Page 1

EchoWave®

Guided Wave Liquid Level Transmitter

LG10 & LG11 Series Manual

Flowline, Inc. | 10500 Humbolt Street, Los Alamitos, CA 90720 p 562.598.3015 f 562.431.8507 w flowline.com MN300840 REV A10

Page 2

Introduction / Table of Contents Step One

EchoWave

®

utilizes TDR (Time Domain Reflectometry) technology. It is best described as low-energy, highfrequency electromagnetic impulses, generated by the sensor’s circuitry that is propagated along the probe as

it is immerged in the liquid to be measured. Impulses hit the surface of the media and part of the impulse

energy is reflected back up the probe to the circuitry. Level Measurement is calculated from the time difference

between the impulses sent and the impulses reflected. The sensor analyzes the level output as a continuous

measurement reading from its analog output. TDR-Sensors are also known as Guided Radars or Guided Wave

Radars (GWR).

NEW FEATURES

Precise continuous level measurement in one device

Complete galvanic insulation of device electronics from its inputs/outputs and the tank potential (no

problems with electrochemical corrosion protection)

Highly robust measurement due to 3-wire design, innovative signal analysis and disturbance signal

suppression

TABLE OF CONTENTS

Introduction: ...................................................................................................................... 2

Specifications: .................................................................................................... 3-4

Dimensions: .......................................................................................................... 5

About this Manual: ................................................................................................ 6

Getting Started (Setup Overview): .................................................................................... 7

Part Numbers: ....................................................................................................... 8

Probe Length: ....................................................................................................... 9

Measurement Range: ......................................................................................... 12

Distance (Height of Liquid) vs. Volume of Liquid: ............................................... 14

Installation (Mounting Considerations): .......................................................................... 15

Installation Tips: ............................................................................................. 17-20

Wiring (Analog Output): .................................................................................................. 21

Common Wiring to Displays, Controllers & PLCs: ......................................... 23-24

Configuration: ................................................................................................................. 25

Step 1 – Install WebCal Software: ...................................................................... 26

USB Fob Interface: .................................................................................. 27

Step 2 – Measure the Tank: ................................................................................ 28

Step 3 - Sensor Configuration: ............................................................................ 29

Step 4 - Dimensional Entry: ................................................................................ 30

Step 5 - Tank Level Configuration: ..................................................................... 31

Step 6 - Write to Unit: .......................................................................................... 32

Empty Signal Scan: ........................................................................................................ 32

Appendix: ........................................................................................................................ 34

Echo Curve: ........................................................................................................ 34

Sensor Configuration: .................................................................................... 35-37

Volumetric Configuration: ............................................................................... 38-40

Tank Level Confirmation: .................................................................................... 41

Write to Unit: ....................................................................................................... 42

Cutting the Probe: .......................................................................................... 43-45

Troubleshooting: ................................................................................................ 47

Warranty: ....................................................................................................................... 48

| 2 MN300840 REV A10

Page 3

Introduction Step One

ELECTRICAL

Analog output: 4 to 20mA

Total load resistance: < 250Ω

Lower range value: 4.0mA (span 0%)

Upper range value: 20.0mA (span 100%)

Supply voltage: 10 to 30VDC (reverse-polarity protected)

Current consumption: <50mA at 24VDC

Start-up time: <6s

Cable terminals: Terminal block [wires 16 to 26 AWG (solid or stranded)]

MEASUREMENT

Reference condition: (dielectric constant [εr] =80, water surface, tank 01m, DN200 metal flange)

Accuracy: ±3mm

Repeatability: <2mm

Resolution: <2mm

Probe type:

Rod: 4mm

Cable: 4mm, type 7x19

Coaxial: 21.34mm (NPT ½", sch. 40)

Probe length [can be ordered in 5mm (0.2”) increments from the reference point]

Rod: 0.61 to 3.0m (2’ to 9.8’)

Cable: 1.0 to 5.5m (3.3’ to 18’)

Coaxial: 0.61 to 3.0m (2’ to 9.8’)

Probe loading

Rod: Maximum lateral load: 6Nm… (0.2kg at 3 m)

Cable: Maximum tensile load: 5kN

Coaxial: Maximum lateral load: 100Nm… (1.67kg at 6 m)

Top dead band: 100mm (4”)

Bottom dead band: 50mm (2”)

APPLICATION SPECIFICATIONS

Intended Installation:

Rod: Metallic tank or below grade concrete basin

Cable: Metallic tank or below grade concrete basin

Coaxial: Non-metallic, plastic, fiberglass or metallic tank or below grade concrete basin

Dielectric [εr] >1.8

Conductivity: No restrictions

Density: No restrictions

MN300840 REV A10 3 |

Page 4

Introduction Step One

APPLICATION SPECIFICATIONS (CONTINUED)

Process temperature

Rod: F: -40° to 302° C: -40° to 150°

Cable: F: -40° to 302° C: -40° to 150°

Coaxial: F: -40° to 266° C: -40° to 130°

Ambient temperature

Operation: F: -13° to 176° C: -25° to 80°C

Storage: F: -40° to 185° C: -40° to 85°C

Application pressure: -14.5 to 250 psi -1bar to 17.2bar

Rate of level change: 1”/s

MECHANICAL SPECIFICATIONS

Wetted materials:

Rod: 1.4404 / 316L, PEEK

Cable: 1.4401 / 316, PEEK

Coaxial: 1.4404 / 316L, PEEK

Housing materials

Housing rating: IP66, NEMA 4

Cable entries: Single cable entry ½” NPT

Cord grip: ½” NPT, Ferrite Bead included

Cord grip material: Nylon

Cord grip cable

Minimum size: 0.170” (4.3mm)

Maximum size: 0.450” (11.4mm)

Process mount: ¾”NPT (G)

Certification:

Compliance: CE: EN61326-1: 2013 & EN55011 Class A Group 1

CRN

RoHS

CSAus: UL Std. No 61010-3 (3rd edition) & CAN/CSA-C22.2 No. 61010-1-12

c

Aluminum alloy EN AC-AlSi9Cu3 (DIN EN 1706), epoxy

Housing body and cover:

spray coating (~70μm) other alloys and coatings on

request.

Cover o-ring: Silicone rubber (Elastosil R 750/50)

Screws; cover locking screw: 1.4301 / 304 external earth terminal

Screw: Tin plated stainless steel 1.4301 / 304

| 4 MN300840 REV A10

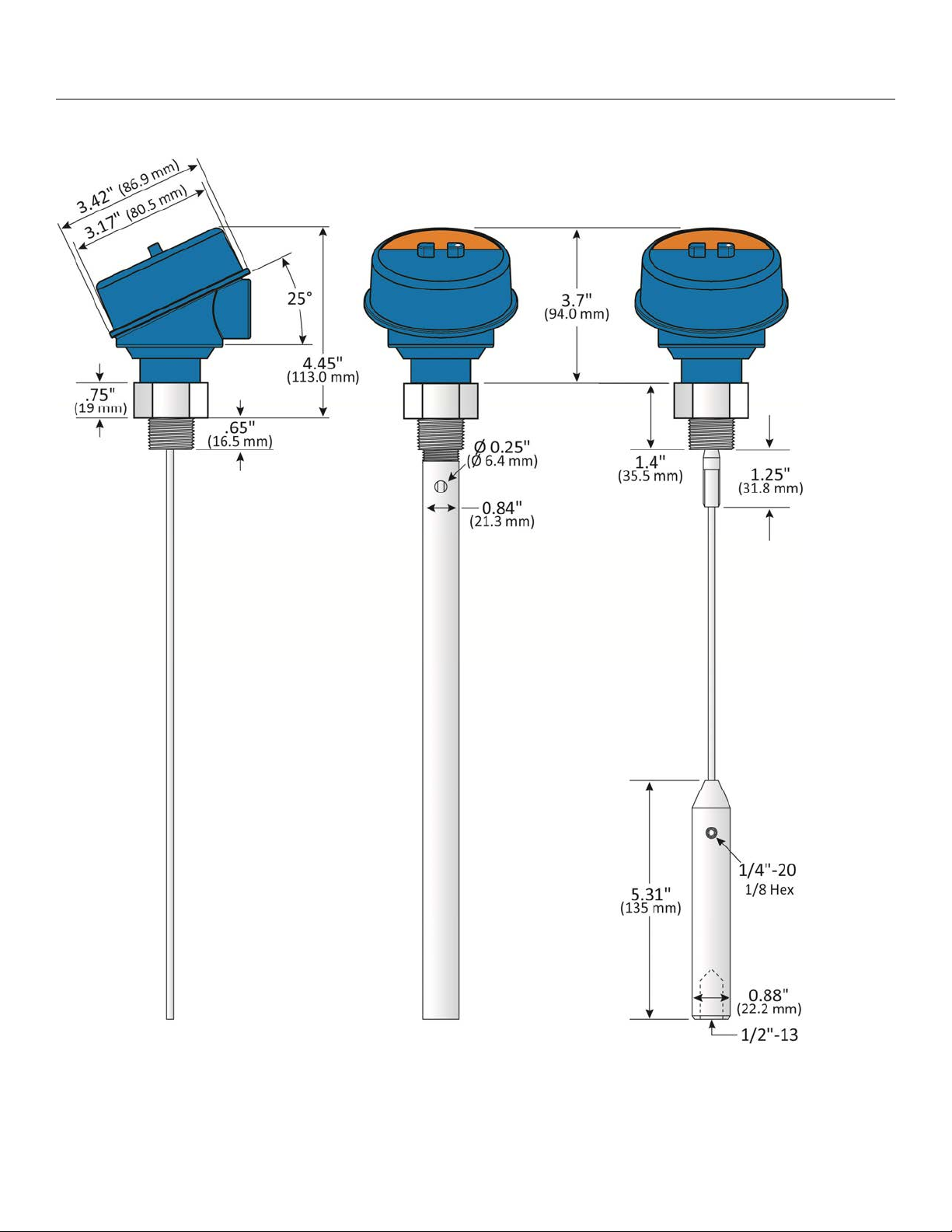

Page 5

Introduction Step One

DIMENSIONS

MN300840 REV A10 5 |

Page 6

Introduction Step One

About this Manual: PLEASE READ THE ENTIRE MANUAL PRIOR TO INSTALLING OR USING THIS

PRODUCT. This manual includes information on the EchoWave

from Flowline

®

. Please refer to the part number located on the switch label to verify the exact model

®

series Guided Wave Radar Level Transmitter

configuration, which you have purchased.

User’s Responsibility for Safety: Flowline® manufactures a broad range of level sensing technologies.

While each of these sensors is designed to operate in a wide variety of applications, it is the user’s

responsibility to select a sensor model that is appropriate for the application, install it properly, perform tests of

the installed system, and maintain all components. The failure to do so could result in property damage or

serious injury.

Proper Installation and Handling: Only professional staff should install and/or repair this product. Never

over tighten the sensor within the fitting. Always check for leaks prior to system start-up.

Wiring and Electrical: A supply voltage of 10 to 30 VDC is required to power the EchoWave®. Electrical

wiring of the transmitter should be performed in accordance with all applicable national, state, and local codes.

Material Compatibility: The enclosure is made of metal. Make sure that it is chemically compatible with

the application media.

Enclosure: While the sensor housing is liquid-resistant the EchoWave® is not designed to be operational

when fully immersed. It should be mounted to insure the enclosure does not come into contact with the

application media under normal operational conditions. The probe is designed for full liquid contact.

Note: If using the Flowline

®

LM90-1001 (liquid tight fitting) on the ½” conduit, the cable minimum is 0.170”

(4.3mm) and the maximum is 0.450” (11.4mm).

Handling Static-Sensitive Circuits/Devices: When handling the transmitter, the technician should follow

these guidelines to reduce any possible electrostatic charge build-up on the technician’s body and the

electronic part.

1. Always touch a known good ground source before handling the part. This should be repeated while

handling the part and more frequently after sitting down from a standing position, sliding across the seat

or walking a distance.

2. Avoid touching electrical terminals of the part unless making connections.

3. DO NOT open the unit cover until it is time to calibrate.

Make a Fail-Safe System: Design a fail-safe system that accommodates the possibility of switch and/or

power failure. Flowline

®

recommends the use of a redundant backup system and alarm in addition to the

primary system.

