Page 1

FlowCon UniQ

INSTALLATION AND OPERATION INSTRUCTION

TEMPERATURE CONTROL

AND AUTOMATIC BALANCING VALVE

FlowCon UniQ 15-20mm

Install the FlowCon UniQ as called for in the

design drawings. Although the performance of

the valve is not affected either way, industry

standards call for balancing devices to be installed on the downstream side of the terminal

unit. INSTALL THE VALVE WITH THE FLOW

DIRECTIONAL ARROW POINTING IN THE

CORRECT DIRECTION.

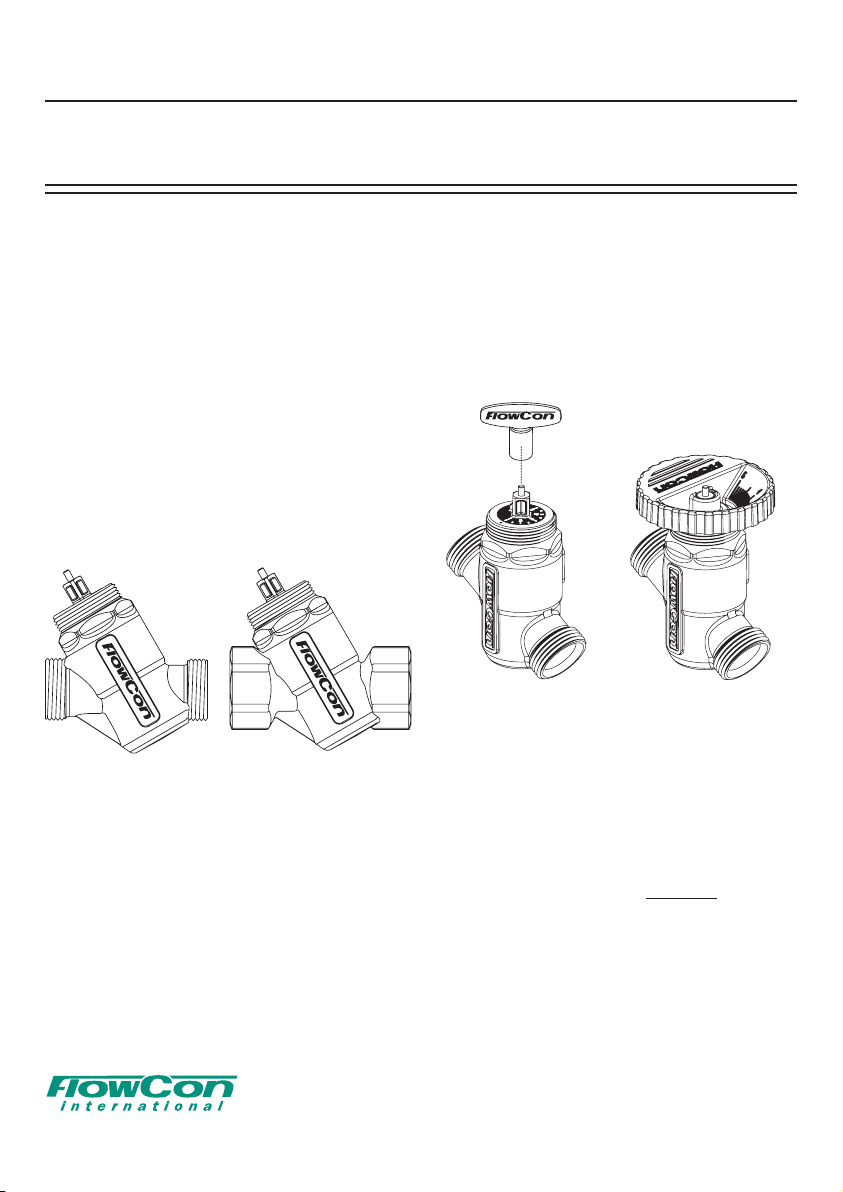

The FlowCon UniQ is available with fixed

20mm male ISO threaded connections fittable

for DN15 EuroCone according to EN215, Annex

A, i.e. figure 1.

