FLORA pp2512uv User Manual

PP2512UV

User's Guide

ADD:GuanlanHi‐techIndustryPark,HuanguanSouthRoad,Baoan

District,Shenzhen,ChinaP.C:518110

TEL:+86‐755‐27521666

FAX+86‐755‐27521866

Victor Xu Page 1 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Table of Contents

LORADIGITALPRINTINGSYSTEM..........................................................................................................................................5

F

DISCLAIMER............................................................................................................................... ........................................5

MANUALUSAGECONDITIONSANDLIMITATIONS.......................................................................................................................5

CONTENTSOFPACKAGE........................................................................................................................................................5

PRINTERINTRODUCTION.......................................................................................................................................................6

TABLE1GENERALFEATURES.............................................................................................................................................6

TABLE2TECHNICALSPECIFICATION......................................................................................................................................6

TABLE3FLORAPP2512UVPRINTERMODELCODING...........................................................................................................7

ABOUTTHEMANUAL...........................................................................................................................................................7

CHAPTER1‐SAFETYOPERATINGINSTRUCTIONS.....................................................................................................................8

1.1 BriefIntroduction.............................................................................................................................................8

1.2 SafetyInformation...........................................................................................................................................8

1.2.1 SolventandInkProperties.......................................................................................................................................8

1.2.2 DangerofFireandExplosion...................................................................................................................................8

1.2.3 Anti‐ultravioletradiation..........................................................................................................................................8

1.2.4 ProperVentil ationandExhaustSystem...................................................................................................................8

1.2.5 Inkandsolventspillage,apotentialriskofFireandexplosion................................................................................9

1.2.6 Highvoltagemayshockpeopleortriggerafire.......................................................................................................9

1.2.7 Printingmediarollsarebulkyandveryheavy.........................................................................................................9

1.3 Fireproofing.....................................................................................................................................................9

1.4 ExhaustSystem................................................................................................................................................9

1.5 HandlingPrecautions.......................................................................................................................................9

1.5.1 PowerSupply...........................................................................................................................................................9

1.5.2 Printer....................................................................................................................................................................10

1.6 RegularInspectionandMaintenance............................................................................................................10

1.7 Consumables..................................................................................................................................................10

CHAPTER2‐PRE‐INSTALL................................................................................................................................................11

2.1 GettingStarted..............................................................................................................................................11

2.2 OperatingConditions.....................................................................................................................................11

2.2.1 InstallationSpace...................................................................................................................................................11

2.2.2 EnvironmentConditions........................................................................................................................................11

2.2.2.1 Operatingtemperatureandhumiditylevels..........................................................................................................11

2.2.2.2 Placeswheretheprintermustnotbeinstalled.....................................................................................................11

2.3 Consumables..................................................................................................................................................11

2.3.1 AvailableMediaTyp es............................................................................................................................................12

CHAPTER3‐EXTERNALVIEWS,PARTNAMESANDFUNCTIONS................................................................................................13

3.1 PrintHeadCarriageAssembly.......................................................................................................................13

3.1.1 PrintheadsPlatform..............................................................................................................................................13

3.1.2 AutoDetectMediaThicknessSensor.....................................................................................................................14

3.1.3 UVLampAssembly................................................................................................................................................14

3.1.4 PressureSensor......................................................................................................................................................15

3.2 MaintenanceStation.....................................................................................................................................15

3.3 RailguideandBeamAssembly......................................................................................................................16

3.3.1 X‐axisRailguideandBeam....................................................................................................................................16

3.3.2 Y‐axisRailguide......................................................................................................................................................16

3.4 ControlPanel.................................................................................................................................................17

Victor Xu Page 2 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

3.4.1 MaintenanceControlPanel....................................................................................................................................17

3.4.2 MovementandUVlampControlPanel..................................................................................................................17

3.4.3 MainCircuitBreaker..............................................................................................................................................18

3.4.4 StartandE‐StopButton.........................................................................................................................................18

3.4.5 VacuumChamberControlValves ...........................................................................................................................18

3.5 ElectricalfixationShelf...................................................................................................................................19

3.6 InkSupplyControlCompartment...................................................................................................................19

3.7 InkBottleCompartment................................................................................................................................19

3.8 UVPowerSupply&VacuumPump................................................................................................................20

CHAPTER4‐WORKINGSYSTEMOFFLORAPP2512UV..........................................................................................................21

4.1 BriefIntroduction...........................................................................................................................................21

4.2 TheKonicaMinoltaPrintheadAssembly.......................................................................................................21

4.3 PCBboards.....................................................................................................................................................22

4.4 Movingsystem...............................................................................................................................................27

4.4.1 X‐axis(Carriagemovingsystem).............................................................................................................................27

4.4.1.1 ServoDriverPack...................................................................................................................................................27

4.4.1.2 Servomotor...........................................................................................................................................................28

4.4.1.3 Rasterreaderandstrip...........................................................................................................................................28

4.4.1.4 Limitedswitch............................................................................................................................... .........................28

4.4.1.5 Anti‐crashSensor............................................................................................................................... ....................29

4.4.2 Y‐axis(Beammovingsystem).................................................................................................................................29

4.4.2.1 ServoDriverPack...................................................................................................................................................29

4.4.2.2 Servomotor...........................................................................................................................................................29

4.4.2.3 Limitedswitchandopticalswitch..........................................................................................................................29

4.4.3 Z‐axis(Autoheightadjustingsystem).....................................................................................................................30

4.4.3.1 Stepperdriver&motor..........................................................................................................................................30

4.4.3.2 Rasterreaderandstrip...........................................................................................................................................31

4.4.3.3 Detectingsensor....................................................................................................................................................31

4.4.3.4 Limitedswitch............................................................................................................................... .........................31

4.5 Inksupply&negativepressuresystem...........................................................................................................32

4.5.1 Inksupplysystem...................................................................................................................................................32

4.5.2 Whiteinkcirculationsystem..................................................................................................................................33

4.5.3 Inkalarmsystem....................................................................................................................................................33

4.5.4 Negativepressuresystem......................................................................................................................................33

4.5.5 Overflowprotectionsystem...................................................................................................................................34

4.5.6 Externalpowersystem...........................................................................................................................................34

4.5.7 Individualpurgesystem.........................................................................................................................................35

4.6 Vacuumsystem..............................................................................................................................................35

4.6.1 VariableVacuumControlSystem...........................................................................................................................35

4.6.2 VacuumChamber...................................................................................................................................................35

4.7 Curingsystem.................................................................................................................................................35

4.7.1 Overheatprotector................................................................................................................................................35

4.7.2 Intelligentcuringmode..........................................................................................................................................36

4.7.3 Twolevelpower.....................................................................................................................................................36

4.7.4 UVlampauto‐shutofffunction..............................................................................................................................36

4.8 Auto‐cleaningsystem.....................................................................................................................................36

4.9 AutomaticRegistrationPinSystem................................................................................................................37

CHAPTER5–INSTALLATIONMANUALOFFLORAPP2512UV....................................................................................................38

5.1 Pre‐InstallationRequirement.........................................................................................................................38

5.2 MachinePre‐Installation................................................................................................................................38

5.3 Installationofsoftware..................................................................................................................................38

5.3.1 InstallationProcedureofPhotoPRINTServerFloraEdition6.1v2..........................................................................38

5.3.2 Installationprocedureoffloradriver.....................................................................................................................41

Victor Xu Page 3 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

5.3.3 Addsetup...............................................................................................................................................................42

5.4 Installprintheads..........................................................................................................................................42

5.5 InkandSolventPreparation...........................................................................................................................45

5.6 Test print........................................................................................................................................................45

5.5.1 Test printtoolbar...................................................................................................................................................45

5.5.2 Setparameter........................................................................................................................................................45

5.5.3 Printheadalignment..............................................................................................................................................47

5.5.3.1 MechanicalAlignment(Y‐Align).............................................................................................................................47

5.5.3.2 InternalAlignment.................................................................................................................................................49

5.5.3.3 RightAlign..............................................................................................................................................................51

5.5.3.4 PrintheadXAlign...................................................................................................................................................52

5.5.3.5 StepAlign............................................................................................................................... ................................53

CHAPTER6‐OPERATIONMANUALOFFLORA PP2512UV......................................................................................................55

6.1 BriefIntroduction...........................................................................................................................................55

6.2 Starting‐upActivities......................................................................................................................................55

6.3 PrintheadJettingCheck................................................................................................................................55

6.4 OperationalapproachofPhotoPrint..............................................................................................................55

6.4.1 PhotoPrintJobFolder............................................................................................................................................55

6.4.2 EditingtheImage...................................................................................................................................................56

6.4.3 WorkFlowTag........................................................................................................................................................57

6.4.4 ColorManagementTag..........................................................................................................................................57

6.4.5 Test PrintTag..........................................................................................................................................................58

6.4.6 AdvanceButton......................................................................................................................................................58

6.5 Shut‐offprocedure.........................................................................................................................................62

6.5.1 Over‐nightprotection.............................................................................................................................................62

6.5.2 Longtermprotection.............................................................................................................................................62

CHAPTER7SERVICEANDMAINTENANCEMANUALOFFLORAPP2512UV................................................................................64

7.1 BriefIntroduction...........................................................................................................................................64

7.2 Maintenanceofprintheads...........................................................................................................................64

7.2.1 FlushingaSelectedPrinthead...............................................................................................................................64

7.2.2 ReplacingthePrinthead........................................................................................................................................64

7.3 MaintenanceofInkSupplyandVacuumLineSystem....................................................................................64

7.3.1 ChangingDefectiveInkPumpandFilter................................................................................................................64

7.3.2 ChangingDefectiveAirPump.................................................................................................................................65

7.4 MaintenanceofPrinterMovingParts............................................................................................................65

7.4.1 MaintenanceofX‐axis............................................................................................................................................65

7.4.2 MaintenanceofY‐axis............................................................................................................................................66

7.4.3 MaintenanceofZ‐axis............................................................................................................................... .............67

7.4.4 Maintenanceofauto‐cleansystem........................................................................................................................67

CHAPTER8‐APPENDICES................................................................................................................................................68

AppendixAMaterialSafetyDataSheetforUVInks...........................................................................................68

AppendixBPreventiveMaintenanceChecklist...................................................................................................72

AppendixCTroubleshootingGuide....................................................................................................................73

AppendixDGlossary...........................................................................................................................................76

Victor Xu Page 4 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Flora Digital Printing System

Flora Digital Printing System, reserves the right to make changes without prior notice to the specifications

and materials contained herein and shall not be responsible for any damages (including consequential)

caused by reliance on the materials presented, including but not limited to typographical, arithmetic, or listing

errors.

