flowair LEO S1, LEO S2, LEO S3, LEO L1, LEO L2 Technical Documentation Operation Manual

...

EN

FAN HEATER

TECHNICAL DOCUMENTATION OPERATION MANUAL

PL

AEROTERMA

DOCUMENTATIE TEHNICA MANUAL DE UTILIZARE

LEO

S1 I S2 I S3 / BMS

L1 I L2 I L3 / BMS

XL2 I XL3 / BMS

(INOX / ST)

2 | www.flowair.com

TABLE OF CONTENTS

1. Application ...............................................................................................4

2. Technical Data .........................................................................................5

3. Installation ................................................................................................8

3.1. Installation –bracket ................................ ..........................................8

3.2. Assembly instructions .......................................................................8

3.3. U-Profiles ..........................................................................................8

4. Connection diagrams ...............................................................................9

5. Start-Up and Operation .......................................................................... 11

6. Service and warranty terms .................................................................... 15

CUPRINS

1. Aplicatii ....................................................................................................4

2. Date tehnice .............................................................................................5

3. Montare ...................................................................................................8

3.1. Montare – suporti ................................................................................8

3.2. Instuctiuni montaj ................................................................................8

3.3. Profile U .............................................................................................8

4. Diagrama conexiuni .................................................................................9

5. Punere in functiune si operare................................................................ 12

6. Service si garantie ................................................................................. 15

www.flowair.com | 3

1. APPLICATION

1. APLICATII

LEO heaters make up a decentralised heating system. The air

streaming through the heat exchanger filled with hot water is warmed

up. Fan heaters are used for heating large volume buildings: general,

industrial and public buildings etc.

The casing of LEO heaters is made from extended polypropylene EPP.

LEO in special version ST has a casing made from powder coated steel.

The devices LEO in special version INOX have casing and air blades

made of austenitic stainless steel.

The devices are designed for indoor use where maximum air dustiness

does not exceed 0,3 g/m3. Units are built using copper, aluminum and

galvanized steel. It is prohibited to install units in the areas where

environment inside can causes in rusting.

Aerotermele LEO formeaza un sistem descentralizat de incalzire. Aerul

care trece prin schimbatorul de caldura plin cu apa calda este incalzit.

Aerotermele sunt folosite pentru a incalzi cladiri cu volum mare: cladiri

uzuale, industriale si publice.

Carcasa aerotermelor LEO este facut din polipropilena expandata EPP.

LEO in versiunea speciala ST are carcasa din otel vopsita. Unitatea

LEO in versiunea speciala INOX are carcasa si lamelele de aer din otel

inox.

Aerotermele sunt destinate pentru uz interior unde concentratia de praf

nu depaseste 0,3 g/m3. Unitatile sun construite din cupru, aluminii si otel

galvanizat. Este interzis sa se monteze aerotermele in zone unde

mediul inconjurator poate cauza ruginirea.