Flammable, Explosive or Hazardous Applications: The EchoWave® sensor is not certified for

application in a hazardous location.

| 6 MN300840 REV A10

Page 7

Getting Started Section Two

SETUP OVERVIEW

Below highlights the initial steps in setting up your sensor for operation.

1. Check Part Number (Section Two)

a. Confirm that the sensor’s part number matches the ordered part number and all components

are provided with the model delivered.

2. Measure Probe & Installation (Section Two)

a. Prior to installation, measure the length of the probe. Confirm that the probe length matches the

actual installation location.

b. If the probe length is too long, refer to Cutting the Probe in Section 8.

c. Understand the location of the sensor’s Measurement Range as well as Minimum Fill-Height

and Maximum Fill-Height settings.

3. Install the sensor (Section Three)

a. Section 3 contains information on the location and mechanical installation of the sensor.

4. Wire the sensor (Section Four)

a. Section 4 contains information on electrical wiring and power requirements for the sensor.

5. Configure Sensor with WebCal™ (Section Five)

a. Section 5 contains information on using the WebCal

®

configuration software.

6. Perform an Empty Scan (Section Six)

a. Section 6 contains information on how to run an empty scan.

b. An empty scan may not be required on a sensor that has a coaxial probe.

MN300840 REV A10 7 |

Page 8

Getting Started Section Two

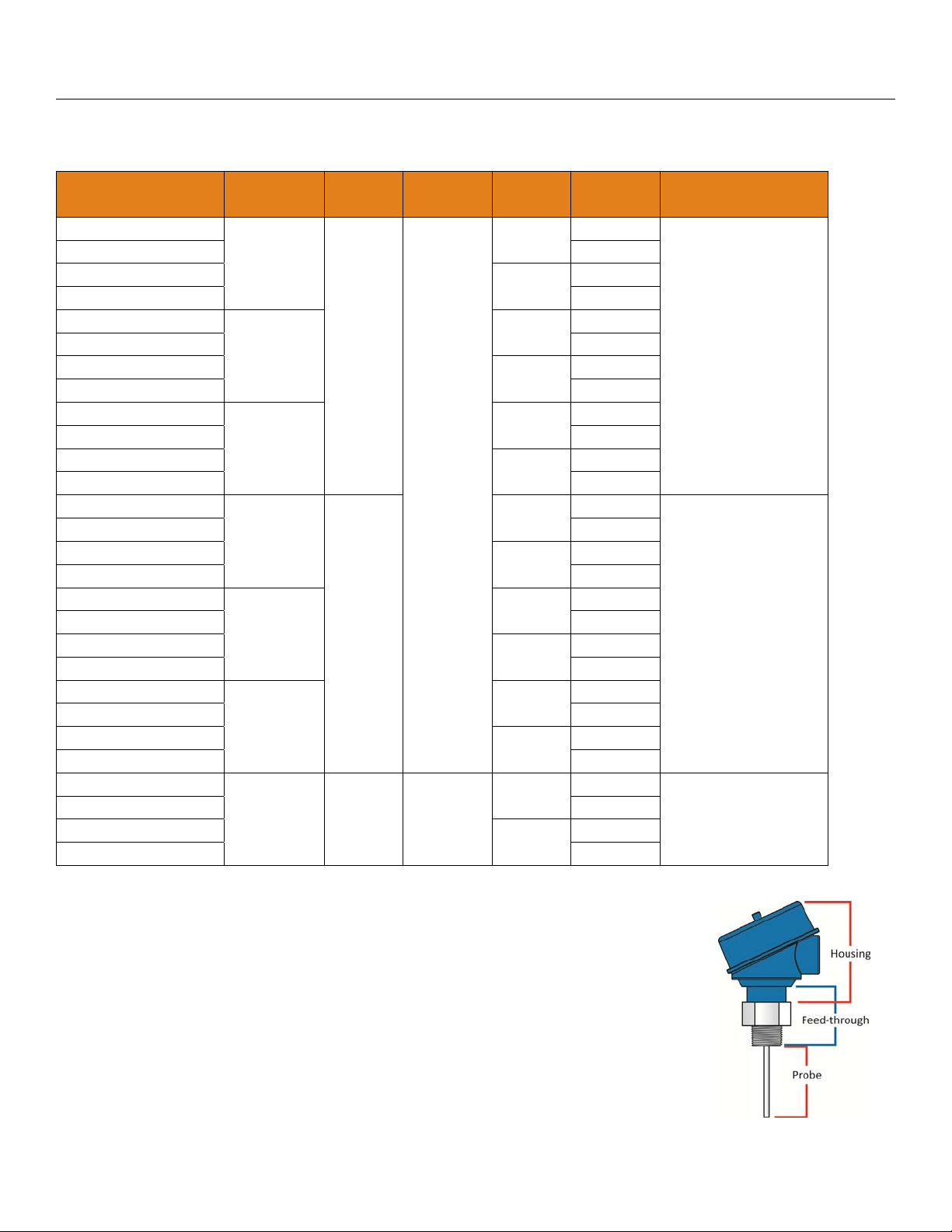

Components: EchoWave

®

is offered in 28 different models. Depending on the model purchased, you may or

may not have been shipped the configuration component shown below.

Part

Number

LG10-0003-00-036

LG10-0003-01-036 Yes

LG10-0013-00-036

LG10-0013-01-036 Yes

LG10-0003-00-072

LG10-0003-01-072 Yes

LG10-0013-00-072

LG10-0013-01-072 Yes

LG10-0003-00-118

LG10-0003-01-118 Yes

LG10-0013-00-118

LG10-0013-01-118 Yes

LG10-1003-00-036

LG10-1003-01-036 Yes

LG10-1013-00-036

LG10-1013-01-036 Yes

LG10-1003-00-072

LG10-1003-01-072 Yes

LG10-1013-00-072

LG10-1013-01-072 Yes

LG10-1003-00-118

LG10-1003-01-118 Yes

LG10-1013-00-118

LG10-1013-01-118 Yes

LG11-2003-00

LG11-2003-01 Yes

LG11-2013-00

LG11-2013-01 Yes

Maximum

Range

3’

(0.91m)

6’

(1.83m)

9.8’

(3m)

3’

(0.91m)

6’

(1.83m)

9.8’

(3m)

18.0’

(5.5m)

Probe

Style

Rod

Coaxial

Cable 316 SS

Mat’l of

Const.

316L SS

Thread Fob Components

¾” NPT

¾” G

¾” NPT

¾” G

¾” NPT

¾” G

¾” NPT

¾” G

¾” NPT

¾” G

¾” NPT

¾” G

¾” NPT

¾” G

The above are standard length models. For custom length probes, add a

length dimension to the end of the part number (i.e. LG10-0003-01-060” or

LG11-2003-01-4.5m). Be sure to indicate the units of measurement.

Coaxial style probe

Cable style probe

1

- includes rod, threaded ½” tube and spacers

2

- includes counterweight

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Housing,

feed-through,

rod style probe

Housing,

feed-through,

coaxial style probe

Housing,

feed-through,

cable style probe

1

2

Quick Start

| 8 MN300840 REV A10

Page 9

Getting Started Section Two

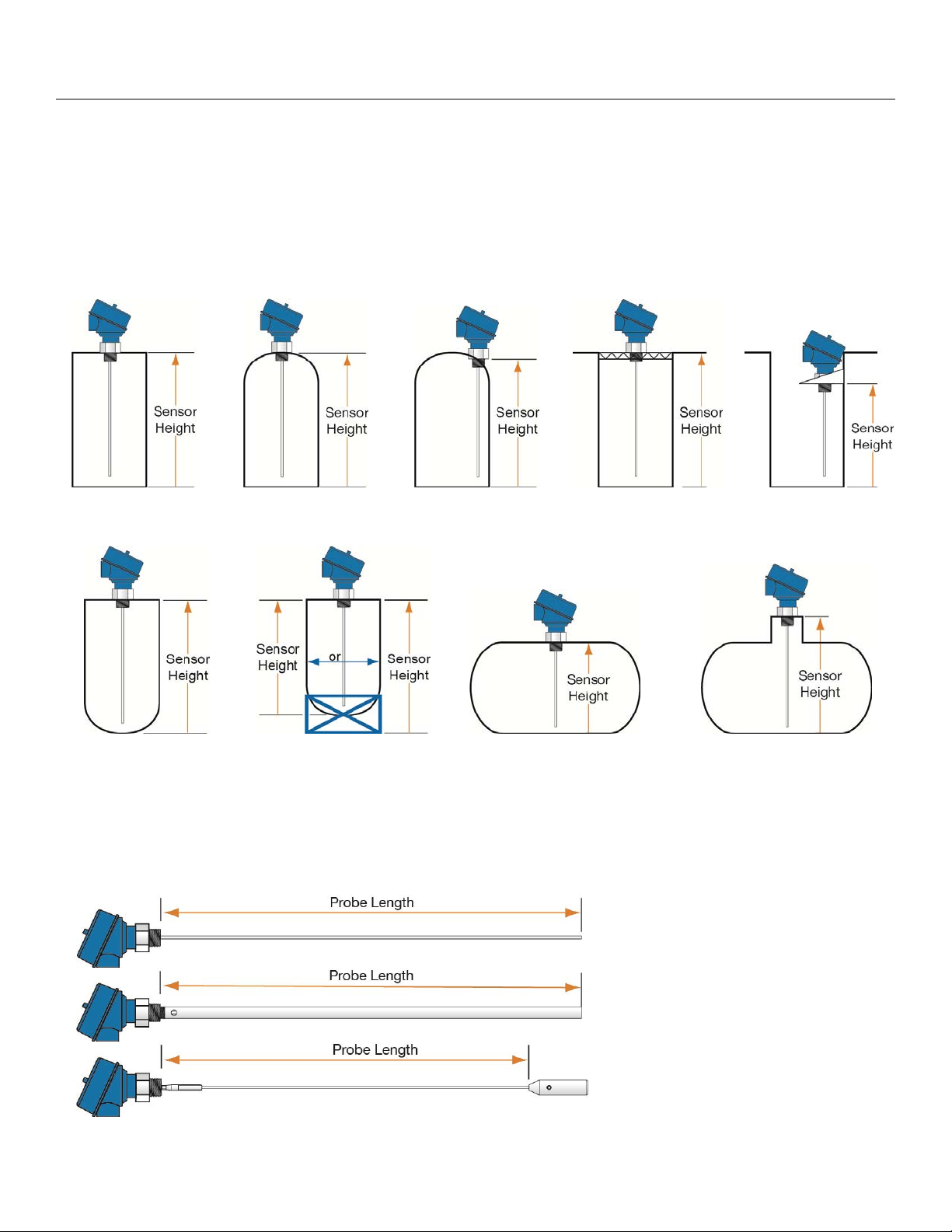

UNDERSTANDING SENSOR HEIGHT

This is a critical setting for EchoWave®. Sensor Height defines the height of the sensor above the bottom of

the tank. The height value must take into account the shape of the tank and any risers, fittings, structures or

extensions associated with the tank or the installation (see examples below). The reference point for definition

of the Sensor Height is always the bottom of the mounting nut.

Simple

Tank

Cone Bottom Raises

Sensor Height

Dome Top Raises

Sensor Height

(SH)

Mounting Fixture

Raises Sensor Height

Sensor Off Center

Changes SH

Simple

Tank

Simple Open

Top Tank

Sensor Extends

into Sump

Lowering SH

Riser Raises

Sensor Height

UNDERSTANDING PROBE LENGTH

The reference point for definition of the probe length [Length] is always the bottom of the threads [bottom of

the feed through (see below)]. Note: This is a different reference location from the Sensor Height. The probe

Length is an important mechanical dimension which is needed to make sure the probe physically fits into the

tank at the anticipated mounting location. Probe length has an influence on the actual measuring range of the

sensor, but it is a different aspect of the sensor.

Rod

Probe

Coaxial

Probe

Cable

Probe

Note: Sensor Height and Probe Length have different reference points for measurement.

