Page 1

Electromagnetic Flow Meter

Owner’s Manual

http://flowmeternara.com/

Address: #910, KolonScienceValley2nd,

#811,Guro-dong,Guro-gu,Seoul,

Korea…………….

TEL: +82-2-2025-0562

FAX: +82-2-2025-0565

Manual No. 090820-4 Rev.A

Page 2

Content

1.0 GENERAL INFORMATION ...............................................................................................2

2.0 SPECIFICATIONS................................................................................................................4

3.0 MODEL AND SELECTION.................................................................................................5

4.0 CAUTIONS FOR INSTALLATION....................................................................................6

5.0 ELECTRICAL WIRING ......................................................................................................9

6.0 PROGRAMMING AND SETUP.......................................................................................... 9

7.0 TROUBLESHOOTING.......................................................................................................13

Copyright Reserved, DONGYANG Corporation 1

Page 3

1.0 GENERAL INFORMATION

This manual will assist you in installing, using and maintaining your DONGYANG flow meter.

It is your responsibility to make sure that all operators have access to adequate instructions

about safe operating and maintenance procedure.………………………………………………

Warning

For your safety, review the major warnings and cautions below before operating your

equipment.……………………………………………………………………………..

1. Use only fluids that are compatible with

the housing material and wetted components

of your meter.

2. When measuring flammable liquids,

observe precautions against fire or explosion.

3. When handling hazardous liquids, always

follow the fluids manufacturer’s safety

precautions.

4. When working in hazardous environments,

always exercise appropriate safety

precautions.

…………………………..

5. During meter removal, fluids may spill.

Follow the fluids manufacturer’s safety

precautions for clean up of minor spills.

…………………………..

6. When tightening the meter, use a

wrench only on the wrench flats. …………...

7. For best results, calibrate the meter at

least 1 time per year.……………………

Product Description

DONGYANG LDG electromagnetic flow meters are intended for fluid measurement in most

industries including water, wastewater, food and beverage, pharmaceutical and chemical.

……….

There are two basic components of DONGYANG electromagnetic flow meter: 1)The Detector,

which includes the flow tube, isolating liner and measuring electrodes, and 2) The Converter,

which is the electronic device responsible for signal processing, flow calculation, display and

output signals.

The materials of construction of the wetted parts (liner and electrodes) should be appropriate for

the specifications on the intended type of service. Review of the compatibilities consistent with

the specifications is recommended.

All DONGYANG’s electromagnetic flow meters are factory tested and calibrated. A calibration

certificate is included in the shipment of each meter.

Copyright Reserved, DONGYANG Corporation 2

Page 4

Unpacking and Inspection

Upon receipt, examine your meter for visible damage. The meter is a precision measuring

instrument and should be handled carefully. Remove the protective plugs and caps for a

thorough inspection. If any items are damaged or missing, contact DONGYANG.

Make sure the flow meter model meets your specific needs. For your future reference, it might

be useful to record this information on nameplate in the manual in case it becomes unreadable

on the meter.

