Page 1

FlowCon SM 15-40mm

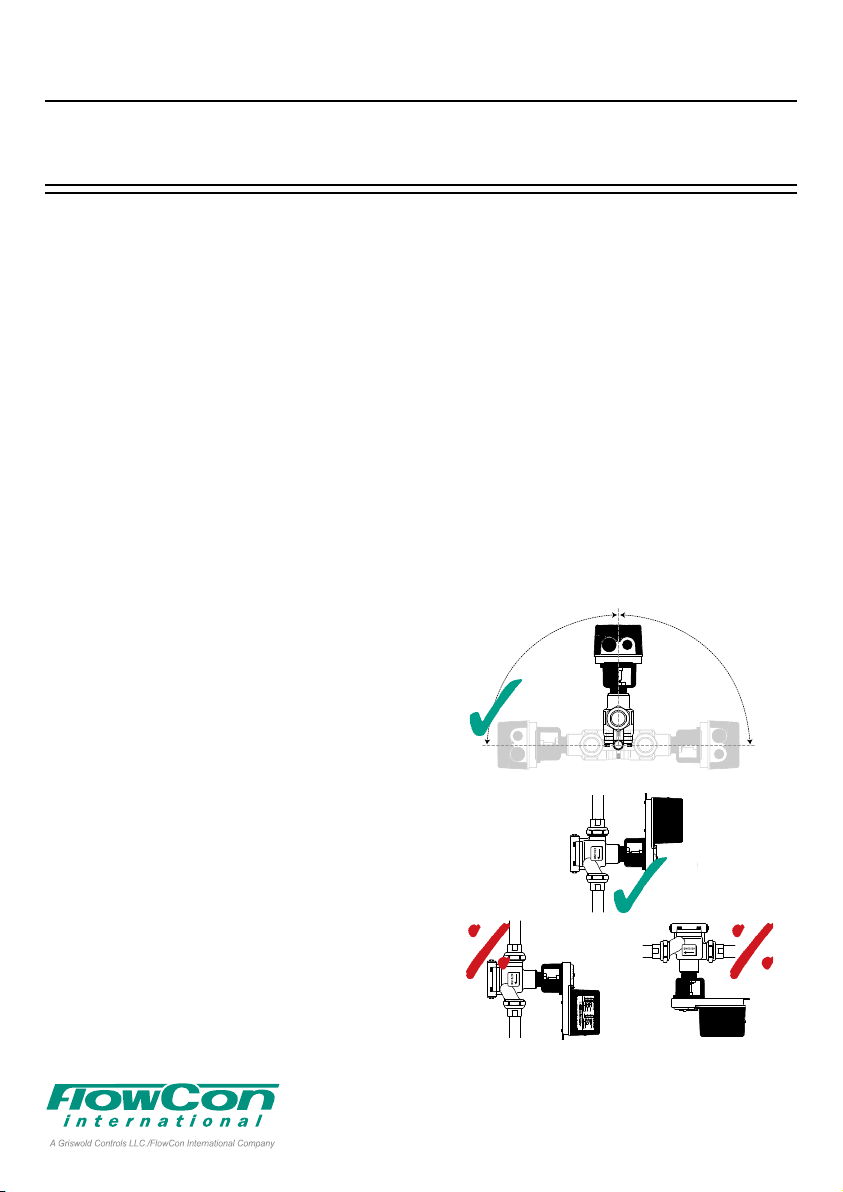

Max 90º Max 90º

Max 90º Max 90º

INSTALLATION AND OPERATION INSTRUCTION

FlowCon SM 15-40mm, 1/2”-1 1/2”

DYNAMIC SELF BALANCING

CONTROL VALVE

Install the FlowCon SM valve either in the

supply or return pipe work for the unit. It is recommended that a strainer be installed prior to

the valve body to prevent damage or blockage

due to debris. INSTALL THE VALVE HOUSING

WITH THE FLOW DIRECTIONAL ARROW

POINTING IN THE CORRECT DIRECTION.

The valve body is available with double union

end connections. Two types of end connections are available for use with the union nut:

Threaded (male or female):

The threads on both the connection and piping should be cleaned carefully.

As these models are union end connected, the

union nuts and the end connections should be

removed for installation.

