Flotec Multi-Stage Pump, FP4432-01 Owner's Manual

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-365-6832

English . . . . . . . . . . . . . . Pages 2-13

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 365-6832

Français . . . . . . . . . . . Pages 14-25

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-365-6832

Español . . . . . . . . . . .Paginas 26-37

©2005 S183 (Rev. 7/13/05)

P.O. Box 342, Delavan, WI 53115

Phone:

1-800-365-6832

Fax:

1-800-526-3757

E-Mail:

info@flotecwater.com

Web Site:

http://www.flotecwater.com

OWNER’S MANUAL

Multi-Stage Pump

NOTICE D’UTILISATION

Pompe multiprofondeur

MANUAL DEL USUARIO

Bomba Multietapas

®

Table of Contents 2

Thank you for purchasing a top quality, factory tested pump.

Page

Warranty..............................................................................................................2

General Safety .....................................................................................................3

Performance.........................................................................................................4

Installation........................................................................................................5-8

Electrical.........................................................................................................8-10

Operation...........................................................................................................11

Repair Parts........................................................................................................12

Troubleshooting .................................................................................................13

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

ATTACH ORIGINAL RECEIPT HERE FOR WARRANTY CONSIDERATION.

FLOTEC warrants to the original consumer purchaser (“Purchaser”) of its products that they are free from defects in material or workmanship.

If within twelve (12) months from the date of the original consumer purchase

any such product shall prove to be defective, it shall be repaired or replaced at

FLOTEC’s option, subject to the terms and conditions set forth below. Your original receipt of purchase is required to determine warranty eligibility.

Exceptions to the Twelve (12) Month Warranty

Ninety (90) Day Warranty:

If within ninety (90) days from original consumer purchase any Drill Pump,

Pitcher Pump, or In-Line Water Filter Cartridge shall prove to be defective, it

shall be replaced, subject to the terms set forth below.

Two (2) Year Warranty:

If within two (2) years from original consumer purchase any 1/3 HP Submersible

Sump Pump or Model FP2800DCC shall prove to be defective, it shall be

repaired or replaced at FLOTEC’s option, subject to the terms and conditions set

forth below.

Three (3) Year Warranty:

If within three (3) years from original consumer purchase any 4” Submersible

Well Pump, or 1/2 HP Submersible Sump Pump, shall prove to be defective, it

shall be repaired or replaced at FLOTEC’s option, subject to the terms and conditions set forth below.

Four (4) Year Warranty:

If within four (4) years from original consumer purchase any FLOODMATE

TM

7000 or IRONMATETMSubmersible Sump Pump shall prove to be defective, it

shall be repaired or replaced at FLOTEC’s option, subject to the terms and conditions set forth below.

Five (5) Year Warranty:

If within five (5) years from original consumer purchase any Pre-Charge water

system tank shall prove to be defective, it shall be repaired or replaced at

FLOTEC’s option, subject to the terms and conditions set forth below.

General Terms and Conditions

Purchaser must pay all labor and shipping charges necessary to replace product

covered by this warranty. This warranty shall not apply to acts of God, nor shall

it apply to products which, in the sole judgement of FLOTEC, have been subject

to negligence, abuse, accident, misapplication, tampering, alteration; nor due to

improper installation, operation, maintenance or storage; nor to other than normal application, use or service, including but not limited to, operational failures

caused by corrosion, rust or other foreign materials in the system, or operation

at pressures in excess of recommended maximums.

Requests for service under this warranty shall be made by returning the defective

product to the Retail outlet or to FLOTEC as soon as possible after the discovery

of any alleged defect. FLOTEC will subsequently take corrective action as

promptly as reasonably possible. No requests for service under this warranty will

be accepted if received more than 30 days after the term of the warranty.

This warranty sets forth FLOTEC’s sole obligation and purchaser’s exclusive

remedy for defective products.

FLOTEC SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL,

OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL

OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE

DURATION OF THE APPLICABLE EXPRESS WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty lasts, so the

above limitations or exclusions may not apply to you. This warranty gives you

specific legal rights and you may also have other rights which vary from state

to state.

Flotec Limited Warranty

FLOTEC • P.O. Box 342 • Delavan, WI U.S.A. 53115

Phone: 1-800-365-6832 • Fax: 1-800-526-3757

E-Mail: info@flotecwater.com • Web Site: http://www.flotecwater.com

Safety 3

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury!

DANGER warns about hazards that will

cause serious personal injury, death or major property

damage if ignored.

WARNING warns about hazards that can

cause serious personal injury, death or major property

damage if ignored.

CAUTION warns about hazards that will or

can cause minor personal injury or property damage if

ignored.

The word NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

ELECTRICAL SAFETY

Wire motor for correct

voltage. See “Electrical”

section of this manual and

motor nameplate.

Ground motor before

connecting to power

supply.

Meet National Electrical

Code, Canadian

Electrical Code, and local

codes for all wiring.

Follow wiring instruc-

tions in this manual

when connecting motor to

power lines.

Make workshops childproof; use padlocks and master

switches; remove starter keys.

Capacitor voltage may be hazardous. To

discharge motor capacitor, hold insulated handle screwdriver BY THE HANDLE and short capacitor terminals

together. Do not touch metal screwdriver blade or capacitor terminals. If in doubt, consult a qualified electrician.

GENERAL INFORMATION

Do not allow pump or any system component to freeze.

To do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

To avoid over pressure hazard and possible injury, install

pressure relief valve capable of passing full pump flow at

75 PSI (517kPa). Pressurized suction may cause pump

body to explode.

Do not touch an operating motor. Modern

motors are designed to operate at high temperatures. To

avoid burns when servicing pump, allow it to cool for 20

minutes after shut-down before handling.

WARNING

Hazardous voltage. Can

shock, burn, or cause

death.

Ground pump before connecting to power supply.

Disconnect power before

working on pump, motor or

tank.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on any

component.

