Flotec FP0F360AC Owner's Manual

®

P.O. Box 342, Delavan, WI 53115

Phone:

1-800-365-6832

Fax:

1-800-526-3757

E-Mail:

info@flotecwater.com

Web Site:

http://www.flotecwater.com

OWNER’S MANUAL

Cyclone Pumping System

NOTICE D’UTILISATION

Système de pompe Cyclone

MANUAL DEL USUARIO

Sistema de bombeo Cyclone

Installation/Operation/Parts

For further operating,

installation, or maintenance

assistance:

Call 1-800-365-6832

English ...................... Pages 2-7

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 365-6832

Français ................. Pages 8-13

Instalación/Operación/Piezas

Para mayor información sobre

el funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-365-6832

Español ...............Paginas 14-19

FP782 (Rev. 2/2/07)

Model FP0F360AC

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Safety 2

SAFETY INFORMATION

Use this pump only on a 115

volt circuit. Pump is equipped

with an approved 3-conductor cord and 3-prong, grounding-type

plug. To reduce the risk of electric shock,

connect it to a properly grounded,

grounding-type receptacle.

If circuit has a 2-prong receptacle, replace

it with a properly grounded 3-prong receptacle installed in accordance with the

National Electrical Code and local codes

and ordinances.

Any extension cord used must be outdoor

grade, gauge 16 AWG or heavier, and not

more than 25’ long.

Risk of fire or explosion if

used to pump flammable liquids or if used

in explosive atmospheres. Pump water

only with this pump. Pump is designed

to pump water at temperatures between

32°-77° F (0°-25° C) only.

Risk of electrical shock. Do

not allow the motor to get wet!

Risk of burns. During nor-

mal operation, motor case may heat

enough to burn you. Do not touch motor

when it is hot.

Do not operate the pump continuously at a

discharge pressure of more than 12 psi

(83 kPa) or discharge lift of more than

28’ (8.5 M), as the motor will exceed the

normal safe operating temperature and

may heat to 180° - 190° F (82° C - 88° C).

NOTICE: This unit is not designed for applications involving salt water or brine! Use

with salt water or brine will void warranty.

