Flora Digital Printing System

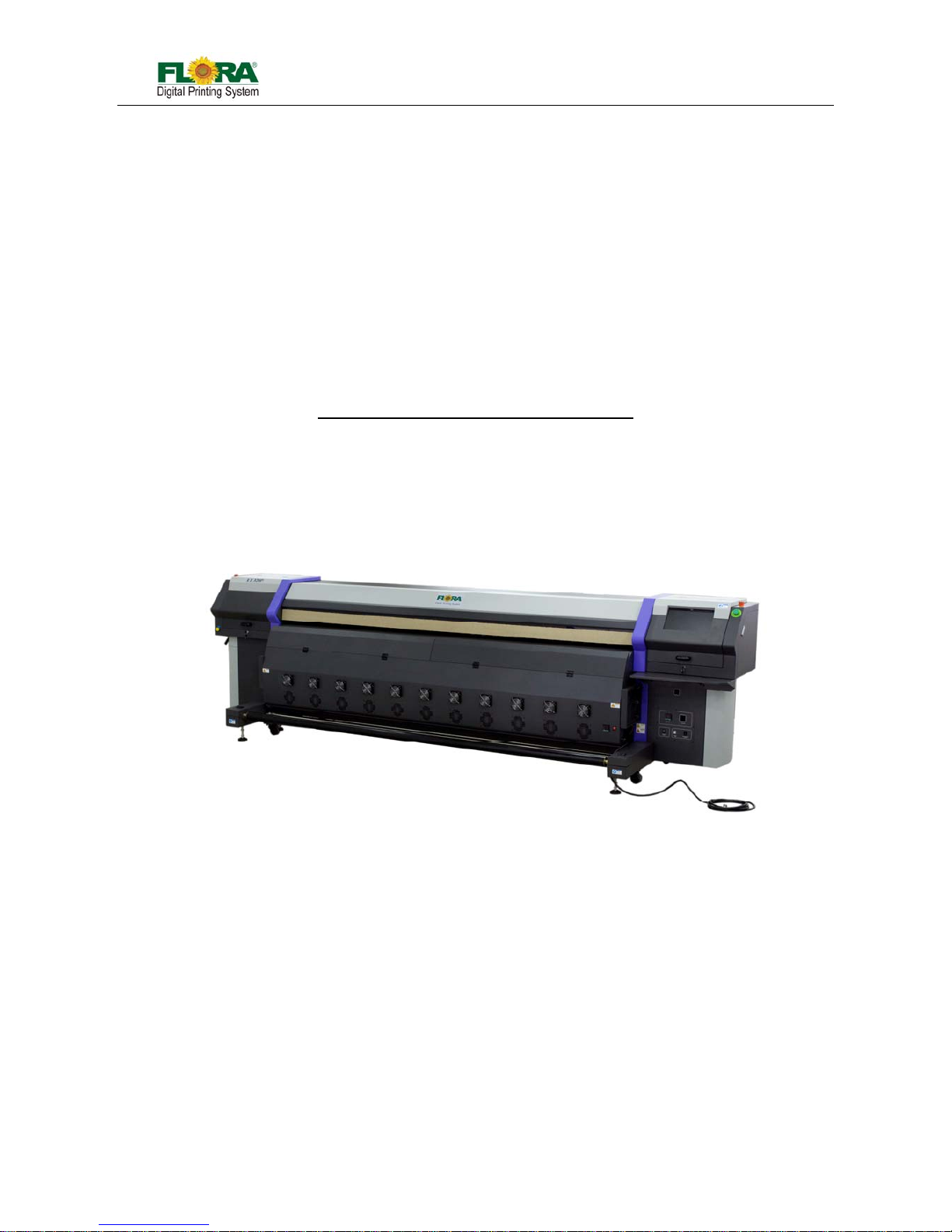

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~1~

Flora

LJ3208P USER GUIDE

2011-7-18

Shenzhen Runtianzhi Image Technology Co.,Ltd

www.floradigital.com.cn

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~2~

FLORA.....................................................................................................................................................................1

LJ3208P USER GUIDE.............................................................................................................................................1

FLORADIGITALPRINTINGSYSTEM............................................................................................................................................5

DISCLAIMER.........................................................................................................................................................................5

MANUALUSEGECONDITIONSANDLIMITATIONS.........................................................................................................................5

CONTENTSOFPACKAGE..........................................................................................................................................................6

PRINTERINTRODUCTION.........................................................................................................................................................6

TABLE1GENERALFEATURES...................................................................................................................................................6

TABLE2TECHNICALSPECIFICATION............................................................................................................................... ............6

TABLE3FLORALJ3208PPRINTERMODELCODING....................................................................................................................7

ABOUTTHEMANUAL............................................................................................................................................................7

CHAPTER1SAFETYOPERATINGINSTRUCTIONS...........................................................................................................................8

1.1 BriefIntroduction...............................................................................................................................................8

1.2 SafetyInformation.............................................................................................................................................8

1.2.1 SolventandInkProperties.........................................................................................................................................8

1.2.2 DangerofFireandExplosion.....................................................................................................................................8

1.2.3 Anti‐ultravioletRadiation...........................................................................................................................................8

1.2.4 ProperVentila ti onandExhaustSystem.....................................................................................................................8

1.2.5 InkandSolventspillage,apotentialriskofFireandexplosion..................................................................................8

1.2.6 Highvoltagemayshockpeopleortriggerafire.........................................................................................................8

1.2.7 Printingmediarollsarebulkyandveryheavy............................................................................................................9

1.3 Fireproofing.......................................................................................................................................................9

1.4 ExhaustSystem..................................................................................................................................................9

1.5 HandlingPrecautions.........................................................................................................................................9

1.5.1 PowerSupply.............................................................................................................................................................9

1.5.2 Printer........................................................................................................................................................................9

1.6 RegularInspectionandMaintenance................................................................................................................9

1.7 Consumables......................................................................................................................................................9

CHAPTER2PREINSTALLREQUIREMENT............................................................................................................................... .....11

2.1 GettingStarted.................................................................................................................................................11

2.2 OperatingConditions.......................................................................................................................................11

2.2.1 InstallationSpace.....................................................................................................................................................11

2.2.2 EnvironmentConditions...........................................................................................................................................11

2.3 ConfigurationofComputer..............................................................................................................................12

2.4 PowerSpecification..........................................................................................................................................12

2.5 SuggestInventoryList......................................................................................................................................12

2.6 AvailableMediaTypes.....................................................................................................................................13

CHAPTER3EXTERNALVIEWS,PARTNAMESANDFUNCTIONS......................................................................................................14

3.1 ComputerStation.............................................................................................................................................15

3.2 MaintenanceStation........................................................................................................................................15

3.3 Carriage&BeamAssembly..............................................................................................................................15

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~3~

3.4 InkSupplyCompartment.................................................................................................................................16

3.5 ElectricalCompartment...................................................................................................................................16

3.6 DryingSystem..................................................................................................................................................16

3.7 Take ‐upSystem&FeedingSystem...................................................................................................................17

3.8 PowerControlPanel.........................................................................................................................................17

CHAPTER4WORKINGSYSTEMOFFLORALJ3208P...................................................................................................................18

4.1 SystemBlockDiagram.....................................................................................................................................18

4.2 PolarisPrintheadIntroduce.............................................................................................................................19

4.3 PrintingControlSystem....................................................................................................................................20

4.3.1 PrintingControlBoard(116‐0401‐132).................................................................................................................... 20

4.3.2 USBBoard(116‐0417‐011).......................................................................................................................................21

4.3.3 ServoCard(116‐0385‐022)..................................................................................................................................22

4.3.4 HPPBoard(116‐0396‐081)..................................................................................................................................23

4.3.5 ConnectorBoard(116‐0402‐020).............................................................................................................................24

4.3.6 RTZ‐16UVMediaBoard‐V1.3(116‐0030‐041)...........................................................................................................24

4.4 MechanicalMovementSystem........................................................................................................................24

4.4.1 X‐axisMovement(CarriageMotionSystem)............................................................................................................25

4.4.2 Y‐axisMovement(MediaFeedingSystem)...............................................................................................................26

4.5 InkSupply&NegativePressureSystem...........................................................................................................28

4.5.1 InkSupplySystem....................................................................................................................................................28

4.5.2 LackofInkWarnin gFunction...................................................................................................................................28

4.5.3 PurgeandFlushindividually.....................................................................................................................................29

4.5.4 NegativePressureSystem........................................................................................................................................29

4.5.5 OverflowProtectionFunction..................................................................................................................................29

4.5.6 Otherpartsintro......................................................................................................................................................30

4.6 FlushingSystem...............................................................................................................................................31

4.7 DryingSystem..................................................................................................................................................32

4.8 Take ‐upandfeedingSystem............................................................................................................................32

CHAPTER5INSTALLATIONMANUALOFFLORALJ3208P............................................................................................................34

5.1 MachinePre‐installation..................................................................................................................................34

5.2 InstallationofSoftware....................................................................................................................................34

5.3.1 InstallPhotoPRINTServerFloraEdition6.1v2..........................................................................................................35

5.3.2 InstallFloraDriver....................................................................................................................................................37

5.3.3 InstallUSBDriver......................................................................................................................................................38

5.3.4 Addsetup.................................................................................................................................................................39

5.3 InstallPrintHeads............................................................................................................................................40

5.4 InkandSolventPreparation.............................................................................................................................43

5.5 HeadAlignment...............................................................................................................................................43

5.5.1 Tes t PrintToolBar.....................................................................................................................................................43

5.5.2 SetParameter&NozzleCheck.................................................................................................................................43

5.5.3 PrintheadYAlignment.............................................................................................................................................44

5.5.4 Vertica lAlignment....................................................................................................................................................47

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~4~

5.5.5 InternalRightAlign...................................................................................................................................................47

5.5.6 InternalLeftAlign............................................................................................................................... ......................49

5.5.7 RightAlign................................................................................................................................................................49

5.5.8 XAlignment..............................................................................................................................................................51

5.5.9 StepAlignment.........................................................................................................................................................52

CHAPTER6OPERATIONMANUALOFFLORALJ3208P...............................................................................................................54

6.1 BriefIntroduction.............................................................................................................................................54

6.2 Starting‐upActivities........................................................................................................................................54

6.3 PrintheadJettingCheck..................................................................................................................................54

6.4 OperationalApproachofPhotoPRINTServerFloraEdition6.1v2....................................................................54

6.4.1 JobFolder.................................................................................................................................................................54

6.4.2 LayoutTag ............................................................................................................................... .................................55

6.4.3 WorkFlowTa g ..........................................................................................................................................................56

6.4.4 ColorManagementTag............................................................................................................................................56

6.4.5 PrintOptionTag.......................................................................................................................................................57

6.5 Shut‐offprocedure...........................................................................................................................................62

6.5.1 Over‐nightprotection............................................................................................................................... ................62

6.5.2 Longtermprotection...............................................................................................................................................62

CHAPTER7SERVICEANDMAINTENANCEMANUALOFFLORALJ3208P........................................................................................63

7.1 BriefIntroduction.............................................................................................................................................63

7.2 Maintenanceofprintheads.............................................................................................................................63

7.2.1 FlushingPrinthead...................................................................................................................................................63

7.2.2 PrimePrinthead......................................................................................................................................................63

7.2.3 ReplacingPrinthead............................................................................................................................... .................63

7.3 MaintenanceofInkSupplyandVacuumLineSystem......................................................................................64

7.3.1 ChangingDefectiveInkPumpandFilter..................................................................................................................64

7.4 MaintenanceofPrinterMovingPart...............................................................................................................64

7.5 AdjustTimingBeltTen s ion ............................................................................................................................... 65

APPENDIXATROUBLESHOOTINGGUIDE................................................................................................................................67

APPENDIXBHOWTOSETNEGATIVEPRESSURESENSOR(CKD)DISPLAY........................................................................70

APPENDIXCGLOSSARY......................................................................................................................................................72

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~5~

Flora Digital Printing System

Flora Digital Printing System, reserves the right to make changes without prior notice to the specifications and

materials contained herein and shall not be responsible for any damages (including consequential) caused by

reliance on the materials presented, including but not limited to typographical, arithmetic, or listing errors.