O-rings are supplied with the valve body and

are used to seal the connections. It is recommended to grease the o-rings with a silicone

grease before installation. IMPORTANT: Never

use mineral oil or petrol based grease or oil

on the o-rings. Please make sure these are

in place in the o-ring grooves in the inlet and

outlet of the valve body, when installing the

housing and REMEMBER TO TIGHTEN THE

UNIONNUTS TO ENSURE SEALING.

Valve bodies are as standard supplied with

body tappings plugged, each plug sealed with

a gasket.

Alternatively, pressure/temperature fittings

(p/t plugs) are available. Before finger mounting the p/t plugs in the body tappings, pls. seal

the threads of the p/t plugs (DO NOT OVER

TIGHTEN).

Fitting and orientation

of the actuator

Pls. install the valve so that the actuator is

located upwards and not lower than the horizontal line to prevent condensation into the

electronics (pls. see figure 1 below).

Figure 1

Max 90º Max 90º

For all threaded connections pls. clear threads

on both valve and piping of debris. Sealant such

as pipe dope or teflon tape is recommended.

WHEN USING HEMP AS PIPE SEALANT,

ENSURE NO STRANDS ARE LEFT IN THE

VALVE OR PIPING.

Soldered end (sweat):

REMOVE THE END CONNECTIONS FROM

THE HOUSING BEFORE SOLDERING. THIS

ENSURES THAT THE O-RINGS AND INTERNAL PARTS ARE NOT DAMAGED BY HEAT.

1A95100 - 08/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 1 -

for mistakes, if any, in any printed material.

