Flotec FPSE3200A, FPSE2800A, FPSE3601A Owner's Manual

OWNER’S MANUAL

Submersible Solids

Handling Pumps

NOTICE D’UTILISATION

Pompes submersibles

pour les matières solides

MANUAL DEL USUARIO

Bombas submergibles para el

manejo de líquidos con sólidos

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-365-6832

English . . . . . . . . . . . . . . Pages 2-6

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 365-6832

Français . . . . . . . . . . . Pages 7-11

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-365-6832

Español . . . . . . . . . .Paginas 12-16

P.O. Box 342, Delavan, WI 53115

Phone: 1-800-365-6832

Fax: 1-800-526-3757

E-Mail: info@flotecwater.com

Web Site: http://www.flotecwater.com

©2005 S185 (Rev. 4/18/05)

3601A SERIES

®

412 0897ASB/NF

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury:

warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

1. Read this manual carefully. Failure to follow these

instructions could cause serious bodily injury and/or

property damage.

2. Check your local codes before installing. You must

comply with their rules.

3. Vent sewage or septic tank according to local codes.

4. Do not install pump in any location classified as

hazardous by National Electrical Code, ANSI/NFPA

70-1990.

Hazardous voltage. Can shock, burn or

cause death. During operation, the pump is in water.

To avoid fatal shocks, proceed as follows if pump needs

servicing:

5A. Disconnect power to outlet box before unplugging

pump.

5B. Take extreme care when changing fuses. Do not

stand in water or put your finger in fuse socket.

5C. Do not modify cord and plug. When using cord and

plug, plug into a grounded outlet only. When wiring

to a system control, connect pump ground lead to

system ground.

6. Do not run pump dry. Dry running can overheat

pump, (causing burns to anyone handling it) and will

void warranty.

7. Pump normally runs hot. To avoid burns when ser-

vicing pump, allow it to cool for 20 minutes after

shut-down before handling it.

8. In normal service, motor should not need oiling.

Motor has been filled at the factory with a special

oil.

AT TACH ORIGINAL RECEIPT HERE FOR WARRANTY CONSIDERATION.

FLOTEC warrants that the products specified in this warranty are free from defects in material or workmanship.

If within the duration of product use by the product owner, any FLOODMATE

®

7000 (FP0S6000A), IRONMATE

®

(FPSC4550A), Sewage Ejector (FPSE3601A), Pedestal Pump (FPPSS5000), or Utility Pump (FPSC1725X), shall prove to

be defective, it shall be repaired or replaced at FLOTEC’s option, subject to the terms and conditions set forth below.

General Terms and Conditions

Owner must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty

shall not apply to acts of God, nor shall it apply to products which, in the sole judgement of FLOTEC, have been subject to negligence, abuse, accident, misapplication, tampering, alteration; nor due to improper installation, operation,

maintenance or storage; nor to excess of recommended maximums as set forth in the owner’s manual.

Requests for service under this warranty shall be made by returning the product to the Retail outlet or to FLOTEC as

soon as possible after the discovery of any alleged defect. FLOTEC will subsequently take corrective aciton as promptly

as reasonably possible.

This warranty sets forth FLOTEC’s sole obligation and purchaser’s exclusive remedy for defective products.

FLOTEC SHALL NOT BE RESPONSIBLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES

WHATSOEVER. THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES,

IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitation on how long

an implied warranty lasts, so the above limitations or exclusions may not apply to you. Although this warranty identified specific remedies you may also have other rights and remedies.

