Page 1

4250 EAST BROADWAY ROAD PHOENIX, ARIZONA 85040 U.S.A.

TELEPHONE (602) 437-1315 FAX (602) 437-4459

FT SERIES

TURBINE FLOWMETERS

and

Maintenance Manual

SERIAL NUMBER_________________________________

The specifications contained in this

manual are subject to change without

notice and any user of these specifications

should verify from the manufacturer that

the specifications are currently in effect.

Otherwise, the manufacturer assumes no

responsibility for the use of specifications

that have been changed and are no longer

in effect.

Installation, Operation

FT SERIES

TURBINE FLOWMETERS

Installation, Operation

and

Maintenance Manual

TM-86675 REV. U

PUBLISHED BY FLOW TECHNOLOGY, INC. – April 2004

Page 2

Thank you for selecting a FLOW TECHNOLOGY, INC. product for your flow measurement

application.

Virtually every major commercial, government, and scientific organization is making use of our

products, expertise and extensive technical support. This is a culmination of years of refinement in our

flowmeter and calibrator designs, which has resulted in the technological leadership in the flow

measurements field, which we enjoy.

We are proud of our quality products, our courteous service and welcome you, as a valued customer, to

our growing family.

i

Page 3

WARRANTY

Limited Warranty. Seller warrants that

goods delivered hereunder will at delivery be

free from defects in materials and

workmanship and will conform to seller's

operating specifications. Seller makes no

other warranties, express or implied, and

specifically makes NO WARRANTY OF

MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE.

Limitation of Liability.

under the warranty shall be limited to

replacing or repairing at Seller's option, the

defective goods within twelve (12) months

from the date of shipment, or eighteen (18)

months from the date of shipment for

destination outside of the United States,

provided that Buyer gives Seller proper

notice of any defect or failure and

satisfactory proof thereof. Defective goods

must be returned to Seller's plant or to a

designated Seller's service center for

inspection. Buyer will prepay all freight

charges to return any products to Seller's

plant, or other facility designated by Seller.

Seller will deliver replacements for defective

goods to Buyer freight prepaid. The

warranty on said replacements shall be

limited to the unexpired portion of the

original warranty. Goods returned to Seller

for which Seller provides replacement under

the above warranty shall become the

property of the Seller.

The limited warranty does not apply to

failures caused by mishandling or

misapplication. Seller's warranty obligations

shall not apply to any goods, which (a) are

normally consumed in operation or (b) have

a normal life inherently shorter than the

warranty period stated herein.

Seller's obligation

In the event that goods are altered or repaired

by the Buyer without prior written approval by

the Seller, all warranties are void. Equipment

and accessories not manufactured by Seller are

warranted only to the extent of and by the

original manufacturer's warranty. Repair or

replacement goods furnished pursuant to the

above warranty shall remain under warranty

only for the unexpired portion of the original

warranty period.

Should Seller fail to manufacture or deliver

goods other than standard products appearing

in Seller's catalog, Seller's exclusive liability

and Buyer's exclusive remedy shall be release

of the Buyer from the obligation to pay

purchase price therefor.

THE FORGOING WARRANTIES ARE IN

LIEU OF ALL OTHER WARRANTIES

WHETHER ORAL, WRITTEN, EXPRESSED,

IMPLIED OR STATUTORY. IMPLIED

WARRANTIES OF FITNESS AND

MERCHANTABILITY SHALL NOT APPLY

SELLER'S WARRANTY OBLIGATIONS AND

BUYER'S REMEDIES THEREUNDER

(EXCEPT AS TO TITLE) ARE SOLELY AND

EXCLUSIVELY AS STATED HEREIN. IN

NO CASE WILL SELLER BE LIABLE FOR

SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGE.

The total liability of Seller (including its

subcontractors) on any claim whether in

contract, tort (including negligence whether

sole or concurrent) or otherwise, arising out of

or connected with, or resulting from the

manufacture, sales, delivery, resale, repair,

replacement or use of any goods or the

furnishing of any service hereunder shall not

exceed the price allocable to the product or

service or part thereof which gives rise to the

claim.