This equipment has been tested and found to comply with the limits for a class A digital device. Pursuant to

part 15 of the FCC Rules, these limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference, in which the user will be required to correct the

interference at his own expense.

This printer is a color inkjet printer that uses a UV-curable ink, supports up to 1800mm of media width, and

has a built-in USB interface.

This manual, the PP 2512UV User's Guide, describes the features of the printer, names of components,

information needed before use, and basic operations, such as how to turn the power ON and OFF, loading

and setting of the media and loading of ink.

The following items should be read before proceeding to Section 1;

− Contents of the package

− Safety precautions

− Handling precautions

− Notion

Notice: Read these items to use the printer safely and properly. Keep this manual in a place where you can

quickly access it any time.

Disclaimer

This is an alpha release of the User's Guide for Flora PP 2512UV printer. We have made every effort to

guarantee the accuracy and integrity of the information in this manual. If you find some errors or omissions,

please bring them to our attention so we can check and correct them accordingly.

This manual can be used as a reference for operation and routine maintenance of the Flora PP 2512UV

printers. It can’t be a replacement for the formal training provided by Shenzhen Runtianzhi Image Technology

Co., Ltd, regarding on how to operate the printers properly. Shenzhen Runtianzhi Image Technology Co., Ltd

will not take any responsibility for the consequences of misusing this manual and appendix.

Manual Usage Conditions and Limitations

The manual includes patent information, which belongs to Shenzhen Runtianzhi Image Technology Co., Ltd.,

the purpose of which is to help the authorized customers. Without the written permission from RTZ Company

and the public declaration, any content of this manual should not be used for other purposes.

The text and images are subject to change without prior notice. Any software mentioned in this manual is

provided by permission. Use or copy of these softwares must be according and to follow prior regulations. If

the information in this manual has changed, there will be no further notice unless it is specified.

Contents of Package

The internal printer components, including the options, are installed on the main unit on delivery. The print

heads and extension table assembly are included on a separated box within the main crate.

Victor Xu Page 5 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

If any parts are missing or damaged, please contact the shop or dealership where you have purchased the

product or the nearest service center.

Printer Introduction

The Flora PP 2512UV printer is a wide format digital printer suitable for small up to medium size business

use. It uses a UV curable ink, which is environment friendly. It provides high productivity and is capable to

replace traditional silkscreen printing. This type of printer is widely used in the fields such as advertisement,

packing, printing, interior decoration, POP board, glass work, flexible packaging, wooden work, printing

circuit board, etc.

Flora PP 2512UV series printers use drop-on-demand and Piezo-electric technology. It can print colorful and

wide image by using the highest 1440x1440 dpi resolution. It can output any size of images with “tile” feature

in the software. Indeed, it is a combination of roll-to-roll and rigid board printer.

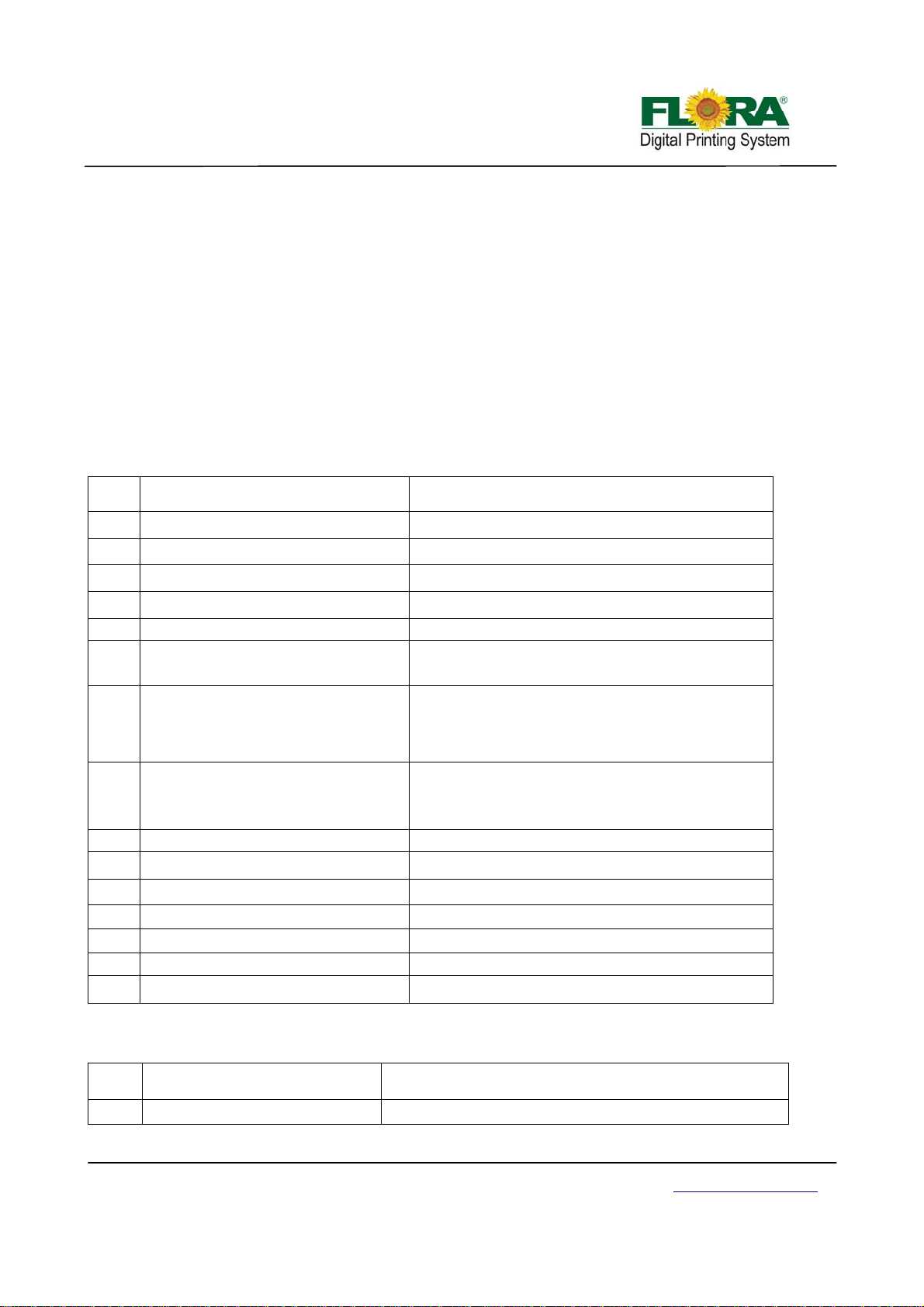

Table 1 General Features

Item

No

1

Printing Method Drop-on-demand Piezo-electric

2

No. of colors 8 (CMYKLmLc+White+Varnish)

3

Ink/Varnish type UV curable

4

Ink reservoir capacity (volume) 4 Li/color (refillable while printing is on progress)

5

Outdoor Durability 2 years for Flora UV curable ink

6 Media handling system

D e s c r i p t i o n Specification

Roll-to-Roll, single sheet, Indexing Conveyor Flat

bed with vacuum

Roll-to-roll including paper, vinyl, adhesive back

7 Media types

vinyl, fabrics, banners, PVC, etc and flat rigid

boards including, corrugated foam, Plexiglas,

Sheet metal, sheet film, ceramic tiles, etc.

