Page 1

MC608A/B

Electromagnetic Transmitter

Installation, Operation and Maintenance Manual

TM-100467, Rev P

Page 2

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 2

Thank you for selecting a Flow Technology, Inc. product for your flow measurement

application.

Virtually every major commercial, government, and scientific organization is making use of our

products, expertise and extensive technical support. This is a culmination of years of

refinement in our flow meter and calibrator designs, which has resulted in the technological

leadership in the flow measurements field that we enjoy.

We are proud of our quality products, our courteous service and welcome you, as a valued

customer, to our growing family.

Flow Technology Inc.

8930 South Beck Ave

Suite #107

Tempe, AZ 85284

Tel: +1 480 240 3400

Fax: +1 480 240 3401

www.ftimeters.com

SF-100834 Rev A

Page 3

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 3

DATE

REVISION

ECO NUMBER

APPROVAL

3/30/2015

H

23714

R. Mann

3/10/2016

J

24189

R. Mann

4/21/2016

K

24255

R. Mann

8/8/16

L

24436

R. Mann

10/3/17

M

24917

R. Mann

11/1/17

N

24949

R. Mann

5/11/18

P

25160

R. Mann

The specifications contained in this manual are subject to change

without notice and any user of these specifications should verify from

the manufacturer that the specifications are currently in effect.

Otherwise, the manufacturer assumes no responsibility for the use of

specifications, which have been changed, and are no longer in effect.

TM-100467 REVISIONS

SF-100834 Rev A

Page 4

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 4

PUBLISHED BY FLOW TECHNOLOGY, INC. – March, 2016

WARRANTY

Limited Warranty

Seller warrants that goods delivered hereunder will at delivery be free from defects in materials and workmanship

and will conform to seller's operating specifications. Seller makes no other warranties, express or implied, and

specifically makes NO WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Limitation of Liability

Seller's obligation under the warranty shall be limited to replacing or repairing at Seller's option, the defective

goods within twelve (12) months from the date of shipment, or eighteen (18) months from the date of shipment

for destination outside of the United States, provided that Buyer gives Seller proper notice of any defect or failure

and satisfactory proof thereof. Defective goods must be returned to Seller's plant or to a designated Seller's

service center for inspection. Buyer will prepay all freight charges to return any products to Seller's plant, or other

facility designated by Seller. Seller will deliver replacements for defective goods to Buyer freight prepaid. The

warranty on said replacements shall be limited to the unexpired portion of the original warranty. Goods returned

to Seller for which Seller provides replacement under the above warranty shall become the property of the Seller.

The limited warranty does not apply to failures caused by mishandling or misapplication. Seller's warranty

obligations shall not apply to any goods that (a) are normally consumed in operation or (b) have a normal life

inherently shorter than the warranty period stated herein. In the event that goods are altered or repaired by the

Buyer without prior written approval by the Seller, all warranties are void. Equipment and accessories not

manufactured by Seller are warranted only to the extent of and by the original manufacturer's warranty. Repair or

replacement goods furnished pursuant to the above warranty shall remain under warranty only for the unexpired

portion of the original warranty period.

Should Seller fail to manufacture or deliver goods other than standard products appearing in Seller's catalog,

Seller's exclusive liability and Buyer's exclusive remedy shall be release of the Buyer from the obligation to pay

purchase price therefore.

THE FORGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES WHETHER ORAL, WRITTEN, EXPRESSED,

IMPLIED OR STATUTORY. IMPLIED WARRANTIES OF FITNESS AND MERCHANTABILITY SHALL NOT APPLY SELLER'S

WARRANTY OBLIGATIONS AND BUYER'S REMEDIES THEREUNDER (EXCEPT AS TO TITLE) ARE SOLELY AND

EXCLUSIVELY AS STATED HEREIN. IN NO CASE WILL SELLER BE LIABLE FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGE.

The total liability of Seller (including its subcontractors) on any claim whether in contract, tort (including

negligence whether sole or concurrent) or otherwise, arising out of or connected with, or resulting from the

manufacture, sales, delivery, resale, repair, replacement or use of any goods or the furnishing of any service

hereunder shall not exceed the price allocable to the product or service or part thereof which gives rise to the

claim.

SF-100834 Rev A

Page 5

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 5

TABLE OF CONTENTS

1 INTRODUCTION ................................................................................................................... 8

1.1 Scope ............................................................................................................................. 8

1.2 Purpose ......................................................................................................................... 8

1.3 Description .................................................................................................................... 8

2 INSTALLATION ..................................................................................................................... 9

2.1 Inspection ...................................................................................................................... 9

2.2 Mechanical Installation of the transmitter to the flow meter ..................................... 9

2.2.1 Compact (mounted on flow meter) ........................................................................ 9

2.2.2 Separate (remote mounted from flow meter) ..................................................... 10

2.2.3 Maximum cable length ......................................................................................... 11

2.2.4 Grounding ............................................................................................................. 11

2.3 Electrical Installation ................................................................................................... 11

2.3.1 MC608A/B terminal locations ............................................................................... 12

2.3.2 Remote mounted converter, without empty pipe detector ................................ 15

2.3.3 Powering the unit ................................................................................................. 17

2.3.4 Wiring of Pulse Output ......................................................................................... 17

2.3.5 Wiring of Frequency Output (only available on MC608A version) ...................... 19

2.3.6 Wiring of 4 – 20mA Analog Output ...................................................................... 19

2.3.7 Wiring of RS485 Output (only available on MC608A version) ............................. 21

2.3.8 Wiring of Programmable Output ......................................................................... 21

2.3.9 Wiring of Programmable Input ............................................................................ 23

2.3.10 Output Notes ........................................................................................................ 23

3 PROGRAMMING THE MC608 CONVERTER ....................................................................... 23

3.1 Programming Overview .............................................................................................. 23

3.2 Converter Passwords .................................................................................................. 24

3.3 Activating MC608B ...................................................................................................... 24

3.4 MC608 Configuration via PC Using MC608 Programming Software .......................... 24

3.4.1 Initial Connection .................................................................................................. 24

3.4.2 Parameter Configuration ...................................................................................... 26

3.4.3 Read Configuration ............................................................................................... 27

3.4.4 Filter Configuration ............................................................................................... 28

3.4.5 Data Logger ........................................................................................................... 29

3.5 MC608 Configuration via the Local Display ................................................................ 30

3.5.1 Overview ............................................................................................................... 30

3.5.2 Data to be Displayed ............................................................................................. 32

3.5.3 Options .................................................................................................................. 33

3.5.4 Counters ................................................................................................................ 33

3.5.5 Parameters ............................................................................................................ 34

3.5.6 I/O ......................................................................................................................... 35

3.5.7 Other ..................................................................................................................... 36

3.5.8 Memory ................................................................................................................. 37

SF-100834 Rev A

Page 6

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 6

4 SPECIFICATIONS ................................................................................................................ 38

5 TROUBLESHOOTING .......................................................................................................... 40

6 ALARM MESSAGES ............................................................................................................ 41

APPENDIX A COOLANT FLOW METER TRANSMITTER (MC608P) ........................................ 42

APPENDIX B MODBUS INPUT REGISTERS - FUNCTION CODE 04 ......................................... 43

APPENDIX C MODBUS HOLDING REGISTER FUNCTION CODES 03 & 16 ............................. 44

APPENDIX D VOLUME AND TIME BASE UNITS CHARTS ....................................................... 46

APPENDIX E EXAMPLES ....................................................................................................... 47

SF-100834 Rev A

Page 7

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 7

LIST OF FIGURES

Figure 1 – MC608A – Mains Powered Unit ..................................................................................... 9

Figure 2 – MC608B – Battery Powered Unit ................................................................................... 9

Figure 3 – Remote mounting ........................................................................................................ 10

Figure 4 – Cable length vs. conductivity ....................................................................................... 11

Figure 5- High voltage: 90 – 264 Vac (PCBA up to version 6-2) .................................................... 12

Figure 6 – Low voltage: 12 – 24 VDC/Vac (PCBA up to version 6-2) ............................................. 13

Figure 7- Low and high voltage (PCBA version 6-3) ...................................................................... 14

Figure 8- Low and high voltage (PCBA from version 6-4) ............................................................. 15

Figure 9 – Remote mounted wiring .............................................................................................. 16

Figure 10 – Clean contact pulse output ........................................................................................ 17

Figure 11 – Active 5 – 20 VDC pulse output ................................................................................. 18

Figure 12 – Active self-powered from version 6-3 ....................................................................... 18

Figure 13 – Frequency output ....................................................................................................... 19

Figure 14 – Loop 4 – 20 mA output .............................................................................................. 19

Figure 15 – Active 4 – 20 mA output ............................................................................................ 20

Figure 16 – Active 4 – 20 mA output ............................................................................................ 20

Figure 17 – RS485 communication ............................................................................................... 21

Figure 18 – Clean contact programmable output ........................................................................ 21

Figure 19 – Active 24 V self-powered programmable output ...................................................... 22

Figure 20 – Active 1-30V programmable output .......................................................................... 22

Figure 21 – Programmable input .................................................................................................. 23

Figure 22 – Main Screen ............................................................................................................... 25

Figure 23 – Parameters Screen ..................................................................................................... 26

Figure 24 – Read Screen ................................................................................................................ 27

Figure 25 – Filter Screen ............................................................................................................... 28

Figure 26 – Data Logger Screen .................................................................................................... 29

Figure 27 – Chart Display Screen .................................................................................................. 30

Figure 28 – Display Overview ........................................................................................................ 32

SF-100834 Rev A

Page 8

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 8

1 INTRODUCTION

1.1 Scope

This manual provides information and guidance for personnel responsible for the installation,

operation, and maintenance of the MC608A/B Electromagnetic Flow Meter Transmitter

supplied by Flow Technology, Inc.

1.2 Purpose

The contents of this manual are for general information and to describe the operational

characteristics of the MC608A/B transmitter. This manual does not include instructions for

special application or factory repair.