ii

Page 4

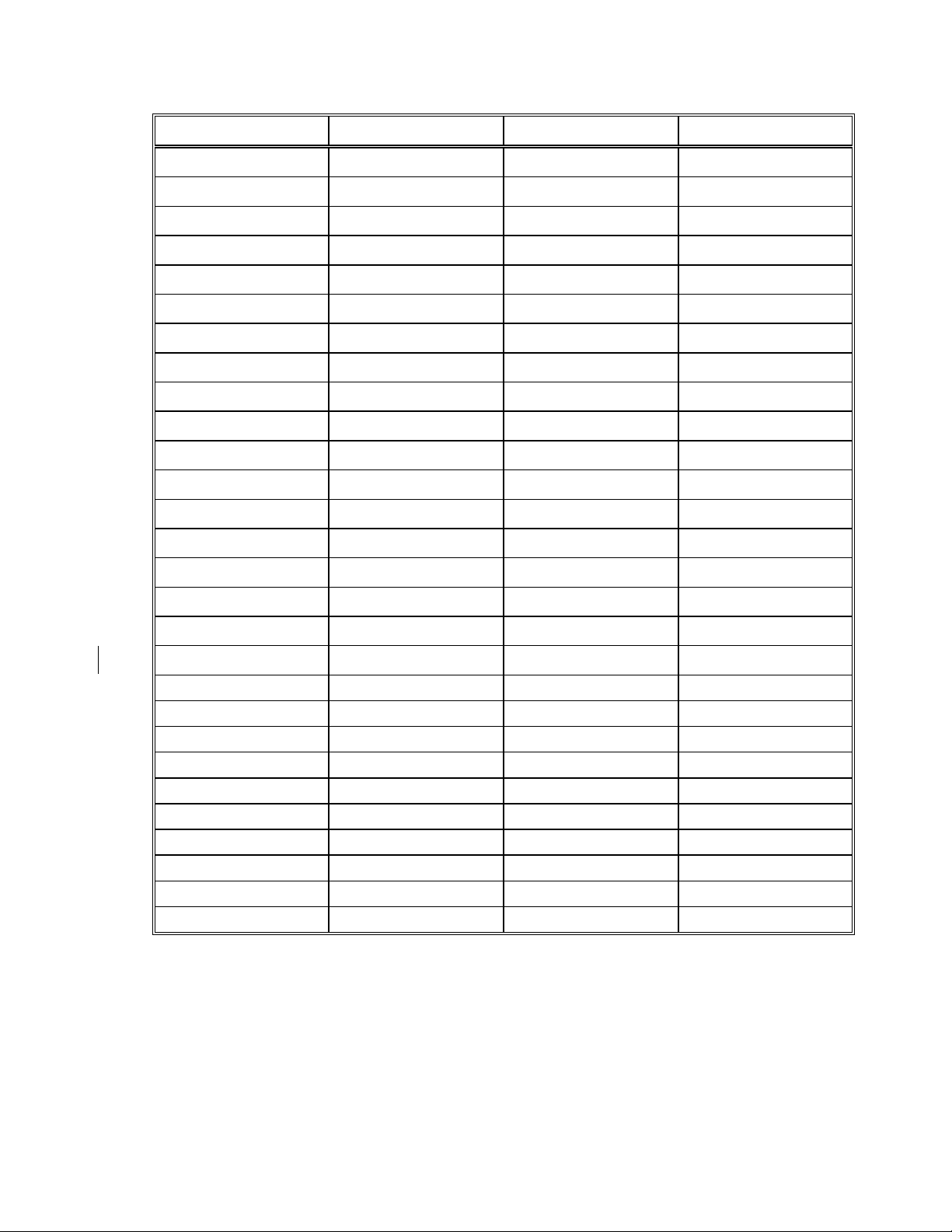

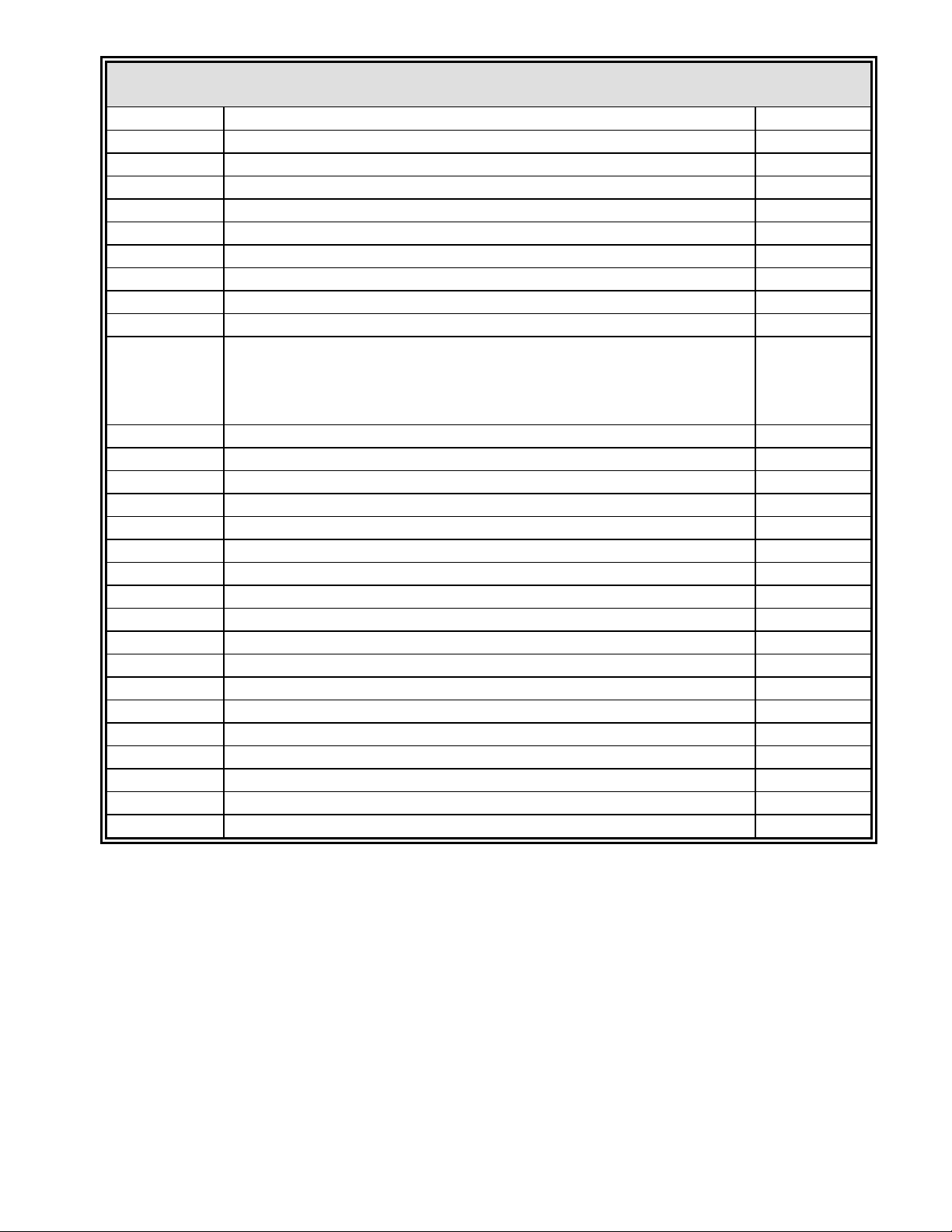

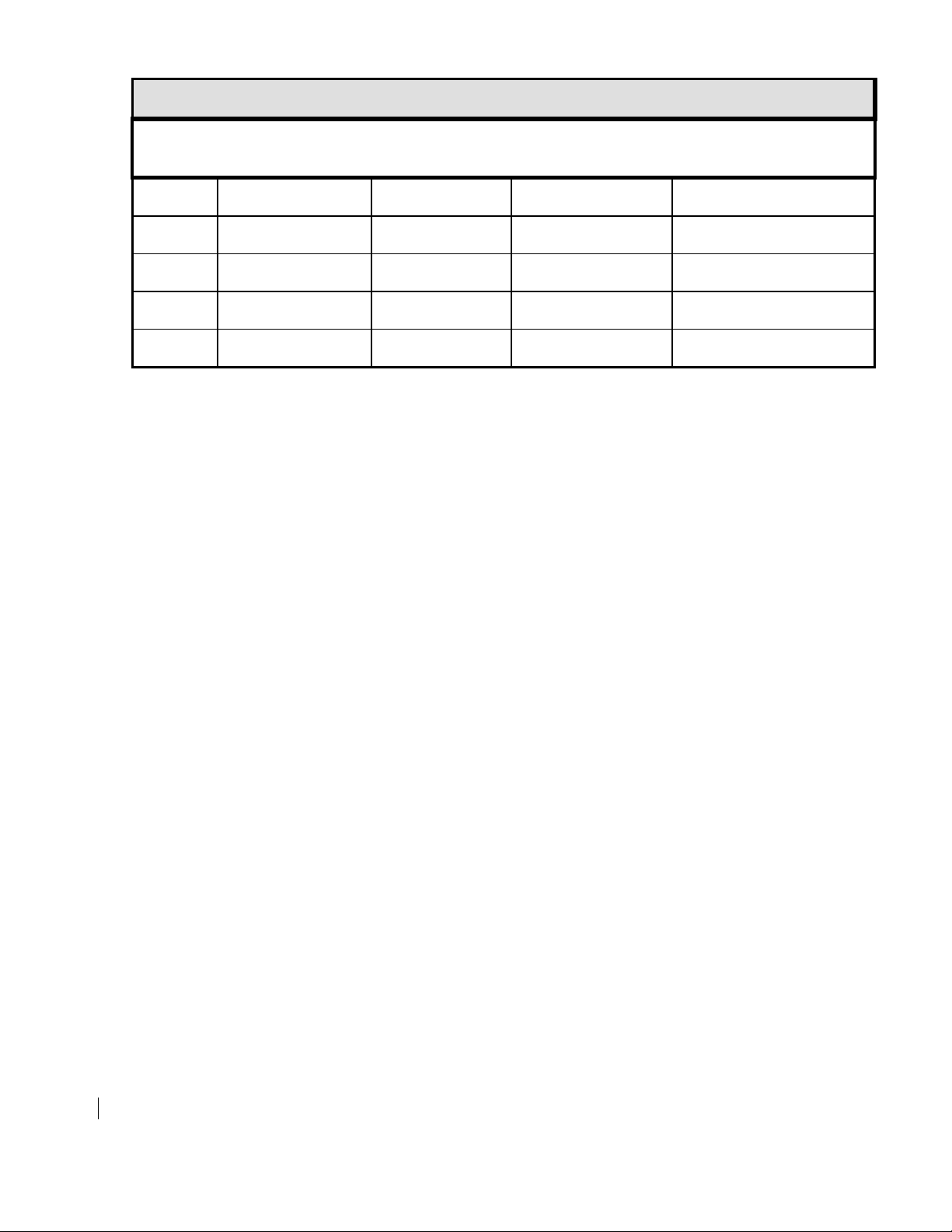

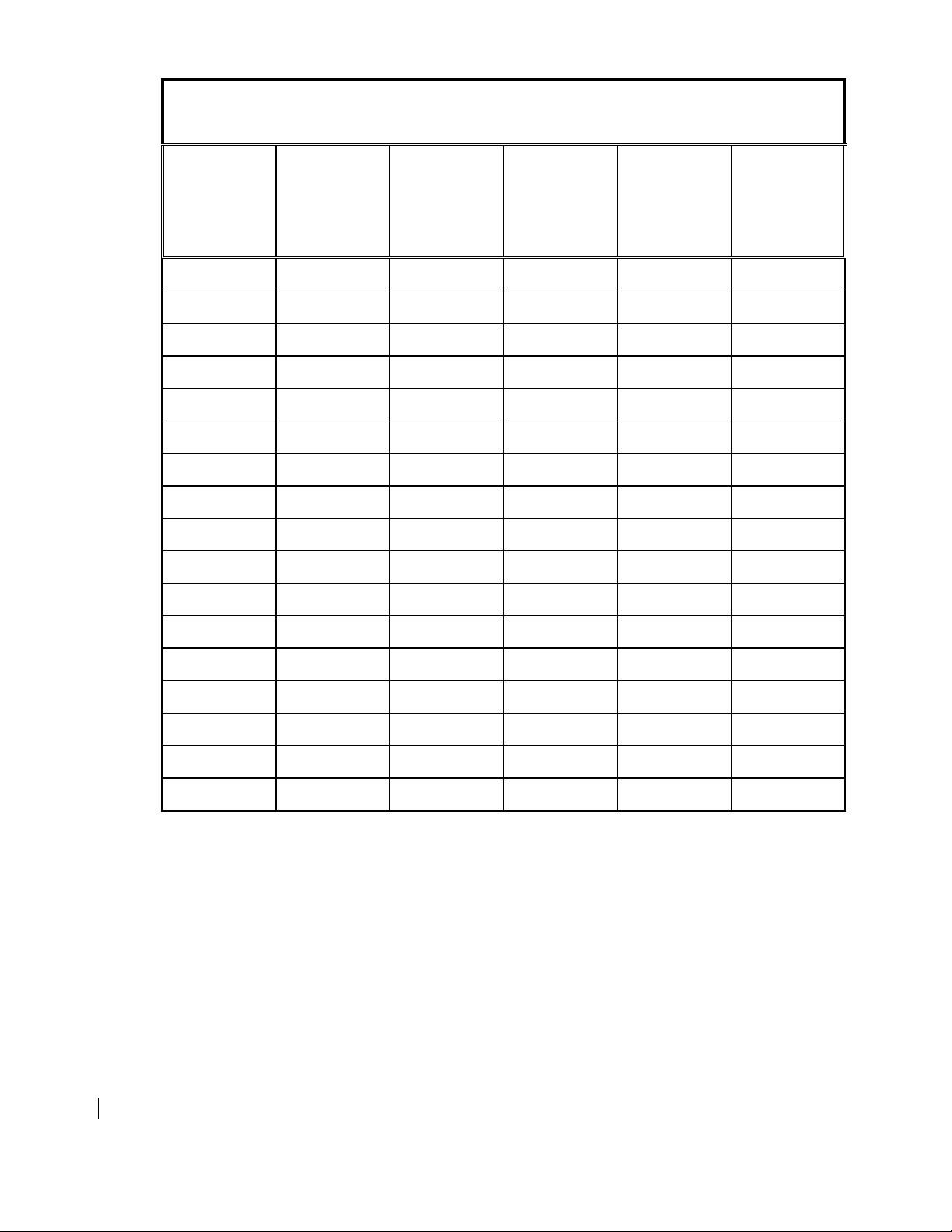

TM-86675

REVISIONS

DATE REVISION ECO NUMBER APPROVAL

A

B

C

D

E

12/22/92 F 10950 T. Roy

07/20/95 G 11278 M. Wusterbarth

06/13/96 H 12451 T. Roy

03/11/97 J 12724, 12744,12752 E. Knowles

08/20/97 K 13001 E. Knowles

02/09/97 L 13195 E. Knowles

06/13/98 M 13319 E. Knowles

05/03/99 N 14098 T Roy

3/11/02 P 15677 J Blasius

11/14/02 R 16185 J Blasius

5/8/03 S 16532 J Blasius

7/21/03 T 16700 J Blasius

4/5/04 U 17286 J Blasius

iii

Page 5

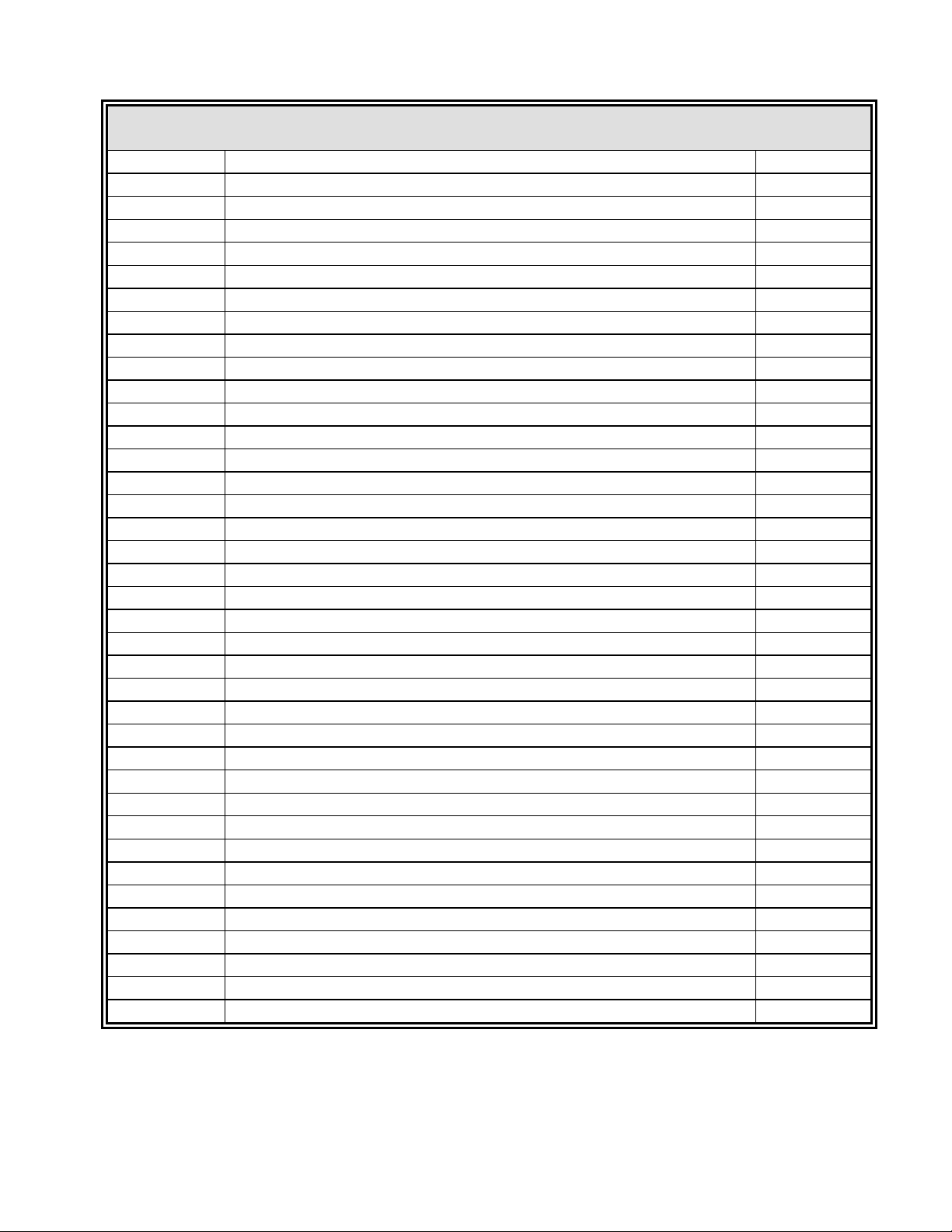

TABLE OF CONTENTS

SECTION TITLE PAGE

1.0 INTRODUCTION 1

2.0 STANDARD LINE FLOWMETER 1

3.0 INSPECTION UPON RECEIPT 2

4.0 MECHANICAL CONNECTIONS 2

4.1 FLOW CONDITIONING 2

4.2 FLOW PULSATIONS 3

4.3 PURGING 3

4.4 INSTALLATION RECOMMENDATION 3

4.5 ORIENTATION AND CALIBRATION 3

4.6 FILTRATION 4

4.7 TORQUE REQUIREMENTS 4

5.0 PICKOFFS 4

5.1 INSTALLATION 4

5.2 EXPLOSION PROOF HOUSINGS 5

5.2.1 PICKOFF INSTALLATION SOCKETS 5

5.3 MAGNETIC PICKOFF 5

5.4 RF PICKOFF 6

6.0 ELECTRICAL CONNECTIONS 6

6.1 CONNECTIONS 6

6.2 CONNECTION CABLE 6

6.3 GROUNDING CONSIDERATIONS 6

6.4 SIGNAL PROCESSING 7

7.0 BIDIRECTIONAL FLOWMETERS 7

8.0 OPERATION 8

8.1 OVER RANGE 8

8.2 UNDER RANGE 8

8.3 TURBINE FLOWMETER LIQUID CHARACTERISTICS 8

8.3.1 INTRODUCTION 8

8.3.2 STANDARD CALIBRATION 8

8.3.3 SINGLE VISCOSITY CALIBRATIONS 9

8.3.4 MULTIPLE VISCOSITY CALIBRATIONS 9

8.4 TURBINE FLOWMETER GAS CHARACTERISTICS 9

8.4.1 INTRODUCTION 9

8.4.2 AIR CALIBRATION 10

8.4.3 SINGLE PRESSURE CALIBRATION 10

8.4.4 MULTIPLE PRESSURE CALIBRATIONS 11

9.0 SPECIFICATIONS AND OPTIONS 11

9.1 END FITTINGS 13

iv

Page 6

TABLE OF CONTENTS (Continued)

SECTION TITLE PAGE

9.2 CALIBRATION 13

9.3 CONSTRUCTION MATERIALS 14

9.4 BEARINGS 14

9.5 PICKOFFS 15

10.0 PERIODIC MAINTENANCE 21

10.1 INSPECTION CLEANING AND STORAGE 21

10.2 REMOVING INTERNALS 22

10.3 GENERAL HANDLING TECHNIQUES 23

10.4 BALL BEARING REPLACEMENT 24

10.4.1 LIQUID FT4-8, AND GAS FT-10, FT-12 25

10.4.2 LIQUID FT6-8, FT8-8, FT-08, FT-10, FT-12, FT-16, FT-20,

FT-24

GAS FT2-8, FT4-8, FT6-8, FT8-8, FT-08, FT-10, FT-12, FT-16,

FT-20, FT-24

10.4.3 LIQUID AND GAS FT-32 26

10.4.4 LIQUID AND GAS FT-40, FT-48, FT-64 27

10.4.5 LIQUID AND GAS FT-96 28

10.4.6 LIQUID AND GAS FT128 29

10.4.7 LIQUID AND GAS FT192 30

10.5 JOURNAL BEARING REPLACEMENT 31

10.5.0.1 REPLACEMENT KITS 31

10.5.0.2 SELF-LUBRICATING BEARINGS 31

10.5.0.3 CARBIDE AND CERAMIC 31

10.5.1 FT-24 AND SMALLER GRAPHITE 32

10.5.2 FT-24 AND SMALLER CERAMIC AND TUNSTEN CARBIDE 33

10.5.3 FT-32 GRAPHITE 34

10.5.4 FT-32 CERAMIC AND TUNGSTEN CARBIDE 35

10.5.5 FT-40, FT48, FT64 CERAMIC AND TUNGSTEN CARBIDE 36

10.5.6 FT-96, FT128 TUNGSTEN CARBIDE 37

10.5.7 FT-192 TUNGSTEN CARBIDE 38

11.0 TROUBLESHOOTING GUIDE 39

12.0 PARTS LIST 44

25

v

Page 7

TABLE OF CONTENTS (TABLES GUIDE)

TABLE # TABLE TITLE PAGE

TABLE 1 TORQUE REQUIREMENTS 4

TABLE 2 FT SERIES FLOWMETER MODEL NUMBERING SYSTEM 12

TABLE 3 BEARING APPLICATION GUIDE 15

TABLE 4 LIQUID SERVICE BALL BEARING 16

TABLE 5 LIQUID SERVICE JOURNAL BEARING 17

TABLE 6 GAS SERVICE BALL BEARING H CODE 18

TABLE 7 GAS SERVICE BALL BEARING A CODE 19

TABLE 8 METER READS HIGH 39

TABLE 9 METER READS LOW 40

TABLE 10 ZERO OUTPUT 41

TABLE 11 INTERMITTENT OPERATION 42

TABLE 12 NON-REPEAT METER OUTPUT 43

TABLE 13 CONSTANT NON-ZERO OUTPUT 44

TABLE 14 LIQUID SERVICE FLOWMETER PARTS LIST FT4-8, FT6-8 45

TABLE 15 LIQUID SERVICE FLOWMETER PARTS LIST FT8-8, FT-08 46

TABLE 16 LIQUID SERVICE FLOWMETER PARTS LIST FT-10, FT-12 47

TABLE 17 LIQUID SERVICE FLOWMETER PARTS LIST FT-16, FT-20 48

TABLE 18 LIQUID SERVICE FLOWMETER PARTS LIST FT-24, FT-32 49

TABLE 19 LIQUID SERVICE FLOWMETER PARTS LIST FT-40, FT-48 50

TABLE 20 LIQUID SERVICE FLOWMETER PARTS LIST FT-64, FT-96 51

TABLE 21 LIQUID SERVICE FLOWMETER PARTS LIST FT-128, FT-192 52

TABLE 22 GAS SERVICE FLOWMETER PARTS LIST (CODE H) FT2-8, FT4-8 53

TABLE 23 GAS SERVICE FLOWMETER PARTS LIST (CODE H) FT6-8, FT8-8 54

TABLE 24 GAS SERVICE FLOWMETER PARTS LIST (CODE H) FT-08 55

TABLE 25 GAS SERVICE FLOWMETER PARTS LIST (CODE H) FT-10, FT-12 56

TABLE 26 GAS SERVICE FLOWMETER PARTS LIST (CODE H) FT-16, FT-20 57

TABLE 27 GAS SERVICE FLOWMETER PARTS LIST (CODE H) FT-24, FT-32 58

TABLE 28 GAS SERVICE FLOWMETER PARTS LIST (CODE H) FT-40, FT-48 59

TABLE 29 GAS SERVICE FLOWMETER PARTS LIST (CODE H) FT-64 60

TABLE 30 GAS SERVICE FLOWMETER PARTS LIST (CODE A) FT2-8, FT4-8 61

TABLE 31 GAS SERVICE FLOWMETER PARTS LIST (CODE A) FT6-8, FT8-8 62

TABLE 32 GAS SERVICE FLOWMETER PARTS LIST (CODE A) FT-08 63

TABLE 33 GAS SERVICE FLOWMETER PARTS LIST (CODE A) FT-10, FT-12 64

TABLE 34 GAS SERVICE FLOWMETER PARTS LIST (CODE A) FT-16, FT-20 65

TABLE 35 GAS SERVICE FLOWMETER PARTS LIST (CODE A) FT-24, FT-32 66

TABLE 36 GAS SERVICE FLOWMETER PARTS LIST (CODE A) FT-40, FT-48 67

TABLE 37 GAS SERVICE FLOWMETER PARTS LIST (CODE A) FT-64, FT-96 68

vi

Page 8

TABLE OF CONTENTS (FIGURES GUIDE)