Performance 4

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

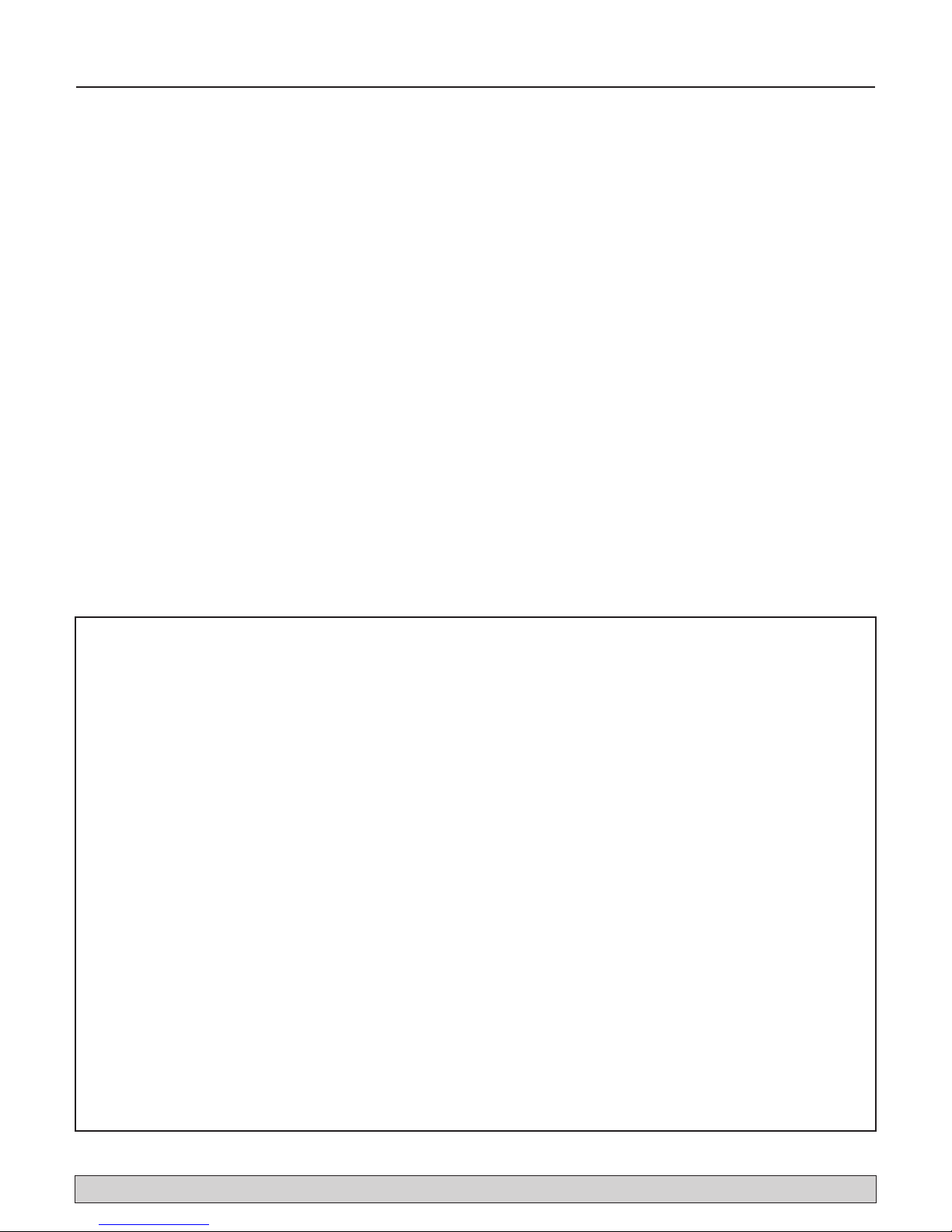

TABLE II – 4” Double Pipe Deep Well Installation Jet Selection Chart

JET

PIPE SIZES

H.P. NO.

SUCT. PRESS

J32P-24

Venturi

1

1-1/4” 1”

#52

Nozzle

J32P-18

Venturi

1

1-1/4” 1”

#52

Nozzle

DISCH

DEPTH TO WATER – FT (M) PERFORMANCE IN GPH (LPH)

PRESS

30 40 50 60 70 80 90 100 110 120 130 140 180 200 220 240 260

PSI(kPa) (9) (12) (15) (18) (21) (24) (27) (30) (33) (36) (40) (43) (55) (61) (67) (73) (79)

20 730 730 730 730 690 580 510 400 320 250 190 — — — — —

(138) (2763) (2763) (2763) (2763) (2612) (2195) (1930) (1514) (1211) (946) (719)

30 730 710 700 695 635 570 475 395 315 250 190 — — — — — —

(207) (2763) (2687) (2650) (2631) (2403) (2157) (1798) (1495) (1192) (946) (719)

40 725 700 695 665 610 550 465 385 300 240 180 — — — — — —

(275) (2744) (2650) (2631) (2517) (2309) (2082) (1760) (1457) (1136) (908) (681)

50 720 690 660 625 575 525 445 365 275 210 165 — — — — — —

(344) (2725) (2612) (2498) (2366) (2176) (1987) (1684) (1382) (1041) (795) (625)

60 700 660 615 570 520 470 400 325 230 180 140 — — — — — —

(413) (2650) (2498) (2328) (2157) (1968) (1779) (1514) (1230) (871) (681) (530)

20 330 330 330 330 330 320 310 305 305 300 290 270 230 190 150 115 80

(138) (1249) (1249) (1249) (1249) (1249) (1211) (1173) (1154) (1154) (1136) (1098) (1022) (871) (719) (568) (435) (303)

30 330 330 330 330 330 320 310 305 305 300 290 270 215 175 135 100 70

(207) (1249) (1249) (1249) (1249) (1249) (1211) (1173) (1154) (1154) (1136) (1098) (1022) (814) (662) (511) (379) (265)

40 330 330 330 325 320 315 310 305 305 300 290 270 195 160 120 80 60

(275) (1249) (1249) (1249) (1230) (1211) (1192) (1173) (1154) (1154) (1136) (1098) (1022) (738) (606) (454) (303) (227)

50 330 330 325 320 315 310 305 305 300 295 280 270 175 140 100 70 50

(344) (1249) (1249) (1230) (1211) (1192) (1173) (1154) (1154) (1136) (1117) (1060) (1022) (662) (530) (379) (265) (189)

60 325 325 320 315 310 305 300 295 285 280 270 255 155 125 85 60 40

(413) (1230) (1230) (1211) (1192) (1173) (1154) (1136) (1117) (1079) (1060) (1022) (965) (587) (473) (322) (227) (151)

JET

PIPE SIZES

DISCH

DEPTH TO WATER – FT (M) PERFORMANCE IN GPH (LPH)

PRESS

H.P. NO.

SUCT. PRESS

PSI(kPa)

30 40 50 60 70 80 90 100 110 120 130 140 180

(9) (12) (15) (18) (21) (24) (27) (30) (33) (36) (40) (43) (55)

J32P-24

20 730 710 705 660 600 480 430 350 210 110 — — —

Venturi (138) (2763) (2687) (2668) (2498) (2271) (1817) (1628) (1325) (795) (416)

30 730 690 675 630 555 470 400 345 205 110 — — —

(207) (2763) (2612) (2555) (2385) (2101) (1779) (1514) (1306) (776) (416)

1 1-1/4” 1 40 730 680 670 600 530 455 390 335 195 105 — — —

(275) (2763) (2574) (2536) (2271) (2006) (1722) (1476) (1268) (738) (397)

#52

50 725 670 640 565 500 435 375 320 180 90 — — —

Nozzle

(344) (2744) (2536) (2422) (2139) (1893) (1646) (1419) (1211) (681) (341)

60 700 640 595 515 450 390 335 285 150 80 — — —

(413) (2650) (2422) (2252) (1949) (1703) (1476) (1268) (1079) (568) (303)

20 330 330 320 320 320 310 300 300 300 300 270 250 140

J32P-18

(138) (1249) (1249) (1211) (1211) (1211) (1173) (1136) (1136) (1136) (1136) (1022) (946) (530)

Venturi

30 330 330 320 320 320 310 300 300 300 300 270 250 130

(207) (1249) (1249) (1211) (1211) (1211) (1173) (1136) (1136) (1136) (1136) (1022) (946) (492)

1 1-1/4” 1” 40 330 330 320 315 310 305 300 300 300 300 270 250 120

(275) (1249) (1249) (1211) (1192) (1173) (1154) (1136) (1136) (1136) (1136) (1022) (946) (454)

#52

50 330 330 315 310 305 300 300 300 300 295 260 250 105

Nozzle

(344) (1249) (1249) (1192) (1173) (1154) (1136) (1136) (1136) (1136) (1117) (984) (946) (397)

60 325 325 310 305 300 295 290 290 290 280 250 235 95

(413) (1230) (1230) (1173) (1154) (1136) (1117) (1098) (1098) (1098) (1060) (946) (889) (360)

Installation 5

PRE-INSTALLATION

1. A pump cannot pump air.

2. Long runs and many fittings increase friction and

reduce flow. Locate pump as close to well as possible. Keep pipe straight and angled up to pump. Use

as few elbows and fittings as possible. Support weight

of pipe.