8 Maximum printing size

2.53 m width

2.53 m x 1.25m for board media

9 Maximum media thickness 100 mm

10 Rip software PhotoPrint V5.3 Flora edition (Windows Xp sp3)

11 Driver software FloraPrint

12 Color management ICC based color , density adjustment curves

13 File format Bitmaps, Tiffs, Jpeg, Postcripts3, Eps, Pdf, etc.

14 Work Flow Rip and Print

15 Warranty 1 year (please consult your local dealer for details)

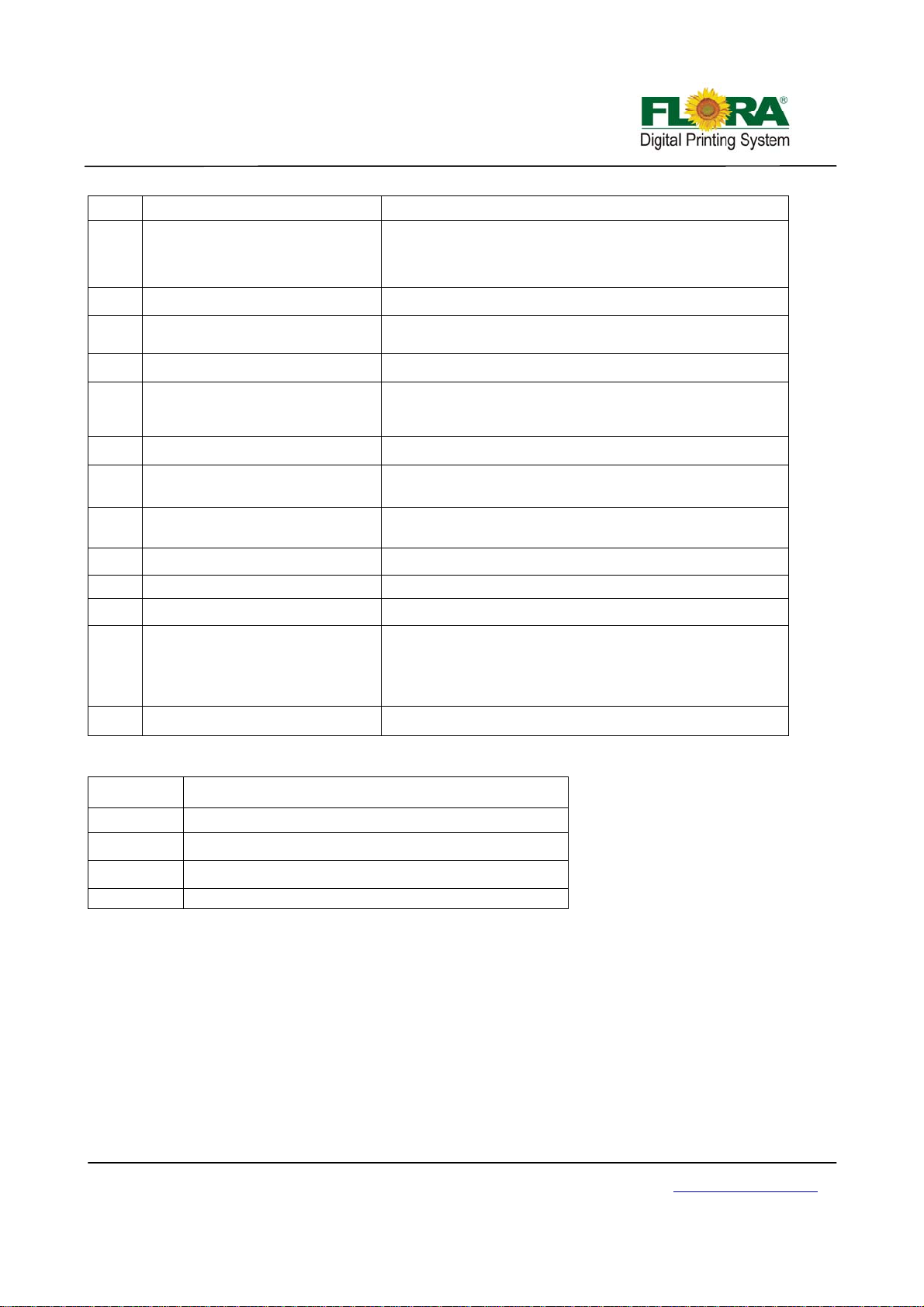

Table 2 Technical Specification

Item

No

1 Model Flora PP 2512UV

Victor Xu Page 6 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

D e s c r i p t i o n Specification

http://www.floradigital.com

2

2 Print Head Binary Drop-on-demand piezo-electric

16 (CMYKLmLc+White+Varnish, 2 print heads/color) or

3 No. of print heads

4 No of colors 4/5/6/7/8

5 Printing resolution option

6 Printing quality option Standard, High and Ultra

7 Printing Speed

8 Media maximum width 2.53 m

PC minimum operating

9

requirement.

11 Operating environment

12 UV lamp power rating 1100 W

13 Room temperature

14 Humidity 40~70%

16 (CMYKLmLc +White) 2 print heads/color and 4 print

heads for White

360x360, 360x1080, 720x720,

720x1440, 1440x1440 dpi

Standard Quality: 54 m

High Quality: 38 m

Ultra Quality 28 m

2

2

/hr

/hr

/hr

3GB RAM, 40Gb HDD, Windows XP Service Pack 3

220VAC/50-60Hz/Single Phase, 2 outlets 25 Amp each.

Distortion: < 0.5%

23~33

ºC

15 Dimensions 4.85m x 2.25m x 1.66m

16 Weight 1200 Kg

Table 3 Flora PP 2512UV Printer Model Coding

Code Explanation

Flora

PP

2512

UV

Brand Name

Flat Bed

maximum width:2500cm, maximum length:1200cm

Ink Type

About the manual

The manual provides the end user all the information related to the machine basic functions, software

installation, machine parameter calibratio n, maintenan ce and troubleshooting of Flora PP 2512UV.

Victor Xu Page 7 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

V

Chapter 1 - Safety Operating Instructions

1.1 Brief Introduction

This chapter introduces the important safety information. Please read and un derstand the safety

information carefully before operating the printer.

1.2 Safety Information

FLORA printer uses the following chemical substances

• All kinds of printing media

• UV Ink

• Cleaning liquid (UV Flush)

1.2.1 Solvent and Ink Properties

• Solvent and Ink are flammable.

• Eye contact with the ink and solvent will break the cornea and weaken the eyesight.

• Contact lens should not be worn when operating printer or when there is n o proper

ventilation.

• Wear safety glasses and gloves while flushing print heads, ink tu be or moving the

ink bottles or containers.

• Solvent and ink can be irritating to eyes, throat and skin. Inhaling the ink fumes

would result in swoon or other symptoms.

• Solvent vapors are heavier than air and may flow and gather in low spot.

This caution symbol represents danger. If this sign is ignored it

may lead to serious injury or damage to the printer .

1.2.2 Danger of Fire and Explosion

Open flames, heat energy or spark around the printer can trigger fire and explosion.

• No smoking, pilot lights, open flames, stoves, heaters or halogen lights should

be turned on within 5m distance from any edge of the printer.

• No portable spark-producing equipment (st atic, electrical or Mechanical) within

5m distance from any edge of the printer.

1.2.3 Anti-ultraviolet radiation

1.2.4 Proper Ventilation and Exhaust Sy stem

Victor Xu Page 8 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

• Wear UV protection glasses and gloves when operating the machine and

avoid being too closer to UV lights.

• When doing maintenance task or being close to the flatbed machine, U

lights must be shut off or close all UV protection doors.

• The vacuum exhaust system must be functioning before the printer operates.

• Do not ignore this safety warning sign to avoid accumulation of flammable

fumes in the area.

http://www.floradigital.com

1.2.5 Ink and solvent spillage, a potential risk of Fire and explosion

1.2.6 High voltage may shock people or trigger a fire

1.2.7 Printing media rolls are bulky and very heavy

1.3 Fireproofing

• Store ink and solvent in proper cabinet for flammable liquid storage.

• Keep ink and solvent containers tightly closed at all times. If a container

has sign of damage/leakage, fix or replace it immediately.

• Clean ink or solvent spillages as soon as possible.

• Only use dry powder, or ca rbon dioxide type of fire extinguishers.

• If there’s no emergency power switch which can shut down all the power,

do not connect the printer to main-power supply.

• When the machine’s power is on, do not open the back cover of machine,

or avoid touching electrical parts.

• The printer or other equipments should be grounded, according to the local

safety electrical connection regulation. The ground volt age should be less

than 3 V.

• Set the machine on smooth ceramic tile or cement ground

• Use specified anti-static floor mat to minimize harmful static build-up.

• Wear hand and foot safety protection gear when loading, unloading and

handling media to avoid serious body injuries.

• Use proper heavy duty handling equipment if available.

Ink and solvent should be clearly labeled and stored in a specific area for flammable liquid and

should be in accordance with local regulations of fireproof and safety standard. Ensure that the

specified fire extinguisher is always available near the storage area and should be cleared from any

obstacle in case of emergency.

1.4 Exhaust System

The printing area should be equipped with sufficient exhaust system. The exhaust should be

installed in such a way build up of fumes is minimized. Best location for the exhaust should be at lowest

level, this way the fumes build-up is minimized. Solvent fumes are heavier than air, so fumes build-up

concentrates on the lower level of the room.

Electrical installations inside the printing area must be in accordance

with local Electrical Safety Regulation

1.5 Handling Precautions

1.5.1 Power Supply

1. Install the printer near an easily accessible electrical outlet.

2. Do not provide power to the printer through the same power line as for other noise

generating devices such as motors.

3. Use a power supply matched with the printer specifica t ion.

4. Connect the power cable directly to an electrical outlet. Do not plug several devices into

Victor Xu Page 9 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

one electrical outlet.

1.5.2 Printer

1. Do not place anything on top of the printer.

2. Do not rest you elbows on the printer.

3. Open and close the top cover gently from the front of the printer with both hands.

4. Before connecting or disconnecting the interface connector, turn the printer OFF.

5. Do not clean the surface of the cover with benzene or paint thinner. The coating may

come off or deteriorate. Wipe the cover with a soft cloth, if the cover is very dirty, use a

cloth moistened with a neutral detergent.

6. Do not touch the ink jet head surface.

1.6 Regular Inspection and Maintenance

The following regular inspection and maintenance must be performed in terms of characte ristics

of the UV-curable ink:

1. Clean the carriage unit and the flat table conveyor surface every day.

2. Make sure that the carriage covers are always replaced.

3. Perform ink supply circuit and print head cleaning when leaving the printer for a long time (2

weeks or more with no power).

4. Perform head cleaning after leaving the printer idle for a long time.

5. Shut off the UV lamp whenever the printer is not in use.

1.7 Consumables

1. Always use the recommended consumables (printing media, ink, ink filters). Failure to follow

this instruction may cause poor printing quality and breakdown.

2. Do not use ink past the expiration date as this may cause a print head breakdown and poor

printing quality.

3. Put a used ink bottle into a plastic bag and dispose of it as an industrial waste. Observe local

regulations for disposal of waste ink bottles.

4. Avoid spilling ink into your skin or clothes. Wash any ink off immediately with soapy water.

5. Check the waste ink container everyday so as not to permit waste ink to leak from you printer.

6. If the waste ink container is being installed or removed, spre ad a stain preventing sheet so as

not to stain the floor with spilled ink.

7. Store ink in a dark and cool place. Never store the ink in high temperatures or direct sunlight,

doing so may cause the ink to deteriorate.

Victor Xu Page 10 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Chapter 2 - Pre-install

2.1 Getting Started

This section provides the necessary information to operate the printer. Familiarize yourself with

the basic of the printer before reading Section 2.

Contents of this section:

− Operating conditions

− Consumables

− External Views, Part Names and Functions

2.2 Operating Conditions

This section describes the operating conditions for the printer.

