Page 1

Warranty, Service & Repair

WARRANTY

Flowline warrants to the original purchaser of its products that such

products will be free from defects in material and workmanship under

normal use and service for a period which is equal to the shorter of

one year from the date of purchase of such products or two years from

the date of manufacture of such products.

This warranty covers only those components of the products which

are non-moving and not subject to normal wear. Moreover, products

which are modified or altered, and electrical cables which are cut to

length during installation are not covered by this warranty.

Flowline’s obligation under this warranty is solely and exclusively

limited to the repair or replacement, at Flowline’s option, of the products (or components thereof) which Flowline’s examination proves to

its satisfaction to be defective. FLOWLINE SHALL HAVE NO

OBLIGATION FOR CONSEQUENTIAL DAMAGES TO PERSONAL OR REAL PROPERTY, OR FOR INJURY TO ANYPERSON.

This warranty does not apply to products which have been subject to

electrical or chemical damage due to improper use, accident, negligence, abuse or misuse. Abuse shall be assumed when indicated by

electrical damage to relays, reed switches or other components. The

warranty does not apply to products which are damaged during shipment back to Flowline’s factory or designated service center or are

returned without the original casing on the products. Moreover, this

warranty becomes immediately null and void if anyone other than service personnel authorized by Flowline attempts to repair the defective

products.

Products which are thought to be defective must be shipped prepaid

and insured to Flowline’s factory or a designated service center (the

identity and address of which will be provided upon request) within

30 days of the discovery of the defect. Such defective products must

be accompanied by proof of the date of purchase.

Flowline further reserves the right to unilaterally wave this warranty

and to dispose of any product returned to Flowline where:

a. There is evidence of a potentially hazardous material present

with product.

b. The product has remained unclaimed at Flowline for longer than

30 days after dutifully requesting disposition of the product.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND

THE DESCRIPTION ON THE FACE OF THIS WARRANTY. This

warranty and the obligations and liabilities of Flowline under it are

exclusive and instead of, and the original purchaser hereby waives, all

other remedies, warranties, guarantees or liabilities, express or

implied. EXCLUDED FROM THIS WARRANTY IS THE

IMPLIED WARRANTY OF FITNESS OF THE PRODUCTS FOR A

PARTICULAR PURPOSE OR USE AND THE IMPLIED WARRANTY OF MERCHANT ABILITY OF THE PRODUCTS.

This warranty may not be extended, altered or varied except by a written instrument signed by a duly-authorized officer of Flowline, Inc.

To register your product with the manufacturer, fill out the enclosed

warranty card and return it immediately to:

Flowline Inc.

10500 Humbolt Street

Los Alamitos, CA90720.

If for some reason your product must be returned for factory service, contact Flowline Inc. to receive a Material Return

Authorization number (MRA) first, providing the following information:

1. Part Number, Serial Number

2. Name and telephone number of someone who can answer

technical questions related to the product and its application.

3. Return Shipping Address

4. Brief Description of the Symptom

5. Brief Description of the Application

Once you have received a Material Return Authorization number,

ship the product prepaid in its original packing to:

Flowline Factory Service

MRA _____

10500 Humbolt Street

Los Alamitos, CA 90720

To avoid delays in processing your repair, write the MRA on the

shipping label. Please include the information about the malfunction with your product. This information enables our service technicians to process your repair order as quickly as possible.

®

Version 1.2A

© 2000 FLOWLINE Inc.

All rights reserved.

Manual # LA900005 08/00

RicoRelay™

Bulk Tank Ultrasonic

Level Controller

Model LA21

Owner’s

Manual

Page 2

Step One

SPECIFICATIONS

Range: 6” to 12 feet (15.2 cm to 3.7 m)

Accuracy: ± 0.25% of span (air)

Resolution: 0.125” (3 mm)

Frequency: 50 kHz

Pulse rate: 3 per second

Beam width: 8° conical

Blocking distance: 6” (15.2 cm) minimum

LED Indication: Power, relay & fail-safety

Fail-safety: Power and echo fail-safe

Supply voltage: 5001: 120 VAC

5801: 18-30 VDC

Set points: 2 per relay

Adjustments: Potentiometer

Relay types: (2) Latched, SPDT

Relay rating: 5001: 250 VAC, 10A, 1/2 hp.

5801: 250 VAC, 10A, 1/4 hp.