3. Be sure well is clear of sand, dirt and scale which

will plug pump and void warranty.

4. Protect pump and piping from freezing. Freezing will

split pipe, damage pump and void warranty. Check

locally for frost protection requirements (usually pipe

must be 12" (30.5 cm) below frost line and pump

must be insulated).

5. Be sure pipes and foot valve are clean and in good

shape. Leaking foot valve due to dirt or scale may

allow pump to lose prime and cause pump failure.

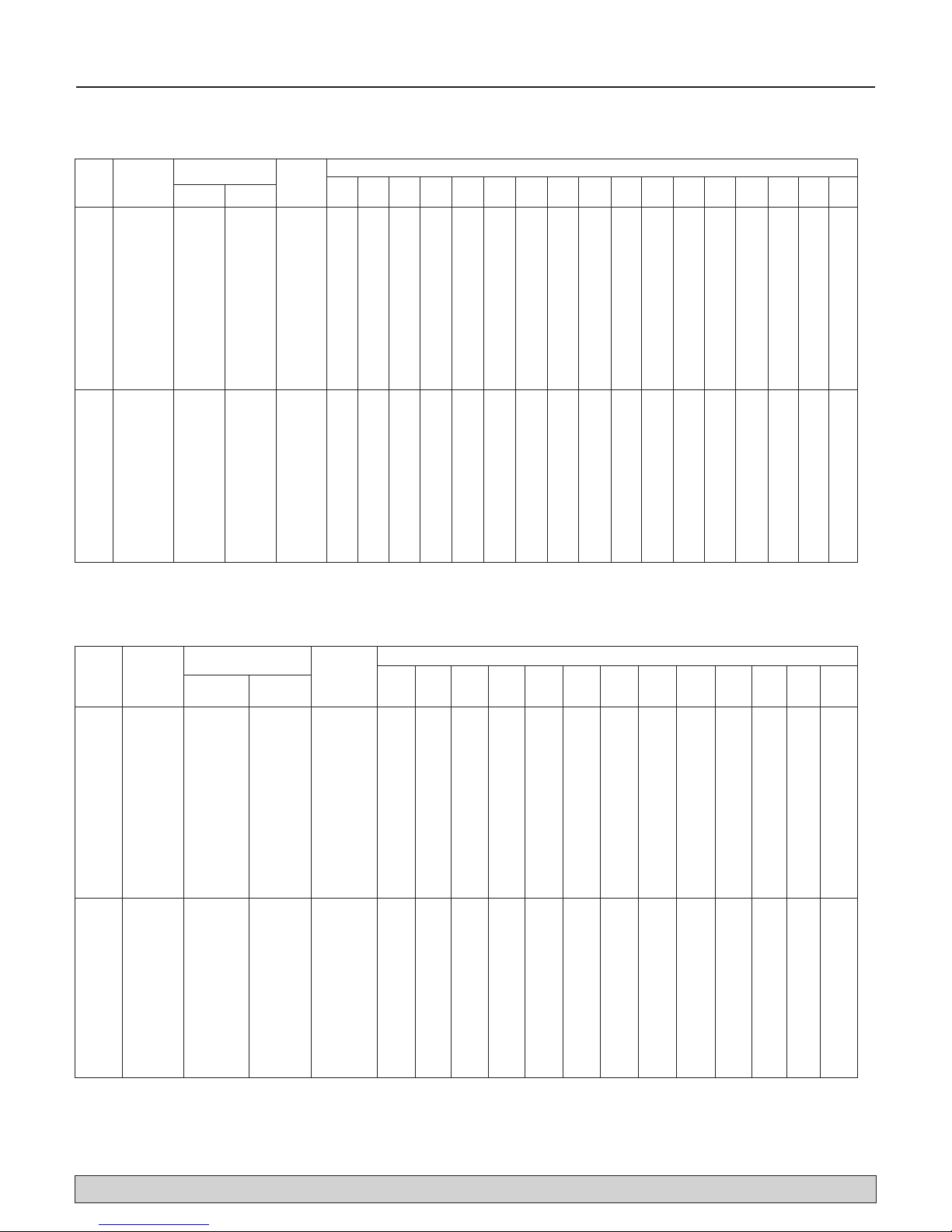

6. No air pockets in suction pipe.

7. No air leaks in suction pipe. Use Teflon tape or

Plasto-Joint Stik to seal pipe joints. Do not use pipe

joint compound. (Figure 1).

NOTICE: A leak in suction may not drip (allows air to

be drawn in). Jet pumps will not pump air or prime

until all joints are sealed properly.

8. Match pump to well. Deep well is 25' (7.6M) or more

to water with pump running. (Figure 2)

NOTICE: Flow in to well must at least equal flow out

through pump! See Performance Chart.

9. Unions installed near pump and well will aid in servicing. Leave room to use wrenches.

10. Pump body may explode if used as

booster pump unless relief valve capable of passing

full pump flow at 75PSI (517kPa) is installed.

11. Be sure to prime pump before starting. Water acts as

lubricant. Starting without water will cause internal

damage and void warranty.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Figure 1 – Suction pipe must not leak

Figure 2 – Match pump to well

g

w

(

w

n

Pipe Joint

No Air Leaks

in Suction Pipe.

If Air Flows

Water Won’t

Compound Will

Damage Plastic.

1" NPT

Plug

Shallow

than 25'

to water

pump ru

Foot

Valve &

Strainer

Well

Casin

Well

Casing

Foot

Valve &

Strainer

Deep well is more

than 25' (7.6M)

to water with

pump running.

Use Teflon Tape.