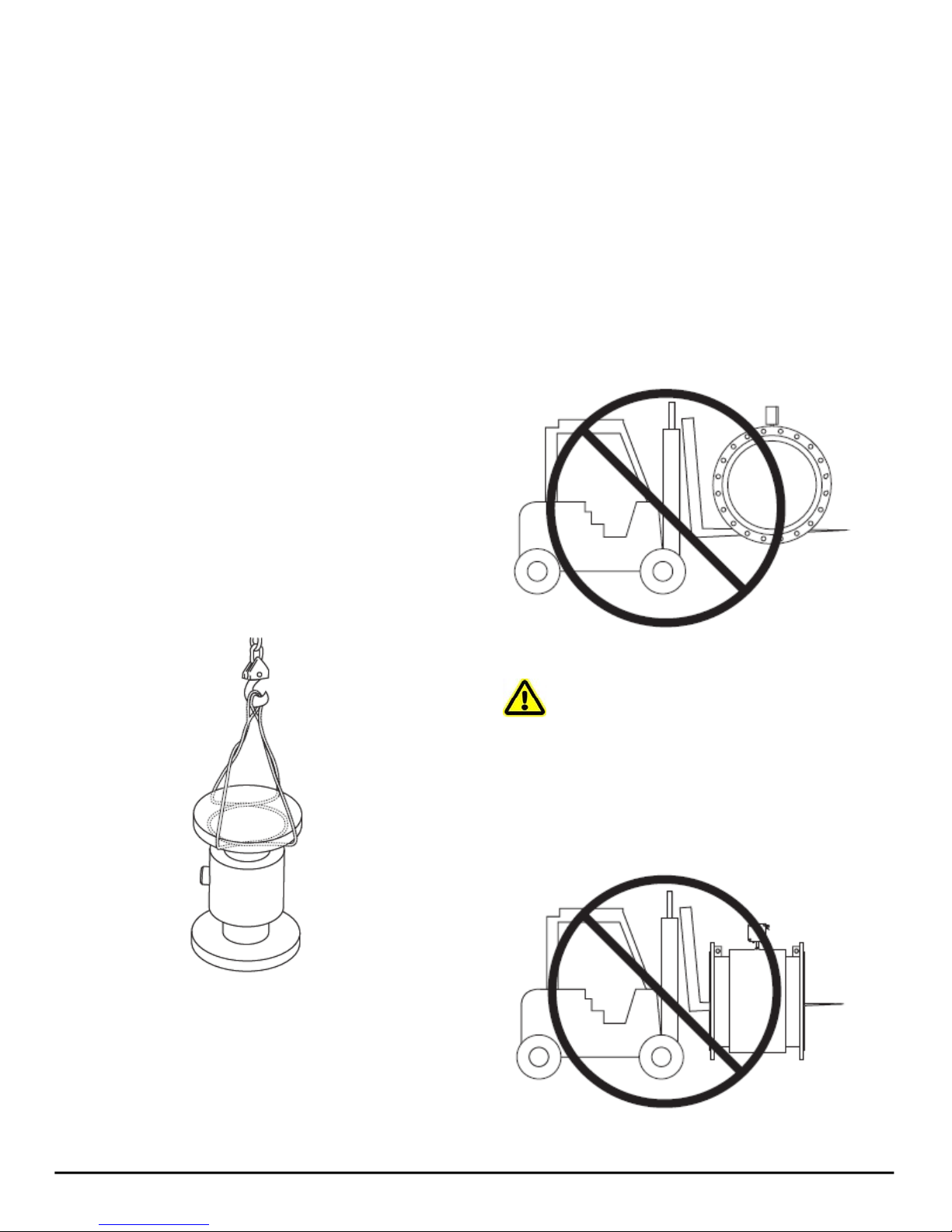

Transportation and Handling

Do not lift the detector from the Converter

housing, the junction box or the connecting

cable. Use lifting lugs for larger sizes is

recommended. Very large meter sizes are

packed and crated with the meter laying on

its side for shipping safety and stability

reasons. In order to lift the meter in vertical

position, it's recommended to use a sling

rigged method as shown below.

If using a forklift, do not lift the detector

from its body between the flanges. The

housing could be accidentally dented and

permanent damage could be caused to the

internal coil assemblies.

Warning: NEVER introduce the

forklift, chains, wire slings or any other

sharp object inside the flow tube for lifting

or handling purpose. This could permanently

damage the isolating liner and could render

the meter inoperable.

Copyright Reserved, DONGYANG Corporation 3

Page 5

2.0 SPECIFICATIONS

Converter:

Power Supply: 85-265Vac (Optional: 18-36

Vdc)

Power Consumption: 10W

Accuracy:

± 0.5% accuracy of rate from 0.5-10 m/s

± 1.0% accuracy of rate from 0.1-0.5 m/s

Repeatability: 0.2%

Minimum Fluid Conductivity:

5.0 micromhos/cm

Flow Direction: Unidirectional or

bidirectional, 2 separate totalizers

(programmable)

Analog Outputs: 4-20mA, 500ohms Max

Load

Output Frequency: Scaled Pulse output,

(open collector) Max 5Khz

Noise Damping: Programmable

Pulse Width: Programmable up to 500ms

Zero-point Stability: Automatic correction

Housing: Cast aluminum, powder coated

paint

Mounting: Integral mount or remote mount

Ambient Temperature: -4 to 140° F (-20 to

60° C)

Detector:

Flow Range: 0.03-10 m/s

Sizes: 10 to 2200 mm

Min. Conductivity: 5 micromhos/cm

Accuracy:

± 0.5% accuracy of rate from 0.5-10 m/s

± 1.0% accuracy of rate from 0.1-0.5 m/s

Electrode Materials:

Standard: 316 Stainless Steel

Optional: Tantalum

Liner Material: PTFE, FEP (Rubber)

Fluid Temperature:

PTFE: 100°C Standard (Customized: 180°C)

FEP: 60°C

Pressure Limits:

1.0 Mpa; Optional 1.6; 2.5; 4.0 Mpa

Coil Power: Pulsed DC

Ambient Temperature: -20°C to 60°C

Pipe Spool Material: 316 Stainless Steel

Meter Housing Material:

Carbon Steel welded

Flanges:

Carbon Steel - Standard (ISO 7005-1)

316 Stainless Steel - Optional

Optional Stainless Steel Grounding Rings

Measurable Flow Rate Range:

Note: The flow range as blow is for recommended use. Consult the factory if you have special

requirement.