FIGURE # TITLE PAGE

FIGURE 1 FLOWMETER BASIC PARTS 1

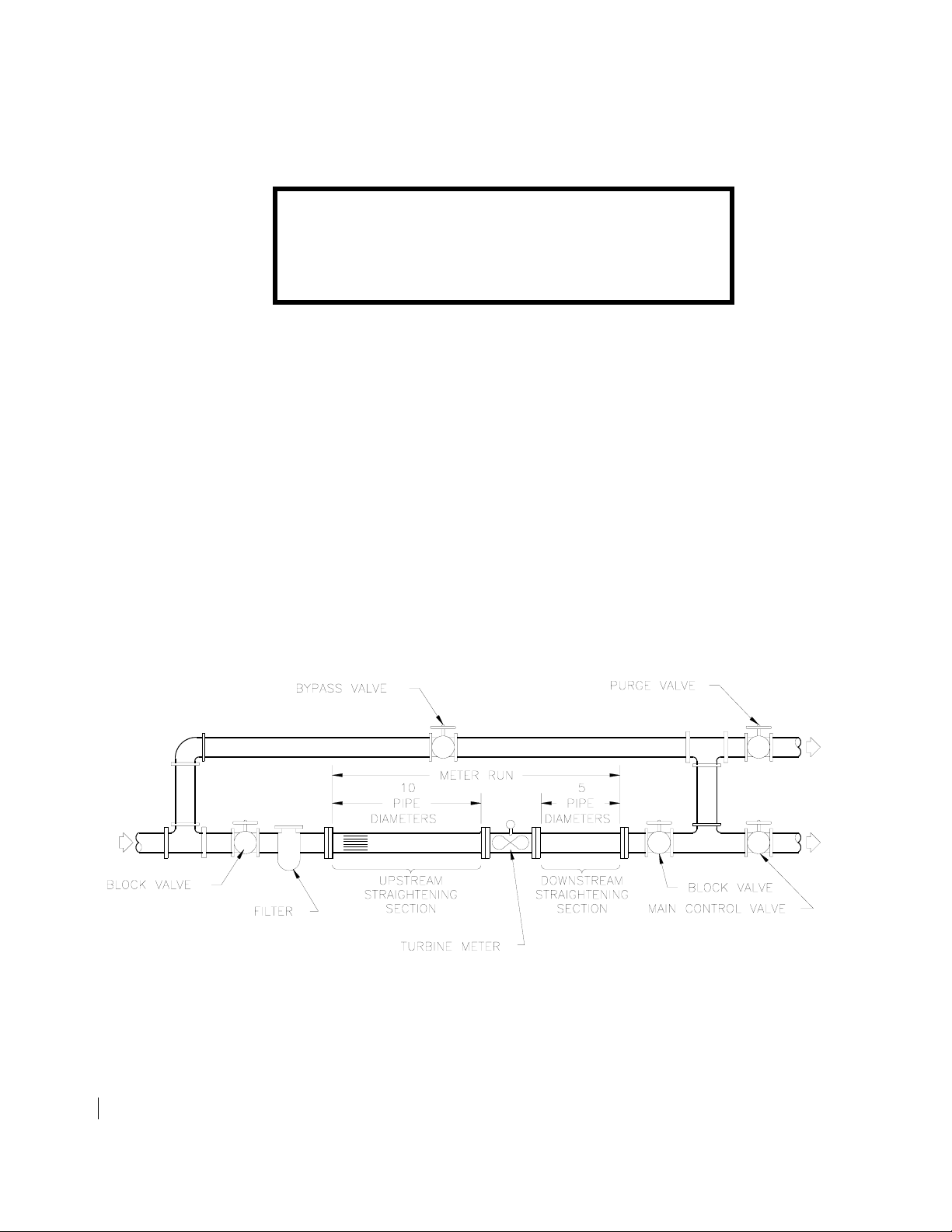

FIGURE 2 3-VALVE BYPASS MANIFOLD PIPE SCHEMATIC 2

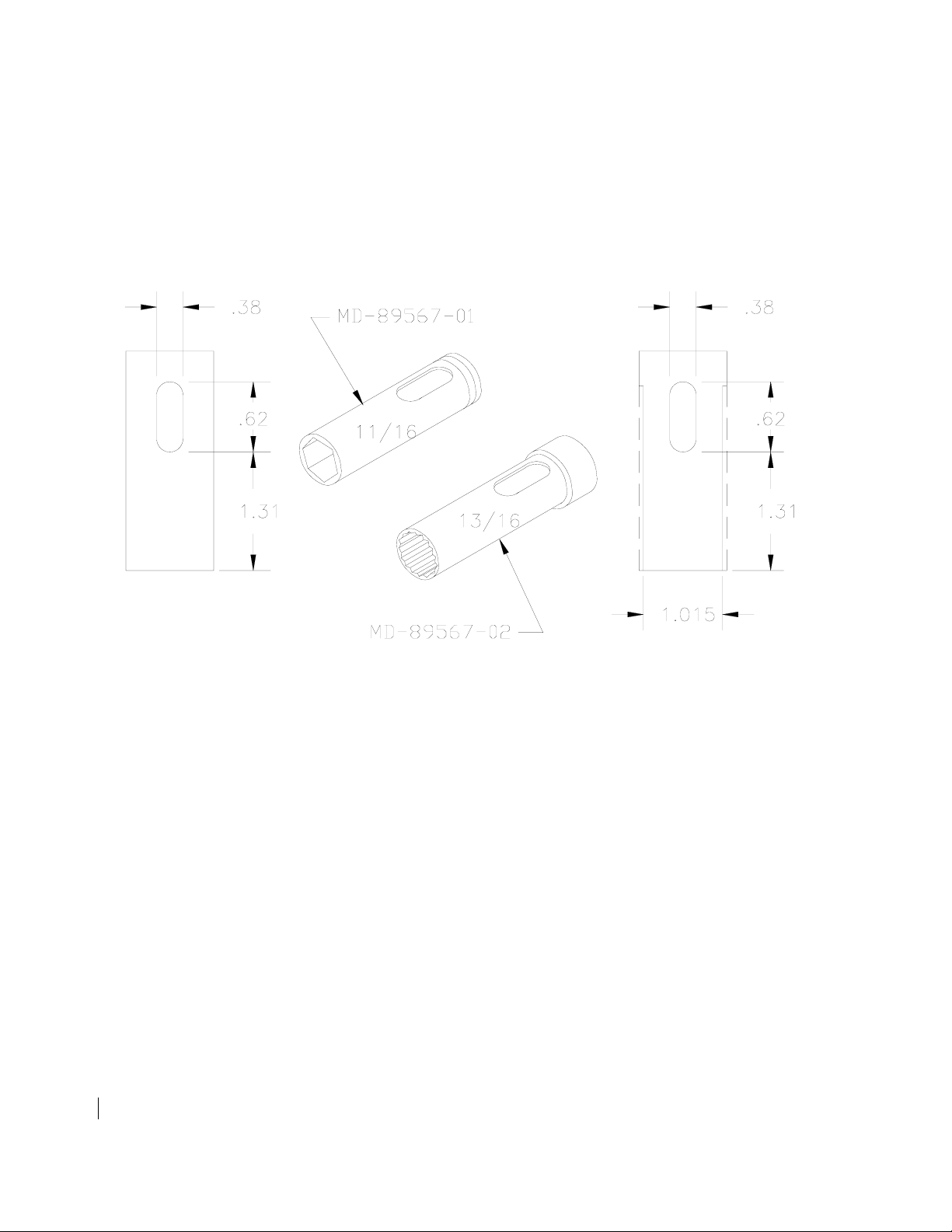

FIGURE 3 PICKOFF INSTALLATION SOCKETS 5

FIGURE 4 DIMENSIONS 20

FIGURE 5 BEARING SEATING 23

FIGURE 6 ILLUSTRATED PARTS BREAKDOWN 69

FIGURE 7 LIQUID AND GAS BEARING (CODE A) FT2-8, FT4-8 70

FIGURE 8 LIQUID AND GAS BEARING (CODE A) FT6-8, FT8-8, FT-08 70

FIGURE 9 GAS BEARING (CODE H) FT2-8, FT8-8, FT6-8, FT8-8 FT-08 71

FIGURE 10 LIQUID AND GAS BEARING (CODE A) FT-10, THRU FT-24 71

FIGURE 11 GAS BEARING (CODE H) FT-10, FT-12 72

FIGURE 12 GAS BEARING (CODE H) FT-16, FT-20, FT-24 72

FIGURE 13 LIQUID AND GAS BEARING (CODE A) AND GAS (CODE H)

FT-32

FIGURE 14 LIQUID BEARING (CODE A) AND GAS (CODE A & H) FT-32,

FT-40, FT-48, FT-64

FIGURE 15 LIQUID AND GAS BEARING (CODE A) FT-96 74

FIGURE 16 LIQUID AND GAS BEARING (CODE A) FT-128 74

FIGURE 17 LIQUID AND GAS BEARING (CODE A) FT-192 75

FIGURE 18 LIQUID BEARING (CODE G & D) FT4-8 THRU FT-08 75

FIGURE 19 LIQUID BEARING (CODE G & D) FT-32 76

FIGURE 20 LIQUID BEARING (CODE E) FT4-8 THRU FT-08 76

FIGURE 21 LIQUID BEARING (CODE E) FT-16, FT-20, FT-24 77

FIGURE 22 LIQUID BEARING (CODE G & D) FT-32 77

FIGURE 23 LIQUID BEARING (CODE E) FT-32 78

FIGURE 24 LIQUID BEARING (CODE G & D) FT-40, FT-48, FT-64 78

FIGURE 25 LIQUID BEARING (CODE G & D) FT-96 79

FIGURE 26 LIQUID BEARING (CODE G & D) FT-128 79

FIGURE 27 LIQUID BEARING (CODE G & D) FT-192 80

73

73

vii

Page 9

1.0 INTRODUCTION

This manual provides information and guidance for the installation, operation and maintenance of the

Standard Line Turbine Flowmeters, manufactured by Flow Technology, Inc., Phoenix, Arizona.

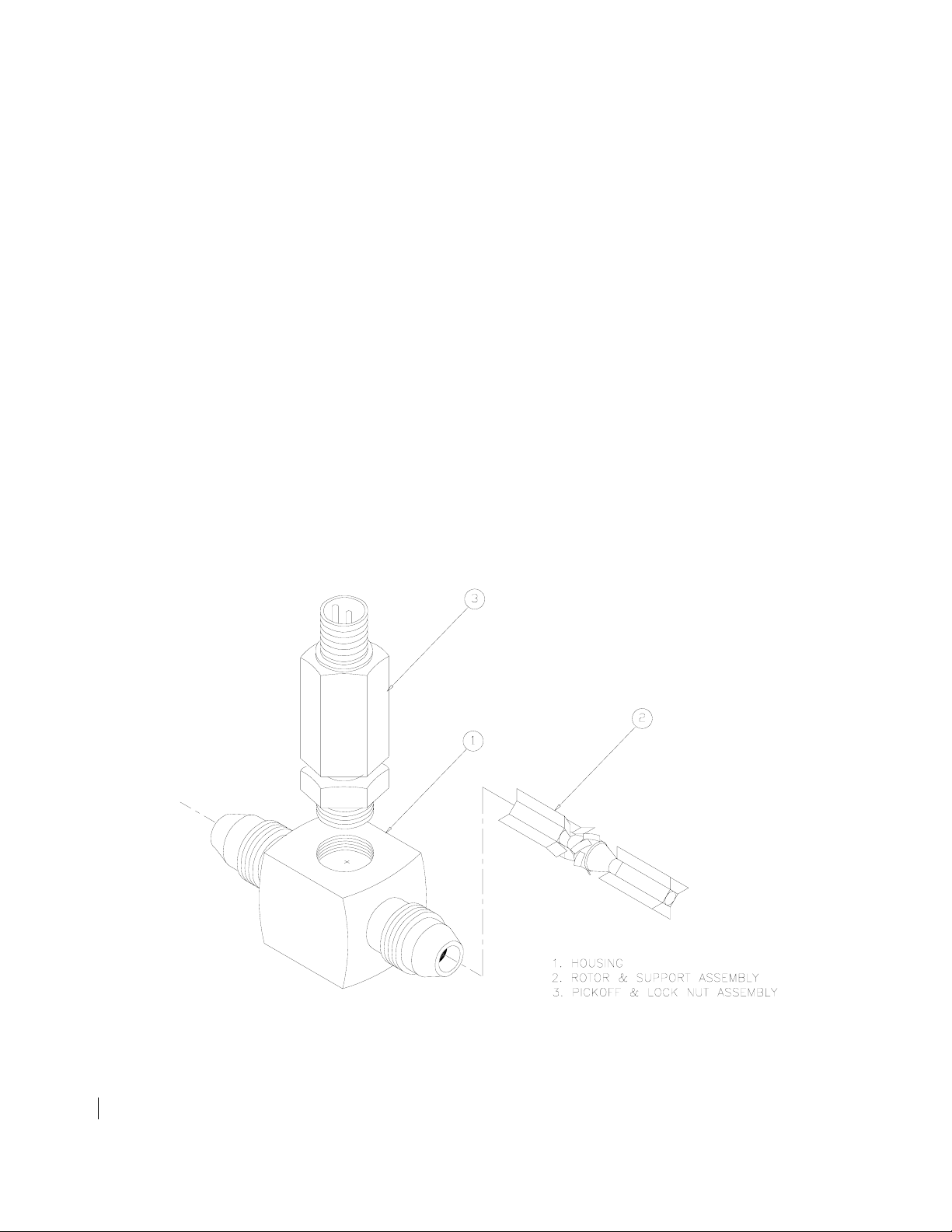

2.0 STANDARD LINE FLOWMETER

The Flow Technology, Inc. Standard Line Turbine Flowmeter is a volumetric flow measuring

instrument. The flow sensing element is a freely suspended, bladed rotor positioned axially in the flow

stream with the flowing fluid pushing against the blades. The rotational speed of the rotor is

proportional to the velocity of the fluid. Since the flow passage is fixed, the turbine rotors rotational

speed is also a true representation of the volume of fluid flowing through the flowmeter. The rotation of

the turbine rotor generates electrical pulses in the pickoff that is attached to the flowmeter housing in

close proximity to the turning rotor. Each one of these pulses represents a discrete volume of fluid. The

frequency or pulse repetition rate represents the volumetric flow rate and the accumulated pulse total

represents the total volume measured. Meters provided for liquid applications are not interchangeable

with meters provided for gas applications. All requests for information concerning a specific meter

should contain the flowmeter model number and the flowmeter serial number.

The Standard Line Flowmeter consists of 3 basic assemblies. (See Figure 1)

Figure 1. Flowmeter Basic Parts

TM-86675 1

Page 10

3.0 INSPECTION UPON RECEIPT

The flowmeter should be unpacked carefully and inspected to verify that no damage occurred during

shipment. Make certain that the internal parts are clean and free from packing materials or debris.

C A U T I O N

The flowmeter is a precision instrument and

may be damaged if pressurized air

is used for cleaning the flowmeter or for

checking the rotation of the rotor.

4.0 MECHANICAL CONNECTIONS

4.1 Flow Conditioning

The turbine flowmeter is sensitive to velocity profile disturbances in the flow stream. For optimizing the

velocity profile it is recommended that a straight run of constant diameter piping with length of at least

10 diameters upstream of the meter and at least 5 diameters downstream be provided. (See Figure 2) The

upstream section should have straightening vanes or other flow conditioners. The presence of major

flow disturbance generators such as pumps, valves or elbows may require longer straight sections. If

swirl is present in the line ahead of the flowmeter installation, a longer straight section or additional

flow conditioning may be required. Flow Technology, Inc. provides an array of innovative state of the

art flow conditioners.