1102 0697

Installation 6

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

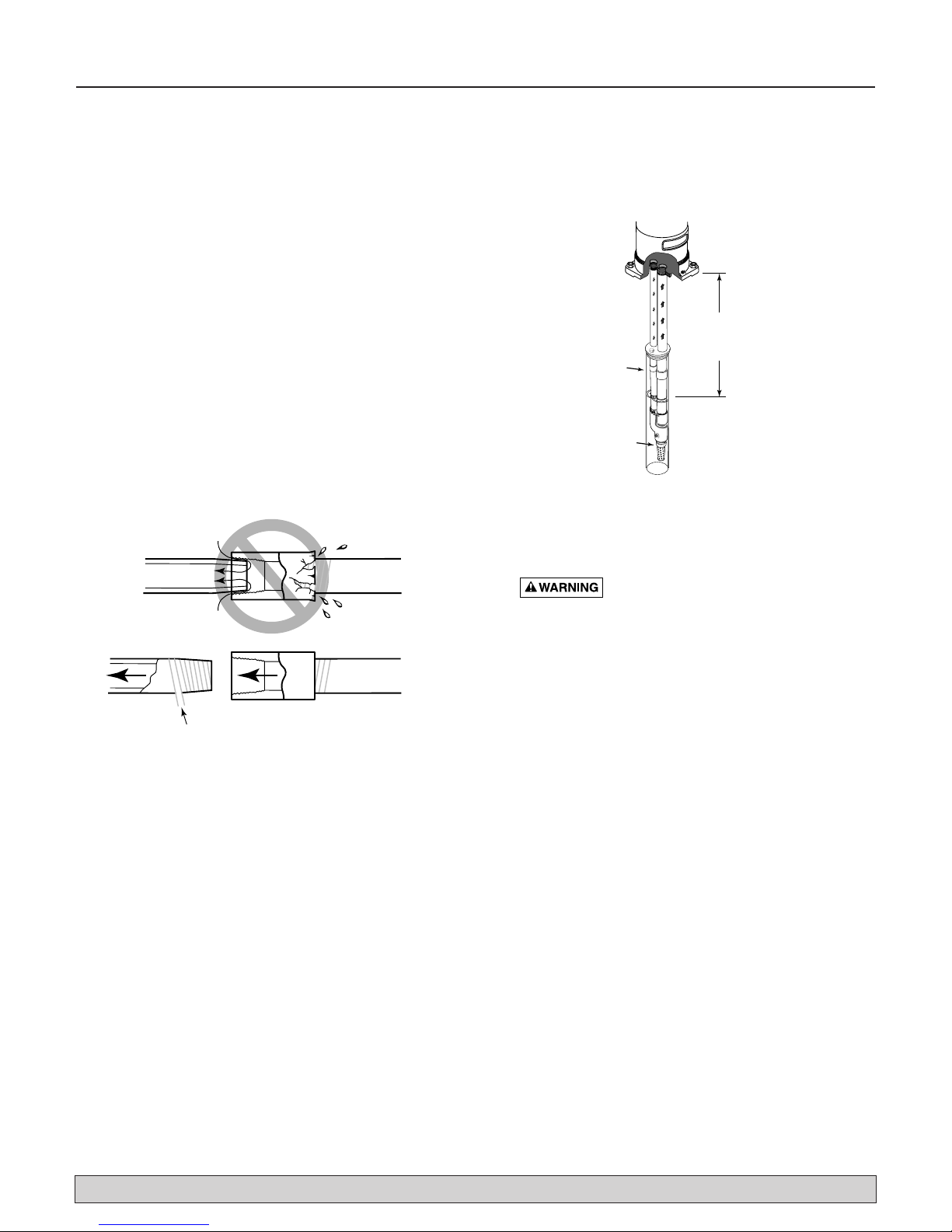

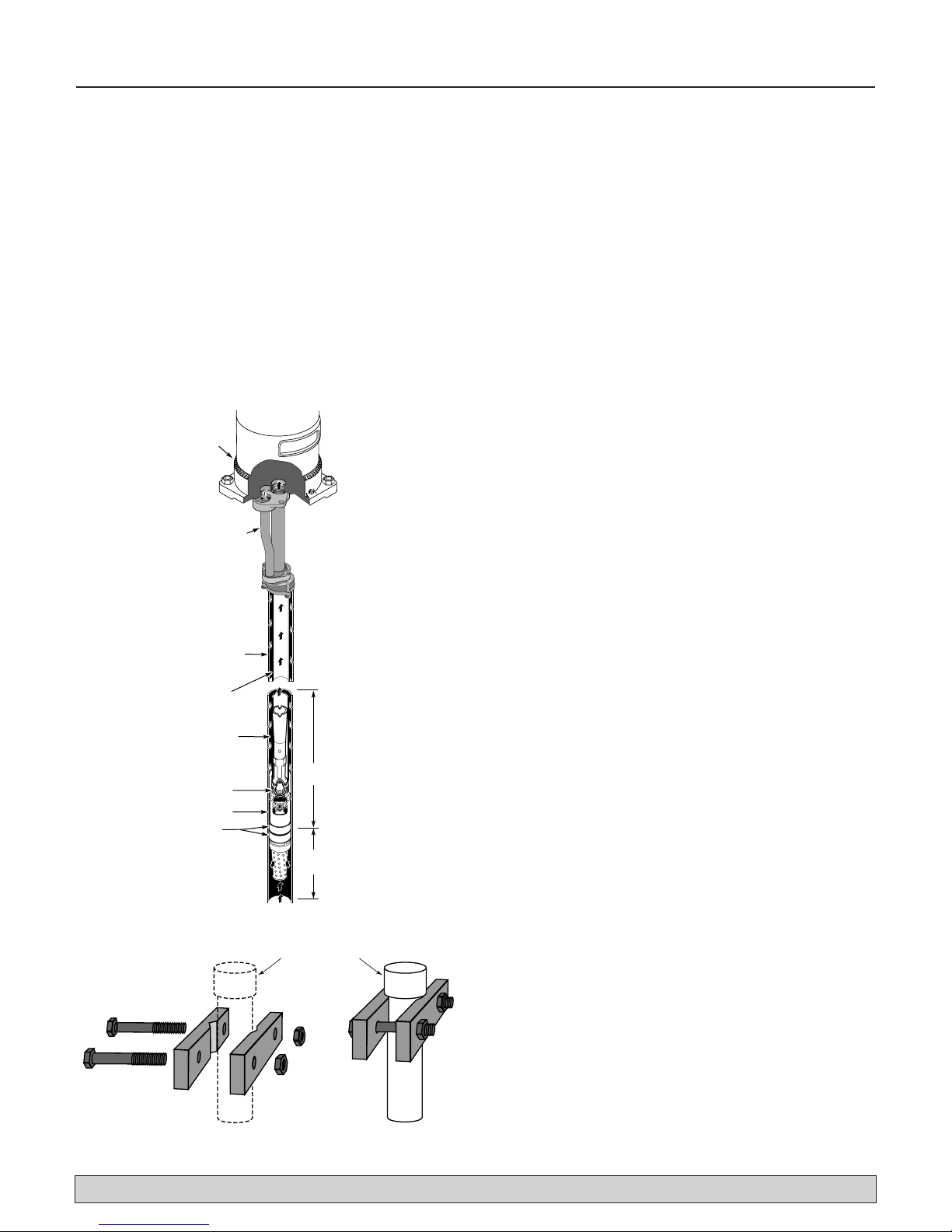

DEEP WELL / DOUBLE PIPE

PIPING IN THE DEEP WELL (Figures 3 & 4)

NOTICE: Deep well installations are either single pipe

(2” wells) or double pipe (4” and larger wells). In a double pipe installation, the larger pipe is the suction pipe

and the smaller pipe is the drive pipe (very deep wells

may use suction and drive pipes of the same diameter).

Suction pipe always aligns with center of pump.

Plastic pipe is ideal for double pipe installations. Due to

its light weight, it is easy to handle and does not usually

require a block and tackle for installation and removal.

PLASTIC PIPE INSTALLATION –

DOUBLE PIPE (Figures 3 & 4)

NOTICE: Use Teflon tape on all male threads on plastic

pipe and fittings to prevent air leaks in suction piping.

1. Inspect jet to make sure that nozzle and venturi

openings are clean and clear.

2. Inspect pipe for any foreign matter or obstructions.

IMPORTANT: Make sure that no foreign matter enters

pipe openings while installing pump.

3. Make sure foot valve operates freely: attach to jet

with a close nipple. Use Teflon tape on male threads.

4. Install nozzle and venturi in deep well jet. Consult

Table II for proper nozzle and venturi.

5. Using Teflon tape on male threads, install special

plastic pipe adapter (supplied with jet package) by

screwing adapter into 1-1/4” tapped hole in ejector

body.

6. Thread a 1” plastic pipe adapter into the 1” tapped

hole in jet body.