4 | www.flowair.com

2. TECHNICAL DATA

2. DATE TEHNICE

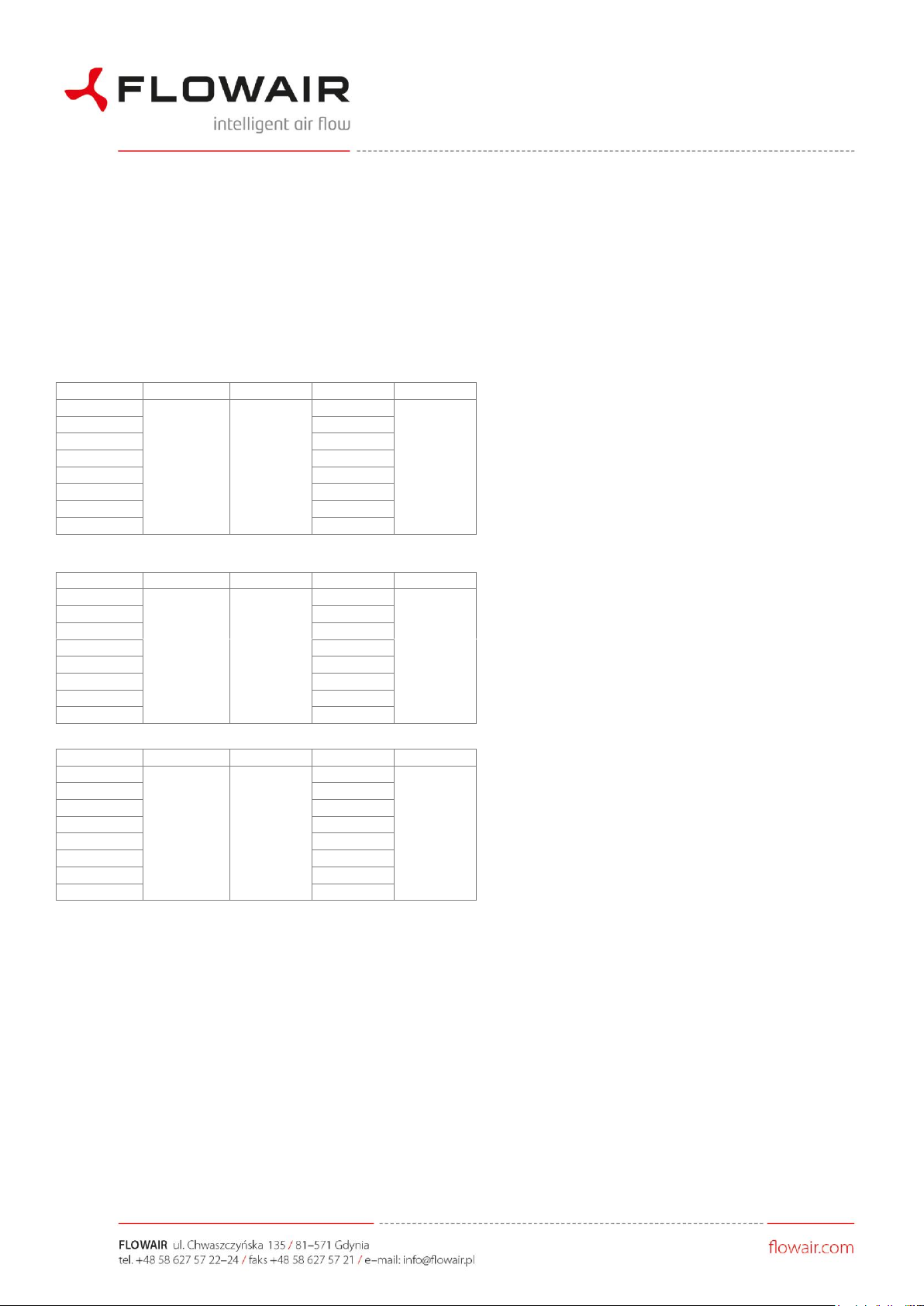

LEO S1 | S2 | S3 / BMS

LEO S1 INOX / ST | S2 INOX / ST | S3 INOX / ST

LEO S1

LEO S2

LEO S3

Gear | Treapta

III

II I III

II I III

II

I

Max airflow [m3/h ] | Debit maxim [m3/h ]

2300

1900

1500

2000

1600

1250

1800

1400

1000

Power supply [V/Hz] | Alimentare electrica [V/Hz] |

230/50

Max current consumption [A] | Curent maxim consumat

[A]

0,5

0,4

0,3

0,6

0,4

0,3

0,6

0,4

0,3

Max power consumption [W] | Putere maxima

consumata [W]

120

90

70

130

90

70

130

90

70

IP/ Insulation class | IP/Clasa izolare

54 /F

Max acoustic pressure level [dB(A)]* | Nivel maxin de

presiune acustica [dB(A)]*

56,3

50,7

43,9

56,3

50,7

43,9

56,3

50,7

43,9

Horizontal range** [m] | Lungime maxima jet aer pe

orizontala** [m]

16,0

13,0

10,0

14,0

11,0

8,5

12,5

9,5

7,0

Vertical range*** [m] | Lungime maxima jet aer pe

verticala*** [m]