Figure 2. 3-Valve Bypass Manifold Pipe Schematic

TM-86675 2

Page 11

4.2 Flow Pulsations

Piping and system components should be arranged to minimize pulsations entering the turbine meter.

Pulsations may cause the meter to read high, and excessive pulsations may cause permanent bearing

damage. Pulsations should be kept below 10% of the current flow rate at the meter location.

C A U T I O N

Pressure should be built up gradually at start-up to avoid possible damage by

over-speeding the rotor. Any severe water hammering from improper start-up or

flow surges during operation must be avoided to prevent over-speeding, shaft or

rotor blade breakage.

NOTE

Water hammering is a term used during start-up (introducing fluid into the

piping) to describe a high velocity flow impact on the turbine rotor. This must be

avoided to prevent damage to the mechanical parts.

4.3 Purging

All flow lines in the meter system should be purged prior to installation of the meter. This will remove

pipe dope, metal shavings, slag and debris that may damage the turbine meter. Control valves should be

located downstream from the turbine meter. (See Figure 2) System start-ups with upstream control

valves in an unfilled system can result in a hydraulic shock on the meter, causing damage and a change

in calibration in liquid systems, or can cause over speed conditions in gas meter systems.

4.4 Installation Recommendation

For liquid flowmeters, it is recommended that the flowmeter be installed so that it remains full of fluid

when the flow ceases. When the flowmeter is left installed in a line that is temporarily out of service and

has been partially or fully drained, severe bearing corrosion may occur. The type and corrosiveness of

the fluid being metered, the type of bearing used in the flowmeter and the length of time the line will be

out of service are factors which may affect the life and operation of the flowmeters. If it is economically

feasible and conditions permit, the flowmeter should be removed, cleaned and stored when there is any

doubt about the fluid level in the line during these out-of-service periods. See section 10.1 inspection

cleaning and storage.

4.5 Orientation and Calibration

The orientation of the turbine flowmeter will influence the nature of the load on the rotor bearings, and

thus, the performance of the meter at low flow rates. For optimum accuracy a turbine meter should be

installed in the same orientation in which it was calibrated. Standard calibration orientation is with the

meter axis horizontal.

TM-86675 3

Page 12

4.6 Filtration

A filter should be installed upstream of the flowmeter. (See Figure 2) For 1/2 inch flowmeters, a 10

micron nominal filter should be used; for 3/4 inch and 1 inch flowmeters, a 20 micron nominal filter

should be installed; for flowmeters 1-1/2 inch in diameter or larger, a 50 micron filter is recommended.

4.7 Torque Requirements

The following table provides the recommended torques in pound-feet for tightening MS-33656 flaredtube end fittings:

TABLE 1

TORQUE REQUIREMENTS

POUND-FEET

SIZE ALUMINUM TUBING STEEL TUBING

MIN. MAX. MIN. MAX.

½” 19 21 37 40

5/8” 27 30 54 58

¾” 35 40 75 85

1” 41 58 100 116

1-1/4” 66 75 126 140

1-1/2” 66 75 158 175

2” 150 166 221 245

5.0 PICKOFFS

5.1 Installation

Pickoffs should bottom in the well of the flowmeter housing but should only be finger tightened to

approximately 4 lb-in (4500 gm-cm max) to prevent distortion of the coil housing. The pickoff is

secured in position by tightening the lock nut to approximately 25 lb-in (30000 gm-cm). The pickoff is

removed by loosening the hex lock nut and unscrewing the pickoff from the housing.

C A U T I O N

Meter pressure ratings are established with a pickoff

installed. Do not operate a flowmeter under pressure

without a pickoff installed.

5.2 Explosion Proof Housings

Flowmeters with explosion proof housings may have the pickoff installed inside a short section of

conduit pipe (spud) that is welded to the housing. Since the spud is longer than the pickoff, the pickoff

cannot be finger tightened directly and an alternate method must be used to install the pickoff. A

modified 11/16-inch deep socket is required to screw the pickoff into the housing and a modified 13/16inch deep socket is used to tighten the lock nut.

TM-86675 4

Page 13

5.2.1 Pickoff Installation Sockets

Modify a standard 11/16-inch deep socket with an elongated 3/8-inch hole as shown in Figure 3. This

socket will fit the pickoff and allow easy feed through of the lead terminals without damaging the leads.

Modify a standard 13/16-inch deep socket with an elongated hole. (See Figure 3) Cut the outside

diameter of the socket to 1.015 inches as shown to permit the socket to tighten the lock nut inside the

conduit without damaging the pickoff leads.

Figure 3. Pickoff Installation Sockets

5.3 Magnetic Pickoff

The magnetic pickoff output is a low level signal that ranges from 10 mV to several volts peak-to-peak.

A pulse amplifier may be needed to convert the pickoff low level signal to a 10 V peak-to-peak pulse

signal suitable for process instrumentation. Typical resistance of magnetic pickoffs are 2275 Ω ± 20%.

5.4 RF Pickoff

The modulated carrier (RF) pickoff must be installed with an appropriate amplifier (consult factory).

The amplifier is needed to convert the modulated carrier signal to a 10 V peak-to-peak pulse signal

suitable for process instrumentation. Typical resistance of modulated carrier pickoffs is 10 Ω ± 10%.

TM-86675 5

Page 14

6.0 ELECTRICAL CONNECTIONS

6.1 Connections

Standard pickoffs are available with a two-contact type MS3102A-10SL-4P connector or with threaded

body and pigtail connectors.

6.2 Connection Cable

The connecting cable between the flowmeter and the electronic instrumentation should be a two

conductor, 22 AWG, shielded and twisted cable with a vinyl jacket (Belden 8761 or equivalent). The

cable should not be installed in a conduit or tray containing power lines, or close to strong

electromagnetic sources such as electric lines, electric motors, transformers, welding machines, or high

voltage lines. These sources may induce transient electrical noise in the coil and cause false pulse

signals. Connections from standard pickoffs are not polarized and may be connected in either position.

For non-standard pickoffs please refer to manufacturer's specifications.

6.3 Grounding Considerations

The shield of the cable is to be grounded at only one point in accordance with the instruction of the

display instrument. Flow Technology, Inc. display instruments specify where the shield is to be

grounded.

TM-86675 6

Page 15

6.4 Signal Processing

An electronic signal conditioning circuit is required to either convert the frequency output of the

flowmeter into a visual presentation on a display or to provide process control signals. Flow

Technology, Inc. manufactures a complete line of electronic packages, which include rate and total

displays, rate converters and microprocessor based units for linearization and temperature / pressure

compensation.

Pickoff Connector Specifications

Standard 2 Pin MS Non-polarized Pins

27-31386 3 Pin MS Pins: A = Coil B = Coil C = N/C

Inductance = 0.350 mh ± 10 % Resistance = 3.5 ohms ± 10 %

Amplified Pickoffs

27-94057

Pick-off w/RTD

RF 27-62730

Mag 27-62731

3 Pin MS

Wire Leads

4 Pin MS

Wire Leads

Pins: A = Power B = Ground C = Pulse

Red = Power Black = Ground White = Pulse

Input Power = 8 to 32 VDC @ 10 ma

Output = 0 to 5 VDC Pulse

Output Impedance = 2.2 K ohms

Mag Amp: Frequency Range = 10 Hz to 10 KHz

Input Sensitivity = 20 MV p-p

RF Amp: Frequency Range = 10 to 3200 Hz

Oscillator Carrier Frequency = 45 KHz

Pins: A=Coil B=Coil Non-polarized

C= RTD high D= RTD low & RTD compensation

Leads: White= Coil Non-polarized

Red= RTD high Black= RTD low & RTD compensation

RTD= 100 Ohm Platinum

7.0 BIDIRECTIONAL FLOWMETERS

Turbine flowmeters can be configured to measure flow in both directions and provide direction-sensing

capability. This is accomplished by adding a second pickoff located with respect to the first pickoff in

such a way as to achieve a 90-phase shift. The location of the pickoffs are determined by the number of

blades on the rotor.

TM-86675 7

Page 16

8.0 OPERATION

8.1 Over Range

In general, turbine flowmeters remain quite linear when they are over ranged, and may not provide any

indication that the instrument is being misused. However, the pressure drop will become excessive and

over speeding of the bearings could cause permanent damage. Bearings may also be damaged by

excessive downstream thrust load. The probability of an over speed condition for a liquid meter usually

occurs during system start up when there is still air in the lines. Air should be bled carefully from the

lines before high flow range is established. The flow rate or output frequency should be monitored to

insure maximum capability is not exceeded. Flow Technologies’s specifications should be consulted for

specific maximum operating flow rates. See tables 4,5,6 and 7. Under extreme conditions, the maximum

operating flow rates can be exceeded for brief periods of time without meter damage. Following are the

maximum allowable over range capabilities:

Bearing Type Liquid Gas

Ball 50% 10%

Pivot 10% 10%

Journal 50% N/A

8.2 Under Range

When used below the minimum specified range, turbine meters may become very non-linear. The

repeatability of the meter may also be reduced due to bearing and magnetic pickoff drag.

8.3 Liquid Turbine Flowmeter Characteristics

8.3.1 Introduction

Optimum performance of a turbine meter system depends upon a valid calibration as well as the correct

selection of supporting equipment. The rotational speed of a turbine rotor depends upon fluid properties

as well as the fluid velocity. The most significant fluid property for a liquid meter is the kinematic

viscosity. As liquid viscosity increases, the slip of the turbine rotor due to viscous drag is increased, and

the rotational speed and hence pick-off frequency is decreased. Due to these effects, the kinematic

viscosity of the calibration fluid should approximate the service conditions as closely as possible.

8.3.2 Standard Calibration

Standard liquid calibrations at FTI are done with MIL-C-7024 Type II solvent or water at room

temperature. The viscosity of these fluids is approximately 1.25 and 1 centistokes respectively. The

standard calibration consists of 10 data points distributed over the normal 10:1 range of the flowmeter.

If viscosities or flow ranges other than these are required, they must be specified.

TM-86675 8

Page 17

8.3.3 Single Viscosity Calibration

If the flowmeter is to be used at a viscosity other than the standard calibration viscosities, an oil blend

calibration should be done on the meter to simulate the operating conditions. The calibration curve

produced will represent the flowmeter’s output characteristics for that specific viscosity. If the

flowmeter is used with liquids having viscosities greater than 3 centistokes, the linearity of the K-factor

will be reduced.

8.3.4 Multiple Viscosity Calibrations

If the viscosity is changing due to varying temperature in the system, the performance characteristics

over a range the viscosities can be established. This is done by performing multiple calibrations at

different viscosities to cover the range of interest. The K-factor of the meter is then plotted as a function

of Hz/v. The K-factor is the number of pulses generated by a flowmeter for every unit volume of fluid

passing through it. Hz is the output frequency of the meter and v is the kinematic viscosity of the fluid in

centistokes. The plot of K vs. Hz/v is commonly referred to as a universal viscosity curve. The data is

plotted in this manner because all points fall on a single smooth curve. To obtain a useful curve,

calibration points for calibrations at several viscosities are required. By observing the output frequency

of the flowmeter and obtaining the viscosity or temperature of the fluid, the value of Hz/v can be

calculated. Using the universal viscosity curve, the value of K corresponding to the known value of Hz/v

can be determined. With the K-factor known, the flow through the meter can be determined from the

expression:

Hz (60)

GPM =

K - factor

8.4 Gas Turbine Flowmeter Characteristics

8.4.1 Introduction

Accurate performance of gas turbine flowmeters depend on a valid calibration that simulates the

conditions the meter will operate in. Changes in the pressure and temperature of a gas directly affect the

density and kinematic viscosity of the fluid. These changing fluid properties affect the performance of

gas flowmeters in much the same way as liquid flowmeters.

TM-86675 9

Page 18

Due to the nature of gasses to be compressed, the volume of gas measured is dependent on the pressure

and temperature as established by Boyle's Law and Charles' Law. Using these relationships, the actual

volume of gas measured can be related to a standard set of conditions that provide useful technical data.

The standard conditions for pressure and temperature used at Flow Technology, Inc. are 14.7 pounds per

square inch absolute (PSIA) and 520 degrees Rankine (60 degrees Fahrenheit) respectively. For proper

conversions, the absolute measurement for pressure and temperature must be used.

The following equation is used to convert the actual volumetric flow rate (QA) in Actual Cubic Feet per

Minute (ACFM) to the equivalent standard flow rate (QS) in Standard Cubic Feet per Minute (SCFM).

P

Q

= Q A ( ---- ) ( ---- )

S

P

T S

A

T A

S

Where:

QS = Standard flow rate in SCFM

QA = Actual measured flow rate in ACFM

PA = Actual measured pressure at pressure tap on meter (PSIA)

PS = Standard Pressure (14.7 PSIA)

TA = Actual measured temperature downstream of meter ( R)

TS = Standard temperature (520 R)

8.4.2 Air Calibration

Gas calibrations at FTI are done using air at ambient conditions. These conditions are typically 14.2

PSIA and 72 F. The standard calibration consists of 10 data points distributed over the normal 10:1

range of the flowmeter. If conditions or flow ranges other than these are required, they must be

specified.

8.4.3 Single Pressure Calibrations

If the flowmeter is to be used at conditions that vary significantly from the standard calibration, a

calibration at equivalent conditions should be performed to simulate the actual operating conditions.

The calibration curve produced will represent the flowmeter's output characteristics for the specified gas

at the actual operating conditions.

TM-86675 10

Page 19

8.4.4 Multiple Pressure Calibrations

Performance characteristics over a range of pressures can be established for operating conditions where

the temperature and pressure are changing. This is done by performing multiple calibrations at different

pressures to cover the range of interest. The information obtained is then plotted on a curve of K-factor

verses Hz/v where the K-factor is the pulses per unit volume generated by the flowmeter and the Hz/v is

the frequency output of the flowmeter divided by the kinematic viscosity of the fluid. The procedure is

similar to liquid meters using the universal viscosity curve. By reading the output frequency of the

flowmeter during operation and dividing it by the kinematic viscosity of the fluid being used, the

volumetric flow rate can be determined by reading the K-factor from the universal viscosity curve and

calculating the flow rate:

Hz (60)

CFM =

K - factor

Electronic instrumentation is available that can be programmed with the universal viscosity curve and

setup with pressure and temperature transducers that will automatically make these calculations and read

out the corrected flow rate.

9.0 SPECIFICATIONS AND OPTIONS

Table 2 shows the complete model numbering system for the FT series flowmeters. The sections that

follow describe the contents of Table 2 in detail.

Tables 3 thru 7 describe the different bearings and their applications.

TM-86675 11

Page 20

TABLE 2

FT MODEL NUMBERING SYSTEM

FT _ _ _ _ _ _ _ _ _ _ __ _ _ _ _ _

BASE MODEL

2-8 Through 192

( 1/2" Through 12" )

END FITTINGS

Refer to Section 9.1

CALIBRATION

Refer to Section 9.2

NON STANDARD UNITS

U = To signify required units of measure

other than GPM or ACFM

R = To signify special calibration flow range

other than normal 10:1 or extended range

B = to signify both changes in units and

special flow range

SERVICE

L = Liquid

G = Gas

P = Gas with pressure tap

CONSTRUCTION MATERIALS

Refer to Section 9.3

BEARINGS

A = Ball Bearing

D = Carbide Journal

E = Graphite Journal

G = Ceramic Journal

H = Ball Bearing Self Lubricating (FT64 & smaller gas meters)

Refer to Section 9.4

PICKOFFS

Refer to Section 9.5

SPECIAL CODE

Special meter configurations will not be addressed in this manual

please contact the factory for a description of the special code.

