeat Time in object 0x1017 shows RO | RW | RW for the Access

Type. This means that run level 0 has read-only permissions while run levels 1 and 2 have

read-write permissions.

3.5.1 Object 0x1000 – Device Type

This object specifies the device profile in effect for the unit. The microLinK pickoff does

not follow a standardized device profile and therefore is zero.

3.5.2 Object 0x1001 – Error Register

This object holds the errors for the device. The following error bits are supported by the

microLinK pickoff.

SF-100828 Rev A

Page 13

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 13

Table 2 - Error Register Bits (from CiA 301)

Bit

Meaning

Supported by

microLinK

0

Generic

Yes 1 Current

No 2 Voltage

No 3 Temperature

No 4 Communication Error

Yes 5 Device Profile Specific

No 6 Reserved (Always 0)

Always 0

7

Manufacturer Specific

Yes

Index

0x1001

Object Name

Error Register

Data Type

UNSIGNED8

Access Type

RO | RO | RO

Index

0x1002

Object Name

Manufacturer Status Register

Data Type

UNSIGNED32

Access Type

RO | RO | RO

If a bit is set to 1, the specified error has occurred.

The generic error is signaled at any error situation. The manufacturer specific error is set

with a:

Temperature sensor error

Viscosity error

Density error

3.5.3 Object 0x1002 – Manufacturer Status Register

This object will always return a 0x00.

Use of this register is reserved for later versions of firmware.

3.5.4 Object 0x1003 – Pre-Defined Error Field

This object contains a history of the errors that have occurred. Subindex 0 contains the

number of errors contained in the history. Writing to subindex 0 clears the history.

When an error occurs, information about the error is placed in the history in subindex 1,

and subindex 0 is incremented. When error information is placed into subindex 1, the

information that was in subindex 1 is shifted into subindex 2, the information that was

in subindex 2 is shifted into subindex 3, etc. If the error is cleared, the cleared error

information is placed in the history in subindex 1, and the subindexes are shifted the

same as if a new error had occurred.

SF-100828 Rev A

Page 14

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 14

The error history can provide additional information about an error. The following

Index

0x1003

Object Name

Pre-Defined Error Field

Data Type

ARRAY

Subindex

0

Object Name

Number of Errors

Data Type

UNSIGNED8

Access Type

RW | RW | RW

Subindex

8

Object Name

Error Field 8

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Index

0x1008

Object Name

Manufacturer Device Name

Data Type

VISIBLE_STRING

Access Type

RO | RO | RO

Index

0x1009

Object Name

Manufacturer Device Name

Data Type

VISIBLE_STRING

Access Type

RO | RO | RO

information is added to the error history when a manufacturer specific error occurs.

0x00011001 Invalid Viscosity

0x00021001 Invalid Density

0x03000000 Invalid Viscosity or Density error cleared

0x????1002 Temperature Sensor Error (Where ???? is additional information

on the sensor fault)

0x03010000 Temperature Sensor Error cleared

0x00??1005 Watchdog Reset (Where ?? is additional startup information)

0x03040000 Watchdog Reset error cleared

…

3.5.5 Object 0x1008 – Manufacturer Device Name

This object holds the device name. For the microLinK product line, the entry is

microLinK.

3.5.6 Object 0x1009 – Manufacturer Hardware Version

This object holds the revision level of the main circuit board inside the pickoff. This value

is also available in object 0x2025sub4.

SF-100828 Rev A

Page 15

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 15

3.5.7 Object 0x100A – Manufacturer Software Version

Index

0x100A

Object Name

Manufacturer Software Version

Data Type

VISIBLE_STRING

Access Type

RO | RO | RO

Index

0x1017

Object Name

Producer Heartbeat Time

Data Type

UNSIGNED16

Access Type

RO | RW | RW

Model Number

Product Code

ULN-C-1-00-1

100721101

ULN-C-1-00-5

100721102

ULN-C-1-00-6

100721103

Index

0x1018

Object Name

Identity Object

Object Type

Record

This object holds the version of the software in the pickoff.

3.5.8 Object 0x1017 – Producer Heartbeat Time

This object holds the cycle time in milliseconds of the heartbeat generated by the

microLinK. Fractional values are not allowed.