7. Install sufficient plastic pipe in well casing to place

jet at the proper depth. (Your well driller should supply this information.)

IMPORTANT: As a guide, the jet should be set at least

10 to 20 ft. (3-6M) below lowest water level with

pump running, but always at least 5 ft. (1.5M) from

bottom of well.

8. Tighten hose clamps on plastic pipe. Use 2 clamps

per joint to prevent air leaks into suction pipe. Clamp

screws should be on opposite sides of pipe. Fill pipes

with water to make sure foot valve and connections

do not leak.

9. Install sanitary well seal on top of well casing; use

steel nipple through well seal.

IMPORTANT: Align locating lugs on adapter flange

and pump base so pump discharge will be aligned

with piping.

10.Install nipple in drive pipe side of adapter flange.

Slide threadless coupling down over drive pipe from

well. Thread adapter flange onto suction pipe from

well and align nipple and drive pipe.

11. Slide threadless coupling up and secure nipple to

drive pipe.

Figure 3 – Over the well installation

Figure 4 – Offset installation

Pump

Gasket

Adapter Flange

Threadless Coupling

Sanitary

Well Seal

1" Drive Pipe

1-1/4" Suction Pipe

Ejector Assembly

Foot Valve & Strainer

474 0194

Pump

Gasket

Adapter Flange

Sanitary

Well Seal

Steel Pipe Nipple

Coupling

1" Plastic Drive Pipe

1-1/4" Plastic Suction Pipe

Special 1-1/4" Plastic Pipe

Adapter. (Supplied with Ejector)

1" Plastic Pipe Adapter

Ejector Assembly

Foot Valve & Strainer

Threadless

Coupling

Installation 7

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

12.Apply gasket to adapter flange. Be sure holes line up.

13.Align locating lugs on pump base with locating lugs

on adapter flange; attach pump to flange with cap

screws provided.

14.See “Discharge Pipe Sizes” for information regarding

correct discharge pipe size.

DEEP WELL / SINGLE PIPE

2" SINGLE PIPE JET DEEP WELL

INSTALLATION (Figures 5 and 6)

Single pipe installations require :

A. Galvanized steel pipe

B. Leather packer-type jet with built-in foot valve

C. Turned couplings (supplied with jet package)

D. Well casing adapter and adapter flange (supplied

with jet package)

E. Offset nipple (supplied with jet package)

F. Pipe holders (see Figure 6B)

1. Place jet in pail of water for two or more hours to

soak cup seals. See Table III for proper venturi and

nozzle.

2. After cup seals are thoroughly soaked, connect jet to

first length of pipe. Use pipe joint compound sparingly on male threads.

NOTICE: Due to normal irregularities in the leather of

the cup seals and the inner walls of the drop pipe, 2"

packer jets do not form a perfect seal. In a dormant

system, water will leak back into well over time and

pump will normally start and cycle to maintain system pressure level.

3. Lower pipe into casing. Use specially turned couplings (included with 2” single pipe jet package) to

increase water flow. Use pipe joint compound sparingly on male couplings threads.

NOTICE: Fill pipe with water as each length is added

to be sure foot valve and connections do not leak.

4. Add lengths of pipe until jet reaches proper depth.

(Contact your local well driller.)

IMPORTANT: As a guide, the jet should be set at least

10 to 20 ft. (3-6M) below lowest water level with

pump running, but always at least 5 ft. (1.5M) from

bottom of well.

5. With jet at the proper depth for your installation,

mark the drop pipe 6” above the top of the well casing, then raise the drop pipe about 18 inches and

clamp it there to allow room to install the casing

adapter, offset nipple, and adapter flange.

6. Cut off the drop pipe at the mark you made in Step 5.

Thread the top of the pipe 1” NPT to take the adapter

flange.

7. Slide the casing adapter over the top of the drop pipe

with bolts in place and leave it loose on the pipe.

8. Thread the drop pipe into the adapter flange; thread

the offset nipple into the adapter flange until it is tight

and aligns with its port inthe casing adapter.

9. Remove pipe holder and lower pipe assembly until

casing adapter seats on well head and offset nipple

seats in casing adapter port. Before tightening casing

adapter bolts, move assembly up and down slightly.

Water pressure in the casing will seal the cup seals.

10.Tighten casing adapter bolts to fasten the casing

adapter to the well casing.

11. Install gasket on adapter flange and bolt pump to

adapter flange.

IMPORTANT: Align locating lugs on adapter flange

and pump base so that pump discharge will be

aligned with piping.

Figure 5 – 2" Single pipe

Figure 6 – Pipeholder details

Pump

mounted

on Casing

Adapter

Offset Nipple

Well Casing

serves as

Drive Pipe

Suction

Pipe

Venturi

Nozzle

Ejector

Cup

Leathers

2357c 0797

Water level

with pump

running

24

J32P-

JET NO.

10 to 20 Feet

5 Feet

or more

Turned Coupling

1387 11

Installation / Electrical 8

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

DISCHARGE PIPE SIZES

1. If increasing discharge pipe size, install reducer in

pump discharge port. Do not increase pipe size by

stages.

2. When pump is set away from the points of water use,

discharge pipe size should be increased to reduce

pressure losses caused by friction.

• Up to 100 ft (30M) run: Same size as pump discharge port.

• 100 ft. to 300 ft (30-91M) run: Increase one pipe

size.

• 300 ft. to 600 ft (91M-183M)run: Increase two

pipe sizes.