TM-86675 12

Page 21

9.1 End Fittings

AE = AN (or MS) external straight

BE = British Standard external pipe threads 1/2" to 4"

NE = NPT external threads, 1/2" to 6"

HB = Hose Barb

WF = Wafer type serrated surface

C1 = 150# Raised Face Flange

C2 = 300# Raised Face Flange

C3 = 600# Raised Face Flange

C4 = 900# Raised Face Flange

C5 = 1500# Raised Face Flange

C6 = 2500# Raised Face Flange

J1 = 150# Ring Joint Flange

J2 = 300# Ring Joint Flange

J3 = 600# Ring Joint Flange

J4 = 900# Ring Joint Flange

J5 = 1500# Ring Joint Flange

J6 = 2500# Ring Joint Flange

D1 = DIN Flange PN16

D2 = DIN Flange PN40

D3 = DIN Flange PN100

D4 = DIN Flange PN160

D5 = DIN Flange PN250

D6 = DIN Flange PN400

9.2 Calibration

KA = 3 Point, K-factor average, in Air

KW = 3 Point, K-factor average, in Water

KS = 3 Point, K-factor average, in Solvent

KB = 3 Point, K-factor average, in Oil Blend

NA = 10 Point, normal 10:1 range, in Air

NW = 10 Point, normal 10:1 range, in Water

NS = 10 Point, normal 10:1 range, in Solvent

NB = 10 Point, normal 10:1 range, in Oil blend

XA = 10 Point, extended range, in Air

XW = 10 Point, extended range, in Water

XS = 10 Point, extended range, in Solvent

XB = 10 Point, extended range, in Oil blend

TA = 20 Point, normal 10:1 range, in Air

TW = 20 Point, normal 10:1 range, in Water

TS = 20 Point, normal 10:1 range, in Solvent

TB = 20 Point, normal 10:1 range, in Oil blend

YA = 20 Point, extended range, in Air

YW = 20 Point, extended range, in Water

TM-86675 13

Page 22

YS = 20 Point, extended range, in Solvent

YB = 20 Point, extended range, in Oil blend

GA = 30 Point, extended range, in Air

GW = 30 Point, extended range, in Water

GS = 30 Point, extended range, in Solvent

GB = 30 Point, extended range, in Oil blend

U2 = Universal Viscosity Curve, 2 viscosities

U3 = Universal Viscosity Curve, 3 viscosities

R1 = Reynolds # Calibration, 10 Point 1 Pressure

R2 = Reynolds # Calibration, 10 Point 2 Pressure

R3 = Reynolds # Calibration, 10 Point 3 Pressure

E1 = Reynolds # Calibration, 20 Point 1 Pressure

E2 = Reynolds # Calibration, 20 Point 2 Pressure

E3 = Reynolds # Calibration, 20 Point 3 Pressure

LW = 10 Point 10:1 Range, in Water, Premium linearity

LS = 10 Point 10:1 Range, in Solvent, Premium linearity

BA = Bidirectional, 1 Pickoff, 10 points each direction, Air

BW = Bidirectional, 1 Pickoff, 10 points each direction, Water

BS = Bidirectional, 1 Pickoff, 10 points each direction, Solvent

BB = Bidirectional, 1 Pickoff, 10 points each direction, Oil blend

CA = Bidirectional, 2 Pickoff, 10 points each direction, Air

CW = Bidirectional, 2 Pickoff, 10 points each direction, Water

CS = Bidirectional, 2 Pickoff, 10 points each direction, Solvent

CB = Bidirectional, 2 Pickoff, 10 points each direction, Oil blend

9.3 Construction Materials

C = 304 Housing, 430F Rotor

D = 304 Housing, 17-4 Rotor

E = 316 Housing, 430F Rotor

G = 316 Housing, 316 Rotor

H = 316 Housing, 17-4 Rotor

N = Hast C Housing, Hast C Rotor

Q = PVC Housing, PVC Rotor

R = Monel 400 Housing, Monel 400 Rotor

T = Carp 20 Housing, Carp 20 Rotor

9.4 Bearing Code

A = 440C Ball Bearings.

D = Carbide Journal - Carbide Shaft and Bearing.

E = Graphite Journal - 316 SST Shaft and Graphite Bearing

G = Ceramic Journal - Ceramic Shaft and Bearings

H = 440C Ball Bearings. (Polymer retainer )

TM-86675 14

Page 23

Table 3

BEARING APPLICATION GUIDE

CODE BEARING TYPE SERVICE BEARING

TEMPERATURE

RATING

A BALL LIQUID OR GAS -450° F TO 300° F 440C SST

MATERIAL

D CARBIDE

JOURNAL

E GRAPHITE

JOURNAL

G CERAMIC

JOURNAL

H BALL LIQUID OR GAS -450° F TO 300° F 440C SST POLYMER

LIQUID UP TO 1200° F C-2 CARBIDE

LIQUID UP TO 500° F 316 SHAFT GRAPH. BRG.

LIQUID UP TO 1200° F ALUMINUM BASED

CERAMIC

RETAINER

Meter temperature rating may be limited by the pickoff temperature rating

9.5 Pickoffs

-1 = RF MS Connector 400 ° F, 27-31199-101

-2 = MAG MS connector 400° F, 27-30880-101

-3 = MAG Explosion Proof 400° F, 27-30880-102 leads / 27-30931-102 EP

-5 = RF Explosion Proof 400° F, 27-31199-102 leads / 27-31949-101 EP

-6 = MAG MS connector 750°F, 27-80666-104

-7 = MAG Explosion Proof 750° F, 27-80666-104 MS / 27-82333-102 EP

-8 = RF MS Cox Equivalent 400° F, 27-84097-102

-9 = RF MS 5/8 Thd. 400° F, 27-84097-101

S8 = RF F & P 400° F, 27-31386-101

-L = RF MS connector 750° F, 27-88628-102

-M = RF Explosion Proof 750° F, 27-88826-103

-Y = RF Explosion Proof (CSA) 400° F, 27-13869-101

-Z = MAG Explosion Proof (CSA) 400° F, 27-13868-101

-U = MAG MS (Factory Mutual) 400° F, 27-32400-101

-X = RF MS (Factory Mutual) 300° F, 27-32404-101

PP = MAG Leads (Factory Mutual) 400

° F, 27-32400-103

SS = RF Leads (Factory Mutual 300° F, 27-32404-103

TT = MAG Explosion Proof (Factory Mutual) 400° F, 27-32400-102

XX = RF Explosion Proof (Factory Mutual) 300

A1 = RF MS Amplified 230

° F, 27-61313-104

° F, 27-32404-102

A2 = MAG MS Amplified 230° F, 27-61313-101

A3 = MAG Explosion Proof 230

° F, 27-61313-102

A4 = MAG Leads Amplified 230° F, 27-61313-103

A5 = RF Explosion Proof Amplified 230

A6 = RF Leads Amplified 230

° F, 27-61313-106

° F, 27-61313-105

TM-86675 15

Page 24

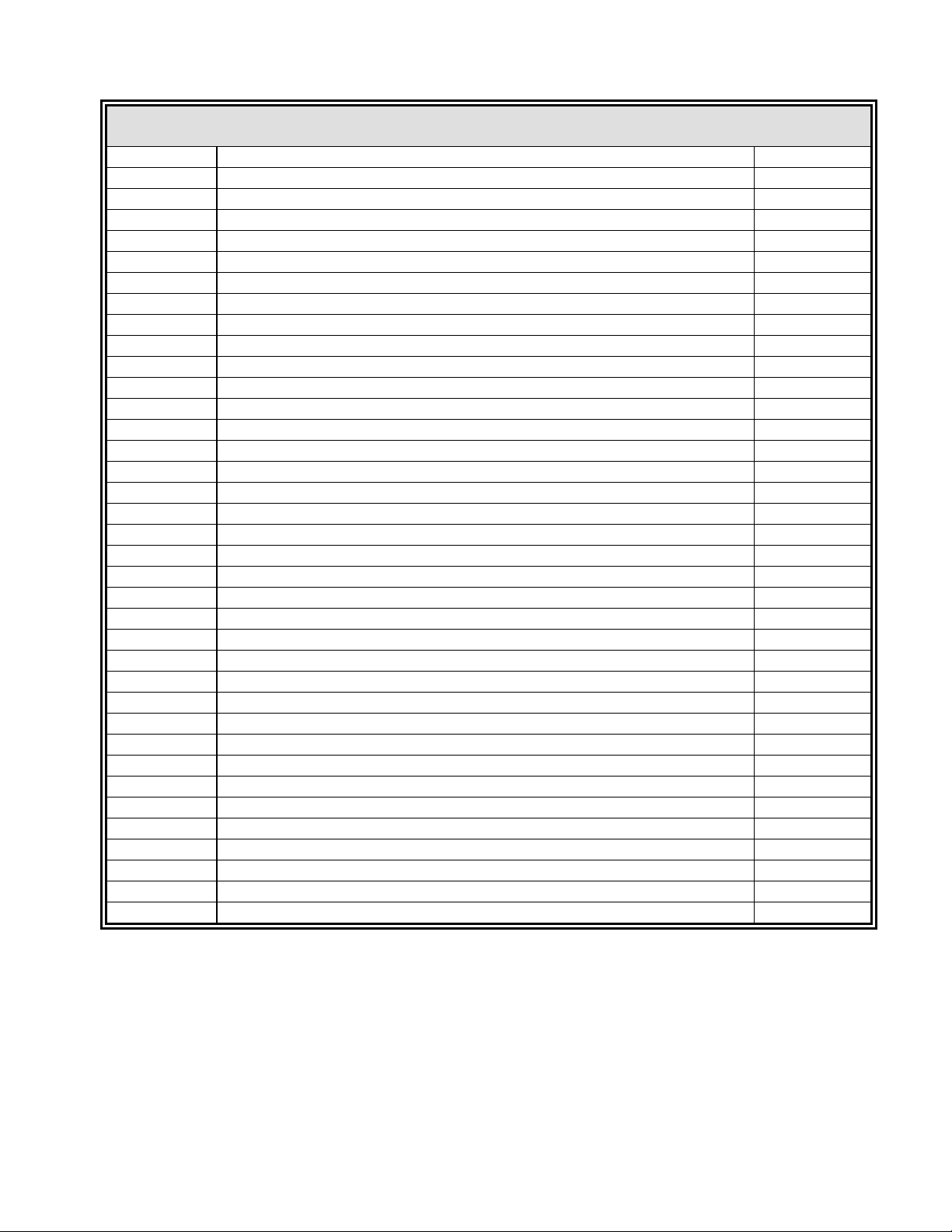

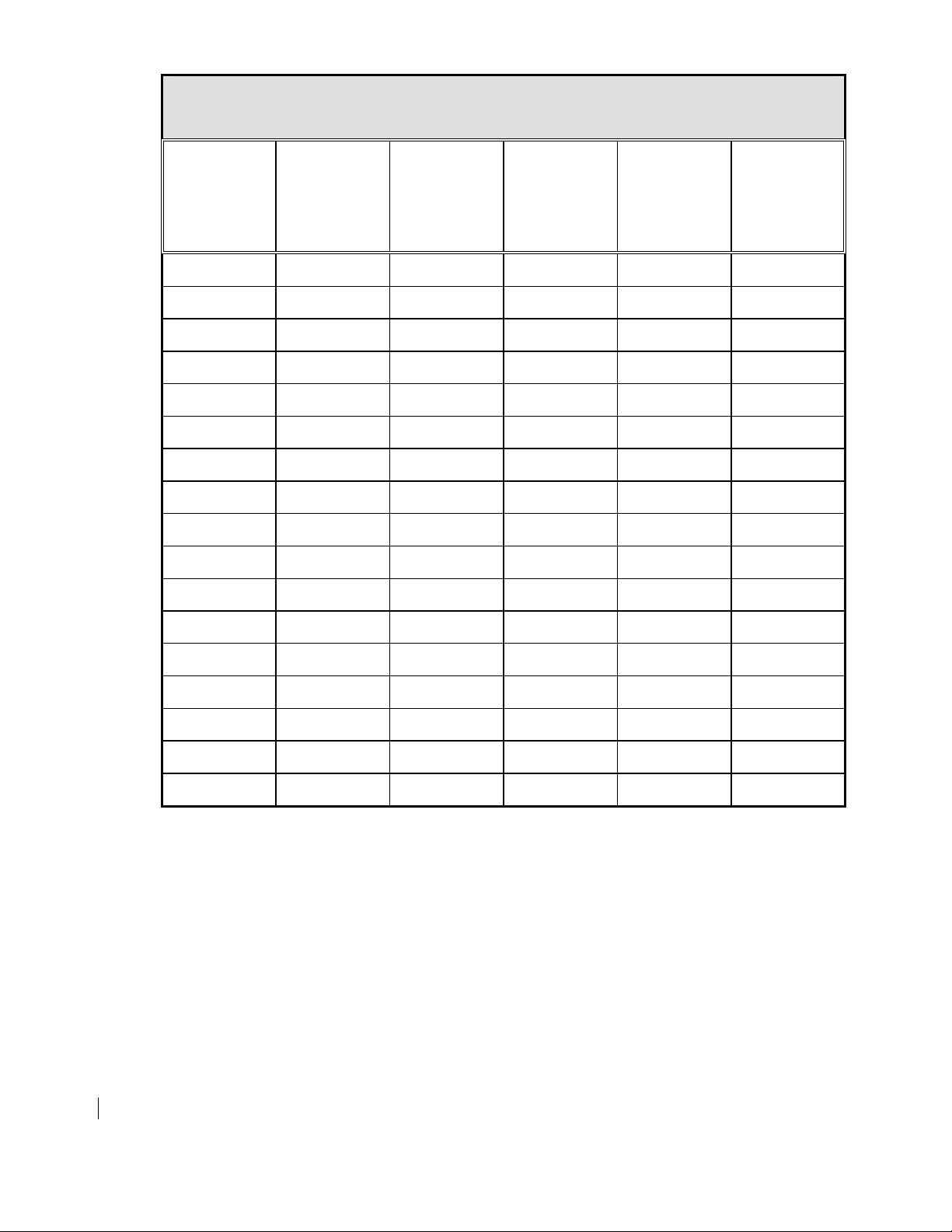

TABLE 4

LIQUID SERVICE - BALL BEARING

MODEL

FT4-8 .25-2.5 .03-3 .1-3 48000 2000

FT6-8 .5-5 .05-5 .12-5 25000 2100

FT8-8 .75-7.5 .08-8 .16-8 16000 2000

FT-08 1-10 .1-10 .2-10 12000 2000

FT-10 1.25 - 12.5 .15-15 .3-15 9600 2000

FT-12 2-20 .25-25 .5-25 5400 1800

FT-16 5-50 .6-60 1-60 2400 2000

FT-20 9-90 1-100 1-100 1300 1950

STD RANGE

10:1 (GPM)

RF & MAG

PICKOFF

EXTENDED

RANGE

(GPM)

RF

PICKOFF

EXTENDED

RANGE

(GPM)

MAG

PICKOFF

NOMINAL

K FACTOR

PULSE/

GALLON

MAX

FREQ.