6,0

5,1

4,1

5,3

4,4

3,5

4,9

3,9

2,9

Max heating water temperature [oC] | Temp. Max. Agent

termic [oC]

120 (INOX / ST: 130)

Max operating pressure [MPa] | Presiune max de

functiunare [MPa]

1,6

Connection | Racorduri

1/2”

Installation | Instalare

Indoor | In interior

Max working temperature [oC] | Temp. Maxima de

functionare [oC]

60

Device mass [kg] | Greutate [kg] |

9,5 (INOX: 13,1, ST: 13,1)

10,4 (INOX: 13,8, ST: 13,8)

10,8 (INOX: 14,3, ST: 14,3)

Mass of device filled with water [kg] |Greutatea

aerotermei plina cu apa [kg]

10,2 (INOX: 13,8, ST: 13,8)

11,6 (INOX: 14,0, ST: 14,0)

12,2 (INOX: 15,7, ST: 15,7)

* Acoustic pressure level has been measured 5m from the unit in a 1500m3 space with a medium sound absorption coefficient | Nivelul presiunii acustice la distanța de 5

m față de unitate, în încăpere cu capacitate medie se absorbție a sunetului și volum de 1500 m3

** Horisontal isothermal range for 0,5 m/s border air stream speed Lungimea jetului de aer izoterm pe orizontala la viteza de 0,5 m/s.

*** Vertical nonisothermal range for ΔT = 5oC and for 0,5 m/s border air stream speed | Lungimea maximă a jetului de aer cald nonizoterm pe verticală la ΔT = 50°C și la

viteza de 0.5 m/s

www.flowair.com | 5

2. TECHNICAL DATA

2. DANE TECHNICZNE

2. TECHNISCHE GEGEVENS

2. ТЕХНИЧЕСКИЕ ПАРАМЕТРЫ

LEO L1 | L2 | L3 / BMS

LEO L1 INOX / ST | L2 INOX / ST | L3 INOX / ST

LEO L1

LEO L2

LEO L3

Gear | Treapta

III

II I III II I III II I

Max airflow [m3/h ] | Debit maxim [m3/h ]

4250

2800

1700

3800

2400

1400

3400

2100

1200

Power supply [V/Hz] | Alimentare electrica [V/Hz] |

230/50

Max current consumption [A] | Curent maxim consumat

[A]

1,4

1,2

0,6

1,5

1,2

0,6

1,5

1,2

0,6

Max power consumption [W] | Putere maxima

consumata [W]

330

240

120

340

240

120

340

240

120

IP/ Insulation class | IP/Clasa izolare

54 /F

Max acoustic pressure level [dB(A)]* | Nivel maxin de

presiune acustica [dB(A)]*

64,1

54,5

42,1

64,1

54,5

42,1

64,1

54,5

42,1

Horizontal range** [m] | Lungime maxima jet aer pe

orizontala** [m]

24,0

15,0

9,5

21,5

13,0

8,0

19,0

11,5

6,5

Vertical range*** [m] | Lungime maxima jet aer pe

verticala*** [m]

8,3

5,6

3,7

7,5

4,9

3,1

6,8

4,4

2,8

Max heating water temperature [oC] | Temp. Max. Agent

termic [oC]

120 (INOX / ST: 130)

Max operating pressure [MPa] | Presiune max de

functiunare [MPa]

1,6

Connection | Racorduri

3/4”

Installation | Instalare

Indoor | In interior

Max working temperature [oC] | Temp. Maxima de

functionare [oC]

60

Device mass [kg] | Greutate [kg] |

14,9 (INOX: 19,4, ST: 19,4)

16,2 (INOX: 20,8, ST: 20,8)

17,8 (INOX: 22,7, ST: 22,7)

Mass of device filled with water [kg] |Greutatea

aerotermei plina cu apa [kg]

15,9 (INOX: 20,4, ST: 20,4)

18,2 (INOX: 22,8, ST: 22,8)

20,5 (INOX: 25,4, ST: 25,4)

* Acoustic pressure level has been measured 5m from the unit in a 1500m3 space with a medium sound absorption coefficient | Nivelul presiunii acustice la distanța

de 5 m față de unitate, în încăpere cu capacitate medie se absorbție a sunetului și volum de 1500 m3

** Horisontal isothermal range for 0,5 m/s border air stream speed Lungimea jetului de aer izoterm pe orizontala la viteza de 0,5 m/s.