1.3 Description

An Electromagnetic Flow Meter works off the principal of Faraday’s Law. In this

application of the principal the flow meter creates an electromagnetic field perpendicular

to the fluid flowing through the meter housing. An electromotive force (voltage) is

generated in a conductive medium when it passed through a magnetic field. The voltage

created is directly proportional to the density of the magnetic field and the velocity of the

conductive medium. Since the conductive medium is the liquid whose flow is to be

measured, and the length between the electrodes and the electromagnetic field strength

is known, therefore the signal generated is proportional to the velocity of the liquid in the

pipe.

In order for this technology to operate correctly the fluid to be measured does need to be

conductive. The minimum fluid conductivity required is 5 µS/cm for most fluids and 20

µS/cm for DI water.

The electromagnetic flow meters are composed of:

The sensor that must be mounted between two portions of pipe by flanges, threaded

joints, or triclamp fittings.

The converter which drives the sensor and displays or transmits data.

The MC 608A/B converter is provided in a cylindrical aluminum instrument enclosure and

can be interfaced to all Flow Technology magnetic flow meters. It can be mounted directly

on top of the flow meter or remote from the flow meter connected through a pair of

cables, whose maximum length depends on the conductivity of the liquid.

The flow meter Ka and Kb coefficients are established during the factory flow meter

calibration. These factors are normally programmed into the MC 608A/B converter at the

factory prior to shipment, however the key pad of the converter allows the user to enter

or modify these coefficients. This key pad also allows the user to set the full scale flow

rate, define the scaled pulse output, adjust alarm set points, and adjust dosage volume.

SF-100834 Rev A

Page 9

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 9

The MC608 is available in two main versions:

MC608A – Mains powered 90…264Vac or 12/24 Vac/dc

MC608B – Battery powered or 12/24Vac/dc

2 INSTALLATION

2.1 Inspection

Verify that all parts listed on the packing list are included with your shipment. Note that

there may be more than one package for your shipment. Please check the factory set up

sheet and verify the meter size, full scale flow rate, and analog/pulse output are set up as

required.

2.2 Mechanical Installation of the transmitter to the flow meter

2.2.1 Compact (mounted on flow meter)

The MC 608A/B converter is supplied mounted directly to the flow meter junction box.

In this configuration all interconnection wiring between the flow meter sensor and the

converter have been completed at the factory. Upon flow meter installation, external

wiring for power input and signal outputs will need to be completed. For optimum

installation flexibility the converter display is capable of rotating up to 180˚.

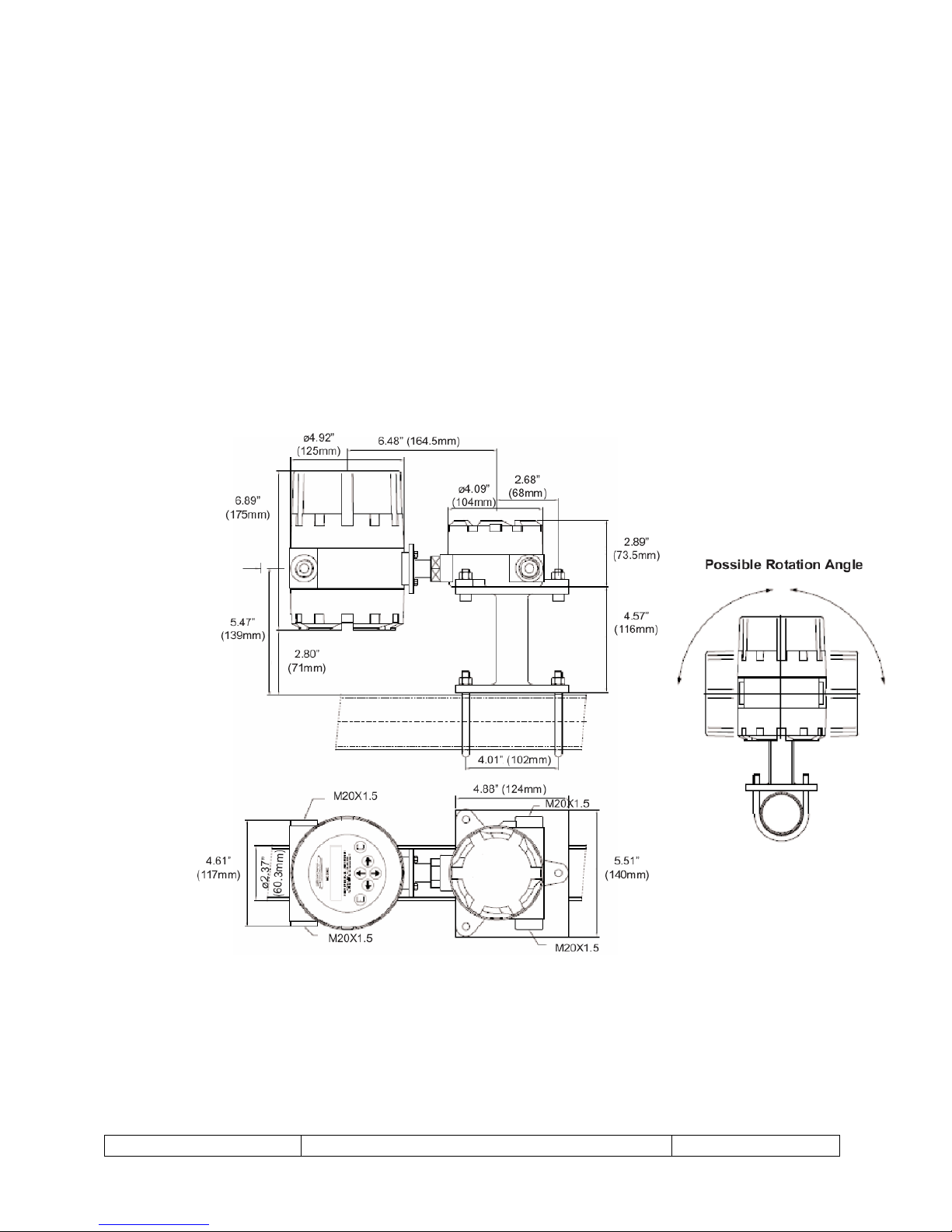

Figure 1 – MC608A – Mains Powered Unit

Figure 2 – MC608B – Battery Powered Unit

SF-100834 Rev A

Page 10

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 10

2.2.2 Separate (remote mounted from flow meter)

The MC 608A and MC 608B converters can be mounted up to a maximum of 328 feet

(100 meters) and 98 feet (30 meters) respectively from the flow meter, dependent on

fluid conductivity. When supplied for remote mounting, the flow meter can optionally

be purchased with various cable lengths for interconnection to the converter. This

interconnection cable can be supplied attached to and resin sealed in the flow meter

junction box or the cables can be supplied separately and attached and sealed in the

field. For optimum installation flexibility the converter display is capable of rotating up

to 180˚.

Figure 3 – Remote mounting

SF-100834 Rev A

Page 11

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 11

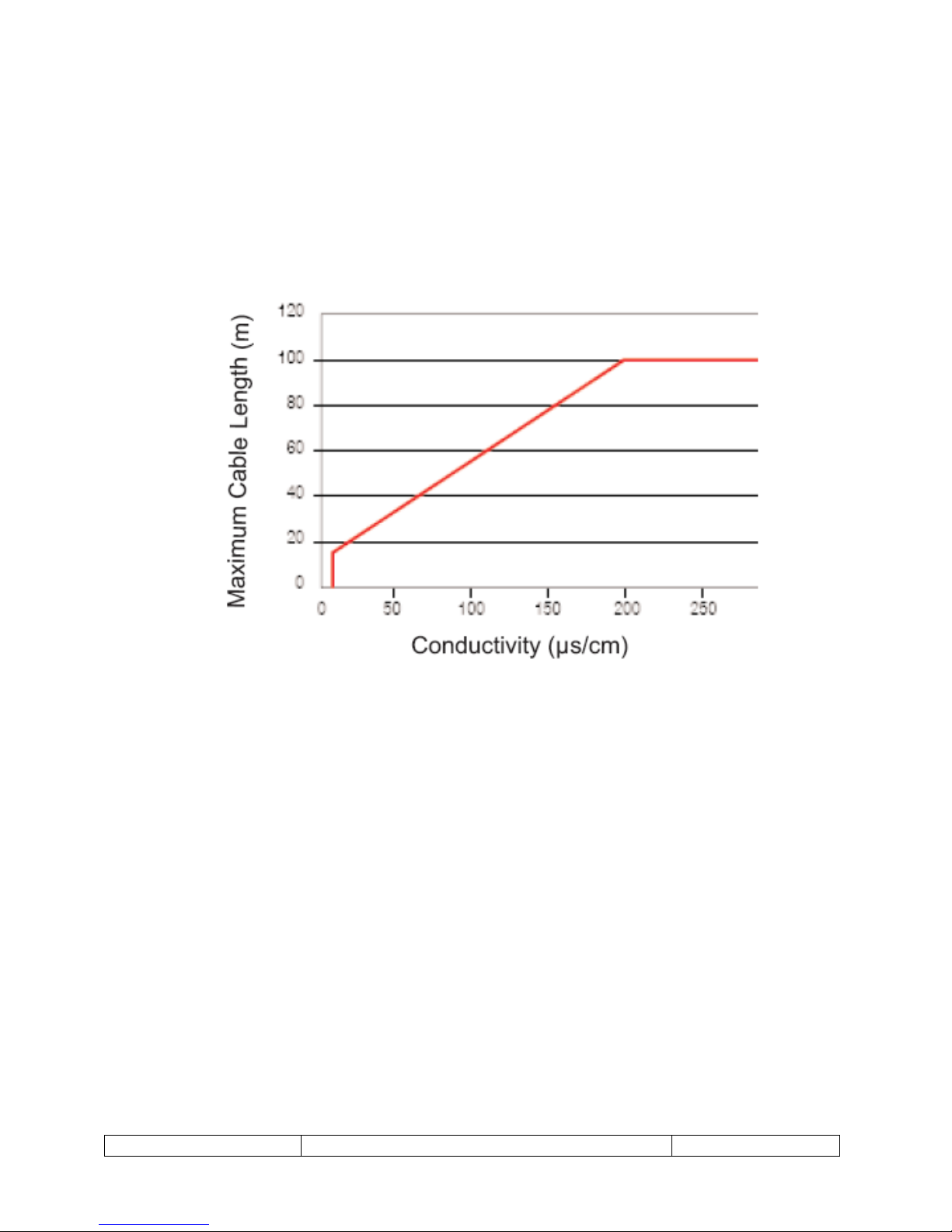

2.2.3 Maximum cable length

When the converter is to be mounted remote from the flow meter, the maximum cable

distance is limited by the conductivity of the fluid to be measured. The maximum

distance is 328 feet (100 meters). Below is a chart to determine maximum cable length

based on the installation operating conditions.