This equipment has been tested and found to comply with the limits for a class A digital device. Pursuant to p art

15 of the FCC Rules, these limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which the user will be required to correct the

interference at his own expense.

This printer is a color inkjet printer that uses a Solvent ink, support s up to 3200mm of media wi dt h, and has one

built-in USB interfaces.

This manual, the LJ3208P User's Guide, describes the features of the printer, names of components,

information needed before use, and basic operations, such a s how to turn the po wer ON and OFF, loading and

setting of the media and loading of ink.

The following items should be read before proceeding to Section 1;

− Contents of the package

− Safety precautions

− Handling precautions

− Notion

Notice: Read these items to use the printer safely and properly. Keep this manual in a place whe re you can

quickly access it any time.

Disclaimer

This is an alpha release of the User's Guide for Flora LJ3208P printer. We have made every ef fort to guara ntee

the accuracy and integrity of the information in this manual. If you find some errors or omissions, please bring

them to our attention so we can check and correct them accordingly.

This manual can be used as a reference for operation and routine maintenance of the Flora LJ3208P printers.

It can’t be a replacement for the formal training provided by Shenzhen Runtianzhi Image Technology Co., Ltd,

regarding on how to operate the printers properly. Shenzhen Runtianzhi Image Technology Co., Ltd will not

take any responsibility for the consequences of misusing this manual and appendix.

Manual Usege Conditions and Limitations

The manual includes patent information, which belongs to Shenzhen Runtianzhi Image Technology Co., Ltd.,

the purpose of which is to help the authorized customers. Without the written permission from RTZ Company

and the public declaration, any content of this manual should not be used for other purposes.

The text and images are subject to change without prior notice. Any software mentioned in this manual is

provided by permission. Use or copy of these softwares must be according and to follow prior regulations. If the

information in this manual has changed, there will be no further notice unless it is specified.

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~6~

Contents of Package

The internal printer components, including the options, are installed on the main unit on delivery. The print

heads and extension table assembly are included on a separated box within the main crate.

If any parts are missing or damaged, please contact the shop or dealership where you have purchased the

product or the nearest service center.

Printer Introduction

The Flora LJ3208P printer is a wide format digital printer suitable for small up to medium size business use. It

uses a Solvent ink. It provides high productivity and is capable to replace traditional silkscreen printing. This

type of printer is widely used in the fields such as advertisement, packing, printing, interior decoration, flexible

packaging, etc.

Flora LJ3208P series printers use drop-on-dema nd and Piezo-electric tech nolog y. It can print colorful and wide

image by using the highest 1200x1200 dpi resolution. It can output any size of images with “tile” feature in the

software.

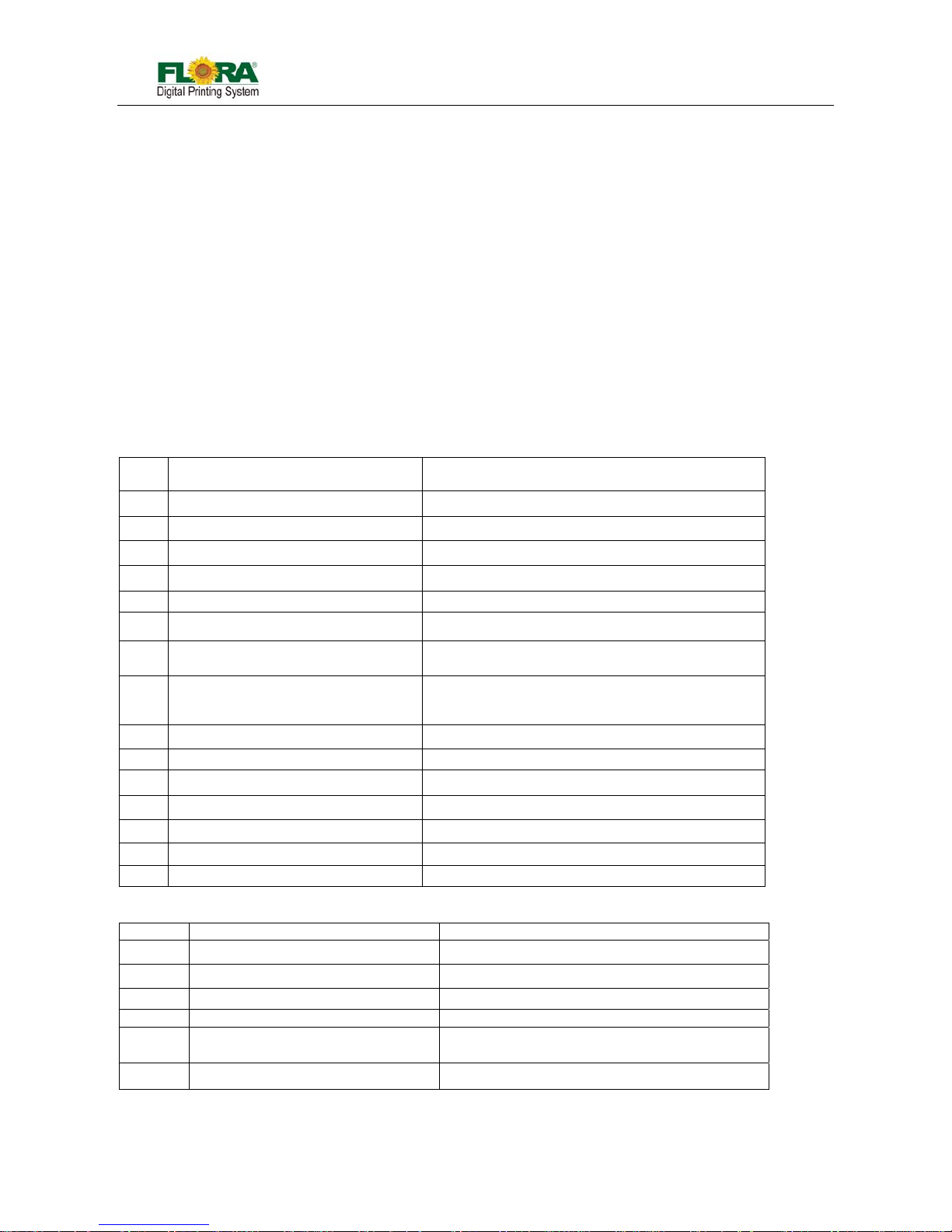

Table 1 General Features

Item

No

Description Specification

1

Printing Method Drop-on-demand Piezo-electric

2

No. of colors 4 (CMYK)

3

Ink Solvent

4

Ink reservoir capacity (volume) 4 Li/color (refillable while printing is on progress)