*** Vertical nonisothermal range for ΔT = 5oC and for 0,5 m/s border air stream speed | Lungimea maximă a jetului de aer cald nonizoterm pe verticală la ΔT = 50°C

și la viteza de 0.5 m/s

2. ТЕХНИЧЕСКИЕ ПАРАМЕТРЫ

6 | www.flowair.com

2. TECHNICAL DATA

2. DATE TEHNICE

2. TECHNISCHE GEGEVENS

2. ТЕХНИЧЕСКИЕ ПАРАМЕТРЫ

LEO XL2 | XL3 / BMS

LEO XL2 INOX / ST | XL3 INOX / ST

LEO XL2

LEO XL3

Gear | Treapta

III II I III II I

Max airflow [m3/h ] | Debit maxim [m3/h ]

5800

4600 2900 5300

4100

2500

Power supply [V/Hz] | Alimentare electrica [V/Hz] |

230/50

Max current consumption [A] | Curent maxim consumat [A]

2,3

1,8 1,4 2,4

1,8

1,4

Max power consumption [W] | Putere maxima consumata [W]

520

370 270 550

370

270

IP/ Insulation class | IP/Clasa izolare

54 /F

Max acoustic pressure level [dB(A)]* | Nivel maxin de presiune acustica

[dB(A)]*

67,5

61,1

52,3 67,5

61,1

52,3

Horizontal range** [m] | Lungime maxima jet aer pe orizontala** [m]

26,0

20,5

13,0

23,5

18,0

11,0

Vertical range*** [m] | Lungime maxima jet aer pe verticala*** [m]

8,5

7,0

4,7

7,7

6,2

4,1

Max heating water temperature [oC] | Temp. Max. Agent termic [oC]

120 (INOX / ST: 130)

Max operating pressure [MPa] | Presiune max de functiunare [MPa]

1,6

Connection | Racorduri

3/4”

Installation | Instalare

Indoor | Wewnątrz pomieszczeń | Binnen | Внутри помещений

Max working temperature [oC] | Temp. Maxima de functionare [oC]

60

Device mass [kg] | Greutate [kg] |

23,2 (INOX: 29,9, ST: 29,9)

26,2 (INOX: 34,2, ST: 34,2)

Mass of device filled with water [kg] |Greutatea aerotermei plina cu apa

[kg]

25,9 (INOX: 32,6, ST: 32,6)

30,3 (INOX: 38,3, ST: 38,3)

* Acoustic pressure level has been measured 5m from the unit in a 1500m3 space with a medium sound absorption coefficient | Nivelul presiunii acustice la distanța

de 5 m față de unitate, în încăpere cu capacitate medie se absorbție a sunetului și volum de 1500 m3

** Horisontal isothermal range for 0,5 m/s border air stream speed Lungimea jetului de aer izoterm pe orizontala la viteza de 0,5 m/s.

*** Vertical nonisothermal range for ΔT = 5oC and for 0,5 m/s border air stream speed | Lungimea maximă a jetului de aer cald nonizoterm pe verticală la ΔT = 50°C

și la viteza de 0.5 m/s

www.flowair.com | 7

S1

S2

S3

L1

L2

L3

XL2

XL3

A

<3,0

<3,0

<3,0

2,5-8,0

2,5-8,0

2,5-8,0

2,5-8,0

2,5-8,0

B

2,5-7,0

2,5-6,0

2,5-6,0

2,5-9,5

2,5-8,5

2,5-8,0

2,5-9,5

2,5-9,0

C

>0,3

>0,3

>0,3

>0,3

>0,3

>0,3

>0,3

>0,3

D

>0,5

>0,5

>0,5

>0,5

>0,5

>0,5

>0,5

>0,5

3. INSTALLATION

3.INSTALARE

Fan heaters can be

mounted to vertical or

horizontal partitions in any

position. During the

montage, the minimal

distances from the walls

and ceiling have to be

kept.