(HZ)

FT-24 15-150 1.6-160 2.5-160 600 1500

FT-32 22-225 2.5-250 3.5-250 350 1300

FT-40 40-400 4.5-450 5.0-450 180 1200

FT-48 65-650 N/A 7.5-750 75 812

FT-64 125-1250 N/A 15-1500 30 625

FT-96 300-3000 N/A 50-3500 28 1400

FT128 550-5500 N/A 60-6000 14 1300

FT160 850-8500 N/A 100-10000 8.5 1200

FT192 1200-12000 N/A 1500-15000 5.0 1000

Notes:

1. Repeatability

2. Linearity = ± .5% of reading except as noted. Values are valid for viscosities of 3 centistokes or less

based on standard 10:1 range.

3. RF Pickoff not applicable for meter sizes FT-48 and larger.

4. Linearity = ± .75% of reading for FT4-8 and FT6-8 when high temp mag pickoff is used.

5. Premium linearity available over select ranges consult factory.

= ± .05%

TM-86675 16

Page 25

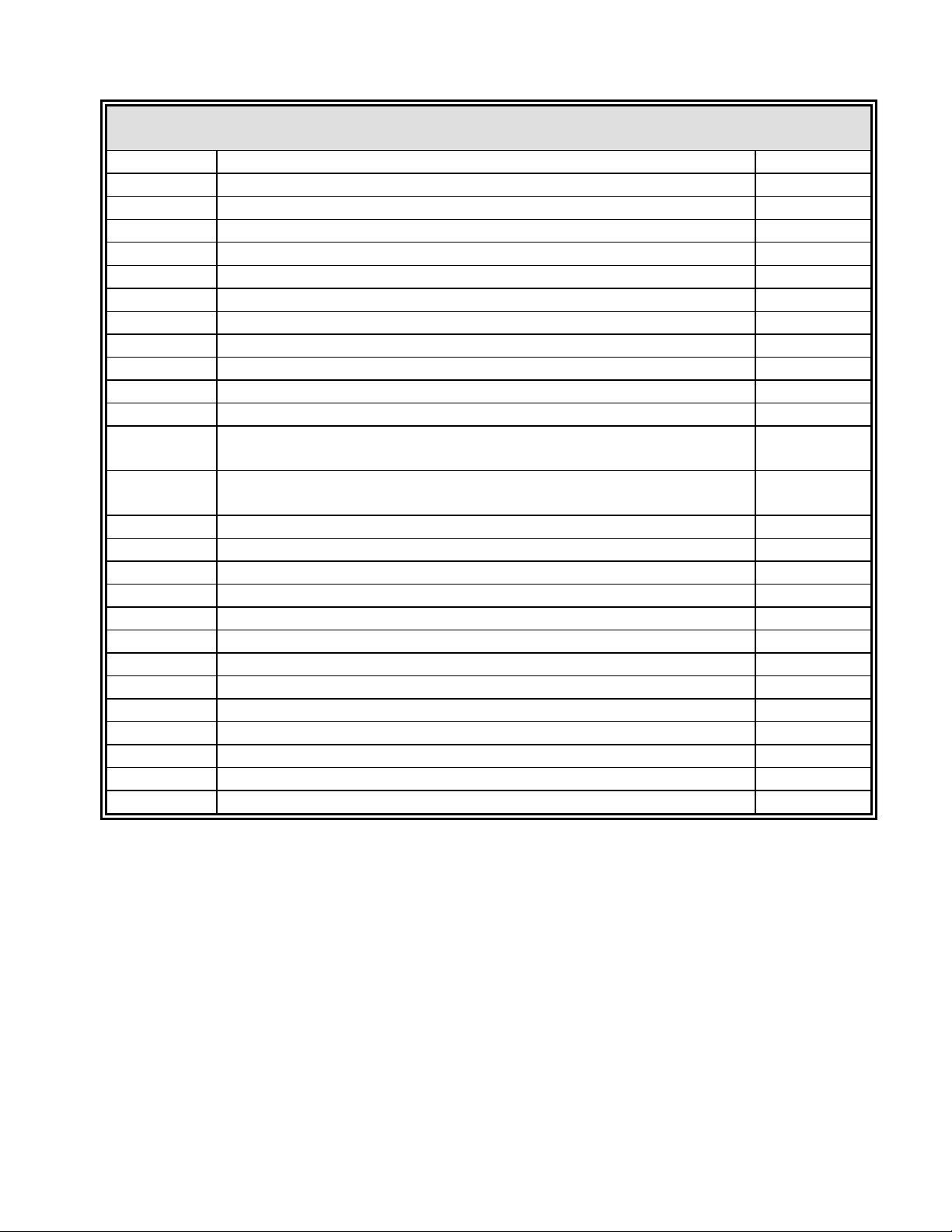

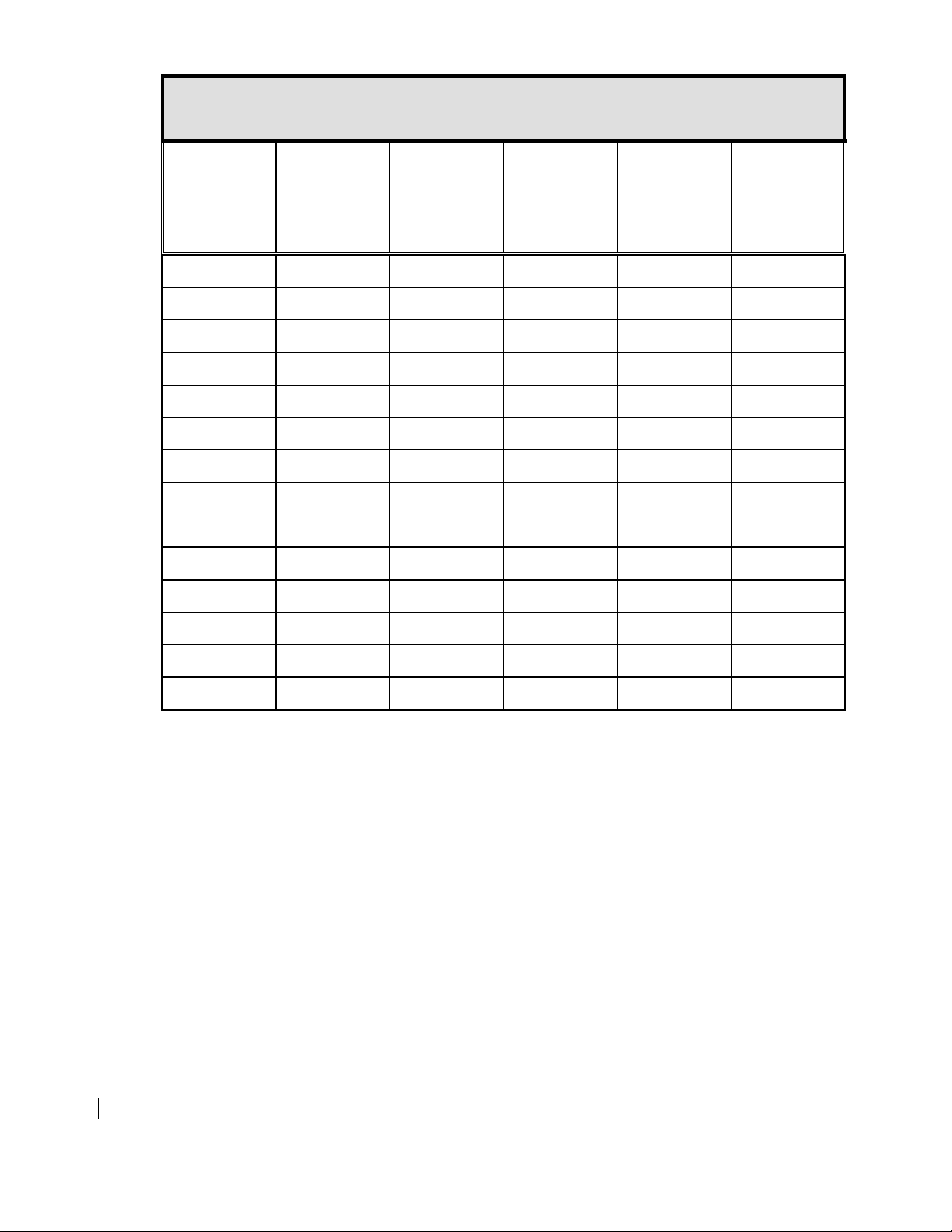

TABLE 5

LIQUID SERVICE - JOURNAL BEARING

MODEL

FT4-8 .25-2.5 .1-3.0 .12-3.0 48000 2000

FT6-8 .5-5.0 .15-5.0 .2-5.0 25000 2000

FT8-8 .75-7.5 .2-8.0 .25-8.0 16000 2000

FT-08 1.0-10.0 .25-10 .3-10 12000 2000

FT-10 1.25 - 12.5 .3-15 .4-15 9600 2000

FT-12 2-20 .5-25 .5-25 6000 2000

FT-16 5-50 1.0-60 1.0-60 2400 2000

FT-20 9-90 1.0-100 1.5-100 1300 1950

STD RANGE

10:1 (GPM)

RF & MAG

PICKOFF

EXTENDED

RANGE

(GPM)

RF

PICKOFF

EXTENDED

RANGE

(GPM)

MAG

PICKOFF

NOMINAL

K FACTOR

PULSE/

GALLON

MAX

FREQ.

(HZ)

FT-24 15-150 1.6-160 2.5-160 600 1500

FT-32 22-220 2.5-250 3.5-250 350 1300

FT-40 40-400 4.5-450 5.0-450 180 1200

FT-48 65-650 N/A 7.5-750 75 812

FT-64 125-1250 N/A 15-1500 30 625

FT-96 300-3000 N/A 50-3500 28 1400

FT128 550-5500 N/A 60-6000 14 1300

FT160 850-8500 N/A 100-10000 8.5 1200

FT192 1200-12000 N/A 150-15000 5.0 1000

Notes:

1. Repeatability = +/- .1% for FT-12 and smaller, +/- .05% for FT-16 and larger.

2. Linearity = +/- .5% of reading except as noted.

Values are valid for viscosities of 3 centistokes or less based upon standard 10:1 range.

3. Linearity is +/- 2% of reading for FT4-8.

4. Linearity is +/- .75% of reading for FT6-8 when high temp mag pickoff is used

5. Premium linearity available over select ranges consult factory.

6. RF pickoff not applicable for meter sizes FT-48 and larger.

TM-86675 17

Page 26

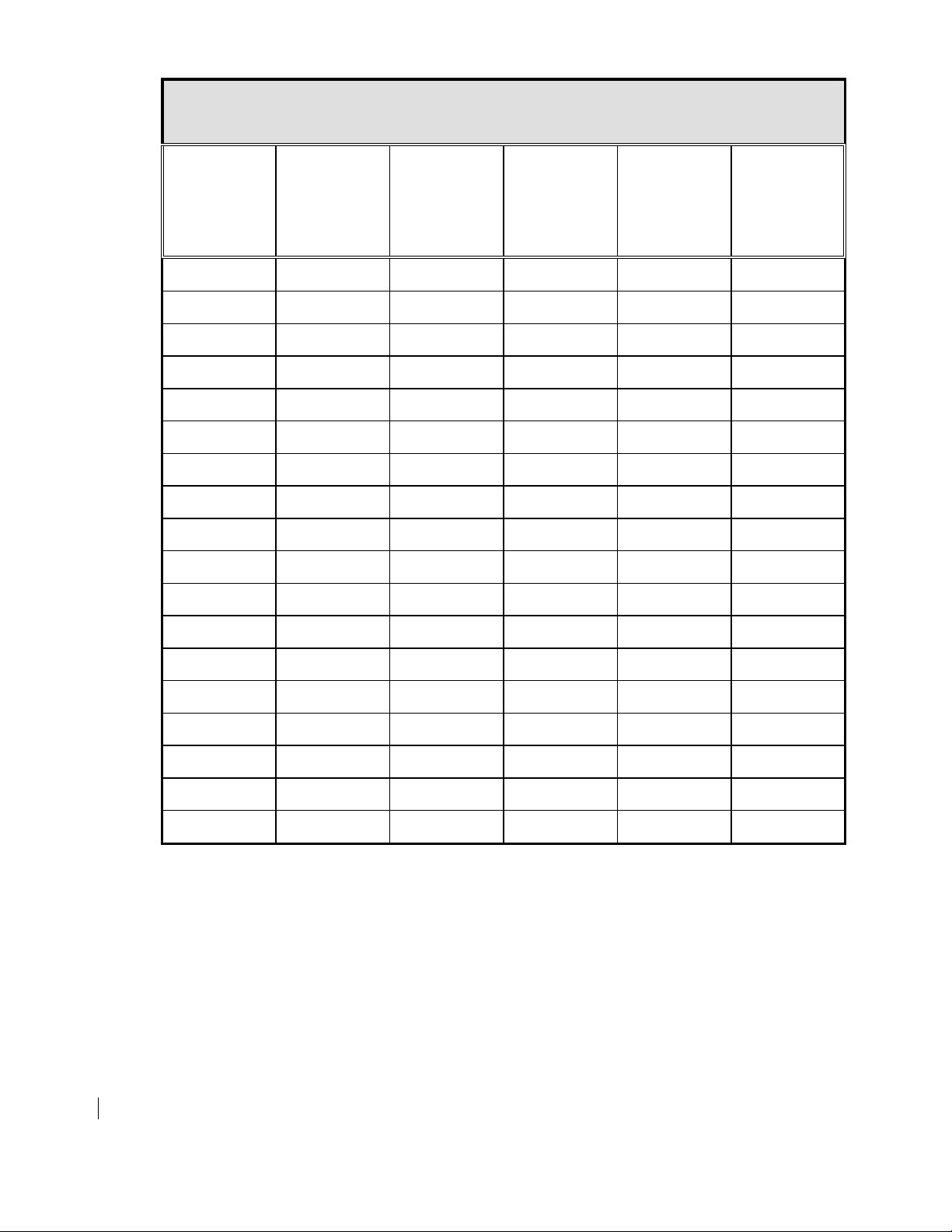

TABLE 6

GAS SERVICE - BALL BEARING “H” CODE

MODEL

FT2-8 .1-1.0 .09-1.25 N/A 114000 1900

FT4-8 .25-2.5 .2-3.0 N/A 40800 1700

FT6-8 .5-5.0 .25-5.0 .4-5.0 24000 2000

FT8-8 .75-7.5 .4-8.0 .5-8.0 16000 2000

FT-08 1.0-10.0 .5-10 .75-10 12000 2000

FT-10 1.25 - 12.5 .6-15 1-15 9600 2000

FT-12 2-20 1-25 1.5-25 6000 2000

FT-16 5-50 1.5-60 2.5-60 2400 2000

STD RANGE

10:1 (ACFM)

RF & MAG

PICKOFF

EXTENDED

RANGE

(ACFM)

RF

PICKOFF

EXTENDED

RANGE

(ACFM)

MAG

PICKOFF

NOMINAL

K FACTOR

PULSE / ACF

MAX

FREQ.