5

Outdoor Durability 1 years for Flora Solvent ink

6 Media handling system Roll-to-Roll with vacuum

7 Drying system Dual Drying System

8 Media types

Roll-to-roll including paper, vinyl, adhesive back

vinyl, fabrics, banners, PVC, etc

9 Maximum printing size 3.2 m width

10 Rip software PhotoPRINT V6.1 Flora edition (Windows 7)

11 Driver software Flora Driver

12 Color management ICC based color, density adjustment curves

13 File format Bitmaps, Tiffs, Jpeg, Postcripts3, Eps, Pdf, etc.

14 Work Flow Rip and Print

15 Warranty 1 year (please consult your local dealer for details)

Table 2 Technical Specification

Item No D e s c r i p t i o n Specification

1 Model Flora LJ3208P

2 Print Head Binary Drop-on-demand Piezo-electric

3 No. of print heads 8 (CMYK, 2 print heads/color)

4 No of colors 4 colors

5 Printing resolution option

300x200, 300x400, 300x600, 600x400,600x600,

600x800, 1200x1200 dpi

6 Printing quality option Standard, High and Ultra

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~7~

7 Printing Speed

Draft Quality: 185 m

2

/hr

Standard Quality: 125 m

2

/hr

High Quality: 92 m

2

/hr

8 Media maximum width 3.3 m

9 PC minimum operating requirement.

Intel Core 2 Duo, Q6600 @2.40GHz

3GB RAM, 250GB HDD, Windows 7 or XP

11 Operating environment

220VAC/50/60Hz/Single Phase, Distortion<

0.5% Heating:3000W, System:3500W

12 Room temperature 23~33 ºC

13 Humidity 40~70%

14 Dimensions 4.83.m x 1.37m x 1.38m

15 Weight 700 Kg

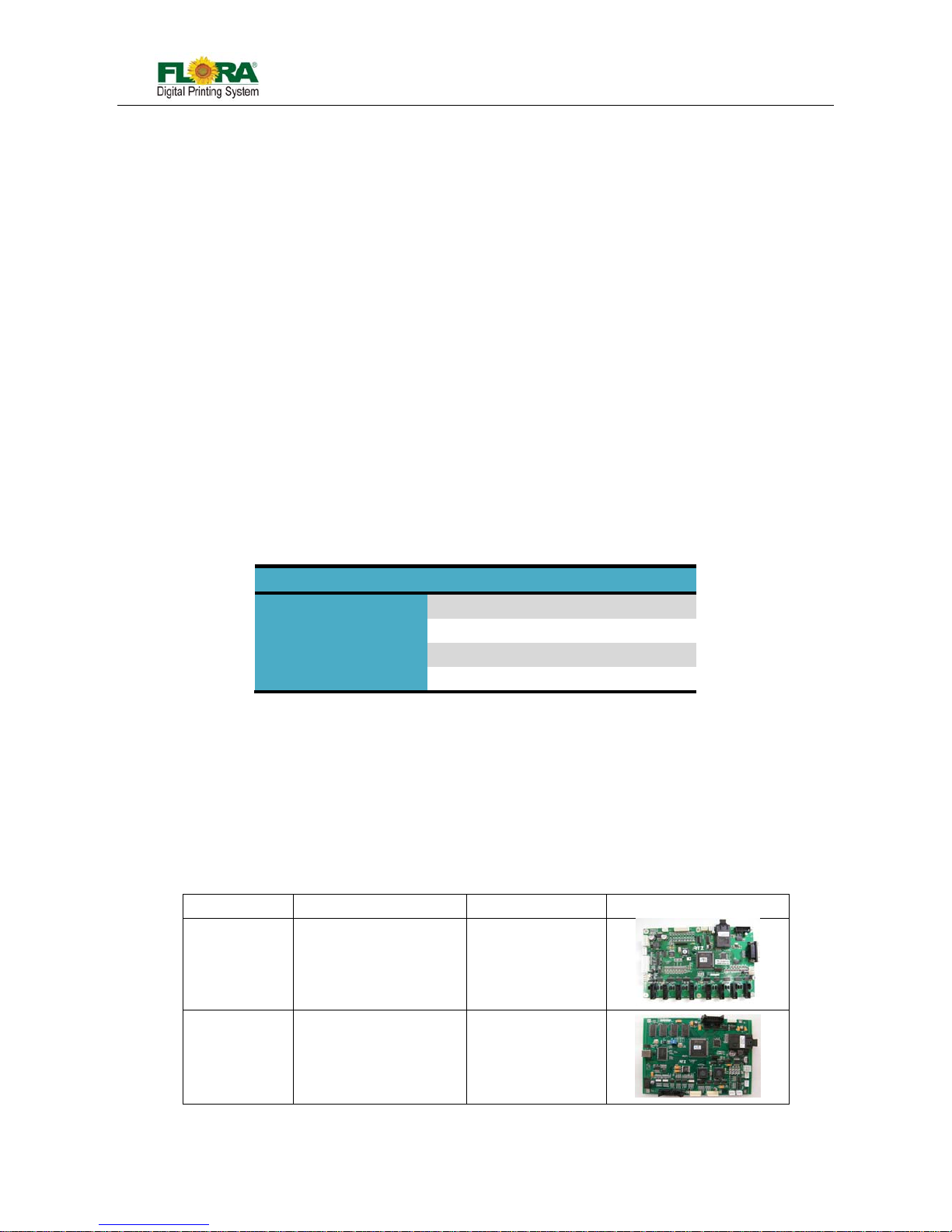

Table 3 Flora LJ3208P Printer Model Coding

Code Explanation

Flora

Brand Name

LJ

Light Jet

3208P

320: maximum width 320cm

8: 8 print heads

P: Polaris head

About The Manual

The manual provides the end user all the information related to the machine basic functions, software

installation, machine parameter calibration, maintenance and troubleshooting of Flora LJ3208P.

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~8~

Chapter 1 Safety Operating Instructions

1.1 Brief Introduction

This chapter introduces the important safety information. Please read and understand the safety

information carefully before operating the printer.

1.2 Safety Information

FLORA printer uses the following chemical substances

z All kinds of printing media

z Solvent Ink

z Cleaning liquid (Solvent Flush)

1.2.1 Solvent and Ink Properties

Solvent and Ink are flammable.

Eye contact with the ink and Solvent will break the cornea and weaken the eyesight.

Contact lens should not be worn when operating printer or when there is no proper

ventilation.

Wear safety glasses and gloves while flushing print heads, ink tube or moving the ink

bottles or containers.

Solvent and ink can be irritating to eyes, throat and skin. Inhaling the ink fumes would

result in swoon or other symptoms.

Solvent vapors are heavier than air and may flow and gather in low spot.

1.2.2 Danger of Fire and Explosion

Open flames, heat energy or spark around the printer can trigger fire and explosion.

No smoking, pilot lights, open flames, stoves, heaters or halogen lights should be

turned on within 5m distance from any edge of the printer.

No portable spark-producing equipment (static, ele ctrical or Mechanical) within 5m

distance from any edge of the printer.

1.2.3 Anti-ultraviolet Radiation

Wear solvent protection glasses and gloves when operating the machine and avoid

being too closer to solvent lights.

When doing maintenance task or being close to the flatbed machine, solvent lights

must be shut off or close all solvent protection doors.

1.2.4 Proper Ventilation and Exhaust System

The vacuum exhaust system must be functioning before the printer operates.

Do not ignore this safety warning sign to avoid accumulation of flammable fumes in the

area.

1.2.5 Ink and Solvent spillage, a potential risk of Fire and explosion

Store ink and Solvent in proper cabinet for flammable liquid storage.

Keep ink and Solvent containers tightly closed at all times. If a container has sig n of

damage/leakage, fix or replace it immediately.

Clean ink or Solvent spillages as soon as possible.

Only use dry powder, or carbon dioxide type of fire extinguishers.

1.2.6 High voltage may shock people or trigger a fire

If there’s no emergency power switch which can shut down all the power, do not

connect the printer to main-power supply.

When the machine’s power is on, do not open the back cover of machine, or avoid

touching electrical parts.

The printer or other equipments should be grounde d, according to the local safety

This caution symbol represents danger. If this sign is ignored it

may lead to serious injury or damage to the printer.

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~9~

electrical connection regulation. The ground voltage should be less than 3 V.

Set the machine on smooth ceramic tile or cement ground

Use specified anti-static floor mat to minimize harmful st atic build-up.

1.2.7 Printing media rolls are bulky and very heavy

Wear hand and foot safety protection gear when loading, unloading and han dling

media to avoid serious body injuries.

Use proper heavy duty handling equipment if available.

1.3 Fireproofing

Ink and Solvent should be clearly labeled and stored in a specific area for flammable liquid and

should be in accordance with local regulations of fireproof and safety standard. Ensure that the specifie d

fire extinguisher is always available near the storage area and should be cleared from any obstacle in

case of emergency.

1.4 Exhaust System

The printing area should be equipped with sufficient exhaust system. The exhaust should be inst alled

in such a way build up of fumes is minimized. Best location for the exhaust should be at lowest level, this

way the fumes build-up is minimized. Solvent fumes are heavier than air, so fumes build-up concentrates

on the lower level of the room.

1.5 Handling Precautions

1.5.1 Power Supply

Install the printer near an easily accessible electrical outlet.

Do not provide power to the printer through the same power line as for other noise

generating devices such as motors.

Use a power supply matched with the printer specification.

Connect the power cable directly to an electrical outlet. Do not plug several devices

into one electrical outlet.

1.5.2 Printer

Do not place anything on top of the printer.

Do not rest you elbows on the printer .

Open and close the top cover gently from the front of the printer with both hands.

Before connecting or disconnecting the interface connector, turn the printer OFF.

Do not clean the surface of the cover with benzene or paint thinner. The coating may

come off or deteriorate. Wipe the cover with a soft cloth, if the cover is very dirty, use a

cloth moistened with a neutral detergent.

Do not touch the ink jet head surface.

1.6 Regular Inspection and Maintenance

The following regular inspection and maintenance must be performed in terms of characteristics of

the solvent ink:

a) Clean the carriage unit and the flat table conveyor surface every day.

b) Make sure that the carriage covers are always replaced.

c) Perform ink supply circuit and print head cleaning when leaving the printer for a long

time (2 weeks or more with no power).

d) Perform head cleaning after leaving the printer idle for a long time.

e) Shut off the solvent lamp whenever the printer is not in use.

1.7 Consumables

z Always use the recommended consumables (printing media, ink, ink filters). Failure to

follow this instruction may cause poor printing quality and breakdown.

z Do not use ink past the expiration date as this may cause a print head breakdown and poor

printing quality.

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~10~

z Put a used ink bottle into a plastic bag and dispose of it as an industrial waste. Observe

local regulations for disposal of waste ink bottles.

z Avoid spilling ink into your skin or clothes. Wash any ink off immediately with soapy water.

z Check the waste ink container everyday so as not to permit waste ink to leak from you

printer.

z If the waste ink container is being installed or removed, spread a stain preventing sheet so

as not to stain the floor with spilled ink.

z Store ink in a dark and cool place. Never store the ink in high temperatures or direct sunlig ht,

doing so may cause the ink to deteriorate.

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~11~

Chapter 2 Preinstall Requirement

This is a pre-install guide for Flora LJ3208P. Customers are recommended to prepare the room and other

necessary devices before the machine arrived and installation. We have made every effort to guarantee the

accuracy and integrity of the information in this guide. Should you find some errors or omissions, please bring

them to our attention so we can check and correct them accordingly.

2.1 Getting Started

This section provides the necessary information to preinstall the printer. Familiarize yourself with the

basic of the printer before reading Section 2.

Contents of this section:

z Operating conditions

z Consumables

2.2 Operating Conditions

This section describes the operating conditions for the printer.

2.2.1 Installation Space

There must be sufficient space around the printer for the replaceme nt of frequently used parts,

for the output of the printed media and for ventilation. In addition, maintenance space, shown below,

is required to repair the printer or replace components.

There must be at least 1m of space in every side at X-axis, at least 1.5m of space at in every

side Y-axis, at least 1m from the top of the machine.

2.2.2 Environment Conditions

2.2.2.1 Operating temperature and humidity levels

The printer should be used within the temperature and humidity ranges as shown below;

Temperature: 20 ºC to 30 ºC

Humidity: 40% to 70%

Note: To obtain better print quality, use the printer within temperature of 25 ºC to 30 ºC.

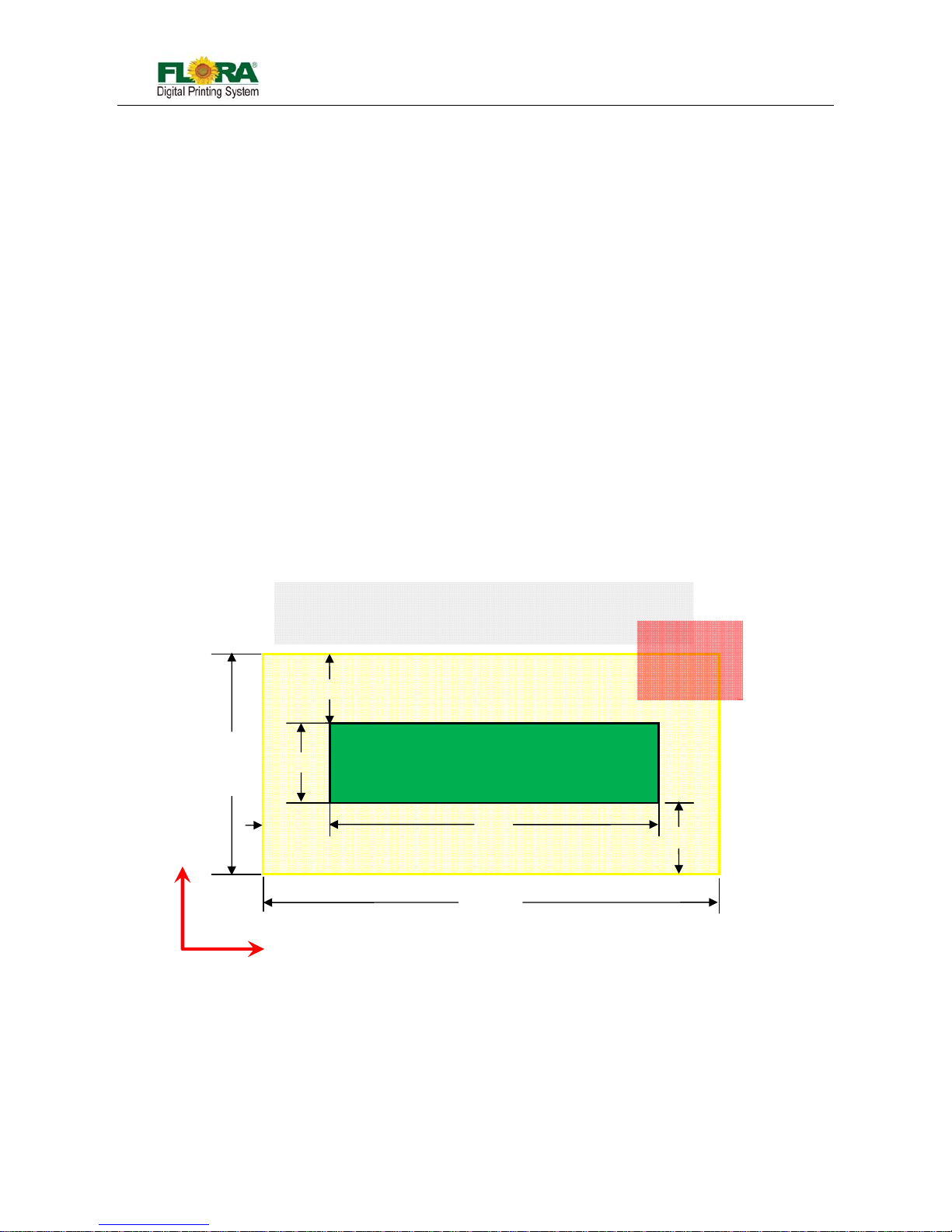

X

Y

Media

LJ 3208P Top View

Power

Distribution

Area

1.0m

4.83m

LJ 3208P Printer

Left

Back

Right

Front

0.96m

1.5m

1.5m

3.96m

6.83m

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~12~

When the operating temperature is lower than 20 ºC or higher than 40º C, printing speed

should be reduced to two-thirds of normal print speed to maintain good print quality.

