Page 1

DataLoop

Loop-Powered Meters

™

LI25 Series Instruction Manual

2 V drop (5.7 V with backlight)

5 Digit LCD, 0.6" (15.2 mm) High

Custom Engineering Units

20 Segment Bar graph Display

Type 4X, NEMA 4X, IP65 Front

Maximum & Minimum Display

Linear, Square Root, or Programmable Exponent

Non-Volatile Memory – No Battery Needed

Flowline, Inc. | 10500 Humbolt Street, Los Alamitos, CA 90720 LIM60000FL2 Rev B

p 562.598.3015 f 562.431.8507 w flowline.com MN301034 rev D

Loop-

Powered

Backlight

Standard!

Page 2

DataLoop™ LI25 Level Controller Instruction Manual

INTRODUCTION

The LI25-2001 is an intrinsically safe and non-incendive loop-powered meter

approved for hazardous area locations. The LI25-1001 is a general-purpose

loop-powered meter for safe area applications. The four front panel buttons make

the setup and programming an easy task. Five digits, bar graph, engineering

units, and trend arrows provide a clear and attractive presentation of the process.

The square root and programmable exponent functions allow for conditioning of

signals from non-linear transmitters without adding external components to the

system and the convenience of scaling without a calibrated signal source make

the LI25 Series the ideal choice for process display applications.

ORDERING INFORMATION

Model Description

LI25-1001 Loop-Powered Panel Meter for Safe Area

LI25-2001 FM & CSA Approved Loop-Powered Panel Meter

Enclosures and Accessories

Model # of

Meters

LM91-1001 1 Plastic NEMA 4X Enclosure Through Cover

LM91-2001 2 Plastic NEMA 4X Enclosure Through Cover

LM92-1001 1 Plastic NEMA 4X Enclosure Inside Cover

LM93-1001 2 Plastic NEMA 4X Enclosure Inside Cover

Description Mounting

REGISTERED TRADEMARKS

NORYL® and LEXAN® are registered trademarks of General Electric Company.

All other trademarks mentioned in this document are the property of their

respective owners.

© 2013 Flowline, Inc. All rights reserved.

Visit our Web Site

http://www.flowline.com

2 MN301034 rev D

Page 3

DataLoop™ LI25 Level Controller Instruction Manual

TABLE OF CONTENTS

INTRODUCTION ................................................................................................... 2

ORDERING INFORMATION ................................................................................. 2

SPECIFICATIONS ................................................................................................ 5

General ............................................................................................................. 5

Input ................................................................................................................. 6

LI25 SERIES COMPLIANCE INFORMATION ...................................................... 7

Ratings and Approvals ..................................................................................... 7

SAFETY INFORMATION ...................................................................................... 7

INSTALLATION ..................................................................................................... 8

Unpacking ........................................................................................................ 8

Panel Mounting ................................................................................................ 8

Connections ................................................................................................... 10

4-20 mA Input Connections ....................................................................... 11

SETUP AND PROGRAMMING ........................................................................... 12

Front Panel Buttons & Status Indicators ........................................................ 13

Main Menu Display Functions & Messages ................................................... 14

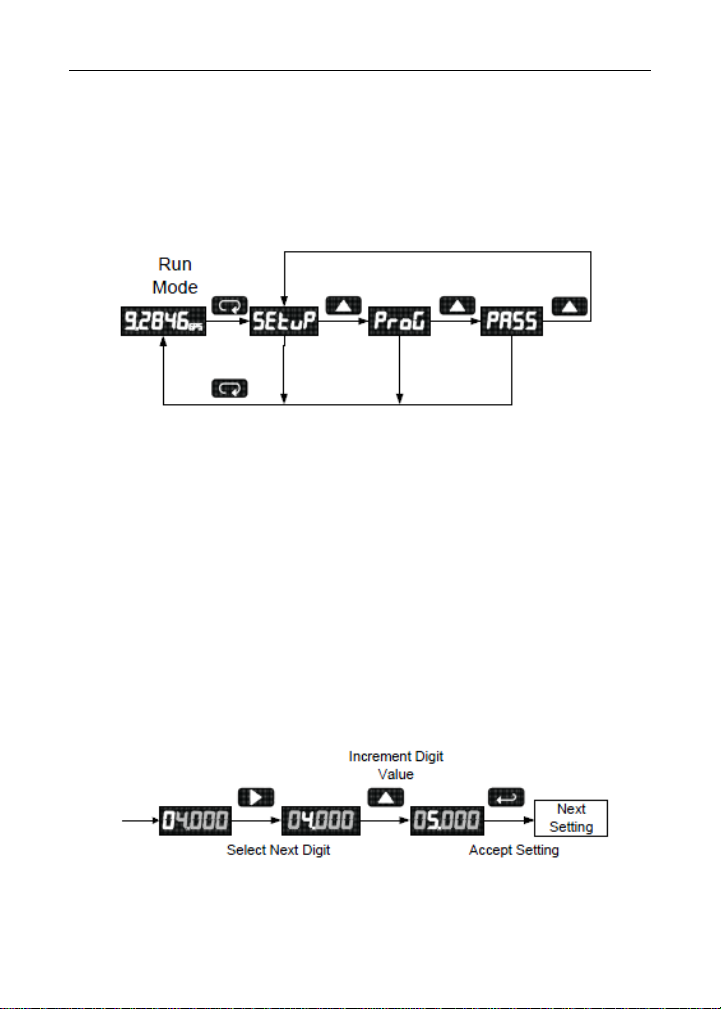

Main Menu ...................................................................................................... 15