(HZ)

FT-20 9-90 2.5-100 5-100 1300 1950

FT-24 15-150 4-160 6-160 600 1500

FT-32 22-220 5-250 8-250 350 1300

FT-40 40-400 9-450 10-450 180 1200

FT-48 65-650 N/A 15-750 75 812

FT-64 125-1250 N/A 30-1500 30 625

Notes:

1. Gas service - Air @ 14.7 PSIA and 60 F.

2. Repeatability = +/- .1%.

3. Linearity = +/- 1.0% of full scale based on standard 10:1 range.

4. MAG Pickoff not applicable for FT2-8.

5. MAG Pickoff range is .35 - 2.5 ACFM for FT4-8.

6. Linearity for FT2-8 is 4% of full scale, repeatability is +/- .5%.

7. Linearity for FT4-8 is 3% of full scale, repeatability is +/- .3%.

8. Linearity for FT6-8 is 1.5% of full scale, repeatability is +/- .15%.

9. RF Pickoff not applicable for meter sizes FT-48 and larger.

TM-86675 18

Page 27

TABLE 7

GAS SERVICE - BALL BEARING “A” CODE

MODEL

FT2-8 .1-1.0 .09-1.25 N/A 93000 1550

FT4-8 .25-2.5 .2-3.0 N/A 45000 2000

FT6-8 .5-5.0 .25-5.0 .4-5.0 24000 2000

FT8-8 .75-7.5 .4-8.0 .5-8.0 16000 2000

FT-08 1.0-10.0 .5-10 .75-10 12000 2000

FT-10 1.25 - 12.5 .6-15 1-15 9600 2000

FT-12 2-20 1-25 1.5-25 6000 2000

FT-16 5-50 1.5-60 2.5-60 2400 2000

STD RANGE

10:1 (ACFM)

RF & MAG

PICKOFF

EXTENDED

RANGE

(ACFM)

RF

PICKOFF

EXTENDED

RANGE

(ACFM)

MAG

PICKOFF

NOMINAL

K FACTOR

PULSE / ACF

MAX

FREQ.

(HZ)

FT-20 9-90 2.5-100 5-100 1300 1950

FT-24 15-150 4-160 6-160 600 1500

FT-32 22-220 5-250 8-250 350 1300

FT-40 40-400 9-450 10-450 180 1200

FT-48 65-650 N/A 15-750 75 812

FT-64 125-1250 N/A 30-1500 30 625

FT-96 300-3000 N/A 70-3500 9.0 467

FT128 550-5500 N/A 120-6000 4.0 325

FT160 850-8500 N/A 200-10000 2.0 240

FT192 1200-12000 N/A 300-15000 1.0 167

Notes:

1. Gas service - Air @ 14.7 PSIA and 60 F.

2. Repeatability = +/- .1%.

3. Linearity = +/- 1.0% of full scale based on standard 10:1 range.

4. MAG Pickoff not applicable for FT2-8.

5. MAG Pickoff range is .35 - 2.5 ACFM for FT4-8.

6. Linearity for FT2-8 is 4% of full scale.

7. RF Pickoff not applicable for meter sizes FT-48 and larger.

TM-86675 19

Page 28

NOTE: 1” NPT enclosure connection is standard on FT-16

and larger wafer meters. Meters smaller than FT-16 will

have pickoff connection only.

Figure 1

MODEL

NO.

PREFIX

FT2-8

FT4-8

FT6-8

FT8-8

FT-08

FT-10

FT-12

FT-16

FT-20

FT-24

FT-32

FT-40

FT-48

FT-64

FT-96

FT128

FT160

FT192

NOMINAL

END

FITTING

(INCH)

½

½

½

½

½

¾

¾

1

1 ¼

1 ½

2

2 ½

3

4

6

8

10

12

150 #

A B

5.00

5.00

5.00

5.00

5.00

5.50

5.50

5.50

6.00

6.00

6.50

7.00

10.00

12.00

14.00

16.00

20.00

24.00

Figure 4. Dimensions

WAFER – STANDARD LINE

MODEL

NO.PREFIX

NOMINAL END

FITTING (INCH)

A B

FT2-8 1/2 1.88 1.38

FT4-8 1/2 1.88 1.38

FT6-8 1/2 1.88 1.38

FT8-8 1/2 1.88 1.38

FT-08 1/2 1.88 1.38

FT-10 3/4 1.94 1.69

FT-12 3/4 1.94 1.69

FT-16 1 2.50 2.00

FT-20 1 1/4 2.50 2.50

FT-24 1 1/2 2.50 2.88

FT-32 2 3.00 3.63

FT-40 2 1/2 5.25 4.13

FT-48 3 5.75 5.00

FT-64 4 5.00 6.18

FT-96 6 6.13 8.50

3.50

3.50

3.50

3.50

3.50

3.88

3.88

4.25

4.63

5.00

6.00

7.00

7.50

9.00

11.00

13.50

16.00

19.00

300 #

A B

5.00

3.75

5.00

3.75

5.00

3.75

5.00

3.75

5.00

3.75

5.50

4.63

5.50

4.63

5.50

4.88

6.00

5.25

6.00

6.13

6.50

6.50

7.00

7.50

10.00

8.25

12.00

10.00

14.00

12.50

16.00

15.00

20.00

17.50

24.00

20.50

600 #

A B

5.00

3.75

5.00

3.75

5.00

3.75

5.00

3.75

5.00

3.75

5.50

4.63

5.50

4.63

5.50

4.88

6.00

5.25

6.00

6.13

6.50

6.50

9.00

7.50

10.00

8.25

12.00

10.75

14.00

14.00

16.00

16.50

20.00

20.00

24.00

22.00

900 #

A B

7.00

4.75

7.00

4.75

7.00

4.75

7.00

4.75

7.00

4.75

5.50

5.13

7.00

5.13

8.00

5.88

8.00

6.25

9.00

7.00

9.00

8.50

9.00

9.63

10.00

9.50

12.00

11.50

14.00

15.00

16.00

18.50

20.00

21.50

24.00

24.00

1500 #

A B

7.00

4.75

7.00

4.75

7.00

4.75

7.00

4.75

7.00

4.75

5.50

5.13

7.00

5.13

8.00

5.88

8.00

6.25

9.00

7.00

9.00

8.50

9.00

9.63

10.00

10.50

12.00

12.25

14.00

15.50

16.00

19.00

20.00

23.00

24.00

26.50

2500 #

A B

7.00

5.25

7.00

5.25

7.00

5.25

7.00

5.25

7.00

5.25

7.00

5.50

7.00

5.50

8.00

6.25

8.00

7.25

9.00

8.00

9.00

9.25

10.00

10.50

10.00

12.00

12.25

14.00

14.00

19.00

16.00

21.75

20.00

26.50

24.00

30.00

TM-86675 20

Page 29

10.0 PERIODIC MAINTENANCE

Maintenance of the Standard Line Flowmeter consists of periodic inspections to insure that the internal

parts have not suffered any corrosion or incrustation by measuring fluid. Should the assembly be

damaged, it should be returned to the factory for exchange or repair.

10.1 Inspection Cleaning and Storage

For inspection and cleaning of internal parts, the rotor and support assembly may be withdrawn from the

housing. The rotor support assembly and the housing may be cleaned with appropriate solvent or

alcohol. If liquid flowmeters are to be stored or out of service for an extended period, it should be

dipped in a light rust proofing preservative or machine oil and capped. Gas flowmeters should be

cleaned and capped to prevent dust or foreign materials.

C A U T I O N

Service for some fluids may require special

cleaning procedures before installation.

Please consult fluid manufacturer and/or

use industry accepted procedures.

One of the largest single sources of poor turbine meter performance is foreign material buildup on

bearings whether they are journal type or ball type. It is recommended that whenever possible, the

turbine meter be thoroughly flushed with an appropriate solvent immediately after use. The solvent

should be chemically neutral, and highly volatile so that complete drying can take place soon after the

flushing operation. Some appropriate solvents would be ethyl alcohol or stoddard solvent.

All turbine flowmeters include some type of bearing for supporting its rotor. The standard line

flowmeter is normally equipped with ball bearings, but journal bearings fabricated of tungsten carbide,

ceramic, epoxy impregnated graphite and other non-metallic materials are also available. If the bearings

in the flowmeter become damaged or worn, the meter should be sent to the factory for bearing

replacement. If this is not possible, a bearing replacement kit is available for most models. All bearings

are not field replaceable. Consult the factory and describe the particular flowmeter before ordering a

bearing replacement kit.

TM-86675 21

Page 30

10.2 Removing Internals

There are several variations of the basic turbine flowmeter design. This section will explain the general

procedure for disassembling Flow Technology, Inc. turbine flowmeters. Refer to the following sections

for detailed instructions on disassembly of specific flowmeters.

CAUTION

Observe flow direction markings carefully. Some of the internal parts are symmetrical

and may fit and function forward and reverse. The calibration will shift due to variations

in the rotor blade edges and the degree of bend in the support trim tabs if installed

incorrectly.

Before removing the housing retaining ring note the orientation of the retaining ring, the

hook on the retaining ring prevents the support/spacer from spinning.

1. Familiarize yourself with the figure applicable to your model before proceeding.

2. Remove the upstream retaining ring, note the orientation.

3. Insert a plastic rod into the downstream end of the meter and gently press against the

downstream support. Select a large enough rod so that it cannot accidentally slip past

the support vanes and impact the rotor. Gently slide the internal assembly out of the

housing being careful not to drop any of the internal parts as they clear the housing.

Maintain compression between the supports to insure that the internals remain

assembled until you have noted the flow direction markings on the supports and the

rotor.

4. Locate the flow direction of the supports and the rotor. The downstream side of the

rotor will have two small marks which are typically hand scribed on the hub. If the

marks are not clear, remark the rotor to assure correct re-assembly. If you use a

marking pen or pencil, be aware that your markings may be removed during cleaning.

5. Spin the rotor slowly, and note any signs of scoring, wobble, damaged or bent blades.

Replace the rotor if it shows any signs of damage.

Important: Do not straighten the tabs

are trim tabs used to improve meter performance. Altering the tab angle will

cause a shift in the K-factor.

6. Clean or replace parts as necessary.

7. Reverse procedure to reinstall. Insure that the flow direction arrow on the internals

match the flow direction arrow on the housing when the internals are reinstalled.

on the support adjacent to the rotor. These

TM-86675 22

Page 31

10.3 General Handling Techniques

1. All work with bearings should be done in a clean, dry, dust and static free area.

2. Consider all foreign materials to be abrasive, corrosive or otherwise destructive.

3. Verify that the shaft and rotor have been cleaned and are free of oil, contamination and

burrs.

4. Keep all bearings in their original unopened packages until ready for installation.

Remove the bearings from their protective packages one at a time, as required.

5. The bearings should be handled with tweezers or other special non-magnetic tools.

6. Never touch high precision bearings with fingers unprotected by finger cots or lint free

gloves.

7. Seat the bearing squarely and apply even pressure to the race making contact. ( See

Figure 5 )

8. When installing a bearing in the rotor apply pressure to the outer race.

9. When installing a bearing onto a shaft, apply pressure to the inner race.

10. Never transfer force between the outer and inner races, or damage could result and

cause increased friction, increased torque, and shortened bearing life.

11. Shock or impact techniques

should never be used to seat

the bearing.

12. Installing the small retaining

rings requires a quality pair

of sharp tweezers and good

dexterity. The bearing

retaining rings are under

spring tension and can easily

shoot out while removing or

installing. Wear eye

protection.

Figure 5. Bearing Seating

TM-86675 23

Page 32

10.4 Ball Bearing Replacement

Ball bearings may be replaced in the field by the customer without significantly changing the flowmeter

performance, provided the downstream orientation of the rotor is maintained. Complete replacement sets

of calibrated internals are also available.

10.4.1 Ball Bearing Replacement For:

Liquid Models: FT4-8

Gas Models Bearing Code H: FT-10; FT-12

Refer to Figures 7, 11

1. Remove the retaining ring (2) from either end of the flowmeter housing, note the orientation.

2. Gently slide the flowmeter rotor support assembly out of the housing, being careful

not to drop any of the internal parts as they clear the housing.

3. Remove the downstream support (6) and the cone (7A) from the shaft (7B). Note on

the FT4-8 flanged meters there is an upstream and downstream spacer (8) between the

support (6) and the retaining ring (2).

4. Note that the rotor (7C) is marked on the downstream side with two lines on the rotor

hub.

5. Gently slide the rotor assembly from the shaft (7B).

6. Slide both bearings (10) and the bearing spacer (11) out of the rotor hub (7C).

7. Verify the retaining ring (9) is in good condition and seated in the center of the rotor.

8. Reverse steps 1 through 5 for re-assembly. Insure the flow direction arrow on the

internals match the flow direction arrow on the housing when the internals are

reinstalled. Insure the rotor (7C) is properly oriented with markings on the

downstream side.

TM-86675 24

Page 33

10.4.2 Ball Bearing Replacement For:

Liquid Models FT6-8; FT8-8; FT-08; FT-10; FT-12; FT-16; FT-20; FT-24

Gas Models

Bearing Code A & H:

Gas Models

Bearing Code A:

Refer to Figure 7, 8, 9, 10 & 12

1. Remove the retaining ring (2) from either end of the flowmeter housing, note the orientation.

2. Gently slide the flowmeter rotor support assembly out of the housing, being careful

not to drop any of the internal parts as they clear the housing.

3. Remove the downstream support (6) and cone (7A) from the shaft (7B). Note on the

flanged FT2-8 thru FT-08 meters there is an upstream and downstream spacer (8)

between the support (6) and the retaining ring (2).

4. Note that the rotor (7C) is marked on the downstream side with two lines on the rotor

hub.

5. Gently slide the rotor assembly from the shaft.

6. Remove the retaining ring (9) from the marked side of the rotor (7C) and slide both

bearings (10) and bearing spacer (11) out of the rotor hub.

Note: No bearing spacers (11) are present on liquid meter sizes FT6-8 through

FT-08. Gas meter models FT2-8 through FT-08 with bearing code H have only

one bearing and no spacer.

7. Install the two new ball bearings (10), spacer (11) as required, and retaining ring (9)

into rotor hub (7C).

8. Reverse steps 1 through 5 for re-assembly. Insure that the flow direction arrow on the

internals match the flow direction arrow on the housing when the internals are

reinstalled. Insure the rotor (7C) is properly oriented with markings on the downstream

side.

FT2-8; FT4-8; FT6-8; FT8-8; FT-08; FT-16; FT-20; FT-24

FT-10; FT-12

TM-86675 25

Page 34

10.4.3 Ball Bearing Replacement For:

Models (Liquid and Gas)

Bearing Code A & H

Refer to Figure 13

1. Remove the retaining ring (2) from either end of the flowmeter housing, note the orientation.

2. Gently slide the complete set of internals out of the housing, being careful not to drop

any of the internal parts as they clear the housing.

3. Remove support (6) from the shaft (7B).

4. Note that the rotor (7C) is marked on the downstream side with two lines on the rotor

hub.

5. Gently slide the rotor assembly from the shaft (7B).

6. Remove the retaining ring (9) from the marked side of the rotor (7C) and slide both

bearings (10) and bearing spacer (11) out of the rotor hub.

7. Install the two new ball bearings (10), spacer (11) and retaining ring (9) into the rotor

hub.

8. Reverse steps 1 through 5 for re-assembly. Insure that the flow direction arrow on the

internals matches the flow direction arrow on the housing when the internals are

reinstalled. Insure the rotor (7C) is properly oriented with markings on the

downstream side.

FT-32

TM-86675 26

Page 35

10.4.4 Ball Bearing Replacement For:

Models (Liquid and Gas)

Bearing Code A & H

Refer to Figure 14

1. Remove the retaining ring (5) from the upstream end of the flowmeter housing (1).

2. Gently slide the complete set of internals out of the housing, being careful not to drop

any of the internal parts as they clear the housing.

