floorex SATELLITE 650 MkII Safety And Operators Manual & Parts Listing

SATELLITE 650 MkII

SAFETY & OPERATORS MANUAL

& PARTS LISTING

20-11-09

SATELLITE 650 MkII

1800 FLOOREX

1800 356 673

Page 1

Table of contents

PAGE 1. Table of contents

PAGE 2. Safety instructions

PAGE 3. Operating instructions

PAGE 4. Operating instructions cont...

PAGE 5. Tooling Removal & Magnetic Plugs

PAGE 6. Axle height adjustment

PAGE 7. Electrical safety

PAGE 8. Problem solving

PAGE 9. Diamond plugs

PAGE 10. 10 & 7” Satellite disks

PAGE 11. 5” Satellite disks

PAGE 12. Main parts breakdown

PAGE 13. Handle Breakdown

PAGE 14. Disk Breakdown

PAGE 15. Parts listing

PAGE 16. Parts listing

PAGE 17. Wiring Diagram

SATELLITE 650 MkII

1800 FLOOREX

1800 356 673

Page 2

Safety instructions

01. Read and understand the instructions on the machine and in this manual and engine manual (if applicable).

Different models may have different parts and controls.

02. Equipment should only be operated by trained personnel, in good physical condition and mental health (not

fatigued). The operator and maintenance personnel must physically be able to handle the bulk weight and power of

this machine.

03. The SATELLITE 650 MkII must only be used according to the instructions given in this manual. Any other work

methods or practices could result in injury or death

04. The SATELLITE 650 MkII has different positions in which the handle can be locked into. These are described in this

manual as ‘OPERATE’, ‘TOOLING REMOVAL’ and LIFT/STORAGE’. See the at the end of this manual for diagrams of

these positions. When to use and when not to use these positions is described throughout this manual

05. This is a one person machine. Maintain a safe operating distance to other personnel. Remember ‘one machine, one

operator’.

06. This equipment is intended for commercial use.

07. For the operators’ safety and the safety of others, always keep all guards and shrouds in place.

08. Never start or run machine when it is unattended.

09. Check for wear on magnetic plugs every 3 hours of use

10. This machine is only intended for use on floor surfaces such as concrete, terrazzo and other hard floor surfaces.

11. The handle height is adjustable with different positions for operator comfort. These positions are shown next to the

locking mechanism as ‘OPERATE’. The SATELLITE 650 must never be started or used with the handle in any other

position other than the ‘OPERATE’ positions’

12. Never attempt to adjust the handle position when the machine is in operation.

13. Never start or run machine with the handle folded or when disk(s) are not in contact with the surface.

14. Do not lend or rent machine without the operating and safety instructions for the machine (and the engine, if

applicable).

15. Wear clothing suitable for the job and for the work place including, safety shoes, hard hat, hearing protection, non

fogging vented safety goggles, and dust mask suitable for dust.

16. Keep body parts or any loose clothing away from moving parts. Failure to comply could result in bodily injury.

17. Do not modify machine in any way. Only use genuine SATELLITE parts and accessories.

18. Repairs should be performed by qualified persons only.

19. Ensure parts have stopped moving and disconnect power or spark plug when servicing or changing blades or

accessories.

20. Never operate machine in rain or if heavy moisture is present.

21. Petrol is extremely flammable and poisonous. Petrol should only be dispensed in well ventilated areas, and only

when engine is cool.

22. WARNING! POISONOUS EXHAUST GASES. Do not operate petrol powered equipment, including generators,

without adequate ventilation. Carbon monoxide is and invisible odorless gas that can harm or can kill.

SATELLITE 650 MkII

1800 FLOOREX

1800 356 673

Page 3

Operating Instructions

01. Wear clothes suitable for the job and for the work place including, safety shoes, hard hat, hearing protection, non-

fogging vented safety goggles, and dust respirator suitable for dust.

02. The SATELLITE 650 MkII must only be used according to the instructions given in this manual. Any other work

methods or practices could result in injury or death

03. WARNING! Disconnect power before moving the Handle to the ‘TOOL REMOVAL’ or ‘LIFT’ positions.

04. WARNING! POISONOUS EXHAUST GASES. Do not operate petrol powered equipment, including generators, without

adequate ventilation. Carbon monoxide is and invisible odorless gas that can harm or can kill.