2.2.1 Installation Space

There must be sufficient space around the printer for the replacement of frequently

used parts, for the output of the printed media and for ventilation. In addition, maintenance

space, shown below, is required to repair the printer or replace compone nts.

2.2.2 Environment Conditions

2.2.2.1 Operating temperature and humidity levels

The printer should be used within the temperature and humidity ranges as shown

below;

Temperature: 20 ºC to 30 ºC

Humidity: 30% to 70%

To obtain better print quality, use the printer within temperature of 20 ºC to 25 ºC.

When the operating temperature is lower than 20 ºC or higher than 40º C,

printing speed is reduced to two-thirds of normal print speed to maintain good

print quality.

2.2.2.2 Places where the printer must not be installed

Do not install the printer in the following places:

A location ne ar a fire

Places exposed to direct sunlight

Places subject to vibration

Places with excessive dust

Places subject to extreme changes in temperature or humidity

Places near an air conditioner or a heater

Places where the printer may get wet

Places near a diazo copier that may generate ammonia gas

Places with poor ventilation

Unstable place

2.3 Consumables

Victor Xu Page 11 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

2.3.1 Available Media Types

The following types of media are available:

9 Paper

9 Advertising banner

9 PVC

9 Mesh Fabrics

9 Adhesive Vinyl

9 Glass Sheets

9 Ceramics

9 Steel Sheets

9 Acrylic Boards

9 KT Boards

9 PVC Boards

9 Foam Boards

Note: Contact our service center for detail

Victor Xu Page 12 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Chapter 3 - External Views, Part Names and Functions

Carriage Assembly

Beam Assembly Flat Bed

Maintenance

Load ink Area

Station

Left Control Panel

Monitor & Key board

Assembly

Right Control Panel

3.1 Print Head Carriage Assembly

The print head carriage assembly houses the print heads, secondary ink tanks, print head

control board, raster reader, negative & positive pressure sensor, carriage height adjustment motor and

the two UV lamps.

Negative pressure

sensor display

Ink tanks

Left UV Lamp

Height adjustment

Assembly

Print Head Carriage Assembly

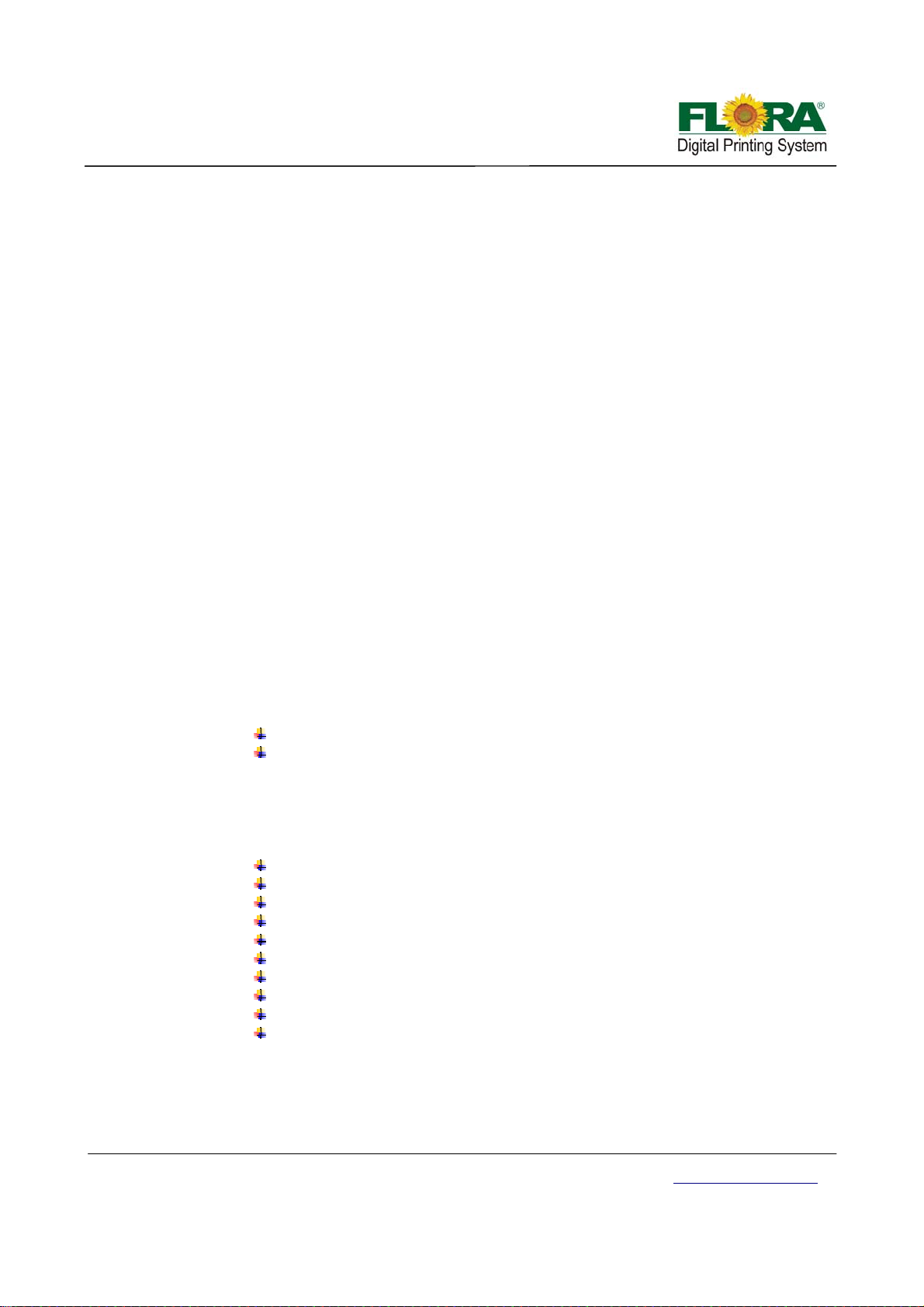

3.1.1 Print heads Platform

This platform is also called carriage platform, which is serves as print heads fixed frame.

There are two kinds of platform because of different print head configuration.

Height adjust knob

Positive pressure

sensor display

Right UV Lamp

Print heads Platform

Victor Xu Page 13 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

y

Two Rows Platform

Three Rows Platform

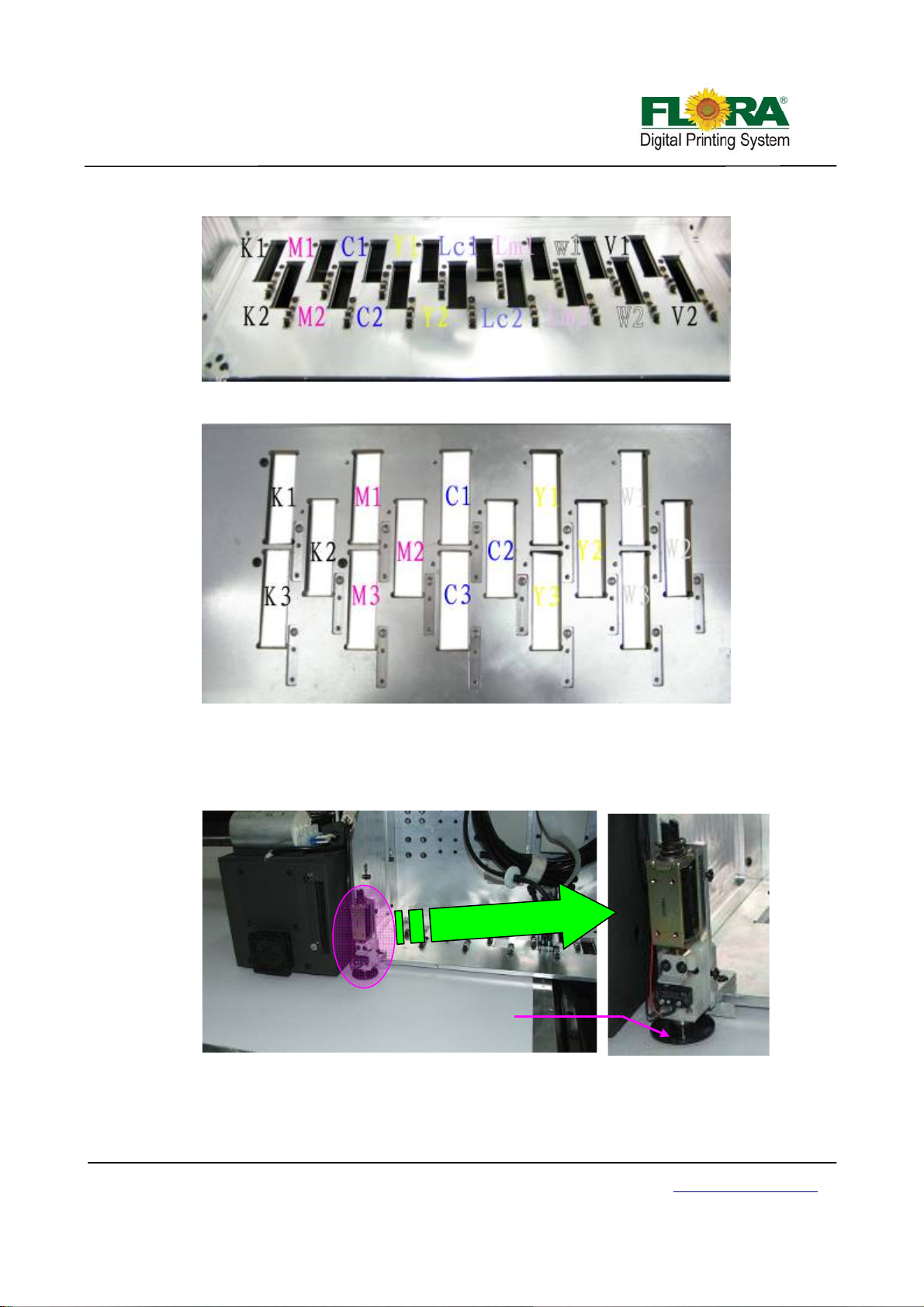

3.1.2 Auto Detect Media Thickness Sensor

This mechanism will perform media thickness check every time you send an image for

printing.