MN300840 REV A10 9 |

Page 10

Getting Started Section Two

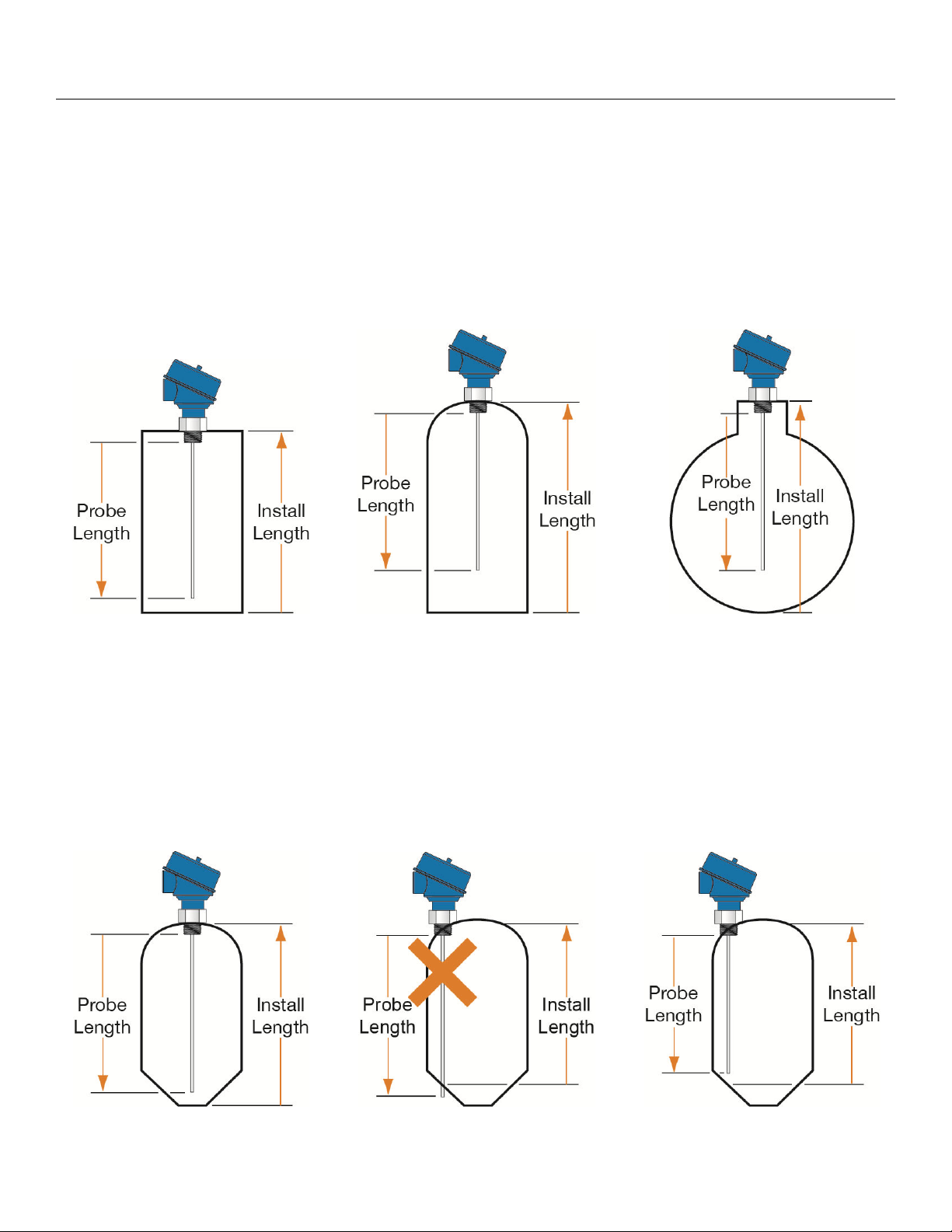

UNDERSTANDING INSTALL LOCATION LENGTH

Measure the space below the actual installation location for the sensor. This distance (install length) must be

greater than the probe length. In many tanks, the install length corresponds to the height of the tank. With

dome top, cone bottom and horizontal tanks, include the added height of the curved surface. Be sure to take

into account the height of fittings, risers, tank flats etc. which may be added for installation. All of the above can

raise the bottom of the probe higher in the tank than what was originally expected resulting in a reduced lowest

level of measurement (see Measurement Range).

Tank with Flat Top

& Flat Bottom

Tank with Dome Top

& Flat Bottom

Horizontal

Tank

CONE AND ROUNDED BOTTOM TANKS

The location of an EchoWave® installed along the top of a dome or cone bottom tank may have an effect on

the installation of the sensor. Be sure to measure from the actual point of installation. Round or cone bottom

tanks will reduce the install height available, depending on install location. If this occurs, either the sensor can

be raised using fittings (see Adding a Riser to Avoid Cutting the Probe) or the probe’s length may be reduced

by cutting the probe (see Cutting the Probe in Section 7).

Install Height >

Probe Length

Install Height <

Probe Length

Install Height >

Probe Length

| 10 MN300840 REV A10

Page 11

Getting Started Section Two

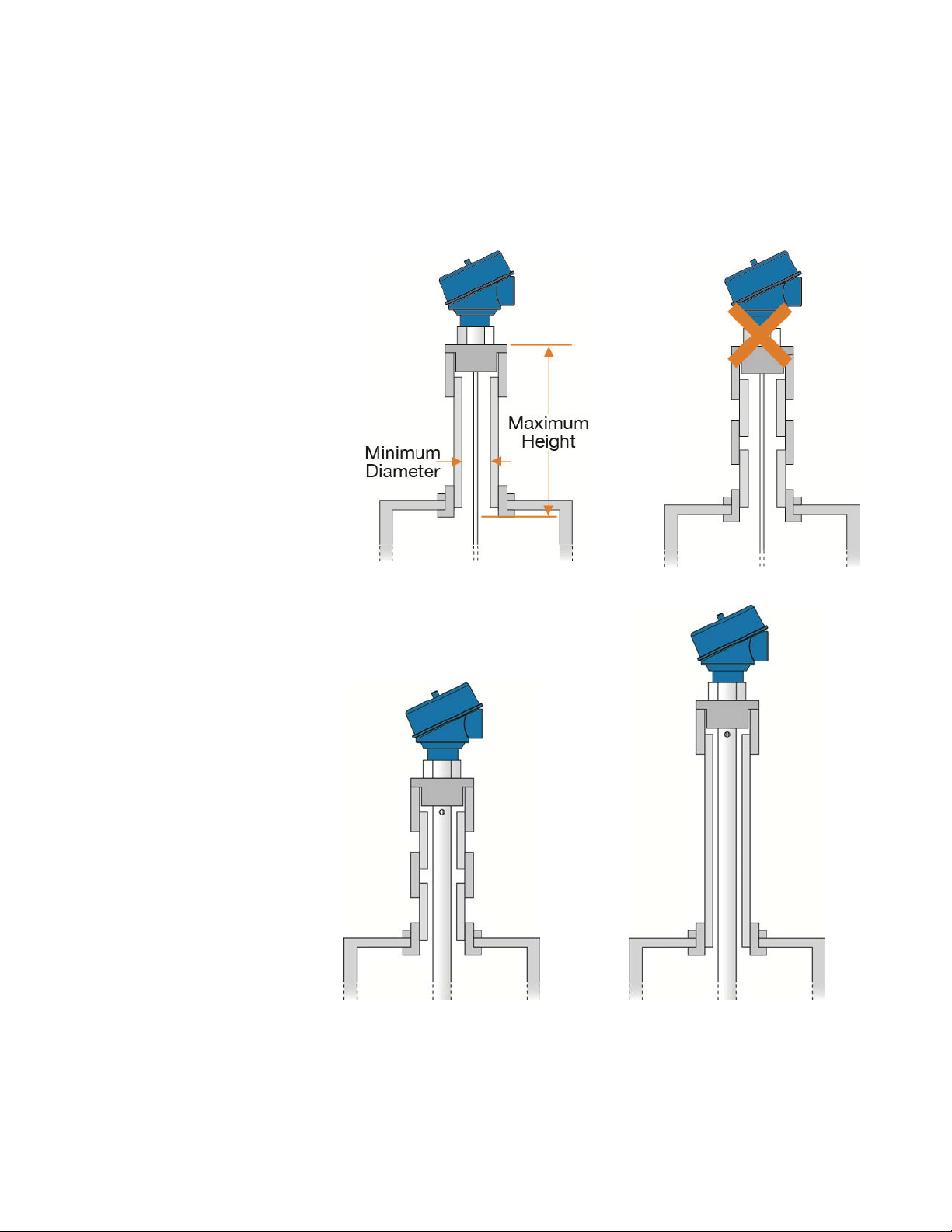

ADDING A RISER TO AVOID CUTTING THE PROBE

In some conditions, a riser may be added to avoid cutting the probe.

Rod and Cable Probes

With the Rod and Cable versions

of the probe, the maximum height

for the riser is 12” (300mm). The

minimum diameter of the riser is 2”

(50mm). The riser must be

metallic in construction using the

least number of fittings

/connections. Note: An Empty

Signal Scan is a requirement so

that the EchoWave

®

can eliminate

the odd geometry created by the

riser.

Least Number of Fittings

Too Many Fittings

Coaxial Probes

With the coaxial probe, there is no

maximum riser height or minimum

riser diameter. This is because the

coaxial shield isolates the physical

changes to the installation from the

sensor’s energy signal. In both

examples, the energy signal

cannot see any changes to the

fitting/connections or from being

installed in an extension that

exceeds the maximum height for

rod and cable probes.

MN300840 REV A10 11 |

Page 12

Getting Started Section Two

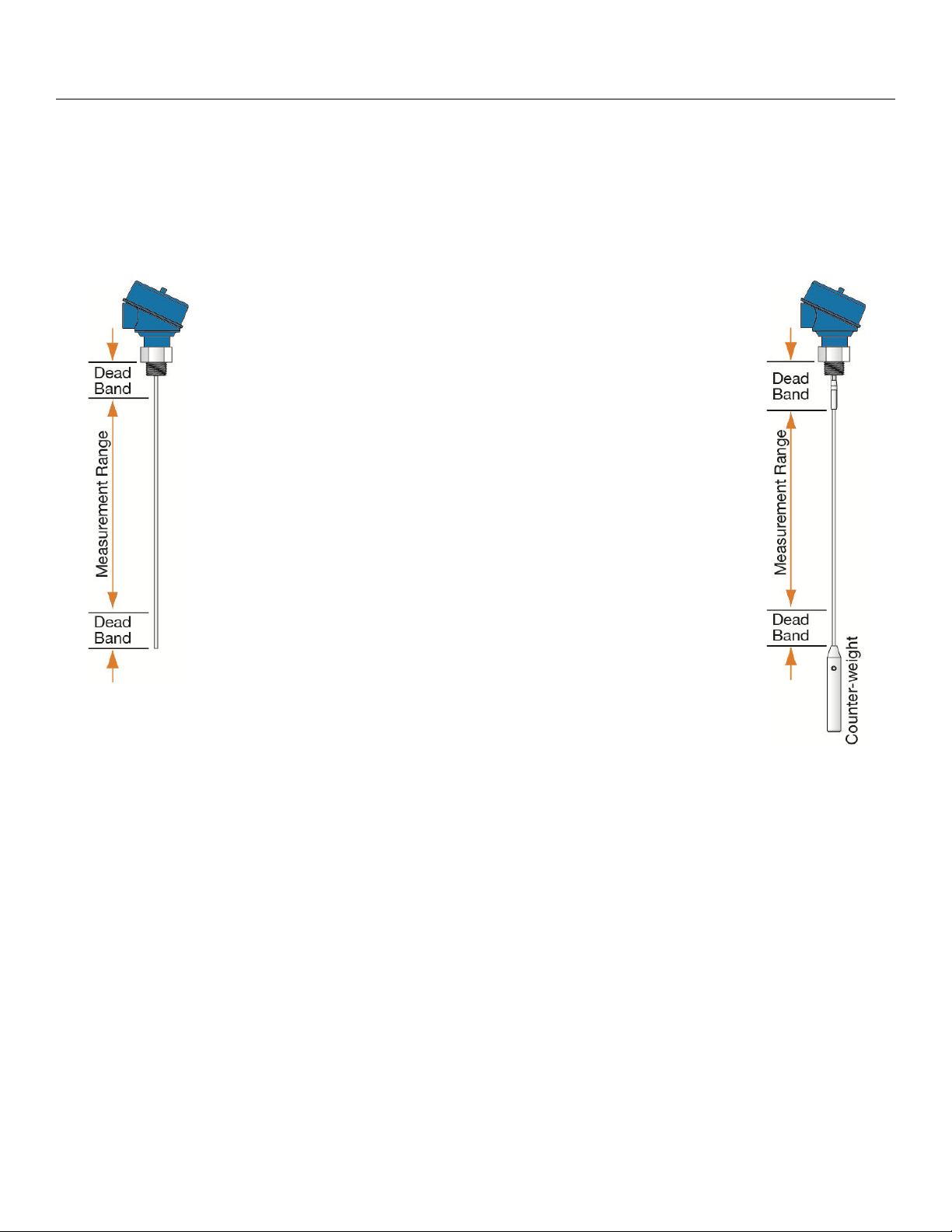

UNDERSTANDING MEASUREMENT RANGE

EchoWave

the presence of unavoidable signal disturbances at both ends of the probe. In these dead band areas the

measurements are non-linear or have reduced accuracy. Therefore, it is not recommended to actually measure

level within these dead band areas. Their length depends on the probe type and the reflectivity

(i.e. dielectric constant) of the liquid to be measured.