Setting Numeric Values .................................................................................. 15

Setting Up the Meter (SETUP) ....................................................................... 16

Setting the Decimal Point (deCpt) ............................................................. 16

Setting the Units Display (units) ................................................................ 17

Programming the Meter (PrOG) ..................................................................... 18

Scaling the Meter (sCAlE) ......................................................................... 19

Calibrating the Meter (CAL) ....................................................................... 20

Recalibrating the internal Calibration Reference (ICAL) ........................... 20

Setting Up the Bargraph (GrApH) ............................................................. 21

Setting Up the Password (PASS) ........................................................................ 22

Locking the Meter ...................................................................................... 22

Unlocking the Meter .................................................................................. 23

Advanced Features Menu ................................................................................... 24

Advanced Features Menu & Display Message ......................................... 25

Math Functions (LnEAR, SQUAr, PrOGE, CUTOF) ................................. 26

Contrast (cOntr) ........................................................................................ 27

Noise Filter (FLtEr) .................................................................................... 27

Noise Filter Bypass (bYPAS) .................................................................... 27

Internal Calibration (ICAL) ........................................................................ 28

MN301034 rev D 3

Page 4

DataLoop™ LI25 Level Controller Instruction Manual

Information Menu (InFO) ........................................................................... 29

Operation ............................................................................................................ 30

Front Panel Buttons Operation ................................................................. 30

Maximum & Minimum (MAX & MIN) ......................................................... 31

MOUNTING DIMENSIONS ................................................................................. 32

Reset Meter to Factory Defaults ..................................................................... 33

Factory Defaults & User Settings .............................................................. 34

TROUBLESHOOTING ........................................................................................ 35

Troubleshooting Tips ------------------------------------------------------------------------ 35

QUICK USER INTERFACE REFERENCE GUIDE -------------------------------------- 36

TABLE OF FIGURES

Figure 1. Panel Cutout and Mounting……………………………………… ............. 9

Figure 2. LI25 Series Rear View ......................................................................... 10

Figure 3. Input Connections with Backlight ......................................................... 11

Figure 4. Input Connections without Backlight .................................................... 11

Figure 5. Meter Dimensions – Side View………………………………….. ........... 33

Figure 6. Case Dimensions – Top View…………………………………… ........... 33

4 MN301034 rev D

Page 5

DataLoop™ LI25 Level Controller Instruction Manual

SPECIFICATIONS

Except where noted all specifications apply to operation at +25°C.

General

DISPLAY Five digits

(

-99999 to 99999)

Four characters

(Engineering Units)

Bar graph 20-segment, 0% to 100% indication.

Trend arrows Up and down trend indication.

Backlight Orange (intensity varies with signal)

DISPLAY

2.5/second

UPDATE RATE

OVERRANGE Display flashes 99999

UNDERRANGE Display flashes -99999

PROGRAMMING

Four front panel buttons

METHOD

NOISE FILTER Programmable from 1 to 199

RECALIBRATION Recalibration is recommended at least every 12 months.

MAX/MIN

DISPLAY

Max/min readings reached by the process are stored until reset by

the user or until power to the meter is turned off.

PASSWORD Programmable password restricts modification of

programmed settings.

NON-VOLATILE

MEMORY

NORMAL MODE

All programmed settings are stored in non-volatile memory for a

minimum of ten years if power is lost.

64 dB at 50/60 Hz

REJECTION

ENVIRONMENTAL Operating temperature range: -30 to 65°C (-40°C allowed)*

Storage temperature range: -40 to 65°C

Relative humidity: 0 to 90% non-condensing

*Below -30°C, the LCD becomes less readable.

CONNECTIONS Removable screw terminals accept 12 to 22 AWG wire

ENCLOSURE &

MATERIALS

1/8 DIN, high impact plastic, UL 94V-0, color: gray

GE Plastics NORYL

blend (PPE PS) Resin

GE Plastics LEXAN

MOUNTING 1/8 DIN panel cutout required. Two panel mounting bracket

assemblies provided

MN301034 rev D 5

0.60" (15.2 mm) high, 7-segment,

automatic lead zero blanking.

0.25" (6.4 mm) high, 14 segment.

®

N190X Polyphenylene Ether & Polystyrene

®

HP92W Polycarbonate (PC) Film

Page 6

DataLoop™ LI25 Level Controller Instruction Manual

TIGHTENING

TORQUE

OVERALL

DIMENSIONS

WEIGHT 5.7 oz (162 g)

WARRANTY See Warranty

Input

ACCURACY

FUNCTION

LOW-FLOW

CUTOFF

TEMPERATURE

DRIFT

DECIMAL POINT

CALIBRATION

RANGE

VOLTAGE DROP Without Backlight With Backlight

EQUIVALENT

RESISTANCE

INPUT

OVERLOAD

Screw terminal connectors: 4.5 lb-in (0.5 Nm)

Mounting screws: 8.0 lb-in max. (0.9 Nm)

4.68" x 2.45" x 3.79" (119 mm x 62 mm x 96 mm)

(W x H x D)

±0.03% of span ±1 count,

square root and programmable exponent: 10-100% FS

Linear, square root, or programmable exponent

-99999 to 99999 (-99999 disables cutoff function)

50 PPM/C from -40 to 65C ambient

Up to four decimal places:

d.dddd, dd.ddd, ddd.dd, dddd.d, or ddddd

An Error message will appear if input 1 and input 2 signals are too

close together.