Figure 4 – Cable length vs. conductivity

2.2.4 Grounding

The sensor and converter must be properly grounded to earth potential for the system

to operate correctly. Earth potential is the reference parameter for the flow meter and

without proper grounding issues with zero offset, or flow indication at zero flow will

occur. The sensors and converters all have earth grounding points that can be used to

insure a direct contact with earth ground.

The Flow Technology electromagnetic flow meters are equipment with a third ground

electrode that eliminates the need for grounding rings when installing the flow meter in

insulating piping.

2.3 Electrical Installation

This section provides the professional installer with information for connecting the

MC608A/B to the user's system.

SF-100834 Rev A

Page 12

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 12

Verify that the power is off before connecting or servicing!

Electrical connection of the device must be carried out by properly trained

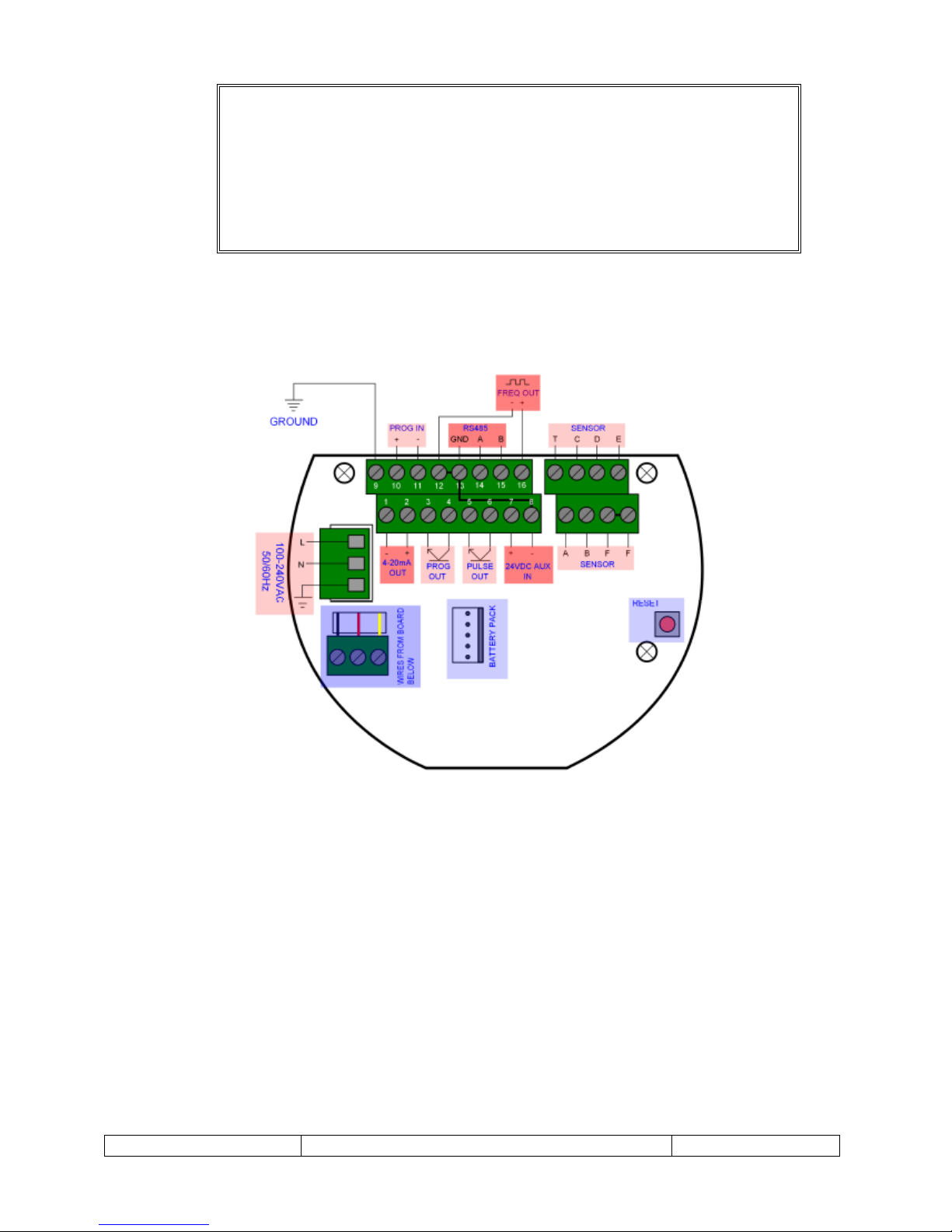

2.3.1 MC608A/B terminal locations

Figure 5- High voltage: 90 – 264 Vac (PCBA up to version 6-2)

WARNING:

personnel!