FLOTEC • P.O. Box 342 • Delavan, WI U.S.A. 53115

Phone: 1-800-365-6832 • Fax: 1-800-526-3757

E-Mail: info@flotecwater.com • Web Site: http://www.flotecwater.com

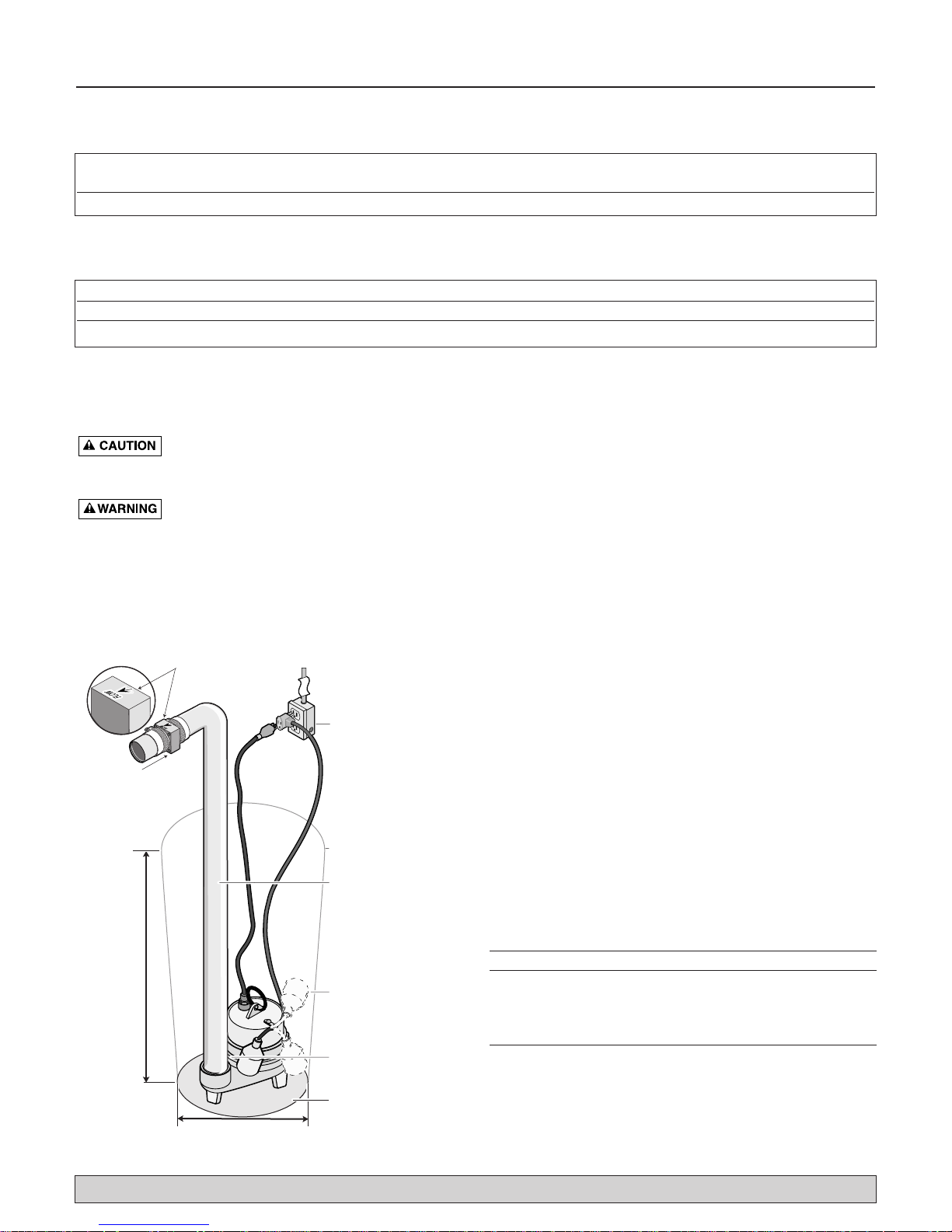

Specifications / Performance / Installation 3

INSTALLATION

(See Figure 1 for Typical Installation instructions.)

Pump must be level when operating. If

motor is tilted, internal start/run switch may overheat and

damage motor.

Risk of electrical shock. Can burn or kill.

Do not lift pump by power cord. See “Cord Lift Warning”

on Page 5. Do not hang pump from discharge pipe or

power cord.

1. Install the pump on a solid, level foundation, or in a

sump pit constructed of tile, concrete, steel or plastic. The recommended minimum diameter of the

sump pit is 18" (46cm) diameter and the minimum

recommended depth is 30" (76cm). Check local

codes for approved materials.