Input

Range

4-20 mA 0.40 mA

2.0 V maximum 5.7 V maximum

100 Ω @ 20 mA 285 Ω @ 20 mA

Over current protection to 2 A max.

Minimum Span

Input 1 & Input 2

6 MN301034 rev D

Page 7

DataLoop™ LI25 Level Controller Instruction Manual

LI25 SERIES COMPLIANCE INFORMATION

Ratings and Approvals

FM Class I, Div 1, 2, Groups ABCD

Class II, Div 1, Groups EFG

Class II, Div 2, Groups FG

Class III, Div 1, 2

Class 1, Zone 0, Group IIC

CSA Class I, Div 1, 2, Groups ABCD

Class II, Div 1, Groups EFG

Class II, Div 2, Groups FG

Class III, Div 1, 2

Class 1, Zone 0, Group IIC

LI25-2001 installation must be performed in

accordance with Control Drawing QS301034-

1

SAFETY INFORMATION

!

CAUTION: Read complete

instructions prior to installation and

operation of the meter.

Installation and service should be performed only by trained

service personnel. Service requiring replacement of internal components must be

performed at the factory.

MN301034 rev D 7

Page 8

DataLoop™ LI25 Level Controller Instruction Manual

INSTALLATION

There is no need to remove the meter from its case to complete the installation,

wiring, and setup of the meter.

Unpacking

Remove the meter from box. Inspect the packaging and contents for damage.

Report damages, if any, to the carrier.

If any part is missing or the meter malfunctions, please contact your supplier or

the factory for assistance.

Panel Mounting

Prepare a standard 1/8 DIN panel cutout – 3.622" x 1.772" (92 mm x

45 mm). Refer to Mounting Dimensions, page 23 for more details.

Clearance: allow at least 4" (102 mm) behind the panel for wiring.

Panel thickness: 0.04" - 0.25" (1.0 mm - 6.4 mm).

Minimum steel/stainless steel panel thickness to maintain watertight rating:

0.06" (1.5 mm).

Note: A steel or stainless steel panel rather than plastic is

recommended in cases where a watertight or dust-tight se al is

required between the meter and the panel.

Remove the two mounting brackets provided with the meter (back-off the two

screws so that there is ¼" (6.4 mm) or less through the bracket. Slide the

bracket toward the front of the case and remove).

Insert meter into the panel cutout.

Install mounting brackets and tighten the screws against the panel. To

achieve a proper seal, tighten the mounting bracket screws evenly until

meter is snug to the panel along its short side. DO NOT OVER TIGHTEN,

as the rear of the panel may be damaged.

8 MN301034 rev D

Page 9

DataLoop™ LI25 Level Controller Instruction Manual

Gasket

Panel

Removable

Connector

A

3.622" (92mm)

Square Corners to 0.060"

1.772"

B

(45mm)

(1.5mm) Max Radius

Panel Cutout

to DIN 43700

Tolerances:

A: +0.032 (+0.8mm)

-0.000 (-0.0mm)

B: +0.024 (+0.6mm)

-0.000 (-0.0mm)

Mounting

Bracket

Mounting

Screw

Figure 1. Panel Cutout and Mounting

Refer to Mounting Dimensions, page 23 for more details.

MN301034 rev D 9

Page 10

DataLoop™ LI25 Level Controller

CONNECTIONS

Instruction Manual

Signal connections are made to a four-terminal removable connector. This section

is only intended for the LI25-1001.

LI25-2001 installation must be performed in accordance with Control

Drawing QS301034-1 in order to meet agency approval ratings.

Observe all safety regulations. Electrical wiring should be

performed in accordance with all agency requirements

and applicable national, state, and local codes to prevent

damage to the meter and ensure personnel safety.

S+ S- B+ B-

Figure 2. LI25 Series Rear View

10 MN301034 rev D

Page 11

DataLoop™ LI25 Level Controller Instruction Manual

4-20 MA INPUT CONNECTIONS

Input connections are made to a four-terminal connector labeled S+|S-|B+|B-.

The loop-powered backlight is an optional configuration and requires a total

maximum voltage drop of 5.7 V. The backlight is recommended for dim lighting

conditions and is enabled when wired as shown in Figure 3. It may be

bypassed if installed in bright lighting conditions to reduce the maximum

voltage drop to 2.0 V as shown in Figure 4.

S+ S- B+ B-

4-20 mA

Power

Supply

Transmitter

Figure 3. Input Connections with Backlight

S+ S- B+ B-

4-20 mA

Power

Supply

Figure 4. Input Connections without Backlight

MN301034 rev D 11

Transmitter

Page 12

DataLoop™ LI25 Level Controller Instruction Manual

SETUP AND PROGRAMMING

• There is no need to recalibrate the meter for

milliamps when first received from the factory.

• The meter is factory calibrated for milliamps prior to

shipment. The calibration equipment is certified to

NIST standards.

Overview

There are no jumpers involved in the setup process of the meter. Setup and

programming is done through the front panel buttons.

After all connections have been completed and verified, apply power to the loop.

For

Quick User Interface Reference Guide go to

page 37

12 MN301034 rev D

Page 13

DataLoop™ LI25 Level Controller

FRONT PANEL BUTTONS & STATUS INDICATORS

Instruction Manual

Button

Symbol

Description Symbol Status

Menu 0%

Right arrow/Reset 100%

Up arrow/Max

Enter/Ack

Bar graph

minimum

Bar graph

maximum

Increasing trend

Decreasing trend

Press the Menu button to enter or exit the Programming Mode at any time.