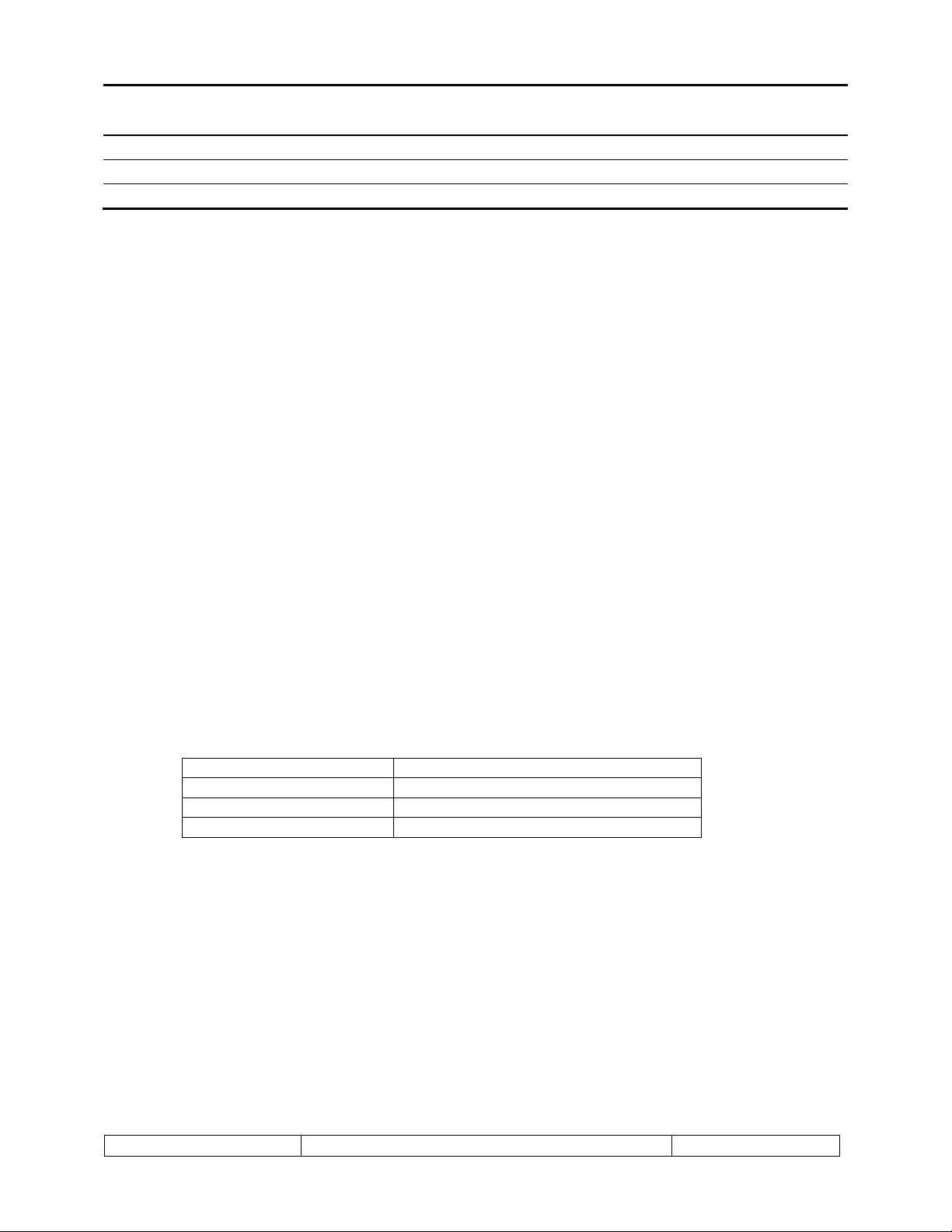

3.5.9 Object 0x1018 – Identity Object

This object holds generic information about the device.

Vendor ID is the unique value of 0x032B, allocated to Flow Technology by the CiA

organization.

Product Code is the code assigned to the product from Flow Technology. This value

is a number representing the model number of the pickoff without the dashes. Table 3

below lists the product codes for the different model numbers.

Table 3 – Product Codes

Revision Number is a revision number for the microLinK product. It consists of a 16bit major revision and a 16-bit minor revision. If the CANopen behavior (EDS) changes,

the major revision is incremented. All other changes will cause the minor revision to

increment.

Serial Number is the serial number of the circuit board inside the pickoff. This is the

same value that appears in object 0x2025sub3.

SF-100828 Rev A

Page 16

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 16

Subindex

1

Object Name

Vendor ID

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Subindex

2

Object Name

Product Code

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Subindex

3

Object Name

Revision Number

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Subindex

4

Object Name

Serial Number

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Index

0x1800

Object Name

Transmit PDO Communication

Parameter 1

Object Type

Record

Subindex

1

Object Name

COB-ID

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Subindex

2

Object Name

Transmission Type

Data Type

UNSIGNED8

Access Type

RO | RO | RO

3.5.10 Object 0x1800 – Transmit PDO Communication Parameter 1

This object holds information about the PDOs the device is able to transmit.

COB-ID is the COB-ID for the data being transmitted.

Transmission Type defines the transmission type of the PDO. Only Transmission

Type 254 is supported.

Inhibit Time is a minimum interval for PDO transmission. The value is defined as a

multiple of 100μs.

Event Timer is the number of milliseconds between transmissions. A value of 0 will

turn off the PDO transmissions.

