Page 1

DIFFERENT PRESSURE CONTROL VALVEFlowCon DPCV

INSTALLATION AND OPERATION INSTRUCTION

FlowCon DPCV 15-50mm

Install the FlowCon DPCV in the return pipework of the riser with connection to the supply

pipework of the riser through the capillary tube

as called for in the design drawings. It is recom

mended that a strainer be installed prior to the

inlet of the capillary tube to prevent damage or

blockage due to debris. INSTALL THE VALVE

HOUSING WITH THE FLOW DIRECTIONAL

TRIANGLE POINTING IN THE CORRECT DI

RECTION.

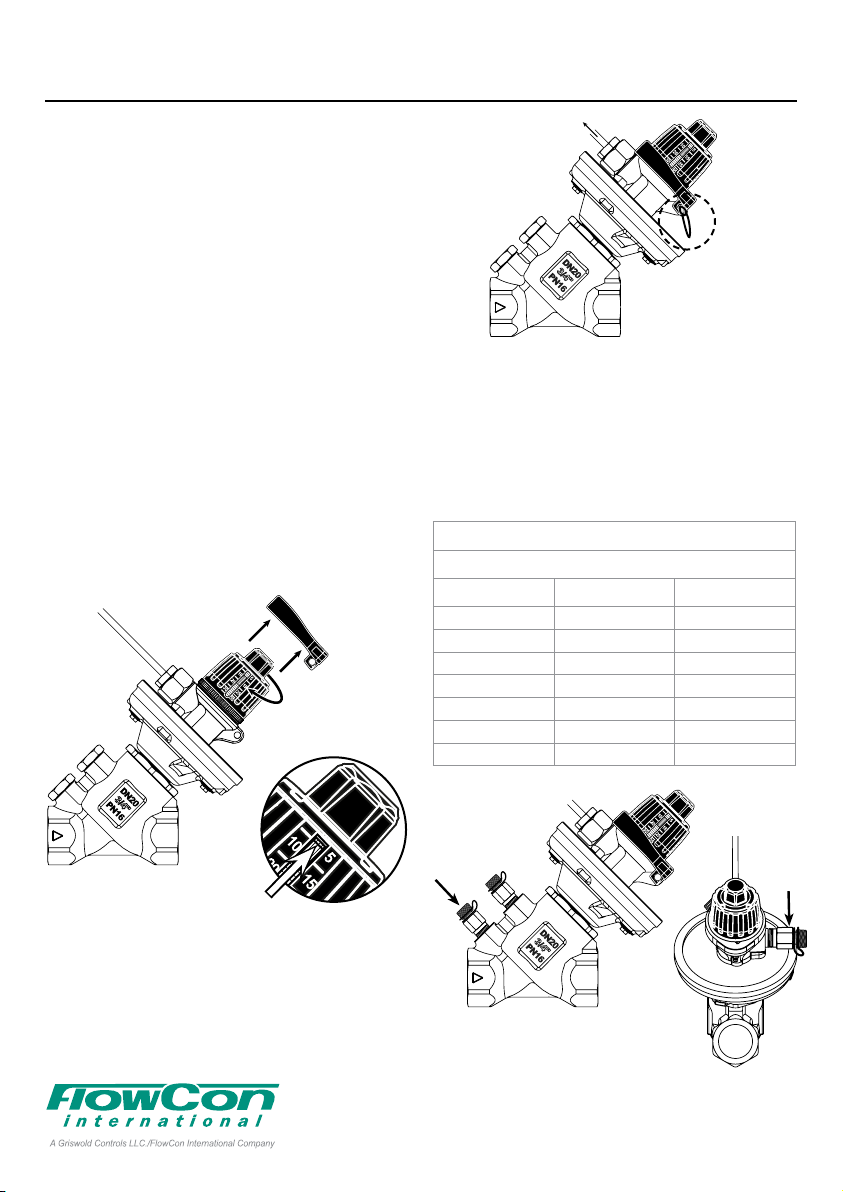

Figure 1

The valve body is available with female threaded

end connections. The thread standard is EN

10226-1, which is a straight metric thread. Please

clear threads on both valve and piping of debris. Sealant such as pipe dope or Teflon tape is

recommended. WHEN USING HEMP AS PIPE

SEALANT, ENSURE NO STRANDS ARE LEFT

IN THE VALVE OR PIPING.