Aeroterma poate fi instalata pe

verticala sau orizontala in orice

pozitie. In timpul instalarii,

distantele minime fata de pereti

si tavan trebuie respectate.

3.1. INSTALLATION –BRACKET

3.1. INSTALARE - SUPORTI

3.2. ASSEMBLY INSTRUCTIONS

3.2. INSTRUCTIUNI MONTAJ

3.3 U-PROFILES (optional)

3.3 PROFILE U

U-profiles should be mounted in corners as drawing

shows. Is not allowed to screw profiles in other

places.

Profilele U trebuie monatate in colturi ca in desenul

alaturat. Nu este permis fixarea profilelor in alte

parti.

!!!

M8 screws are in set with bracket | Suruburile M8 sunt in set

impreuna cu consola

8 | www.flowair.com

4. CONNECTION DIAGRAMS

4. DIAGRAMA CONEXIUNI

www.flowair.com | 9

4. CONNECTION DIAGRAMS

4. DIAGRAMA CONEXIUNI

BMS

EN: When connecting DRV modules to the T-box controller or BMS, you

have to binary set addresses on each (each DRV must have individual

address) DRV module by DIP-switch SW1. To address modules check if

the power supply is turned off, than set then the addresses as shown in the

table, than turn on the power supply .|

RO: Cand se conecteaza modulele DRV la controlerul T-box sau la BMS,

trebuie setata adresa pe fiecare (fiecare DRV trebuie sa aiba o adresa

individuala) modul DRV pe DIP-switch SW1. Pentru a seta adresa

modulelor verificati daca alimentarea electrica este oprita, apoi setati

adresa ca in table, pe urma poriniti alimentarea cu curent.

.

SRQ3d

10 | www.flowair.com

EN: It is possible to connect up to 31 modules DRV and control them with

one T-box controller .|

RO: Este posibil sa se conecteze pana la 32 de module DRV si sa le

controlam cu un T-box.

EN: DRV modules can be connected to the BMS (Building Management

System). |

RO: Modulele DRV pot fi conectarte la BMS (Building Management

System). |

WARNING: The connection must be carried out with 3-wire (recommended

UTP) to connectors DRV IN

ATENTIE: Legaturile trebuie facute cu 3 fire (recomandat UTP) la conectorii

DRV IN

BMS / GBS

www.flowair.com | 11

5. START-UP AND OPERATION

Guidelines for System Connection

The connection should be executed in a way which does not induce

stresses.

It is recommended to install vent valves at the highest point of the

system.

The system should be executed so that, in the case of a failure, it is

possible to disassemble the device. For this purpose it is best to use

shut-off valves just by the device.

The system with the heating medium must be protected against an

increase of the heating medium pressure above the permissible value

(1.6 MPa).

While screwing exchanger to pipeline - connecting stubs has to be hold

by wrench.

Start Up

Before connecting the power supply check the correctness of connection

of the fan motor and the controllers. These connections should be

executed in accordance with their technical documentation.

Before connecting the power supply check whether the mains voltage is

in accordance with the voltage on the device data plate.

Before starting the device check the correctness of connection of the

heating medium conduits and the tightness of the system.

The electrical system supplying the fan motor should be additionally

protected with a circuit breaker against the effects of a possible shortcircuit in the system.

Starting the device without connecting the ground conductor is forbidden.

Operation

The device is designed for operation inside buildings, at temperatures

above 0oC. In low temperatures (below 0ºC) there is a danger of freezing

of the medium.

The manufacturer bears no responsibility for damage of the heat

exchanger resulting from freezing of the medium in the exchanger. If

operation of the device is expected at temperatures lower than 0º, then

glycol solution should be used as the heating medium, or special

automatic systems should be used for protecting against freezing of the

medium in the exchanger.

It is forbidden to place any objects on the heater or to hang any objects

on the connecting stubs.

The device must be inspected periodically. In the case of incorrect

operation of the device it should be switched off immediately.