Press the Right arrow button to move to the next digit or decimal position

during programming.

Press the Up arrow button to scroll through the menus, decimal point, or to

increment the value of a digit.

Press the Enter/Ack button to access a menu or to accept a setting.

Press and hold the Menu button for five seconds to access the Advanced

features of the meter.

MN301034 rev D

13

Page 14

DataLoop™ LI25 Level Controller Instruction Manual

MAIN MENU DISPLAY FUNCTIONS & MESSAGES

The meter displays various functions and messages during setup, programming,

and operation. The following table shows the main menu functions and

messages in the order they appear in the menu.

Display Parameter Action/Setting

units

DeCpt

sCalE

Inpt1

DspL1

Inpt2

DsPl2

Error

Graph

Pass

unloc

Locd

99999

-99999

Units Enter the Units menu

Decimal point Set decimal point

Scale Enter the Scale menu

Input 1 Calibrate input 1 signal or program input 1

Display 1 Program display 1 value

Input 2 Calibrate input 2 signal or program input 2

Display 2 Program display 2 value

Error Error, calibration not successful, check signal

Graph Enter the Graph menu

Password Enter the Password menu

Unlocked Program password to lock meter

Locked Enter password to unlock meter

Flashing

display

value

value

Overrange condition

Underrange condition

14 MN301034 rev D

Page 15

DataLoop™ LI25 Level Controller Instruction Manual

Main Menu

The main menu consists of the most commonly used functions: Setup, Program,

and Password.

Press Menu button to enter Programming Mode then press Up arrow button

to scroll main menu.

Press Menu, at any time, to exit and return to Run Mode. Changes made to

settings prior to pressing Enter/Ack are not saved.

Changes to the settings are saved to memory only after pressing

Enter/Ack.

The display moves to the next menu every time a setting is

accepted by pressing Enter/Ack.

Setting Numeric Values

The numeric values are set using the Right and Up arrow buttons. Press Right

arrow to select next digit and Up arrow to increment digit.

The digit being changed blinks.

Press the Enter/Ack button, at any time, to accept a setting or Menu button to

exit without saving changes.

MN301034 rev D 15

Page 16

DataLoop™ LI25 Level Controller Instruction Manual

The decimal point is set using the Right or Up arrow button in the Setup-decimal

point menu.

Setting Up the Meter (SETuP)

The Setup menu is used to select:

1. Decimal point position

2. Engineering units display

Press the Enter/Ack button to access any menu or press Up arrow button to

scroll through choices. Press the Menu button to exit at any time.

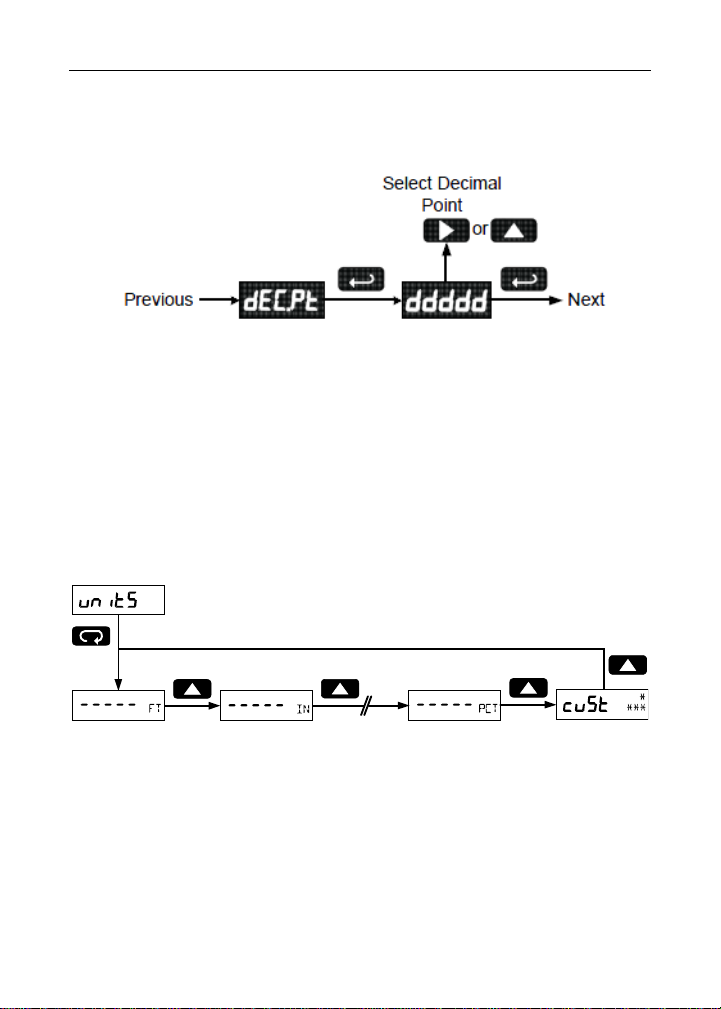

Setting the Decimal Point (

deCpt)

Decimal point may be set with up to four decimal places or with no decimal point

at all.

Pressing the Right or Up arrow moves the decimal point one place to the right

until no decimal point is displayed, then it moves to the left most position.

Setting the Decimal Point (

deCpt)

Decimal point may be set with up to four decimal places or with no decimal point

at all.