Page 2

FlowCon SM 15-40mm

DYNAMIC SELF BALANCING

CONTROL VALVE

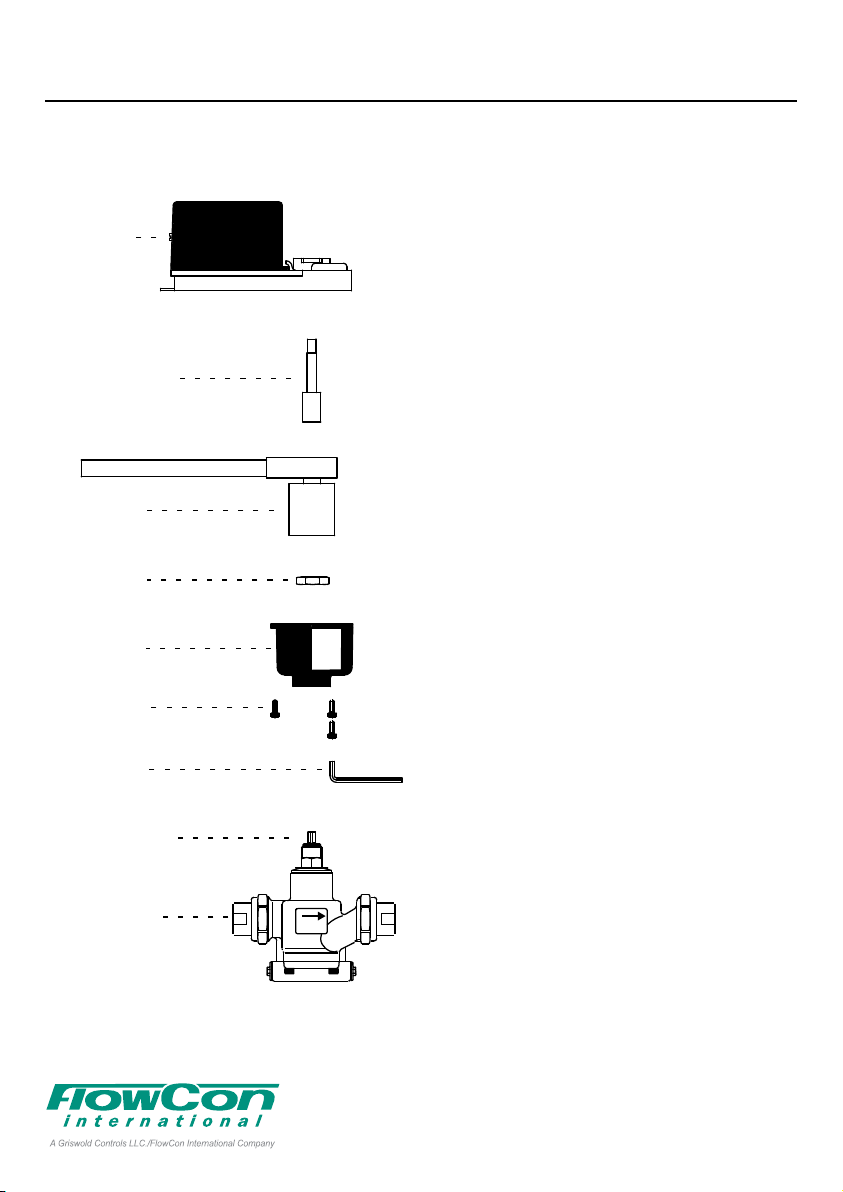

Valve and actuator mounting components and

tool are shown in figure 2.

Actuator

Cover

Screw

Spindle/

Shaft Adapter

Socket &

Rachet

Brass

Nut

Mounting

Bracket

Socket Head

Screws

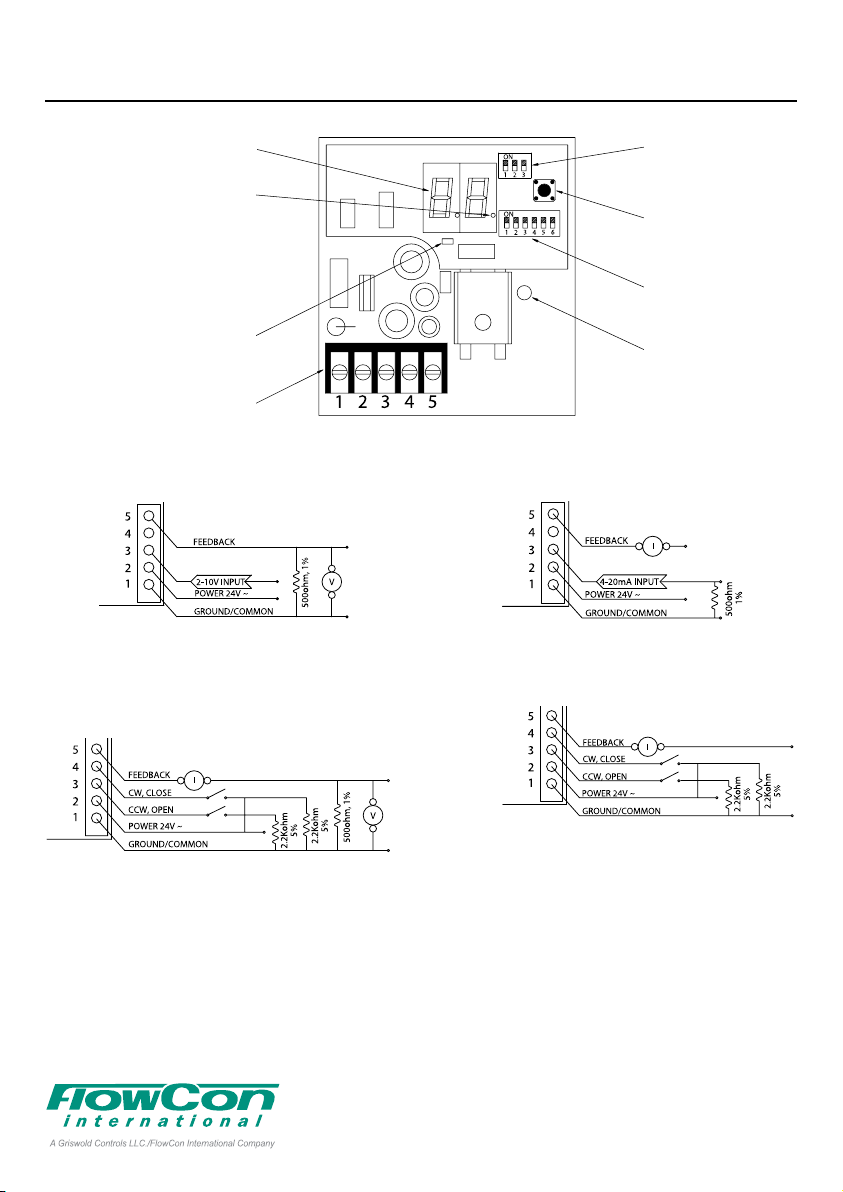

Actuator wiring and programming

Remove the actuator cover by loosening the

cover screw. Figure 3 illustrates the actuator

circuit board layout and all relevant components when programming the actuator. Set

the maximum flow DIP switches (refer to table

on page 6). If adjusting the DIP switch settings after power has been connected, press

the reset button to input the new setting.