It is forbidden to use a damaged device. The manufacturer bears no

responsibility for damage resulting from the use of a damaged device.

If it is necessary to clean the exchanger, be careful not to damage the

aluminium lamellas.

For the time of performing inspection or cleaning the device, the electrical

power supply should be disconnected.

In case water is drained from the device for a longer period of time, the

exchanger tubes should be emptied with compressed air.

It is not allowed to make any modification in the unit. Any modification

causes in warranty loss.

Periodic inspections

To keep proper technical parameters Flowair recommends periodic

service (every 6 months) of fan heaters on behalf of the user.

During inspections user should:

Check heat exchanger, if is it filled with dirt or dust. If necessary - use

pressurized air stream to clean the exchanger’s lamellas,

Check heat exchanger, if is it filled with dirt or dust. If necessary - use

pressurized air stream to clean the exchanger’s lamellas,

Check fan blades, in case of dirt use damp cloth and remove dirt,

Check bracket installation,

Check heat exchanger and hydraulic connection correctness,

Check wires insulation,

Check power supply,

Check medium flow,

Check levelling of the unit.

12 | www.flowair.com

5. PORNIREA SI FUNCTIONAREA

Ghid pentru realizarea legaturilor

Conexiunea trebuie realizate in sensul in care nu se formeaza tensiuni.

Este recomandat sa se instaleze aerisitor in cel mai inalt punct al

instalatiei.

Instalatia trebuie facuta in asa fel, incat in caz de defectiune, sa fie

posibila dezinstalarea unitatii. Pentru acest lucru este bine sa se

foloseasca robineti de izolare a echipamentului.

Instalatia cu agent termic trebuie protejata impotriva cresterii presiunii

agentului termic peste valoarea permisa (1,6 MPa).

In timpul conectarii schimbatorului la tevi – racordurile trebuie insurubate

cu o cheie

Pornirea

Inainte de a alimenta cu curent electric, verificati corectitudinea legaturilor

la motorul ventilatorului si la controler. Aceste legaturi trebuie facute

conform documentatiei tehnice aferente.

Inainte de a alimenta cu curent electric, verificati daca tensiune de

alimentare este conform tensiunii trecute pe placa de date a

echipamentului.

Inainte de pornire verificati corectitudinea legaturilor tevilor.

Instalatia electrica care alimenteaza motorul ventilatorului ar trebui

protejat aditional de o siguranta impotriva posibilelor scurt circuite.

Pornirea echipamentului fara a fi conectat la impamantare este interzisa.

Exploatare

Aeroterma este destinata utilizarii in interiorul cladirilor, la temperaturi de

peste 0oC. La temperature scazute (sub 0oC) exista riscul de inghet a

agentului termic.

Producatorul nu isi asuma nici o responsabilitate pentru deteriorarile

schimbatorului de caldura datorate inghetarii agentului termic.Daca

aeroterma va functiona la temperaturi mai mici de 0oC , atunci folositi

un amestec de glycol cu apa, sau un sistem de protectia automata

antiinghet a agentului termic in schimbatorul de caldura

Este interzisa amplasarea obiectelor pe aeroterma sau atarnarea lor de

racordurile aerotermei.

Aeroterma trebuie verificata periodic. In caz de functionare incorecta,

aeroterma trebuie oprita imediat.

Este interzisa folosirea unui dispozitiv defect. Producatorul nu isi

asuma nici o responsabilitate pentru deteriorarile suferite din cauza

folosirii unei aeroterme defecte.

Este necesara curatarea schimbatorului, aveti grija sa nu deteriorati

lamelele din aluminiu.

In timpul verificarii sau caratarii aerotermei, alimentarea electrica trebuie

intrerupta.

In cazul in care aeroterma este fara agent termic o perioada mai lunga de

timp, tevile schimbatorului trebuie golite cu aer comprimat.

Este interzisa sa se faca modificari asupra dispozitivului. Orice modificare

duce la pierderea garantiei.

Inspectii periodice

Pentru a mentine parametrii tehnici optimi, Flowair recomanda o

intretinere periodica ( la fiecare 6 luni) a aerotermelor efectuat de

utilizator.