®

level transmitters have small dead band areas at both the top and bottom of the probe. It is due to

The Measurement Range of LG10/LG11 series extends between the

top and bottom dead band areas; this is the area in which a sensor will

have the specified measurement performance. It is recommended that

the maximum and minimum levels to be measured in the tank are

actually within the Measurement Range of the sensor. The span

between the lower range value [4mA] and the upper range value [20mA]

of the current output is proportionally equal from 0 to 100% of your

continuous level measurement reading. It is recommended that the span

between these two range values stays within the Measurement Range.

The [Top Dead Band], closest to the threads, is set to 4” (100mm). This

is measured from the top of the threads down to the probe. This is

consistent for all styles of probe. Note: the measurement location for the

Top Dead Band is different to the measurement location for the probe

length.

The [Bottom Dead Band], closest to the end of the probe, is set to 2”

(50mm). This is measured from the end of the probe on rod and coaxial

probes. For cable probes, it is measured from the top of the counterweight. The counter-weight must be included with the dead band as the

sensor’s inactive area.

| 12 MN300840 REV A10

Page 13

Getting Started Section Two

®

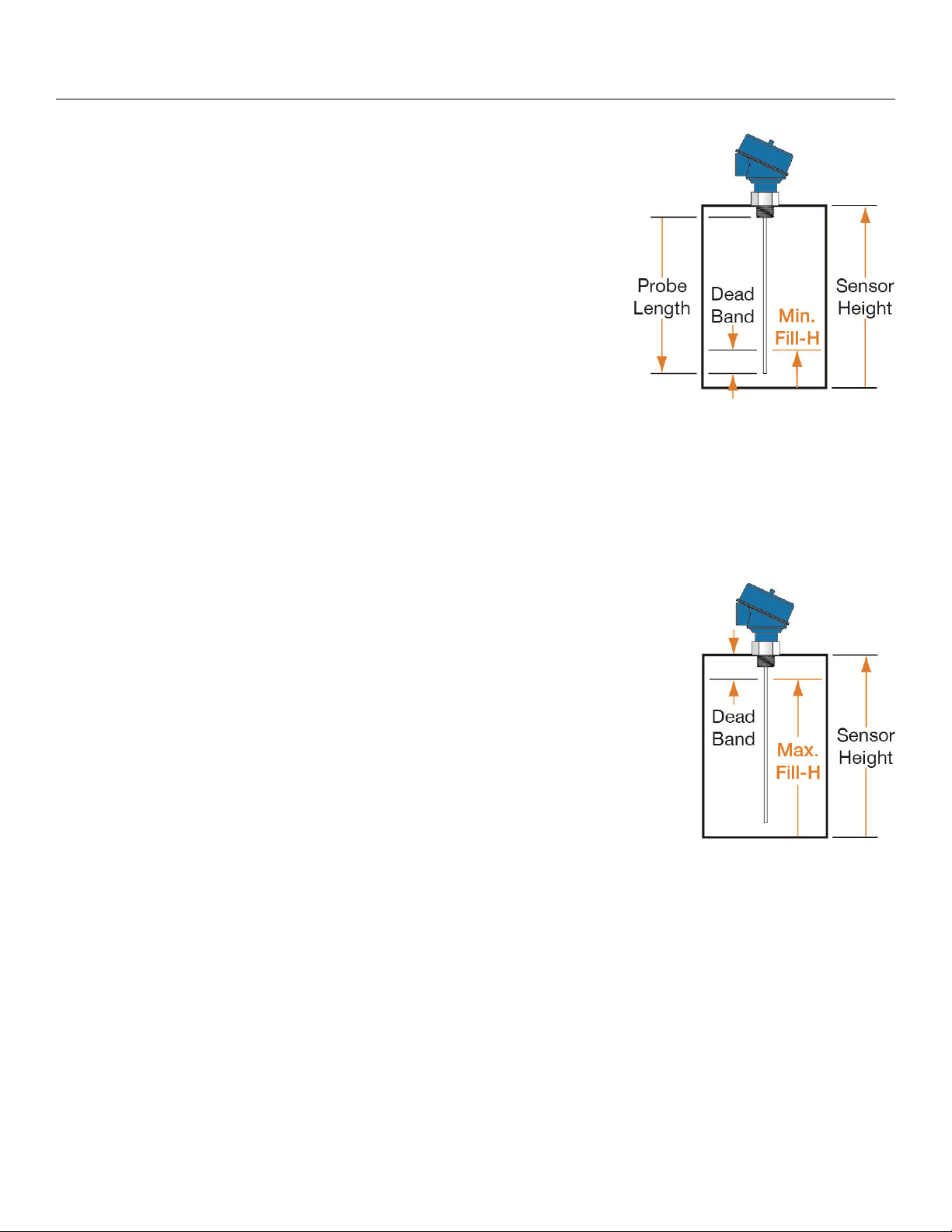

UNDERSTANDING MINIMUM FILL-HEIGHT (PUTTING IT ALL TOGETHER)

EchoWave

from the bottom of the tank to the top of the Bottom Dead Band. As

shipped from the factory, Min. Fill-H is where the 4mA current is located

and is the lowest point on the probe where the sensor can detect a liquid

level. Any point below this position will stop at 4mA. The Min. Fill-H is

influenced by the Sensor Height (SH), Probe Length (P), Height of the

Threads [0.65” (16.5mm)] and Bottom Dead Band.

Min. Fill-H = (SH) – [0.65” (16.5mm)] – (P) + (Bottom Dead Band)

With a cable probe, include the height of the counter-weight.

Switch output to volumetric will allow Min. Fill-H to be set to (0).

If the 4-20 mA output is reversed (20mA at bottom and 4mA at

Note: Because of the bottom dead band, the Minimum Fill-Height can never be at the end of the probe.

Note: The configuration of the sensor (Distance or Volume) will affect the current output at Minimum Fill-

Height. Upon selecting Distance, the current will be set to 4mA at Min Fill-H. However, upon selecting volume,

the current at Min Fill-H will be the calculated based upon 4mA being set at the bottom of the tank [see

Distance (Height of Liquid) vs. Volume of Liquid].

®

has a Minimum Fill-Height (Min. Fill-H), which is measured

top), then the level will max out at 20 mA when the level falls

below the Min. Fill-H.

Understanding Maximum Fill-Height

EchoWave

has a Maximum Fill-Height (Max. Fill-H), which is measured from the

bottom of the tank to the Top Dead Band. As shipped from the factory, Max. Fill-H

defines the 20mA current depicting the highest point on the probe where the

sensor detects liquid level. Any point above this position will stop at 20mA. The

Max. Fill-H is influenced by the Sensor Height (SH), Height of the Threads [0.65”

(16.5mm)] and Top Dead Band.

Max. Fill-H = (SH) – [0.65” (16.5mm)] – (Top Dead Band)

The Max. Fill-H may be decreased to lower the 20mA location, but it cannot

be raised above its original setting.

If the 4-20 mA output is reversed (20mA at bottom and 4mA at top), then

the level will max out at 4 mA when the level rises above the Max. Fill-H.

Note: Because of the top dead band, the Maximum Fill-Height can never be at the bottom of the threads.

MN300840 REV A10 13 |

Page 14

Getting Started Section Two

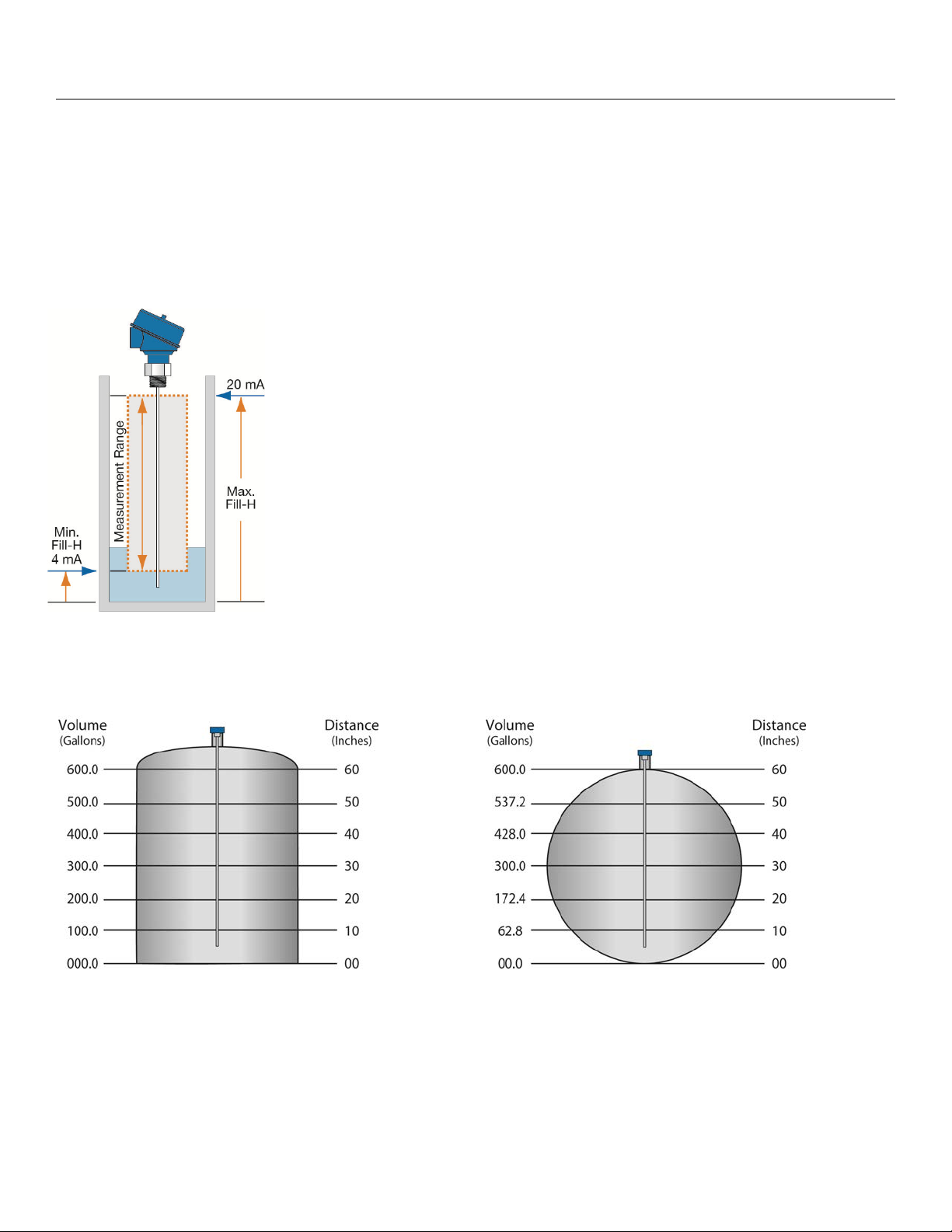

DISTANCE (HEIGHT OF LIQUID) VS. VOLUME OF LIQUID

®

With WebCal

of liquid) or volume of a liquid. The location of the empty current will adjust depending on which configuration

method is selected.