05. Be sure all equipment is tested and tagged prior to use on any job.

06. Inspect entire area to be ground before grinding and remove any bolts or concrete nails (etc) that could damage

tooling or the machine and which could cause a hazardous situation.

07. Ensure there are no obstacles or existing structures that could present a hazard to the operator. If so, take necessary

action to eliminate the hazard.

08. Fold handle to the ‘TOOLING’ position and ensure it is locked in place, then tilt machine back so handle is resting

along the floor.

09. The machine takes a set of three (3) tools. Be sure the tools are of even height.

10. Install appropriate diamond tooling or other available tooling into the machine. Only use genuine SATELLITE tooling.

Failure to comply could result in bodily injury.

11. Tilt machine back onto the disk and put the handle in one of the ‘OPERATE’ positions. Adjust the position to one that

you are comfortable with.

12. Never attempt to adjust the handle position when the machine is in operation.

13. Connect machine to suitable power outlet. Only use heavy duty power lead suitable for high current use (preferably

2.5mm² cable), no longer than 15 meters.

14. If no power is available within the specified distance, have a qualified person install a suitable power outlet closer to

your work. Alternatively use 4mm² cable for up to 40 meters.

15. Connect a suitable dust extractor to the machine via a 38 or 50mm flexible hose. The machine is designed to take

the standard 50mm hose ends to make connection of dust extractors easy and hassle free.

16. Keep machine clear of drainage pits, grates, steps or major lips or such hazard. Failure to comply could result in

bodily injury and or could damage the machine or property.

17. Ensure machine is on a level surface and handle is in one of the ‘OPERATE’ positions

18. This machine is designed to operate with the wheels in contact with the floor at all times. Do not operate with

wheels off the floor.

19. The SATELLITE 650 MkII has axle height adjustment to make it easy to adjust the machine so it doesn’t cause fatigue

on the operator. To set axle height, adjust the axle height leaver to the vertical position, or midpoint. This is a good

starting point. After initial operation the axle can be adjusted. The axle lever must be set as far back (toward

operator) as possible without creating excess force on the operator during operation. See 24 below.

20. Switch on the dust extractor.

SATELLITE 650 MkII

1800 FLOOREX

1800 356 673

Page 4

Operating Instructions cont…

21. Hold the handles firmly and switch the SATELLITE 650 MkII on by pushing the green button.

22. The controls on the SAT650 MkII include an over load device. It is there to protect the controls and motor from

irreparable damage. If it trips it indicates a problem. (i.e.; undersize power lead or poor power to your power

supply). Refer earlier in this section for recommendations on power leads. Rectify the problem or decrease load on

the Satellite 650 by using tooling with more surface area, or place weights supplied on the brackets on handle for

this purpose.

23. Continuing to use the SATELLITE 650 when constant tripping occurs, VOIDS THE WARRANTY.

24. Do not attempt to make any adjustments while the machine is in operation. Any adjustments must only be

performed when machine is stopped and power disconnected.

25. In the event of the machine pulling to one side all the time; adjust the axle height to obtain the best result. (See

‘AXLE HEIGHT’). This machine is designed to operate with the wheels in contact with the floor at all times. Do not

operate with wheels off the floor.

26. After a few minutes of grinding check the wear of the diamond tooling. This will pay handsomely if the diamonds are

wearing out fast due to soft concrete / abrasive concrete. There is a wide range of diamonds available to suit every

need. See Section ‘DIAMOND TOOLING SELECTION GUIDE’.

27. Check for wear on magnetic plugs every 3 hours of use

28. See Section ‘PROBLEM SOLVING’ for tips on how to grind faster on tough concrete and how other problems can be

rectified.

29. WARNING! As with any diamond tooling, breathable silica may be generated by use and maintenance of this

machine. Silica can cause severe and permanent lung damage, cancer, and or other serious diseases. Do not breathe

the dust. Do not rely on your sight or smell to determine if dust is in the air. Silica may be in the air without a visible

dust cloud. If air monitoring for silica is not provided by your employer at your work site, you must wear appropriate

respiratory protection when operating or maintaining this equipment. Consult your employer for proper respiratory

protection.