SF-100828 Rev A

Page 17

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 17

Subindex

3

Object Name

Inhibit Time

Data Type

UNSIGNED16

Access Type

RO | RW | RW

Subindex

4

Object Name

Reserved

Data Type

N/A

Access Type

N/A

Subindex

5

Object Name

Event Timer

Data Type

UNSIGNED16

Access Type

RO | RW | RW

Index

0x1801

Object Name

Transmit PDO Communication

Parameter 2

Object Type

Record

Subindex

1

Object Name

COB-ID

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Subindex

2

Object Name

Transmission Type

Data Type

UNSIGNED8

Access Type

RO | RO | RO

3.5.11 Object 0x1801 – Transmit PDO Communication Parameter 2

This object holds information about the PDOs the device is able to transmit. See the

previous section.

COB-ID is the object number for the data being transmitted.

Transmission Type defines the transmission/reception character of the PDO.

Inhibit Time is a minimum interval for PDO transmission. The value is defined as a

multiple of 100μs. The value is not allowed to be changed while the PDO exists.

Event Timer is the number of milliseconds between transmissions. A value of 0 will

turn off the PDO transmissions.

SF-100828 Rev A

Page 18

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 18

Subindex

3

Object Name

Inhibit Time

Data Type

UNSIGNED16

Access Type

RO | RW | RW

Subindex

4

Object Name

Reserved

Data Type

N/A

Access Type

N/A

Subindex

5

Object Name

Event Timer

Data Type

UNSIGNED16

Access Type

RO | RW | RW

Index

0x1A01

Object Name

TPDO Mapping Parameter 1

Object Type

Record

Subindex

1

Object Name

VolumeRatePDO

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Subindex

2

Object Name

MassRatePDO

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Index

0x1A00

Object Name

TPDO Mapping Parameter 2

Object Type

Record

Subindex

1

Object Name

RawFrequencyPDO

Data Type

UNSIGNED32

Access Type

RO | RO | RO

3.5.12 Object 0x1A00 – TPDO Mapping Parameter 1

This object holds the mapping for the PDOs the device is able to transmit.

3.5.13 Object 0x1A01 – TPDO Mapping Parameter 2

This object holds the mapping for the PDOs the device is able to transmit.

SF-100828 Rev A

Page 19

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 19

Subindex

2

Object Name

LiveTemperaturePDO

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Index

0x2010

Object Name

Flow Totals

Object Type

Array

Subindex

1

Object Name

Volume Total 1

Data Type

REAL32

Access Type

RO | RW | RW

Subindex

2

Object Name

Volume Total 2

Data Type

REAL32

Access Type

RO | RW | RW

Subindex

3

Object Name

Mass Total 1

Data Type

REAL32

Access Type

RO | RW | RW

3.5.14 Object 0x2010 – Flow Totals

This object holds the total amount of volume and mass that has passed through the flow

meter since the last reset of the total. Each total can be individually reset by writing a

zero to that total. The total can also be preset to a specific value by writing the desired

preset value to the total. The total’s value is stored in EEPROM when power is removed

from the microLinK. Note that re-programming the unit with Visual LinK will reset all

totals to zero.

Volume Total 1 is the total volume of fluid since the last time the totalizers were

last reset. See 0x2060 for more information regarding unit identifiers.

Volume Total 2 is the total volume of fluid since the last time the totalizers were

last reset. See 0x2060 for more information regarding unit identifiers.

Mass Total 1 is the total mass of fluid since the last time the totalizers were last

reset. See 0x2060 for more information regarding unit identifiers.

Mass Total 2 is the total mass of fluid since the last time the totalizers were last

reset. See 0x2060 for more information regarding unit identifiers.

SF-100828 Rev A

Page 20

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 20

Subindex

4

Object Name

Mass Total 2

Data Type

REAL32

Access Type

RO | RW | RW

Index

0x2011

Object Name

Flow Rates

Object Type

Array

Subindex

1

Object Name

Volume Rate

Data Type

REAL32

Access Type

RO | RO | RO

Subindex

2

Object Name

Mass Rate

Data Type

REAL32

Access Type

RO | RO | RO

Index

0x2012

Object Name

Raw Frequency

Data Type

REAL32

Access Type

RO | RO | RO

3.5.15 Object 0x2011 – Flow Rates

This object holds the current flow rate values. See TM-100736 for more information on

how the flow rate values are calculated.

Volume Rate is the current volumetric flow rate. See 0x2060 for more information

regarding unit identifiers.

Mass Rate is the current mass flow rate. See 0x2060 for more information regarding

unit identifiers.

3.5.16 Object 0x2012 – Raw Frequency

This object holds the current raw flow meter frequency. This is a measured value.

3.5.17 Object 0x2013 – Live Temperature

This object holds the current fluid temperature. Note this value will either be from the

internal temperature sensor (measured value) or from object 0x2055sub2 depending on

the value of 0x2055sub1. See 0x2060 for more information regarding unit identifiers.