Note: The empty (4mA) location is placed at a different location based upon selecting distance (liquid height)

or liquid volume.

, the LG10/LG11 series can be configured to operate as a device that reads the distance (height

Distance (Height of Liquid): When the EchoWave

®

is configured to read the

distance (height of the liquid), the default for the sensor Empty will be at the

bottom of the measurement range (end of the probe minus the bottom dead

band). This is where 4mA will be set. The default for sensor Full will be at the

top of the measurement range (Top Dead Band), where 20mA will be set. The

20mA can be set by the Maximum Fill-Height.

Volume of Liquid: When the LG10 series is configured to read the volume of

liquid, the output will track the volume of the tank as the level increases and

decreases. Like Distance, the Empty and Full settings will default to the low

and high end of the Measurement Range. The location of the 20 mA can be

adjusted with the Maximum Fill-Height settings. However, the shape of the

tank can influence the current output, depending upon the tank being linear or

non-linear (see below).

Linear Tank Example

Note: In the above illustration, 10” of liquid will

always be equal to 100 gallons of liquid (1” = 10

gallons).

Non-Linear Tank Example

Note: In the above illustration, 1” of liquid does not

equal 10 gallons. The 10” at the bottom represents a

rise of 62.8 gallons. As a change between 10” and

20” represents an increase of 109.6 gallons (i.e.

172.4 gallons – 62.8 gallons).

| 14 MN300840 REV A10

Page 15

Installation Section Three

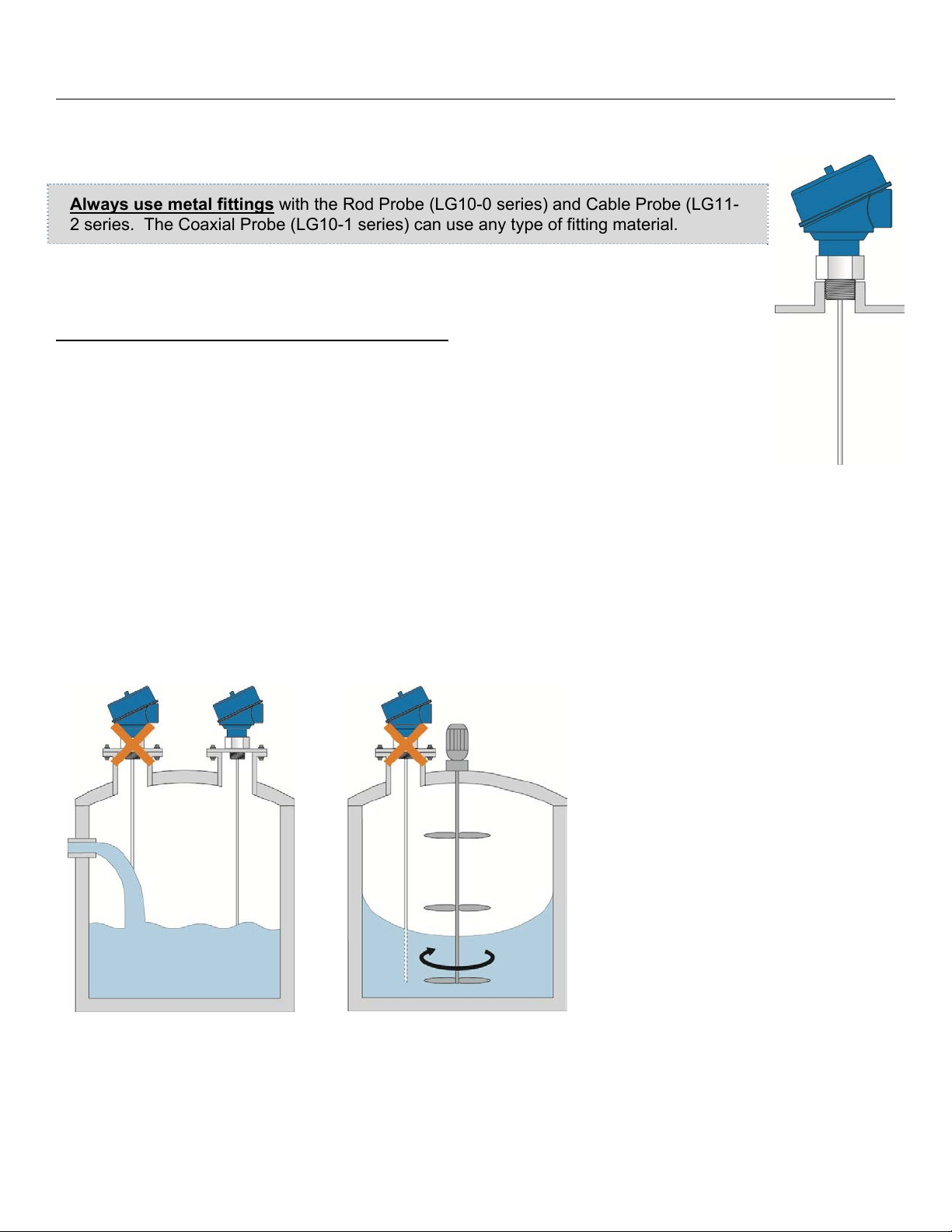

EchoWave

®

is mounted vertically into the tank via its connection thread. It is then screwed directly into a

standard threaded tank connection, i.e. tank adapter, bushing, weld-in socket, or it can be

screwed into a flange which is connected to a tank nozzle.

Always use metal fittings with the Rod Probe (LG10-0 series) and Cable Probe (LG11-

2 series. The Coaxial Probe (LG10-1 series) can use any type of fitting material.

LG10/LG11 series should not be welded directly into the tank. Neither should flanges be

welded onto the sensor. Welding on the metal parts of EchoWave

®

will cause serious

damage to the transmitter.

®

Do not lift or handle the EchoWave

probe connection. EchoWave

®

should be handled by the hexagon or the lower section of the

by its probe: This will cause excessive stress on the

housing. Do not screw in the sensor by its housing. It should be tightened only via its

hexagon (wrench size 32mm).

The end user has to ensure proper sealing of the sensor connection; based upon process

conditions, i.e. temperature, pressure and resistance against the process liquid’s

atmosphere.

For NPT thread connections, pressure-tight joints require a sealant directly on the threads.

In the case that the LG10/LG11 series is delivered with a detached probe (cable version only), attach the probe

onto the small threaded stud below the hexagon. Make sure to avoid cross threading or misaligning the

threads.

MOUNTING CONSIDERATIONS

The probes should be installed so that they are not directly impacted by liquids flowing out of the filling inlet.

They should neither touch nor sway towards other objects inside the tank or the tank/nozzle walls; e.g. by

agitator or mixer swirls. In

applications with very strong fluid

movements which can also cause

excessive lateral force on the

probe, it is recommended to

anchor the probe. The anchoring

fixtures are end user supplied.

MN300840 REV A10 15 |

Page 16

Installation Section Three

MOUNTING CONSIDERATIONS (CONTINUED)

The rod and cable probes are suitable for a very wide range of applications

in liquids. However, the signal has a wider detection radius around the

rod/cable. Therefore, it is more responsive for measurement signal

disturbances that are overcome by a few Mounting Considerations (see below)

as well as simple configuration adjustments to the sensor. In most cases it is

enough to activate and utilize the powerful LG10/LG11 series empty signal

scan feature. It works most efficiently on stationary interference targets like tall

and narrow nozzles or close-by objects.

In case a non-stationary interference target is close to the rod probe, like slowly

rotating agitator blades causing problems with the measurement, it is recommended

to use the coaxial probe. In any case, the rod and cable probes should never get in

direct contact with the tank/nozzle wall or other objects in the tank.

Nozzle diameter >2” (50mm) >2” (50mm) +

Rod Cable Coaxial

(1)

Nozzle height <12” (300mm) <12” (300mm) +

Clearance to tank wall or other internal objects >4” (100mm) >4” (100mm)

+

Clearance between probe end and tank bottom >0.1” (2mm) >0.1” (2mm) +

Diameter of bypass chamber / stilling well >1” (25mm) >1” (25mm) +

(2)

Metallic tank or below grade concrete basin + + +

Non-metallic or plastic tank NR NR +

+ = Recommended

(1)

+

= Enough diameter to fit in the coaxial tube (0.677” / 17.2mm)

(2)

+

= Enough diameter to fit in the coaxial tube (0.677” / 17.2mm) with allocated room around the

probe for liquid flow through the bypass chamber / stilling well

NR = Not Recommended

The rod probe is also the recommended probe type for mounting the LG10 series into bypass chambers or

stilling wells. In this case, plastic centering spacers are needed to prevent the probe from contacting the wall.

The cable probe is recommended for installations in tall tanks where limited installation headroom is available.

Its performance characteristics and mounting considerations are similar to the rod probe.

The coaxial probe does not have restrictions regarding mounting position, tank connection, proximity to the tank

wall and other objects inside the tank. The coaxial probe is recommended for installing LG10 series into a nonmetallic tank or open pit.

| 16 MN300840 REV A10

Page 17

Installation Section Three

INSTALLATION TIPS

Tall and Narrow Risers

Rod and Cable probes can be installed in tall and

narrow risers under the following criteria:

Nozzle Diameter must be >2” (50mm),

Nozzle Height must be <12” (300mm),

Riser must be metallic,

An empty signal scan is required after

installation.

Coaxial probes are not affected by tall and narrow

risers.

Difficult Tank or Riser Geometries

Rod and Cable probes must follow the criteria below:

Tall and Narrow Risers criteria must be

followed,

Nozzle diameter remains the same diameter,

Nozzle Diameter does not decrease,

Nozzle Diameter may get larger, but an empty

signal scan is required.

Coaxial probes are not affected by the shape of the

tank or the geometry of the nozzle as the above is not

applicable.

Close to Side Wall or Internal Obstructions

Rod and Cable probes must follow the criteria below:

>4” (100mm) from the side wall,

>4” (100mm) from any objects or obstructions

within the tank,

An empty signal scan may be required after

installation.

Coaxial probes are not affected by the distance from

the side wall or from other objects / obstructions within

the tank.

Moving Probe

Rod and Cable probes must follow the criteria below:

Avoid applications where the movement of the

tank will cause the probe to swing or touch

objects and obstructions in the tank or the side

wall of the tank.

Avoid applications where the tank is

truck/vehicle mounted.

Coaxial probes are not affected by the movement of

liquid within a stationary tank.

MN300840 REV A10 17 |

Page 18

Installation Section Three

INSTALLATION TIPS (CONTINUED)

Liquid Spray

Rod and Cable probes must avoid any liquid that sprays or

pours onto the probe.

Coaxial probes are not affected by liquid straying on parts

that are above the liquid surface. However, avoid installing

probe where liquid will pour onto the probe.

Non-Stationary Documents

Rod and Cable probes follow the criteria below:

>4” (100mm) from any objects or obstructions within

the tank,

An empty signal scan may be required after

installation,

Non-stationary objects must not be moving when

empty signal scan is preformed.

Coaxial probes are not affected by the movement of nonstationary objects, such as mixer blades or pump lifting

chains.

Note: All probes (rod, cable and coaxial) can be affected by

any liquid vortex created by a mixer.

Measurement Readings at the Very Top or Bottom of

Tank

Rod and Cable probes do not have the outer tube and must

adhere to all mounting requirements, specifically:

>4” (100mm) from any objects or obstructions within

the tank, including the bottom of the tank,

Criteria for difficult tank or riser geometries must be

followed.

Coaxial probes can easily be mechanically mounted to

ensure the measurement of liquid up to a full or empty tank.

Because the coaxial is encased within the outer tube, the

sensor is self-contained so other objects or obstructions are

not an issue. This makes raising or lowering the sensor

simple and straight forth.

| 18 MN300840 REV A10

Page 19

Installation Section Three

INSTALLATION TIPS (CONTINUED)

Non-Metallic Tanks

Unlike coaxial, rod and cable probes have no containment

mechanism. This energy must be contained by the tank wall,

requiring that all rod and cable probe sensors be installed in

metallic tanks or within below grade concrete sumps.