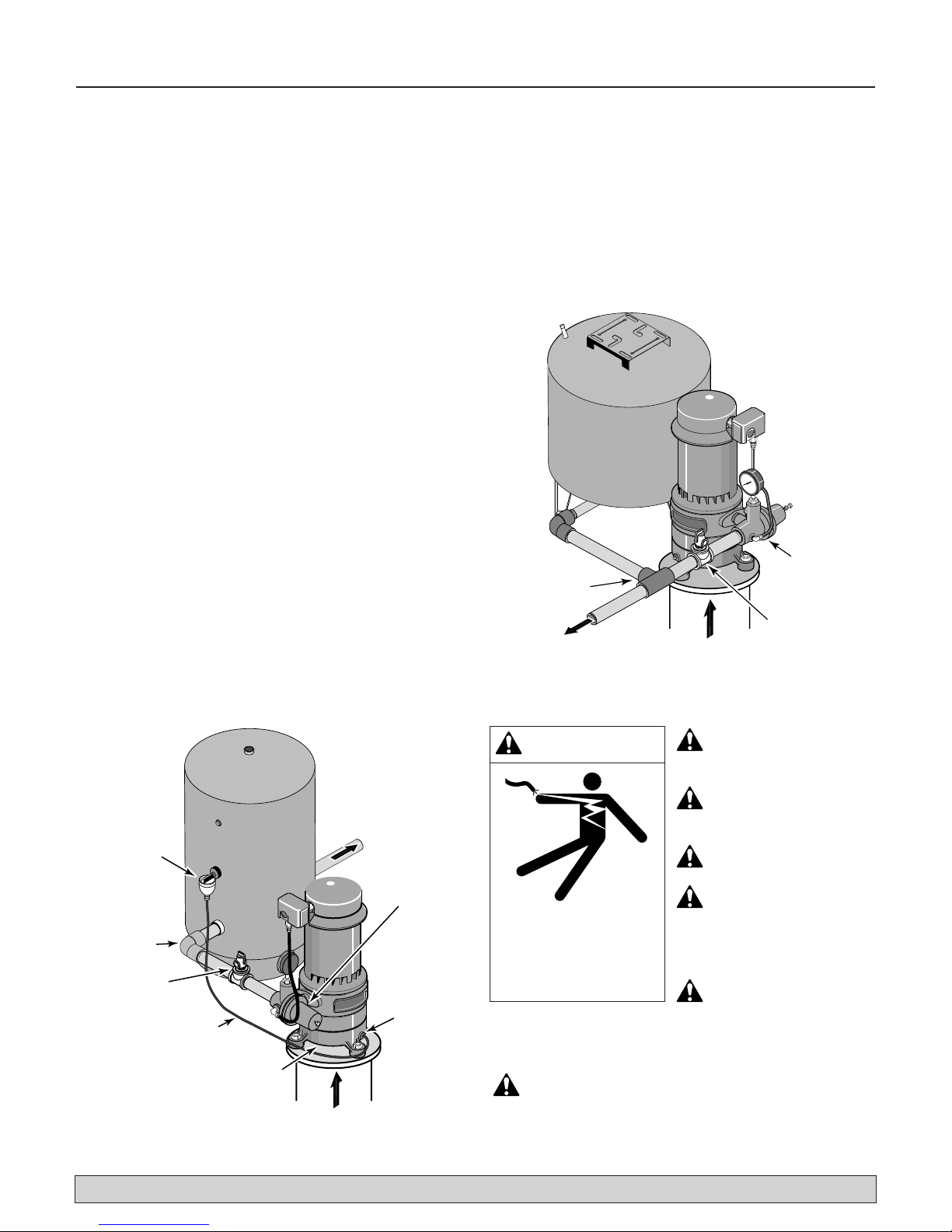

PRESSURE TANK INSTALLATION –

DEEP WELL

A pressure tank provides a reservoir of water under pressure and maintains a cushion of air pressure to prevent

pipe hammering and possible damage to plumbing components. When water is drawn off through house fixtures,

pressure in tank is lowered and pressure switch starts

pump.

STANDARD TANK CONNECTION (Figure 7)

With a standard tank - an air volume control (AVC) adds

air to the tank when needed.To connect AVC to pump,

thread a 1/8” compression fitting into tapped hole on

front of pump. Cut tubing to length to reach AVC; assemble to fitting on pump and to AVC on tank. See installation instructions provided with tank and AVC for details.

PRECHARGED TANK CONNECTION

(Figure 8)

No AVC is necessary with a precharged tank. A

precharged tank contains a factory provided air charge.

IMPORTANT: Pump pressure switch is set for a 40-60 PSI

(275-414kPa) range and requires a tank pre-charge of 38

PSI (262 kPa) for proper operation. See tank owner’s

manual for air charge. An annual check on tank air

charge is recommended.

ELECTRICAL

Ground motor before

connecting to electrical

power supply.

Failure to ground motor

can cause severe or fatal

electrical shock hazard.

Do not ground to a gas

supply line.

To avoid dangerous or

fatal electrical shock,

turn OFF power to motor

before working on electrical

connections.

Supply voltage must be

within ±10% of name-

plate voltage. Incorrect voltage can cause fire or seriously damage motor and voids warranty. If in doubt consult a licensed electrician.

Use wire size specified in Wiring Chart. If possible,

connect pump to a separate branch circuit with no

other appliances on it.

Figure 7 – Pump on standard tank - shallow well

Figure 8 – Pump with pre-charged tank

WARNING

Hazardous voltage. Can

shock, burn, or cause

death.

Ground pump before connecting to power supply

Pre-Charged

Pressure Tank

6

40

0

20

80

100

Pressure

1" Discharge

2358b 0697

Regulator

Relief Valve

Standard Tank

Air Volume

Control

(AVC)

1" Discharge

Relief Valve

AVC Tubing

Well Seal

2355b 0697

Pressure

Regulator

AVC

Port

Electrical 9

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

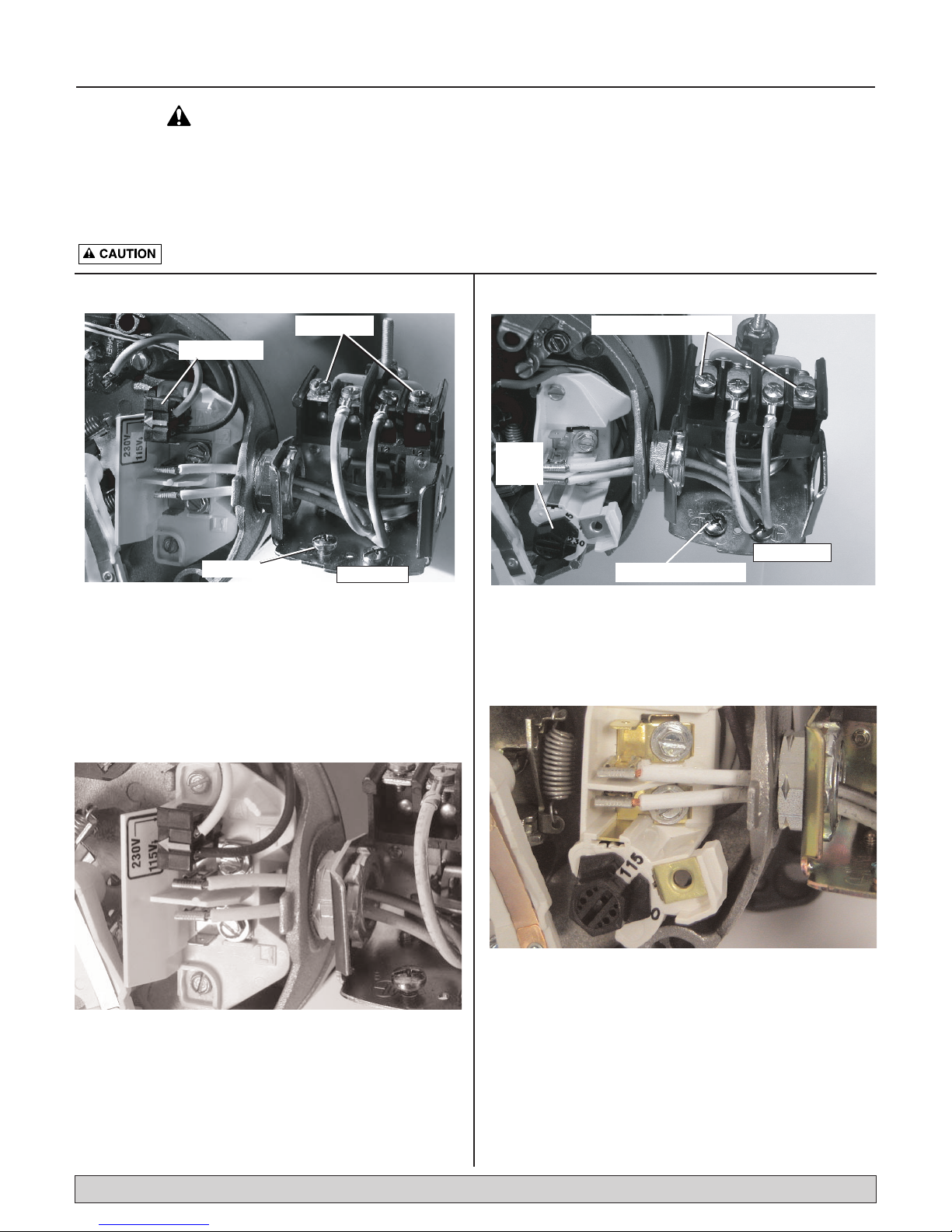

Plug Type Voltage Selector

Voltage is factory set to 230 volts. To change to 115 volts:

1. Make sure power is off.

2. Pull the voltage change plug off of the tabs.

3. Move the voltage change plug to the 115 volt position. The plug will now cover 2 metal tabs and the

arrow on the plug will line up with the 115V arrow on

the label (see Figure 10).