Relay mode: Selectable NO or NC

Relay latch: ON or OFF

Hysteresis: Adjustable over range

Temperature rating: F: -40° to 140°

C: -40° to 60°

Temp. compensation: Automatic over entire range

Pressure rating: 30 psi (2 bar) @ 25 (C., derated @ 1.667 psi

(.113 bar) per (C. above 25 (C.

Enclosure rating: NEMA 4X (IP65)

Enclosure material: Polypropylene, U.L. 94VO

Transducer material: PVDF

Mounting conn.: 2” NPT (2” G)

Mounting gasket: Viton (2” G) metric only

Conduit connection: 1/2” NPT

CE compliance: EN 50082-2 immunity

(pending) EN 55011 emission

EN 61010-1 safety

About Ultrasonic Technology:

An ultrasonic sound wave is pulsed three times per second from the

base of the transducer. The sound wave reflects against the process

medium below and returns to the transducer. The microprocessor

based electronics measures the time of flight between the sound generation and receipt, and translates this figure into the distance between

the transmitter and process medium below.

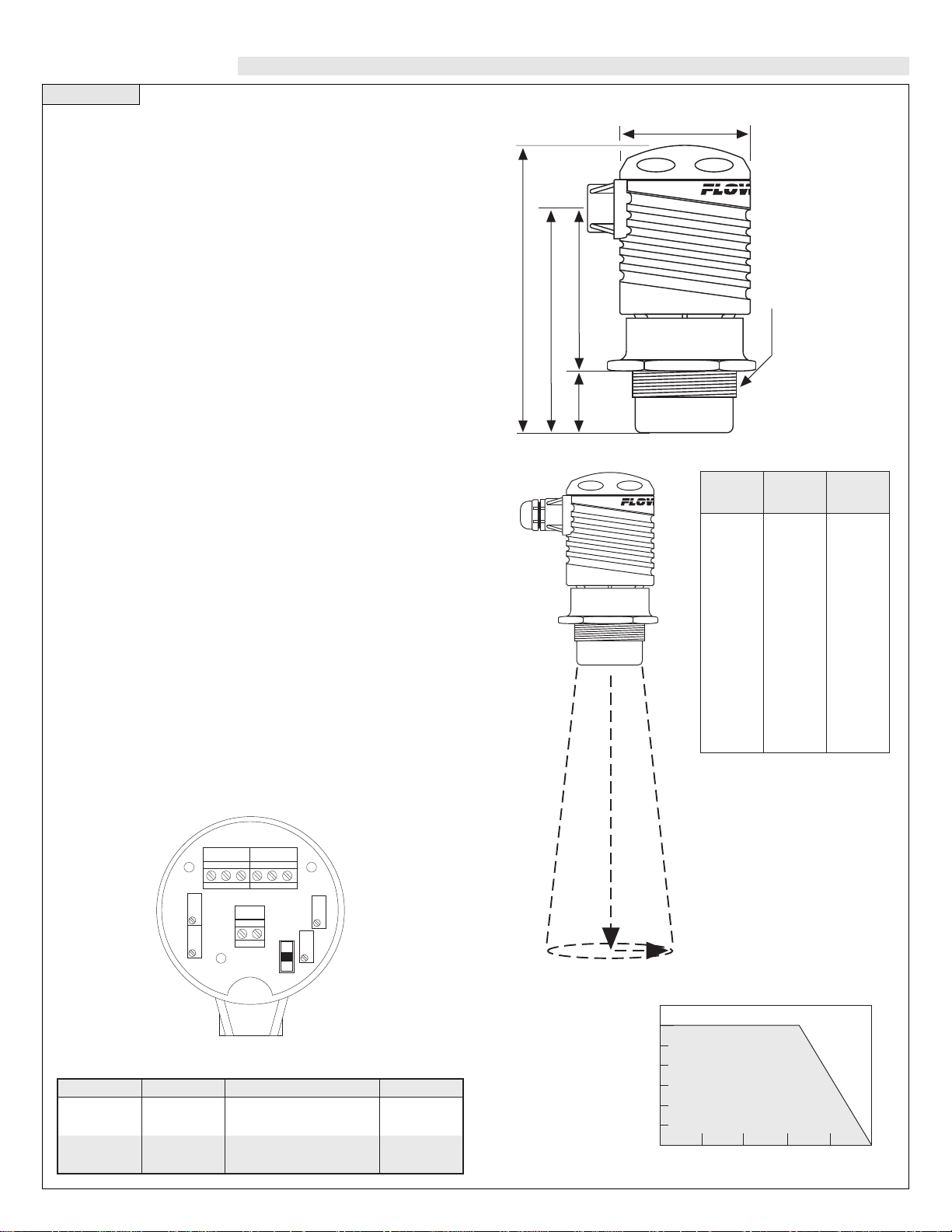

Beam Cone Radius:

RicoRelay Model Chart:

Temperature/Pressure Derating Chart:

RicoRelay Faceplate:

Dimensions:

6.3" (159 mm)

3.6 (92 mm)

4.9" (124 mm)

2.8" (71 mm)

1.3"

(32 mm)

2" NPT (2" G)

R

D

Tem erature/Pressure Derating

35

30

25

20

15

10

05

00

-40 -20 00 20 40 60

Operating Pressure (psi)

Temperature (°C)

Unacceptable

Range

Acceptable

Range

Model

LA21-5001

LA21-5801

LA21-5061

LA21-5861

Power

120 VAC

18-30 VDC

120 VAC

18-30 VDC

Mounting

2” NPT

2” NPT

2” G

2” G

Relay

250 VAC, 10A, 1/2 Hp.

250 VAC, 10A, 1/4 Hp.

250 VAC, 10A, 1/2 Hp.

250 VAC, 10A, 1/4 Hp.

NC C NO NC C NO

ON ON

LO

HI

LO

HI

RELAY 1

RELAY 2

L1 L2

AC

POWER

LO

HI

OP

Radius

Inches

Range

Feet

Radius

cm

1

2

3

4

5

6

7

8

9

10

11

12

1.2

2.1

2.9

3.7

4.9

5.4

6.2

7.1

7.9

8.8

9.6

10.4

3.1

5.2

7.3

9.5

11.6

13.7

15.9

18.0

20.1

22.3

24.4

26.5

Page 3

Step Two Step Three

SAFETY PRECAUTIONS GUIDE TO CONTROLS

About this Manual:

PLEASE READ THE ENTIRE MANUAL PRIOR TO

INSTALLING OR USING THIS PRODUCT. This manual

includes information on the RicoRelay™ bulk tank Ultrasonic

relay controller from FLOWLINE: LA21-5_01 and LA21-5_61.

Please refer to the part number located on the sensor label to verify the exact model which you have purchased.

User’s Responsibility for Safety:

FLOWLINE manufactures a wide range of liquid level sensors and

technologies. While each of these sensors is designed to operate in

a wide variety of applications, it is the user’s responsibility to select

a sensor model that is appropriate for the application, install it

properly, perform tests of the installed system, and maintain all

components. The failure to do so could result in property damage

or serious injury.

Proper Installation and Handling:

Because this is an electrically operated device, only properlytrained staff should install and/or repair this product. Use a proper

sealant with all installations. Note: Always install the 2” Viton gasket with the LA21-5_61. The G threaded version of the

RicoRelay™ will not seal unless the gasket is installed properly.

Never overtighten the transmitter within the fitting. Always check

for leaks prior to system start-up.

Wiring and Electrical:

A supply voltage of 120 VAC is used to power the LA21-50_1 controller. The sensor systems should never exceed a maximum of 120

volts AC. The supply voltage used to power the LA21-58_1 series

controller should never exceed a maximum of 30 volts DC.

Electrical wiring of the sensor should be performed in accordance

with all applicable national, state, and local codes.

Material Compatibility:

The RicoRelay™ enclosure is made of Polypropylene (PP). The

transducer is made of Polyvinylidene Fluoride (PVDF). Make sure

that the model which you have selected is chemically compatible

with the application liquids it will contact.

Enclosure:

While the transmitter housing is liquid-resistant when installed

properly, it is not designed to be immersed. It should be mounted

in such a way that the enclosure and diaphragm do not come into

contact with fluid.

Make a Fail-Safe System:

Design a fail-safe system that accommodates the possibility of

transmitter or power failure. In critical applications, FLOWLINE

recommends the use of redundant backup systems and alarms in

addition to the primary system.

Flammable, Explosive and Hazardous Applications:

The LA21 controller systems should not be used within flammable

or explosive applications.

1. Power indicator: This green LED lights when AC power is ON.

LED will also flash when a lost echo condition occurs.