SF-100834 Rev A

Page 13

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 13

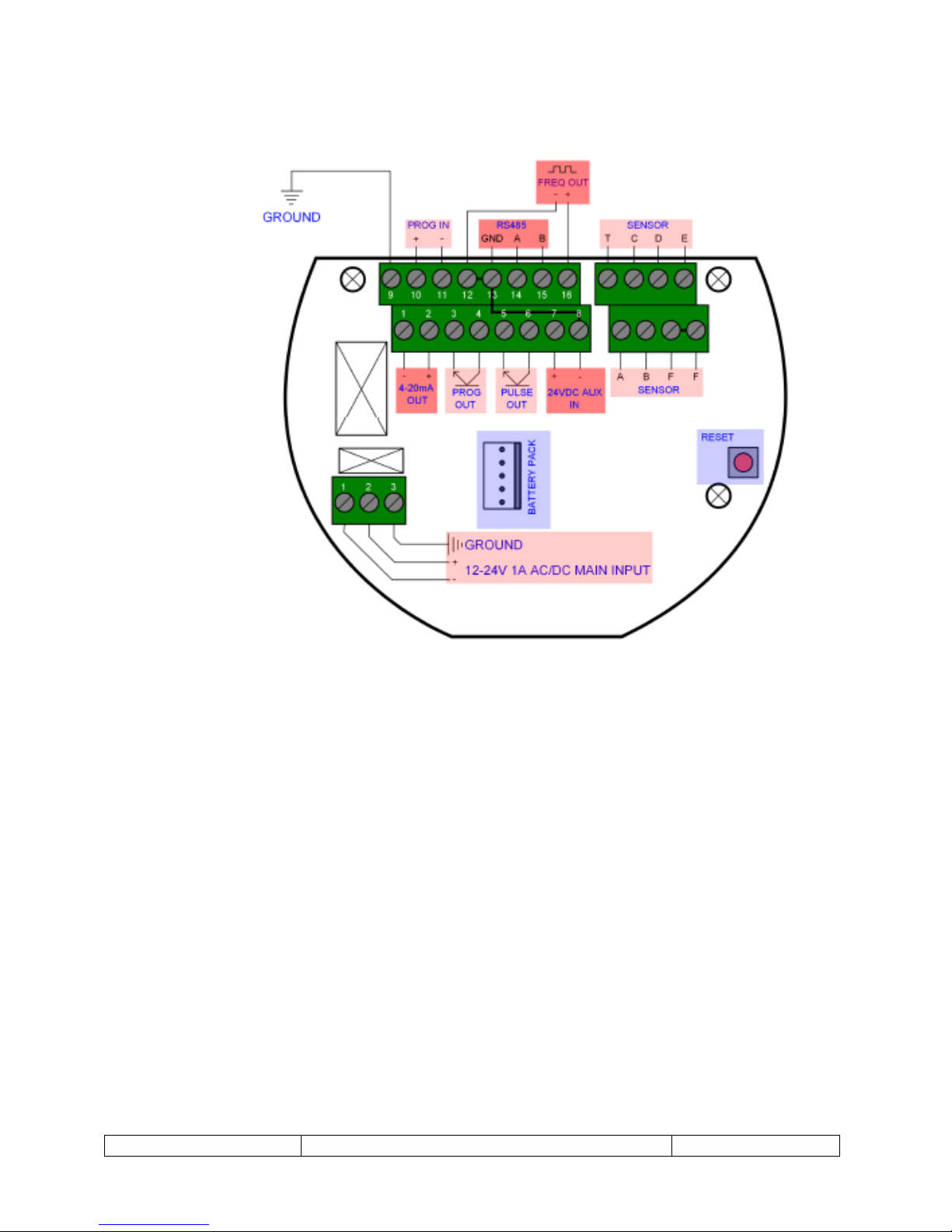

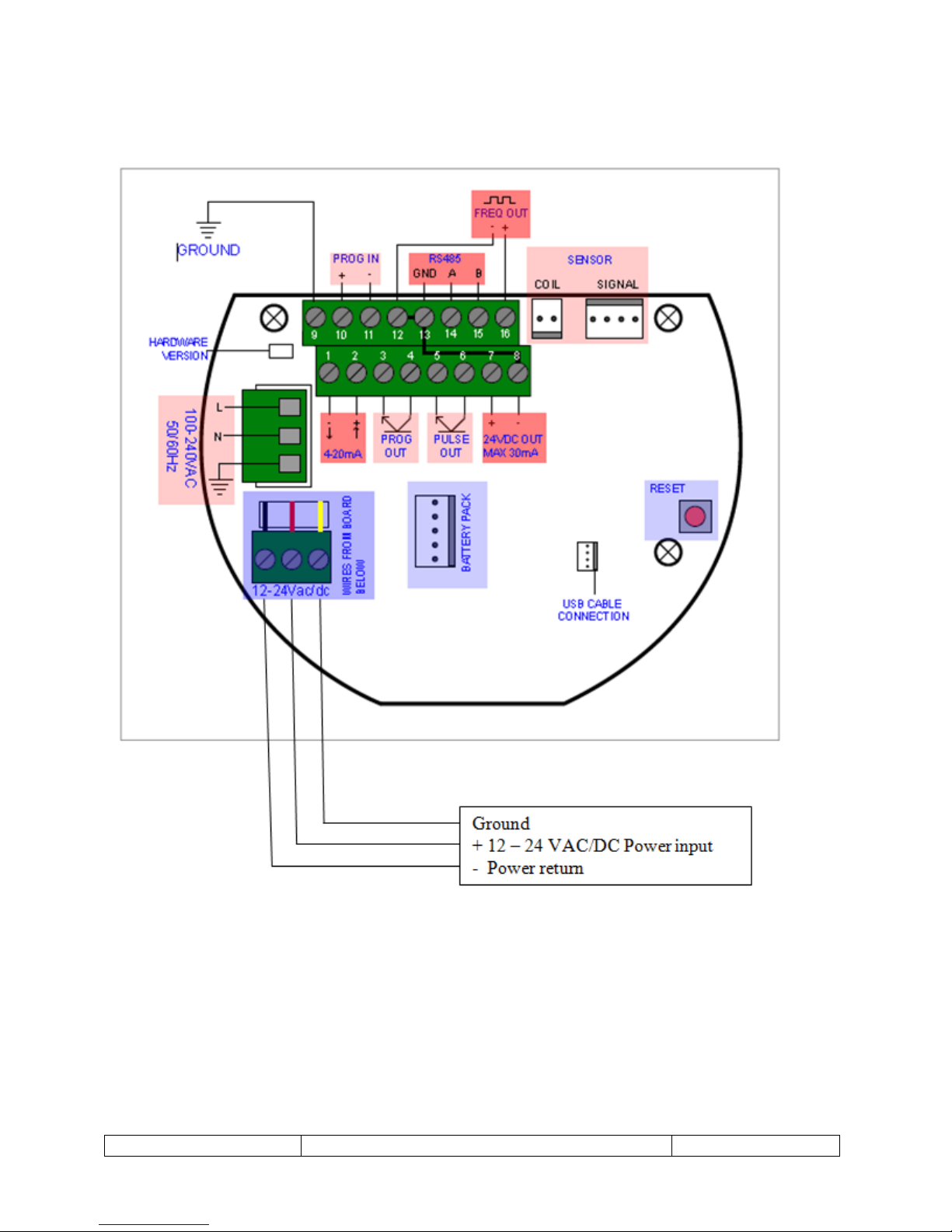

Figure 6 – Low voltage: 12 – 24 VDC/Vac (PCBA up to version 6-2)

SF-100834 Rev A

Page 14

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 14

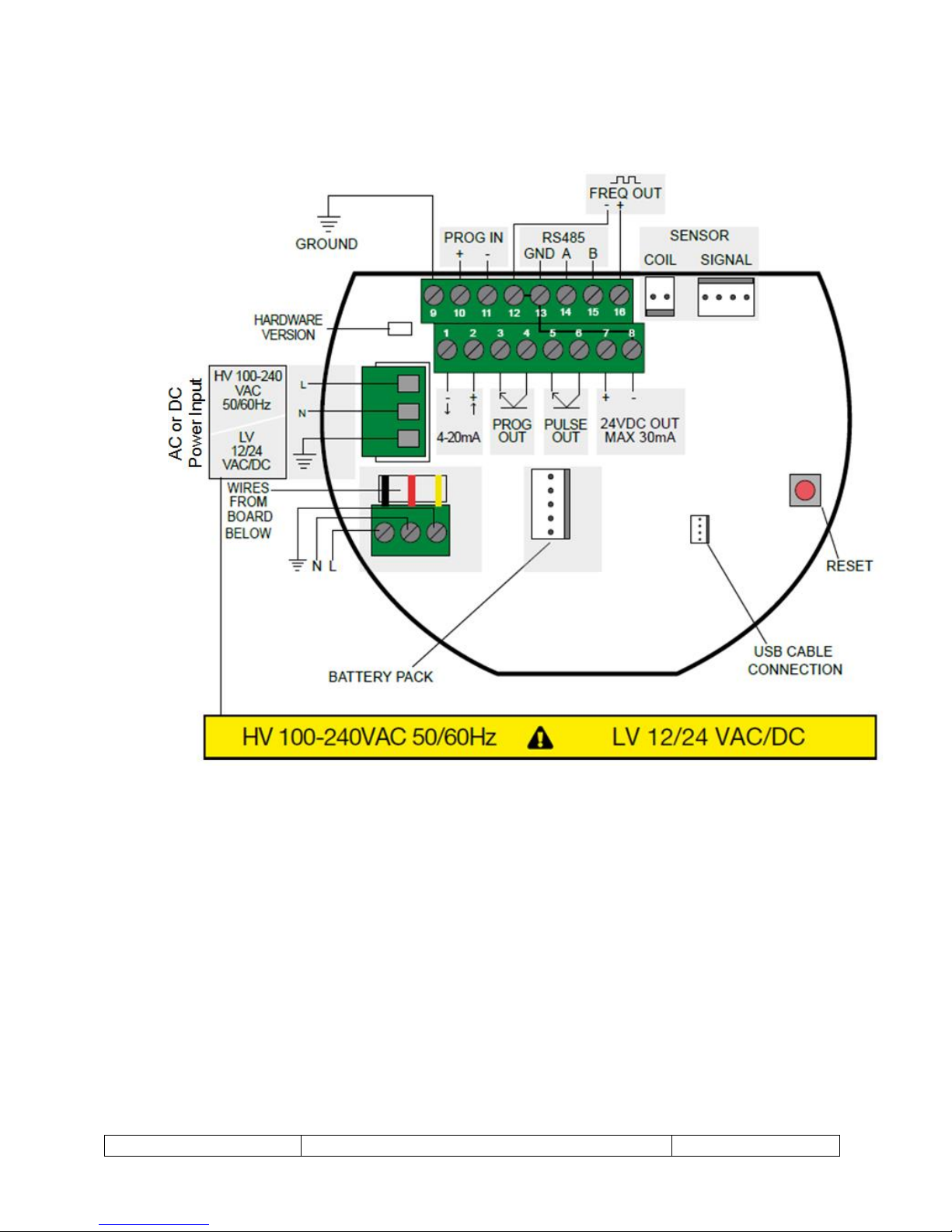

Figure 7- Low and high voltage (PCBA version 6-3)

SF-100834 Rev A

Page 15

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 15

Figure 8- Low and high voltage (PCBA from version 6-4)

Note: Line (L) and Neutral (N) terminals are not polarity sensitive when used with DC

power.

2.3.2 Remote mounted converter, without empty pipe detector

The remote mounted version of the MC 608A/B converter is supplied with an auxiliary

junction box where cables, C012 and C013 from the flow meter junction box will need to

be connected. The converter is normally supplied scaled for a specific flow meter. Please

check the program sheet supplied with the equipment to ensure the converter is

connected to the proper flow meter. Cables C012 and C013 are supplied with metal

ends and identifying letters. Refer to the diagram below for correct terminal location.

SF-100834 Rev A

Page 16

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 16

Figure 9 – Remote mounted wiring

SF-100834 Rev A

Page 17

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 17

2.3.3 Powering the unit

MC608A: 90 to 264 Vac, or 12 to 24 VAC/Vac

MC608B: Battery powered by lithium battery pack, or 12 to 24 VDC

2.3.4 Wiring of Pulse Output

Clean contact (MC608A/B)

The device connected (PLC/external pulse meter) supplies its digital input with the

required voltage to detect the pluses. The MC608 acts as a digital switch. (Maximum

voltage: 30VDC, 50mA maximum current)

Figure 10 – Clean contact pulse output

Active 5-20 VDC (MC608A/B)

The device connected (PLC/external pulse meter) is a passive digital input that accepts

the voltage supplied to it by the external supply system used. (Maximum voltage 5 – 30

VDC, maximum current 50mA)

SF-100834 Rev A

Page 18

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 18

Figure 11 – Active 5 – 20 VDC pulse output

Active 24V self-powered (MC608A/B from version 6-3)

The device connected ((PLC/external pulse meter) is a passive digital input that accepts

a 24V voltage level. It must not provide any additional voltage. The internal power

supply 24 VDC is used to provide the necessary voltage. (Maximum voltage 24VDC,

maximum current 30mA).

Figure 12 – Active self-powered from version 6-3

SF-100834 Rev A

Page 19

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 19

2.3.5 Wiring of Frequency Output (only available on MC608A version)

Figure 13 – Frequency output

2.3.6 Wiring of 4 – 20mA Analog Output

Loop powered (MC608 version 6-3 and later)

The connected 4-20mA receiver is a loop powered model, powering the current loop

itself.

Figure 14 – Loop 4 – 20 mA output

SF-100834 Rev A

Page 20

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 20

Active (MC608 version 6-3 and later)

The connected 4-20mA receiver is a passive milliamp-meter; the internal MC608 24 VDC

power supply must be connected as shown. (24VDC loop voltage of 24 VDC, maximum

impedance of 800 ohm)

Figure 15 – Active 4 – 20 mA output

Active (MC608 version 6-1 and 6-2)

The connected 4-20mA receiver is a passive milliamp meter; the internal MC608 24 VDC

power supply is internally connected. (24VDC loop voltage of 24 VDC, maximum

impedance of 800 ohm.)