3.1.3 UV Lamp Assembly

UV lamp assembly is a device for curing UV ink. The curing mode can be controlled by

Victor Xu Page 14 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

This part will detect the top

surface of the media

Carriage Assembl

Media Height Detector Assembly

http://www.floradigital.com

Wi

blad

y

control panel and software.

AC power

Cable

Heat

dissipation

Fans

3.1.4 Pressure Sensor

Left UV Lamp Right UV Lamp

The negative pressure display setting parameters are programmed to control the maximum

positive pressure thereby protecting the print head from excessive pressure.

There are two pressure sensors in total for every printer: one controlling negative pressure,

while the other one controlling positive.

Enlarge View

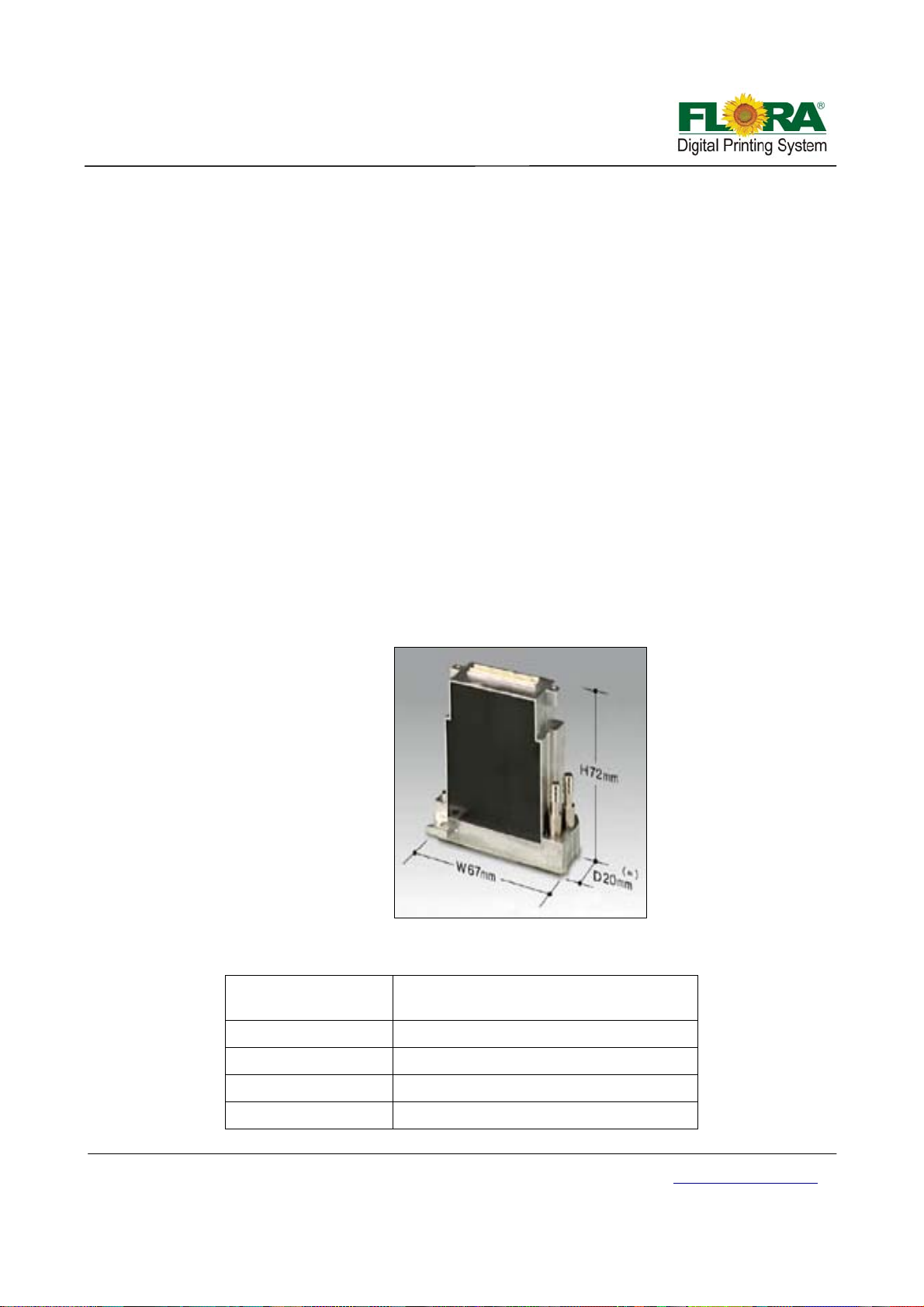

3.2 Maintenance Station

It is also called print head cleaning system where you do ink purging/ priming then wiping the

excess ink off the print head nozzles.

per

Left UV light

e

reflector

Negative

Pressure Sensor

Carriage Assembly

Maintenance Station

Positive

Pressure Sensor

Waste Tra

Right UV light

reflector

Victor Xu Page 15 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

V

y

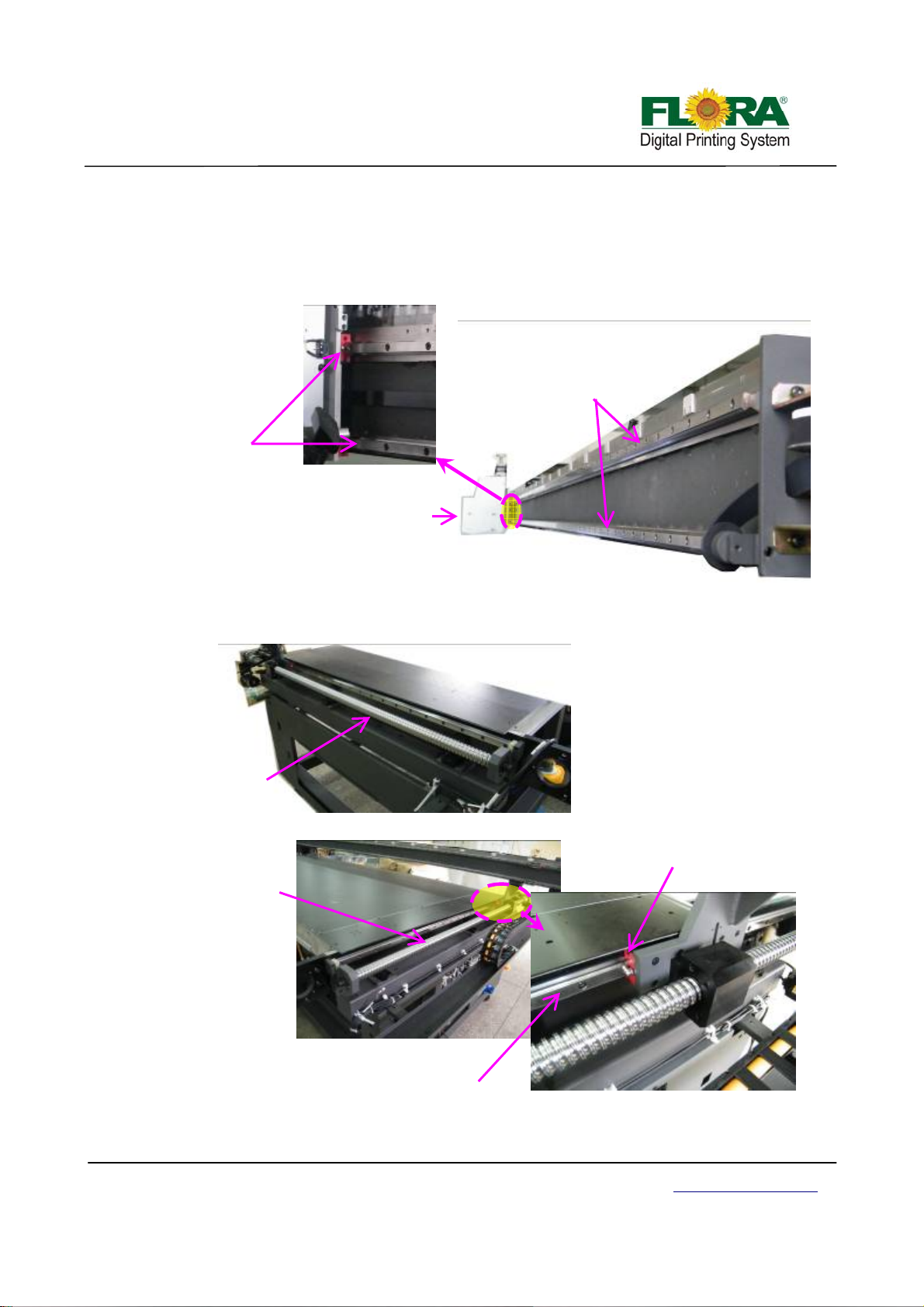

3.3 Rail guide and Beam Assembly

Rail guide supports pathway for carriage and Beam moving, and the beam serves as frame for

rail guide mounting.