2.2.2.2 Places where the printer must not be installed

Do not install the printer in the following places:

A location near a fire

Places exposed to direct sunlight

Places subject to vibration

Places with excessive dust

Places subject to extreme changes in temperature or humidity

Places near an air conditioner or a heater

Places where the printer may get wet

Places near a diazo copier that may generate ammonia gas

Places with poor ventilation

Unstable place

2.3 Configuration of Computer

z Intel Core 2 Duo, Q6600 @2.40GHz

z 3G RAM

z 250G Hard disk

z DVD-ROM

z USB 2.0 port(at least 2)

Notice: This is only for reference, which is used to test in our company! Recommend to use

Brand Computer.

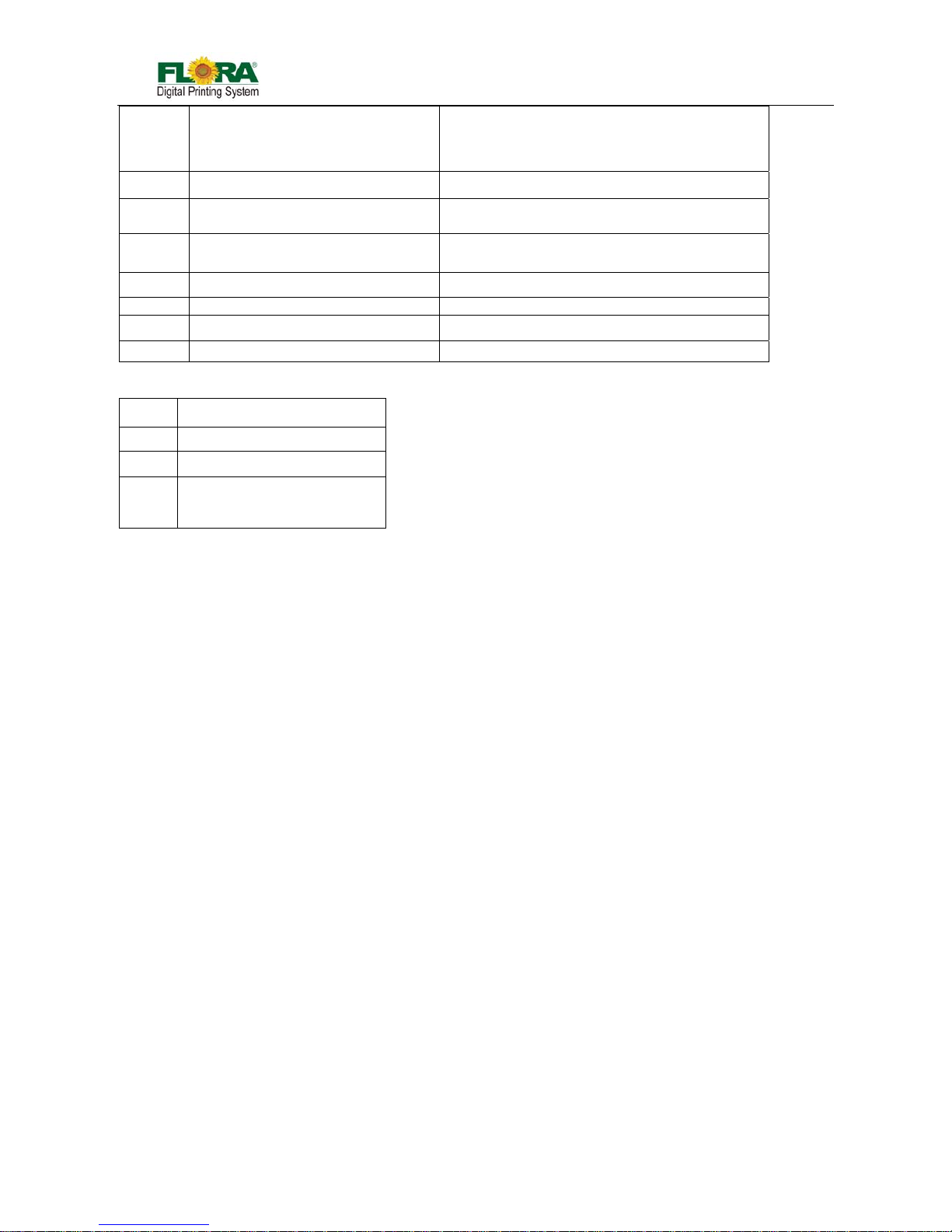

2.4 Power Specification

System Power Heating Power

Rated voltage

220VAC (±5%) 220VAC (±5%)

Rated currency

25A 16A

Input power frequency

50/60HZ 50/60HZ

Phase

Single-phase Single-phase

Electrical Safety:

z The machine should be grounded, according to the local safety electrical regulation.

z The grounding should be less than 3V.

z Use specified anti-static floor matting to minimize the harmful static buildup.

z Use ESD Ground Strap when handling Print heads and any Electronic Boards to avoid any

electric static discharge that may damage these part s.

z Do not open the cover where electrical spare parts are located to avoid possible electrical

shock.

Notice: AVR or UPS is recommended to keep supplying stable power to the machine!

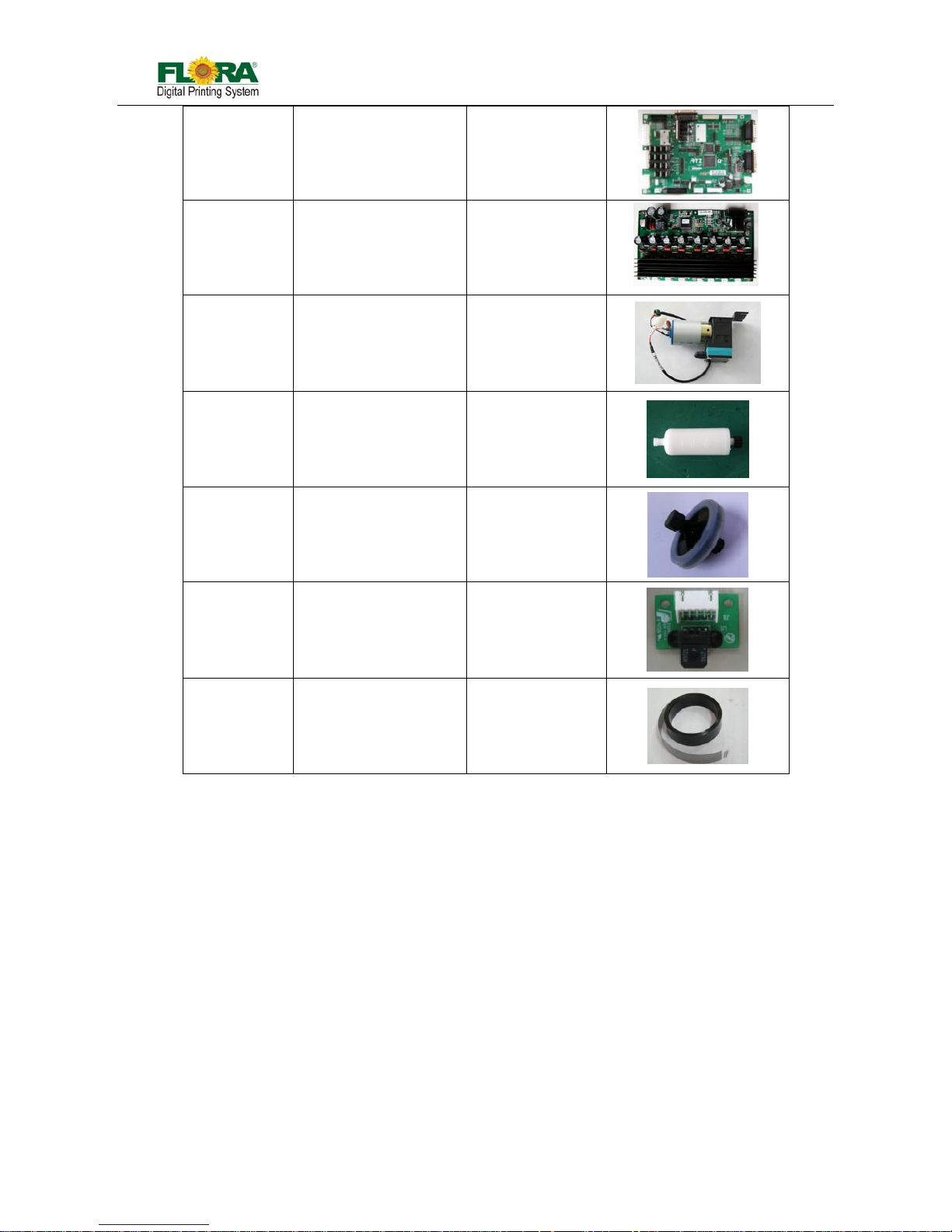

2.5 Suggest Inventory List

PN Part Name Number/Machine Photo

1 16 -04 01-132 Printing Control Board 1pcs

116-0417-011 USB Board 1pcs

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~13~

116-0385-022 Servo Card 1pcs

116-0396-081 HPP Board 1pcs

312-0015-233 Ink Pump 9pcs

141-0487-000 Ink Pump Filter 9pcs

141-0428-006 Disc Filter 16pcs

116-0340-020 Raster Reader 1pcs

141-0134-004 Raster Strip

1pcs

2.6 Available Media Types

The following types of media are available:

z Paper

z Advertising banner

z PVC

z Mesh Fabrics

z Adhesive Vinyl

Note: Contact our service center for detail!