Figure 16 – Active 4 – 20 mA output

SF-100834 Rev A

Page 21

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 21

2.3.7 Wiring of RS485 Output (only available on MC608A version)

Figure 17 – RS485 communication

Note: The MC608 transmitter is not supplied with a PC to RS485 converter. If

communication with the transmitter is require an aftermarket USB or RS232 to RS485

converter will be required.

2.3.8 Wiring of Programmable Output

Clean contact (MC608A/B)

The device connected provides its digital input with the required voltage to detect the

logic level. The MC608 acts as a digital switch. (Maximum voltage: 30 VDC, 50mA

maximum current)

Figure 18 – Clean contact programmable output

SF-100834 Rev A

Page 22

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 22

Active 24V self-powered (MC608 version 6-3 and later)

The device is connected to a passive input that accepts a digital voltage equal to 24 V. It

must not provide any additional voltage.

The internal power supply 24 VDC is used to provide the necessary voltage. (Voltage

24V, maximum current 30mA)

Figure 19 – Active 24 V self-powered programmable output

Active 5-30V (MC608A/B)

The connected device is a passive digital input that accepts the voltage level provided by

the external power supply. (Voltage 5-30V, maximum current 50mA)

Figure 20 – Active 1-30V programmable output

SF-100834 Rev A

Page 23

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 23

2.3.9 Wiring of Programmable Input

Figure 21 – Programmable input

2.3.10 Output Notes

1) Connect only one output at a time with internal power supply. The maximum current

on terminals 7 and 8 is 30 mA.

2) The battery powered MC608B is only equipped with a pulse output and the 4-20mA

output in loop power mode.

3 PROGRAMMING THE MC608 CONVERTER

3.1 Programming Overview

SF-100834 Rev A

Page 24

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 24

The configuration of the MC608 can be performed in three different ways:

1. Through the 4 push buttons located on the front mask of the converter, accessed by

unscrewing the front panel glass

2. Via PC through the RS485 MODBUS output and the configuration software program

supplied by FTI. A USB or RS232 to RS485 converter is not supplied with the MC608

converter.

3. Via PC through the IrDA port located on the front of the converter on top of the display

and the configuration software program.

3.2 Converter Passwords

The converter is built with three different levels of protection. Passwords can be

modified.

Level I: 608111

Level II: 709222

Level III: 231042

3.3 Activating MC608B

Under normal operation the MC608B is operating in “sleep mode”. Sleep mode conserves

battery life while continuing to functionally operate the unit.

To wake the unit for programming or reading the values on the display, swipe the

supplied magnet (black plastic housing in conduit opening) vertically on the front mask

near the word “activate”.

3.4 MC608 Configuration via PC Using MC608 Programming Software

3.4.1 Initial Connection

Use a USB adapter for direct communication to a PC or an IrDA interface unit.

Install the MC608 software and connect the unit to the PC and turn it on with the

magnet (for MC608B), select RS485 or IrDA communication and press on the CONNECT

button (see below screen shot of the MC608 program).

SF-100834 Rev A

Page 25

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 25

Figure 22 – Main Screen

With the MC608 correctly connected the configuration parameters can now be read and

modified. There are 5 menu screens:

1. PARAMETERS

2. READ

3. FILTERS

4. DATALog

5. CHART

SF-100834 Rev A

Page 26

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 26

3.4.2 Parameter Configuration

Figure 23 – Parameters Screen

Technical units define:

The time base of measurement (seconds, minutes, hours, days)

Flow Rate Volume defines the volumetric rate units of measure (Gals, Liters, Cubic

meters, barrels etc.)

Counters Volume defines the volumetric unit of measure for the counters/totalizers.

The I/O section defines:

Pulses volume TU – unit of measure for the pulse & frequency outputs.

Pulse volume – defines the volume per unit pulse.

Pulse width

FS Frequency defined the output frequency corresponding to full scale flow rate.

The maximum frequency 10,000Hz.

Mode AUX3 – programmable output used for high/low alarm or reverse flow.

Ing. Prog. – programmable input used for reset of partial totals.

SF-100834 Rev A

Page 27

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 27

The Alarm section defines:

Min Flow Rate Alarm. Defines the % of full scale flow such that if the flow rate falls

below this set point an alarm will be activated.

Max Flow Rate Alarm. Defines the % of full scale flow such that if the flow rate

exceeds this set point an alarm will be activated.

The LCD section defines:

Display contrast

Backlight intensity

How long the display will remain active.

The DataLogger section defines:

The logging interval. This can be set from 4 seconds to 16 minutes.

3.4.3 Read Configuration

On the “READ” configuration Tab the user can view the instantaneous flow rate and

view the counters/totalizers. Only the “PARTIAL” totals can be reset to zero by pressing

the respective zero button.

Figure 24 – Read Screen

SF-100834 Rev A

Page 28

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 28

3.4.4 Filter Configuration

Figure 25 – Filter Screen

The following filters can be configured:

Damping. Increasing damping increases the stability of the displayed value through

Peak Cut: A peak cut off value can be set as a percentage of the full scale flow rate.

Low Flow Cut Off. A low flow cut off value can be set as a percentage of the full

Filter Bypass. Enter a value as percentage of full scale so that any instantaneous

For example, in the case that this parameter has a value of 50%

SF-100834 Rev A

increased averaging; the larger the number the higher the damping.

If there are peaks in the flow rate measurement, their value will be limited to the

value expressed. For example, by setting the value at 10%, any instantaneous spikes

greater than 10% of the full scale value will be limited not to exceed the 10% value.

scale flow rate. If the actual flow rate of the liquid is less than the low flow cut off

value, then the instrument will display 0.

step changes greater than the set value will bypass the digital filter and display the

actual flow. The filter bypass can be useful to speed the response of the meter to

large changes in flow rate such as opening or closing valves and starting pumps.

Page 29

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 29

IF: The flow rate varies 50% more than the previous value.

THEN: The flow rate shown will reflect the actual step change

IF: The flow step change is less than 50% of the full scale value

THEN: The digital filter will be applied and the flow rate shown will slowly reach the

actual value.

Measurement Average. This option increases the stability of the reading by

enlarging the actual measurement filter.

3.4.5 Data Logger

The data logger that was configured on the PARAMETERS tab displays: Date, time,

counter, instantaneous flow rate, temperature and battery condition.

Figure 26 – Data Logger Screen

To read and download the data from the memory of the flow meter select the START

and END row to read the data. The “Get Last Log” will load the last available log.

Press the READ Log button to download the data,

SF-100834 Rev A

Page 30

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 30

Press SAVE CSV to save the data to your PC in CSV format.

Press “Reset Data Log” button to erase the memory of the converter.

After reading the data, the data is displayed graphically by going to the CHART tab, see

picture below:

Figure 27 – Chart Display Screen

3.5 MC608 Configuration via the Local Display

3.5.1 Overview

The MC608 can be configured using the 4 push buttons located on the front mask of the

converter: To access unscrew the front cover.

The programming menu is simply accessed by pressing the Menu button. The menu has

been divided into the following groups:

Options

SF-100834 Rev A

Page 31

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 31

Counters

Parameters

I/O

Others

Memory

Follow the chart below for an overview of the available functions.

SF-100834 Rev A

Page 32

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 32

3.5.2 Data to be Displayed

The display is divided into 3 mil areas.

The top area shows the symbols for status information, together with the indication on

the duration of the battery (MC608B), or power indication (MC608A), as well as the

alarm symbols and instantaneous reading of the flow rate.

The central area shows a linear graph of the flow rate shown in percentage on the full

scale flow rate.

The area at the bottom can be selected by the customer and the possible options are:

o T+ total positive counter

o P+ partial positive counter

o T- total negative counter

o P- partial negative counter

o Date and time

To select the required value simply click on the button corresponding to the arrow and

make your selection, or select Menu ˃ Options ˃ View ˃ Options ˃ Last row.

Figure 28 – Display Overview

SF-100834 Rev A

Page 33

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 33

3.5.3 Options

3.5.3.1 Technical Units

Flow rate volume: Select the volume technical unit for the instantaneous flow rate

Flow time base: Select the time base for the instantaneous flow rate.

Counter volume: Select the volume technical unit for the counters

Pulse volume: Select the volume unit for the pulses.

3.5.3.2 Measurement Frequency

Measuring time. If operating in battery powered mode, select the measuring time

of the system between 16 and 120 seconds.

Note: The factory setting is 32 seconds. Any reduction of the factor will affect

battery life when using MC608B in battery mode.

3.5.3.3 Display

LCD Backlight Level. Increase or decrease the level of the backlight.

Backlight off. Increase or decrease shut off time of the backlight of the display.

LCD contrast. Modify the contrast of the display.

Note: Any modification of the display can affect battery life when using the MC608B

in battery mode.

3.5.3.4 View Options

Defines the default display information with selection between:

o T+ total positive counter

o P+ partial positive counter

o T- total negative counter

o P- Partial negative counter

o Date & time

3.5.3.5 Language

The following languages may be selected:

o English

o Spanish

o Portuguese

o Italian

3.5.4 Counters

Four different counters are available in the MC608 converter. Two positive counters,

and two negative counters. Only partial counters can be set to zero.

SF-100834 Rev A

Page 34

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 34

3.5.5 Parameters

3.5.5.1 Ka Setup

KA is the main calibration factor of the flow meter – this location allows the user to

modify the calibration factor if required.

Note: Only authorized personnel should change the Ka factor. The Ka factor must be

the same as the flow meter sensor. Check the Ka factor on the flow meter name

plate.

3.5.5.2 Diameter Setup

This location allows the user to set the diameter of the flow meter.