For each end of the capillary tube start by mount

ing the big nut with the gasket () in the valve

and proceed as shown in figure 2. Pull the small

nut () onto the copper tube () with the thread

toward the end of the tube, and then push the

cutting ring () onto the tube as far as possible.

Push the copper tube into the hole of the big nut

and screw the small nut into the big nut with a

wrench using 12-15Nm.

Figure 2

When the DPCV is installed with the capillary

tube in place and the system is operational,

please vent the capillary tube as shown in figure

3. Open the highest elevated screw byturning it

counter-clockwise max. 2 rotations until water

runs constantly from it, and then close it again.

Figure 3

The capillary tube is available with ¼” straight

male end connections with gaskets for sealing.

One end is mounted on the upper part of the

DPCV instead of the black plastic

plug. The other end is mounted at the inlet of the

riser fx. in a FlowCon ABS.

1H95000 - 04/2016

Denmark Dubai USA Singapore www.owcon.com

As standard, the valve body is supplied with

plugs in the body tappings. Each plug is sealed

FlowCon International assumes no responsibility

- 1 -

for mistakes, if any, in any printed material.

Page 2

with a gasket. Alternative to plugs, pressure/temperature fittings (p/t plugs) are available

upon request for the DPCV valve. Before finger

mounting the p/t plugs in the tappings please

seal the threads of the p/t plugs (DO NOT OVER

TIGHTEN).

Pump pressure

Please do not use the FlowCon DPCV in sys

with pump pressures higher than 210kPaD.

tems

DIFFERENT PRESSURE CONTROL VALVEFlowCon DPCV

Figure 5

Setting the DPCV

To change the setting, please remove the black

lock ring () and turn the black top part by hand

() as shown in figure 4 (do not use more than

1 Nm force). Turn the black top part clockwise to

increase and counter-clockwise to decrease the

setting. The setting can be seen directly on the

valve because the scale is printed on the top part

(which is turned) and the setting is defined by the

groove in the brass part inside the top part .

Figure 4

To make the setting tamper-proof, please return

the lock ring so that the small holes in the lock

ring will align with the small hole in the housing

in order to fasten the lock ring with a cable binder

as shown in figure 5.

To reach settings in between the settings in ta

ble 1, please measure the differential pressure

as shown in figure 6 (P2÷P1) while turning the

black top until the measurement shows the de

sired setting. The same procedure can be used

to get a more precise setting if required.

FlowCon DPCV

General Settings

Setting kPaD psid

5 5 0.7

10 10 1.5

15 15 2.2

20 20 2.9

25 25 3.6

30 30 4.4

35 35 5.1

Table 1

P2

Figure 6

P1

1H95000 - 04/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 2 -

for mistakes, if any, in any printed material.