Hazardous

voltage

Installation 3

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

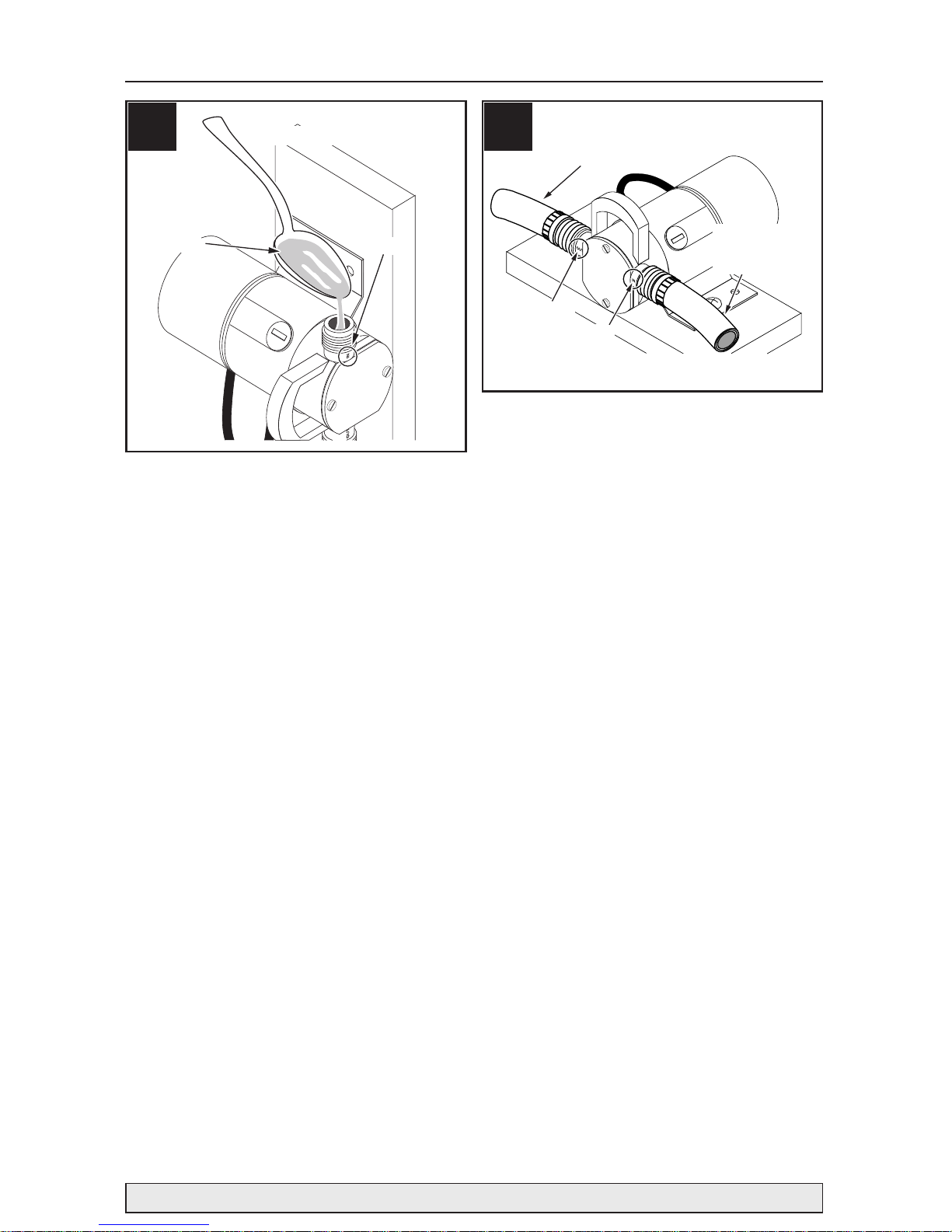

OIL THE PUMP

Oil the pump with 1/2 tablespoon food

grade mineral or vegetable oil with each

use. Pour the oil in the ‘IN’ port. Three 1/2

tablespoon oil packets are included.

NOTICE: The pump depends on the liquid

being pumped for lubrication.

DO NOT RUN THE PUMP DRY!

If the pump does not start to move water in

30 seconds or less, recheck the installation

and plumbing.

Mount the pump solidly on a stable

platform.

USE 1/2" HOSE (OR LARGER)

Use a reinforced hose on the inlet. The

pump should be less than 10’ above and

less than 25’ to one side of the water

source. Make the outlet hose as short as

possible – 25’ or less.

Check the washer in the inlet fitting to

make sure it is airtight. If this joint leaks

air, the pump will not operate.

IN

IN

Oil

Do Not Run Pump Dry!