Coaxial probes can be installed in any type of tank, including nonmetallic tanks. This is because the outer tube acts as an insulator

preventing the sensor’s energy emanating beyond the probe.

Stilling Wells / Bypass Chambers

Installations within a stilling well or a bypass chamber are

recommended with a rod probe. A metallic pipe is required. A

coaxial probe can be used in a stilling well or bypass chamber if

required. Note: Never use a cable probe within a stilling well or

bypass chamber.

Make sure that the probe does not come into contact with the

inner wall of the stilling well or bypass chamber

o Non-metallic spacers may be required to keep the

probe within the center of the stilling well or bypass

chamber

Make sure the liquid is able to freely fill, empty and that no

residue remains within the stilling well or bypass chamber.

All other mounting criteria must be observed

An Empty Signal Scan may be required after installation

Limited Headroom

When installing in a tank where there is limited space above the top of

the tank, the cable probe is the recommended solution. The cable

probe design allows for the probe to be installed through a small

space above the tank.

The rod and coaxial probes may be installed as long as the probes

are not damaged or bent and as long as the sensor is not held by the

probe (sensor must be held by the head).

All other mounting criteria must be observed.

MN300840 REV A10 19 |

Page 20

Installation Section Three

INSTALLATION TIPS (CONTINUED)

Tall Tanks

The rod and coaxial probes have a maximum insertion length of

9.8’ (3m). For metal or concrete tanks that are taller/deeper, the

cable probe can be used for lengths up to 18.0’ (5.5m).

The maximum length is based from the bottom of the

threads.

o Note: the coaxial probe consists of a rod probe

with a metal outer tube installed around the

original rod. The bottom of the mounting threads

are used as the reference point for measurement.

Side Mount Bracket (LM50 Series)

Rod and Cable probes can be installed with the side mount

bracket under the following criteria:

The side wall or any object / obstructions do not come

within 4” (100mm) from the probe

Any movement of the liquid will not cause the probe to

swing into the side wall or any object / obstruction

The tank must be metallic or a below grade concrete

basin

An empty signal scan may be required after installation

A metal plate of 6” in diameter may be required if there is

no roof to the tank/basin

Coaxial probes are not affected by the side mount bracket.

Probe Too Long

For information on cutting the probe, see Cutting the Probe within the Appendix, Section 7.

| 20 MN300840 REV A10

Page 21

Wiring Section Four

Analog Output (4-20 mA): The analog output of the EchoWave

®

is a sourced 4-20 mA control circuit. The

typical way to use this feature is to connect a positive supply to the (+) input terminal, a negative supply to the

(-) input terminal and to connect the current output out of the 420 (+) terminal. The device that accepts the 420 mA current signal must reference the same negative supply listed above (see diagram below).

SampleWiringDiagram

Diagram will change based upon

the sensor’s configuration, use

WebCal™ to view appropriate

wiringdiagram.

The cabling should be shielded and twisted to minimize EMI interference. Its shield should be connected at either

end and never connected at both ends. Typically 18 to 24 gauge wire is used in this application.

GENERAL NOTES FOR ELECTRICAL CONNECTIONS, USAGE AND SAFETY

Where personal safety or significant property damage can occur due to a spill, the installation must

have a redundant backup safety system installed.

Wiring should always be completed by a licensed electrician.

Protect the sensor from excessive electrical spikes by isolating the power, whenever possible.

Supply voltage should never exceed 30 VDC.

Make sure that the power supply does not have a current more than 2A or that there is 2A rated fuse

in the electrical circuit that energizes the device.

The sensor materials must be chemically compatible with the liquids to be measured.

Design a fail-safe system for possible sensor and/or power failure.

Never use the sensor in environments classified as hazardous.

MN300840 REV A10 21 |

Page 22

Wiring Section Four

WIRE CONNECTIONS

The housing has single cable entry and can be attached to screw plugs, cord grips or conduit with the ½” NPT

thread. Note: the customer must confirm the suitability of those connectors for the specific application

requirements and cabling; and replace them when necessary. IP66-rated screw plugs and cord grips have to

be properly mounted and tightened around cable of suitable type and diameter to ensure the IP66 rating of the

housing.

Note: A liquid-tight cord grip and ferrite bead are included with the

sensor (see Specification Section for cord grip data).

Note: Always include the ferrite bed when using the cord grip or

when using non-metallic conduit.

Note: Always shield the signal wire per instructions on the wiring diagram.

Conduit Connection Cord Grip (Liquid Tight)

Ferrite Bead

Liquid-Tight Cord grip

Avoid Condensation in the Conduit

You can give your instrument additional

protection against moisture penetration by

leading the conduit connection or cable

downward in front of the cable entry.

Condensation in the conduit will thus not enter

the sensor enclosure.

| 22 MN300840 REV A10

Page 23

Wiring Section Four

COMMON WIRING TO DISPLAY, CONTROLLERS & PLC’S

Below is a quick review of wiring the EchoWave® to common display, controllers and PLC’s.

DataView™ LI55 Series

Level Controller

DataLoop™ LI23 Series

Level Indicator Without Backlight

Commander™ LI90 Series

Multi-Tank Level Controller

DataLoop™ LI23 Series

Level Indicator with Backlight

Note: 4-20 mA signal wire requires shielding (power supply wires may use the same shielding as the signal

wire). Shield wire can be connected at either end. Never connect shield wire at both ends. EchoWave is a 3wire transmitter and should never be wired as a 2-wire loop device.

MN300840 REV A10 23 |

Page 24

Wiring Section Four

COMMON WIRING TO DISPLAY, CONTROLLERS & PLC’S (CONTINUED)

Below is a quick review of wiring the EchoWave

®

to common display, controllers and PLC’s.

Generic Loop

Powered Display

DataPoint™ LC52 Series

Level Controller

(JWB mode)

Generic PLC

Note: LC52 shipped from factory with jumper in JWA

mode. Jumper must be switched to JWB mode for

operation with the EchoWave

®

.

Note: 4-20 mA signal wire requires shielding (power supply wires may use the same shielding as the signal

wire). Shield wire can be connected at either end. Never connect shield wire at both ends. EchoWave is a 3wire transmitter and should never be wired as a 2-wire loop device.

| 24 MN300840 REV A10

Page 25

Configuration Section Five

EchoWave

®

can be configured before installation or within the tank. The transmitter features non-volatile

memory, so any setting configured before installation will not be lost when the sensor is powered down. To

configure, follow the steps below:

1. Install WebCal

a. Go to www.flowline.com/webcal-software/

b. Review how USB

®

Software

®

and select language version.

Fob interfaces with EchoWave® and your computer.

2. Measure the Tank

a. Begin by measuring the key tank and fitting dimensions.

b. Correct tank dimensions will result in accurate sensor measurement.

3. Sensor Configuration

a. Configures Loop Fail-Safe, Output at Empty, Startup Condition & Dielectric Range for the sensor.

4. Dimensional Entry

a. Distance Mode (default).

i. Basic information for operation including Sensor Height, Probe Length, Max. Fill-Height.

5. Tank Level Confirmation

a. Confirm the values are accurate for the application.

6. Write to Unit

a. Uploads configuration into the sensor.

b. Access to a customer wiring diagram.

MN300840 REV A10 25 |

Page 26

Configuration Section Five

STEP 1 – INSTALL WEBCAL® SOFTWARE

EchoWave® is configured through WebCal®*, a PC software program. WebCal® is a free download from

®

Flowline’s website. You must download and install WebCal

(version 6.5 or greater) prior to plugging in

the USB® Fob. Please go to flowline.com/webcal-software, and select your language version.

WEBCAL® SYSTEM REQUIREMENTS

Windows® XP, Vista, 7, 8, 10

32 or 64-bit system

1 USB

®

2.0 port

10 mB hard drive space

256 mB RAM

Internet connection

* For complete information on the WebCal

®

software, please refer to the WebCal® manual located at

flowline.com/webcal-software.

| 26 MN300840 REV A10

Page 27

Configuration Section Five

USB® FOB INTERFACE

EchoWave

Before plugging your Fob into your computer’s USB

6.5 or greater) on your computer.

Connect the red, green, white and black terminals on the Fob to the corresponding terminals within the

EchoWave

®

communicates with WebCal® (version 6.5 or greater) through a USB® interface called a Fob.

®

. Tighten the screws on the terminals and plug your Fob into the USB® port of your computer.

®

port, be sure that you have installed WebCal® (version

WIRING IS IDENTICAL FOR ALL SERIES OF ECHOWAVE

The maximum cable distance between the computer and EchoWave® is 15’. This only applies when

configuring the EchoWave

Once EchoWave

®

is configured and prior to installation, disconnect all wires from the center two terminals

®

.

®

to prevent a short of the configuration circuit

Note: When using the Fob, do not add VDC power. The Fob, when connected to the computer, will provide

®

the required power to the EchoWave

* For complete information on the WebCal

.

®

(version 6.5 or greater) software, please refer to the WebCal®

manual located at flowline.com/webcal-software.

MN300840 REV A10 27 |

Page 28

Configuration Section Five

STEP 2 - MEASURE THE TANK

Measuring the tank is one of the most important aspects in

configuring the sensor. When measuring the tank, take

into account the location of the sensor with respect to

fittings, risers, dome tops and bottoms, and identify where

the measurements are taken from the sensor. The Sensor

Height is influenced by the installation location. Sensors

mounted along the sloped portion of the tank will result in a

lower (HEIGHT) value. On the other hand, sensors

installed in risers/nozzles will result in a higher (HEIGHT)

value.

The basic measurements (Sensor Height, Probe Length, Max. Fill-H and Man. Fill-H) for configuration are

described below:

1. SENSOR HEIGHT - Distance from the Top of Sensor’s

Threads (sensor’s measurement location) to the bottom

of the tank.

a. The Sensor Height is typically set to the bottom

of the tank.

b. This setting determines the 4mA location.

2. PROBE LENGTH – Actual physical length of probe.

a. The Probe Length is measured from the bottom

of the threads to the end of the probe.

3. MAX. FILL-H - Distance from the bottom of the tank to

the level of liquid where the tank is full.

a. This setting determines the 20 mA location.

b. The MAX. FILL-H is typically set to the liquid full

level.

c. 20mA cannot be set within the sensor’s upper

dead band [4” (10cm) from top

of the threads].

d. Largest MAX. FILL-H value will be as follows:

Largest MAX. FILL-H = SENSOR HEIGHT – 4” (10cm)

4. MIN. FILL-H - Distance from the bottom of the tank to the lowest portion of the probe when level can be

detected.

a. This setting determines the 4 mA location.

b. The MIN. FILL-H is automatically calculated by WebCal

®

.

c. 4mA cannot be set within the sensor’s lower dead band [2” (5cm) from end of the probe].

d. Smallest MIN. FILL-H value will be as follows:

Smallest MIN. FILL-H = SENSOR HEIGHT – Probe Length - 2” (5cm)

| 28 MN300840 REV A10

Page 29

Configuration Section Five

With EchoWave

Follow steps 3 to 6 to configure the transmitter using WebCal

open the help menu of WebCal

WebCal

®

, please contact a Flowline® application engineer at (562) 598-3015. Note: For complete information

on the WebCal

STEP 3 – SENSOR CONFIGURATION

®

connected to your computer, open the WebCal® software by clicking on the WebCal® icon.

®

for more instructions on WebCal®. If you need additional assistance using

®

software, please refer to the WebCal® manual located at flowline.com/webcal-software.

®

. Click “Help” in the lower right hand corner and

Configures the Loop Fail-Safe, Output at Empty, Startup Condition, Probe Type and Dielectric Range.

Out of Range

Flowline suggests setting the Loop Fail-safe to

HOLD Last Value in application where the liquid

level falls below the end of the probe or rises

above the Max. Fill-H.

If the level only falls below the end of the

probe, then EMPTY can be used.

If the level only rises above the Max. Fill-H,

then FULL can be used.

Note: Never allow the liquid to rise into the top dead band of the sensor (within 4” from the top of the

threads.