2. Relay indicators: These red LED’s will light whenever the trans-

mitter energizes the relay , in response to the proper condition with

the set points.

3. AC Power terminals (LA21-50_1 series only): Connection of

120 VAC power to the controller. Polarity (neutral and hot) does

not matter.

3. DC Power terminals (LA21-58_1 series only): Connection of

18 to 30 VDC power to the controller. Please observe the Polarity

(positive and negative) of the terminal.

4. Relay terminals (NC, C, NO): Connect the device you wish to

control (pump, valve, alarm etc.) to these terminals: supply to the

COM terminal, and the device to the NO or NC terminal as

required. The switched device should be a noninductive load of

not more than 10 amps; for reactive loads the current must be derated or protection circuits used. When the red LED is ON and the

relay is in the energized state, the NO terminal will be closed and

the NC terminal will be open.

5. Relay Potentiometers: Adjusts the switching positions for each

relay with its own independent Hi and Lo adjustment.

6. Selector Switch: Allows for independent adjustment of the Hi or

Lo setting.

Warning

Always install the 2" V iton gasket with all versions of the LA215_61. The G threaded version of the RicoRelay will not seal

unless the gasket is installed properly.

NC C NO NC C NO

ON ON

LO

HI

LO

HI

RELAY 1

RELAY 2

L1 L2

AC

POWER

LO

HI

OP

1

3

4

2

5

6

24

5

5

5

Page 4

Step Four Step Five

WIRING INSTALLATION

FLOWLINE’s LA21 controller may be installed through the top wall

of a tank. Installation requires a 2" NPT (G) fitting or blind flange.

1. Install the appropriate 2" fitting in the top wall of the tank. Prior

to installation, make sure that the fitting has been installed properly and checked for leaks. Use a proper sealant at the time of

installation to ensure a liquid-tight seal. Secondly, make sure that

the fittings threads are not damaged or worn.

2. Insert the controller into the fitting and tighten to hand tight.

3. Always check for leaks prior to system start-up. To ensure proper installation, a complete leak test and simulation of actual

process conditions should be preformed.

Fitting Installation Flange Installation

Observe the Flange Chart

to the left to determine

the maximum depth for a

flange installation.

Warning

Do not install the LA21 in pressurized applications above 30 psi.

Always install the 2" V iton gasket with all versions of the LA21-

5_61. The G threaded version of the LA21-5_61 will not seal

unless the gasket is installed properly and checked for leaks.

Use a proper sealant at the time of installation to ensure a liquidtight seal. Secondly, make sure that the fittings threads are not

damaged or worn.

A supply voltage of 120 VAC is used to power the LA21 controller.

Electrical wiring of the sensor should be performed in accordance

with all applicable national, state, and local codes.

Wiring AC Power to LA21 (models LA21-50_1):

Polarity does not matter for the LA21-50_1. Do not exceed the 120

VAC power rating. The 2 relays can be connected to pumps, valves,

alarms, PLC’s, etc. as long as they do not exceed the 10A, 250 VAC,

1/2 Hp rating. Below illustrates using the same 120 VAC power suppling the LA21-50_1 to control two independent pumps directly.

Wiring DC Power to LA21 (models LA21-58_1):

Please observe polarity for the LA21-58_1. The 2 relays can be connected to pumps, valves, alarms, PLC’s, etc. as long as they do not

exceed the 10A, 250 VAC, 1/4 Hp rating. Below illustrates using the

same VDC power suppling the LA21-58_1 to control a high level and

low level alarm directly.

Wiring to the Relays:

The 2 relays are isolated from the power required to operate the

LA21. The relays can be used to control a device on a separate power

system. The illustration below demonstrates the LA21-50_1 controlling two alarms powered from a different power supply. All relay ratings will still apply.