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~14~

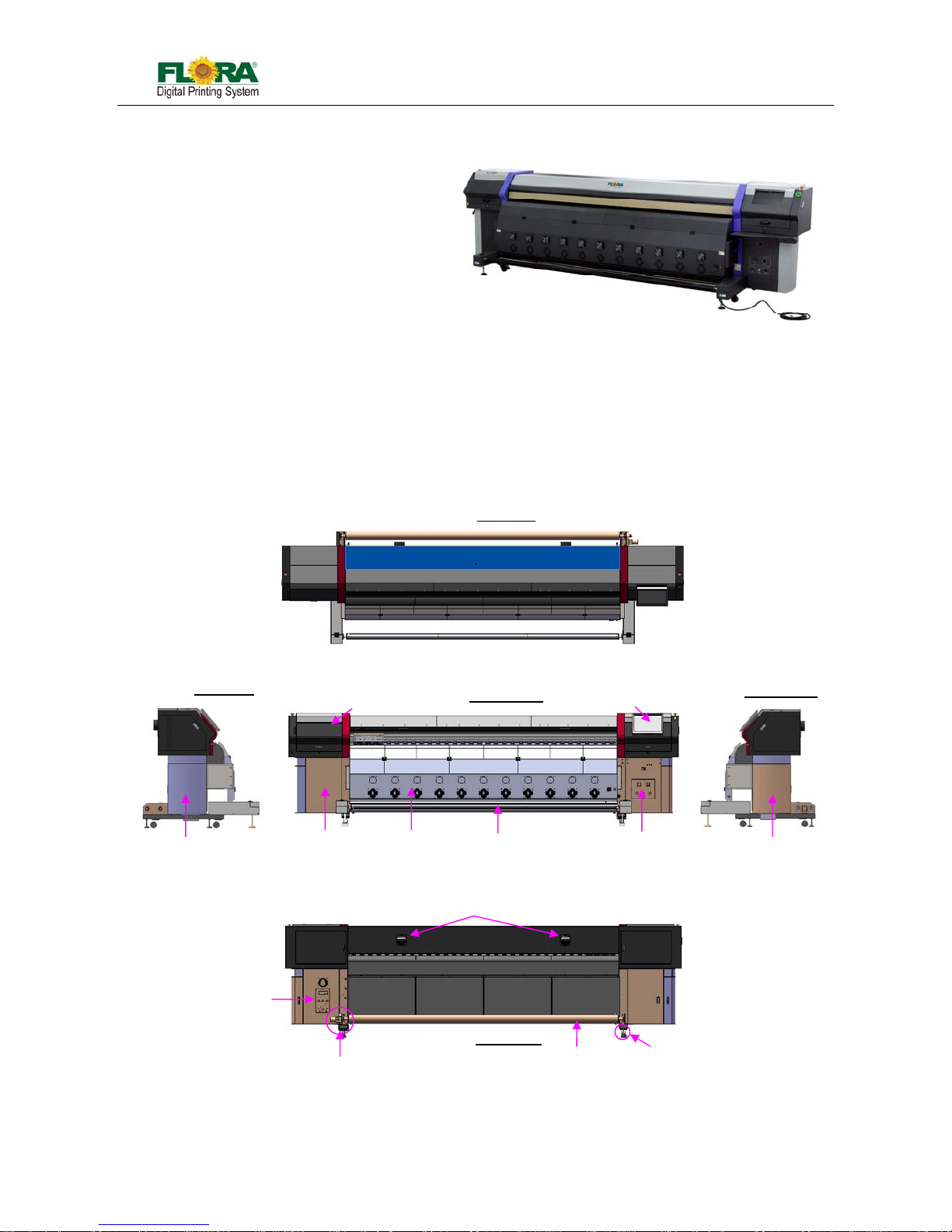

Chapter 3 External Views, Part Names and Functions

The mechanical design parts/assembly of the

machine are grouped according to its function;

namely, the print head carriage, the x-axis

movement mechanism, the y-axis movement

mechanism, the roll media feeding and take-up

mechanism, the ink supply compartment, the

electrical control cabinet and the printing platform.

The printing system control is a modular control

that has the dedicated controller board for a specific function. Othe r controller board function s as a stand-alone

control, like the roll media feeding and take-up control board, that has no communication and no interlock with

the other controller board, it needs only the power supply from the machine. The mechanics, the electronics

and the standard electrical parts are harnessed together to form a system for large format printing application.

LJII-series Perspective View

Fig.3-1Top View

(Back Side)

(Front Side)

Fig.3-2 Left View

Ink Supply Control

Compartment

Fig.3-4 Right View

Computer

Compartment

Fig.3-3 Front View

Ink Bottle

Compartment

Drying Plate

Drying Fans

Roll Media

Take-up Roller

Heater Controller

and Roll Media

Control Switches

User Interface

(UI)/Monitor

Maintenance

Station

Fig.3-5 Back View

ELCB and Circuit

Breakers

Roll Media

Feeding Roller

Roll Media

Feeding Motor

Roller Wheel

and Adjustable

Footing

Exhaust Fan

Ducting Port

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~15~

3.1 Computer Station

Computer station is control centre, which is located at right side of the machine! It takes charge early

treatment before printing including image ripping and print mode setting. Most function starts to work

when get the command from computer.

3.2 Maintenance Station

Maintenance station is in right compartment. When the carria ge stopped working, it will come back to

station. All the maintenance performance should be done here.

3.3 Carriage & Beam Assembly

The print head carriage assembly houses the print heads, secondary ink tanks, print head control

board, raster reader, ne gative pressure sensor.

Rail guide serves as pathway for carriage moving, and the beam serves as frame for rail guide

mounting.

Fig.3.2-1 Maintenance Panel

Vacuum Toggle

Switch

Flush Toggle

Switch

A

ir flow Control

Fig.3.2-2 Maintenance Station

Purge Button

Waste ink Tray

Fig.3.3-1 Carriage Assembly

Ink Tank

PH Plate

Fig.3.3-2 Beam&Pinch Roller&Plate

Carriage

Printing Platform

Rail Guide

Pinch Roller

Fig.3.1-1 Monitor&Keyboard&Mouse

Monitor

Key Board &

Mouse Bracket

Fig.3.1-2 Computer

PC

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~16~

3.4 Ink Supply Compartment

Ink supply station contains two compartments. One is on the right side for ink pumps and filter, while

the other one is on the back right side for ink bottles.

3.5 Electrical Compartment

Electrical compartment is a shelf for mounting USB Board, Servo Card, Media Board, transformer

and DC power supply. It is built in steel frame.

3.6 Drying System

Because of speciality of the ink, one drying system is necessary for output job. This system is fixed in

front of the machine, including Hot drying and Cold drying system.

Fig.3.4-1 Ink Pump Compartment

Buzze

r

Bulk Filte

r

Ink Pump

A

ir Pump

Flush Pump

Fig.3.4-2 Ink Bottle Compartment

Ink Bottle

Waste ink Bottle

Fig.3.6-1 Drying System

Heating Plate

Hot wind Fans

Cold Air Fans

Power Inlet

Fig.3.6-2 Fan Switch &Temp. Controller

Hot-Fans Switch

Cold-Fans Switch

Temp. Controller

Fig.3.5-1 Electrical Shelf

Media Sensor

Transformer

36VDC Power Supply

24VDC Power Suppl

y

Take-up Media PCB

Feeding Media PCB

USB Board

Servo Card

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~17~

3.7 Take-up System & Feeding System

Take-up system in the front of the machine is used to roll up the output media, while the feeding

system fixed behind the machine used for roll down the media for feeding.

3.8 Power Control Panel

Power control panel is fixed behind the machine on the right side! On this pa nel, there is one inlet

used for main power input, three built-in outlets two of which are used for computer and monitor.

All the power breakers are also built on this panel!

Fig.3.7-1 Take-up System

Tension Ba

r

Take-up Rolle

r

Motor Box

Fig.3.7-2 Feeding System

Feeding Motor

Feeding Roller

Media Hoop

Fig.3.7-3 Control Panel

Back Heat Controller

Take-up Switch

Transition Button

Feeding Switch

Fig.3.8-1 Power Control Panel

Main power Breaker

Computer outlet

Main Power Inlet

System Breaker

Heating Breaker

Monitor Outlet

Backup Outlet

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~18~

Chapter 4 Working System of Flora LJ3208P

The Flora LJ3208P large format printer is using raster image technology to process photos stored in computer.

It is one of the most innovative products, which combines photo digital technology with high precision engine

driver. It produces super wide printouts for business use.

It is a high-technology equipment with a user friendly operating system with simple operational and

maintenance procedures. Though simple, it is composed of several precise systems. In this chapter, we will

introduce the system components and operator guide.

4.1 System Block Diagram

Fire signal

HPP Board

USB_IF

Board

Control Si

gna

l

Level, Pressure Signal

Monitor &

Keyboard

Mouse

Host Computer

USB2

.

0

Servo Card

Ink Pumps

(24Vdc)(CMYK)

- Buzzer

- Flush Pump

- Air/Vac Pump

Home

Left LS

Right

Switches

& Signal:

- Flush

- Prime

Printing Control

Board

IT Level

Sensors

IPT Level

Sensor

NP

Sensor

Raster

Encoder

O

p

tical fiber

Image Data,

Clock, DC

Supply & Heater

Control signals

PHd Temp.

Sensor Signal

K2

Y2

C1

M2

Y1

M1

C2

K1

Power Supply

+36Vdc

+36Vdc Supply

Power Supply

+24Vdc

+24Vdc

220Vac

Supply

Temp.