SF-100828 Rev A

Page 21

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 21

Index

0x2013

Object Name

Live Temperature

Data Type

REAL32

Access Type

RO | RO | RO

Index

0x2021

Object Name

Flow Constants

Object Type

Array

Subindex

1

Object Name

Reserved

Data Type

N/A

Access Type

N/A

Subindex

2

Object Name

TimeBase

Data Type

UNSIGNED32

Access Type

RO | RO | RW

Subindex

3

Object Name

Reserved

Data Type

N/A

Access Type

N/A

3.5.18 Object 0x2021 – Flow Constants

This object holds the information for the conversion of time units.

TimeBase value is the number of seconds in the current time unit. For example if the

current time unit is minutes, TimeBase will be 60. For hours, TimeBase will be 3600.

3.5.19 Object 0x2022 – Frequency Information

This object holds various parameters associated with measuring the frequency of the

rotor and generating the linearized output frequency.

Low Freq Cutoff is the lowest raw frequency the microLinK will use. All raw

(measured) frequencies below this value will be considered zero.

Meter Overspeed Freq sets the maximum allowed raw frequency of the flow

meter. If the raw frequency goes above this value the value in 0x2022sub3 is

incremented by one. This is not a cutoff. If the frequency measured by the microLinK

goes above this value, the raw frequency used is the measured frequency.

Meter Overspeeds is a counter for the number of time the raw frequency has

exceeded the value in 0x2022sub2.

SF-100828 Rev A

Page 22

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 22

Averaging Factor is used to average the incoming raw frequency as shown below.

1

)*(

ctorveragingFaFrequencyA

dFrequencyNewMeasurectorveragingFaFrequencyAquencyAverageFre

quencyAverageFre

Index

0x2022

Object Name

Frequency Information

Object Type

Array

Subindex

1

Object Name

Low Freq Cutoff

Data Type

REAL32

Access Type

RO | RW | RW

The higher the value, the slower the microLinK’s response to frequency change is.

Permissible values are from 0 to 250. See TM-100736 for more information regarding

this object.

Note: Averaging Factor values from 251 to 254 are used for extreme averaging.

251: Averaging Factor = 500

252: Averaging Factor = 1000

253: Averaging Factor = 1500

254: Averaging Factor = 2000

Min Scaling Freq is the frequency which corresponds to the minimum flow rate.

Frequency by definition cannot be negative.

Min Rate is the flow rate which corresponds to the Min Scaling Freq.

Max Scaling Freq is the frequency which represents the maximum flow rate.

Max Rate is the flow rate corresponding to the Max Scaling Freq.

Volumetric or Mass Flow determines if the linearized output frequency

represents volume or mass flow. It is set to 1 for volumetric flow rate and 2 for mass

flow rate. A value of 0 turns the linearized frequency output off.

Average Limit is used to increase the response time with a high Averaging Factor. A

very high value effectively disables the average limit. A value of less than one disables

the averaging factor. If the new measured frequency is greater than the Average

Frequency multiplied by the Average Limit (or less than the Average Frequency divided

by the Average Limit), the new measured frequency is put directly into Average

Frequency. See TM-100736 for more information regarding the Average Limit.

SF-100828 Rev A

Page 23

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 23

Subindex

2

Object Name

Meter Overspeed Freq

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

3

Object Name

Meter Overspeeds

Data Type

UNSIGNED16

Access Type

RO | RO | RO

Subindex

4

Object Name

Averaging Factor

Data Type

UNSIGNED8

Access Type

RO | RW | RW

Subindex

5

Object Name

Min Scaling Freq

Data Type

REAL32

Access Type

RO | RW | RW

Subindex

6

Object Name

Min Rate

Data Type

REAL32

Access Type

RO | RW | RW

Subindex

7

Object Name

Max Scaling Freq

Data Type

REAL32

Access Type

RO | RW | RW

Subindex

8

Object Name

Max Rate

Data Type

REAL32

Access Type

RO | RW | RW

Subindex

9

Object Name

Volumetric or Mass Flow

Data Type

UNSIGNED8

Access Type

RO | RW | RW

Subindex

A

Object Name

Average Limit

Data Type

REAL32

Access Type

RO | RW | RW

3.5.20 Object 0x2023 – Customer Information

This object holds various pieces of customer information.

SF-100828 Rev A

Page 24

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 24

Customer Name is the name of the customer for which the product was initially built.

Index

0x2023

Object Name

Customer Information

Object Type

Array

Subindex

1

Object Name

Customer Name

Data Type

VISIBLE_STRING

Access Type

RW | RW | RW

Subindex

2

Object Name

Job Number

Data Type

VISIBLE_STRING

Access Type

RW | RW | RW

Subindex

3

Object Name

PO Number

Data Type

VISIBLE_STRING

Access Type

RW | RW | RW

This field must contain 30 characters. If the name is shorter than 30, additional

characters (e.g. spaces or nulls) must be added to the end.