1

IN

OUT

1/2" or Larger

Outlet Hose

4837A 0205

Water OUT

Water IN

1/2" or Larger

Reinforced

Inlet Hose

2

Installation 4

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

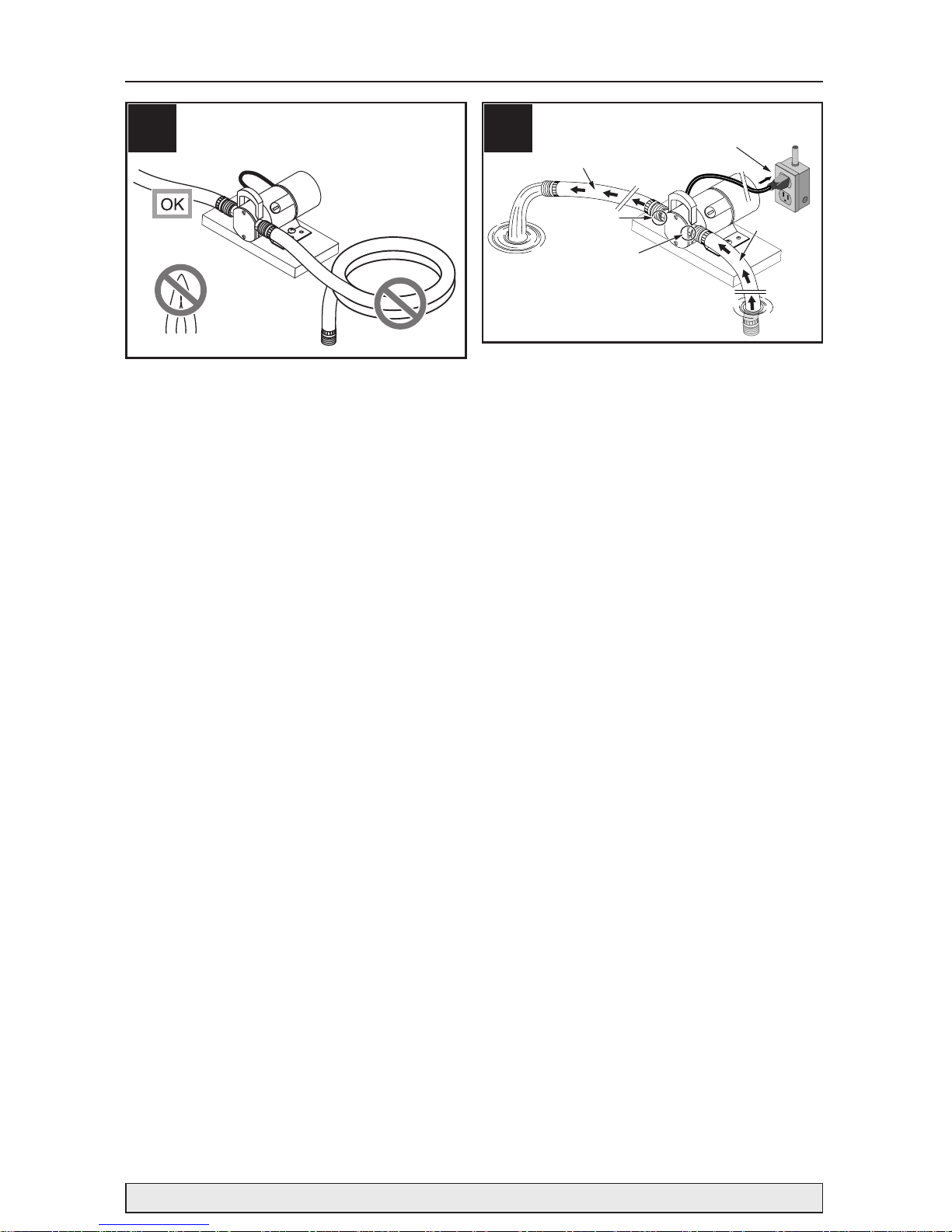

KEEP THE HOSES AS STRAIGHT

AS POSSIBLE

To reduce friction, do not coil or kink the

hoses. When pumping from a well or

stream, raise the inlet hose a few inches off

the bottom to avoid sucking in sand, silt or

pebbles (which can disable the impeller).

Install a strainer or the Pud-L-Scoop

TM

(included only with Model FP0F360AC) to

protect the pump from large solids .

NOTICE: Attach the Pud-L-Scoop

TM

to the

end of the inlet line and place it in at least

1/2" of water at the lowest point to be

pumped. Be sure all connections are air tight.

INLET HOSE GOES IN THE

WATER; OUTLET HOSE STAYS

OUT OF THE WATER. MOTOR

MUST STAY DRY

Make sure all inlet connections are tight

(no air leaks) and the inlet hose is in the

water. Make sure the end of the outlet hose

is

not

under water. If the outlet is under

water, the pump may not work.