Controller

Solid State

Relay

Heaters

- Printing Platform

- Drying Platform

Sensor

Media

Take-Up

PCB

Media

Feeding

PCB

Media Sensor Media Sensor

Y-axis motion

X-axis motion

Dir/Step

signal

36Vdc

Power

X-axis

Servo

Driver

Servo

Motor

(X-axis

Encode

r

Dir/Step

signal

36Vdc

Power

Y-axis

Servo

Driver

Servo

Motor

(

Y

-axis

Encode

r

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~19~

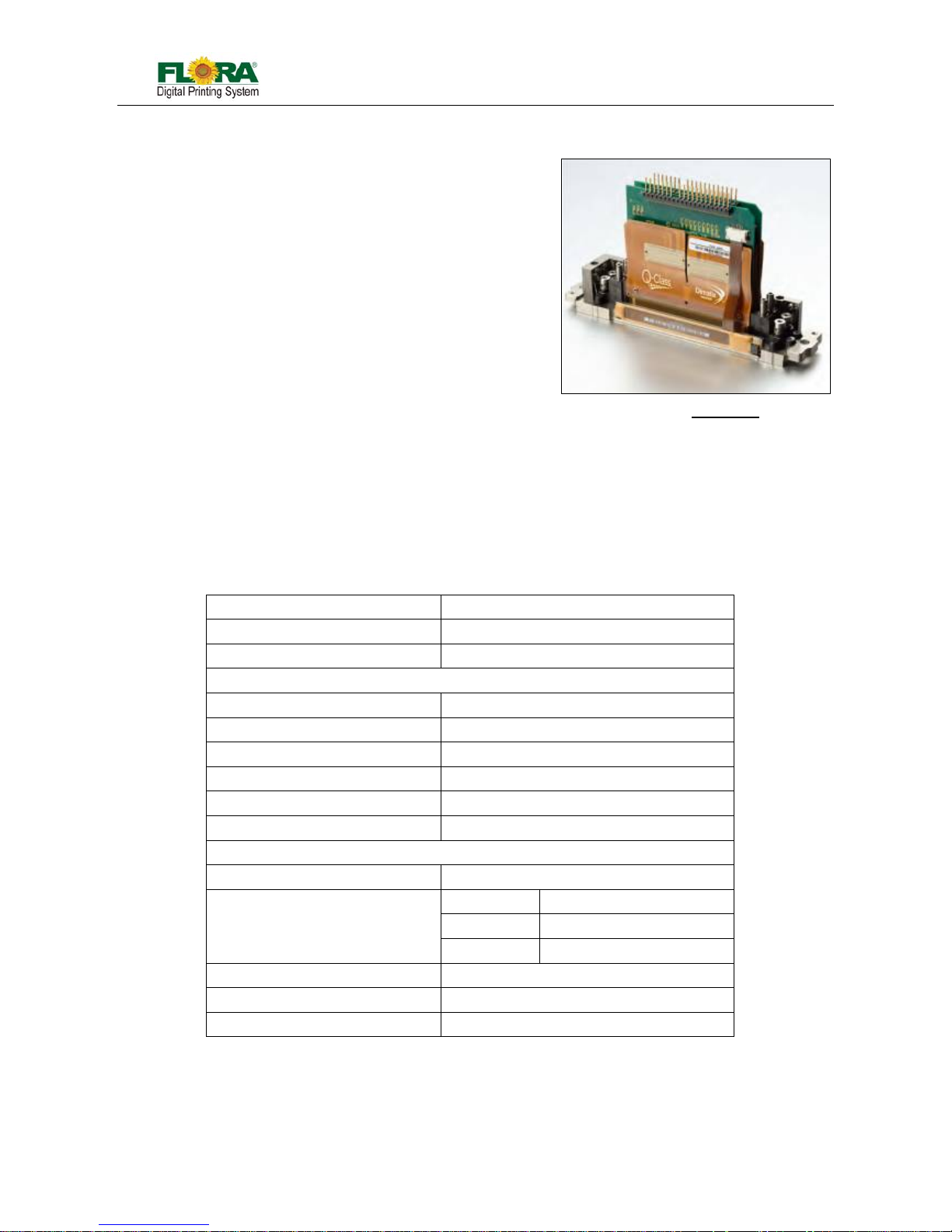

4.2 Polaris Print head Introduce

Feature:

35 picoliter nominal drop size

512 individual addressable nozzles

Incorporates versaDropTM binary jetting

capability

Excellent channel-to-channel uniformity

High frequency continuous operation

Designed for long service life

Integral mounting bezel with precision

features

Configurable for single and two-color

operation

Optimized for high viscosity jetting fluids

Built-in heaters and temperature sensors

Operation up to 60°C(140°F)

Simplified field repair with no special tools required

Supports UV-curable, solvent and aqueous-based inks

Technology Specification Table:

Parameter Polaris PQ-512/35AAAPrint head

Number of addressable jets 512

Print width 64.897mm(2.555inches)

NOZZLE SPACING

Single color(4 rows of jets)

127 microns [0.005in.](200 dpi)

Two color(2 rows of jets/per color) 254 microns [0.01in.](100 dpi)

Jet straightness ,1 sigma* 2.0mrad[0.11°]

Nominal drop velocity 8m/s

Calibrated drop mass 35ng

Compatible jetting fluids solvent-curable, organic solvents, aqueous

BINARY OPERATION

Adjustment for drop size 35-80 picoliters

Productivity Drop size Maximum Frequency

35 pl 30kHz

80 pl 13kHz

Operating temperature range Up to 60°C

Fluid viscosity at jetting 10 to 14 centipoise

Dry weight 160ams

Fig. 4.2-1 Print head

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~20~

4.3 Printing Control System

4.3.1 Printing Control Board (116-0401-132)

The print head control board controls and drives the jetting parameters of the print heads.(as

below). Functions of the board are as follow:

Receiving optical signal from USB Board ,change it into electric signal and sep arate

the image data & control order from the signal ;as the same time,combine level

signal , negative signal , raster signal etc., then change them into optical signal and

send them to USB Board

Supplying power & clock to print head to drive it work

Detecting automatically: detecting level of ink tank is full or not ; detecting negative

pressure is in the range of setting or not ; reading raster signal

Level indicator:

When the tank is full, the responsible indicator will turn on!

Fig.4.3.1-1 Printing Control Board

DC 24V

USB J6

Level Sensor

USB J11

NP Sensor

Raster

Reader

HPB J2

Y1 Y2M2M1

C1 C2 K1 K2

Linking

indicator

Working

indicato

r

Status

indicator

Level

indicator

Powe

r

indicato

r

Common Port

Indicator

Tanks are full

Fig.4.3-1 Printing Control Board

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~21~

Note: D8~D15 are normal on, while D7 is off. Because the negative pressure tank is always

empty.

Power indicator:

All of these four LEDS will be normal on.

D3: 3.3V

D4: 5V

D5: 24V

D6: 24V

Status indicator:

D56: Fire indicator working normally: on

D57: Configuring indicator working normally: on

D58: TX indicator Transmitting data: on

D59: RX indicator Receiving data: on

Working indicator:

D16: Temperature indicator: heating, on; or it will be off.

D17: Working indicator: shine all the time

D18: Raster reader indicator: Carriage moving, on; carriage stopping, off

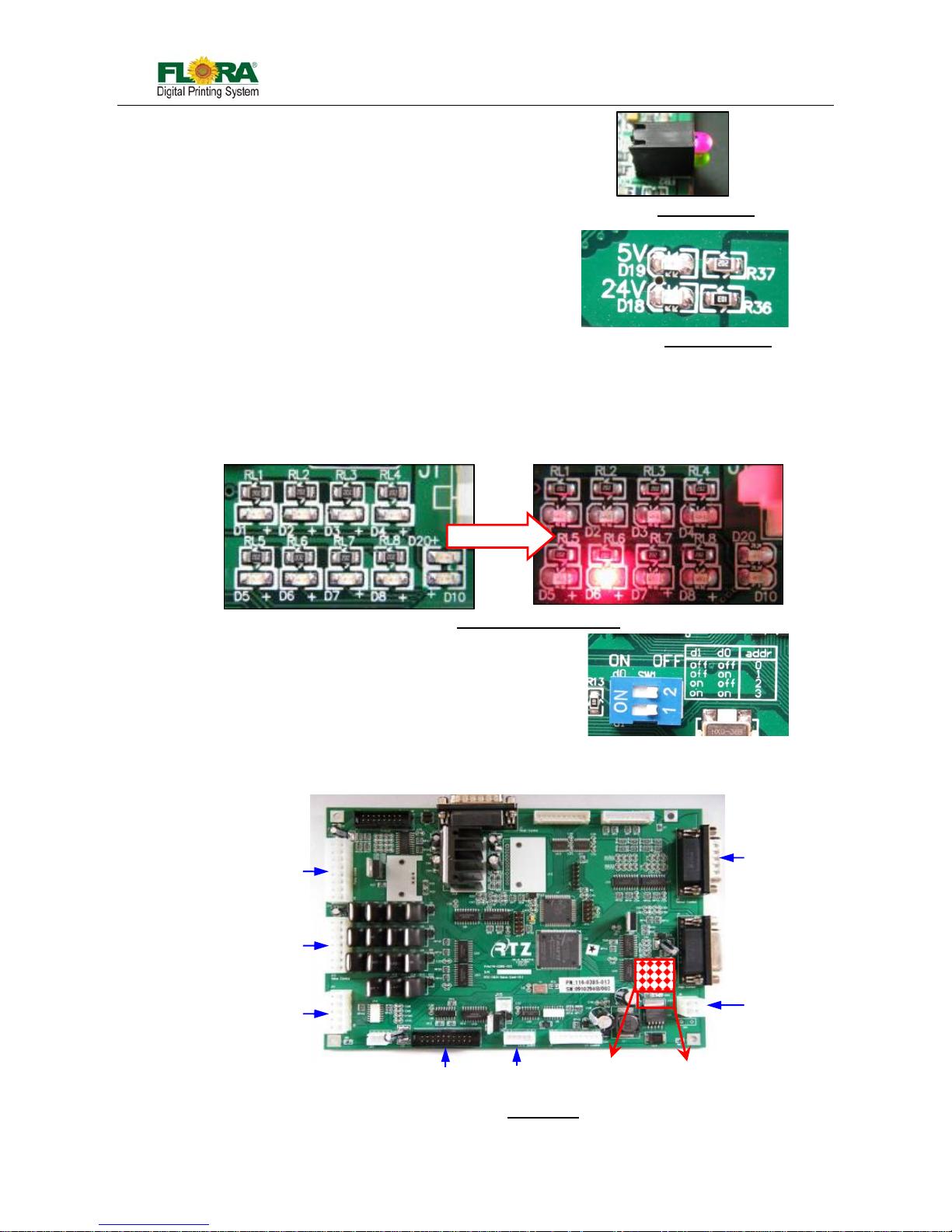

4.3.2 USB Board (116-0417-011)

The board is an interface between computer and printer, including functions as follow:

Apply data of image from computer and save it into the buffer, waiting the data request

from the printing control board

Conform the data and the order from computer, convert electric signal into light signal

and transmit it to the Printing control board; receive light signal form Printing control

board, convert them into electric signal and extract after separating them.

Communicate with the other boards, servo driver and computer, to coordinate the

whole printer working.

Take order form computer and control motion of the X axis and Y axis

D7 D8 D9 D10 D11 D12 D13 D14 D15

color NP Y M C K K C M Y

Fig.4.3.1-2 Indicators

Fig.4.3.2-1 USB Board

USB Indicator

Motion Indicator

PHB J1

PC

Communication

indicator

Linking

Indicator

PHB J11

SCB J7

Power

Indicator

5VDC

X-axis SD

Y-axis SD

SCB J5

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~22~

USB indicator:

Green Led: working indicator, normally on;

Red Led: Error indicator, normally off

Power indicator:

D18: 24V power indicator normal on

D19: 5V power indicator normal on

Communication indicator:

D1, D2, D3: null

D4: Hidem indicator Communication: on

D5: Print head board indicator Communication: on

D6: Y-axis indicator Y motor moving: on

D7: Servo Card indicator Communication: on

D8: X-axis indicator Y motor moving: on

D10: TX indicator Transmitting data: on

D20: RX indicator Receiving data: on

Dial Switch

D0=off; D1=off

4.3.3 Servo Card(116-0385-022)

This board serves as assistant functions control board.

Control pump supply ink automatically

Ink-supplying timeout warning,limited switch protection,error indication

Fig.4.3.2-4 Communication Indicators

Working

Air pump1#

buzze

r

Ink pump

Priming button

USB J10

DC24V

Limited

switch

USB J5

Power

indicator

Nixie

Tube

Fig.4.3.3-1 Servo Card

Fig.4.3.2-2 USB Indicators

Fig.4.3.2-3 Power Indicators

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~23~

Power indicator:

Power is ok, on; or, off.

Nixie Tube:

Show the error number.

0 No problem 1 Lack of ink

2 Negative problem 3 Movement problem

Error indicator----Nixie Tube

If the digital LED shows 0, it means everything is ok, with no problem.

Number 1 means that there is no ink in the secondary tank:

¾ First, check the ink bottle: make sure the ink bottle is not empty, if there is no

ink ,then load ink;

¾ Second, check the ink pump to see if it is working, replace it if necessary;

¾ Third, check the sensor: make sure the sensor can detect the level exactly,

otherwise change it;

¾ If everything can’t work still, change Servo Card.

Number 2 means some ink over flowed, which also means there is ink in the

negative pressure tank:

¾ Check the ink indicator LED is light or not, it means there is ink in the IPT

when it’s on. Then you need to suck ink out from the tank syringe b efore start

the machine

Number 3 means the movement system has problem

¾ First, check the servo driver report the error or not: if there is a error, shut

down the power of the machine and restart it.