MN300840 REV A10 29 |

Page 30

Co

n

P

N

v

o

S

e

y

y

c

SdP

f

e

w

S

T

f

e

n

r

m

t

f

t

e

M

e

u

e

s

a

m

e

m

c

p

m

c

h

O

a

f

o

u

m

e

w

u

C

H

p

r

d

s

b

a

e

:

U

e

b

e

a

d

o

c

n

e

s

m

e

t

M

S

e

f

T

H

b

o

y

e

e

e

STE

figurati

4 – DIMEN

n

IONAL EN

RY:

ection Fiv

Distanc

change i

categor

settings

settings

Mode (de

n liquid leve

. For Volum

ou must e

an be ente

ensor Heig

istance fro

robe Leng

o

the probe

F

ill-Height:

p

osition to th

ault): Outp

l will reflect

tric output

ter for Dist

ed on the

ht: Sets th

the Empty

h: Sets the

o the botto

Sets the lo

Full level

t of sensor

linearly to t

, refer to V

nce Mode

ain configu

location o

level positi

physical len

of the mo

ation for 20

osition (se

is based on

e current o

LUMETRI

re Sensor

ration scree

the sensor

n to the To

gth of the p

nting threa

A. It is ba

below).

the distanc

tput. Note

CONFIG

eight, Prob

n.

above the

of the Thr

obe. It is b

s.

ed on the

(height of

Most appli

RATION o

Length an

ottom of th

ads of the

sed on the

istance fro

liquid) in th

ations will

page ??.

d Max Fill-

tank. It is

ensor (see

distance fr

the Empt

tank. Any

all into this

he three

. All three

ased on th

below).

m the end

level

ote: In th

alue will al

Distance

ays indicat

ode, the 4

the distan

A location

e the 4mA

ill always

location is

e 2” from th

bove the b

e end of th

ttom of the

probe. Th

ank.

Min-Fill-H

| 30

N300840 REV A1

0

Page 31

Configuration Section Five

STEP 5 – TANK LEVEL CONFIRMATION:

Verify the Height Units, Sensor Height, Probe Length, Maximum Fill-Height & Minimum Fill-Height. All values

were calculated in the previous Dimensional Entry window.

STEP 6 – WRITE TO UNIT:

This WebCal®* operation uploads configuration into the sensor. Other features in the section include providing

a custom wiring diagram specific to the signal output and saving the configuration file to your hard drive.

VolumetricSensorOutput

TheVolumetricModebutton will

be highlighted in Blue when a

volumeoutputisselected.

* For complete information on the WebCal

flowline.com/webcal-software.

MN300840 REV A10 31 |

®

software, please refer to the WebCal® manual located at

Page 32

Empty Signal Scan Section Six

EMPTY SIGNAL SCAN

The Empty Signal Scan is a powerful disturbance signal suppression feature of EchoWave®. The sensor scans

its entire probe length for any disturbance/interference signals within the application that could potentially be

misinterpreted as level readings by memorizing and suppressing them during operation. Therefore, the

LG10/LG11 series only recognizes the actual level signals caused by the liquid being measured.

The Empty Signal Scan is intended for the rod & cable probe, since its signal has a wider detection

radius around the probe making it more responsive for measurement signal disturbances. An

Empty Signal Scan is typically not required for the coaxial probe.

The Empty Signal Scan works most efficiently on stationary interference targets like tall and narrow risers or

close-by objects/obstructions. To enable an Empty Signal Scan, the EchoWave

®

has to be mounted in its final

position. The tank has to be completely empty. This will ensure a reliable identification of the actual

disturbance signals only. In case there are non-stationary interference targets close to the rod probe (slowly

rotating agitator blades or streams of liquid filling into the tank), it is recommended to use the coaxial probe.

ACTIVATE EMPTY SIGNAL SCAN

When EchoWave® is shipped, this feature is deactivated. To initiate a

Empty Signal Scan, use the following instructions:

1. Make sure the LG10/LG11 series is installed in its final

installation position.

2. Make sure the liquid is at its lowest level (empty).

a. Performing an Empty Signal Scan when the tank is not

empty will create an incorrect scan. It can affect the

sensors performance especially at liquid levels below the

Empty Signal Scan tank level.

3. Press and hold the SCAN button for 6 seconds.

a. The LED will begin to flash Orange indicating the empty

signal scan has begun, release the button.

b. Upon completion of the empty scan, a solid green LED will return

c. If the empty scan is not successful. The LED will flash red

ERASE EMPTY SIGNAL SCAN

If there is a need to erase or turn off the Empty Signal Scan, perform the following: First remove power to the

EchoWave

®

. Next, hold down the SCAN button while applying power to the sensor. When the LG10/LG11

series acquires a signal (LED will flash Green), the disturbance signal scan will be erased.

No other setting or functions will be affected when this step is preformed.

The Empty Signal Scan cannot be retrieved once erased.

A new disturbance signal scan must be preformed for this function to operate again.

®

The Empty Signal Scan can also be erased using WebCal

software. Please refer to the instructions on the

following page.

| 32 MN300840 REV A10

Page 33

Empty Signal Scan Section Six

VIEWING THE EMPTY SIGNAL SCAN

The Empty Signal Scan can be viewed with the WebCal

consult a Flowline

®

representative for reviewing of the signal data. To view, follow the directions below:

1. Activate an Empty Signal Scan (see instructions in Empty Signal Scan, Section 6).

2. Connect EchoWave

®

to WebCal® software via Fob

3. Click on Diagnostics Tab on the main WebCal

4. In the Select Signal Data pull down, select Empty Signal Scan.

5. The Empty Signal Scan will be displayed in the window.

®

®

screen

software (version 6.5 and greater). Note: Always

ERASE EMPTY SIGNAL SCAN WITH WEBCAL®

If there is a need to erase or turn off the empty signal scan, perform the following:

1. Disconnect the sensor from the application wiring.

2. Connect EchoWave

3. Click on Diagnostics Tab on the main WebCal

®

to WebCal® software via Fob.

®

screen.

4. Click on Erase Empty Signal Scan.

MN300840 REV A10 33 |

Page 34

Appendix Section Seven

ECHO CURVE

This function displays the primary echo return(s) that the sensor is seeing graphically as well as the location

and amplitude of the return(s). It can be used to confirm the correct level reading by the sensor or to

troubleshoot any false signals. There is a two step process involving the creating and viewing of an Echo

Curve. Note: Always consult a Flowline

#1 - CREATE AN ECHO CURVE

To create an Echo Curve, use the following instructions:

1. Make sure the LG10/LG11 series is installed within the actual

application.

a. Echo Curve will not provide any useful information when

placed outside of the application.

2. Press and hold the SCAN button for 1 second (LED will turn off),

then release.

3. Echo Curve is completed.

a. To view, you must connect the sensor to WebCal

Note: LG10/LG11 series can store a single Empty Signal Scan and a single

Echo Curve.

®

representative for reviewing of the signal data.

®

.

#2 - VIEWING THE ECHO CURVE

The Echo Curve can be viewed with the WebCal® software (version 6.5 and greater). To view, follow the

directions below:

1. Create an Echo Curve (see

instructions above).

®

2. Connect EchoWave

WebCal

®

software via Fob

3. Click on Diagnostics Tab on

the main WebCal

to

®

screen

4. In the Select Signal Data pull

down, select Echo Curve.

5. The Echo Curve will be

displayed in the window.

| 34 MN300840 REV A10

Page 35

Appendix Section Seven

This section of WebCal

®

is where you select the sensor configuration settings. Start from the top and work to

the bottom, choosing the sections that are applicable to your configuration. All configuration settings must be

selected before you can Write to Unit.

SENSOR CONFIGURATION

LOOP FAIL-SAFE

This feature allows you to select the fail-safe current output if the

sensor looses echo confidence (LOST). When the sensor regains

echo confidence, the output current will revert back to the current level

condition.

Hold Last Value - The output will remain in the same state as

the last validated echo detected. Example: If the output was

6.7mA just prior to the lost signal, the sensor will continue to

output 6.7mA until echo confidence is regained.

Empty - The output will revert to the current value for an

empty condition. When 4 mA at Bottom is selected, the

sensor will output 4 mA during a fail-safe condition. If 20 mA

at Bottom is selected, the sensor will output 20 mA during a

fail-safe condition.

Full - The output will revert to the current value for a full

condition. When 4 mA at Bottom is selected, the sensor will

output 20 mA during a fail-safe condition. If 20 mA at

Bottom is selected, the sensor will output 4 mA during a failsafe condition.

Overfill (21mA) - The sensor will output 21mA during a fail-

safe condition.

Overfill (22mA) - The sensor will output 22mA during a fail-

safe condition.

Note: Right click on any item to open the help menu. To reset the configuration table, press the Clear Screen

button.

Note: Choose Hold Last Value setting when your

Falling Below Probe

Rising Above Max. Fill-H

application level either falls below the end of the

probe or rises above the Max. Fill-H setting. An

alternative solution is to choose Empty setting if the

level only falls below the end of the probe or

choose Full if the level rises above the Max. Fill-H.

Choose Hold Last Value

or Empty

Choose Hold Last Value

or Full

MN300840 REV A10 35 |

Page 36

Appendix Section Seven

SENSOR CONFIGURATION (CONTINUED)

OUTPUT AT EMPTY

This feature allows you to select the orientation of the 4 to 20mA

output (4 to 20 mA or 20 to 4 mA). Choose which output setting best

fits the application. Factory default is 4mA at bottom and 20mA at top

as this configuration scenario is an industry standard. When

connecting your sensor to a display, you must account for your output

orientation setting.

4mA at Bottom - The output current will be 4mA when the

sensor measures an empty tank and 20mA when the sensor

measures a full tank.

20mA at Bottom - The output current will be 20mA when the

sensor measures an empty tank and 4mA when the sensor

measures a full tank.

STARTUP CONDITION

This feature allows you to select the startup current when power is

first applied to the sensor. The sensor will consume the selected

power while it is acquiring the liquid level. When the correct level

has been identified, the output will adjust to the level output. Use

this feature to avoid false alarms with the controller when power is

first applied to the sensor.

Empty - The current output will revert to the selected current

value for an empty condition.

o 4 mA at Bottom - The sensor will output 4 mA while

the sensor powers up.

o 20 mA at Bottom - The sensor will output 20 mA while

the sensor powers up.

Mid Tank (12 mA) – The sensor will output 12 mA while the

sensor powers up.

Full - The output will revert to the selected current value for a

full condition.

o 4 mA at Bottom - The sensor will output 20 mA while

powering up.

o 20 mA at Bottom - The sensor will output 4 mA while the

sensor powers up.

Overfill (22mA) - The sensor will output 22mA while the

sensor powers up.

Note: Right click on any item to open the help menu. To reset the configuration table, press the Clear Screen

button.

| 36 MN300840 REV A10

Page 37

Appendix Section Seven

SENSOR CONFIGURATION (CONTINUED)

PROBE TYPE

This feature allows you to select the type of probe attached to the

feed-through. It is critical to select the correct type of probe.

Rod - Recommended for installations in liquids, in bypass

chambers and stilling wells (when combined together with

the rod emulate a coaxial probe).

Cable - Recommended for installations in tall tanks and

where limited headroom is available.

Coaxial - Recommended for the use with clean liquids only.

It cannot be used with viscous, crystallizing, adhesive,

coating, or sticky liquids; fibrous liquids, sludge, slurry, pulp

DIELECTRIC RANGE

This feature allows you to select the dielectric range, which sets the

amplitude threshold within the sensor.

or any liquids containing solid particles.

Water based media (water, H2SO4, HCl)

o 40 to 100

o 20 to 39.9

o 10 to 19.9

Varying dielectrics (Alcohols, Ethyl Acetate, Caster Oil)

o 9 to 9.9

o 8 to 8.9

o 7 to 7.9

o 5 to 5.9

o 4 to 4.9

o 3 to 3.9

o 6 to 6.9

Typical Hydrocarbons (Diesel Fuel, Mineral Oil, Solvents)

o 2 to 2.9

Note: Only change the probe type when the probe has been physically changed. Never change this setting to

improve sensor performance. This will only cause issue with the operation of EchoWave

®

. Right click on any

item to open the help menu. To reset the configuration table, press the Clear Screen button

Note: It is very important to select the correct range for the dielectric value of the liquid. Choosing an incorrect

range will affect the performance of the sensor. Reference a website such as http://flowline.com for dielectric

information.

Note: Right click on any item to open the help menu. To reset the configuration table, press the Clear Screen

button.