3.5.5.3 Filter Setup

Flow cutoff. A low flow cut off value can be set as a percentage of the full scale flow

rate. If the actual flow rate of the liquid is less than the low flow cut off value, then

the instrument will display 0.

Damping. Increasing damping increases the stability of the displayed value through

increased averaging; the larger the number the higher the damping.

Peak Cut: A peak cut off value can be set as a percentage of the full scale flow rate.

If there are peaks in the flow rate measurement, their value will be limited to the

value expressed. For example, by setting the value at 10%, any instantaneous spikes

greater than 10% of the full scale value will be limited not to exceed the 10% value.

Filter Bypass. Enter a value as percentage of full scale so that any instantaneous

step changes greater than the set value will bypass the digital filter and display the

actual flow. The filter bypass can be useful to speed the response of the meter to

large changes in flow rate such as opening or closing valves and starting pumps.

For example, in the case that this parameter has a value of 50%

IF: The flow rate varies 50% more than the previous value.

THEN: The flow rate shown will reflect the actual step change

IF: The flow step change is less than 50% of the full scale value

THEN: The digital filter will be applied and the flow rate shown will slowly reach

the actual value.

Measurement Average. This option increases the stability of the reading by

enlarging the actual measurement filter. To increase the stability, increase the value

in this sub-menu.

3.5.5.4 Sensor Offset

Displays the zero offset of the flow meter

SF-100834 Rev A

Page 35

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 35

3.5.5.5 Zero Finder

This setting is used to perform the instrument zero calibration. Before performing

the zero calibration ensure that:

o The sensor is full of liquid

o The liquid is perfectly stationary

o The sensor has the correct electrical ground

3.5.5.6 Flow Rate Alarms

Max flow: Set the maximum value of the flow rate as a percentage of the full scale

value. The factor default setting is “disabled”. The max flow threshold by be set

from 5% to 200% of the full scale value. Setting this parameter to 200% disables this

function.

Min flow: Set the minimum value of the flow rate as a percentage of the full scale

value. The factor default setting is “disabled”. The min flow threshold by be set

from 1% to 5% of the full scale value. Setting this parameter to 1% disables this

function

3.5.6 I/O

3.5.6.1 Pulse Out

Pulse Quantity

Define the pulse significance i.e. volume / unit pulse. Note: pulse volume and

duration settings differ between transmitter models MC608A and MC608B

- MC608A (powered version) Parameter calculation.

Vp = volume per pulse expressed in liters

Tp = Pulse width expressed in seconds

Q = flow rate in liters / second

For a given pulse width (Tp): Vp > Qmax*2Tp

For a given volume per pulse (Vp): Tp < Vp/2Qmax

- MC608B (battery version) Parameter calculation.

For a given pulse width (Tp): Vp > Qmax*20Tp

For a given volume per pulse (Vp): Tp < Vp/20Qmax

Pulse time on

o Select the “on” time duration of the pulse on a range between 1 and 1999 ms.

Reverse flow (off/on)

SF-100834 Rev A

Page 36

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 36

o Acting on this function, in the case of negative flow, the pulses will be

enabled/disabled.

Note: High pulse output frequencies and “on” times longer than 100 ms will

adversely affect battery life.

3.5.6.2 Frequency Output

Full scale frequency: Set the maximum frequency corresponding to the full scale

flow rate value. The selectable range is 100Hz to 10KHz.

3.5.6.3 Program Output

The programmable status output can be set to:

o Enable/disable

o Reverse flow

o Max flow alarm

o Min flow alarm

o Batching

o Excitation failure

o Empty Pipe

3.5.6.4 Program Input

The programmable input can be set to:

o External partial positive total zeroing

o External partial negative total zeroing

o External partial positive and negative total

3.5.7 Other

3.5.7.1 System Info

Displays the system information. These values cannot be modified by the end user

3.5.7.2 Time/Date

Shows the date, time, motherboard temperature, battery condition for the MC608B

battery powered unit.

3.5.7.3 Graph

Displays the graph of measured flow rate.

3.5.7.4 Simulation

The MC608 has a built in flow simulator to verify and adjust the pulse output to any

connected device.

Note: When using the flow simulation, the counters will not increase in value.

SF-100834 Rev A

Page 37

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 37

3.5.7.5 Communication

Baud rate. Allows the adjustment of the RS485 baud-rate between the range 2400

and 115,700 bps.

MODBUS address. Allows the adjustment of the MODBUS communication address

between 1 and 255.

3.5.8 Memory

3.5.8.1 Load User Copy

Allows to load customized settings

3.5.8.2 Save User Copy

Allows to save customized settings

3.5.8.3 Load Factory Settings

Allows to load factory settings

3.5.8.4 Data Logger

Show last row: Displays last information logged. Date, time, counter, instantaneous

flow rate, temperature, battery condition.

3.5.8.5 Full Erase

Erases the memory of the converter

3.5.8.6 Log Interval

Defines logging interval. 1 minute minimum / maximum 120 minutes

SF-100834 Rev A

Page 38

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 38

4 SPECIFICATIONS

Parameter

Specification

Converter Installation

Compact or remote versions

MC608A up to 100 meters from sensor

MC608B up to 30 meters from sensor

Converter Case

Aluminum epoxy painted IP68 rated to 1.5 meters, with front

window in toughened glass. Note: Coolant version (MC608P) is

IP66 rated.

Electrical Connections

Cable glands, plastic, M20x1.5

Connection Cables

Supplied by FTI

Power Supply

MC608A

90…264Vac

12/24 Vac/dc

MC608B

Battery powered supply or 12/24Vac/dc

Expected life T=0/50°C – Internal battery pack 3-6 years;

internal and external battery pack 6-10 years

Inputs / Outputs

Active analog 4-20mA

Digital pulse output maximum 1000Hz duty cycle max 50%

Programmable digital output

Digital pulse output active frequency 0…10kHz (requires

external 24VDC)

All outputs are optically isolated

Pulse output maximum capacity +/- 30VDC 50mA

Serial Communication

MODBUS RTU interface on RS485

IrDA interface for communicating with laptop or hand held

device.

Temperature Range

Ambient: -20°C to 80°C (-4°F to 176°F)

Storage: -30°C to 80°C (-22°F to 176°F)

Accuracy

0.20% of reading value (over calibrated range)

Repeatability

0.10% of reading value

Sampling Frequency

Programmable 5, 3, 1, 1/15, 1/30, 1/60, 1/120, 1/240, 1/480 Hz

Measuring Stability Time

3 seconds

Display

Graphic LCD – 128x64 pixels, 50x25mm visual area

Programmable backlighting

Simultaneous display of rate, totals, status flags

Programmable display content

SF-100834 Rev A

Page 39

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 39

Parameter

Specification

Programming

With push buttons on display PCB

By PC with dedicated software via RS485 MODBUS RTU

communication protocol.

By Irda interface with laptop or hand held device

Units of Measure

Settable for individual counters, flow indication and pulse o/p

USgal, bbl, oz, gal, ft3, in3, m3,hl, dal, l, dl, cl, ml

Reference Time

Selectable time units: s, m, h, days

Process Data Logger

4MB flash memory, 200,000 lines of data (one line includes:

instant flow, 2 counters, date, time, PCB temperature).

Diagnostic Data Logger

64Kb EEPROM, 2000 lines of data (one line includes: date, time,

PCB temperature, error codes, user actions with changes made).

Not programmable and tamper/reset proof.

Electrical Conductivity

5uS/cm, 20uS/cm minimum for DI water

Recommended Velocity

-10 to 10 m/s

Approvals

MC 608 A/B meets all the requirements established by the

EC directives.

Electromagnetic compatibility: Directive 2004/108/EC,

Harmonized standards EN 61326-1:2006; EN 55011:2009;

EN61000-3 (2/3); EN 61000-4 (2/3/4/5/6/8/11)

Low voltage directive: Directive 2006/95/EC

SF-100834 Rev A

Page 40

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 40

5 TROUBLESHOOTING

Symptom

Possible Remedies

Converter is showing a flow rate with no flow.

1) Check if the sensor and liquid are

correctly grounded.

2) Check that the sensor is full of fluid.

3) Electrical conductivity of the fluid is too

low or is not compatible with the material

used for the sensor electrodes.

4) Perform manual zero finder. (Menu –

Parameters, sub menu – zero finder)

5) Check value of low flow cut off.

Flow Reading is highly unstable.

1) Check if the sensor and liquid are

correctly grounded.

2) There is air in the pipe. Avoid bubbles by

selecting a more suitable position for the

sensor.

3) Set filters as follows:

Set Damping to 150

Reduce Peak Cut filter

Increase Bypass filter

External pulse totalizer shows results different

from what is expected.

1) Test the output with the internal flow

simulator and the converter pulse counter

system simulating a flow rate with System

– Simulator.

The display is off and does not turn on.

1) Check to insure supply voltage is

available.

2) Check that supply voltage matches the

name plate on the converter.

3) If the unit is a MC608B battery powered

unit, check the battery life and replace as

needed.

Liquid is flowing in pipe, but there is no

display,

1) Reduce the low flow cut off filter (factory

setting is 2% of the full scale)

SF-100834 Rev A

Page 41

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 41

6 ALARM MESSAGES

Alarm Message

Possible Cause and Solutions

Excitation failure

1) Incorrect cable connections.

2) Sensor damaged. Damaged lining or

electrodes. Possible infiltration of liquid

inside the sensor.

3) Converter damaged.

Recommend performing a test on the

sensor circuit between coils A – B: 50 – 250

Ohm.

Measurement error

Check for correct installation of sensor.

With pipe full between a or B and ground ˃

100MOhm.

Empty Pipe

This message is displayed with sensors that

have 4 electrodes. Indicates the alarm of

empty pipe, or partially empty.

If the alarm is indicating the pipe is

partially full when you are sure it is full, go

to:

Main Menu, Parameters, Empty Pipe Th.

Move the slide bar toward the “F” and

press “test”. The alarm should be

removed.