¾ Secondly, check the limited switch: the left & right limited switches are used

for protection. If the switch is pressed, it will stop the motor from working. So

you must make sure that switch is ok and it hasn’t been pressed by carriage

or any other thing.

¾ Third, check the motor can work normally or not. If necessary, change it.

¾ Forth, if it still can work, change the USB Board.

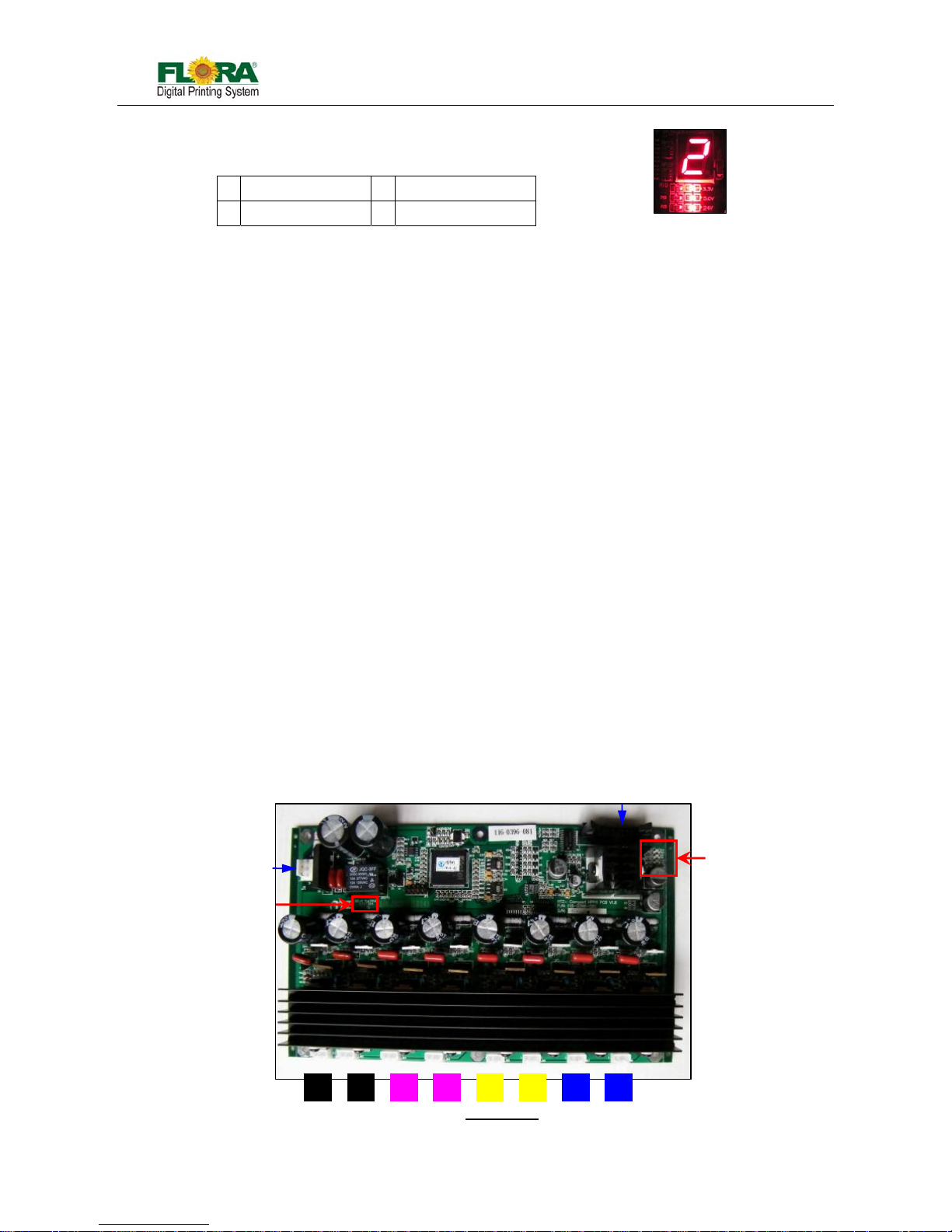

4.3.4 HPP Board(116-0396-081)

The board is an 8-channel high-voltage DC pulse generator, designed to provide fire pulses

necessary to actuate piezoelectric elements in Spectra Polaris heads.

Features:

Up to 8 separate channels of fire pulse outputs

Each output channel capable of driving up to 512 nozzles

Programmable fire pulse amplitudes, from 50V to 120V

Programmable fire pulse widths, from 1 to 10us

Fig.4.3.3-2 Nixie Tube

Fig.4.3.4-:1 HPP Board

Y1 Y2M2M1 C1 C2K1 K2

Working

Indicato

r

AC110

V

PHB J10

Power

indicator

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~24~

Power indicator:

D1: 24V power indicator normal on

D2: 5V power indicator normal on

D3: 15V power indicator normal on

4.3.5 Connector Board(116-0402-020)

This board is used as interface board for Print head and the Print head Control Board thru a

16-pin flexible data cable. It is fixed on the print head by insert to the pin of Print head.

Power indicator:

D1: 5V power indicator normal on

D2: high-voltage pulse indicator bright periodically normal on

4.3.6 RTZ-16UV Media Board-V1.3(116-0030-041)

Taking-up or feeding media automatically

4.4 Mechanical Movement System

Movement system is very important part of the machine, which directly decides the printing pr eci sion!

There are two movement system, X-axis movement(Carriage movement) and Y-axis(Media Feeding).

1 2 Model

ON ON Take-up board

OFF OFF Feed board

Fig.4.3.5-1: Connector Board

Working indicator

PHB PB0

HPB JB1

Swing switch

Motor

Optical switch

Optical switch

Shift switch

Shift switch

24V input

Model setting

switch

Working

indicator

F

ig. 4.3.6-1: Media Board

Fig.4.3.4-1 Power Indicator

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~25~

Both the Carriage and Feeding assembly are driven by servomotors, which are controlled by their

respective Servo Driver can prove high precision motion as to enhance the printing quality.

4.4.1 X-axis Movement (Carriage Motion System)

X-axis movement System serves for carriage which will drive the print head moving. The Serv o

Motor is responsible for the carriage movement from left and

right. The print head carriage is driven by the Servo Motor

through the timing belt attached to its gear pulley.

4.4.1.1 Servo Driver & Motor

This machine used ACS806 Servo drive and

motor as powerplant. The servo driver installed at the right

side behind the Beam, while the servo motor installed at

the right side of the beam. Servo driver is a transfer

station, which will get movement signal from USB Board

then control the motor working.

4.4.1.2 Raster Reader (116-0340-020) & Strip (141-0134-004)

Raster reader is a optical reader, raster strip is a rasterized transparent plastic. They

work together generate fire signal that will be send to Printing control Board. The raster reader

is fixed on the right side of the carriage, while the strip is installed along the beam.

Notice: The raster reader set-up must up to standard.

4.4.1.3 Limited Switch & Protection Rubber

There are three limit switches for used as electrical protector on this machine. Two of

which are installed at the left end of the beam at carria ge home posi tion. The left most serves as

limit switch for carriage left stroke and the inner side serves as the home position switch. The

third is installed at the right most end of the rail serves as the limit switch for carriage right

DC Power Suppl

y

Step and

Direction

Signal

Servomotor

Power Signal

Encoder

Feedback

Signal

Servomotor 150W

PN: 141-0506-010

Servo Driver ACS806

PN: 141-0505-010

Fig. 4.4.1.1-1: Servo Driver Connecti o n

F

ig. 4.4.1.2-2: Raster Reader

Set-up

Fig. 4.4.1-1:

Servo Driver & Motor

Moto

r

Driving Pulley

Bracket

A

C Servo Driver

Fig. 4.4.1.1-2: Pulley

Dual Pulle

y

Fig. 4.4.1.2-1: Raster Reader

Raster Reader

Raster Strip

Raster Reader Bracket

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~26~

stroke.

Besides limited switches, there are two protection rubbers used as mechanical

protector. They are fixed on the side of beam.

4.4.2 Y-axis Movement (Media Feeding System)

The DC Servo Motor is a brush-commutated DC motor which is responsible for the forward

and backward movement of the Media. This motor is powered by 36VDC. To precise movement of

the media feeding is controlled by a servomotor with a closed-loop feedback signal from the encoder

coupled on the shaft of the motor. The step and direction signal is mainly controlled from the USB

Board and this signal is amplified by the Servo Driver to drive the Servomotor.

4.4.2.1 Servo Driver & Motor

This machine used ACS806 Servo drive and motor as powerplant. The servo driver

installed at the right side behind the Beam, while the servo motor inst alled at the right side of the

beam. Servo driver is a transfer station, which will get movement signal from USB Board then

control the motor working.

Home Position Switch

Right Limit Switch

Left Limit Switch

Fig. 4.4.1.3-1: Limited Switches

Pulley

Motor

Pulley

Feeding

Shaft

Timing

Belt

Fig. 4.4.2-1: Feeding Mechanical

Fig. 4.4.2-2: Front View

Fig. 4.4.2-3: Servo Driver & Motor

A

C Servo Drive

r

Y

-axis Motor

DC Servo Driver

Left Rubber Stopper

Fig. 4.4.1.3-2: Rubber Stopper

Right Rubber Stopper

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~27~

4.4.2.2 Pinch Roller & Printing platform

Pinch rollers are used to press the media against the knurl-rollers. It used to hold (grip)

the media while on y-axis movement (stepping operation). It helps keep the media from slipping

during printing. The printing platform keeps the media flat by the use of suction mechanism in

which the suction fans can be switched on/off by the operator. The printing platform is equipped

with a set of heaters and can be heated up by turning on the heater controller with the desired

temperature level.

Servomotor 150W

PN: 141-0509-000

Fig. 4.4.2.1-1: Servo Driver & Motor

Servo Driver DCS810

PN: 141-0510-000

Step and

Direction

Signal

Encoder

Feedback

Signal

36VDC Power Suppl

y

Servomotor

Power Signal

Vacuum Suction Fan

(141-0092-010)

Tension Sprin

g

Tensioning

Screws

Fig. 4.4.2.2-2: Adjustment of

Pinch Roller Pressure

Fig. 4.4.2.2-1: Array of Pinch Rollers

Roll Media

X-axis

Beam

Hold Down

Shaft

Printing

Platform

Y

-axis Shaft

Heat Belt

(141-0484-000)

Pinch Roller Lever

Fig. 4.4.2.2-3: Printing Platform Chamber and Suction Fan

Vacuum Chamber

Heaters are

glued on this

This fan is installed

below the vacuum

Chamber

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~28~

4.5 Ink Supply & Negative Pressure System

System Circuit:

4.5.1 Ink Supply System

The ink Bottle/Barrel serves as the main reservoir for ink

supply, should be refilled in a timely manner so continuous supply

of ink will not be interrupted during printing. The level of ink inside

the bottle/barrel can be monitored visually or using the buzzer

system. Refilling is done manually.

The ink pumps suck and discharge the ink into the

secondary ink tank. A five-micron filter is being provided to

prevent the secondary tank from being contaminated by

unwanted particles, which are inherent in the ink. Ink level sensor

inside the secondary ink tank sends an open or close contact

signal to the Print head control board and Ink control board to

control the operation of the pumps. An optional micro filter is

added to enhance the filtering of ink before it flows into the print

heads.