3.3.1 X-axis Rail guide and Beam

Bearing slider

Enlarge View

Carriage Assembly

Dual Liner Lead Rail

Beam Assembl

3.3.2 Y-axis Rail guide

Left lead screw

Left View

Liner bearing

Right lead screw

Right

iew

Liner lead rail

Victor Xu Page 16 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Enlarge View

butto

A

3.4 Control Panel

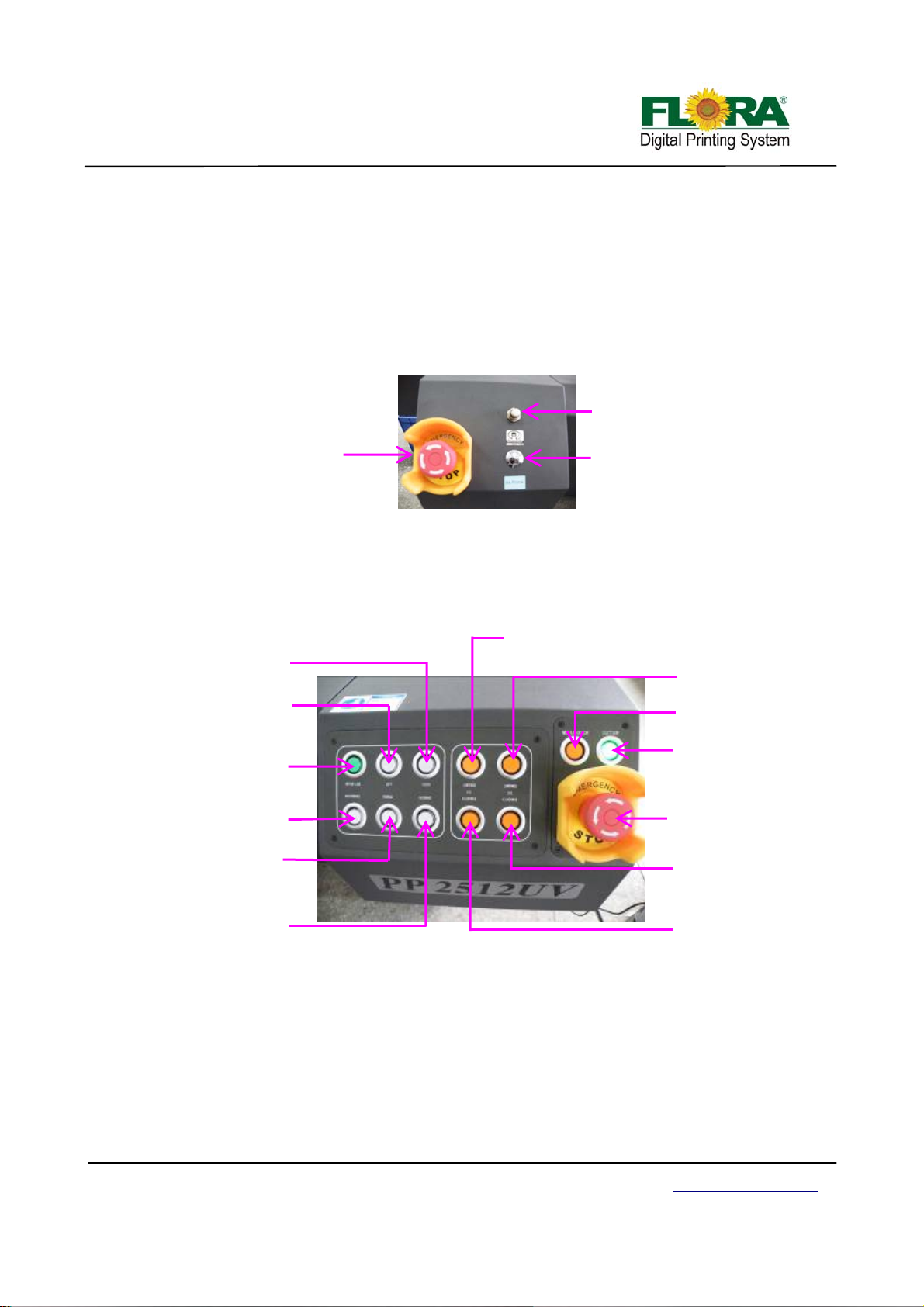

3.4.1 Maintenance Control Panel

The maintenance control panel is placed at left should er.

The ink prime button is use to purge ink out of the print head nozzles, which will help purge

the print head.

The negative pressure regulator can be used to adjust negative pressure.

The E-stop button will shut off main power supply to this machine when emergency situation,

which will protect the print head from damaged.

3.4.2 Movement and UV lamp Control Panel

E-stop button

Negative Pressure

Regulator

Priming Button

The operation panel serves as the interface between the machine and the operator. The

machine is set online or off line through the on line/off line button. Once the machine is offline from

the computer, the movement of the machine can be operated from the operation panel. The UV

lamp can be turned on or off from the operational panel.

Right

Left button

n

UV1 low power button

UV2 low power

button

Locator button

On/off line button

ir blower button

Maintenance button

E-stop button

Forward button

UV2 high power

button

Backward button

Enlarged View of Control Panel

UV1 high power

button

On line/Off line Button: This button will set the printer to be connected or disconnected

with the computer. Push to set on line and push again to set off line. If the machine is off line

the button lamp is turned on, or it will be turned off.

Maintenance Button: The carriage will start automatic print head nozzle clean up

procedure. It will purge ink to the print head to refresh the nozzles and perform suction

cleaning.

Left Button: This button if the printer is set offline will move the carriage to the left.

Right Button: This button if the printer is set offline will move the carriage to the right.

Victor Xu Page 17 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Forward Button: Pressing this button will make the beam towards the operator.

Backward Button: Pressing this button will make the beam away from the operator.

UV Buttons: The UV Buttons will turn on/off the UV lamps. UV1 Buttons controls the left UV

lamp while the UV2 controls the right UV lamp.

Media guide Button: This button will pop up the pin to help locate the media.

Suction Button: This button will change the air flow direction in the vacuum chamber, which

will help to push the media away from the flat bed.

3.4.3 Main Circuit Breaker

Main power switch controls the AC power input.

System power switch controls the DC power for PCB boards etc.

Suction pump switch controls the vacuum on or off.

Main power double

throw-Switch

System power single

throw-Switch

Suction Pump single

throw-Switch

3.4.4 Start and E-Stop Button

The start button is placed below the control panel. This switch will not work if the emergency

stop button is not released. To release the E-stop button simply turn is according to arrow head

direction. Pressing the start button will restore electrical power to the printer.

The emergency stop button is placed at the front corners edges of the machine. Once it is

activated/ pressed, electrical power for the printer controls is cut-off.

E-Stop Button

Start Button

3.4.5 Vacuum Chamber Control Valves

The vacuum flat bed is divided into four (4) vacuum chambers. Vacuum area could be

adjusted according to the media size. The numbers on the flat bed signifies the valve number, so if

you want to print on 1.2 m x 0.6 m size media you can close valves B, C and D leaving vacuum

chamber A open.

D

C

B

A

Flat Bed View

Left valve

Victor Xu Page 18 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

Right valve

http://www.floradigital.com

(

)

(

)

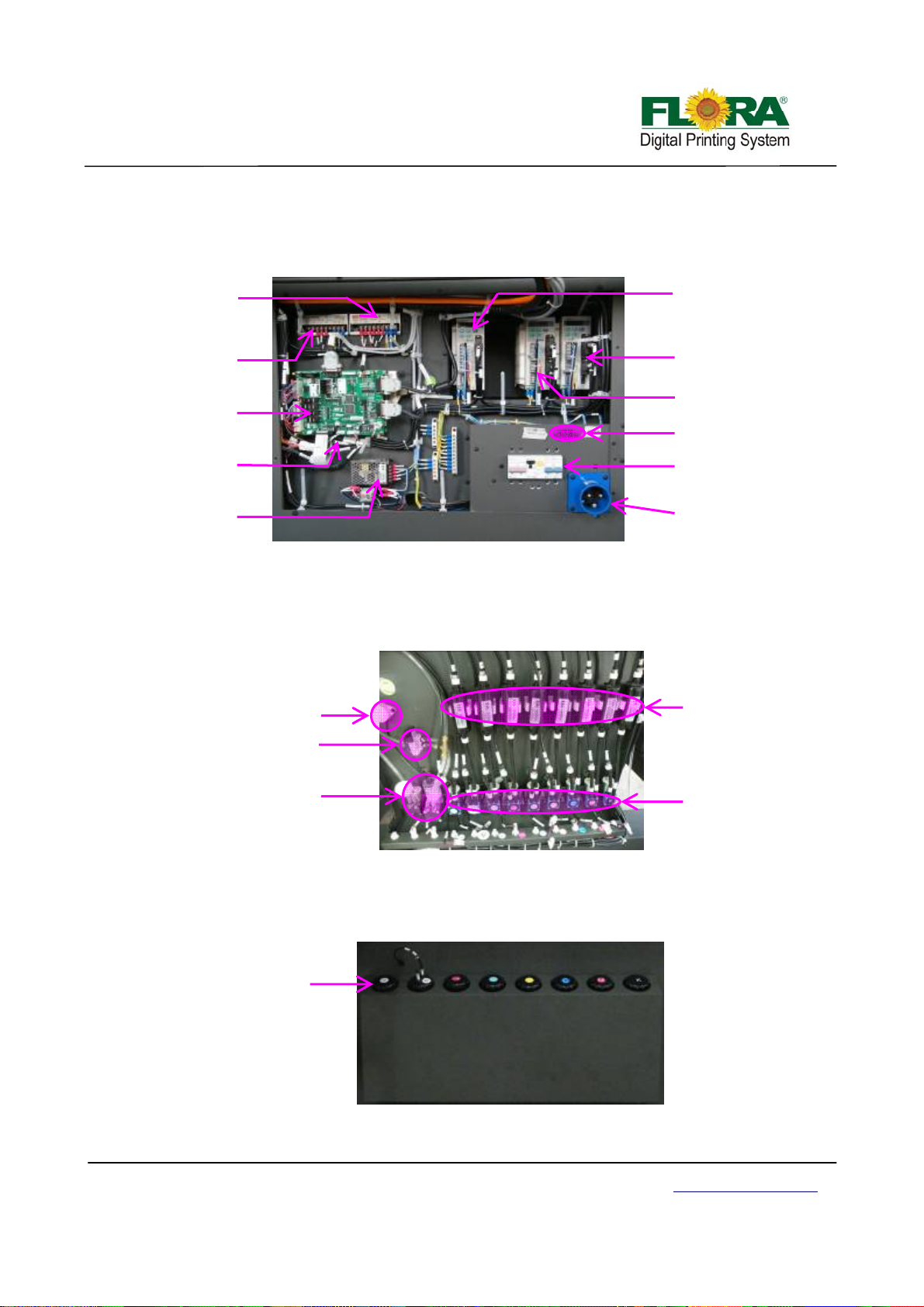

3.5 Electrical fixation Shelf

The electrical control panel contai ns the servo motor drivers for the Beam Movement servo

motors, Carriage servo motor and Media Feeding and Take-Up System servo motor, DC Power supplies,

Servo card, USB_IF control board and the Main Circuit breaker.