Pulse accumulation

1) Pulse frequency incorrect

Change the volume and/or pulse duration

settings.

Supply voltage

1) Supply voltage out of operating range

2) Converter damaged

Check the power supply network.

Data logger full

Download the data to a PC and erase the

memory of the converter.

SF-100834 Rev A

Page 42

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 42

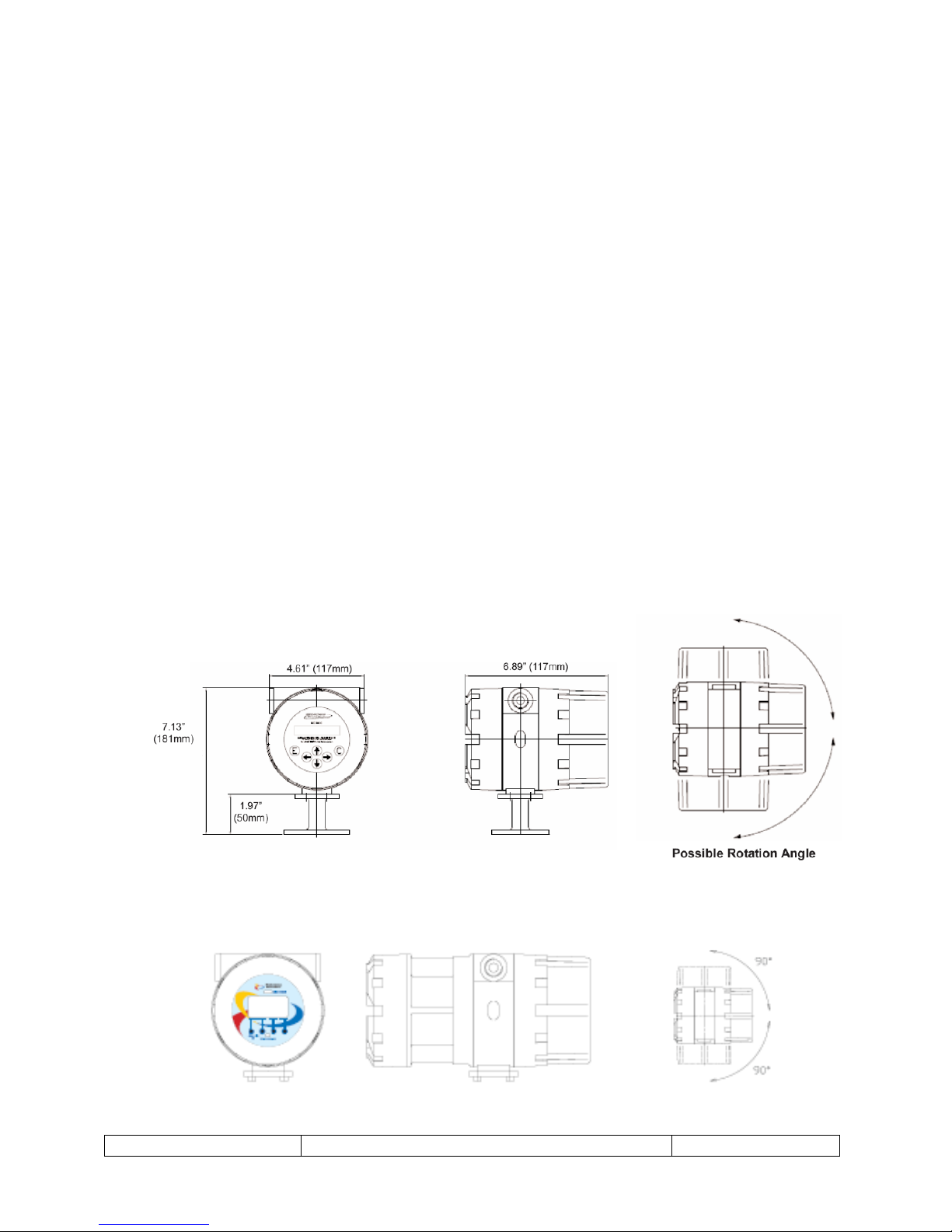

Appendix A Coolant Flow Meter Transmitter (MC608P)

The EL4000 series coolant meters have a unique transmitter configuration and enclosure. The

flow meter and transmitter come prewired with six meters of cable and a cable interconnection

a short distance from the flow meter. The transmitter enclosure is light weight plastic which can

be panel or wall mounted. The wiring and programming of the coolant transmitter (MC608P) is

the same as the MC608A version defined in this manual. Dimensional information for the

transmitter housing is provided below.

SF-100834 Rev A

Page 43

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 43

Appendix B Modbus Input Registers - Function Code 04

MODBUS

REGISTER

MODBUS

ADDRESS

Num.

Bytes

Data

Type

Description

DATA TYPE

Access

(Read/Write)

3:0001

0000

4

FLOAT

Instantaneous measurement fluid velocity in m/s

m/s

R

3:0003

0002

4

FLOAT

Instantaneous measurement flow rate in m3/s

m3/s

R

3:0005

0004

4

FLOAT

Instantaneous measurement flow rate in kg/s

kg/s

R

3:0007

0006

4

FLOAT

Counter total positive in m3

m3

R

3:0009

0008

4

FLOAT

Counter total negative in m3

m3

R

3:0011

0010

4

FLOAT

Counter partial positive in m3

m3

R

3:0013

0012

4

FLOAT

Counter partial negative in m3

m3

R

3:0015

0014

4

FLOAT

Specific weight set for mass counters in kg/m3

kg/m3

R

3:0017

0016

4

FLOAT

Counter total positive in kg

kg

R

3:0019

0018

4

FLOAT

Counter total negative in kg

kg

R

3:0021

0020

4

FLOAT

Counter partial positive in kg

kg

R

3:0023

0022

4

FLOAT

Counter partial negative in kg

kg

R

3:0025

0024

2

INT16

Index volume unit current flow rate

See volume units table

R

3:0026

0025

2

INT16

Index volume unit current time flow rate

See time units table

R

3:0027

0026

4

FLOAT

Measure instantaneous fluid flow in the units set

Reg-0024 / reg-0025

R

3:0029

0028

2

INT16

Index volume unit counter current set

See volume units table

R

3:0030

0029

4

FLOAT

Counter total positive in the current volume unit

reg-0028

R

3:0032

0031

4

FLOAT

Counter total negative in the current volume unit

reg-0028

R

3:0034

0033

4

FLOAT

Counter partial positive in the current volume unit

reg-0028

R

3:0036

0035

4

FLOAT

Counter partial negative in the current volume

unit

reg-0028

R

3:0038

0037

4

FLOAT

Pulse volume in m3

m3

R

3:0040

0039

2

INT16

Pulse volume in the current volume unit

See volume units table

R

3:0041

0040

4

FLOAT

Pulse volume in the set volume unit

reg-0039

R

3:0043

0042

4

FLOAT

PCB temperature

°C/°F

R

3:0047

0046

2

INT16

Sampling Frequency

0: Continuous *

1: Battery *

2: Any

3: Continuous

4: Seconds

R

3:0048

0047

2

INT16

Current year

YY

R

3:0049

0048

2

INT16

Current month

MM

R

3:0050

0049

2

INT16

Current day

DD

R

3:0051

0050

2

INT16

Hours

hh

R

3:0052

0051

2

INT16

Minutes

mm

R

3:0054

0053

4

FLOAT

Full scale (FS) in the current volume unit *

reg-0024/reg-0025

R

3:0056

0055

4

FLOAT

Actual flow rate % on the FS *

%

R

FC04 Read Input Registers (read-only variables)

(*)FW version 3.00 and later

SF-100834 Rev A

Page 44

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 44

Appendix C Modbus Holding Register Function Codes 03 & 16

MODBUS

REGISTER

MODBUS

ADDRESS

Num.

Bytes

Data

Type

Description

DATA TYPE

Access

(Read/Write)

CMD16 (*)

4:1002

1001

2

UINT

Firmware version FW

0207hex=2.07

R

4:1003

1002

2

UINT

Hardware version HW

0501hex=5.01

R

4:1004

1003

2

UINT

Baudrate (TIA-485)

Default 9600

R

4:1005

1004

2

BYTE

Device Modbus 1-255

Default 1

R

4:1006

1005

2

BOOL

Format FLOAT on Modbus

0=FLOAT (default)

1=Reverse FLOAT

R/W

4:1011

1010

2

BYTE

Reserved

Reserved

R/W

4:1012

1011

2

UINT

Reserved

Reserved

R/W

4:1020

1019

8

ASCII

Converter model

8 digits - ex.: “MC 608B”

R

4:1024

1023

10

ASCII

Converter’s part number

Factory value (9 digits)

R

4:1029

1028

4

ULONG

Converter’s serial number

Progressive production number

R

4:1031

1030

12

UINT

Coupled sensor model

12 digits - ex.: “MUT1100J”

R

4:1037

1036

10

ASCII

Sensor’s part number

Factory value (9 digits)

R

4:1042

1041

2

UINT

Coupled sensor’s diameter

Diameter (1 - 4000) mm

R

4:1043

1042

2

BYTE

Empty pipe

1=available; 0=not available

R

4:1045

1044

20

BYTE

Note

Internal references

R

4:1055

1054

4

FLOAT

Full scale m3/h

Referent value alarms/display

R/W

4:1061

1060

2

BYTE

Percentage back light level display

0 - 100 %

R/W

4:1062

1061

2

BYTE

Time-out back light display

0 - 30 second

>30 always on

R/W

4:1063

1062

2

BYTE

LCD contrast

24 - 50

R/W

4:1064

1063

2

BYTE

Language display

0=English

1=Italian

2=Spanish

3=Portuguese

4=French *

R/W

4:1065

1064

2

BYTE

Set last line of the display

0=Total positive counters;

1=Partial positive counters;

2= Total negative counters;

3=Partial negative counters;