Every time the print heads eject/fire ink droplets, the ink

flows and fills the space left by droplets. A negative pressure

system is responsible for holding the ink from flowing out of the

print head nozzles.

4.5.2 Lack of Ink Warning Function

Ink alarm system plays a part in caution when the ink bottle is empty or the secondary tank is

not full.

The level sensor in the bottle detects the level of ink. The print head board will send the level

signal to the servo card. The servo card will process this signal then control the pump working, if the

pump works more than 25s, it will stop all the pump working and activate the buzzer. Meanwhile, the

Servo Card will report error 2.

Fig. 4.5.1: System Circuit

Fig. 4.5.1.1: Ink Supply

Compartment

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~29~

As warning happened, Click “flood ” check box in the sof t ware!

4.5.3 Purge and Flush individually

Individual purge system allows for easy convenient respective maintenance of print head,

which will help saving ink also.

If the machine doesn’t work for more than 3 days, flush all the print heads with solvent is

recommended. And whe n the nozzles are blocked seriously, flush is also available.

These two functions are available on this flora machine.

Notice: The valve must be turned with the correct Valve Key.

Situation needs to prime:

¾ Load ink

¾ Some nozzles not work or blocked

Situation needs to flush:

¾ Many nozzles are blocked

¾ Before you don’t want to use machine for long

¾ Before you load ink after long time no using the machine

Principle of air exhaust is like injecting water into one tube. After water was injected into the

tube from one side, bubble will be pushed out from the other side.

¾ Exhaust when there is some bubble in the tube。

Note: Whatever prime, flush or purge, perform it one color at one time. Turn off the other ink

valves. This can make sure that there is big enough pressure..

4.5.4 Negative Pressure System

Negative pressure system is used to hold the ink from dripping out of the print head nozzles.

Pressure settings varied on every machine. The recommended setting range is from -2. 3 to -2.7Kpa.

Too low negative pressure setting will result to ink dripping or print head cannot jet ink.

Too high neg ative pressure setting will cause ink starving over time and ink overflow in the

negative pressure line system.

4.5.5 Overflow Protection Function

Ink protection tank serves as the ink overflow protection for the vacuum line system. If overflow

happens, the ink will flow into this tank, once the ink reaches the maximum level, the sensor will shut

off the print head control board. Without the ink protect tank, the vacuum system will fail to function if

Fig. 4.5.3.1: Ink Tank Valve

(312-0010-031)

Close

Ink Position

Flush Position

Purging Printin

g

Flushin

g

Closed

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~30~

5/2 way

Valve

Push-button

Activated

5/2-way V alve(331-0329-000)

Curren

t

Value

Se

t

Value

Pressure Sensor

(312-0078-014)

the tubes are filled with overflowed ink.

There are one ink protection tanks fixed behind the secondary ink tanks!

Note: There are three actual scenarios where the overflow happens.

1. The ink overflow situation will happen when the ink tank level sensor fails to detect the full

level while the ink pump tends to turn-on and ink is keep on flowing into the ink supply circuit;

hence, ink will flow towards the ink protect tank (IPT).

2. The ink level wire connection is wrong at the print head control board connection port.

3. The ink pump wire connection is wrongly connected (reverse connection with the other ink

pump).

4.5.6 Other parts intro

Pressure Sensor

The pressure sensor is an electronic programmable

sensor that is used to detect both the negative and positive

pressure. The tube line is provided to connect the sensing port of

the pressure sensor to the IPT. Any level of pressure i n the IPT is

online displayed and sensed to signal the appropriate output

(OUT1 or OUT2) to further trigger the part/component to protect

the negative pressure system. The parameter setting is set by

the sensor panel keypad; this parameter is used to program the

sensor output control characteristic and display indication.

Pressure Regulator (Flow Control Valve)

The flow control valve is actually a pneumatic valve that is used to

restrict the flow of air. In the negative pressure circuit, the flow control

valve is adjusted appropriately to achieve the right negative pressure

needed by the ink supply system. Adjusting the flow control valve will

in-turn adjust the negative pressure that goes to the print heads; therefore,

acquiring the correct amount of force to hold the ink just on the mouth of

every print head nozzle holes.

5/2 way Valve (Purge Button)

A mechanically activated pneumatic valve serves

as to switch-over the negative pressure to positive

pressure. At normal operation, the suction effect of

negative pressure (vacuum) is connected towards print

heads. During the ink priming operation, the 5/2-way

pneumatic valve is manually activated, the air (positive

pressure) will replace the vacuum and flows towards the

print heads and therefore the ink in the print heads are

Flow Control Valve

(331-0239-000)

A

djustment

Knob

Fig. 4.5.521: Shut-off Valve

(141-0436-001)

Open

Close

Fig. 4.5.5.1: Ink Protect Tank (IPT)

(312-0010-031)

Drain

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~31~

Pump

24Vdc

Connect

to

Solvent

Bulk

Filter

Luer

purged out through all nozzles. In this operation, the nozzles are being cleaned from slight

contamination of small debris, and micro-bubbles will be forced out.

Maintenance Toggle Button

Solvent Flush Toggle Switch – used for flushing the solvent into

the Print head. This is being done if you want to remove the ink

out of the Print head or to remove any clogging from the Print

head.

Media Suction Switch – vacuum switch to make sure that the

media is laid down flat on the printing platform.

Negative Pressure Adjustment – used to adjust the Negative

Pressure value as being shown in the Pressure Gauge

4.6 Flushing System

This system provides solvent flushing for all print heads. A solvent

pump is provided to pump the solvent from the solvent bottle to ink tank

manifold then it is distributed through the ink tank manifold. The manifold

valve can be turned individually to appropriately enable the flow of solvent

flush to each particular print head. The solvent pump i s turn-on/acti vated by

a toggle switch that provides the 24Vdc to the solvent pump unit.

The solvent flushing can be done to all print heads at the same time or

only print head at one time by closing and opening the ink tank valves

accordingly. Solvent flush is necessary if there is stubborn clogging in the

print head nozzles or when the machine will not operate over night

Notice: If had to replace the ink , all ink line must be flush to clear!.

Fig. 4.6-1:

Solvent Pump

Ink

Tank

Flush

LCF Disc

Filter

(5um.)

Solvent

Flush

Bottle

M

High Level

Low Level

Solvent

Pump

Level Sensor

(Optional)

Bulk Ink Filter

(5um.)

Magnetic

Floater

Ink

inlet

Negative

Pressure

24Vdc

Motor

Print

Head

Manifold

Valve

Flushing

Switch

+24Vdc

Fig. 4.6-2: Flush Circuit

Fig. 4.5.6-1: Maintenance Panel

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~32~

4.7 Drying System

For this model there are two drying system for high speed output drying! One is Heating System

which temperature of heating can be setting by manually, the other one is Cold Fans System.

4.8 Take-up and feeding System

During printing, the roll media indexes forward by the stepping action of the Y-axis Servomotor that

rotates the Pinch Roller. Henceforth, after a certain number of indexes, the roll media will clear the

Feeding Optical Sensor. The clearing of optical sensor will activate the DC Motor to rotate the spooler

roller and lay forward the media until the optical sensor is blocked. This automatic action is kept on

cycling as the printing process is on progress.

On the other hand, when the roll media at the front side becomes loosed and the Front Optical

Sensor is blocked, the Take-up DC Motor will then rotate to wind (spool-in) the printed media. During the

winding of the printed media, the Front Optical Sensor will be cleared and then will automatically stop the

DC Motor. The rotation of the Take-up Roller in Auto Mode energizes the DC Motor (clockwise rotation)

with the image prints turning outside the roller while the Manual Mode turns the other direction which

loosen up the media from the roller .

On the other hand, the Feeding Roller System has a transition switch to change the direction of the

Fig. 4.7-4: LionPower Connetion

Fig. 4.7-1: Drying System

Fig. 4.7-2: Back Heating

Temperature Sensor

Heating Belt

Thermoregulator

Fig. 4.7-3: Control Panel

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~33~

Feeding Roller depends upon the printing-side orientation of the media.

Fig. 4.8-4: Take up Roller Assembly

Fig. 4.8-5: Feeding Roller

Auto

Off

Manual

Fig. 4.8-2: Feeding and Take-Up Switches

Fig. 4.8-3: Media Sensor

Fig. 4.8-1: Spooling Set-up of the Media

Tension

Bar

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~34~

Chapter 5 Installation Manual of Flora LJ3208P

5.1 Machine Pre-installation

z The minimum working area should content the space for the operator to move around the

machine conveniently and safely.

z Prepare the necessary AC plug on the power cord attached to the machine. Ple ase see the

Technical Specification table for the power requirements.

z If the PC is not supplied with the machine, customer must meet the minimum PC

specification requirement to be used in this machine

z Safety signs must be available within the working area.

z Exhaust System must be provided for the solvent and Ink fumes. Please note that fumes

are heavier than air so it is most likely the concentration happens at the lower level of the

room.

z Lightings should be sufficient enough.

z Flammable Storage Ca binet for the Ink and flushing solution stock is highly recommended

to secure them very well.

z Waste Container should be available for ink and flushing liquid waste as well as ink/solvent

contaminated cloth inside the Printing area.

z Waste disposal should be in accordance with your local laws governing Hazardous Waste

Disposal.

Once the machine is placed and all spare parts are thoroughly checked, start doing the following

pre-installation activities:

z Install the drying device.

z Check the height of the Print head Carriage over the printing plat fo rm. The h eight sho uld be

at least 3mm above the media printing surface.

z Check the movement of the Print head Carriage for any obstruction by moving it manually

from one end to the opposite end.

z Install the LCD Panel / Monitor and the PC, keyboard and mouse to be used on this

machine.

z Place the CPU to the computer compartment provided if applicable.

5.2 Installation of Software

This model supports both Windows 7 and Windows XP. For Windows XP, USB Driver need to be

installed manually. And the account type of computer must be Administrator. And the account must be

active as below:

1) Right click on Computer Icon, choose “Manager”;

2) There is coming with 【Computer Manager Windows】 as below. Click on “Local User and

Group”, you will find two folders in list;

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~35~

3) Click “User” folder, you wil l find Account in the left windows as above;

4) Right click on “Administrator”, Choose “Proprieties” and click it;

5) 【Administrator Proprieties Windows】 will come out. Activate the account by un-tick the check

box as below;

6) click “Apply” and “OK”, then finished

5.3.1 Install PhotoPRINT Server Flora Edition 6.1v2

7) Turn-on the Main Power to give power to the PC and Monitor.

8) Insert the CD supplied with the machine with label PhotoPrint 6.1V2 for the necessary

installation.

9) Then screen will prompt you with 【Choose Setup Language】 window; Select which language

you will use. Then click “OK”. Starting 【InstallShield Wizard…. 】

Flora Digital Printing System

Model LJ320P

Copyright 2011@ Shenzhen Runtianzhi Image Technology Co.,Ltd. By Victor Xu

~36~

10) The Application Installer S etup will now prep are the Install Shiel d for the setup process,then

click “Next”. You will get a window for 【License Agreement】, please choose “I accept the

terms of the license agreement”

11) Click “Next” ,then 【Select Features】 and the 【Select Program Folder】 screen window

will show up.

12) Then you will get a window for 【Setup Status】, wait it finish.

13) The 【Product Selection】 window will comes in after that. Please enter password which you