FlowCon UniQ is similarly available with femaleby-female threaded connections DN15 or DN20,

i.e. figure 2.

Figure 1 Figure 2

For all threaded connections please clear threads

on both valve and piping of debris. Sealant such

as pipe dope or teflon

thread sealings.

WHEN USING HEMP AS PIPE SEALANT,

ENSURE NO STRANDS ARE LEFT IN THE

VALVE OR PIPING.

EuroCone fittings should seal with UniQ housing

without extra sealant.

tape is recommended on

Setting the valve:

The desired flow rate is chosen by adjusting the

valve (turned from setting 1.0 and up), with a

special designed key for a rough setting of the

valve (figure 3) or a large FlowCon adjustment

wheel for a micrometer setting (figure 4). There is

only one correct way to place the wheel on the

valve. Make sure there is no gap between the

wheel and the FlowCon UniQ.

Figure 3 Figure 4

The key or wheel are used to adjust the scale

on the top of the valve. Position is defined by

a “dot” marked on the edge of the housing top.

Once the correct flow rate has been selected,

the actuator can be applied. Please see specific installation instruction for selected actuator.

It is important to adjust the valve according to the setting needed BEFORE pressure

is applied to the system.

1B95038 01/2014

Denmark Dubai USA Brasil Singapore www.owcon.com

- 1 -

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

Page 2

FlowCon UniQ

FlowCon UniQ

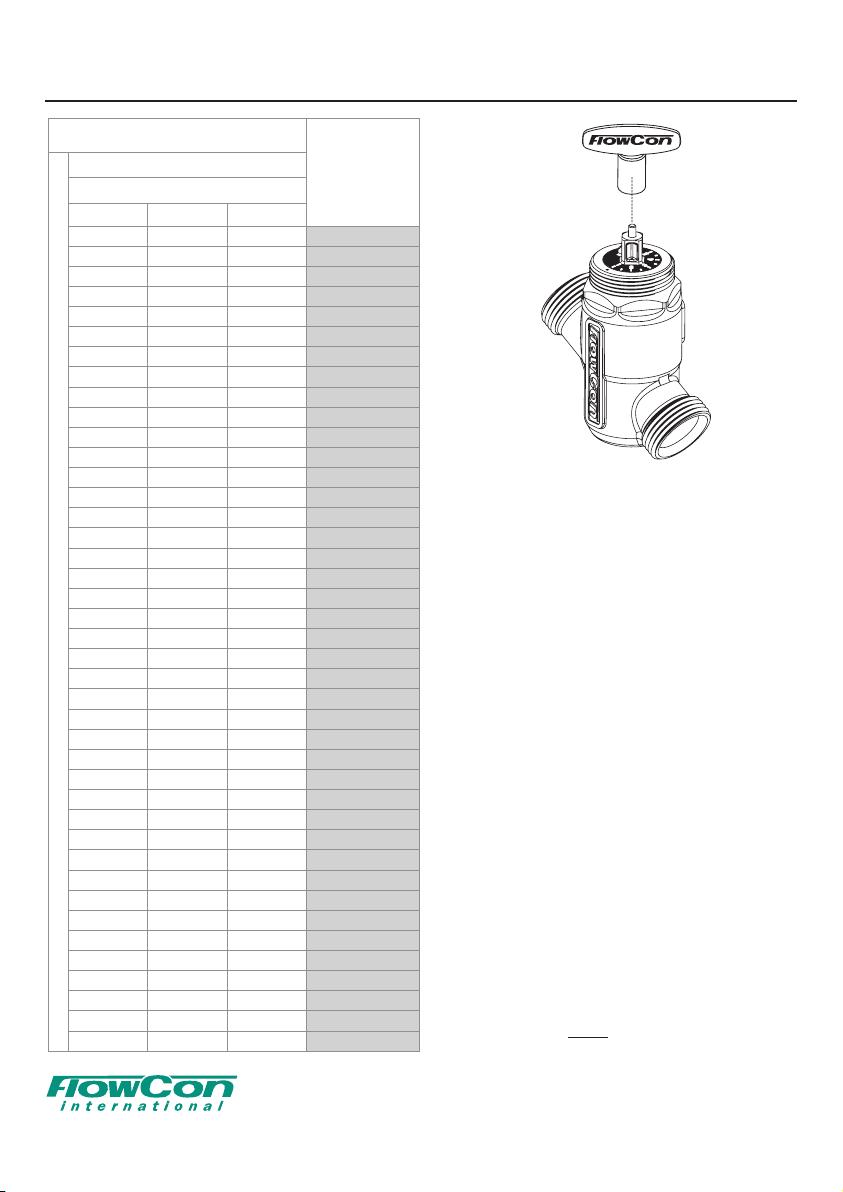

15/20mm · 1/2” / 3/4”

1

10

-200 kPaD · 1.51-29 psid

l/sec l/hr GPM

0.0056 20.3 0.089 1.0

0.0100 36.0 0.158 1.1

0.0157 56.7 0.249 1.2

0.0223 80.1 0.353 1.3

0.0291 105 0.461 1.4

0.0360 129 0.570 1.5

0.0426 153 0.675 1.6

0.0489 176 0.775 1.7

0.0549 198 0.869 1.8

0.0604 218 0.957 1.9

0.0657 237 1.041 2.0

0.0708 255 1.121 2.1

0.0757 273 1.199 2.2

0.0806 290 1.277 2.3

0.0856 308 1.356 2.4

0.0908 327 1.439 2.5

0.0963 347 1.526 2.6

0.1022 368 1.618 2.7

0.1084 390 1.716 2.8

0.1149 414 1.820 2.9

0.1218 439 1.930 3.0

Nominal ow rate

0.1291 465 2.044 3.1

0.1365 491 2.162 3.2

0.1440 518 2.281 3.3