NC C NO NC C NO

ON ON

LO

HI

LO

HI

RELAY 1

RELAY 2

L1 L2

AC

POWER

LO

HI

OP

HOT NEUTRAL

Flange

Inner Diameter

Inch (cm)

3 (7.6)

4 (10.2)

5 (12.7)

6 (15.2)

7 (17.8)

8 (20.3)

Flange

Depth

Inch (cm)

3 (7.6)

7 (17.8)

11 (27.9)

15 (38.1)

19 (48.3)

26 (66.0)

Depth

Inner Diameter

VACUUM

Do not install

LA21 at an

angle

Avoid

interference from

side of tank

Avoid

interference from

obstructions in

tank

LA21 will not

operate in

vacuum

NC C NO NC C NO

ON ON

LO

HI

LO

HI

RELAY 1

RELAY 2

+ -

AC

POWER

LO

HI

OP

Positive Negative

NC C NO NC C NO

ON ON

LO

HI

LO

HI

RELAY 1

RELAY 2

L1 L2

AC

POWER

LO

HI

OP

HOT NEUTRAL

POSITIVE NEGATIVE

18-30 VDC

18-30 VDC

120 VAC

120 VAC

Flange Chart

Page 5

Step Six Step Seven

CALIBRATION CALIBRATION

Power LED Indication

The LA21 features a single Green LED which indicates power and

fail-safe conditions. During normal operation, the LED will be ON

continuously to indicate that the controller has power and a strong

echo signal return strength.

Should the LED begin to FLASH, this indicates that the LA21 has

lost the acoustic signal and has gone into a fail-safe condition. During

the lost echo condition, both relays will energize indicating a full tank

condition. Once re-acquired, the LED will turn back ON continuously and the relays will return to their proper state. Note: during a failsafe condition, both relays will energize. Design your system such

that an energized relay state is a fail-safe condition.

Relay LED Indication

The LA21 features dual Red LED’s which indicate relay status.

When the LED is On, the corresponding relay is energized. When the

LED is Off, the corresponding relay is de-energized.

NC C NO NC C NO

ON ON

LO

HI

LO

HI

RELAY 1

RELAY 2

L1 L2

AC

POWER

LO

HI

OP

Relay 2

Red LED

Relay 1

Red LED

Power

Green

LED

Hi Set

Point

Lo Set

Point

Relay Energized

Relay De-energized

No Change To Relay

Relay LED Indication II

The relay’s in the LA21 will energize when the liquid level is above

both Hi and Lo points. The relay will de-energize when the level falls

below both the Hi and Lo points.

Low Level Alarm

The goal is to make sure that the liquid level does

not fall below a certain point. If it does, an alarm is

supposed to sound, alerting the operator of a low

level condition.

To do this, connect the alarm to the NC side of the

relay. Connect the source of power to the Com terminal of the relay.

In this application, the switch point is normally wet.

In this condition, the relay will be energized so the

alarm will not sound: i.e., the Red relay LED will be

On. If the fluid level falls below the low switch point,

the relay de-energizes, which closes the alarm circuit

and the alarm sounds.

High Level Alarm

In the same manor, this system

can be used to sound an alarm

when fluid reaches a high

level, with just a change in the

location of the switch point

and the reversing of the relay.

The alarm is now connected to

the NO side of the relay.

The sensor is normally dry. In

this condition, the relay will be

de-energized so the alarm does

not sound: i.e., the Red relay

LED should be Off. If the fluid

level rises to the high sensor

point, the sensor goes on, the relay energizes, and the alarm sounds.

Single Point Relay

Each relay can be used as a high or low level alarm. The instructions

below can be used for either function.

1. Turn on 120 VAC power supply.

2. Turn the Hi and Lo potentiometers for the

relay fully clockwise (about 18 turns).

3. Set the input level to its set point.

4. Flip selector switch to Hi.

5. Adjust Hi potentiometer counter-clockwise

until the LED for that relay just turns ON.

6. Turn Lo potentiometer for the relay fully

counter-clockwise (about 18 turns).

7. Flip selector switch to Lo.

8. Adjust Lo potentiometer clockwise until the

LED for that relay turns OFF.

9. Adjust Lo potentiometer counter-clockwise 1/4 turn, LED will

turn ON.

10. Repeat steps 3 to 9 for the other relay.

11. Flip selector switch to OP.

Note:to protect the loads, the relay set points should be adjusted

before the loads are connected.

Note:calibrate the LA21 to a static liquid level or stationary object.

Note: Low level alarm is wired NC and

the high level alarm is wired NO.

(LA21-50_1 Shown)

120 VAC

Warning

A supply voltage of 120 VAC is used to power the LA21-50_1

series controller. If making adjustments during powered operation,

use extreme caution and use only insulated tools. Also, calibrate

all models of the LA21 to a static liquid level or stationary object.

Wiring should be preformed by qualified personnel in accordance

with all applicable national, state and local electrical codes.