Job Number is the sales order number on which the product was initially built. This

field must contain 20 characters. If the name is shorter than 20, additional characters

(e.g. spaces or nulls) must be added to the end.

PO Number is the purchase order on which the product was initially built. This field

must contain 20 characters. If the name is shorter than 20, additional characters (e.g.

spaces or nulls) must be added to the end.

3.5.21 Object 0x2024 – Model Numbers

This object holds the various model numbers for the unit.

Meter Model Number is the model number of the mating flow meter. This field

must contain 18 characters. If the name is shorter than 18, additional characters (e.g.

spaces or nulls) must be added to the end.

Meter Tag Number is the customer tag number of the mating flow meter. This field

must contain 18 characters. If the name is shorter than 18, additional characters (e.g.

spaces or nulls) must be added to the end.

Electronic Model Number is the model number of the microLinK pickoff. This

field must contain 18 characters. If the name is shorter than 18, additional characters

(e.g. spaces or nulls) must be added to the end.

SF-100828 Rev A

Page 25

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 25

Electronic Tag Number is the customer tag number of the microLinK pickoff.

Index

0x2024

Object Name

Model Numbers

Object Type

Array

Subindex

1

Object Name

Meter Model Number

Data Type

VISIBLE_STRING

Access Type

RW | RW | RW

Subindex

2

Object Name

Meter Tag Number

Data Type

VISIBLE_STRING

Access Type

RW | RW | RW

Subindex

3

Object Name

Electronic Model Number

Data Type

VISIBLE_STRING

Access Type

RW | RW | RW

Subindex

4

Object Name

Electronic Tag Number

Data Type

VISIBLE_STRING

Access Type

RW | RW | RW

This field must contain 18 characters. If the name is shorter than 18, additional

characters (e.g. spaces or nulls) must be added to the end.

3.5.22 Object 0x2025 – Serial Numbers

This object holds the various serial numbers for the unit.

Meter Serial Number is the serial number of the mating flow meter. This field

must contain 12 characters. If the name is shorter than 12, additional characters (e.g.

spaces or nulls) must be added to the end.

Electronic Serial Number is the serial number of the microLinK pickoff. This

field must contain 12 characters. If the name is shorter than 12, additional characters

(e.g. spacesor nulls) must be added to the end.

Board Serial Number is the serial number of the circuit board inside the pickoff.

This is the same value that appears in object 0x1018sub4.

Hardware Version is the revision level of the circuit board inside the pickoff.

SF-100828 Rev A

Page 26

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 26

Index

0x2025

Object Name

Serial Numbers

Object Type

Array

Subindex

1

Object Name

Meter Serial Number

Data Type

VISIBLE_STRING

Access Type

RO | RO | RW

Subindex

2

Object Name

Electronic Serial Number

Data Type

VISIBLE_STRING

Access Type

RO | RO | RW

Subindex

3

Object Name

Board Serial Number

Data Type

UNSIGNED32

Access Type

RO | RO | RO

Subindex

4

Object Name

Hardware Version

Data Type

VISIBLE_STRING

Access Type

RO | RO | RO

Index

0x2026

Object Name

Programming Information

Object Type

Array

Subindex

1

Object Name

Programming Date

Data Type

UNSIGNED32

Access Type

RO | RO | RW

Subindex

2

Object Name

Technician Name

Data Type

VISIBLE_STRING

Access Type

RO | RO | RW

3.5.23 Object 0x2026 – Programming and Calibration Information

This object holds information about the last time the pickoff was programmed.

Programming Date is the last date the pickoff was last programmed with Visual

LinK. The format of the date is such that April 25, 2012 is written as 20120425.

Technician Name is the name of the technician who did the programming. This field

must contain 12 characters. If the name is shorter than 12, additional characters (e.g.

spaces or nulls) must be added to the end.

SF-100828 Rev A

Page 27

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 27

Index

0x2030

Object Name

Curve Data

Object Type

Array

Subindex

1

Object Name

Freq/Visc 1

Data Type

UNSIGNED32

Access Type

RO | RO | RW

Subindex

2

Object Name

Kf 1

Data Type

UNSIGNED32

Access Type

RO | RO | RW

Subindex

3B

Object Name

Freq/Visc 30

Data Type

UNSIGNED32

Access Type

RO | RO | RW

Subindex

3C

Object Name

Kf 30

Data Type

UNSIGNED32

Access Type

RO | RO | RW

3.5.24 Object 0x2030 – Curve Data

This object holds the composite curve data pairs for the flow meter. There are 30 data

pairs in the object. The pairs are in ascending order by frequency over viscosity. If less

than 30 pairs are available for use, the last pair must be repeated for the remainder of

the table.

Freq/Visc [1|2|3|…|30] is the value for frequency divided by viscosity. The

units for freq/visc are Hz/cSt.