Figures 4-8 illustrate the different signal requirements, i.e. Analog 2-10V, Analog 4-20mA

and Digital Tri-state and how to apply

resistors and wires. Connect the wiring

according to the selected input signal.

500ohm resistors (the blue ones) are supplied

for 4-20mA to 2-10V conversion and connected

as illustrated in figure 4 (2-10V) or figure 5

(4-20mA).

Two 2.2Kohm resistors (the brown ones) are

supplied for special consideration for digital/

tri-state control. In this mode the actuator is

sensitive to induced electrical voltages from

other sources. To prevent such interference,

wire one 2.2Kohm resistor between pins 1 and

4 and the second 2.2Kohm resistor between

pins 1 and 3 (see figures 6 and 7).

Hex

Key

Spindle/Shaft

Valve Body

Figure 2

1A95100 - 08/2016

DN15/20

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 2 -

for mistakes, if any, in any printed material.

Page 3

FlowCon SM 15-40mm

Figure 3

Position in rotations

LED Off: Actual valve position

rotations displayed

LED On: Maximum rotation

setting displayed

(alternates every 10 sec.)

Programming and

indication LED

Wiring terminal strip

DYNAMIC SELF BALANCING

CONTROL VALVE

Programming DIP

switches

Reset and

recalibration button

Maximum ow DIP

switches

Manual override

clutch

(DO NOT OPERATE

WHILE POWER IS

CONNECTED)

Figure 4

Figure 6

ANALOG

2-10VDC input and

2-10VDC feedback

DIGITAL TRI-STATE

2-10VDC feedback

Figure 5

Figure 7

ANALOG

4-20mA input and

4-20mA feedback

DIGITAL TRI-STATE

4-20mA feedback

1A95100 - 08/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 3 -

for mistakes, if any, in any printed material.

Page 4

FlowCon SM 15-40mm

DYNAMIC SELF BALANCING

CONTROL VALVE

The actuator is factory preset for an analog signal. If the signal requirement must be

changed, proceed with the instruction below:

Remove power and set all

programming DIP switches

to OFF.

Apply power and within 10

seconds, press and

release the reset button.

The programming and

indication LED should

start blinking.

Turn programming DIP switch #1, #2 or #3 ON,

then OFF to select signal requirement.

Switch #1:

Digital/3-PointFloating/Tri-state.

Switch #2:

PWM Pulse

Width Modulation.

(not available on SM.0.0.0.1)

Switch #3:

Analog

2-10V or 4-20mA.

For Normally Closed set

programming switch #1 to OFF.

Failsafe Open or

Failsafe Closed function setting

This function applies to battery back up failsafe models only. It provides power storage to

drive the actuator either open to the maximum

flow setting or fully closed in the event of a

power supply failure. As standard the actuator

is set to Failsafe Closed.

For Failsafe Open set

programming switch #2 to ON.

For Failsafe Closed set

programming switch #2 to OFF.

Actuator Zero and Span adjustment

Remove power from the actuator. Re-apply

power to terminal 2 and

within 10 seconds, press

and hold the reset button

until the indication LED

blinks once.

Release the reset button.

The indication LED should

remain illuminated.

Normally Open or

Normally Closed function setting

The actuator is delivered from factory set to

Normally Closed and an analog control signal

so that a minimum signal of 2V or 4mA will

close the valve and maximum signal of 10V

or 20mA will open the valve to selected maxi-

Apply the new zero voltage

to terminal 3 (any value

between 0 and 7VDC).

Press and release the reset

button to memorize this value.

The LED should blink once as

confirmation.

mum flow. If changing to Normally Open, see

below:

For Normally Open set

programming switch #1 to ON.

1A95100 - 08/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 4 -

for mistakes, if any, in any printed material.

Page 5

FlowCon SM 15-40mm

DYNAMIC SELF BALANCING

CONTROL VALVE

Apply the new maximum voltage to terminal 3

(any value between 3 and 10VDC and at least

3VDC greater than the zero value).