16 MN301034 rev D

Page 17

DataLoop™ LI25 Level Controller Instruction Manual

Pressing the Right or Up arrow moves the decimal point one place to the right

until no decimal point is displayed, then it moves to the left most position.

Setting the Units Display (units)

The meter can be set to display a combination of three alphanumeric characters

for engineering units or for identification (eg. FT, IN, M, CM, GAL, L). There is

also a fourth alphanumeric character located above this row, which supports a

degrees symbol and “x10” symbol (eg. °C, °F, x103, x106, x109).

Preconfigured units are available for feet (FT), inches (IN), meters (M),

centimeters (CM), gallons (GAL), liters (L), percent (%), and

percent (PCT).

A custom unit or tag may be entered as well, by selecting cust.

Press the Up arrow to scroll through unit options. Press Enter/Ack to select a

preconfigured unit or the custom unit or tag.

Entering a Custom Unit or Tag

Select Custom (cust) from the Units menu by pressing the Enter/Ack button. The

cursor will then show up in the left-most digit of the bottom three alphanumeric

tag characters.

Press Right arrow to select the next digit, and the Up arrow to cycle through the

alphanumeric characters available.

MN301034 rev D 17

Page 18

DataLoop™ LI25 Level Controller Instruction Manual

The upper right alphanumeric character may also be selected. This character

includes degree symbols and a degrees symbol and “x10” symbol (eg. °C, °F,

x103, x106, x109).

Press the Enter/Ack button, at any time, to accept the programmed unit or tag.

Press the Menu button to exit without saving changes.

18 MN301034 rev D

Page 19

DataLoop™ LI25 Level Controller Instruction Manual

Programming the Meter (prOG)

It is very important to read the following information, before proceeding to

program the meter:

• There is no need to recalibrate the meter for milliamps when first received

from the factory.

• The meter is factory calibrated for milliamps prior to shipment. The

calibration equipment is certified to NIST standards.

• Use the Scale menu to enter scale parameters without applying a live

signal.

• Alternatively, use the Calibrate menu to apply a signal from a calibrator or a

4-20 mA transmitter to calibrate the meter.

The Program menu contains the Calibrate and the Scale menus. Inputs may be

calibrated or scaled to any display within the range of the meter.

Additional parameters, not needed for most applications, are programmed with

the Advanced features menu, see Advanced Features Menu, page 25.

Error Message (

Error)

An error message indicates that the calibration or scaling process was not

successful.

After the error message is displayed, the meter reverts to input 1, allowing the

appropriate input signals to be applied.

The error message might be caused by one of the following conditions:

1. Minimum input span requirements not maintained.

2. Input 1 signal inadvertently applied to calibrate input 2.

Minimum Input Span

The minimum input span is the minimum difference between input 1 and input 2

signals required to complete the calibration or scaling of the meter. The minimum

span is 0.40 mA.

MN301034 rev D 19

Page 20

DataLoop™ LI25 Level Controller Instruction Manual

Scaling the Meter (sCAlE)

The 4-20 mA input can be scaled to display the process in engineering units.

A signal source is not needed to scale the meter; simply program the inputs and

corresponding display values.

Press Ack to Accept Setting

Press Up to Set Digit Value

Press Right to Select Next Digit

Press Menu to Exit at any Time

For instructions on how to program

numeric values see Setting Numeric

Values, page 17.

20 MN301034 rev D

Page 21

DataLoop™ LI25 Level Controller Instruction Manual

Calibrating the Meter (Cal)

To scale the meter without a signal

source refer to Scaling the Meter

sCAlE), page 21.

(

The meter can be calibrated to display the process in engineering units by

applying the appropriate input signal and following the calibration procedure.

The use of a calibrated signal source is strongly recommended.

Press Ack to Accept Setting

Press Up to Set Digit Value

Press Right to Select Next Digit

Press Menu to Exit at any Time

1. Press the Up arrow button to scroll to the Calibration menu (CAL) and press

Enter/Ack.

2. The meter displays inpt1. Apply a known signal and press Enter/Ack. Trend

arrows are displayed while accepting the signal.

3. After the signal is accepted, the meter displays dspl1. Press Enter/Ack,

enter a corresponding display value for the signal input, and press

Enter/Ack to accept.

4. The meter displays inpt1. Apply a known signal and press Enter/Ack. Trend

arrows are displayed while accepting the signal.

5. After the signal is accepted, the meter displays dspl2. Press Enter/Ack,

enter a corresponding display value for the signal input, and press

Enter/Ack to accept.

Recalibrating the Internal Calibration Reference (

The Internal Calibration (

ICAL) menu, located in the Advanced features menu, is

used to recalibrate the internal calibration reference. Recalibration is

recommended at least every twelve months. Refer to Internal Calibration (

page 30 for instructions.

MN301034 rev D 21

ICAL)

ICal),

Page 22

DataLoop™ LI25 Level Controller Instruction Manual

Setting Up the Bargraph (GrApH)

The meter can be set to display a bargraph proportional to the percentage

process reading within a user-defined span.

The span is determined by values entered for 0% and 100%.

If the 0% and 100% values are the same as the values that were entered for

display 1 and display 2, respectively, from the scale or calibrate steps, then it is

not necessary to modify them.

The bargraph may be disabled by selecting OFF from the bargraph menu.