Kf [1|2|3|…|30] is the value for the K-Factor. The units for K-Factor are pulses per

volume. See 0x2060 for more information regarding unit identifiers.

…

3.5.25 Object 0x2040 – Density Data

This object holds the fluid density data pairs for the three different fluids. There are 20

data pairs for each of the three fluids in the object. The pairs are in ascending order by

temperature. If less than 20 pairs are available for use, the last pair must be repeated

for the remainder of each portion of the table.

SF-100828 Rev A

Page 28

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 28

T[1|2|3|…|20] is the value for temperature. See 0x2060 for more information

Index

0x2040

Object Name

Density Data

Object Type

Array

Subindex

1

Object Name

T1 Fluid 1

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

2

Object Name

D1 Fluid 1

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

27

Object Name

T20 Fluid 1

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

28

Object Name

D20 Fluid 1

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

29

Object Name

T1 Fluid 2

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

2A

Object Name

D1 Fluid 2

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

4F

Object Name

T20 Fluid 2

Data Type

REAL32

Access Type

RO | RO | RW

regarding unit identifiers.

D[1|2|3|…|20] is the value for density. See 0x2060 for more information regarding

unit identifiers.

…

…

SF-100828 Rev A

Page 29

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 29

Subindex

50

Object Name

D20 Fluid 2

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

51

Object Name

T1 Fluid 3

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

52

Object Name

D1 Fluid 3

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

77

Object Name

T20 Fluid 3

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

78

Object Name

D20 Fluid 3

Data Type

REAL32

Access Type

RO | RO | RW

Index

0x2041

Object Name

Viscosity Data

Object Type

Array

Subindex

1

Object Name

T1 Fluid 1

Data Type

REAL32

Access Type

RO | RO | RW

…

3.5.26 Object 0x2041 – Viscosity Data

This object holds the fluid viscosity data pairs for the three different fluids. There are 20

data pairs for each of the three fluids in the object. The pairs are in ascending order by

temperature. If less than 20 pairs are available for use, the last pair must be repeated

for the remainder of each portion of the table.

T[1|2|3|…|20] is the value for temperature. See 0x2060 for more information

regarding unit identifiers.

v[1|2|3|…|20] is the value for viscosity in cSt.

SF-100828 Rev A

Page 30

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 30

Subindex

2

Object Name

v1 Fluid 1

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

27

Object Name

T20 Fluid 1

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

28

Object Name

v20 Fluid 1

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

29

Object Name

T1 Fluid 2

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

2A

Object Name

v1 Fluid 2

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

4F

Object Name

T20 Fluid 2

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

50

Object Name

v20 Fluid 2

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

51

Object Name

T1 Fluid 3

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

52

Object Name

v1 Fluid 3

Data Type

REAL32

Access Type

RO | RO | RW

…

…

SF-100828 Rev A

Page 31

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 31

Subindex

77

Object Name

T20 Fluid 3

Data Type

REAL32

Access Type

RO | RO | RW

Subindex

78

Object Name

v20 Fluid 3

Data Type

REAL32

Access Type

RO | RO | RW

Index

0x2042

Object Name

Fluids

Object Type

DEFSTRUCT

Subindex

1

Object Name

Active Fluid

Data Type

UNSIGNED8

Access Type

RO | RW | RW

Subindex

2

Object Name

Fluid 1 Name

Data Type

VISIBLE_STRING

Access Type

RO | RW | RW

Subindex

3

Object Name

Fluid 2 Name

Data Type

VISIBLE_STRING

Access Type

RO | RW | RW

Subindex

4

Object Name

Fluid 3 Name

Data Type

VISIBLE_STRING

Access Type

RO | RW | RW

…

3.5.27 Object 0x2042 – Fluids

This object holds the active fluid number and the names for the three fluids.

Active Fluid lists the fluid number that is active. Valid entries are 1, 2, or 3.

Fluid [1|2|3|] Name is the name of the fluid. This field must contain 12

characters. If the name is shorter than 12, additional characters (e.g. spaces or nulls)

must be added to the end. The name of the fluid is informational only and has no effect

on the operation of the microLinK.

SF-100828 Rev A

Page 32

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 32

3.5.28 Object 0x2050 – Density

Index

0x2050

Object Name

Density

Data Type

REAL32

Access Type

RO | RO | RO

Index

0x2051

Object Name

Density

Data Type

REAL32

Access Type

RO | RO | RO

Index

0x2052

Object Name

COE

Data Type

REAL32

Access Type

RO | RO | RW

Index

0x2042

Object Name

Temperature Correction

Object Type

DEFSTRUCT

This object holds the current density as calculated from the live temperature reading in

object 0x2013, the active fluid listed in 0x2042sub1, and the fluid temperature-density

data in 0x2040. See 0x2060 for more information regarding unit identifiers.