Press and release the

reset button to memorize

this value. The indication

LED should blink once as

confirmation and then

cease to be illuminated.

The actuator will now operate with the new

zero value and span.

FAILURE: If the LED provides 3 sequences of

4 blinks, the zero and span programming was

unsuccessful. This may occur if the difference

between the zero and maximum voltages was

not equal or grater than 3VDC.

NOTE: The feedback signal will always be 420mA or 2-10V and independent of the zero

and span adjustment.

Circuit board diode

over-torque warning signal

Continual blinking indicates that the actuator

torque output limit has been exceeded.

This may have been caused by debris in the

valve internals. Disconnect power and manually operate the valve to clear the debris.

Re-apply power. The actuator will automatically recalibrate and reset. If the problem reoccurs, remove the valve body and check for

debris.

Manual over-ride operation

Remove actuator cover and DISCONNECT

POWER. Failure to disconnect power may

cause damage to the actuator gears. Fit the

manual over-ride key (FlowCon No. ACC0001)

onto the valve spindle. Press the clutch. Rotate

the manual over-ride key to open or close the

valve as required.

Figure 8

General

Water must always be suitable treated, clean

and free of debris. It is recommended that a

strainer be installed prior to the valve body to

prevent damage or blockage due to debris.

Ensure that the valve is not in the fully closed

position when filling the system with water.

Further, it is recommended not to exceed

maximum differential pressure control range.

Warranty obligation

Failure to abide by all recommendations as

per this installation and operation instruction

will void warranty.

For latest updates please see www.flowcon.com

1A95100 - 08/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 5 -

for mistakes, if any, in any printed material.

Page 6

FlowCon SM 15-40mm

Maximum ow rate limitation DIP switch settings

Maximum Flow Rate

DN15-DN25 · 1/2”-1” DN25-DN40 · 1”-1 1/2”