4. Attach the incoming power leads to the two outer

screws on the pressure switch as shown in Figure 9.

5. Attach the ground wire to one of the grounding

connections, shown in Figure 9.

6. If there are other wires, they should be capped.

7. Reinstall the Motor end cover.

Dial Type Voltage Selector

Voltage is factory set to 230 volts. To change to 115 volts:

1. Make sure power is off.

2. Turn the dial counter-clockwise until 115 shows in the

dial window as shown in Figure 12.

3. Attach the incoming power leads to the two outer

screws on the pressure switch as shown in Figure 11.

4. Attach the ground wire to the grounding connections

as shown in Figure 11.

5. If there are other wires, they should be capped.

6. Reinstall the Motor end cover.

NOTE: 1/2 HP motors are wired for 115 volts only, and have no motor wiring to change.

Your motor terminal board (located under the motor end cover) should look like one of those below.

If the motor can operate at either 115 or 230 volts, it is set at the factory to 230 volts. Do not change motor wiring if

line voltage is 230 volts, or if you have a single voltage motor.

Never wire a 115 volt motor to a 230 volt line.

Motor Switch Settings

Figure 9:Voltage set to 230 volts, Plug Type

Figure 10:Voltage set to 115 volts, Plug Type

Figure 11:Voltage set to 230 volts, Dial Type

Figure 12:Voltage set to 115 volts, Dial Type

Disconnect power before working on pump, motor, pressure switch, or wiring.

Power Connections

Voltage Change Plug

Ground Wire Connection

Pressure Switch

Power Supply Connections

Voltage

Change

Dial

Pressure Switch

Ground Wire Connection

Electrical 10

Wiring (Figure 9)

1. Install, ground, wire and maintain pump in accordance with your local electrical code and all other

codes/ordinances that apply. Consult your local

building inspector for local code information.

2. Ground pump permanently using wire of size and

type specified by approved local or national codes.

Risk of explosion. Do not ground to gas

supply line.

3. Connect ground wire first. Connect to ground first,

then to green grounding terminal provided on pres-

sure switch identified as GRD. Ground connection

MUST be made to this terminal. Do not connect

motor to electrical power supply until unit is permanently grounded; otherwise serious or fatal electrical

shock hazard may be caused.

4. For best ground connection, connect to grounded

lead in service panel or to metal underground water

pipe or well casing at least 10 ft. (3 M) long. If plastic

pipe or insulated fittings are used, run ground wire

directly to metal well casing or use ground electrode

furnished by the power company.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

MAX. BRANCH FUSE DISTANCE IN FEET (M) FROM MOTOR TO SUPPLY

MOTOR VOLTS LOAD RATING 0 - 100 101 - 200 201 - 300

HP AMPS AMPS* (0 - 30) (30 - 61) (61 - 91)

1 115/230 19.2/9.6 20/15 10/14 (5/2mm2) 8/12(7/3mm2) 6/12(13/3mm2)

WIRING CHART – Recommended Wire and Fuse Sizes

(*)Time delay fuse or circuit breakers are recommended in any motor circuit.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Operation 11

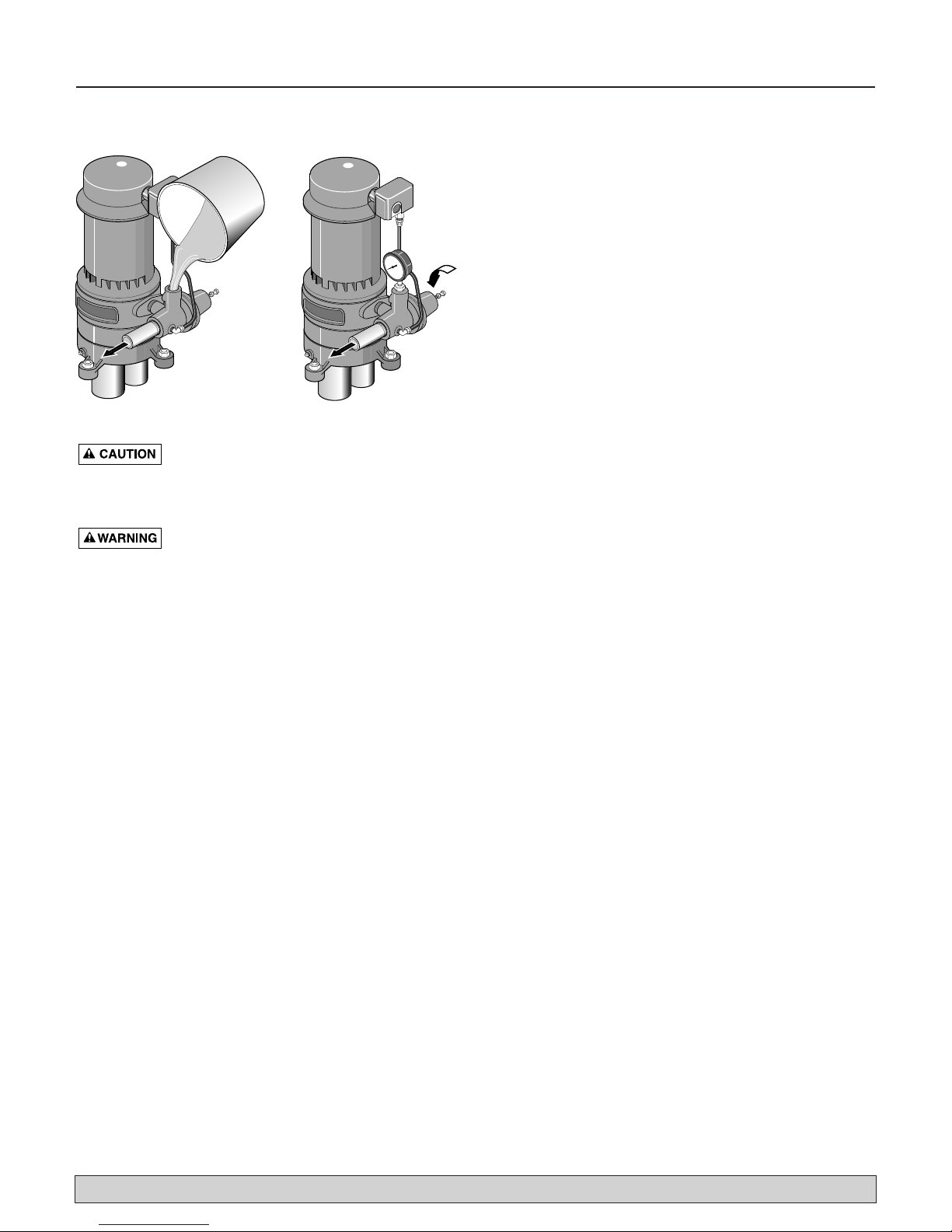

PRIMING THE PUMP (Figure 13)

NEVER run pump dry. Running pump without water may cause pump to overheat, damaging seal

and possibly causing burns to persons handling pump.