NOTICE: Pump should not be installed on clay, earth

or sand surfaces. Clean the area around the pump of

small stones and gravel which could clog the pump.

Keep the pump inlet screen clear.

2. Thread a 2” discharge pipe into the pump 2” NPT

discharge port. Be careful to avoid stripping or crossing threads.

Piping – Effluent Applications

(3/4" or Less Solids)

Piping must be 1-1/2" minimum to carry volume of

pump discharge. Check local codes to determine if a

check valve is required in your system. In cold climates,

check valves are not used to prevent effluent from freezing in piping.

Piping – Sewage Applications

(2" or Less Solids)

In any case, piping must not be smaller than pump

discharge.

When installed in a sewage system, pipe must be capable

of handling semi-solids of at least 2” (5.1 cm) diameter.

The rate of flow in the discharge pipe must keep any

solids present in suspension in the fluid. To meet minimum flow requirements (2 feet (.6 m) per second in discharge line), size pipe as follows:

A Pipe Size Of: Will Handle a Flow Rate Of:

1-1/2” (3.8 cm) 12 GPM (45 LPM)

2” (5.1 cm) 21 GPM (79 LPM)

2-1/2” (6.3 cm) 30 GPM (113 LPM)

3” (7.6 cm) 48 GPM (181 LPM)

NOTICE: Use Teflon™ tape on pipe connections. Do

not use ordinary pipe joint compound on plastic pipe or

pump. Pipe joint compound can attack plastics and damage pump.

TM

E.I. DuPont de Nemours and Company Corporation.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

GPH (LITERS) AT DISCHARGE FT. OF HEAD

5 (1.5m) 10 (3m) 15 (4.6m) 20 (6.1m) 25 (7.6m)

FPSE3601A 7320(27,709) 5400(20,441) 2700(10,221) – –

PERFORMANCE

FPSE Individual Branch Circuit Dual Element Time

Model H.P. Voltage Required (Amps) Delay Fuse Amps

3601A 1/2 115 20 20

SPECIFICATIONS

Figure 1

Flow

Directional

Arrow

115V Properly

Grounded

Outlet

2" Checkvalve

Do Not Mount

Vertically

Sump Pit

2" Discharge

Pipe

30"

18"

Be sure the

float switch can

swing through

it's entire arc.

Drill a 3/16"

vent hole here.

Install pump on

a hard, level surface.

Electrical / Operation / Service 4

3. To reduce motor noise and vibrations, a short length

of rubber hose can be connected into discharge line

near pump using suitable clamps.

4. If the pump discharge line is exposed to outside subfreezing atmosphere, then the portion of line

exposed must be installed so any water remaining in

pipe will drain to outfall by gravity. Failure to do this

can cause water trapped in discharge to freeze

which could result in damage to pump.

5. Install a 2” check valve in the horizontal portion of

the discharge pipe. Make certain, the flow indicating

arrow, points away from the pump. This check valve

will keep the water from either running back into the

basin or into the area being pumped out when the

pump is not running. Check valve should be a free

flow valve that will easily pass solids.

NOTICE: For best performance of check valve when

handling solids, do not install it with discharge angled

more than 45° above the horizontal. Do not install check

valve in a vertical position as solids may settle in valve

and prevent opening on startup.

6. Drill a 3/16” (4.7mm) hole in discharge pipe about

1"-2” (2.5 - 5.1cm) above pump discharge connection (but below check valve) to prevent airlocking

the pump.

7. Insert the float switch piggy-back plug into a properly grounded outlet and the pump plug into the piggyback plug.

8. Check the installation by observing the pump operation through one complete cycle. Make sure that no

parts of the assembly interfere with the float switch.

Risk of flooding. May cause personal injury

or property damage. Failure to make this operational

check may lead to improper operation, premature failure, and flooding.

ELECTRICAL

Hazardous voltage. Can shock, burn, or

cause death. When installing, operating, or servicing this

pump, follow safety instructions listed below.

Step 1. DO NOT splice the electrical power cord.