22 MN301034 rev D

Page 23

DataLoop™ LI25 Level Controller Instruction Manual

Setting Up the Password (PASS)

The Password menu is used to program a five-digit password to prevent

unauthorized changes to the programmed parameter settings.

Locking the Meter

Enter the Password menu and program a five-digit password.

For instructions on how to program numeric values see Setting Numeric Values,

page 16.

Record the password for future reference. If appropriate, it may be recorded in

the space provided.

Model:

Serial Number:

Password:

_ _ _ _ _

MN301034 rev D 23

Page 24

DataLoop™ LI25 Level Controller Instruction Manual

Unlocking the Meter

If the meter is password protected, the correct password must be entered in

order to make changes to the parameter settings.

Entering the correct five-digit number sets the password to 00000, disabling the

protection. The meter remains unlocked until a new password is programmed or the

former password is re-programmed using the Password menu.

Changes to the programmed parameter settings are allowed only with the password set

to 00000.

If the password entered is incorrect, the meter displays Locd (Locked) for about

three seconds, then it returns to Run Mode. To try again, press Enter/Ack while

the Locked message is displayed.

Forgot the Password?

The password may be disabled by the following

procedure:

1. Note display reading prior to pressing the

Menu button. Ignore decimal point and

sign.

2. Access the Password menu, add 2 to the

noted reading and enter that number as

the password (e.g. display reading = -1.23,

password = 00125).

24 MN301034 rev D

Page 25

DataLoop™ LI25 Level Controller Instruction Manual

Advanced Features Menu

To simplify the setup process, functions not needed for most applications are

located in the Advanced features menu.

Press and hold the Menu button for five seconds to access the Advanced

features of the meter

.

MN301034 rev D 25

Page 26

DataLoop™ LI25 Level Controller Instruction Manual

Advanced Features Menu & Display Messages

The following table shows the Advanced features menu functions and messages

in the order they appear in the menu.

Display Parameter Action/Setting

Funct

LnEAr

SquAr

ProGE

Cutof

contr

fltEr

bypAs

TrEnd

-ON-

-Off-

ICal

Info

rESEt

Function

Linear

Square Root

Programmable

Exponent

Low-Flow Cutoff

Contrast

Filter

Bypass

Trend Arrows

On

Off

Initial calibration

Meter

information

Reset Defaults

Enter Function menu

Set linear scaling

Set square root extraction

Set programmable exponent

Set low-flow cutoff

Enter contrast adjustment menu

Set noise filter value

Set filter bypass value

Enable or disable trend arrows

Enable trend arrow display

Disable trend arrow display

Enter initial calibration for process inputs

Show software number and version, or reset to

defaults

Restore factory default parameter settings

For instructions on how to program

numeric values see Setting Numeric

Values, page 17.

26 MN301034 rev D

Page 27

DataLoop™ LI25 Level Controller Instruction Manual

Math Functions (lnEAr, SquAr, ProGE, Cutof)

The LI25 SERIES provides a number of math functions to condition outputs from

linear and non-linear transmitters.

Linear (

lnEAr)

Meters are set up at the factory for linear function. The linear function provides a

display that is linear with respect to the input signal.

Square Root (

SquAr)

The square root function is used to linearize the signal from a differential

pressure transmitter and display flow rate in engineering units.

Programmable Exponent (

ProGE)

The programmable exponent function is used to linearize the level signal in

applications using weirs and flumes and display flow rate in engineering units.

Upon selecting programmable exponent (Prog.E), the meter prompts entry of a

5-digit value between 0.5000 and 3.0000 as the exponent.

Low-Flow Cutoff (

CutoF)

The low-flow cutoff feature allows the meter to be programmed so that the oftenunsteady output from a differential pressure transmitter, at low flow rates, always

displays zero on the meter.The cutoff value may be programmed from -99999 to

99999. Below the cutoff value, the meter will display zero. Selecting either square

root or programmable exponent will set the cutoff value to 0. Program the cutoff

value to -99999 to disable.

MN301034 rev D 27

Page 28

DataLoop™ LI25 Level Controller Instruction Manual

Contrast (contr)

LCD contrast is adjustable through the front panel buttons. Select contr and

increase level using Up Arrow/Max button. Settings 1 through 9 will be displayed

on the screen as 11111 to 99999. Settings 1 through 4 are usually best when

viewing from below the angle perpendicular to the display. Settings 5 through 9

are usually best when viewing straight on (meter is at eye level) or when viewing

from above.

Noise Filter (

fltEr)

Most applications do not require changing this parameter. It is intended to help

attain a steady display with an unsteady (noisy) input signal.

The field selectable noise filter averages any minor or quick changes in the input

signal and displays the reading with greater stability.

Increasing the filter value will help stabilize the display, however this will reduce

the display response to changes on the input signal.

The filter level may be set anywhere from 1 to 199.

Noise Filter Bypass (

bypAs)

The meter can be programmed to filter small input changes, but allow larger input

changes to be displayed immediately, by setting the bypass value accordingly.

If the input signal goes beyond the bypass value, it will be displayed immediately

with no averaging done on it.

The noise filter bypass value may be set anywhere from 0.2 to 99.9. It

corresponds to percentage of full scale.

Increasing the bypass value may slow down the display response to changes on

the input signal.

Pressing the Right Arrow/Reset button will also bypass the filter and provide an

instant update.

28 MN301034 rev D

Page 29

DataLoop™ LI25 Level Controller Instruction Manual

Internal Calibration (ICal)

• There is no need to recalibrate the meter for milliamps when first

received from the factory.