0.1515 546 2.400 3.4

0.1589 572 2.516 3.5

0.1658 597 2.627 3.6

0.1723 620 2.730 3.7

0.1782 642 2.823 3.8

0.1833 660 2.903 3.9

0.1874 675 2.969 4.0

0.1907 686 3.020 4.1

0.1929 695 3.056 4.2

0.1943 699 3.078 4.3

0.1947 701 3.084 4.4

0.1951 702 3.091 4.5

0.1952 703 3.092 4.6

0.1958 705 3.102 4.7

0.1976 711 3.130 4.8

0.2015 725 3.192 4.9

0.2086 751 3.305 5.0

Setting

TEMPERATURE CONTROL

AND AUTOMATIC BALANCING VALVE

Figure 5

Accuracy: Greatest of either ±10% of controlled ow rate or

±5% of maximum ow rate.

Note 1: Min. ΔP=10 x √setting

1B95038 01/2014

Denmark Dubai USA Brasil Singapore www.owcon.com

- 2 -

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

Page 3

FlowCon UniQ

Assembly drawing FlowCon UniQ:

A: FlowCon UniQ valve

(here with 20mm male (ISO) suitable for

DN15 EuroCone)

B: Adjustment key

C: Adjustment wheel

D: EuroCone union end connections

(here 15mm male)

E: Actuator (here EV.0.2).

B

A

TEMPERATURE CONTROL

AND AUTOMATIC BALANCING VALVE

E

C

D

General.

It is recommended flushing the system before

installing the FlowCon UniQ. Please make

sure the entire pipeline is flushed. If it is not

D

Warranty obligation.

Failure to abide by all recommendations as per

this installation and operation instruction will void

warranty.

Figure 6

possible to flush the system unless the FlowCon

UniQ is installed, please make sure to adjust

For latest updates please see www.flowcon.com

the setting to 5.0. Water must always be

suitable treated, clean and free of debris. It is

recommended that a strainer be installed prior to

the valve body to prevent damage or blockage

due to debris. Ensure that the valve is not in the

fully closed position when filling the system with

water.

1B95038 01/2014

Denmark Dubai USA Brasil Singapore www.owcon.com

- 3 -

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

Page 4

FlowCon UniQ

TEMPERATURE CONTROL

AND AUTOMATIC BALANCING VALVE

1B95038 01/2014

Denmark Dubai USA Brasil Singapore www.owcon.com

- 4 -

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

Loading...

Loading...