Step 2. DO NOT allow electrical cord plug to be sub-

merged.

Step 3. DO NOT use extension cords. They are a fire

hazard and can reduce voltage sufficiently to prevent pumping and/or damage motor.

Step 4. DO NOT handle or service pump while it is con-

nected to power supply.

Step 5. DO NOT remove grounding prong from plug or

modify plug.To protect against electrical shock,

the power cord is a three-wire conductor and

includes a 3-prong grounded plug. Plug pump

into a 3-wire, grounded, grounding-type receptacle. Connect pump according to electrical codes

that apply.

For automatic operation, plug or wire pump into an automatic float switch or pump controller. Pump will run continuously when plugged directly into an electrical outlet.

Connect or wire pump to its own individual branch circuit

with no other outlets or equipment in the circuit. Size

fuses or circuit breakers according to chart on Page 3.

Risk of electrical shock and fire. Can burn or

cause death. Be sure that power supply information

(Voltage/Hertz/Phase) on pump motor nameplate matches

incoming power supply exactly. Install pump according to

all electrical codes that apply.

OPERATION

NOTICE: Do not allow pump to run in a dry sump. It

will void the warranty and may damage the pump.

An automatic overload protector in the motor will pro-

tect motor from burning out due to overheating/overloading. When motor cools down, overload protector will

automatically reset and start motor.

If overload trips frequently, check for cause. It could be a

stuck impeller, wrong/low voltage, or electrical failure in

motor. If an electrical failure in the motor is suspected,

have it serviced by a competent repairman.

Pump is permanently lubricated. No oiling or greasing is

required.

SERVICE

Hazardous voltage. Can shock, burn, or

cause death. Before removing pump from basin for ser-

vice, always disconnect electrical power to pump and

control switch.