Fill pump with water before starting.

NEVER run pump against closed discharge.

To do so can boil water inside pump, causing hazardous

pressure in unit and possibly scalding persons handling

pump.

NOTICE: Open water system faucets before priming

pump for the first time.

1. Remove pressure gauge.

A. Close regulator valve (turn clockwise).

B. Fill pump and suction pipe with water.

C. Replace pressure gauge, using teflon tape on

thread; tighten gauge.

IMPORTANT: If a priming tee and plug have been provided for a long horizontal run, fill suction pipe through

tee and replace plug. (Remember: teflon tape plug.)

2. Start Pump:

Pressure should build rapidly to 50 PSI (345 kPa) or

more as jet and pump prime.

IF NO PRESSURE OR NO WATER, REPEAT

STEP No.1 two or three times to remove entrapped

air from suction pipes.

3. If, after priming pump several times and no water is

pumped, make sure that:

A. Suction pipe is in the water and has no leaks.

NOTE: Air can leak in where water won’t leak out.

Make sure all joints are tight.

B. Control valve, check valve, or foot valve is

installed and operating correctly.

C. Pump is not trying to lift water more than 25 feet

(7.6M) (shallow well) or more than rated lift for

deep well jet used (including compensation for

horizontal piping). See “Performance and Jet

Chart” for your installation.

D. Pump is not airlocked, suction port should be

highest point in suction pipe; no sags in suction

pipe (run it straight and angled slightly upward

from well head to pump).

NOTE: For deep well installation, go to step 4.

Shallow well installations go to step 6.

4. Once unit has primed and pressure is stabilized,

slowly open regulator valve (turn counterclockwise)

until pressure falters (pressure gauge needle flutters).

Close control valve (turn clockwise) slightly until

pressure stabilizes. This setting provides maximum

flow.

5. Pump may draw well down far enough to lose its

prime. If so, close regulator valve until pressure is stable throughout pumping cycle. Close faucets and

allow pump to pressurize tank and shut off.

6. Check system by alternately opening and closing

faucets in the system. With faucets open, pressure

will drop until pump starts; with faucets closed, pressure will build up until pump shuts off.

7. There are conditions of deep well operation when the

regulator valve may be completely open without any

faltering of pressure. In this case, operate pump with

regulator valve open.

Figure 13 – Fill Pump

60

40

20

80

100

2360a 0697

2361a 0697

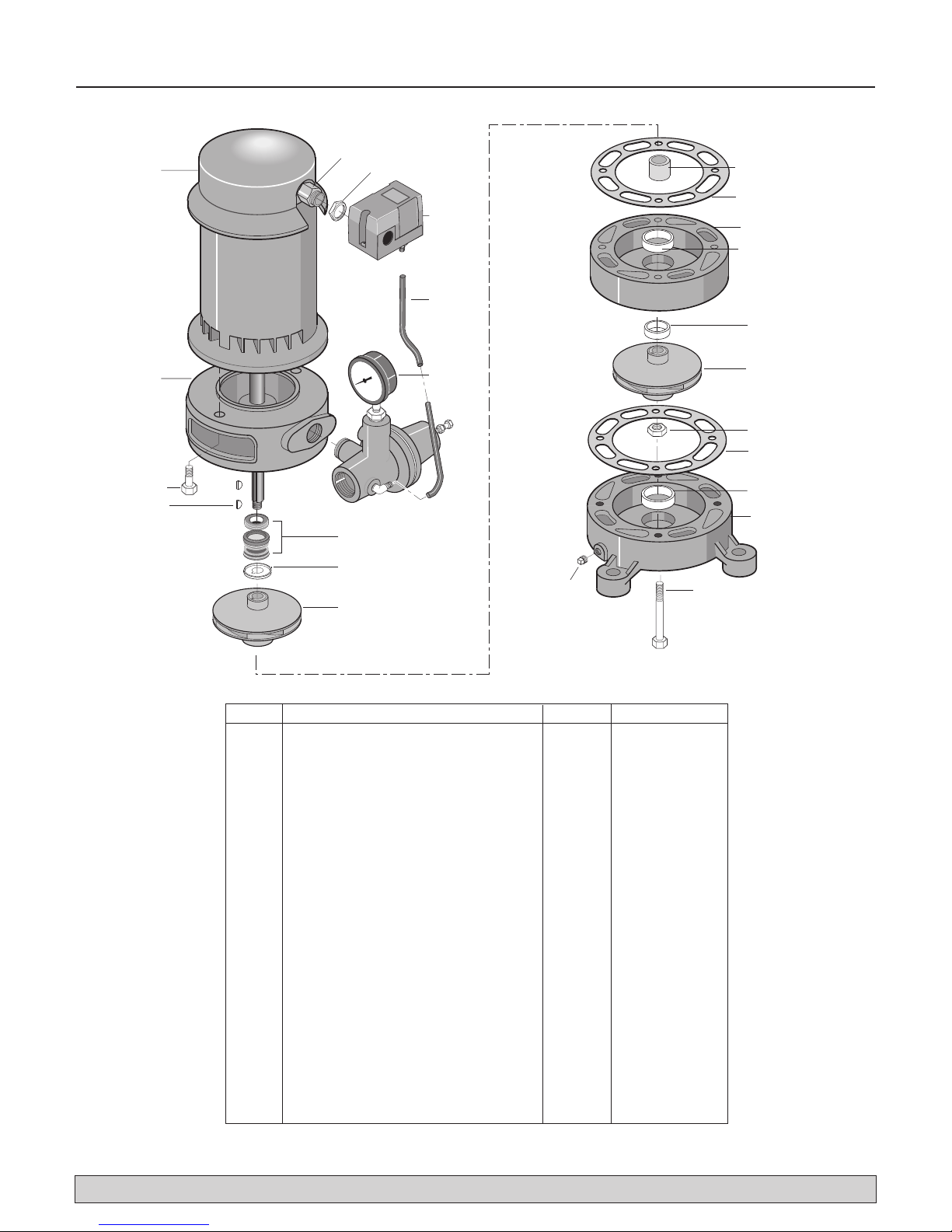

Repair Parts 12

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

* Standard hardware item, available locally.

Key No. Part Description Qty. FP4432-01

1 Motor 1 A300EH

2 1/2" Connector 1 U43-13C

3 1/2" Locknut 1 *

4 Pressure Switch 1 U217-1228

5 1/4" Tubing 1 *

6 Pressure Regulator Assembly 1 J212-24E

7 Pump Adapter 1 L2-16A

8 3/8-16 x 1" Capscrew 2 *

9 #3 Woodruff Shaft Key 2 U65-15SS

10 Shaft Seal 1 17351-0101A

11 Spring Holder 1 J24-11

12 Impeller 2 J105-76P

13 Impeller Spacer 1 J43-23

14 Gasket 2 J20-11

15 Intermediate Volute 1 J101-26

16 Wear Ring 2 J23-10

17 Wear Ring 1 J23-11

18 Impeller Nut 1 U36-175D

19 Base Volute 1 J101-33

20 3/8 - 16 x 4-1/4" Capscrews 2 *

21 1/4" NPT Square Head Pipe Plug 1 *

2

1

3

13

14

4

15

16

5

17

60

40

20

7

80

100

6

12

18

14

8

9

16

19

10

11

21

20

12

1281 0705

Loading...

Loading...