Diameter (mm) 10 15 20 25 32 40 50 65

Qmin (m3/h) 0.08 0.34 0.34 0.53 0.87 1.35 2.1 3.5

Qmax (m3/h) 2 8 8 12 20 32 49 84

Diameter (mm) 80 100 125 150 200 250 300 350

Qmin (m3/h) 5.4 8.5 13 19 34 53 76 104

Qmax (m3/h) 127 197 310 445 791 1236 1780 2423

Diameter (mm) 400 450 500 550 600 700 800 900

Qmin (m3/h) 136 191 212 263 305 415 543 760

Qmax (m3/h) 3165 4294 4945 6322 7122 9693 12660 17634

Copyright Reserved, DONGYANG Corporation 4

Page 6

3.0 MODEL AND SELECTION

Model Selection (See Table 1)

Table 1. Model Selection Guidance

Model Suffix Code

LDG-

□ /□ /□ /□ /□ /□ /□ /□ /□

Description

Diameter

combination

Electrode

Material

Signal Output

Liner material

Display Unit

10-2200mm

S Integrated type

L

Remote type

M Stainless steel 316

T Ti

D Ta

H Hastelloy alloy

P Pt

N

Ni

0 No output

1

4-20mA/1-5KHz

X FEP

F

PTFE

0 No display unit

1

Display unit

Communication

Grounding Ring

Maximum Flow

Copyright Reserved, DONGYANG Corporation 5

0 No communication

1 RS485

2

MODBUS

0 No grounding ring

1

Grounding ring

Maximum flow

(n)

(measuring range) m

3

/h

Page 7

4.0 CAUTIONS FOR INSTALLATION

Mounting Positions

• Pipes must be fully filled with liquids. It

is essential that pipes remain fully filled

at all times, otherwise flow rate

indications may be affected and

measurement errors may be caused.

• Avoid Air Bubbles. If air bubbles enter

a measurement pipe, flow rate

indications may be affected and

measurement errors may be caused.

• Avoid all pipe locations where the flow

is pulsating, such as in the outlet side of

piston or diaphragm pumps.

• Avoid locations near equipment

producing electrical interference such as

electric motors, transformers, variable

frequency, etc.

• Install the meter with enough room for

future access for maintenance purposes.

• The mag meter isolating liner, whether

if it is PTFE or Rubber, is not intended

to be used as gasket material. Standard

gaskets (not provided) should be

installed to ensure a proper hydraulic

seal. When installing the gaskets, make

sure they are properly centered to avoid

flow restriction or turbulence. Do not

use graphite or any electrically

conductive sealing compound to hold

the gaskets in place during installation.

This could affect the reading accuracy

of the measuring signal.

Warning: Precaution for direct sunshine and rain when the meter is installed outside.

Required Lengths of Straight Runs

For optimum accuracy performance, it is required to provide sufficient inlet and outlet straight

pipe runs. An equivalent to 3 diameters of straight pipe is required on the inlet side, and 2

diameters on the outlet side. There are no special requirements for standard concentric pipe

reducers. See diagram1 for required straight runs when there is altering device.

Diagram 1. Required straight runs

Copyright Reserved, DONGYANG Corporation 6

Page 8

Special Notice

♦ When the meter contains removable coverplates. Leave the coverplate installed unless

accessory modules specify removal. Don’t remove the coverplates when the meter is

powered, or electrical shock and explosion hazard can be caused.

Flange Connections

The flange follows GB/T 9119-2000 (ISO 7005-1) RF (Raised Face).

Note: flange can be customized following other criterias.

Use a gasket between the meter flange and mating flange. Determine the material of the gasket

based on the operating conditions and type of fluid.………………………………………….

Note: Do not over tighten the flange bolts. This may cause the gasket to be compressed into the

flow stream and may decrease the accuracy of the meter.

Installation Dimensions

See Figure 1 and Table 2 for detailed dimensions.

Figure 1: Drawings for Integrated/Remote Electromagnetic Flow Meter

Copyright Reserved, DONGYANG Corporation 7

Page 9

Table 2. Dimensions (Unit: mm)

Diameter DN a D Do n × Φ A

10 230 90 60 4 × 14

15 230 95 65 4 × 14

20 230 105 75 4 × 14

25 230 115 85 4 × 14

32 230 140 100 4 × 18

40 230 150 110 4 × 18

50 230 165 125 4 × 18

65 230 185 145 8 × 18

80 230 200 160 8 × 18

100 230 220 180 8 × 18

125 280 245 210 8 × 18

150 280 285 240 8 × 22

200 310 340 295 12 × 22

250 360 405 355 12 × 22

300 460 460 410 12 × 22

350 460 520 470 16 × 22

400 460 580 525 16 × 26

450 460 640 585 20 × 26

500 600 715 650 20 × 26

600 600 840 770 20 × 30

700 700 895 840 24 × 33

800 800 1015 950 24 × 33

900 900 1110 1050 28 × 33

1000 1000 1230 1160 28 × 36

1200 1200 1405 1340 32 × 33

1400 1400 1630 1560 36 × 36

1600 1600 1830 1760 40 × 36

1800 1800 2045 1970 44 × 39

2000 2000 2265 2180 48 × 42

2200 2200 2405 2315 52 × 45

Copyright Reserved, DONGYANG Corporation 8

Page 10

5.0 ELECTRICAL WIRING

Warning: Electrical Hazard

Disconnect power before beginning installation.