Plug the cord into a 3-wire, 115 volt,

60 Hz, grounded A.C. outlet.

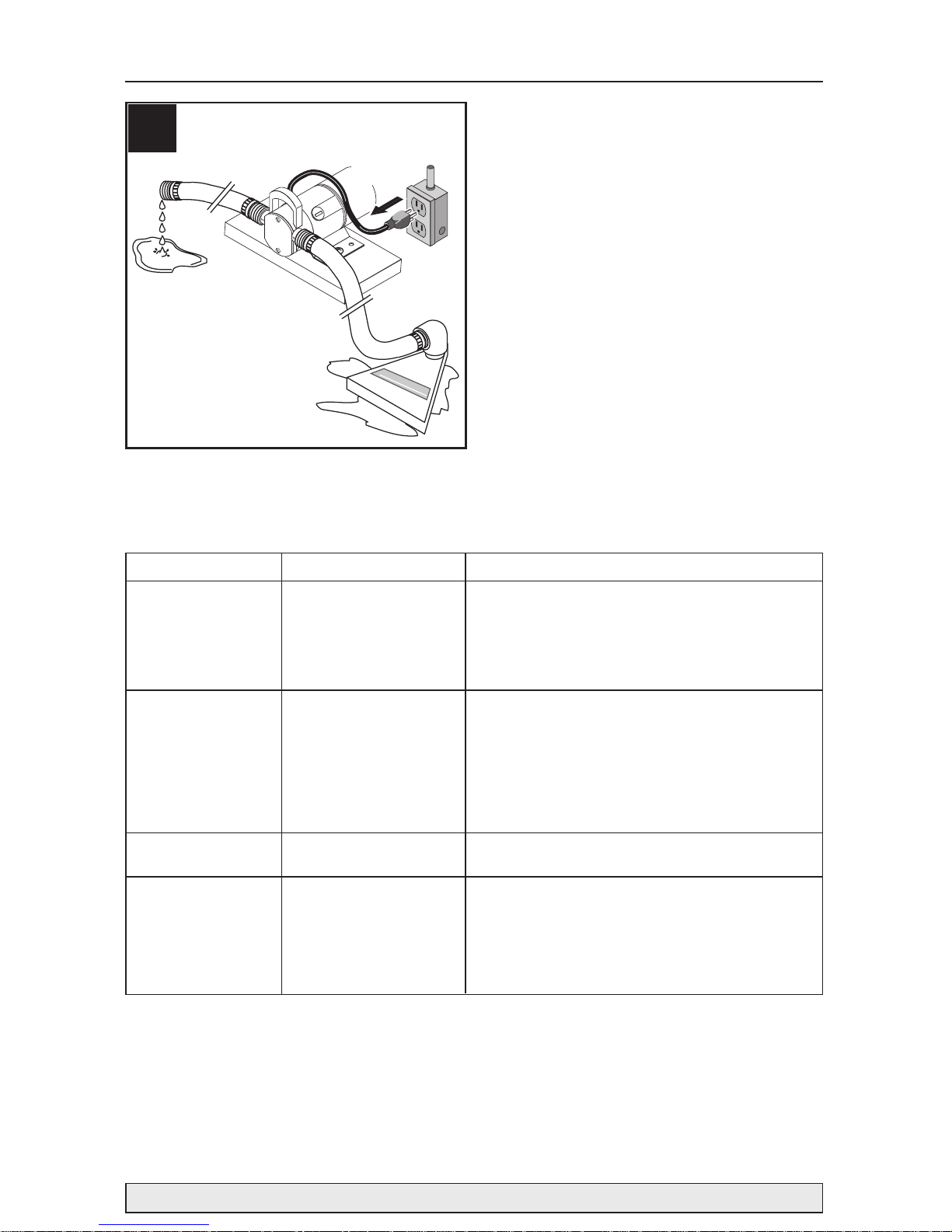

You should get water in 30 seconds or less.

If not, add more oil and repeat the process.

If your pump does not prime on the second try, check the impeller and the inside

of the pump head for wear. Replace as

needed.

In rare cases you may need to prime the

pump. To prime it, fill the suction hose

with water, put it back in the water source,

and start the pump.

The motor must have air circulation

around it for proper cooling. This pump

will lift water 12’; trying to lift water more

than 12’ can cause the motor to run hot.

The motor has a thermal overload which

will stop it if it gets too hot. If the motor

stops, allow it to cool for 30 minutes

before trying to start it again.

No kinks!

No Coils!

Straight

Hose!

3

IN

Water IN

Water OUT

Outlet Hose

Plug in pump to start it.

NOTE: If you don’t get water in

30 seconds or less, add more oil

and repeat the process.

See Step 1.

Inlet Hose

4

Installation 5

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

UNPLUG THE PUMP

Unplug the pump before all the water is

completely gone.

DO NOT RUN PUMP DRY!

PERFORMANCE

The pump will deliver 350 gallons/1325

liters per hour with an unrestricted discharge line. If the discharge line is restricted or raised and the pressure on the pump

outlet port increases, it will pump less

water.

NOTICE: This pump’s motor has brushes.

Inspect the brushes frequently; replace

them if they’re worn.

Unplug

5

SYMPTOM PROBABLE CAUSE(S) CORRECTIVE ACTION

Pump stops without Pump has overheated Wait for overload to reset; pump will automatically

warning and thermal overload restart

has tripped

Discharge hose too long Use shorter hose or reduce lift

or discharge lift higher

than 28’

Pump Won’t Prime Pump body not oiled Add oil through inlet port (see Page 3)

Suction hose too long or Use 1/2

" Suction hose, 25’ long or less

too small (the shorter the hose, the better)

Worn impeller Replace impeller

Suction leaks Replace hose washer, check for leaks in hose

Suction hose kinked Straighten out suction hose

or coiled

Pump leaks Shaft U-cup seal leaks Replace shaft seal

Cover O-Ring leaks Replace cover O-Ring

Pump runs, pumps Worn impeller Replace impeller

little or no water

Bad motor brushes Replace motor brushes

Bad U-cup shaft seal Replace shaft seal

(pump will leak)

Suction or discharge hose Straighten out hose

kinked or coiled

TROUBLESHOOTING CHART

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Repair Parts 6

Pump Head Assembly No. RP4940-22

includes Key Nos. 1 through 7.

Service Kit No. FP003414S-01

includes 1 each of Key Nos. 3, 4, and 6.

Brush Kit No. FP003415S

includes a pair of replaceable brushes, springs,

and caps, Key No. 10.

Pud-L-Scoop

TM

No. FP000349A

includes the Pud-L-Scoop

TM

, and a 6’ garden

hose with washer.

Key Part

No. Description Qty.

1 10-32x1-3/4 Phil. Hd Screw* 2

2 End Cover / Wear Plate 1

3 O-Ring 1

4 Impeller 1

5 Insert 1

6 U Cup Seal 1

7 Pump Body 1

8 Slinger 1

9 Motor** 1

10 Motor Brush and Spring Set 1 Pair

* Standard hardware item; purchase locally.

** If motor fails, replace entire pump.

MODEL FP0F360AC-09

REPAIR PARTS

Brush must enter

square hole.

Match brush curve

to armature curve

12

34567 89 10

Brush Installation

Loading...

Loading...