Note: If making adjustments during powered operation, go slow, use

extreme caution and use only insulated tools.

Note:A dry calibration is possible when using a solid target. Position

the LA21 in a secure location at the exact distances required.

High

Alarm

Low

Alarm

HOT NEUTRAL

ON ON

RELAY 1

NC C NO NC C NO

HI

LO

POWER

L1 L2

HI

OP

AC

LO

RELAY 2

HI

LO

High

Alarm

or

Low

Alarm

Page 6

Step Eight Step Nine

CALIBRATION

General:

The LA21 series controller itself requires no periodic maintenance

except cleaning as required. It is the responsibility of the user to determine the appropriate maintenance schedule, based on the specific

characteristics of the application liquids.

Cleaning Procedure:

1. Power: Make Sure that all power to the transmitter, controller

and/or power supply is completely disconnected.

2. Sensor Removal: In all through-wall installations, make sure

that the tank is drained well below the sensor prior to removal.

Carefully, remove the sensor from the installation.

3. Cleaning the Sensor: Use a soft bristle brush and mild detergent, carefully wash the transducer of the LA21. Do not use a

harsh abrasive such as steel wool or sandpaper, which might damage the surface of the transmitter. Do not use incompatible solvents which may damage the PVDF transducer or the transmitters

PP body.

4. Sensor Installation: Follow the appropriate steps of installation as outlined in the installation section of this manual.

Controller Logic

For all controllers, please use the following guide to understand the

operation of the LA21-5__1.

1. Power LED: Make sure the Green power LED is On when

power is supplied to the controller.

2. Relay LED(s): The relay(s) LED(s) on the LA21 will be energized when the level is above the Hi point and de-energized when

the level is below the Lo point. When the level is between the Hi

and Lo points, the relay will no change its state.

Relay Logic:

The relay can either be an independent relay (high or low level alarm)

or can be a latching relay (automatic fill or empty).

High Level Low Level Automatic

Alarm Alarm Control

Automatic Fill:

This system consists of a tank with a pump that is controlled by the

LA21. We connect the pump to the NC side of the relay. When the

relay is de-energized, the pump will turn On and fill the tank. When

the relay is energized, the pump will turn Off and stop filling the tank.

NOTE: If the pump motor load

exceeds the rating of the controller’s relay, a stepper relay of

higher capacity must be used as

part of the system design.

Automatic Empty:

Note that a similar system logic

can be used for an automatic

empty operation simply by controlling a pump that pumps

fluid out of the tank instead of

into it. However, note that the

pump will now be connected to

the NO side of the relay. When

the relay is energized, the pump will turn On and empty the tank.

When the relay is de-energized, the pump will turn Off and stop emptying the tank.

Latching Relay

1. Turn on 120 VAC power supply.

2. Turn the Hi and Lo potentiometers for the

relay fully counter-clockwise (about 18

turns).

3. Set the input level to its low set point.

4. Flip selector switch to Lo.

5. Adjust Lo potentiometer clockwise until the

LED for that relay just turns OFF.

6. Turn Hi potentiometer for the relay fully

clockwise (about 18 turns)

7. Flip selector switch to Hi.

8. Set input level to its highest point.

9. Adjust Hi potentiometer counter-clockwise until the LED for that

relay turns ON.

10. Repeat steps 3 to 9 for the other relay.

11. Flip selector switch to OP.

Note:to protect the loads, the relays should be adjusted before the

loads are connected.

Note:calibrate the LA21 to a static liquid level or stationary object.

MAINTENANCE

Note: Auto fill pumps are wired NC and

auto empty pumps are wired NO.

(LA21-50_1 Shown)

120 VAC

Note: If making adjustments during powered operation, go slow, use

extreme caution and use only insulated tools.

Note:Adry calibration is possible when using a solid target. Position

the LA21 in a secure location at the exact distances required.

HOT NEUTRAL

ON ON

RELAY 1

NC C NO NC C NO

HI

L1 L2

OP

AC

LO

POWER

RELAY 2

HI

HI

LO

LO

High

Level

Set Point

Low

Level

Set Point

Energized

Point

Hi Set

De-energized

Relay

Relay

Energized

Point

Lo Set

De-energized

Relay

Relay

Energized

Point

Hi Set

No Change

To Relay

Point

Lo Set

De-energized

Relay

Relay

Loading...

Loading...