• The meter is factory calibrated for milliamps prior to shipment. The

calibration equipment is certified to NIST standards.

The internal calibration allows the user to scale the meter without applying a

signal. The use of a calibrated signal source is necessary to perform the internal

calibration of the meter. Check calibration of the meter at least every 12 months.

Notes:

• The signal source must have a full-scale accuracy of 0.01% or better

between 4 and 20 mA in order to maintain the specified accuracy of the LI25

Series.

• Allow the meter to warm up for at least 15 minutes before performing the

internal calibration procedure.

The Internal calibration menu is part of the Advanced features menu.

1. Press and hold the Menu button for five seconds to access the Advanced

features of the meter.

2. Press the Up arrow button to scroll to the Internal calibration menu (ICAL)

and press Enter/Ack.

3. The meter displays 4.000 mA. Apply a 4.000 mA signal and press

Enter/Ack. The display shows both trend arrows for a moment while the

meter is accepting the signal.

4. After the signal is accepted, the meter displays 8.000 mA. Apply an 8.000

mA signal and press Enter/Ack. The display shows both trend arrows for a

moment while the meter is accepting the signal.

5. Continue, as in the previous step, for the remaining signals: 12.000 mA,

16.000 mA, and 20.000 mA.

Error Message (Error)

An error message indicates that the calibration or scaling process was not

successful. After the error message is displayed, the meter reverts to the

previous signal prompt, allowing the appropriate input signal to be applied. The

error message might be caused by inadvertently leaving the signal at the

previous level.

MN301034 rev D 29

Page 30

DataLoop™ LI25 Level Controller Instruction Manual

Information Menu (info)

The Information menu is located in the Advanced features menu, to access

Information menu see Advanced Features Menu, page 25.

It shows software and version number. To determine the software version of a

meter:

1. Go to the Information menu (info) and press Enter/Ack button. The number

shown is the software number.

2. Press Enter/Ack again to display the release version.

30 MN301034 rev D

Page 31

DataLoop™ LI25 Level Controller Instruction Manual

Operation

Front Panel Buttons Operation

MN301034 rev D 31

Page 32

DataLoop™ LI25 Level Controller Instruction Manual

Maximum & Minimum Readings (Max& MiN)

The maximum and minimum (peak & valley) readings reached by the process

are stored in the meter since the last reset or power-up. The meter shows MIN or

MAX to differentiate between run mode and max/min display.

1. Press Up arrow/Max button to display maximum reading since the last

reset/power-up.

2. Press Up arrow/Max again to display the minimum reading since the last

reset/power-up.

3. Press Enter/Ack to hold Max/Min display reading, the meter will continue to

track new Max/Min readings.

4. If Enter/Ack is not pressed, the Max/Min display reading will time out after

ten seconds and the meter will return to display the actual reading.

5. Press Right arrow/Reset button to reset Max/Min while reading is being

displayed. Max/Min display readings are reset to actual reading.

32 MN301034 rev D

Page 33

DataLoop™ LI25 Level Controller Instruction Manual

MOUNTING DIMENSIONS

1.76"

(45mm)

2.45"

(62mm)

0.59"

(15mm)

3.2"

(81mm)

Figure 5. Meter Dimensions – Side View

2.50"

(64mm)

3.61"

(92mm)

4.68"

(119mm)

MN301034 rev D 33

Figure 6. Case Dimensions – Top View

Page 34

DataLoop™ LI25 Level Controller Instruction Manual

RESET METER TO FACTORY DEFAULTS

When the parameters have been changed in a way that is difficult to determine

what’s happening, it might be better to start the setup process from the factory

defaults.

Instructions to load factory defaults:

1. Enter the Advanced features menu by holding the Menu button for 5

seconds. Press Up arrow until info is shown.

2. Press and hold Right arrow/Reset for five seconds, press

Enter/Ack when display flashes reset.

Note: If Enter/Ack is not pressed within three seconds, display returns to

Information menu.

3. The meter goes through an initialization sequence (same as on power-up),

and loads the factory default settings.

34 MN301034 rev D

Page 35

DataLoop™ LI25 Level Controller Instruction Manual

FACTORY DEFAULTS & USER SETTINGS

The following table shows the factory setting for most of the programmable

parameters on the meter. Next to the factory setting, the user may record the

new setting for the particular application.

Model: ______________ S/N: _______________ Date: _________

Parameter Display Default Setting User Setting

Units

Decimal point

Scaling

Input 1

Display 1

Input 2

Display 2

Bargraph

Bargraph 0%

Bargraph 100%

Password

Advanced

Features

Function

Contrast

Cutoff

Filter

Bypass

Trend Arrows

rnA

Dd.ddd

SCALE

InPt1

Dspl1

InPt2

Dspl2

GrapH

0 PCT

100 PCT

pass

Funct

contr

Cutof

Flter

Bypas

Trend

mA

3 places

4.000 mA

4.000

20.00 mA

20.000

On (enabled)

4.000

20.000

00000 (unlocked)

Linear

5 (55555)

-99999 (disabled)

1

0.2

On (enabled)

MN301034 rev D 35

Page 36

DataLoop™ LI25 Level Controller Instruction Manual

TROUBLESHOOTING

The rugged design and the user-friendly interface of the meter should make it

unusual for the installer or operator to refer to this section of the manual.

If the meter is not working as expected, refer to the recommendations below.