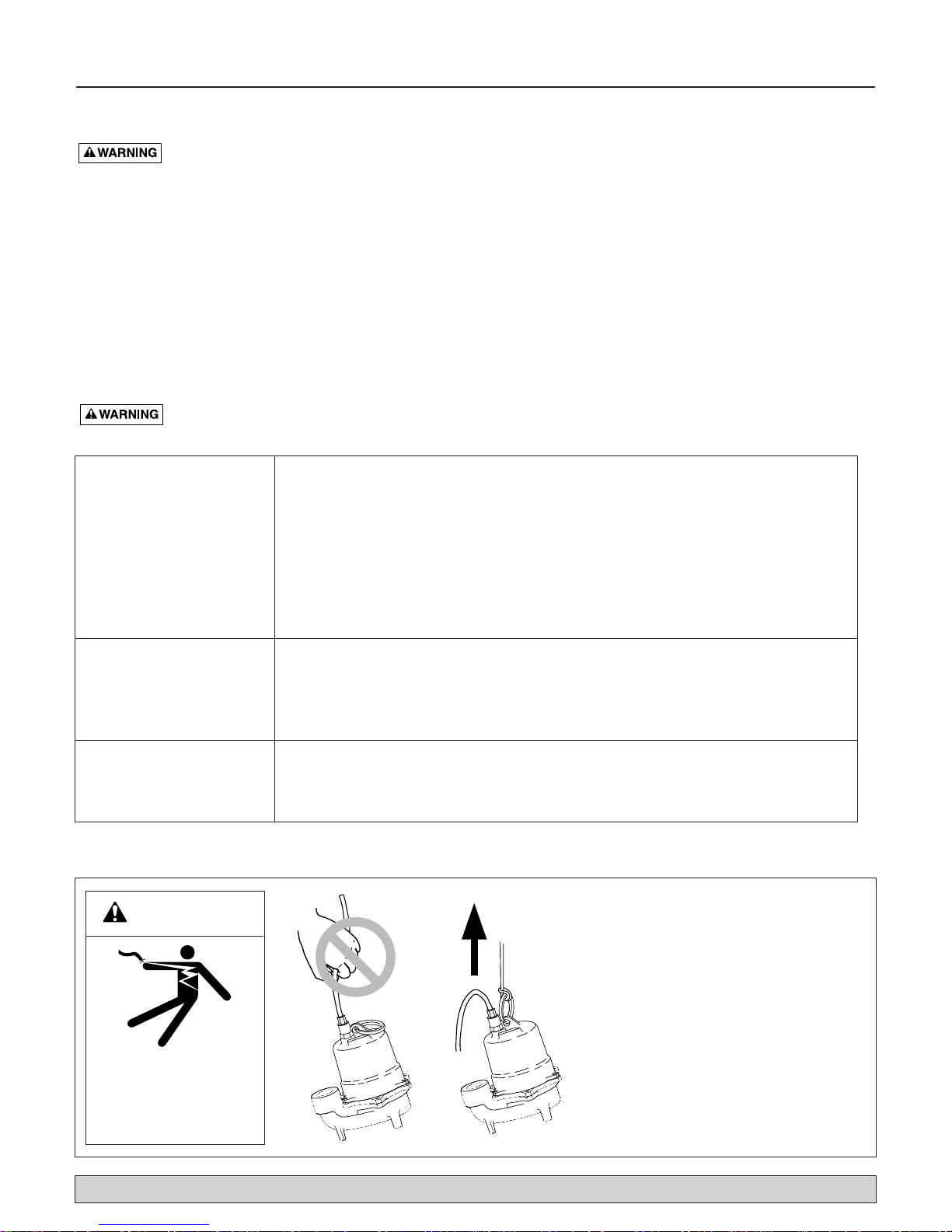

Risk of electrical shock. Can burn or kill.

Do not lift pump by power cord. See “Cord Lift Warning”

on Page 5.

Submerge pump in a disinfectant solution (chlorox or

chlorine) for at least one hour before disassembling

pump.

The pump motor contains a special lubricating oil which

should be kept clean and free of water at all times.

Check operation by filling sump with water and observing pump operation through one complete cycle.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Service / Troubleshooting 5

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

A. Pump fails to operate:

B. Pump fails to empty sump:

C. Pump will not shut off:

Risk of sudden starts. Can result in electrical

shock or pinching of hands or tools. If power to pump is on

when thermal overload resets, pump may start without

warning. Disconnect power before servicing pump.

1. Check to be sure that power cord is securely plugged into outlet. Disconnect power to

outlet before handling pump or motor.

2. Check to be sure you have electrical power.

3. Check that liquid fluid level is high enough to activate switch or controller.

4. Check to be sure that 3/16" (4.7 mm) vent hole in discharge pipe is not plugged.

5. Check for blockage in pump inlet, impeller, check valve or discharge pipe.

6. Thermal overload may have tripped. Test start pump; if it starts and then stops immediately, disconnect from power source for 30 minutes to allow motor to cool, then reconnect to power source. Check for cause of overheating/overloading.

7. Check the float switch operation for maximum possible clearance.

1. Be sure all valves in discharge valve are fully open.

2. Clean out discharge pipe and check valve.

3. Check for blockage in pump inlet or impeller.

4. Pump not sized properly. A higher capacity pump may be required.

5. Check the float switch operation for maximum possible clearance.

1. Check switch or controller automatic floats for proper operation, location and clearance.

See installation instructions for switch/controller.

2. If pump is completely inoperative or continues to malfunction, consult your local

serviceman.

1. Attempting to lift or support pump by

power cord can damage cord and cord

connections.

2. Cord may pull apart, exposing bare

wires with possibility of fire or electrical

shock.

3. Lifting or supporting pump by power

cord will void warranty.

4. Use lifting ring or handle on top of

pump for all lifting/lowering of pump.

Disconnect power to pump before doing

any work on pump or attempting to

remove pump from sump.

Risk of electrical

shock.

Can burn or kill.

Do not lift pump by

power cord.

WARNING

TROUBLESHOOTING

Risk of flooding. May cause personal injury

or property damage. Failure to make this operational

check may lead to flooding and premature failure.

NOTICE: This unit is not designed for applications

involving salt water or brine! Use with salt water or brine

will void warranty.

Loading...

Loading...