Page 3

DIFFERENT PRESSURE CONTROL VALVEFlowCon DPCV

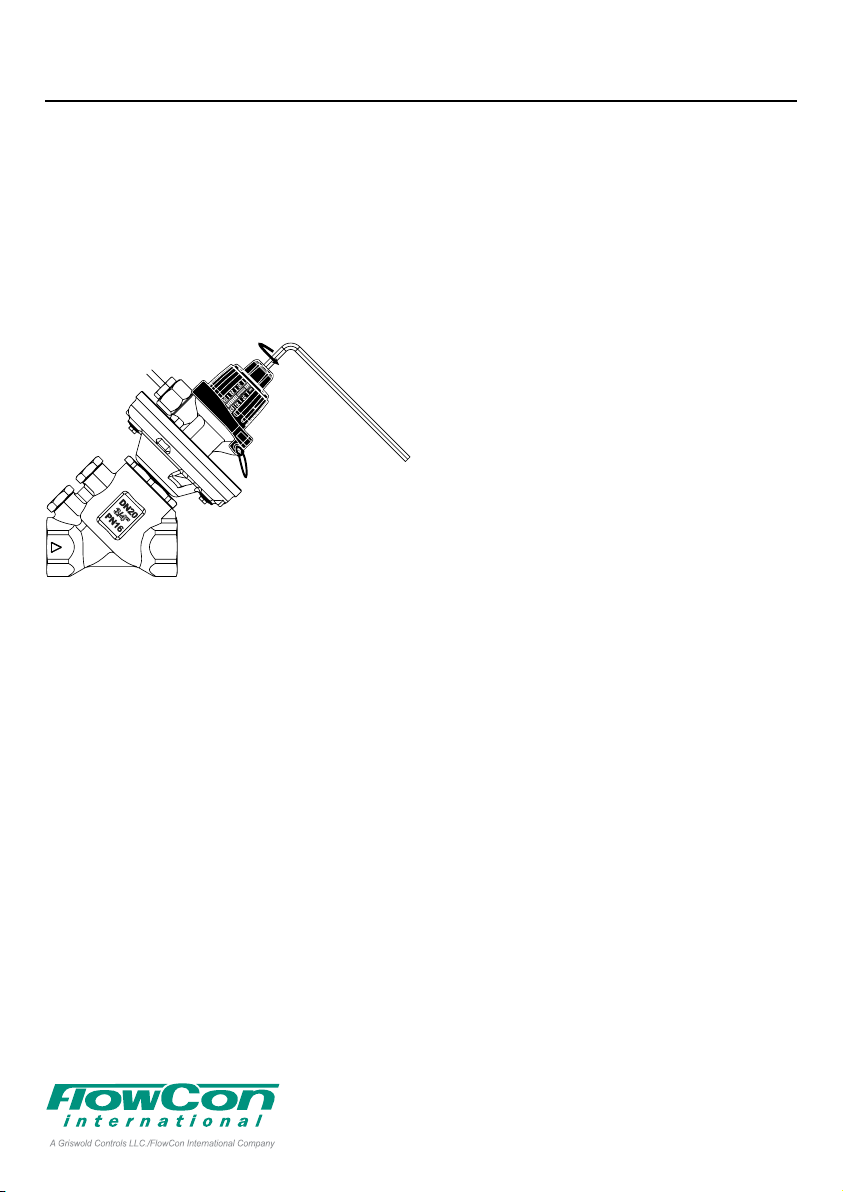

Using the DPCV as a shut-off valve

To use the FlowCon DPCV as a shut-off valve

please use a 4mm hex key on the top as shown

in figure 7. Turn the hex key clockwise (several

rotations) until end point to close the valve, and

counter-clockwise until end point to open the

valve and in order for it to function as a differen

tial pressure control valve again (the setting is

kept). Be sure not to use more than 1Nm torque.

Figure 7

-

General

Water must always be suitably treated, clean

and free from debris. It is recommended that a

strainer be installed prior to the inlet of the capil

lary tube to prevent damage or blockage due to

debris. Further, it is recommended not to exceed

the maximum operational differential pressure.

Warranty obligation

Failure to abide by all recommendations as per

this installation and operation instruction will void

warranty.

When manually operating the valve do not use

more than 1 Nm torque. Using more than 1 Nm

torque will void warranty.

For latest updates please see www.flowcon.com

1H95000 - 04/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 3 -

for mistakes, if any, in any printed material.

Page 4

DIFFERENT PRESSURE CONTROL VALVEFlowCon DPCV

1H95000 - 04/2016

Denmark Dubai USA Singapore www.owcon.com

FlowCon International assumes no responsibility

- 4 -

for mistakes, if any, in any printed material.

Loading...

Loading...