Verificati schimbatorul de caldura, daca este plin cu mizerie sau praf.

Daca este necesar, folositi un jet de aer sub presiune pentru a curata

lamele schimbatorului.

Verificati palele ventilatorului, daca este cu praf sau murdarie curatati cu

o carpa

Verificati montajul suportilor

Verificati racordurile hidraulice si schimbatorul de caldura

Verificati izolatia firelor

Verificati alimentarea electrica

Verificati debitul agentului termic

Verificati pozitia aerotermei

www.flowair.com | 13

6. SERVICE AND WARRANTY TERMS

6. SERVICE SI CONDITIILE GARANTIEI

Please contact your dealer in order to get acquitted with the

warranty terms and its limitation.

In the case of any irregularities in the device operation, please

contact the manufacturer’s service department.

The manufacturer bears no responsibility for operating the

device in a manner inconsistent with its purpose, by persons

not authorised for this, and for damage resulting from this!

Made in Poland

Made in EU

Manufacturer: FLOWAIR GŁOGOWSKI I BRZEZIŃSKI SP.J.

ul. Chwaszczyńska 135, 81-571 Gdynia

tel. +48 58 669 82 20, fax: +48 58 627 57 21

e-mail: info@flowair.pl

www.flowair.com

Va rugam contactati S.C. TECHNOVA INVEST S.R.L. pentru conditii de

garantie.

In cazul unei functionari defectuoase , luati legatura cu departamentul de

service a producatorului.

Producatorul nu isi asuma nici o raspundere pentru functionarea in

alte scopuri decat cel pentru care a fost produs, utilizarea de catre

persoane neautorizate si pentru defectiunile cauzate de acestea.

Made in Poland

Made in EU

Producator: FLOWAIR GŁOGOWSKI I BRZEZIŃSKI SP.J.

ul. Chwaszczyńska 135, 81-571 Gdynia

tel. +48 58 669 82 20, fax: +48 58 627 57 21

e-mail: info@flowair.pl

www.flowair.com

14 | www.flowair.com

Deklaracja zgodności / Declaration Of Conformity / Conformiteitsverklaring / Декларация о соответствии

FLOWAIR

ul. Chwaszczyńska 135, 81-571 Gdynia

tel. +48 58 669 82 20, fax: +48 58 627 57 21

e-mail: info@flowair.pl www.flowair.com

FLOWAIR Nederland

Kantoor: Minervum 7268, 4817 ZM Breda, The Netherlands

tel. +31(0)76 - 581 53 11, fax. +31(0)76 - 587 22 29

e-mail: info@flowair.nl ; www.flowair.nl

Niniejszym deklarujemy, iż wodne nagrzewnice powietrza / FLOWAIR hereby confirms that heating unit / FLOWAIR verklaart

hierbij dat verwarmingsunits / Компания FLOWAIR декларирует, что водяные воздухонагреватели:

LEO: S1, S1 BMS, S2, S2 BMS, S3, S3 BMS, (ST/INOX)

LEO: L1, L1 BMS, L2, L2 BMS, L3, L3 BMS, (ST/INOX)

LEO: XL2, XL2 BMS, XL3, XL3 BMS, (ST/INOX)

zostały wyprodukowane zgodnie z wymaganiami następujących Dyrektyw Unii Europejskiej /

were produced in accordance to the following Europeans Directives / zijn geproduceerd in overeenstemming met de volgende

Europese Richtlijnen / произведены согласно требованиям Директива Европейского Союза:

1. 2014/30/UE – Kompatybilności elektromagnetycznej / Electromagnetic Compatibility (EMC) / Elektromagnetische

compatibiliteit (EMC) / Электромагнитная совместимость (ЭМС) технических средств,

2. 2006/42/WE – Maszynowej / Machinery / Machine / Машины и Механизмы,

3. 2014/35/UE – Niskonapięciowe wyroby elektryczne / Low Voltage Electrical Equipment (LVD) / Laagspanningsrichtlijn