32-320 kPaD · 4.6-46 psid 40-320 kPaD · 5.8-46 psid

SM.1.1 SM.2.1

l/sec l/hr GPM l/sec l/hr GPM 1 2 3 4 5 6 Rotations

0.176 634 2.79 0.513 1850 8.14 ON ON ON ON ON ON 1.0

0.195 703 3.10 0.573 2060 9.09 OFF ON ON ON ON ON 1.1

0.214 771 3.40 0.632 2280 10.0 ON OFF ON ON ON ON 1.2

0.233 838 3.69 0.690 2480 10.9 OFF OFF ON ON ON ON 1.3

0.251 902 3.97 0.746 2690 11.8 ON ON OFF ON ON ON 1.4

0.268 964 4.25 0.802 2890 12.7 OFF ON OFF ON ON ON 1.5

0.285 1020 4.52 0.856 3080 13.6 ON OFF OFF ON ON ON 1.6

0.301 1080 4.78 0.909 3270 14.4 OFF OFF OFF ON ON ON 1.7

0.317 1140 5.03 0.961 3460 15.2 ON ON ON OFF ON ON 1.8

0.332 1200 5.27 1.01 3640 16.0 OFF ON ON OFF ON ON 1.9

0.347 1250 5.51 1.06 3820 16.8 ON OFF ON OFF ON ON 2.0

0.362 1300 5.74 1.11 4000 17.6 OFF OFF ON OFF ON ON 2.1

0.376 1350 5.96 1.16 4170 18.4 ON ON OFF OFF ON ON 2.2

0.390 1400 6.18 1.20 4330 19.1 OFF ON OFF OFF ON ON 2.3

0.403 1450 6.39 1.25 4500 19.8 ON OFF OFF OFF ON ON 2.4

0.416 1500 6.60 1.29 4660 20.5 OFF OFF OFF OFF ON ON 2.5

0.428 1540 6.79 1.34 4810 21.2 ON ON ON ON OFF ON 2.6

0.440 1590 6.98 1.38 4970 21.9 OFF ON ON ON OFF ON 2.7

0.452 1630 7.17 1.42 5120 22.5 ON OFF ON ON OFF ON 2.8

0.463 1670 7.35 1.46 5260 23.2 OFF OFF ON ON OFF ON 2.9

0.474 1710 7.52 1.50 5400 23.8 ON ON OFF ON OFF ON 3.0

0.485 1750 7.69 1.54 5540 24.4 OFF ON OFF ON OFF ON 3.1

0.495 1780 7.86 1.58 5680 25.0 ON OFF OFF ON OFF ON 3.2

0.505 1820 8.01 1.61 5810 25.6 OFF OFF OFF ON OFF ON 3.3

0.515 1850 8.17 1.65 5940 26.2 ON ON ON OFF OFF ON 3.4

0.524 1890 8.31 1.69 6070 26.7 OFF ON ON OFF OFF ON 3.5

0.533 1920 8.46 1.72 6190 27.3 ON OFF ON OFF OFF ON 3.6

0.542 1950 8.60 1.75 6310 27.8 OFF OFF

0.550 1980 8.73 1.79 6430 28.3 ON ON OFF OFF OFF ON 3.8

0.559 2010 8.86 1.82 6550 28.8 OFF ON OFF OFF OFF ON 3.9

0.567 2040 8.99 1.85 6660 29.3 ON OFF OFF OFF OFF ON 4.0

0.574 2070 9.11 1.88 6770 29.8 OFF OFF OFF OFF OFF ON 4.1

0.582 2090 9.23 1.91 6870 30.3 ON ON ON ON ON OFF 4.2

0.589 2120 9.34 1.94 6980 30.7 OFF ON ON ON ON OFF 4.3

0.596 2150 9.45 1.97 7080 31.2 ON OFF ON ON ON OFF 4.4

0.603 2170 9.56 1.99 7180 31.6 OFF OFF ON ON ON OFF 4.5

0.609 2190 9.66 2.02 7280 32.1 ON ON OFF ON ON OFF 4.6

0.616 2220 9.76 2.05 7370 32.5 OFF ON OFF ON ON OFF 4.7

0.622 2240 9.86 2.07 7460 32.9 ON OFF OFF ON ON OFF 4.8

0.628 2260 9.96 2.10 7550 33.3 OFF OFF OFF ON ON OFF 4.9

0.634 2280 10.0 2.12 7640 33.7 ON ON ON OFF ON OFF 5.0

0.639 2300 10.1 2.15 7730 34.0 OFF ON ON OFF ON OFF 5.1

0.645 2320 10.2 2.17 7810 34.4 ON OFF ON OFF ON OFF 5.2

0.650 2340 10.3 2.19 7890 34.8 OFF OFF ON OFF ON OFF 5.3

0.655 2360 10.4 2.21 7970 35.1 ON ON OFF OFF ON OFF 5.4

0.661 2380 10.5 2.24 8050 35.5 OFF ON OFF OFF ON OFF 5.5

0.666 2400 10.6 2.26 8130 35.8 ON OFF OFF OFF ON OFF 5.6

0.671 2410 10.6 2.28 8200 36.1 OFF OFF OFF OFF ON OFF 5.7

0.676 2430 10.7 2.30 8280 36.5 ON ON ON ON OFF OFF 5.8

0.680 2450 10.8 2.32 8350 36.8 OFF ON ON ON OFF OFF 5.9

0.685 2470 10.9 2.34 8420 37.1 ON OFF ON ON OFF OFF 6.0

Maximum Flow Rate

DIP Switch Settings

ON OFF OFF ON 3.7

Rotations

From Closed

DYNAMIC SELF BALANCING

CONTROL VALVE

Stem

Example illustrated above:

ON-OFF-ON-ON-OFF-OFF

which gives a max ow of:

SM.1.1 - 0.685l/sec and

SM.2.1 - 2.34l/sec

(rotation 6.0).

Accuracy: Greatest of either

±5% of controlled ow rate or

±2% of maximum ow rate.

1A95100 - 08/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 6 -

for mistakes, if any, in any printed material.

Page 7

FlowCon SM 15-40mm

Assembly drawing

FlowCon SM

A: Valve housing

B: Actuator

C1: P/t plug (2 pcs.)

C2: Plug and gasket (2 of each)

D: Union end connections.

B

Figure 9

DYNAMIC SELF BALANCING

CONTROL VALVE

D

A

D

C1 C1C2C2

1A95100 - 08/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 7 -

for mistakes, if any, in any printed material.

Page 8

FlowCon SM 15-40mm

Own Notes:

DYNAMIC SELF BALANCING

CONTROL VALVE

1A95100 - 08/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 8 -

for mistakes, if any, in any printed material.

Loading...

Loading...