3.5.29 Object 0x2051 – Viscosity

This object holds the current viscosity as calculated from the live temperature reading in

object 0x2013, the active fluid listed in 0x2042sub1, and the fluid temperature-viscosity

data in 0x2041. The units for this value are cSt.

3.5.30 Object 0x2052 – COE

This object holds the coefficient of expansion for the flow meter housing material. The

units for this value are in./in./°F or m/m/°C depending on the temperature units

specified in 0x2060sub6.

3.5.31 Object 0x2053 – Temperature Correction

This object holds the information regarding temperature correction. It is possible to

apply a slope and offset correction to the internal temperature measurement to achieve

better accuracy. The correction works as shown below.

Multiply is the value for M shown in the equation above. The default value is 1.0.

Add is the value for A shown in the equation above. The default value is 0.

SF-100828 Rev A

Page 33

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 33

Subindex

1

Object Name

Multiply

Data Type

REAL32

Access Type

RO | RW | RW

Subindex

2

Object Name

Add

Data Type

REAL32

Access Type

RO | RW | RW

Index

0x2054

Object Name

Calibration Temperature

Data Type

REAL32

Access Type

RO | RO | RW

Index

0x2055

Object Name

Temperature Source

Object Type

DEFSTRUCT

3.5.32 Object 0x2054 – Calibration Temperature

This object holds the temperature value at which that the flow meter was calibrated.

This value can also be referred to as the reference temperature or T0. It is used in the

Strouhal-Roshko correction factors. The units for this value are listed in 0x2060sub6.

3.5.33 Object 0x2055 –Temperature Source

This object holds the information specifying the temperature measurement source. The

microLinK pickoff has an integral temperature sensor to determine the fluid

temperature. Alternatively, the fluid temperature can be sensed using an external

temperature measurement device. The externally measured temperature can then be

placed in object 0x2055sub2.

Enable External Temperature is a flag to determine if an externally measured

temperature should be used for the fluid temperature. Valid entries are 0 (use integral

temperature sensor for the fluid temperature) or 1 (use the value in object 0x2055sub2

for the fluid temperature).

Fluid Temperature is the current externally measured temperature value. The

units for this value must match those listed in 0x2060sub6. Note that population of this

object is only available through SDO communication.

If Enable External Temperature is set to 1, the CAN master must acquire the

fluid temperature from an external device and then program the measured temperature

into the microLinK. This allows use of a specialized thermometer for more accurate fluid

temperature measurements.

SF-100828 Rev A

Page 34

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 34

Subindex

1

Object Name

Enable External Temperature

Data Type

UNSIGNED8

Access Type

RO | RW | RW

Subindex

2

Object Name

Fluid Temperature

Data Type

REAL32

Access Type

RO | RW | RW

Index

0x2057

Object Name

Fault Temperature

Data Type

REAL32

Access Type

RO | RO | RW

3.5.34 Object 0x2057 – Fault Temperature

This object holds the temperature value to be used if the integral temperature sensor

encounters a fault. The units for this value are listed in 0x2060sub6.

3.5.35 Object 0x2060 – Units

This object holds the various unit names for values stored.

Note: (except for 0x2060sub6) these entries do not have any effect on calculations for

operating parameters. They are strictly for user convenience. Use caution when

making changes to objects; values must have consistent units. It is highly

recommended that configuration changes be performed using Visual LinK.

Volume Flow Rate Units holds the unit name for volumetric flow. This field must

contain 10 characters. If the name is shorter than 10, additional characters (e.g. spaces

or nulls) must be added to the end. The name stored in this object is informational only.

Changing the name stored in this object has no effect on the microLinK’s operation. The

name stored in this object is set by Visual LinK based on the Accumulated Volume Units

and the Timebase choices.

Accumulated Volume Units holds the unit name for accumulated (total) volume.

This field must contain 10 characters. If the name is shorter than 10, additional

characters (e.g. spaces or nulls) must be added to the end. The name in this object is

informational only. Changing the name stored in this object has no effect on the

microLinK’s operation. The name in this object is used by Visual LinK to store the volume

units used in programming the microLinK. While changing the name in this object has no

effect on the microLinK operation, changing the name will prevent Visual LinK from

retrieving valid calibration data from the microLinK.

SF-100828 Rev A

Page 35

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 35

Mass Flow Rate Units holds the unit name for mass flow. This field must contain

Index

0x2060

Object Name

Data Units

Object Type

Array

Subindex

1

Object Name

Volume Flow Rate Units

Data Type

VISIBLE_STRING

Access Type

RO | RO | RW

Subindex

2

Object Name

Accumulated Volume Units

Data Type

VISIBLE_STRING

Access Type

RO | RO | RW

10 characters. If the name is shorter than 10, additional characters (e.g. spaces or nulls)

must be added to the end. The name stored in this object is informational only.

Changing the name stored in this object has no effect on the microLinK’s operation. The

name stored in this object is set by Visual LinK based on the Accumulated Mass Units

and the Timebase choices.