4=Date; *

5 = Exp; *

R/W

4:1066

1065

2

BYTE

Flow rate volume

See volume units table

R/W

4:1067

1066

2

BYTE

Time base flow rate time

See time units table

R/W

4:1068

1067

2

BYTE

Totalizers volume

See volume units table

R/W

4:1069

1068

2

UINT

Liquid specific weight value *

kg/m3

R/W

4:1070

1069

2

BYTE

Temperature units *

0 = °C

1 = °F

R/W

4:1071

1070

2

BYTE

Visualized pulses on display

See volume units table

R/W

4:1072

1071

4

FLOAT

Pulse volume in ml

Value x 0.1

* Value

R/W

4:1074

1073

2

UINT

Pulses time ON

(value +1) x 0.5 mS

* 1 - 1999 mS (def 10)

R/W

FC03 – Read Holding Register

FC16 – Write Holding Register

SF-100834 Rev A

Page 45

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 45

4:1077

1076

2

BYTE

Pulses/frequency output Mode *

0= Out pulses + Out Freq :

PWM

1 = Only frequency Out

R/W

4:1078

1077

2

BYTE

Enable pulses also with negative flow *

0 = Off

1= On

R/W

4:1081

1080

2

BYTE

Programmable input setup

0=Disabled

1=Set zero P2=Set zero P+

3=Set zero P+ e P-

R/W

4:1082

1081

2

BYTE

Programmable output setup

0=Disabled

1=Reverse flow

2= Max flow threshold

3= Min flow threshold

4= Max/min threshold

5= Dosage *

6 = Excitation failure *

7 = Empty pipe alarm *

R/W

4:1083

1082

2

UINT

Frequency out full scale

100 - 10000 Hz

R/W

4:1084

1083

2

BYTE

Programmable output logic *

0 = Norm. Open

1 = Norm. Closed

R/W

4:1085

1084

4

FLOAT

Dosage volume *

1 - 1000000 (TU Counters)

R/W

4:1101

1100

2

UINT

Damping Filter (average number of

samples visualized) **

5 - 500

1 – 500 *

R/W

4:1102

1101

2

BYTE

Percentage cut-off

0 - 50 % FS (def 2%)

R/W

4:1103

1102

2

BYTE

Percentage by-pass filter

2 - 95 % FS ( def 10%)

R/W

4:1104

1103

2

BYTE

Percentage peak-cut

1 - 25 % FS ( def 5%)

R/W

4:1105

1104

2

BYTE

Line frequency 50hz/60Hz

50Hz , 60Hz

R/W

4:1106

1105

2

UINT

Average filter

1 - **Damping

R/W

4:1111

1110

2

BYTE

Flow rate alarm (MAX) on the FS

5% - 100%

*(MIN + 5%) - 100%

255 = OFF

R/W

4:1112

1111

2

BYTE

Flow rate alarm (MIN) on the FS

1% - (MAX – 5%)

*0% - (MAX – 5%)

255 = OFF

R/W

4:1132

1131

2

BYTE

Datalogger sampling frequency

Value (1 - 240) x 4 sec

* 1 - 120 minutes

R/W

(*) FW version 3.00 and later

FS = Full scale

SF-100834 Rev A

Page 46

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 46

Appendix D Volume and Time Base Units Charts

Volume Units

1 2 3 4 5 6 7 8 9

10

11

12

13

ml

cl

dl l dal

hl

m3

Ml

in3

ft3

gal

bbl

oz

Time Units

1 2 3

4

/s

/min

/h

/GG

SF-100834 Rev A

Page 47

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 47

Appendix E Examples

address

function

register word 03EDhex

data count word 0001hex

CRC 16 word

data start

address HI

data start

address LOW

data BYTE

count HI

data BYTE count

LOW

CRC LOW

CRC HI

Device ID (1-255)

03

03h

EDh

00 1 CRC16

address

function

data BYTE

count

register 00AFhex word value

CRC 16 word

data BYTE

HI

data BYTE LOW

CRC LOW

CRC HI

Device ID

03 2 00

0=FLOAT

1=FLOAT reverse

CRC16

address

function

register word

03EDhex

data count word

0001hex

data BYTE

count

register 00AFhex word

value

CRC 16 word

data

start

address

HI

data

start

address

LOW

data

BYTE

count

HI

data

BYTE

count

LOW

data

BYTE HI

data BYTE LOW

CRC

LOW

CRC HI

Device ID

(1-255)

16

03h

EDh

00

01h

2h

00

0=FLOAT

1=FLOAT

reverse

CRC16

address

function

register word 03EDhex

data count word 0001hex

CRC 16 word

data start

address HI

data start

address

LOW

data BYTE

count HI

data BYTE

count LOW

CRC

LOW

CRC HI

Device ID

16

03h

EDh

00

01h

CRC16

Address 1005 - FLOAT ON MODBUS FORMAT

This setting inverts the order of the two words making up the 32-bit FLOAT and allows you to read and write data

as FLOAT or FLOAT reverse

Address 1005=03EDh Reading required description

Query chart

Read response explanation

Response example chart

Write request description

Query chart

Write response explanation

Response example chart

SF-100834 Rev A

Page 48

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 48

Example R/W BYTE Register

address

function

register word 03F2hex

data count word 0001hex

CRC 16 word

data start

address HI

data start

address LOW

data BYTE

count HI

data BYTE count

LOW

CRC LOW

CRC HI

Device ID (1-255)

03

03h

F2h

00 1 CRC16

address

function

data BYTE

count

register 03F2hex word value

CRC 16 word

data BYTE HI

data BYTE LOW

CRC LOW

CRC HI

Device ID

03 2 00

20 - 240 s

CRC16

address

function

register word

03F2hex

data count word

0001hex

data BYTE

count

register 03F2hex word

value

CRC 16 word

data

start

address

HI

data

start

address

LOW

data

BYTE

count

HI

data

BYTE

count

LOW

data

BYTE HI

data BYTE

LOW

CRC

LOW

CRC HI

Device ID

(1-255)

16

03h

F2h

00

01h

2h

00

20 - 240 s

CRC16

address

function

register word 03F2hex

data count word 0001hex

CRC 16 word

data start

address HI

data start

address

LOW

data BYTE

count HI

data BYTE

count LOW

CRC

LOW

CRC HI

Device ID

16

03h

F2h

00

01h

CRC16

Address 1010 – AUTOMATIC POWER OFF TIME (batteries)

This value represents the time (in seconds) of the automatic power-off, exclusively for the version with battery

power supply

Address 1010=03F2h Read request description

Query chart

Write request description

Response example chart

Write request description

Query chart

Write request description

Response example chart

SF-100834 Rev A

Page 49

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 49

Example R/W Unit Register

address

function

register word 0411hex

data count word 0001hex

CRC 16 word

data start

address HI

data start

address LOW

data BYTE

count HI

data BYTE count

LOW

CRC

LOW

CRC HI

Device ID (1-255)

03

04h

11h

00 1 CRC16

address

function

data BYTE

count

register 0411hex word value

CRC 16 word

data BYTE HI

data BYTE LOW

CRC LOW

CRC HI

Device ID

03 2 1 - 4000 mm

CRC16

address

function

register word

0411hex

data count word

0001hex

data BYTE

count

register 0411hex word

value

CRC 16 word

data

start

address

HI

data

start

address

LOW

data

BYTE

count

HI

data

BYTE

count

LOW

data

BYTE HI

data BYTE

LOW

CRC LOW

CRC HI

Device ID

(1-255)

16

04h

11h

00

01h

2h

1 - 4000 mm

CRC16

address

function

register word 0411hex

data count word 0001hex

CRC 16 word

data start

address HI

data start

address

LOW

data BYTE

count HI

data BYTE

count LOW

CRC

LOW

CRC HI

Device ID

16

04h

11h

00

01h

CRC16

Address 1041 – SETTING THE COUPLED SENSOR DIAMETER

This value indicates the diameter of the coupled sensor in mm

Address 1041=0411hRead request description

Query chart

Read request description

Response example chart

Write request description

Query chart

Write request description

Response example chart

SF-100834 Rev A

Page 50

TM-100467, Rev P

MC608A/B/P Transmitter Manual

Page 50

Example R/W FLOAT Register

address

function

register word 041Ehex

data count word 0001hex

CRC 16 word

data start

address HI

data start

address LOW

data BYTE

count HI

data BYTE count

LOW

CRC

LOW

CRC HI

Device ID (1-255)

03

04h

1Eh

00 2 CRC16

address

function

data BYTE

count

register 041Ehex word

value

register 041Fhex word

value

CRC 16 word

data BYTE HI

data BYTE

LOW

data BYTE HI

data BYTE

LOW

CRC LOW

CRC HI

Device ID

03

4

word LOW

word HI (FLOAT reverse)

word HI

word LOW (FLOAT reverse)

CRC16

address

function

register word

041Ehex

data count

word 0002hex

data

BYTE

coun

t

register 041Ehex

word value

register 041Fhex

word value

CRC 16

word

data

start

address

HI

data start

address

LOW

data

BYTE

count

HI

data

BYTE

count

LOW

data

BYTE

HI

data

BYTE

LOW

data

BYTE

HI

data

BYTE

LOW

CRC

LO

W

CRC

HI

Device ID

(1-255)

16

04h

1Eh

00

02h

4h

word LOW

word HI (FLOAT

reverse)

word HI

word LOW (FLOAT

reverse)

CRC16

address

function

register word 041Ehex

data count word 0002hex

CRC 16 word

data start

address HI

data start

address

LOW

data BYTE

count HI

data BYTE

count LOW

CRC LOW

CRC HI

Device ID

16

04h

1Eh

00

02h

CRC16

Address 1054 – FULL SCALE m3/h

The purpose of this function is to set the FS full scale (always expressed in m3/h), to which all the settings relative

to the latter will make reference.

Address 1054=041EhRead request description

Query chart

Read request description

Response example chart

Write request description

Query chart

Write request description

Response example chart

SF-100834 Rev A

Loading...

Loading...