SATELLITE 650 MkII

1800 FLOOREX

1800 356 673

Page 5

Tooling Removal & Magnetic Plugs

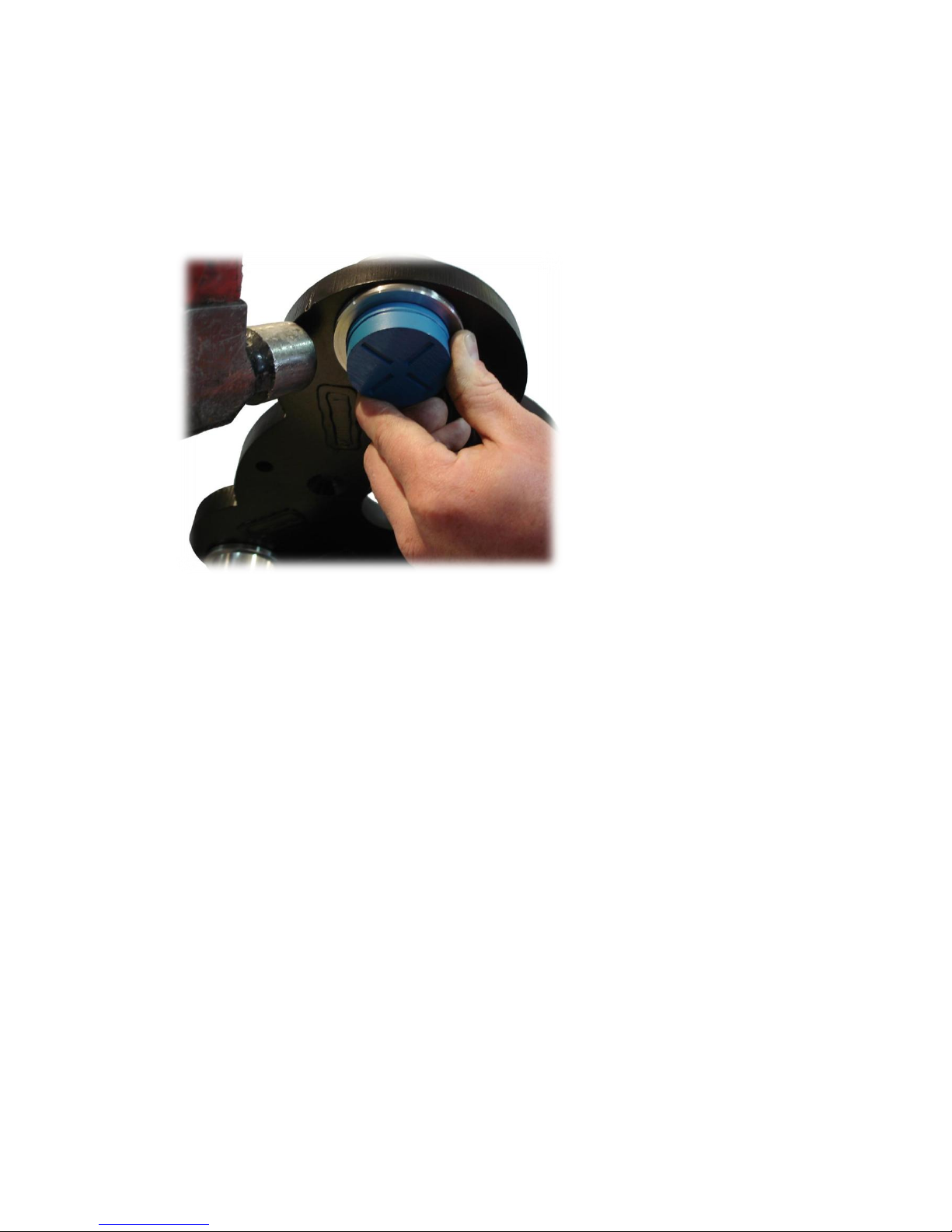

01. To remove tooling from the magnetic plugs, Tilt the machine as per instructions in the operating instructions and

grasp hold of the diamond disk and give it a sharp pull away from the main black disk.

02. To remove the plug from the main black disk strike the black disk beside the taper insert as shown below.

03.

04. The magnetic plugs must be cleaned every time the insert is removed.

05. Ensure the insert is not worn more than 30% through where the blade runs on the insert

06. Clean out the hole in the plug where the inert goes. Ensure there are no particles or pieces of steel (such as staples

ETC).

07. Refit the insert on the blade and put the two onto the plug ensuring the insert goes completely into the plug

Loading...

Loading...