Accumulated Mass Units holds the unit name for accumulated (total) mass. This

field must contain 10 characters. If the name is shorter than 10, additional characters

(e.g. spaces or nulls) must be added to the end. The name in this object is informational

only. Changing the name stored in this object has no effect on the microLinK’s

operation. The name in this object is used by Visual LinK to store the volume units used

in programming the microLinK. While changing the name in this object has no effect on

the microLinK operation, changing the name will prevent Visual LinK from retrieving

valid calibration data from the microLinK.

Density Units holds the unit name for fluid density. This field must contain 10

characters. If the name is shorter than 10, additional characters (e.g. spaces or nulls)

must be added to the end. The name stored in this object is informational only.

Changing the name stored in this object has no effect on the microLinK’s operation. The

name stored in this object is set by Visual LinK based on the Accumulated Mass Units

and the Accumulated Volume Units choices.

Temperature Units holds the unit name for fluid temperature. This field must

contain 10 characters. If the name is shorter than 10, additional characters (e.g. spaces

or nulls) must be added to the end. The name in this object controls the units of the

integral temperature sensor in the microLinK. Note that changing these units does not

change the temperature values anywhere else in the microLinK configuration. Changing

the temperature units in this object without changing all of the viscosity and density

tables will result in invalid viscosities and densities being calculated and used by the

microLinK. For best results use Visual LinK to convert to all of the required values in the

microLinK to different temperature units.

SF-100828 Rev A

Page 36

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 36

Subindex

3

Object Name

Mass Flow Rate Units

Data Type

VISIBLE_STRING

Access Type

RO | RO | RW

Subindex

4

Object Name

Accumulated Mass Units

Data Type

VISIBLE_STRING

Access Type

RO | RO | RW

Subindex

5

Object Name

Density Units

Data Type

VISIBLE_STRING

Access Type

RO | RO | RW

Subindex

6

Object Name

Temperature Units

Data Type

VISIBLE_STRING

Access Type

RO | RO | RW

Index

0x20FF

Object Name

Boot Loader Entry

Data Type

UNSIGNED32

Access Type

RW | RW | RW

Index

0x2106

Object Name

Power On Counter

Data Type

UNSIGNED32

Access Type

RO | RO | RO

3.5.36 Object 0x20FF – Boot Load Entry

This object is the entry point for system passwords. Valid entries are:

0x0FF to set run level 0

0xC5EF to set run level 1

0xACC355 to set run level 2

3.5.37 Object 0x2106 – Power On Counter

This object holds the number of power on cycles since the last factory reset. This may be

useful in diagnosing power supply problems.

3.5.38 Object 0x2107 – Run Level

This object holds the current run level based on passwords entered in 0x20FF

SF-100828 Rev A

Page 37

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 37

Index

0x2107

Object Name

Run Level

Data Type

UNSIGNED8

Access Type

RO | RO | RO

Index

0x2108

Object Name

CANbus Active COM Parameters

Object Type

Array

Subindex

1

Object Name

CAN Node ID

Data Type

UNSIGNED8

Access Type

RO | RO | RO

Subindex

2

Object Name

CAN BitRate

Data Type

UNSIGNED8

Access Type

RO | RO | RO

3.5.39 Object 0x2108 – CANbus Active COM Parameters

This object holds CAN network information that is currently active.

CAN Node ID is the currently active node ID on the CAN network.

CAN BitRate is the currently active CAN network speed. Valid values are:

1 = 20kBit/s

2 – 50kBit/s

3 = 125kBit/s

4 – 250kBit/s

5 = 500kBit/s

6 – 800kBit/s

7 = 1000kBit/s

3.5.40 Object 0x2109 – CANbus Bootup COM Parameters

This object holds CAN network information that will be active after a power cycle.

CAN Node ID is the node ID on the CAN network after a power cycle.

CAN BitRate is the CAN network speed after a power cycle. Valid entries are:

1 = 20kBit/s

2 – 50kBit/s

3 = 125kBit/s

SF-100828 Rev A

Page 38

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 38

4 – 250kBit/s

Index

0x2108

Object Name

CANbus Bootup COM Parameters

Object Type

Array

Subindex

1

Object Name

CAN Node ID

Data Type

UNSIGNED8

Access Type

RO | RW | RW

Subindex

2

Object Name

CAN BitRate

Data Type

UNSIGNED8

Access Type

RO | RW | RW

5 = 500kBit/s

6 – 800kBit/s

7 = 1000kBit/s

SF-100828 Rev A

Page 39

TM-100823, Rev A

microLinK CANbus Implementation Manual

Page 39

Appendix A Model Number Break Down

ULN-C-1-00aaxx

aa Package Configuration

-1 = MS Connector

-5 = Flying Leads with NPT

-6 = Flying Leads without NPT

xxx Specials – Determined by FTI at time of order

SF-100828 Rev A

Loading...

Loading...