(LVD) / Низковольтное оборудование (LVD),

4. 2009/125/WE – Produkty związane z energią / Energy-related products (ErP 2015) / Richtlijn energiegerelateerde

producten (ErP 2015) / Энергопотребляющие продукты

oraz zharmonizowanymi z tymi dyrektywami normami / and harmonized norms ,with above directives / en geharmoniseerde

normen, met de bovenstaande richtlijnen / а также в соединении с данными директивами стандартами

PN-EN ISO 12100:2012 Bezpieczeństwo maszyn -- Ogólne zasady projektowania -- Ocena ryzyka i zmniejszanie ryzyka /

Safety Of Machinery - General Principles For Design - Risk Assessment And Risk Reduction /

Veiligheid van Machines - Basisbegrippen voor ontwerp - Risicobeoordeling en risicoreductie /

Безопасность машин – Общие принципы проектировки – Оценка риска и уменьшение риска.

PN-EN 60204-1:2010 Bezpieczeństwo maszyn — Wyposażenie elektryczne maszyn — Część 1: Wymagania ogólne /

Safety of machinery − Electrical equipment of machines − Part 1: General requirements / Veiligheid

van machines - Elektrische uitrusting van machines - Deel 1: Algemene eisen / Безопасность

машин. Электрооборудование машин и механизмов.

Часть 1. Общие требования.

PN-EN 60034-1:2011 Maszyny elektryczne wirujące – Część 1: dane znamionowe i parametry / Rotating electrical

machines — Part 1: Rating and performance / Roterende elektrische machines - Deel 1:

Beoordeling en prestatie / Вращающиеся электрические машины. Номинальные данные и

характеристики.

PN-EN 61000-6-2:2008 Kompatybilność elektromagnetyczna. Część 6-2: Normy ogólne. Odporność w środowiskach

przemysłowych / Electromagnetic compatibility (EMC). Generic standards. Immunity for industrial

environments / Elektromagnetische compatibiliteit (EMC). Algemene normen Immuniteit voor

industriële omgevingen / Электромагнитная совместимость (ЭМС) - Часть 6-2: Общие стандарты -

Помехоустойчивость для промышленных обстановок.

Gdynia, 12.04.2018

Product Manager

www.flowair.com | 15

Model

Item

Symbol

Value

Unit

LEO S1

Heating

capacity

P

rated,h

2,7**

kW

LEO S2

5,7**

LEO S3

7,0**

LEO L1

6,9**

LEO L2

10,8**

LEO L3

13,9**

LEO XL2

20,2**

LEO XL3

25,7**

** heating capacity for parameters: inlet water temp. 45°C, water

temperature drop 5°C, room air temp. 20°C.

Model

Item

Symbol

Value

Unit

LEO S1

Total

electric

power input

P

elec

0,12

kW

LEO S2

0,13

LEO S3

0,13

LEO L1

0,33

LEO L2

0,34

LEO L3

0,34

LEO XL2

0,52

LEO XL3

0,55

Model

Item

Symbol

Value

Unit

LEO S1

Sound

power level

L WA

71,4

dB

LEO S2

71,4

LEO S3

71,4

LEO L1

79,2

LEO L2

79,2

LEO L3

79,2

LEO XL2

82,6

LEO XL3

82,6

COMMISSION REGULATION (EU) 2016/2281

Contact details:

FLOWAIR GŁOGOWSKI I BRZEZIŃSKI SP.J., ul. Chwaszczyńska 135, 81-571 Gdynia

Information relevant for disassembly, recycling and/or disposal at end-of-life:

Unassembly should be carried out by a person with appropriate authorizations. After disassembly, waste should be segregated:

housing: made of EPP or steel or INOX - recyclable

heat exchanger: copper, aluminum, steel - recyclable

fan: dispose of in accordance with the rules for the disposal of electrical equipment"

Unit name: LEO

Capacity control: 3-speed

16 | www.flowair.com

www.flowair.com | 17

Numer katalogowy: 52836

Indeks: MT-DTR-LEO-SLXL-EN-PL-NL-RU-V2

18 | www.flowair.com

Loading...

Loading...