3. Remove one of the self-locking nuts (3), from one end of the shaft (7).

4. Remove support (4), cone (8), and spacer (11) or (9) from the shaft (7). Note wider

spacer (9) is on the downstream side.

5. Note that the rotor (6) is marked on the downstream side with two lines on the rotor

hub.

6. Gently slide the rotor assembly (6) and sleeve (14) from the shaft (7).

7. Remove the retaining ring (10) from the marked side of the rotor (6) and slide both

ball bearings (13) and bearing spacer (12) out of the rotor hub.

8. Install the two new ball bearings (13), spacer (12) and retaining ring (10) into the rotor

hub. Slide sleeve (14) back into the inside diameter of the ball bearings (13).

9. Reverse steps 1 through 6 for re-assembly. Insure that the flow direction arrow on the

internals matches the flow direction arrow on the housing when the internals are

reinstalled. Insure the rotor (6) is properly oriented with markings on the downstream

side.

FT-40; FT-48; FT-64

TM-86675 27

Page 36

10.4.5 Ball Bearing Replacement For:

Model Liquid & Gas

Bearing Code A:

Refer to Figure 15

1. Remove the retaining ring (5) from the upstream end of the flowmeter housing (1).

2. Remove the self-locking nut (3) and washer (15) from the upstream end of the shaft (7).

3. Remove the upstream support (4), cone (8) and spacer (11) from the shaft (7).

4. Gently pull the shaft (7) out from the downstream end of the housing (1) until it

passes through the rotor assembly (6).

5. Gently remove the rotor assembly (6) and sleeve (14) from the upstream end of the

housing (1).

6. Note that the slots on the outside ring of the rotor (6) are on the downstream side.

7. Remove the bearing retaining ring (10) from the downstream side of the rotor (6)

and slide both ball bearings (13) and the center spacer (12) out of the rotor hub.

8. Install the new ball bearings (13) and spacer (12) in the rotor hub (6) and secure

with bearing retaining ring (10).

9. Slide the rotor assembly (6) and sleeve (14) onto the shaft (7), for rotors with rings

make sure the teeth are facing downstream.

10. Slide the spacer (11), cone (8), upstream support assembly (4), and washer (15)

onto the shaft (7).

11. Tighten the self-locking nut (3) on the upstream end of the shaft (7).

12. Install the retaining ring (5) in the housing.

FT-96

TM-86675 28

Page 37

10.4.6 Ball Bearing Replacement For:

Model Liquid & Gas

Bearing Code A:

Refer to Figure 16

1. Remove the retaining ring (5) from the upstream end of the flowmeter housing (1).

2. Remove the self-locking nut (3) and washer (15) from the upstream end of the shaft (7).

3. Remove the upstream support (4), cone (8) and spacer (9) from the shaft (7).

4. Gently pull the shaft (7) out from the downstream end of the housing (1) until it

passes through the rotor assembly (6).

5. Gently remove the rotor assembly (6) from the upstream end of the housing (1).

6. Note that the slots on the outside ring of the rotor (6) are on the downstream side.

7. Remove the bearing retaining ring (10) from the downstream side of the rotor (6)

and slide both ball bearings (13) and the center spacer (12) out of the rotor hub.

8. Install the new ball bearings (13) and spacer (12) in the rotor hub (6) and secure

with bearing retaining ring (10).

9. Slide the rotor assembly (6) onto the shaft (7), making sure the teeth on the ring are

on the downstream side.

10. Slide the spacer (9), cone (8), upstream support assembly (4), and washer (15) onto

the shaft (7).

11. Tighten the self-locking nut (3) on the upstream end of the shaft (7).

12. Install the retaining ring (5) in the housing.

FT-128

TM-86675 29

Page 38

10.4.7 Ball Bearing Replacement For:

Model Liquid & Gas

Bearing Code A:

Refer to Figure 17

1. Remove the retaining ring (5) from the upstream end of the flowmeter housing (1).

2. Remove the self-locking nut (3) from the upstream end of the shaft (7).

3. Remove the upstream support assembly (4) and spacer (11) from the shaft (7).

4. Gently pull the shaft (7) out from the downstream end of the housing (1) until it

passes through the rotor assembly (6).

5. Gently remove the rotor assembly (6) and sleeve (14) from the upstream end of the

housing (1).

6. Note that the slots on the outside ring of the rotor (6) are on the downstream side.

7. Remove the bearing retaining ring (10) from the downstream side of the rotor (6)

and slide both ball bearings (13), the center spacer (12), wave spring (16), and

spacers (17) out of the rotor hub.

8. Install the new ball bearings (13), spacer (12), wave spring (16) and spacers (17) in

the rotor hub (6) and secure with bearing retaining ring (6).

9. Slide the rotor assembly (6) and sleeve (14) onto the shaft (7), making sure the teeth

on the ring are on the downstream side.

10. Slide the spacer (11) and upstream support assembly (4) onto the shaft (7).

11. Tighten the self-locking nut (3) on the upstream end of the shaft (7).

12. Install the retaining ring (5) in the housing.

FT-192

TM-86675 30

Page 39

10.5 Journal Bearing Replacement

Flow Technology, Inc. has bearing replacement kits available for turbine flowmeters equipped with

journal bearings. The use of a replacement kit will allow the customer to repair the flowmeter in the

field. To maintain accuracy it is necessary that the meter be recalibrated or the entire internal assembly

be replaced with a compete set of calibrated internals. Journal bearings have the same basic design as

their ball bearing counterparts, however, instead of removable ball bearings with spacers and retaining

rings, the journal bearings are pressed into the rotor and utilize a special cone (or washer) for a thrust

surface. The procedure for removing and inserting the internal assembly from the flowmeter housing is

the same for journal and ball bearing flowmeters.

10.5.0.1 Replacement Kits

The part numbers for replacement rotating assembly kits can be obtained from the parts list in this

manual. Complete sets of calibrated internals are available and strongly recommended over replacing

only the rotating assembly. Complete calibrated internals can be ordered by specifying the flowmeter

model and serial number.

10.5.0.2 Self-Lubricating Bearings

For epoxy impregnated graphite and non-metallic (Teflon, Torlon, etc.) journal bearings, the

replacement kit consists of a journal bearing, rotor and shaft assembly (includes a sleeve on FT-32) that

replaces the existing rotor subassembly. The rotor, journal bearing, and shaft comprise a factory

matched set of components designed for a specific flowmeter.

10.5.0.3 Carbide and Ceramic

The replacement kits for tungsten carbide or ceramic journal bearings on the FT-24 and smaller meters

consist of a journal bearing, shaft, rotor and cone assembly. The upstream and downstream cones have

carbide or ceramic thrust washers installed. These are factory-matched components. Replacement

rotating assembly kits are not available for FT-32 meters. Contact factory for replacement of complete

internals. The replacement kits for tungsten carbide and ceramic journal bearings for FT-40 and larger

meters consist of a journal bearing, rotor, sleeve and thrust washers. These are factory-matched

components.

TM-86675 31

Page 40

10.5.1 Journal Bearing Replacement For:

Model: FT-24 and smaller

Journal Material: Graphite (and other self-lubricating materials)

Refer to Figures 20 and 21

1. Remove the retaining ring (2) from the upstream end of the housing (1), note the orientation.

2. Gently slide the flowmeter rotor support assembly out of the housing being careful not

to drop any of the internal parts as they clear the housing. FT4-8 thru FT-08 will have

support spacers.

3. Remove the upstream support (6) and cone assembly (15A) from the shaft (15B). This

is a close tolerance fit and may require twisting the supports to free the shaft.

4. Remove shaft (15B) and rotor assembly (15C) from the downstream support (6) and

cone assembly (15A).

5. Install the new rotor (15C) and journal bearing assembly (15D) into the downstream

support (6) and cone assembly (15A). Observe the downstream marking on the rotor.

The flange of the journal bearing marks the downstream side of the rotor on the FT-16

and larger.

6. Install the upstream support (6) and cone assembly (15A) on the new rotor assembly.

7. Install the completed assembly into the flowmeter housing by inserting the downstream

support in accordance with the flow direction arrow on the housing.

8. Install the upstream retaining ring (2) (same orientation before removing) and check to make sure

that the rotor (15C) rotates in the housing.

TM-86675 32

Page 41

10.5.2 Journal Bearing Replacement For:

Model: FT-24 and smaller

Journal Material: Ceramic and Tungsten Carbide

Refer to Figures 18 and 19

1. Remove the retainer ring (2) from the upstream end of the housing (1), note the orientation.

2. Gently slide the flowmeter rotor support assembly out of the housing, being careful

not to drop any of the internal parts as they clear the housing. FT4-8 thru FT-08 will

have support spacers.

3. Remove both support (6) and cone assemblies (7A) from the shaft (7B). This is a close

tolerance fit and may require twisting the supports to free the shaft.

4. Install cone assemblies (7A) into both supports (6).

5. Install rotor (7C) and journal bearing assembly (7D) in the downstream support (6)

and cone assemblies (7A).

6. Install upstream support (6) and cone assemblies (7A) on the new rotor assembly

(7C).

7. Install the completed assembly into the flowmeter housing by inserting the downstream

support in accordance with the flow direction arrow on the housing.

8. Install the upstream retaining ring (2) (same orientation before removing) and check to make sure

that the rotor (7C) rotates in the housing.

TM-86675 33

Page 42

10.5.3 Journal Bearing Replacement For:

Model: FT-32

Journal Material: Graphite (and other self-lubricating materials)

Refer to Figure 23

1. Remove the retaining ring (2) from the upstream end of the housing (1), note the orientation.

2. Gently slide the complete set of internals out of the housing, being careful not to drop

any of the internal parts as they clear the housing.

3. Remove the upstream support (6) from the shaft (14).

4. Remove the rotor assembly (15C) from the shaft (14).

5. Install rotor (15C) and journal bearing assembly (15D) on the shaft (14). Observe the

downstream marking on the rotor. The flange of the journal bearing (15D) marks the

downstream side of the rotor.

6. Install the support (6) on the shaft (14).

7. Install the completed assembly into the flowmeter housing by inserting the downstream

support in accordance with the flow direction arrow on the housing.

8. Install the upstream retaining ring (2) (same orientation before removing) and check to make sure

that the rotor (15C) rotates in the housing.

TM-86675 34

Page 43

10.5.4 Journal Bearing Replacement For:

Model: FT-32

Journal Material: Ceramic or Tungsten Carbide

Refer to Figure 22

1. Remove the retaining ring (2) from the upstream end of the housing (1), note the orientation.

2. Gently slide the complete set of internals out of the housing, being careful not to drop

any of the internal parts as they clear the housing.

3. Remove the upstream support (6) from the shaft (14).

4. Remove the rotor assembly (16C) from the shaft (14).

5. Install rotor (16C) and journal bearing assembly (16D) on the shaft (14). Observe the

downstream marking on the rotor.

6. Install the support (6) on the shaft (14).

7. Install the completed assembly into the flowmeter housing by inserting the downstream

support in accordance with the flow direction arrow on the housing.

8. Install the upstream retaining ring (2) (same orientation before removing) and check to make sure

that the rotor (16C) rotates in the housing.

TM-86675 35

Page 44

10.5.5 Journal Bearing Replacement For

Model: FT-40; FT-48; and FT64

Journal Material: Ceramic and Tungsten Carbide

Refer to Figure 24

1. Remove the retaining ring (5) from the upstream end of the housing (1).

2. Gently slide the complete set of internals out of the housing, being careful not to

drop any of the internal parts as they clear the housing.

3. Remove one of the self-locking nuts (3) from the end of the shaft (7).

4. Remove the upstream support (4) and cone (8) from the shaft (7).

5. Remove the sleeve (10), thrust washers (9), bearing (11) and rotor (6) from the

shaft.

6. Install rotor (6), journal bearing (11), thrust washers (9), and sleeve (10) on the

shaft against the downstream support (4) and cone (8). Observe the downstream

marking on the rotor. Insure that the groove on the thrust washers face the bearing.

7. Install the upstream support (4) and cone (8) on the shaft against the new rotor

assembly (6).

8. Tighten the self-locking nuts (3) on the end of the shaft (7).

9. Install the completed assembly into the flowmeter housing by inserting the

downstream support in accordance with the flow direction arrow on the housing.

10. Install the retaining ring (5) and check to make sure that the rotor (6) rotates in the

housing.

TM-86675 36

Page 45

10.5.6 Journal Bearing Replacement For:

Model: FT-96; and FT-128

Journal Material: Tungsten Carbide

Refer to Figures 25 and 26

1. Remove the retaining ring (5) from the upstream end of the flowmeter housing

(1).

2. Remove the self locking nut (3) and washer (15) from the upstream end of the

shaft (7).

3. Remove the upstream support (4), cone (8) and thrust washer (9) from the shaft

(7).

4. Gently pull the shaft (7) out from the downstream end of the housing (1) until it

passes through the rotor assembly (6).

5. Gently remove the rotor assembly (6), sleeve (10), and downstream thrust washer

(9) from the upstream end of the housing (1).

6. Note that the slots on the outside ring of the rotor (6) are on the downstream side.

7. Install rotor (6), journal bearing (11), thrust washers (9) and sleeve (10) on the

shaft against the downstream support (4) and cone (8). Insure the groove on the

thrust washers face the bearing.

8. Slide the support (4), cone (8) and washer (15) onto the shaft.

9. Tighten the self-locking nuts (3) on the end of the shaft (7).

10. Install the retaining ring (5) and check to make sure that the rotor (6) rotates in the

housing.

TM-86675 37

Page 46

10.5.7 Journal Bearing Replacement For:

Model: FT-192

Journal Material: Tungsten Carbide

Refer to Figure 27

1. Remove the retaining ring (5) from the upstream end of the flowmeter housing (1).

2. Remove the self-locking nut (3) from the upstream end of the shaft (7).

3. Remove the upstream support assembly (4) and thrust washer (9) from the shaft

(7).

4. Gently pull the shaft (7) out from the downstream end of the housing (1) until it

passes through the rotor assembly (6).

5. Gently remove the rotor assembly (6), sleeve (10), and thrust washer (9) from the

upstream end of the housing (1).

6. Note that the slots on the outside ring of the rotor (6) are on the downstream side.

7. Install rotor (6), journal bearing (11), spacer (9), thrust washer (9) and sleeve (10),

on the shaft against the downstream support assembly (4). Insure the groove on the

thrust washers face the bearing.

8. Slide the support assembly (4) onto the shaft (7).

9. Tighten the self-locking nuts (3) on the end of the shaft (7).

10. Install the retaining ring (5) and check to make sure that the rotor (6) rotates in the

housing.

TM-86675 38

Page 47

11.0 TROUBLESHOOTING GUIDE

The following guide shows some of the common problems that may occur during the operation of

turbine flowmeters. Various causes are given for each problem including a description of the cause and

the corrective action to be taken.

TABLE 8

Meter Reads High

Probable Cause Corrective Action

Line not full of fluid, gas

jetting through meter (liquid meter only).

Cavitation, fluid vaporizes as it slips over rotor blades

(liquid meter only).

Cavitation of the fluid as it passes through the meter.

Meter installed backwards. Check to see if the flow direction arrow on the

Internals installed backwards. Verify internals are installed properly.

Meter installed in different orientation than when

calibrated.

Flowmeter is not mated to proper electronics. Check data sheets and assemble system correctly.

Operating fluid has a different kinematic viscosity

than the original calibration.

Electronics picking up noise.

A.C. signals override flowmeter signals and are

detected as pulses.

Flange gasket is protruding in to flow stream creating

jetting.

Foreign material upstream or in flowmeter creating