Terminal Configuration

Electrical

L/+

Shock Hazard

N/-

I+

I -

F+

F -

Terminal Wiring

Warning: The mag flow meter is powered by EITHER 220Vac OR 24V DC. Please use

right power supply or maybe cause permanent damage on meter.

6.0 PROGRAMMING AND SETUP

The display panel comes preprogrammed from the factory and in most instances will not require

any additional manipulation. However, if you will be using the flow signal outputs or need to

reprogram the meter to suit your particular needs, it will be necessary to familiarize yourself

with the programming procedures.

Figure 2. Enter Parameter and Display Panel Illustration

Copyright Reserved, DONGYANG Corporation 9

Page 11

Figure 3. Detailed Illustration for Menu - Basic

Copyright Reserved, DONGYANG Corporation 10

Page 12

Figure 4. Detailed Illustration for Menu - System

Copyright Reserved, DONGYANG Corporation 11

Page 13

Figure 5. Detailed Illustration for Menu – Calibration

Notice: The Menu - Detail is only for factory programming, and it’s not permitted for user to

change these setting in Menu – Detail.

…………………………………...

Copyright Reserved, DONGYANG Corporation 12

Page 14

7.0 TROUBLESHOOTING

Symptom Probable Cause Solution

Measurement is not

accurate

Flow rate indication

is unstable

No Display

1. Parameter wrong

Check the parameters (Transmitter,

K-factor and size)

2. Pipe is not fully filled Check if meter is fully filled

Make sure meter is properly

1. Grounding issue

grounded to a good earth ground

Make sure fluid does not contain air

2. Air

bubbles

Make sure Converter is not too

3. Converter location – outside

close to sources of electrical

electrical interference

interference

1. No power Apply correct power

2. Incorrect power Check power value

Check power input/output

3. Wiring connections

connections

4. Fuse blown Replace fuse

Copyright Reserved, DONGYANG Corporation 13

Page 15

Limited Warranty Policy

DONGYANG hereby provides a limited warranty against defects in materials and

workmanship. This product includes a 1-year warranty. The warranty period shall begin on the

date of the original new equipment purchase. Warrantor’s obligation hereunder shall be limited

to repairing defective workmanship or replacing or repairing any defective parts.。。

In the event Purchaser believes the DONGYANG product is defective, the product must be

returned to DONGYANG, transportation prepaid by Purchaser, within the appropriate warranty

period relative to the product. If DONGYANG’s inspection determines the workmanship or

materials are defective and the required maintenance has been performed and, has been properly

installed and operated, the product will be either repaired or replaced, at DONGYANG’s sole

determination, free of additional charge, and the goods will be returned, transportation paid by

DONGYANG, using a transportation method selected by DONGYANG.…

Prior to returning the product to DONGYANG, Purchaser must obtain a Returned Material

Authorization (RMA) Number from DONGYANG’s Customer Service Department within 30

days after discovery of a purported breach of warranty, but not later than the warranty period;

otherwise, such claims shall be deemed waived.

If DONGYANG’s inspection reveals the DONGYANG product to be free of defects in material

and workmanship or such inspection reveals the goods were improperly used, improperly

installed, and/or improperly selected for service intended, DONGYANG will notify the

purchaser in writing and will deliver the goods back to Purchaser upon receipt of Purchaser's

written instructions and agreement to pay the cost of transportation. If Purchaser does not

respond within thirty (30) days after notice from DONGYANG, the goods will be disposed of in

DONGYANG’s discretion.

DONGYANG does not warrant the product to meet the requirements of any safety code or other

jurisdiction, and Purchaser assumes all risk and liability whatsoever resulting from the use

thereof, whether used singlely or in combination with other machines or apparatus.

This warranty shall not apply to any DONGYANG product or parts thereof, which have been

repaired outside DONGYANG’s factory or altered in any way, or have been subject to misuse,

negligence, or accident, or have not been operated in accordance with DONGYANG’s printed

instructions or have been operated under conditions more severe than, or otherwise exceeding,

FOR NON-WARRANTY REPAIRS OR CALIBRATIONS, consult DONGYANG for current

repair/calibration charges. Have the following information available BEFORE contacting

DONGYANG:

1. P.O. number to cover the COST of the repair/calibration,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to the product.

Copyright Reserved, DONGYANG Corporation 14

Loading...

Loading...