MN300840 REV A10 37 |

Page 38

Appendix Section Seven

VOLUMTRIC CONFIGURATION

The sensor may be configured in volumetric

units (Gallons or Liters) or Distance (Height

of Liquid) units (inches, cm, feet or meters).

WebCal

Liquid) with units of Inches. To change

units or change from Distance to Volume,

press the Volumetric Mode button as

located near the center of the window.

Note: The Volumetric Mode button will be

highlighted in Blue when a volume output is

selected.

®

will default to Distance (Height of

| 38 MN300840 REV A10

Page 39

Appendix Section Seven

Shape Selection Window: This window will shows the different tank shape options available in WebCal

®

.

Vertical Cylinder

Vertical Cylinder with Cone Bottom

Horizontal Cylinder with End caps

Horizontal Cylinder with Spherical Ends

Spherical

Rectangular

Strapping Table – Use this feature for manual entry

of measured tank distances and volumes.

Select any of the above tank shapes and press OK to

confirm.

Dimensional Entry - Vertical Cylinder Example

Choose the Sensor Output Units as Distance or Volume. After choosing the Sensor Output Units, select the

units of measurement in the pull down to the left.

Distance Volume

Inches

Cm

Feet

Meters

Distance – Sensor Output Units (Vertical Cylinder Example)

Enter the dimensions of the tank. You must

enter data in all fields shown.

Sensor Height: Distance from the bottom of

the tank to the top of the threads.

Max. Fill Height: Distance from the bottom

of the tank to the operational full level of

liquid (20mA). This setting defines the

location of full current output and is the top of

the sensor’s measurement range.

Min. Fill Height: Distance from the bottom of

the tank to the operational empty level of

liquid (4mA). This setting defines the location

of empty current output and is the bottom of

the sensor’s measurement range.

Units of Measurement

Gallons

Liters

Probe Length: Distance of the probe from the bottom of the threads (feed through) to the end of the probe.

MN300840 REV A10 39 |

Page 40

Appendix Section Seven

Volume – Sensor Output Units (Vertical Cylinder Example)

Enter the dimensions of the tank. You must enter data

in all fields shown.

Sensor Height: Distance from the bottom of the tank

to the top of the threads.

Max. Fill Height: Distance from the bottom of the

tank to the operational full level of liquid (20mA). This

setting defines the location of full current output and is

the top of the sensor’s measurement range.

Min. Fill Height: Distance from the bottom of the tank

to the operational empty level of liquid (4mA). This

setting defines the location of empty current output

and is the bottom of the sensor’s measurement range.

Tank Height: Distance from the bottom of the tank to the top of the straight side wall.

Diameter: Distance of the inside tank diameter.

Probe Length: Distance of the probe from the bottom of the feed through to the end of the probe.

Volume – Tank Capacity (Vertical Cylinder Example): After entering the dimensions, press the Capacity

button to show the Calculated Capacity of the tank. If the Calculated Capacity is slightly different than the

expected capacity, click on the Adjust Capacity box and enter the expected capacity of the tank. If the

Adjusted Capacity is more than 10% of the Calculated Capacity, recheck the dimensions information entered

above.

When all dimensions are entered, press the Apply button to return to the previous Configuration window.

Apply – Transfers the dimensions to the original Configuration window.

Tanks – Returns to the previous Shape Selection window.

Cancel – Returns to the Configuration window without saving any information.

Help – Jumps to the Help menu.

| 40 MN300840 REV A10

Page 41

Appendix Section Seven

TANK LEVEL CONFIRMATION

This section of WebCal

under the Dimensional entry window. To edit these settings, you must go back to the Dimensional entry

window via the Volumetric Mode button.

Height Units: Units selected for configuration. When used as a device to measure the distance (height

of liquid), the options are inches, cm, feet or m. When used as a device to measure the volume of

liquid, the options are gallons or liters.

Sensor Height: Distance from the bottom of the tank to the bottom of the top of the threads.

Max. Fill-Height: Distance from the bottom of the tank to the operational full level of liquid (20mA).

This setting defines the location of full current output and is the top of the sensor’s measurement range.

Min. Fill-Height: Distance from the bottom of the tank to the operational empty level of liquid (4mA).

This setting defines the location of empty current output and is the bottom of the sensor’s measurement

range.

Probe Length: Total length of the probe from the bottom of the probe to the bottom of the threads

(feed through).

o Cable version only: The height of the counter-weight is included in this measurement.

Capacity: The total volume of the tank. Only shown when gallons or liters are selected.

Maximum Current: Displayed value of the largest operational current of the sensor’s measurement

range. Typically 20mA when Output @ Empty is set to 4mA.

Maximum Volume: Displayed value of the largest operational volume of the sensor’s measurement

range. This is the calculated volume of liquid at the Max. Fill-Height. This feature is only shown when

the sensor is selected to measure the volume of liquid in the tank.

Minimum Current: Displayed value of the smallest operational current of the sensor’s measurement

range. This value is dependent on the location of the Min. Fill-Height.

Minimum Volume: Displayed value of the smallest operational volume of the sensor’s measurement

range. This is the calculated volume of liquid at the Min. Fill-Height. This feature is only shown when

the sensor is selected to measure the volume of liquid in the tank.

Note: By extending the empty (4mA) to the bottom of the tank, the 4-20 mA output will track the volume of the tank.

This allows any local display to read the actual volume of liquid without the need for any unique configuration. This

feature is very useful with any non-linear tanks such as horizontal, spherical or tanks with cone bottoms.

®

is where you confirm the values set in the previous step. The values were entered

HeightUnits

Max.Fill‐H

Min.Fill‐H

Capacity

SensorHeight

ProbeLength

Max.Volume

Max.Current

Min.Current

Min.Volume

MN300840 REV A10 41 |

Page 42

Appendix Section Seven

WRITE TO UNIT

After you have entered configurations,

selected and configured the Tank Shape and

entered the Tank Values, click “Write to Unit”

and load the configuration into the memory of

the sensor. When completed, this

configuration will remain inside the sensor

memory and will not change unless the sensor

is connected to WebCal

®

and a new

configuration is written to the sensor. Loss of

Write to Unit

Wiring diagram

Factory Config

Save Config File

power will not change or lose the configuration

within sensor memory.

Next, use the file management features to save your configuration by clicking “Save Config File” and print

your wiring diagram by clicking “Wiring Diagram.”

®

“Save Config File” will save this configuration as a text file which can be loaded back into WebCal

by

pressing the “Open Config File” button. It is good practice to save the configuration file for each different

configuration with a unique name for easy identification. If using multiple sensors in identical applications, then

use of a single configuration file is recommended.

“Wiring Diagram” will display a PDF file showing the unique wiring for the specific configuration created in

WebCal

®

. The PDF can be printed or emailed. It is good practice to save the wiring diagram as a backup.

“Factory Reset” will return the sensor to its original factory configuration. The factory probe lengths will return

to the original maximum range. Sensors with pre-cut lengths of 36” (91.4cm), 72” (182.9cm) and custom

lengths will also return to the original factory configuration of 118.1” (300cm) for Rod and Coaxial probes and

216.5” (549.9cm) for Cable probes. Note: Make sure to re-enter the correct probe length and click on Write to

Unit before installing the EchoWave

®

.

Probe Style Sensor Probe Length

Rod

Coaxial

Cable (includes

counter-weight)

LG10-0_ _ _-_ _-_ _ _

LG10-1_ _ _-_ _-_ _ _

LG11-2_ _ _-_ _-_ _ _

118.1”

(300cm)

118.1”

(300cm)

216.5”

(549.9cm)

| 42 MN300840 REV A10

Page 43

Appendix Section Seven

CUTTING THE PROBE

If the length of the probe is too long (touches bottom of tank, prevents the sensor from being threaded into the

tank or a shorter length is required for the application), the probe can be cut to length in the field. Note: The

most important requirement for cutting the probe is to protect the housing from being dropped, banging into

other objects or swinging freely. Follow the instructions for the appropriate probe style.

ROD

Place the probe on a sturdy surface.

Measure and mark the location for the cut.

Secure the rod to prevent it from moving during cutting.

o Be sure to secure the housing to prevent it from moving when the probe is cut.

Use a saw with a blade designed to cut 316L SS to cut the probe.

o Examples include hack saw, diamond wheel rotary tool, etc.

o Once the probe is cut, trim/file the fresh cut.

Install the probe per mounting instructions.

COAXIAL

Place the probe on a sturdy surface.

Measure and mark the location for the cut on the coaxial shield.

Unthread the coaxial shield from the GWR sensor.

MN300840 REV A10 43 |

Page 44

Appendix Section Seven

Measure and mark the location for the cut on the exposed rod.

o Use the coaxial shield as a guide to confirm both cuts are at the same length.

Cutting the rod

o Secure the rod to prevent it from moving during cutting.

Be sure to secure the housing to prevent it from moving when the probe is cut.

o Use a saw with a blade designed to cut 316L SS to cut the probe.

Examples include hack saw, diamond wheel rotary tool, etc.

Once the probe is cut, trim/file the fresh cut.

o Attach a spacer to the end of probe.

Offset the spacer approx. 1/8” (3mm) from the end of the probe.

Make sure the remaining spacers are no further than 39.4” (1m) apart.

Secure retaining rings on each side of the spacer.

Note: Do not weld the spacers to the probe.

Cutting the coaxial shield

o Secure the coaxial shield to prevent it from moving during cutting.

o Use a pipe cutter with a blade designed to cut 316L SS to cut the coaxial shield.

A hack saw can be used to cut the coaxial shield if the pipe cutter is too difficult.

Use the initial cut of the pipe cutter as a score line for the hack saw.

Once the coaxial shield is cut, trim/file the fresh cut.

Slide the coaxial shield over the rod making sure not to move the spacers.

Thread the coaxial shield to the GWR sensor.

Install the probe per mounting instructions.

| 44 MN300840 REV A10

Page 45

Appendix Section Seven

CABLE

Place the probe on a sturdy surface.

Measure the location for the cut on the cable.

Wrap the cable with electrical tape along the area of the cut.

o This will prevent the cable from fraying while being cut.

Mark the location of the cut on the electrical tape.

Loosen the (¼–20, ⅛ Hex) set screws in the counterweight and remove from the cable.

Secure the cable to prevent it from moving during cutting.

o Be sure to secure the housing to prevent it from moving when the probe is cut.

Using a wire cutter or a rotary tool, cut the cable.

o Once the probe is cut, remove the tape keeping the cable intact.

Insert the freshly cut cable into the counterweight and tighten the (¼–20, ⅛ Hex) set screws.

Install the probe per mounting instructions.

MN300840 REV A10 45 |

Page 46

Appendix Section Seven

FACTORY SETTINGS

From Bottom

(Lowest point of probe)

From Top

(Bottom of Mounting Nut)

Probe

Style

Rod

Coaxial

Cable

(includes

counter-weight)

Note: Cable versions of the LG10/LG11 series must account for the counterweight attached to the end of the

probe.

Sensor

LG10-0_ _ _-_ _

LG10-1_ _ _-_ _

LG11-2_ _ _-_ _

Probe

Length

118.1”

(300cm)

118.1”

(300cm)

216.5”

(549.9cm)

4mA 20mA 4mA 20mA

2.0”

(50.8mm)

2.0”

(50.8mm)

7.9”

(200.7mm)

114.8”

(2915mm)

114.8”

(2915mm)

219.1”

(5566mm)

116.8”

(2966mm)

116.8”

(2966mm)

216.2”

(5145mm)

(85.1mm)

(85.1mm)

(85.1mm)

3.4”

3.4”

3.4”

| 46 MN300840 REV A10

Page 47

Appendix Section Seven

TROUBLESHOOTING

PROBLEM SOLUTION

No LED.

LED flashes Red.

Sensor is locked on a level

above the true level.

Sensor is not receiving power (10 to 30 VDC). Check wiring to the

sensor as well as the power supply.

Sensor cannot acquire a valid level reading. Make sure the sensor is

installed properly within the application and the probe is touching liquid.

Sensor is likely acquiring a false echo from some interference close to

the probe. Running an Empty Signal Scan should address this issue.

You may have received a probe that was cut from its original factory

Probe Length is greater than