Power Supply 1

24 Vdc

Power Supply 2

(15 Vdc)

Servo Card

USB_IF Board

Power Supply 3

15 Vdc

Electrical Control Chamber

Servo Driver for

Carriage

Servo Driver for Beam

Right Servo motor

Servo Driver for Beam Left

Servo motor

NP Extend Power Inlet

Main Circuit

Breaker

AC Power Inlet

3.6 Ink Supply Control Compartment

It is located on the side of the ink bottles compartment. The buzzer, negative pressure air pump

and the corresponding ink supply pumps are mounted on the ink supply control compartment.

Solenoid Valve

Buzzer

Air pump

3.7 Ink Bottle Compartment

It serves as a compartment for ink and waste bottles and is located at the back of the machine.

Ink supply control compartment

Ink bottle

compartment

Ink Bottle Compartment

Ink filter

Ink pump

Victor Xu Page 19 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

3.8 UV Power Supply & Vacuum Pump

The UV power supply provides power to UV lamps and the intensity of light can be adjusted to

Low or High. While the Media suction pumps provide suction on the flat bed to hold the media in place

while printing is on progress. Vacuum manifold enhance the suction strength.

Vacuum pump

UV power supply

2.5 Starting the printer

1. Make sure there is no media or materials on top of conveyor belt specifically along the path

of carriage during printing.

2. Plug the machine power cord to the electrical power sou rce outlet.

3. Check and reset all emergency stop buttons.

4. Turn on the circuit breaker, leaving the breaker for the vacuum pump turned off.

5. Turn on the computer and plug the Dongle if necessary.

6. Press the machine start button.

7. Open the maintenance compartment door to show the print head carriage status.

8. Open the negative pressure shut-off valves both at the front and back.

9. Activate the ink prime toggle switch.

10. Press the on line/off line button on the control panel to disconnect the machine from PC.

11. Press maintenance button, this will automatically start the suction cleaning of the print heads.

12. Test the movement of the printer by moving the carriage using the operation panel. Left, right,

forward and backward, to check mechanical functionality.

13. When everything is verified to be functional, set the printer to on line by pressing the on

line/off line button.

14. Open the Photoprint software and machine is ready for operation.

Victor Xu Page 20 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Chapter 4 - Working System of Flora PP 2512UV

4.1 Brief Introduction

The Flora PP 2512UV large format printer is using raster image technology to process photos

stored in computer. It is one of the most innovative products, which combines photo digital technology

with high precision engine driver. It produces super wide printouts for busine ss use.

and maintenance procedures. Though simple, it is composed of several precise systems. In this chapter,

we will introduce the system components and operator guide.

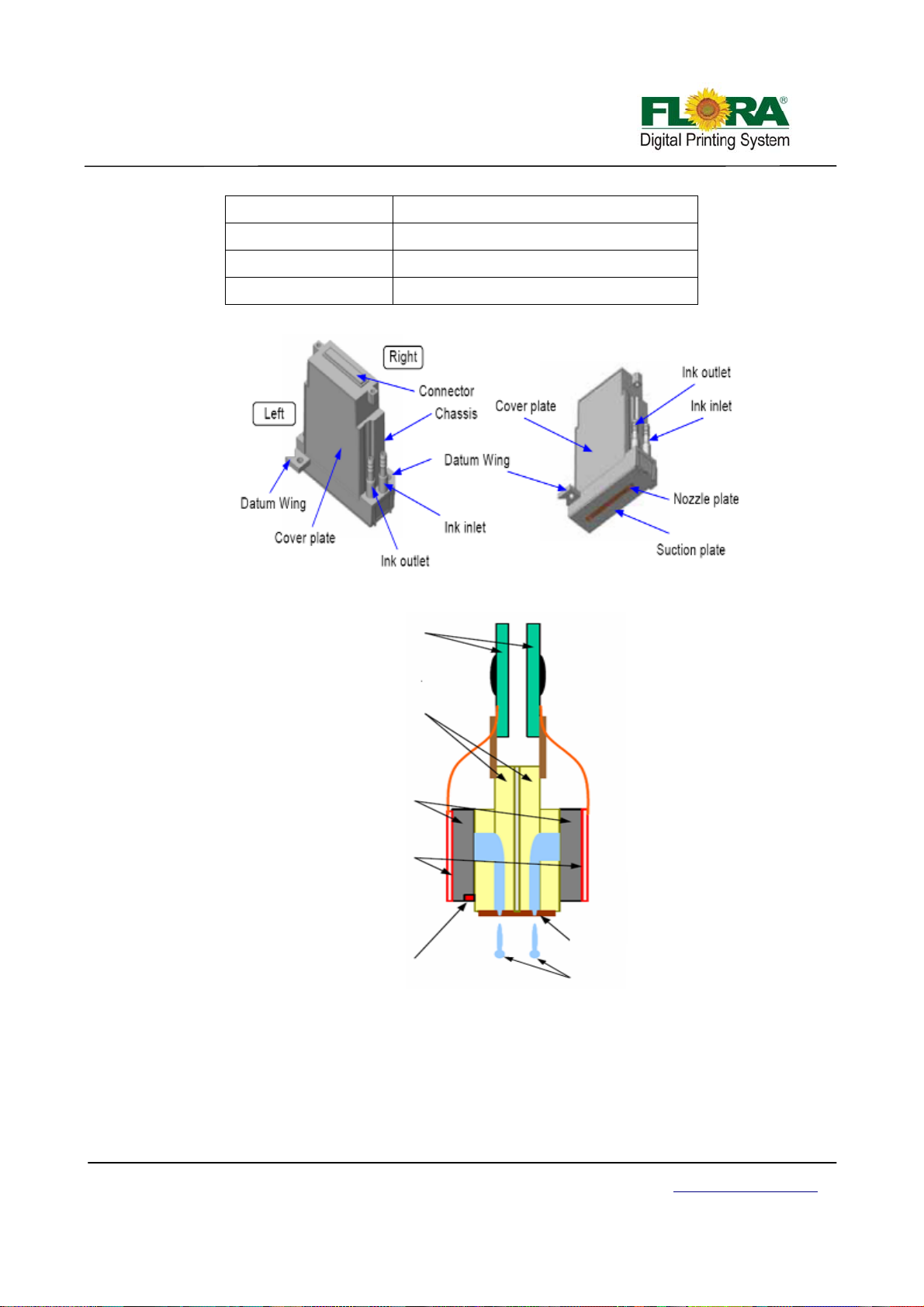

4.2 The Konica Minolta Print head Assembly

high-speed and compact inkjet print head lineup suitable for both wide format and industrial applications.

move by applying an electric field across it. Ink channels composed of piezo walls can eject small drops

of ink in accordance with the electrical signals applied to the electrodes on the walls.

generate a pressure wave inside the channel. This mechanical ejection principle allows a wide range of

inks including oil and solvents, which is a great advantage when compared with the thermal ejection

inkjet head.

It is a high technology equipment with a user friendly operating system with simple operational

In a high quality and high performance configuration, Konica Print head offers a high-resolution,

Konica Minolta print heads are based on piezo-electric materials (PZT), in which can be made to

The KM512 Print Head is driven by “shear mode”, in which the walls bend inward and outward to

This section introduces the KM512 Print Head technologies.

Konica Minolta Print head Dimensions

Main Features:

Technology

Piezo Drop On Demand (Shared Wall 3

Cycle)

Number of Nozzles 512 Nozzles (256 nozzles x 2 rows)

Resolution 360 dpi

Nozzle Spacing 70.5um pitch (141 um pitch×2 rows)

Maximum Frequency 12.8 kHz

Victor Xu Page 21 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Drop Volum e/Size 14 pL