Troubleshooting Tips

Symptom Check/Action

No display or faint display

Rate display unsteady

Not able to change setup or

programming, Locd is displayed

Meter displays error message during

calibration (error)

Meter displays

1. 99999

2. -99999

Display stuck showing a number and

MAX or MIN

Display response is too slow

If the display locks up or the meter does

not respond at all

Display shows blurry, hard-to-read

digits in below freezing temperatures

(less than -18°C or 0°F).

Other symptoms not described above

1. Check connections.

2. Increase contrast setting in

Advanced menu.

3. Perform hard reset by temporarily

shorting S+ and S- terminals for a few

seconds.

Increase filter setting in Advanced menu.

Meter is locked, enter correct five-digit

password to unlock.

Check:

1. Signal connections

2. Minimum input span requirements

Check:

1. Input signal within range.

2. When using square root or

programmable exponent, cutoff must be

zero or greater.

Press Menu to exit Max/Min

display readings.

Check filter and bypass values to see if they

can be lowered.

Perform hard reset by temporarily shorting S+

and S- terminals for a few seconds and then

removing short.

Increase the filter setting to 10 or greater and

the bypass setting to 50 or greater. This will

slow the display response rate, but digits will

be steady and appear more clearly.

Call Technical Support for

assistance.

36 MN301034 rev D

Page 37

DataLoop™ LI25 Level Controller Instruction Manual

QUICK USER INTERFACE REFERENCE GUIDE

MN301034 rev D 37

Page 38

DataLoop™ LI25 Level Controller Instruction Manual

Push button Function

Menu Go to Programming Mode or leave Programming,

AdvancedFeatures, and Max/Min Modes.

Right ArrowMove to next digit or decimal point position. Reset Total.

Up Arrow Move to next selection or increment digit. Go to Max/Min Mode.

Enter/Ack Accept selection/value and move to next selection. Toggle

Rate/Total.

Hold to Acknowledge Alarm.

Menu held for 5 seconds enters Advanced Features

Max/Min Mode

While in Run Mode, pressing Up Arrow will initiate Max/Min Mode. Up Arrow

togglesbetween Max & Min displays, and Right Arrow resets the Max/Min to the

currentvalue. Press Menu or wait 10 seconds to return to Run Mode. Pressing

Enter/Ack willdisable the 10 second timeout and continuously display Max or Min.

38 MN301034 rev D

Page 39

DataLoop™ LI25 Level Controller Instruction Manual

WARRANTY

Flowline warrants to the original purchaser of its products that such products will

be free from defects in material and workmanship under normal use and service

in accordance with instructions furnished by Flowline for a period of two years

from the date of manufacture of such products. Flowline's obligation under this

warranty is solely and exclusively limited to the repair or replacement, at

Flowline's option, of the products or components, which Flowline's examination

determines to its satisfaction to be defective in material or workmanship within

the warranty period. Flowline must be notified pursuant to the instructions below

of any claim under this warranty within thirty (30) days of any claimed lack of

conformity of the product. Any product repaired under this warranty will be

warranted only for the remainder of the original warranty period. Any product

provided as a replacement under this warranty will be warranted for the full two

years from the date of manufacture.

RETURNS

Products cannot be returned to Flowline without Flowline's prior authorization. To

return a product that is thought to be defective, go to flowline.com, and submit a

customer return (MRA) request form and follow the instructions therein. All

warranty and non-warranty product returns to Flowline must be shipped prepaid

and insured. Flowline will not be responsible for any products lost or damaged in

shipment.

LIMITATIONS

This warranty does not apply to products which: 1) are beyond the warranty

period or are products for which the original purchaser does not follow the

warranty procedures outlined above; 2) have been subjected to electrical,

mechanical or chemical damage due to improper, accidental or negligent use; 3)

have been modified or altered;. 4) anyone other than service personnel

authorized by Flowline have attempted to repair; 5) have been involved in

accidents or natural disasters; or 6) are damaged during return shipment to

Flowline. Flowline reserves the right to unilaterally waive this warranty and

dispose of any product returned to Flowline where: 1) there is evidence of a

potentially hazardous material present with the product; or 2) the product has

remained unclaimed at Flowline for more than 30 days after Flowline has dutifully

requested disposition. This warranty contains the sole express warranty made by

Flowline in connection with its products. ALL IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMITATION, THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE

EXPRESSLY DISCLAIMED. The remedies of repair or replacement as stated

above are the exclusive remedies for the breach of this warranty. IN NO EVENT

SHALL FLOWLINE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

MN301034 rev D 39

Page 40

DataLoop™ LI25 Level Controller Instruction Manual

DAMAGES OF ANY KIND INCLUDING PERSONAL OR REAL PROPERTY OR

FOR INJURY TO ANY PERSON. THIS WARRANTY CONSTITUTES THE

FINAL, COMPLETE AND EXCLUSIVE STATEMENT OF WARRANTY TERMS

AND NO PERSON IS AUTHORIZED TO MAKE ANY OTHER WARRANTIES

OR REPRESENTATIONS ON BEHALF OF FLOWLINE. This warranty will be

interpreted pursuant to the laws of the State of California. If any portion of this

warranty is held to be invalid or unenforceable for any reason, such finding will

not invalidate any other provision of this warranty.

For complete product documentation, video training, and technical support, go to

flowline.com.

For phone support, call 562-598-3015 from 8am to 5pm PST, Mon - Fri.

(Please make sure you have the Part and Serial number available.)

40 MN301034 rev D

Loading...

Loading...