Drop Speed 6 ± 0.5 m/s

Printing Width 36.03 mm

Heater Temperature Under 55 ºC

Drive Board

Head Chip

Manifold

Left Side

Right Side

Heater

Thermistor

Parts of the Konica Minolta

Nozzle Plate

Ink Jet

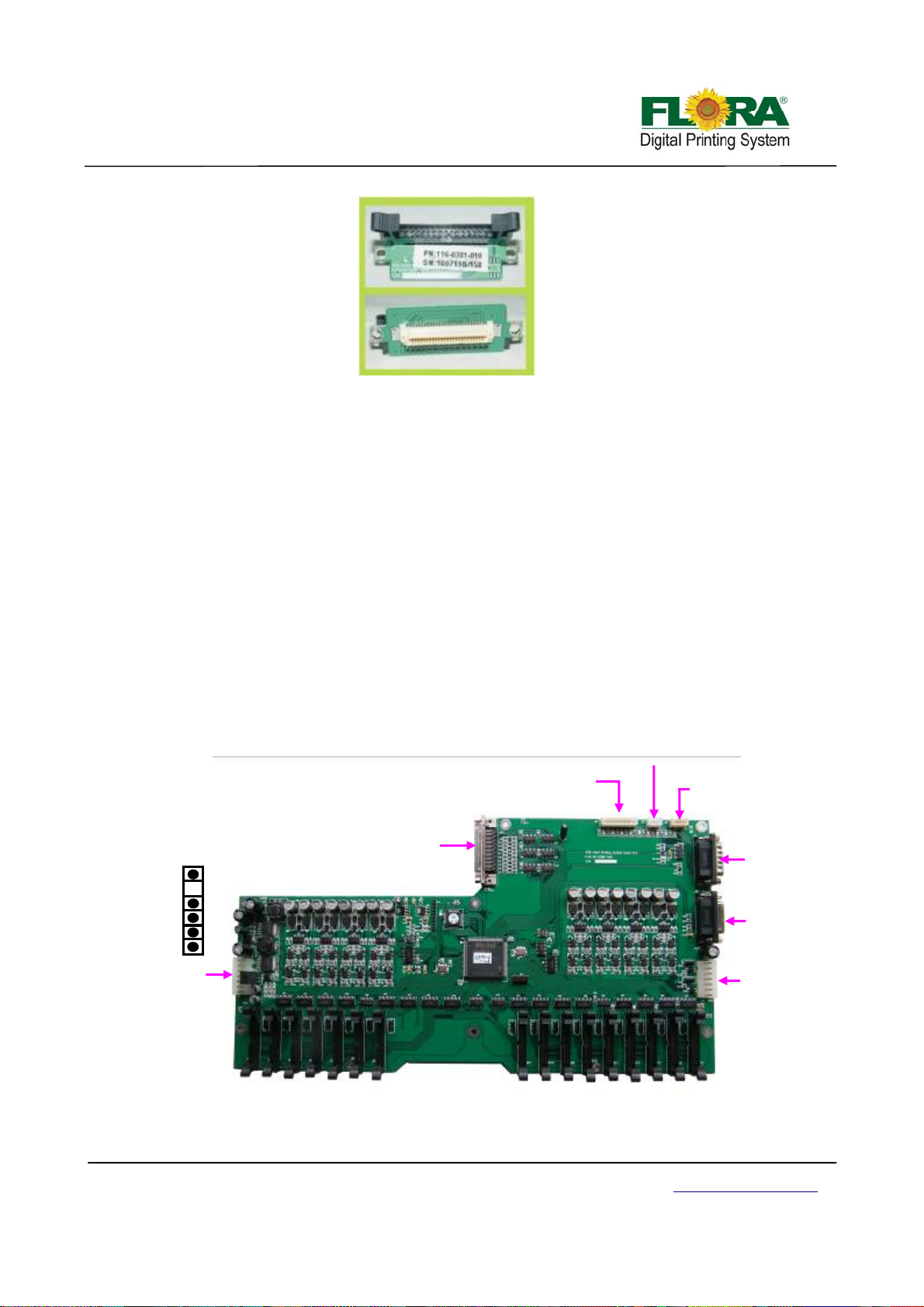

4.3 PCB boards

4.3.1 Print Head Connector Board

This board is used a s interface board for Print head and the Print head Control Board thru a

30-pin flexible data cable. It is fixed on the print head by two fixation screws,

Victor Xu Page 22 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

No use

15Vdc

15Vdc

24Vdc

J1 to Power

Source (15/24

Vdc)

Print Head Connector Board

4.3.2 Print head Control Board

The image data is fetched by the Print Head Control Board from the USB_IF buffer through

the Image Data Cable (UCBJ10PHBJP1) and 100-pin JP1 AMP connector. The image is then

processed by the image data processor and dispatch to the print heads. The printheads fires the

ink depending on the binary status read by the Raster Reader which is sent to the print head

control board.

Likewise, the print head heating control is also integrated into the Print Head Control Board.

Thus, the print head temperature can be accessed from the Floraprint driver graphical user

interface or GUI.

The carriage displacement pulse signal is sent from the encoder reader to the print head

control board through PHBJ9ENR1 into J9 D-sub connector.

The secondary ink tank level sensor signal from the secondary ink tanks pass through cable

J2 and into the J2 connector of the print head control board. If the secondary ink tanks are full,

corresponding LED indicators will turn on near the J4 connector. The binary status for the

secondary ink tank level is then sent to the Servo Driver Board through cable SCBJ7PHBJ7. It is

then processed on the Servo Control Board to activate the ink pump motors.

The shutters of the UV lamps were also controlled from the Print Head Control Board.

J3 No Use

J4 To Negative

Pressure Sensor

J7 to Servo

Control Board

J6 to Raster

strip reader

J5 UV Lamp

Shutter Control

GND

GND

J2 to ink level sensors

JP1 to USB IF

Victor Xu Page 23 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Interfaces for print heads:

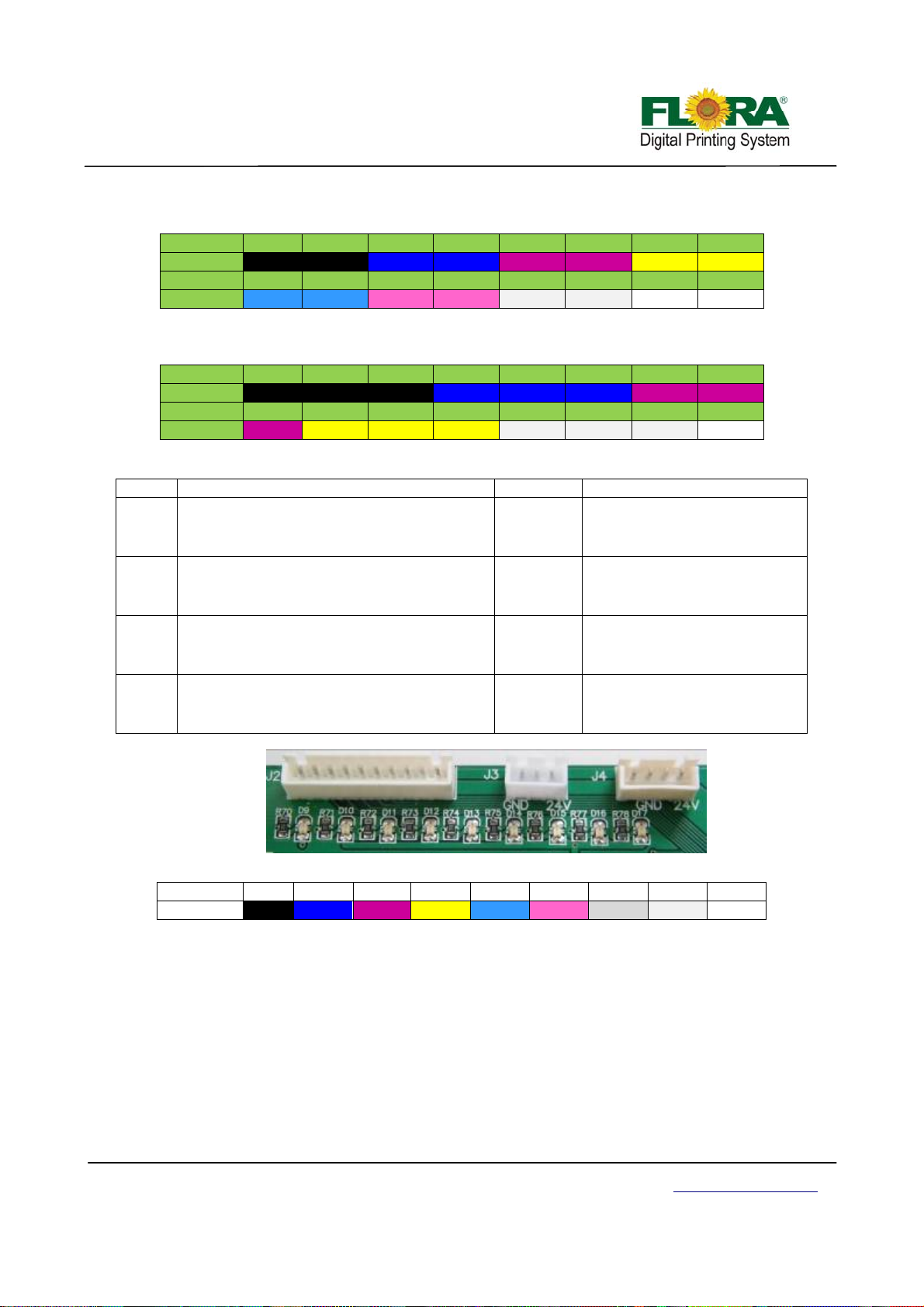

Carriage platform with two rows print heads:

PORT JB1 JB2 JB3 JB4 JB5 JB6 JB7 JB8

COLOR

PORT

COLOR

**Double white just replaceV1, V2 with W3, W4

Carriage platform with three rows print heads:

PORT JB1 JB2 JB3 JB4 JB5 JB6 JB7 JB8

COLOR

PORT

COLOR

K1 K2 C1 C2 M1 M2 Y1 Y2

JB9 JB10 JB11 JB12 JB13 JB14 JB15 JB16

Lc1 Lc2 Lm1 Lm2 W1 W2 V1 V2

K1 K2 K3 C1 C2 C3 M1 M2

JB9 JB10 JB11 JB12 JB13 JB14 JB15 JB16

M3 Y1 Y2 Y3 W1 W2 W3

Function of LEDs

LED Function description LED Function description

D1

D2

D3

D4

Power indicator for 24V

normal:on

abnormal:off

Power indicator for heat of print head 15V

normal:on

abnormal:off

Power indicator for 5V

normal:on

abnormal:off

Raster indicator

Carriage moving:light

Carriage keeping still:off

D5

D6

D9~D17

—— ————

Work indicator

Board work normally:shine

abnormal:off

Temperature indicator

heating:on

no heating:off

Level indicator

Tank full:on

not full:off

Ink level indicators for every color:

LED D9 D10 D11 D12 D13 D14 D15 D16 D17

COLOR K C M Y Lc Lm W V NP

*K: Black, C: Cyan, M: Magenta, Y: Yellow, Lm: Light magenta, Lc: Light cyan, W: White, V: Varnish,

NP: Negative pressure

4.3.3 USB Interface Board

The USB board is the main interface of the machine to PC. The image data and control

information are transmitted from the PC USB port to the USB port of this board. The

communication and image data transfer are conveyed through the 100-pin data cable.

For this particular printer model, the USB board is also used to communicate with and

control the servo driver control board.

There is a separate control circuitry designed to control the x-axis and y-axis movement. It

conveys a signal for the servomotor step and direction; and hence, the servo driver can be able

Victor Xu Page 24 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Loading...

Loading...